Comparative Effect of UV, UV/H2O2 and UV/H2O2/Fe on Terbuthylazine Degradation in Natural and Ultrapure Water

Abstract

:1. Introduction

2. Materials and Methods

2.1. Photoreactors

- (i)

- Batch-type ultraviolet reactor: Laboratory-scale complete mix photoreactor from the commercial company LUZCHEM, equipped with 14 low-pressure mercury lamps (254 nm), with a lamp intensity of 0.15 w m−2 and an average illumination of 175 foot-candles. It is equipped with a temperature control system, exposure time, irradiation power and stirring system. Before starting the experiments, the equipment was left on for 10 min to stabilise the light intensity of the lamps. The samples, previously doped with 0.5 mg L−1 terbuthylazine, were placed in a 50-mL quartz reactor and introduced into the photoreactor, always in the same position, controlling the irradiation time and the power of the lamps.

- (ii)

- Semi-continuous UV reactor: This reactor consists of a vessel in which the sample to be treated is deposited and sucked in by a peristaltic pump with a flow control system that pumps the sample into the reactor where it is treated with UV radiation (Figure 1). In this case, UV-C light provided by a low-pressure mercury lamp with a power of 40 W is used. The speed control of the pump controls the flow rate, which makes it possible to work with different exposure times or different flow rates and, thus, to determine the dose received at each moment.

2.2. Studied Matrices

2.3. Applied Advanced Oxidation Processes

2.4. Analytical Methods

2.5. Reagents

2.6. Data Processing

3. Results and Discussion

3.1. Experiments Carried out in a Batch Reactor

3.1.1. Degradation of Terbuthylazine in Ultrapure Water Carried out in a Batch Reactor

3.1.2. Degradation of Terbuthylazine in Groundwater (Spring Water) Carried out in a Batch Reactor

3.1.3. Degradation of Terbuthylazine in Surface Water (Gaditana Area) Carried out in a Batch Reactor

3.2. Experiments Performed in a Semi-Continuous Reactor

3.2.1. Degradation of Terbuthylazine in Ultrapure Water Performed in a Semi-Continuous Reactor

3.2.2. Degradation of Terbuthylazine in Groundwater (Spring Water) Performed in a Semi-Continuous Reactor

3.2.3. Degradation of Terbuthylazine in Surface Water (Gaditana Area) Performed in a Semi-Continuous Reactor

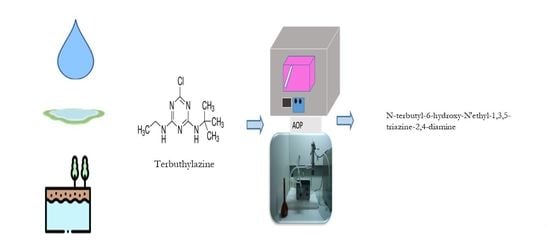

3.3. Degradation Products of Terbuthylazine after Application of AOPs in Ultrapure Water

3.4. Comparison of the Results Obtained in the Two Different Reactors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- United Nations. Transforming Our World by 2030: A New Agenda for Global Action Zero. Draft of the Outcome Document for the UN Summit to Adopt the Post-2015 Development Agenda; United Nations: New York, NY, USA, 2015; Available online: https://digitallibrary.un.org/record/803352?ln=es (accessed on 12 February 2022).

- Wolff, S.; Schrammeijer, E.A.; Schulp, C.J.E.; Verburg, P.H. Meeting global land restoration and protection targets: What would the world look like in 2050? Glob. Environ. Chang. 2018, 52, 259–272. [Google Scholar] [CrossRef]

- Peterson, M.A.; Collavo, A.; Ovejero, R.; Shivrain, V.; Walsh, M.J. The challenge of herbicide resistance around the world: A current summary. Pest. Manag. Sci. Spec. Issue Glob. Herbic. Resist. Chall. 2017, 74, 2246–2259. [Google Scholar] [CrossRef] [PubMed]

- Talaviya, T.; Shah, D.; Patel, N.; Yagnik, H.; Shah, M. Implementation of artificial intelligence in agriculture for optimisation of irrigation and application of pesticides and herbicides. Artif. Intell. Agric. 2020, 4, 58–73. [Google Scholar] [CrossRef]

