Analysis of the Effect of Vehicle, Driving and Road Parameters on the Transient Performance and Emissions of a Turbocharged Truck

Abstract

:1. Introduction

- (a)

- (b)

- a much more detailed vehicle model has been incorporated in the simulation code, facilitating better evaluation of the vehicle’s true behavior on the road; and

- (c)

- a detailed parametric study of the effect of various critical vehicle, driving and road parameters will be conducted in order to assess their importance on both performance and emissions from a typical medium to heavy-duty vehicle equipped with a turbocharged diesel engine.

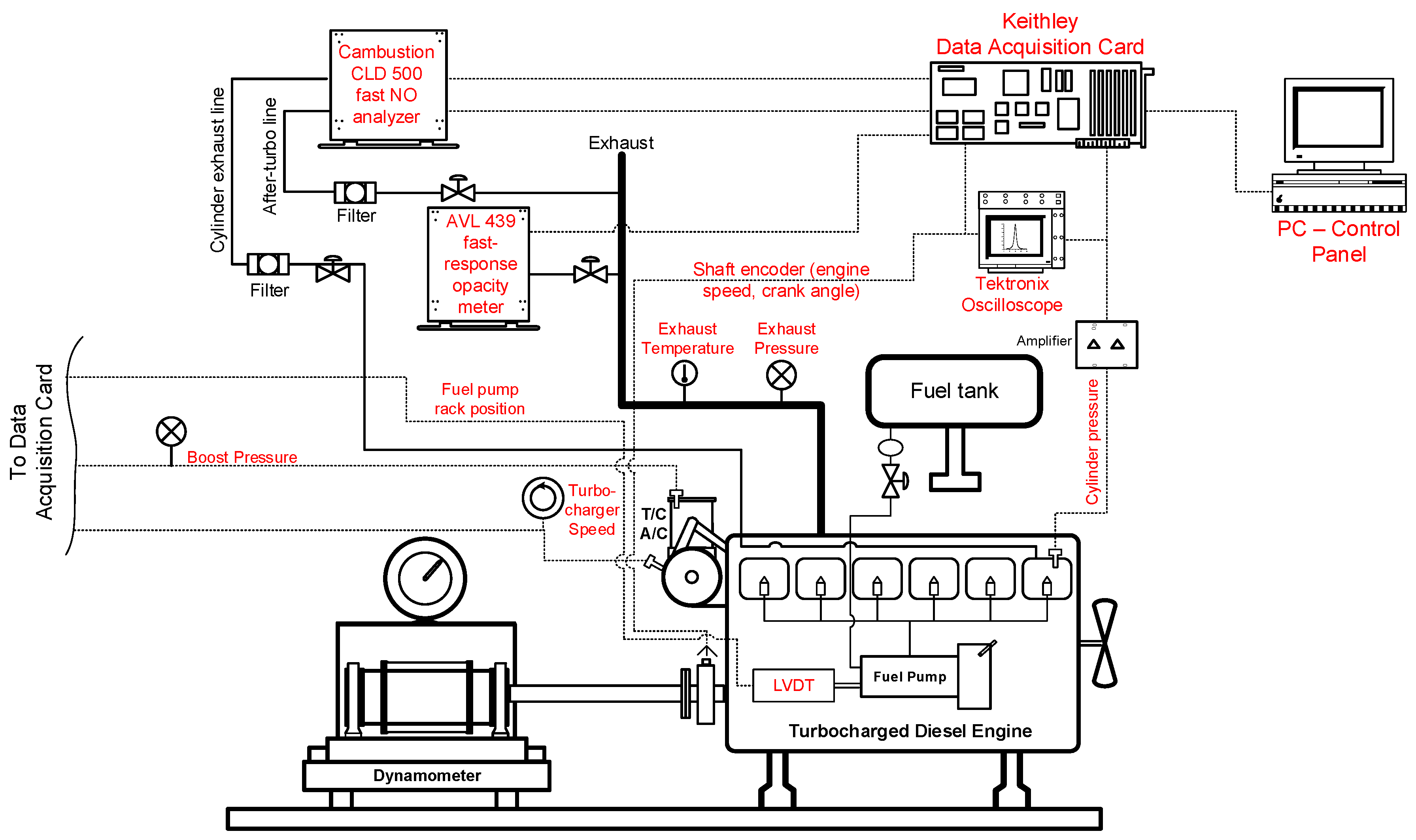

2. Methodology—Engine and Vehicle Model

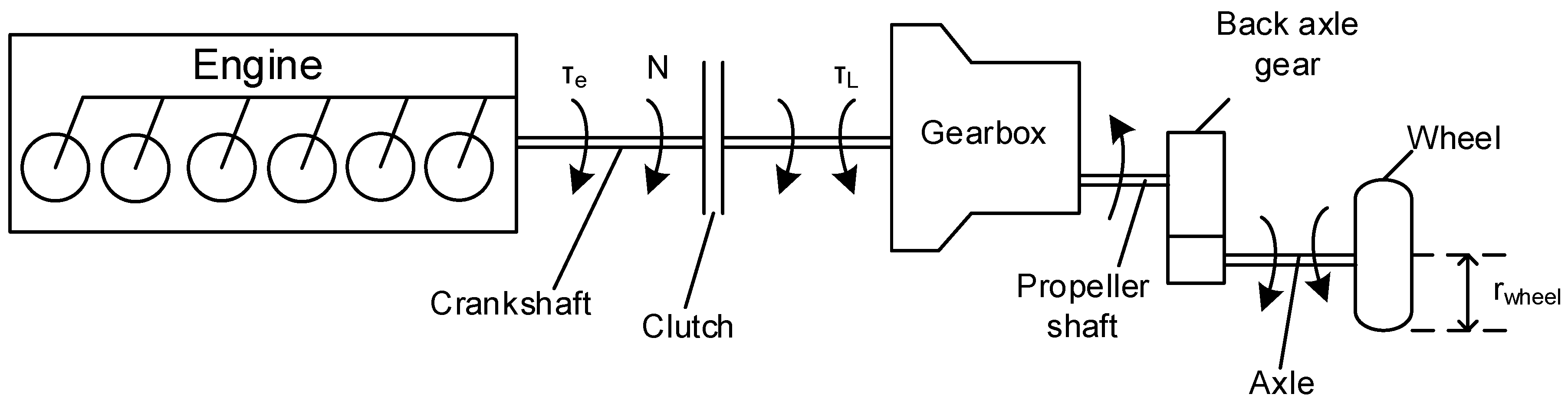

- From the vehicle speed, we were able to calculate the actual engine torque and speed based on a drive-train model (Figure 3) for the vehicle concerned [26,27]. The vehicle model employed in this work has been considerably upgraded from the previously mentioned publications, incorporating, among other things, the effect of the [28,29,30]:

- ➢

- Inertia of the equivalent rotating masses (engine, driveshaft, wheels),

- ➢

- Tires (inflation pressure, resistance, slip and friction coefficient),

- ➢

- Road (gradient and friction coefficient),

- ➢

- Transmission (gear number and ratio, speed-dependent mechanical efficiency etc.),

- ➢

- Differential (final drive ratio, inertia, etc.), and finally the

- ➢

- Driver (simulates the specific driving habits, for example gear shift duration).

- Afterwards, we perform an interpolation of the digitized engine map to estimate the steady-state fueling and emissions at the exact load and speed operating point.

- The next step is to apply correction coefficients to the previous mentioned quasi-steady emissions evaluating the ‘real’ transient emissions profile; these coefficients were evaluated after the extensive transient testing of the engine in hand mentioned above, and are specific to each transient event (e.g., load increase or speed change) that the engine experiences.

