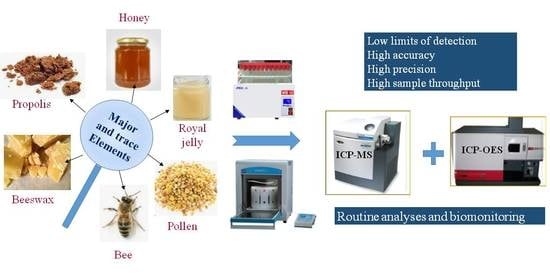

Effectiveness of Different Sample Treatments for the Elemental Characterization of Bees and Beehive Products

Abstract

:1. Introduction

2. Results and Discussion

2.1. Preliminary Evaluation of Digestion Efficiency

2.2. Selection of ICP Instrument

2.3. Analytical Performances

2.3.1. Linearity

2.3.2. Limit of Detection and Quantification

2.3.3. Precision, Trueness and Recovery Study

2.3.4. Mixture Reagent Digestion

2.4. Analysis of Commercial Beehive Products

3. Materials and Methods

3.1. Instrumentation

3.2. Reagents

3.3. Sample Preparation Methods

3.3.1. Open-Vessel Water Bath-Assisted Digestion

3.3.2. Closed-Vessel Microwave-Assisted Digestion

3.4. Quality Assurance and Control

3.5. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Massimi, L.; Ristorini, M.; Astolfi, M.L.; Perrino, C.; Canepari, S. High resolution spatial mapping of element concentrations in PM10: A powerful tool for localization of emission sources. Atmos. Res. 2020, 244, 105060. [Google Scholar] [CrossRef]

- Manigrasso, M.; Protano, C.; Astolfi, M.L.; Massimi, L.; Avino, P.; Vitali, M.; Canepari, S. Evidences of copper nanoparticle exposure in indoor environments: Long-term assessment, high-resolution field emission scanning electron microscopy evaluation, in silico respiratory dosimetry study and possible health implications. Sci. Total Environ. 2019, 653, 1192–1203. [Google Scholar] [CrossRef]

- Canepari, S.; Castellano, P.; Astolfi, M.L.; Materazzi, S.; Ferrante, R.; Fiorini, D.; Curini, R. Release of particles, organic compounds, and metals from crumb rubber used in synthetic turf under chemical and physical stress. Environ. Sci. Pollut. Res. 2018, 25, 1448–1459. [Google Scholar] [CrossRef]

- Canepari, S.; Astolfi, M.L.; Marcovecchio, F.; Maretto, M.; Perrino, C. Seasonal variations in the concentration and solubility of elements in atmospheric particulate matter: A case study in Northern Italy, E3S Web of Conferences. EDP Sci. 2013, 1, 20002. [Google Scholar] [CrossRef]

- Marconi, E.; Canepari, S.; Astolfi, M.L.; Perrino, C. Determination of Sb (III), Sb (V) and identification of Sb-containing nanoparticles in airborne particulate matter. Procedia Environ. Sci. 2011, 4, 209–217. [Google Scholar] [CrossRef] [Green Version]

- Astolfi, M.L.; Canepari, S.; Catrambone, M.; Perrino, C.; Pietrodangelo, A. Improved characterisation of inorganic components in airborne particulate matter. Environ. Chem. Lett. 2006, 3, 186–191. [Google Scholar] [CrossRef]

- Al-Alam, J.; Chbani, A.; Faljoun, Z.; Millet, M. The use of vegetation, bees, and snails as important tools for the biomonitoring of atmospheric pollution—A review. Environ. Sci. Pollut. Res. 2019, 26, 9391–9408. [Google Scholar] [CrossRef]

- Protano, C.; Canepari, S.; Astolfi, M.L.; de Meo, S.D.O.; Vitali, M. Urinary reference ranges and exposure profile for lithium among an Italian paediatric population. Sci. Total Environ. 2018, 619, 58–64. [Google Scholar] [CrossRef]

- Astolfi, M.L.; Protano, C.; Marconi, E.; Massimi, L.; Piamonti, D.; Brunori, M.; Vitali, M.; Canepari, S. Biomonitoring of Mercury in Hair among a Group of Eritreans (Africa). Int. J.Environ. Res. Public Health 2020, 17, 1911. [Google Scholar] [CrossRef] [Green Version]

- Astolfi, M.L.; Protano, C.; Schiavi, E.; Marconi, E.; Capobianco, D.; Massimi, L.; Ristorini, M.; Baldassarre, M.E.; Laforgia, N.; Vitali, M.; et al. A prophylactic multi-strain probiotic treatment to reduce the absorption of toxic elements: In-vitro study and biomonitoring of breast milk and infant stools. Environ. Int. 2019, 130, 104818. [Google Scholar] [CrossRef]

- Ristorini, M.; Astolfi, M.L.; Frezzini, M.A.; Canepari, S.; Massimi, L. Evaluation of the efficiency of Arundo donax L. leaves as biomonitors for atmospheric element concentrations in an urban and industrial area of central Italy. Atmosphere 2020, 11, 226. [Google Scholar] [CrossRef] [Green Version]