- Huang, X.; He, J.; Yan, X.; Hong, Q.; Chen, K.; He, Q.; Zhang, L.; Liu, X.; Chuang, S.; Li, S.; et al. Microbial catabolism of chemical herbicides: Microbial resources, metabolic pathways and catabolic genes. Pestic. Biochem. Physiol. 2017, 143, 272–297. [Google Scholar] [CrossRef] [PubMed]

- CHL. Report Proposal for Harmonised Classification and Labelling Based on Regulation; (EC) No 1272/2008 (CLP Regulation); Annex VI; Part. 2. (Substance Name: Terbuthylazine, EC Number: 227-637-9, CAS Number: 5915-41-3); ECHA: Helsinki, Finland, 2014. [Google Scholar]

- Lovaković, B.T.; Pizent, A.; Kašuba, V.; Kopjar, N.; Micek, V.; Mendaš, G.; Dvoršćak, M.; Mikolić, A.; Milić, M.; Žunec, S.; et al. Effects of sub-chronic exposure to terbuthylazine on DNA damage, oxidative stress and parent compound/metabolite levels in adult male rats. Food Chem. Toxicol. 2017, 108, 93–103. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (USEPA). Registration Eligibility Decisions (REDs) Database on Tterbuthylazine (5915-41-3). (USEPA 738-R-95-005). 2012. Available online: https://archive.epa.gov/pesticides/reregistration/web/pdf/2645.pdf (accessed on 12 February 2022).

- Wang, X.; Liu, Q. Spatial and temporal distribution characteristics of triazine herbicides in typical agricultural regions of Liaoning, China. Bull. Environ. Contam. Toxicol. 2020, 105, 899–905. [Google Scholar] [CrossRef]

- Tasca, A.L.; Puccini, M.; Clematis, D.; Panizza, M. Electrochemical removal of Terbuthylazine:Boron-Doped Diamond anode coupled with solid polymer electrolyte. Environ. Pollut. 2019, 251, 285–291. [Google Scholar] [CrossRef]

- Navarro, S.; Vela, N.; Giménez, M.J.; Navarro, G. Persistence of four s-triazine herbicides in river, sea and groundwater samples exposed to sunlight and darkness under laboratory conditions. Sci. Total Environ. 2004, 329, 87–97. [Google Scholar] [CrossRef] [PubMed]

- Council Directive 2000/60/EC of the European Parliament and of the Council of 23 October 2000 Establishing a Framework for Community Action in the Field of Water Policy; European Council: Strasbourg, France, 2000.

- Ministerio de Agricultura, Alimentación y Medio Ambiente. Royal Decree 817/2015, of 11 September, Which Establishes the Criteria for Monitoring and Assessment of Surface Water Status and Environmental Quality Standards; Ministerio de Agricultura, Alimentación y Medio Ambiente: Madrid, Spain, 2015. [Google Scholar]

- European Food Safety Authority (EFSA). Conclusion on the peer review of the pesticide risk assessment of the active substance terbuthylazine. EFSA J. 2011, 9, 133. [Google Scholar] [CrossRef] [Green Version]

- Brühl, C.A.; Bakanov, N.; Köthe, S.; Eichler, L.; Sorg, M.; Hörren, T.; Mühlethaler, R.; Meinel, G.; Lehmann, G.U.C. Direct pesticide exposure of insects in nature conservation areas in Germany. Sci. Rep. 2021, 11, 24144. [Google Scholar] [CrossRef]

- Mladinic, M.; Zeljezic, D.; Shaposhnikov, S.A.; Collins, A.R. The use of FISH-comet to detect c-Myc and TP 53 damage in extended-term lymphocyte cultures treated with terbuthylazine and carbofuran. Toxicol. Lett. 2012, 211, 62–69. [Google Scholar] [CrossRef] [PubMed]

- EU. Commission Implementing Regulation 2019/291 of 19 February 2019 amending Implementing Regulation (EU) No 540/2011 as regards the extension of the approval periods of the active substances 1-naphthylacetamide, 1-naphthylacetic acid, acrinathrin, azoxystrobin, fluazifop p, fluroxypyr, imazalil, kresoxim-methyl, oxyfluorfen, prochloraz, prohexadione, spiroxamine, tefluthrin and terbuthylazine. Off. J. Eur. Union 2019, L48, 17–19. Available online: http://data.europa.eu/eli/reg_impl/2019/291/oj (accessed on 12 February 2022).

- Tasca, A.L.; Puccini, M.; Fletcher, A. Terbuthylazine and desethylterbuthylazine: Recent occurrence, mobility and removal techniques. Chemosphere 2018, 202, 94–104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De la Cruz, N.; Esquius, L.; Grandjean, D.; Magnet, A.; Tungler, A.; de Alencastro, L.F.; Pulgarín, C. Degradation of emergent contaminants by UV, UV/H2O2 and neutral photo-Fenton at pilot scale in a domestic wastewater treatment plant. Water Res. 2013, 47, 5836–5845. [Google Scholar] [CrossRef]

- Xu, J.; Guo, Y.; Yang, Q.; Bai, X.; Lu, R.; Liu, M.; Kuang, Z.; Zhang, L.; Li, J. Enhanced cyanogen chloride formation after UV/PS and UV/H2O2 pre-oxidation and chlorination in natural river water. J. Environ. Sci. 2023, 126, 48–57. [Google Scholar] [CrossRef]

- Zhang, A.; Ding, Y.; Jia, A.; Park, M.; Daniels, K.D.; Nie, X.; Wu, S. Removal of 26 corticosteroids, potential COVID-19 remedies, at environmentally relevant concentrations in water using UV/free chlorine, UV/monochloramine, and UV/hydrogen peroxide. Environ. Sci. Water Res. Technol. 2022, 8, 1078–1091. [Google Scholar] [CrossRef]

- Álvarez, P.M.; Quiñones, D.H.; Terrones, I.; Rey, A.; Beltrán, F.J. Insights into the removal of terbuthylazine from aqueous solution by several treatment methods. Water Res. 2016, 98, 334–343. [Google Scholar] [CrossRef]

- Lányi, K.; Dinya, Z. Photodegradation study of some triazine-type herbicides. Microchem. J. 2003, 75, 1–13. [Google Scholar] [CrossRef]

- Minero, C.; Pramauro, E.; Pelizzetti, E.; Dolci, M.; Marchesini, A. Photosensitized transformations of atrazine under simulated sunlight in aqueous humic acid solution. Chemosphere 1992, 24, 1597–1606. [Google Scholar] [CrossRef]

- Beltran, F.J.; García-Araya, J.F.; Acedo, B. Advanced oxidation of atrazine in water—I. Ozonation. Water Res. 1994, 28, 2153–2164. [Google Scholar] [CrossRef]

- Cerreta, G.; Roccamante, M.A.; Oller, I.; Malato, S.; Rizzo, L. Contaminants of emerging concern removal from real wastewater by UV/free chlorine process: A comparison with solar/free chlorine and UV/H2O2 at pilot scale. Chemosphere 2019, 236, 124354. [Google Scholar] [CrossRef] [PubMed]

- Sanlaville, Y.; Guittonneau, S.; Mansour, M.; Feicht, E.A.; Meallier, P.; Kettrup, A. Photosensitized degradation of terbuthylazine in water. Chemosphere 1996, 33, 353–362. [Google Scholar] [CrossRef]

- Moradi, M.; Elahinia, A.; Vasseghian, Y.; Dragoi, E.N.; Omidi, F.; Khaneghah, A.M. A review on pollutants removal by Sono-photo-Fenton processes. J. Environ. Chem. Eng. 2020, 8, 104330. [Google Scholar] [CrossRef]

- Verma, M.; Haritash, A.K. Degradation of amoxicillin by Fenton and Fenton-integrated hybrid oxidation processes. J. Environ. Chem. Eng. 2019, 7, 102886. [Google Scholar] [CrossRef]

- Legrini, O.; Oliveros, E.; Braun, A.M. Photochemical processes for water treatment. Chem. Rev. 1993, 93, 671–678. [Google Scholar] [CrossRef]

- Cuerda-Correa, E.M.; Alexandre, M.F.; Fernández-González, C. Advanced oxidation processes for the removal of antibiotics from water. An overview. Water 2020, 12, 102. [Google Scholar] [CrossRef] [Green Version]

- Prada-Vásquez, M.A.; Estrada-Flórez, S.E.; Serna-Galvis, E.F.; Torres-Palma, R.A. Developments in the intensification of photo-Fenton and ozonation-based processes for the removal of contaminants of emerging concern in Ibero-American countries. Sci. Total Environ. 2021, 765, 142699. [Google Scholar] [CrossRef]