- Vitali, M.; Antonucci, A.; Owczarek, M.; Guidotti, M.; Astolfi, M.L.; Manigrasso, M.; Avino, P.; Bhattacharya, B.; Protano, C. Air quality assessment in different environmental scenarios by the determination of typical heavy metals and Persistent Organic Pollutants in native lichen Xanthoria parietina. Environ. Pollut. 2019, 254, 113013. [Google Scholar] [CrossRef]

- Massimi, L.; Conti, M.E.; Mele, G.; Ristorini, M.; Astolfi, M.L.; Canepari, S. Lichen transplants as indicators of atmospheric element concentrations: A high spatial resolution comparison with PM10 samples in a polluted area (Central Italy). Ecol. Indic. 2019, 101, 759–769. [Google Scholar] [CrossRef]

- Conti, M.E.; Canepari, S.; Finoia, M.G.; Mele, G.; Astolfi, M.L. Characterization of Italian multifloral honeys on the basis of their mineral content and some typical quality parameters. J. Food Compos. Anal. 2018, 74, 102–113. [Google Scholar] [CrossRef]

- Losfeld, G.; Saunier, J.B.; Grison, C. Minor and trace-elements in apiary products from a historical mining district (Les Malines, France). Food Chem. 2014, 146, 455–459. [Google Scholar] [CrossRef]

- Dżugan, M.; Wesołowska, M.; Zaguła, G.; Kaczmarski, M.; Czernicka, M.; Puchalski, C. Honeybees (Apis mellifera) as a biological barrier for contamination of honey by environmental toxic metals. Environ. Monit. Assess. 2018, 190, 101. [Google Scholar] [CrossRef]

- Lambert, O.; Piroux, M.; Puyo, S.; Thorin, C.; Larhantec, M.; Delbac, F.; Pouliquen, H. Bees, honey and pollen as sentinels for lead environmental contamination. Environ. Pollut. 2012, 170, 254–259. [Google Scholar] [CrossRef]

- Zhou, X.; Taylor, M.P.; Davies, P.J.; Prasad, S. Identifying sources of environmental contamination in European honey bees (Apis mellifera) using trace elements and lead isotopic compositions. Environ. Sci. Technol. 2018, 52, 991–1001. [Google Scholar] [CrossRef]

- Matin, G.; Kargar, N.; Buyukisik, H.B. Bio-monitoring of cadmium, lead, arsenic and mercury in industrial districts of Izmir, Turkey by using honey bees, propolis and pine tree leaves. Ecol. Eng. 2016, 90, 331–335. [Google Scholar] [CrossRef]

- Smith, K.E.; Weis, D.; Amini, M.; Shiel, A.E.; Lai, V.W.M.; Gordon, K. Honey as a biomonitor for a changing world. Nat. Sustain. 2019, 2, 223–232. [Google Scholar] [CrossRef]

- Pohl, P.; Sergiel, I.; Stecka, H. Determination and fractionation of metals in honey. Crit. Rev. Anal. Chem. 2009, 39, 276–288. [Google Scholar] [CrossRef]

- Herrero-Latorre, C.; Barciela-García, J.; García-Martín, S.; Peña-Crecente, R.M. The use of honeybees and honey as environmental bioindicators for metals and radionuclides: A review. Environ. Rev. 2017, 25, 463–480. [Google Scholar] [CrossRef]

- Pascual-Maté, A.; Osés, S.M.; Fernández-Muiño, M.A.; Sancho, M.T. Methods of analysis of honey. J. Apic. Res. 2018, 57, 38–74. [Google Scholar] [CrossRef]

- Álvarez-Ayuso, E.; Abad-Valle, P. Trace element levels in an area impacted by old mining operations and their relationship with beehive products. Sci. Total Environ. 2017, 599, 671–678. [Google Scholar] [CrossRef] [PubMed]

- van der Steen, J.J.; de Kraker, J.; Grotenhuis, T. Spatial and temporal variation of metal concentrations in adult honeybees (Apis mellifera L.), Environ. Monit. Assess. 2012, 184, 4119–4126. [Google Scholar] [CrossRef] [Green Version]

- Ajtony, Z.; Bencs, L.; Haraszi, R.; Szigeti, J.; Szoboszlai, N. Study on the simultaneous determination of some essential and toxic trace elements in honey by multi-element graphite furnace atomic absorption spectrometry. Talanta 2007, 71, 683–690. [Google Scholar] [CrossRef]

- Packer, A.P.; Giné, M.F. Analysis of undigested honey samples by isotope dilution inductively coupled plasma mass spectrometry with direct injection nebulization (ID-ICP-MS). Spectrochim. Acta B 2001, 56, 69–75. [Google Scholar] [CrossRef]

- Madejczyk, M.; Baralkiewicz, D. Characterization of Polish rape and honeydew honey according to their mineral contents using ICP-MS and F-AAS/AES. Anal. Chim. Acta 2008, 617, 11–17. [Google Scholar] [CrossRef]

- Conti, M.E.; Botrè, F. Honeybees and their products as potential bioindicators of heavy metals contamination. Environ. Monit. Assess. 2001, 69, 267–282. [Google Scholar] [CrossRef]