- Feng, Y.; Qing, W.; Kong, L.; Li, H.; Wu, D.; Fan, Y.; Lee, P.H.; Shih, K. Factors and mechanisms that influence the reactivity of trivalent copper: A novel oxidant for selective degradation of antibiotics. Water Res. 2019, 149, 1–8. [Google Scholar] [CrossRef]

- Gallard, H.; De Laat, J.; Legube, B. Spectrophotometric study of the formation of iron(III)-hydroperoxy complexes in homogeneous aqueous solutions. Water Res. 1999, 33, 2929–2936. [Google Scholar] [CrossRef]

- Arts, A.; Schmuhl, R.; de Groot, M.T.; van der Schaaf, J. Fast initial oxidation of formic acid by the Fenton reaction under industrial conditions. J. Water Process. Eng. 2021, 40, 101780. [Google Scholar] [CrossRef]

- Haber, F.; Weiss, J. The catalytic decom position of hydrogen peroxide by Iron salts. Proc. R. Soc. A 1934, 147, 332–351. [Google Scholar]

- Gultekin, I.; Ince, H.I. Degradation of Reactive Azo Dyes by UV/H2O2: Impact of Radical Scavengers. J. Environ. Sci. Health 2004, 39, 1069–1081. [Google Scholar] [CrossRef] [PubMed]

- Krupińska, I. Impact of the oxidant type on the efficiency of the oxidation and removal of iron compounds from groundwater containing humic substances. Molecules 2020, 25, 3380. [Google Scholar] [CrossRef]

- Leresche, F.; Torres-Ruiz, J.A.; Kurtz, T.; von Gunten, U.; Rosario-Ortiz, F.L. Optical properties and photochemical production of hydroxyl radical and singlet oxygen after ozonation of dissolved organic matter. Environ. Sci. Water Resour. Technol. 2021, 7, 346–356. [Google Scholar] [CrossRef]

- Liao, C.H.; Gurol, M.D. Chemical oxidation by photolytic decomposition of hydrogen peroxide. Environ. Sci. Technol. 1995, 29, 3007–3014. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.G.; Gao, N.Y.; Chu, W.H.; Li, L.; Zhang, Y.J.; Gu, J.S.; Gu, Y.L. Photochemical degradation of ciprofloxacin in UV and UV/H2O2 process: Kinetics, parameters, and products. Environ. Sci. Pollut. Res. 2013, 20, 3202–3213. [Google Scholar] [CrossRef] [PubMed]

- Bottoni, P.; Grenni, P.; Lucentini, L.; Caracciolo, A.B. Terbuthylazine and other triazines in Italian water resources. Microchem. J. 2013, 107, 136–142. [Google Scholar] [CrossRef]

- Carra, I.; Sánches Pérez, J.A.; Malato, S.; Autín, O.; Jefferson, B.; Jarvis, P. Performance of different advanced oxidation processes for tertiary wastewater treatment to remove the pesticide acetamiprid. J. Chem. Technol. Biotecehnol. 2014, 91, 72–81. [Google Scholar] [CrossRef]

- Devi, L.G.; Munikrishnappa, C.; Nagaraj, B.; Rajashekhar, E. Effect of chloride and sulfate ions on the advanced photo Fenton and modified photo Fenton degradation process of Alizarin Red, S. J. Mol. Catal. A Chem. 2013, 374–375, 125–131. [Google Scholar] [CrossRef]

- Templeton, M.R.; Andrews, R.C.; Hofmann, R. Impact of iron particles in groundwater on the UV inactivation of bacteriophages MS2 and T4. J. Appl. Microbiol. 2006, 101, 732–741. [Google Scholar] [CrossRef]

- Paterlini, W.C.; Nogueira, R.P. Multivariate analysis of photo-Fenton degradation of the herbicides tebuthiuron, diuron and 2,4-D. Chemosphere 2005, 58, 1107–1116. [Google Scholar] [CrossRef] [PubMed]

- Canonica, S. Oxidation of aquatic organic contaminants induced by excited triplet states. CHIMIA Int. J. Chem. 2007, 61, 641–644. [Google Scholar] [CrossRef] [Green Version]

- Gao, H.; Zepp, R.G. Factors influencing photoreactions of dissolved organic matter in a coastal river of the southeastern United States. Environ. Sci. Technol. 1998, 32, 2940–2946. [Google Scholar] [CrossRef]

- National Center for Biotechnology Information. PubChem Compound Summary for CID 22206, Terbuthylazine; PubChem. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Terbuthylazine (accessed on 12 February 2022).

- Acero, J.L.; Stemmler, K.; von Gunten, U. Degradation kinetics of atrazine and its degradation products with ozone and OH radicals: A predictive tool for drinking water treatment. Environ. Sci. Technol. 2000, 34, 591–597. [Google Scholar] [CrossRef]

- Sorlini, S.; Gialdini, F.; Stefan, M. UV/H2O2 oxidation of arsenic and terbuthylazine in drinking water. Environ. Monit. Assess. 2014, 186, 1311–1316. [Google Scholar] [CrossRef]

| Parameter | Unit | Ultrapure Water | Surface Water | Groundwater |

|---|---|---|---|---|

| pH | pH units | 5.57 | 8.43 | 8.35 |

| Conductivity | µS/cm | 1.3 | 504 | 560 |

| Chloride ions | mg/L | 0 | 24 | 18 |

| Total hardness | mg/L | 0 | 20.5 | 26 |

| Bicarbonates | mg/L | 0 | 167 | 228 |

| Aluminium | mg/L | 0 | 126 | 67 |

| TOC | mg/L | 0 | 1.3 | <0.1 |

| Terbuthylazine | µg/L | 0 | <0.05 | <0.05 |

| Matrices | Process | Photoreactor | Hydrogen Peroxide (mg/L) | Fe (mg/L) | Reaction Time |

|---|---|---|---|---|---|

| Ultrapure water | Ultraviolet irradiation | LUZCHEM | -- | -- | 0, 1, 2, 4, 6, 8, 10 (min) |

| Semi-continuous UV | -- | -- | 0, 20, 40, 60, 80, 100, 120 (s) | ||

| Surface water | Photolysis of H2O2 with UV irradiation | LUZCHEM | 2.5 | -- | 0, 0.5, 1, 2, 3, 4, 5 (min) |

| Semi-continuous UV | -- | 0, 20, 40, 60, 80, 100, 120 (s) | |||

| Groundwater | Photo-Fenton with UV irradiation | LUZCHEM | 2.5 | 0.25 | 0, 0.5, 1, 2, 3, 4, 5 (min) |

| Semi-continuous UV | 0, 20, 40, 60, 80, 100, 120 (s) |

| CAS Number | 5915-41-3 |

|---|---|

| Molecular formula | C9H16ClN5 |

| Molecular weight | 229.71 |

| Vapour pressure (mPa) at 20 °C | 0.15 |

| Density at 20 °C (g/mL) | 1.1 |

| Photoreactor | Matrices | AOP | Degradation (%) | Initial Chloride (mg L−1) | Final Chloride (mg L−1) | Initial TOC (mg L−1) | Final TOC (mg L−1) | Initial H2O2 (mg L−1) | Final H2O2 (mg L−1) |

|---|---|---|---|---|---|---|---|---|---|

| LUZCHEM | Ultrapure water | UV | 94.71 | 2.36 | 2.40 | 3.87 | 1.76 | -- | -- |

| UV + H2O2 | 94.34 | 2.36 | 2.40 | 3.44 | 2.58 | 2.53 | 2.24 | ||

| UV + H2O2 + Fe | 94.60 | 2.35 | 2.38 | 2.64 | 2.14 | 2.19 | 0.23 | ||

| Groundwater (Tempul spring) | UV | 94.83 | 18.90 | 19.09 | 2.18 | 1.73 | -- | -- | |

| UV + H2O2 | 94.78 | 18.50 | 18.65 | 2.33 | 1.86 | 2.49 | 2.00 | ||

| UV + H2O2 + Fe | 94.20 | 18.82 | 18.80 | 2.43 | 2.20 | 2.24 | 1.57 | ||

| Surface Water (Gaditana area) | UV | 93.93 | 43.65 | 43.98 | 3.13 | 3.03 | -- | -- | |