- Gutiérrez, M.; Molero, R.; Gaju, M.; van der Steen, J.; Porrini, C.; Ruiz, J.A. Assessment of heavy metal pollution in Córdoba (Spain) by biomonitoring foraging honeybee. Environ. Monit. Assess. 2015, 18, 651. [Google Scholar] [CrossRef]

- Sajtos, Z.; Herman, P.; Harangi, S.; Baranyai, E. Elemental analysis of Hungarian honey samples and bee products by MP-AES method. Microchem. J. 2019, 149, 103968. [Google Scholar] [CrossRef]

- Mračević, S.Đ.; Krstić, M.; Lolić, A.; Ražić, S. Comparative study of the chemical composition and biological potential of honey from different regions of Serbia. Microchem. J. 2020, 152, 104420. [Google Scholar] [CrossRef]

- Bazeyad, A.Y.; Al-Sarar, A.S.; Rushdi, A.I.; Hassanin, A.S.; Abobakr, Y. Levels of heavy metals in a multifloral Saudi honey. Environ. Sci. Pollut. Res. 2019, 26, 3946–3953. [Google Scholar] [CrossRef]

- Oliveira, S.S.; Alves, C.N.; Morte, E.S.B.; Júnior, A.D.F.S.; Araujo, R.G.O.; Santos, D.C.M.B. Determination of essential and potentially toxic elements and their estimation of bioaccessibility in honeys. Microchem. J. 2019, 151, 104221. [Google Scholar] [CrossRef]

- Grainger, M.N.; Hewitt, N.; French, A.D. Optimised approach for small mass sample preparation and elemental analysis of bees and bee products by inductively coupled plasma mass spectrometry. Talanta 2020, 214, 120858. [Google Scholar] [CrossRef]

- Sadowska, M.; Gogolewska, H.; Pawelec, N.; Sentkowska, A.; Krasnodębska-Ostręga, B. Comparison of the contents of selected elements and pesticides in honey bees with regard to their habitat. Environ. Sci. Pollut. Res. 2019, 26, 371–380. [Google Scholar] [CrossRef] [Green Version]

- Giglio, A.; Ammendola, A.; Battistella, S.; Naccarato, A.; Pallavicini, A.; Simeon, E.; Tagarelli, A.; Giulianini, P.G. Apis mellifera ligustica, Spinola 1806 as bioindicator for detecting environmental contamination: A preliminary study of heavy metal pollution in Trieste, Italy. Environ. Sci. Pollut. Res. 2017, 24, 659–665. [Google Scholar] [CrossRef]

- González-Martín, M.I.; Revilla, I.; Betances-Salcedo, E.V.; Vivar-Quintana, A.M. Pesticide residues and heavy metals in commercially processed propolis. Microchem. J. 2018, 143, 423–429. [Google Scholar] [CrossRef]

- Voica, C.; Iordache, A.M.; Ionete, R.E. Multielemental characterization of honey using inductively coupled plasma mass spectrometry fused with chemometrics. J. Mass Spectrom. 2020, 55, e4512. [Google Scholar] [CrossRef]

- Raeymaekers, B. A prospective biomonitoring campaign with honey bees in a district of Upper-Bavaria (Germany). Environ. Monit. Assess. 2006, 116, 233–243. [Google Scholar] [CrossRef]

- Vieira, H.P.; Nascentes, C.C.; Windmöller, C.C. Development and comparison of two analytical methods to quantify the mercury content in honey. J. Food Compos. Anal. 2014, 34, 1–6. [Google Scholar] [CrossRef]

- Morgano, M.A.; Martins, M.C.T.; Rabonato, L.C.; Milani, R.F.; Yotsuyanagi, K.; Rodriguez-Amaya, D.B. A comprehensive investigation of the mineral composition of Brazilian bee pollen: Geographic and seasonal variations and contribution to human diet. J. Braz. Chem. Soc. 2012, 23, 727–736. [Google Scholar] [CrossRef] [Green Version]

- da Silva, P.M.; Gauche, C.; Gonzaga, L.V.; Costa, A.C.O.; Fett, R. Honey: Chemical composition, stability and authenticity. Food Chem. 2016, 196, 309–323. [Google Scholar] [CrossRef] [PubMed]

- Bastos, D.H.M.; Bastos, M.; Barth, O.M.; Rocha, C.I.; Cunha, I.B.d.S.; de Carvalho, P.; Torres, E.A.S.; Michelan, M. Fatty acid composition and palynological analysis of bee (Apis) pollen loads in the states of São Paulo and Minas Gerais. Brazil. J. Apic. Res. 2004, 43, 35–39. [Google Scholar] [CrossRef]

- Pettine, M.; Casentini, B.; Mastroianni, D.; Capri, S. Dissolved inorganic carbon effect in the determination of arsenic and chromium in mineral waters by inductively coupled plasma-mass spectrometry. Anal. Chim. Acta 2007, 599, 191–198. [Google Scholar] [CrossRef]

- Allain, P.; Jaunault, L.; Mauras, Y.; Mermet, J.M.; Delaporte, T. Signal enhancement of elements due to the presence of carbon-containing compounds in inductively coupled plasma mass spectrometry. Anal. Chem. 1991, 63, 1497–1498. [Google Scholar] [CrossRef]

- US EPA. SW-846 Test Method 6020B: Inductively Coupled Plasma—Mass Spectrometry; United States Environmental Protection Agency: Cincinnati, OH, USA, 1994.