| UV + H2O2 | 94.69 | 42.79 | 42.86 | 2.05 | 1.85 | 2.49 | 1.86 | ||

| UV + H2O2 + Fe | 92.45 | 43.23 | 43.28 | 1.93 | 1.87 | 2.10 | 1.43 | ||

| Semi-continuous | Ultrapure water | UV | 90.62 | 2.34 | 2.38 | 2.28 | 0.45 | -- | -- |

| UV + H2O2 | 91.56 | 2.44 | 2.48 | 2.16 | 1.73 | 2.57 | 2.24 | ||

| UV + H2O2 + Fe | 90.38 | 2.39 | 2.41 | 2.61 | 1.92 | 2.27 | 1.94 | ||

| Groundwater (Tempul spring) | UV | 89.59 | 19.03 | 19.47 | 0.73 | 0.51 | -- | -- | |

| UV + H2O2 | 90.53 | 18.50 | 18.44 | 2.24 | 1.66 | 2.43 | 2.29 | ||

| UV + H2O2 + Fe | 90.14 | 18.81 | 18.72 | 1.66 | 1.51 | 1.95 | 1.62 | ||

| Surface water (Gaditana area) | UV | 87.34 | 26.13 | 26.02 | 1.65 | 1.65 | -- | -- | |

| UV + H2O2 | 91.64 | 24.93 | 24.91 | 3.09 | 2.82 | 2.57 | 2.57 | ||

| UV + H2O2 + Fe | 90.88 | 25.04 | 24.91 | 4.04 | 3.33 | 2.14 | 2.10 |

| Photoreactors | AOPs | Matrices | Kinetic Constants | ||

|---|---|---|---|---|---|

| Ultrapure Water | Groundwater | Surface Water | |||

| LUZCHEM | UV | 0.010 | 0.005 | 0.009 | k, min−1 |

| UV/H2O2 | 0.012 | 0.010 | 0.011 | ||

| UV/H2O2/Fe | 0.012 | 0.009 | 0.011 | ||

| Semi-Continuous | UV | 0.019 | 0.018 | 0.017 | k, s−1 |

| UV/H2O2 | 0.021 | 0.020 | 0.022 | ||

| UV/H2O2/Fe | 0.022 | 0.020 | 0.021 | ||

| Composition Elemental | Exact Mass (m/z) | Retention Time (min) | Proposed Structure and Name |

|---|---|---|---|

| TBA C9H16ClN5 | 230.1161 | 2.98 |  N-tert-butyl-6-chloro-N′-ethyl-1,3,5-triazine-2,4-diamine; (terbuthylazine) |

| 2-OH-TBA C9H17N5O | 212.1508 | 0.75 |  N-tert-butyl-6-hydroxy-N′-ethyl-1,3,5-triazine-2,4-diamine |

| Photoreactors | Lamp Intensity (W m−2) | Time (s) | Doses UV-C (W.s m−2) |

|---|---|---|---|

| LUZCHEM | 0.15 | 30 | 4.5 |

| 60 | 9.0 | ||

| 120 | 18.0 | ||

| 180 | 27.0 | ||

| 240 | 36.0 | ||

| 300 | 45.0 | ||

| 600 | 90.0 | ||

| Semi-continuous | 1.87 | 20 | 37.4 |

| 40 | 74.8 | ||

| 60 | 112.2 | ||

| 80 | 149.6 | ||

| 100 | 187.0 | ||

| 120 | 224.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrades, J.A.; Lojo-López, M.; Egea-Corbacho, A.; Quiroga, J.M. Comparative Effect of UV, UV/H2O2 and UV/H2O2/Fe on Terbuthylazine Degradation in Natural and Ultrapure Water. Molecules 2022, 27, 4507. https://doi.org/10.3390/molecules27144507

Andrades JA, Lojo-López M, Egea-Corbacho A, Quiroga JM. Comparative Effect of UV, UV/H2O2 and UV/H2O2/Fe on Terbuthylazine Degradation in Natural and Ultrapure Water. Molecules. 2022; 27(14):4507. https://doi.org/10.3390/molecules27144507

Chicago/Turabian StyleAndrades, José Antonio, Manuel Lojo-López, Agata Egea-Corbacho, and José María Quiroga. 2022. "Comparative Effect of UV, UV/H2O2 and UV/H2O2/Fe on Terbuthylazine Degradation in Natural and Ultrapure Water" Molecules 27, no. 14: 4507. https://doi.org/10.3390/molecules27144507