- Nóbrega, J.A.; Pirola, C.; Fialho, L.L.; Rota, G.; de Campos Jordão, C.E.K.M.A.; Pollo, F. Microwave-assisted digestion of organic samples: How simple can it become? Talanta 2012, 98, 272–276. [Google Scholar] [CrossRef] [Green Version]

- Muller, A.L.; Oliveira, J.S.; Mello, P.A.; Muller, E.I.; Flores, E.M. Study and determination of elemental impurities by ICP-MS in active pharmaceutical ingredients using single reaction chamber digestion in compliance with USP requirements. Talanta 2015, 136, 161–169. [Google Scholar] [CrossRef]

- Latimer, G.W.; Association of Official Analytical Chemists International (AOAC). Official Methods of Analysis of AOAC International; AOAC International: Gaithersburg, MD, USA, 2012. [Google Scholar]

- Bilandžić, N.; Đokić, M.; Sedak, M.; Kolanović, S.B.; Varenina, I.; Končurat, A.; Rudan, N. Determination of trace elements in Croatian floral honey originating from different regions. Food Chem. 2011, 128, 1160–1164. [Google Scholar] [CrossRef]

- Leme, A.B.; Bianchi, S.R.; Carneiro, R.L.; Nogueira, A.R. Optimization of sample preparation in the determination of minerals and trace elements in honey by ICP-MS. Food Anal. Methods 2014, 7, 1009–1015. [Google Scholar] [CrossRef]

- Döker, S.; Aydemir, O.; Uslu, M. Evaluation of digestion procedures for trace element analysis of Cankiri, Turkey honey by inductively coupled plasma mass spectrometry. Anal. Lett. 2014, 47, 2080–2094. [Google Scholar] [CrossRef]

- Chen, M.; Ma, L.Q. Comparison of three aqua regia digestion methods for twenty Florida soils. Soil Sci. Soc. Am. J. 2001, 65, 491–499. [Google Scholar] [CrossRef] [Green Version]

- Abbruzzini, T.F.; Silva, C.A.; Andrade, D.A.D.; Carneiro, W.J.D.O. Influence of digestion methods on the recovery of iron, zinc, nickel, chromium, cadmium and lead contents in 11 organic residues. Rev. Bras. Ciênc. Sol. 2014, 38, 166–176. [Google Scholar] [CrossRef] [Green Version]

- Das, S.; Ting, Y.P. Evaluation of wet digestion methods for quantification of metal content in electronic scrap material. Resources 2017, 6, 64. [Google Scholar] [CrossRef] [Green Version]

- Edgell, K. USEPA Method Study 37 SW-846 Method 3050 Acid Digestion of Sediments, Sludges, and Soils; US Environmental Protection Agency, Environmental Monitoring Systems Laboratory: Washington, DC, USA, 1989.

- Astolfi, M.L.; Protano, C.; Marconi, E.; Massimi, L.; Brunori, M.; Piamonti, D.; Migliara, G.; Vitali, M.; Canepari, S. A new treatment of human hair for elemental determination by inductively coupled mass spectrometry. Anal. Methods 2020, 12, 1906–1918. [Google Scholar] [CrossRef]

- Bizzi, C.A.; Barin, J.S.; Garcia, E.E.; Nóbrega, J.A.; Dressler, V.L.; Flores, E.M. Improvement of microwave-assisted digestion of milk powder with diluted nitric acid using oxygen as auxiliary reagent. Spectrochim. Acta B 2011, 66, 394–398. [Google Scholar] [CrossRef]

- Astolfi, M.L.; Marconi, E.; Protano, C.; Vitali, M.; Schiavi, E.; Mastromarino, P.; Canepari, S. Optimization and validation of a fast digestion method for the determination of major and trace elements in breast milk by ICP-MS. Anal. Chim. Acta 2018, 1040, 49–62. [Google Scholar] [CrossRef]

- Phan-Thien, K.Y.; Wright, G.C.; Lee, N.A. Inductively coupled plasma-mass spectrometry (ICP-MS) and-optical emission spectroscopy (ICP–OES) for determination of essential minerals in closed acid digestates of peanuts (Arachis hypogaea L.). Food Chem. 2012, 134, 453–460. [Google Scholar] [CrossRef]

- Pick, D.; Leiterer, M.; Einax, J.W. Reduction of polyatomic interferences in biological material using dynamic reaction cell ICP-MS. Microchem. J. 2010, 95, 315–319. [Google Scholar] [CrossRef]

- D’Ilio, S.; Petrucci, F.; D’Amato, M.; di Gregorio, M.; Senofonte, O.; Violante, N. Method validation for determination of arsenic, cadmium, chromium and lead in milk by means of dynamic reaction cell inductively coupled plasma mass spectrometry. Anal. Chim. Acta 2008, 624, 59–67. [Google Scholar] [CrossRef]

- May, T.W.; Wiedmeyer, R.H. A table of polyatomic interferences in ICP-MS. At. Spectrosc. 1998, 19, 150–155. [Google Scholar]

- Martínez-Sierra, J.G.; San Blas, O.G.; Gayón, J.M.; Alonso, J.G. Sulfur analysis by inductively coupled plasma-mass spectrometry: A review. Spectrochim. Acta B 2015, 108, 35–52. [Google Scholar] [CrossRef]

- Mandel, J. The Statistical Analysis of Experimental Data; John Wiley & Sons: New York, NY, USA, 1964; pp. 1–410. [Google Scholar]

- Cubadda, F.; Raggi, A.; Testoni, A.; Zanasi, F. Multielemental analysis of food and agricultural matrixes by inductively coupled plasma-mass spectrometry. J. AOAC Int. 2002, 85, 113–121. [Google Scholar] [CrossRef] [Green Version]

- Nardi, E.P.; Evangelista, F.S.; Tormen, L.; Pierre, T.D.S.; Curtius, A.J.; de Souza, S.S.; Junior, F.B. The use of inductively coupled plasma mass spectrometry (ICP-MS) for the determination of toxic and essential elements in different types of food samples. Food Chem. 2009, 112, 727–732. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EU) 2015/1005 of 25 June 2015 amending Regulation (EC) No 1881/2006 as regards maximum levels of lead in certain foodstuffs. Off. J. Eur. Union 2015, 161, 9–13. [Google Scholar]

- Codex Alimentarius. Joint FAO/WHO Food Standards Programme; Twenty-fourth Session; Codex Alimentarius Commission: Geneva, Switzerland, 2001. [Google Scholar]

- Jorhem, L.; Engman, J.; Schröder, T. Evaluation of results derived from the analysis of certified reference materials–a user-friendly approach based on simplicity. Fresenius J. Anal. Chem. 2001, 370, 178–182. [Google Scholar] [CrossRef]

- U.S. EPA. Method 3051A (SW-846): Microwave Assisted Acid Digestion of Sediments, Sludges, and Oils; Revision 1; United States Environmental Protection Agency: Washington, DC, USA, 2007.

- Cava-Montesinos, P.; Cervera, M.L.; Pastor, A.; de la Guardia, M. Room temperature acid sonication ICP-MS multielemental analysis of milk. Anal. Chim. Acta 2005, 531, 111–123. [Google Scholar] [CrossRef]

- Astolfi, M.L.; Marconi, E.; Protano, C.; Canepari, S. Comparative elemental analysis of dairy milk and plant-based milk alternatives. Food Control 2020, 116, 107327. [Google Scholar] [CrossRef]

- Magnusson, B.; Örnemark, U. (Eds.) Eurachem Guide: The Fitness for Purpose of Analytical Methods—A Laboratory Guide to Method Validation and Related Topics, 2nd ed.; Eurachem: Teddington, UK, 2014; ISBN 978-91-87461-59-0. Available online: www.eurachem.org (accessed on 7 September 2020).

- Hornung, R.W.; Reed, L.D. Estimation of average concentration in the presence of nondetectable values. Appl. Occup. Environ. Hyg. 1990, 5, 46–51. [Google Scholar] [CrossRef]

- Siegel, S.; Castellan, N.J., Jr. Non Parametric Statistics for the Behavioral Sciences, 2nd ed.; McGraw-Hill: Milan, Italy, 1992; p. 477. [Google Scholar]

Sample Availability: Not available. |

| Isotope/Element b | Internal Standard c | LLOQ–ULOQ d mg kg−1 | ||||||

|---|---|---|---|---|---|---|---|---|

| LODA | LODB | LODB1 | N e | Honey and Beeswax | N e | Bees, Pollen, Propolis, and Royal Jelly | ||

| 27Al | 45Sc | 0.06 | 0.02 | 0.02 | 4 | 0.5–5 | 5 | 1.05–21 |

| 75As f | 79Y | 0.001 | 0.001 | - | 6 | 0.05–2 | 6 | 0.05–2 |

| 11B | 45Sc | 0.2 | 0.1 | 0.1 | 5 | 2.75–55 | 5 | 2.75–55 |

| 137Ba | 115In | 0.4 | 0.2 | 0.2 | 5 | 0.2–5 | 4 | 7–100 |

| 9Be | 45Sc | 0.00002 | 0.00002 | 0.00002 | 7 | 0.05–5 | 7 | 0.05–5 |

| 209Bi | 232Th | 0.00004 | 0.00006 | 0.00005 | 6 | 0.05–2 | 6 | 0.05–2 |

| 44Ca | 79Y | 11 | 5 | 14 | 4 | 100–1000 | 4 | 1000–10000 |

| 112Cd | 115In | 0.00004 | 0.00001 | 0.00001 | 7 | 0.05–110 | 7 | 0.05–110 |

| 140Ce | 115In | 0.00006 | 0.00004 | 0.0001 | 5 | 0.25–5 | 5 | 0.25–5 |

| 59Co | 45Sc | 0.0005 | 0.0004 | 0.0008 | 6 | 0.25–10 | 6 | 0.25–10 |

| 52Crf | 79Y | 0.001 | 0.0008 | - | 7 | 0.05–5 | 4 | 1–10 |

| 133Cs | 115In | 0.00004 | 0.00002 | 0.00001 | 7 | 0.05–5 | 7 | 0.05–5 |

| 65Cu | 79Y | 0.003 | 0.002 | 0.002 | 6 | 0.05–2 | 9 | 0.1–100 |

| 56Fe | 79Y | 0.02 | 0.01 | 0.01 | 4 | 1–10 | 9 | 2.5–5000 |

| 71Ga | 79Y | 0.00005 | 0.00001 | 0.00001 | 4 | 0.1–1 | 4 | 0.1–1 |

| 39K | 45Sc | 5 | 3 | 0.7 | 6 | 50–2500 | 6 | 50–2500 |

| 139La | 115In | 0.00004 | 0.00006 | 0.00005 | 7 | 0.05–5 | 7 | 0.05–5 |

| 7Li | 45Sc | 0.0008 | 0.0008 | 0.0005 | 7 | 0.05–5 | 7 | 0.05–5 |

| 24Mg | 45Sc | 0.9 | 0.3 | 1.0 | 5 | 100–2500 | 5 | 50–1000 |

| 55Mn | 79Y | 0.002 | 0.002 | 0.003 | 4 | 0.2–2 | 6 | 5.2–200 |

| 98Mo | 103Rh | 0.0003 | 0.0001 | 0.0001 | 7 | 0.05–110 | 7 | 0.05–110 |

| 23Na | 45Sc | 0.6 | 0.4 | 0.3 | 5 | 100–2500 | 7 | 25–2000 |

| 93Nb | 103Rh | 0.00001 | 0.000007 | 0.00002 | 5 | 0.05–1 | 5 | 0.05–1 |

| 60Ni | 45Sc | 0.002 | 0.003 | 0.003 | 6 | 0.05–2 | 7 | 0.2–20 |

| 31P | 45Sc | 0.7 | 1 | 0.7 | 5 | 5–100 | 4 | 1100–5000 |

| 208Pb | 232Th | 0.001 | 0.001 | 0.001 | 7 | 0.05–5 | 4 | 7–100 |

| 85Rb | 79Y | 0.0003 | 0.0003 | 0.00007 | 5 | 0.05–1 | 4 | 20–200 |

| 121Sb | 115In | 0.0004 | 0.0002 | 0.0001 | 7 | 0.05–5 | 7 | 0.05–5 |

| 76Se | 79Y | 0.02 | 0.007 | 0.01 | 4 | 0.2–2 | 4 | 0.2–2 |

| 28Si | 45Sc | 9 | 8 | 10 | 4 | 10–100 | 4 | 50–500 |

| 118Sn | 115In | 0.0002 | 0.0001 | 0.0001 | 7 | 0.05–5 | 7 | 0.05–5 |

| 88Sr | 79Y | 0.008 | 0.02 | 0.02 | 5 | 5.5–110 | 5 | 5.5–110 |

| 125Te | 115In | 0.0003 | 0.0003 | 0.0002 | 5 | 0.05–1 | 5 | 0.05–1 |

| 49Ti | 45Sc | 0.002 | 0.003 | 0.0007 | 9 | 0.05–50 | 9 | 0.05–50 |

| 205Tl | 232Th | 0.00006 | 0.00003 | 0.00001 | 5 | 0.05–1 | 5 | 0.05–1 |

| 238U | 232Th | 0.00001 | 0.00001 | 0.00001 | 7 | 0.05–5 | 7 | 0.05–5 |

| 51V | 79Y | 0.0003 | 0.0006 | 0.00003 | 6 | 0.1–5 | 4 | 1–10 |

| 182W | 232Th | 0.0003 | 0.0002 | 0.00006 | 7 | 0.05–5 | 7 | 0.05–5 |

| 66Zn | 79Y | 0.09 | 0.04 | 0.09 | 5 | 2–50 | 4 | 70–1000 |

| 90Zr | 79Y | 0.0001 | 0.00009 | 0.0001 | 6 | 0.05–2 | 6 | 0.05–2 |

| Isotope/Element a | Method A | Method B | ||||

|---|---|---|---|---|---|---|

| %CVr Intraday (n = 3) | %CVR Interday (n = 9) | %R (n = 3) | %CVr Intraday (n = 3) | %CVR Interday (n = 9) | %R (n = 3) | |

| 27Al | 1.8–24 | 1.5–25 | 96–126 | 5.4–27 | 15–25 | 97–124 |

| 75As | 1.8–21 | 17–27 | 88–124 | 5.0–29 | 17–30 | 90–119 |

| 11B | 0.2–24 | 6.5–19 | 84–102 | 2.2–32 | 7.6–25 | 86–100 |

| 137Ba | 0.6–23 | 11–25 | 103–122 | 1.2–21 | 17–30 | 101–112 |

| 9Be | 0.9–13 | 8.2–24 | 86–97 | 14–22 | 21–30 | 90–101 |

| 209Bi | 1.8–17 | 11–21 | 85–107 | 3.1–25 | 19–31 | 86–110 |

| 44Ca | 1.4–12 | 7.2–25 | 79–127 | 5.7–26 | 14–26 | 82–127 |

| 112Cd | 0.7–19 | 9.1–25 | 83–100 | 1.5–22 | 19–30 | 83–104 |

| 140Ce | 1.1–19 | 8.7–26 | 96–123 | 1.0–25 | 10–30 | 98–119 |

| 59Co | 0.8–13 | 1.1–25 | 81–105 | 0.4–27 | 9.2–27 | 84–102 |

| 52Cr | 0.7–19 | 2.0–22 | 91–101 | 8.9–26 | 20–31 | 94–107 |

| 133Cs | 0.7–6.4 | 9.1–25 | 99–123 | 3.3–14 | 3.3–30 | 99–119 |

| 65Cu | 1.3–23 | 4.6–23 | 82–121 | 1.1–18 | 5.4–28 | 87–111 |

| 56Fe | 0.5–7.7 | 3.6–13 | 88–120 | 0.9–25 | 5.9–25 | 92–116 |

| 71Ga | 1.2–23 | 13–24 | 83–130 | 1.1–25 | 7.4–31 | 86–130 |

| 39K | 0.9–22 | 1.3–21 | 87–124 | 0.8–10 | 6.7–13 | 87–121 |

| 139La | 1.2–10 | 5.0–24 | 90–114 | 0.5–24 | 8.1–29 | 92–114 |

| 7Li | 0.2–11 | 3.8–24 | 90–118 | 1.5–23 | 14–21 | 90–120 |

| 24Mg | 0.01–9.0 | 5.2–25 | 82–108 | 0.5–19 | 7.0–23 | 82–110 |

| 55Mn | 0.4–17 | 12–25 | 84–125 | 0.7–24 | 3.7–24 | 86–115 |

| 98Mo | 0.3–6 | 10–25 | 95–117 | 1.9–25 | 1.9–25 | 94–114 |

| 23Na | 0.6–6.7 | 4.9–21 | 80–125 | 2.2–17 | 6.5–26 | 84–122 |

| 93Nb | 1.5–20 | 8.0–24 | 85–122 | 3.6–22 | 11–27 | 86–116 |

| 60Ni | 0.9–17 | 13–22 | 83–97 | 0.4–23 | 8.6–29 | 82–99 |

| 31P | 0.5–11 | 4.2–20 | 80–122 | 0.5–23 | 5.7–25 | 81–123 |

| 208Pb | 1.6–23 | 12–24 | 80–121 | 2.7–24 | 16–27 | 86–116 |

| 85Rb | 3.6–11 | 4.5–25 | 96–120 | 0.8–23 | 7.3–30 | 92–117 |

| S | 7.5–9.1 | 6.8–11 | 96–110 | 1.7–10 | 4.1–11 | 97–111 |

| 121Sb | 0.2–17 | 11–26 | 81–100 | 13–23 | 15–27 | 84–98 |

| 76Se | 0.4–18 | 16–26 | 83–108 | 3.4–24 | 13–30 | 82–102 |

| 28Si | 1.4–15 | 4.2–26 | 101–126 | 1.8–21 | 4.1–28 | 98–122 |

| 118Sn | 2.0–14 | 5.7–26 | 81–101 | 2.7–23 | 15–31 | 86–101 |

| 88Sr | 1.3–15 | 0.6–25 | 89–121 | 0.5–24 | 15–34 | 84–119 |

| 125Te | 0.7–15 | 7.0–26 | 81–89 | 3.0–17 | 27–30 | 81–90 |

| 49Ti | 1.2–22 | 6.8–18 | 95–128 | 0.2–19 | 3.5–30 | 96–118 |

| 205Tl | 1.6–19 | 13–20 | 94–124 | 1.0–19 | 11–24 | 96–120 |

| 238U | 1.7–21 | 9.8–29 | 87–110 | 1.9–21 | 15–26 | 87–110 |

| 51V | 0.3–19 | 9.4–25 | 83–111 | 1.2–22 | 10–30 | 86–106 |

| 182W | 1.8–7 | 19–26 | 84–113 | 0.6–15 | 11–30 | 84–116 |

| 66Zn | 0.3–24 | 5.2–25 | 88–126 | 1.3–21 | 10–29 | 86–124 |

| 90Zr | 1.2–21 | 11–25 | 90–112 | 2.3–17 | 13–31 | 92–114 |

| Element | Honey 1 | Honey 2 | Honey 3 | Honey 4 | Honey 5 | Honeydew 1 | Honeydew 2 | Beeswax | Pollen | Royal Jelly | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M | SD | M | SD | M | SD | M | SD | M | SD | M | SD | M | SD | M | SD | M | SD | M | SD | |

| Al | 0.09 | 0.02 | 0.187 | 0.078 | 6.33 | 0.43 | 2.48 | 0.22 | 0.153 | 0.027 | 0.439 | 0.035 | 1.65 | 0.03 | <LOD | - | 3.68 | 0.29 | 0.054 | 0.025 |

| As | <LOD | - | <LOD | - | <LOD | <LOD | <LOD | - | <LOD | - | <LOD | - | <LOD | - | 0.012 | 0.011 | <LOD | - | ||

| B | 6.56 | 0.32 | 0.697 | 0.045 | 3.60 | 0.25 | 3.99 | 0.03 | 7.75 | 0.16 | 4.54 | 0.10 | 7.33 | 0.46 | <LOD | - | 5.73 | 0.67 | 1.37 | 0.16 |

| Ba | 0.083 | 0.007 | <LOD | - | 1.93 | 0.08 | 0.627 | 0.043 | 0.0522 | 0.0053 | 0.113 | 0.011 | 0.891 | 0.061 | <LOD | - | 2.15 | 0.42 | <LOD | - |

| Be | <LOD | - | <LOD | - | 0.00091 | 0.00016 | 0.00117 | 0.00019 | <LOD | - | <LOD | - | 0.00183 | 0.00032 | <LOD | - | 0.00052 | 0.00037 | <LOD | - |

| Bi | <LOD | - | <LOD | - | 0.000516 | 0.000042 | <LOD | - | <LOD | - | 0.00057 | 0.00013 | 0.000270 | 0.000069 | <LOD | - | <LOD | - | <LOD | - |

| Ca | 91 | 6 | 38.6 | 8.7 | 181 | 24 | 154 | 21 | 51.1 | 6.8 | 50 | 12 | 118 | 8 | <LOD | - | 547 | 103 | 165 | 43 |

| Cd | 0.000218 | 0.000058 | <LOD | - | 0.00104 | 0.00034 | <LOD | - | <LOD | - | 0.00115 | 0.00022 | 0.00087 | 0.00010 | <LOD | - | 0.0642 | 0.0063 | <LOD | - |

| Ce | 0.00117 | 0.00015 | 0.000372 | 0.000087 | 0.0145 | 0.0012 | 0.0187 | 0.0012 | 0.00096 | 0.00025 | 0.00234 | 0.00017 | 0.0419 | 0.0018 | 0.00098 | 0.00023 | 0.0055 | 0.0026 | 0.000850 | 0.0002 |

| Co | 0.00630 | 0.00007 | 0.00130 | 0.00031 | 0.0107 | 0.0005 | 0.0107 | 0.0005 | 0.00174 | 0.00030 | 0.0176 | 0.0008 | 0.0241 | 0.0020 | <LOD | - | 0.158 | 0.017 | 0.00123 | 0.00023 |

| Cr | 0.00561 | 0.00074 | 0.0063 | 0.0017 | 0.0123 | 0.0016 | 0.0127 | 0.0033 | <LOD | - | 0.0146 | 0.0022 | 0.0587 | 0.0055 | 0.0204 | 0.0060 | 0.0547 | 0.0061 | 0.0340 | 0.0026 |

| Cs | 0.00443 | 0.00034 | 0.00062 | 0.00010 | 0.787 | 0.045 | 0.565 | 0.029 | 0.00245 | 0.00065 | 0.00365 | 0.00013 | 0.547 | 0.037 | 0.000292 | 0.000091 | 0.0142 | 0.0034 | 0.00063 | 0.00013 |

| Cu | 0.261 | 0.013 | 0.0623 | 0.0073 | 0.747 | 0.039 | 1.01 | 0.02 | 0.153 | 0.010 | 1.97 | 0.02 | 3.30 | 0.14 | <LOD | - | 5.82 | 0.89 | 4.26 | 0.41 |

| Fe | 2.93 | 0.41 | 1.81 | 0.19 | 2.68 | 0.31 | 4.28 | 0.96 | 0.58 | 0.13 | 2.54 | 0.25 | 4.50 | 0.35 | 0.31 | 0.15 | 24.0 | 8.3 | 9.23 | 0.75 |

| Ga | 0.00247 | 0.00035 | 0.00240 | 0.00029 | 0.042 | 0.011 | 0.0140 | 0.0012 | 0.00173 | 0.00035 | 0.00224 | 0.00048 | 0.0201 | 0.0025 | <LOD | - | 0.0436 | 0.0072 | <LOD | - |

| K | 1340 | 24 | 89 | 2 | 4661 | 341 | 3708 | 36 | 732 | 8 | 6520 | 46 | 2399 | 157 | <LOD | - | 3703 | 592 | 2520 | 260 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Astolfi, M.L.; Conti, M.E.; Marconi, E.; Massimi, L.; Canepari, S. Effectiveness of Different Sample Treatments for the Elemental Characterization of Bees and Beehive Products. Molecules 2020, 25, 4263. https://doi.org/10.3390/molecules25184263

Astolfi ML, Conti ME, Marconi E, Massimi L, Canepari S. Effectiveness of Different Sample Treatments for the Elemental Characterization of Bees and Beehive Products. Molecules. 2020; 25(18):4263. https://doi.org/10.3390/molecules25184263

Chicago/Turabian StyleAstolfi, Maria Luisa, Marcelo Enrique Conti, Elisabetta Marconi, Lorenzo Massimi, and Silvia Canepari. 2020. "Effectiveness of Different Sample Treatments for the Elemental Characterization of Bees and Beehive Products" Molecules 25, no. 18: 4263. https://doi.org/10.3390/molecules25184263