3. Vehicle and Engine Results during Typical Transient Schedules

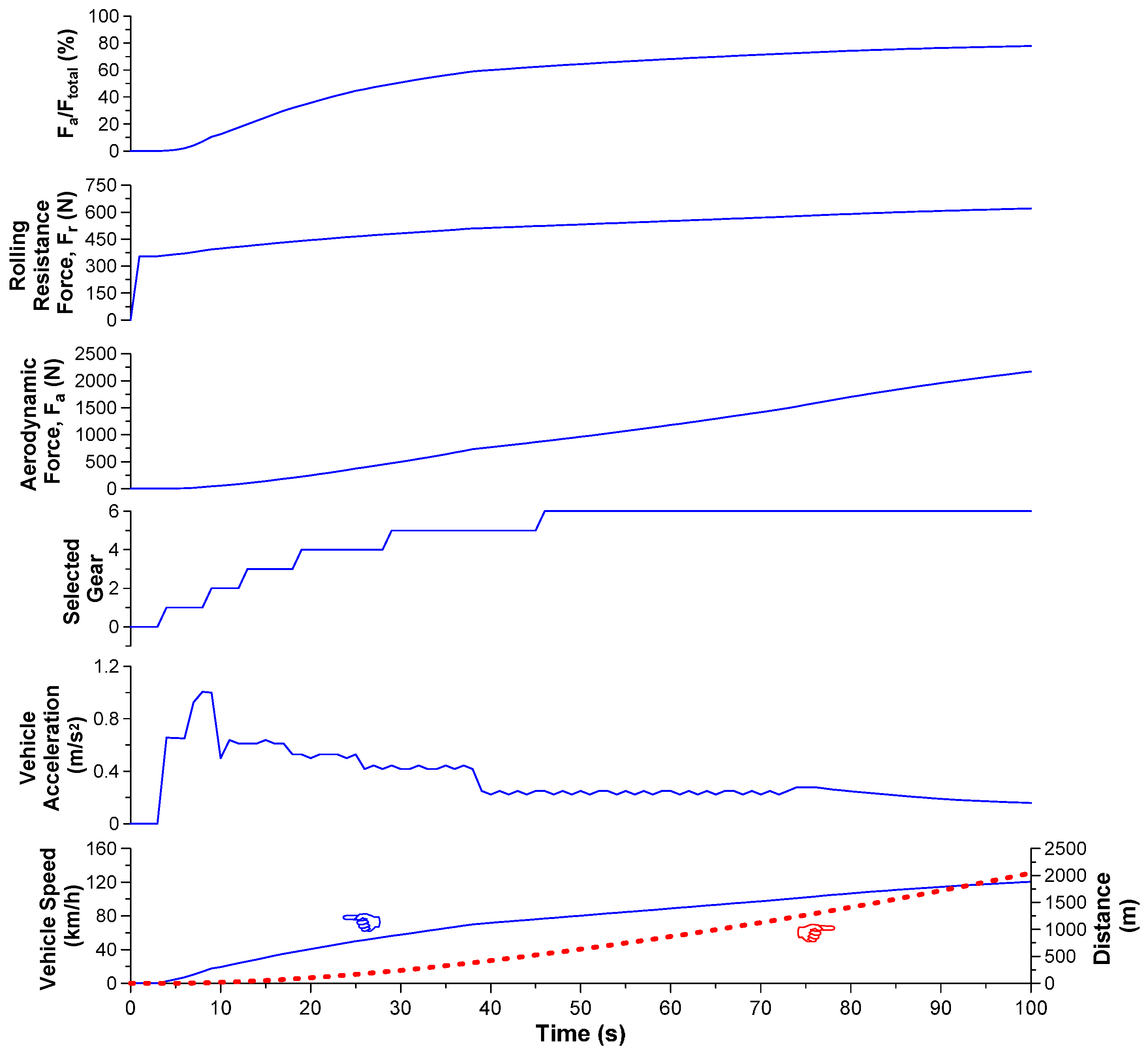

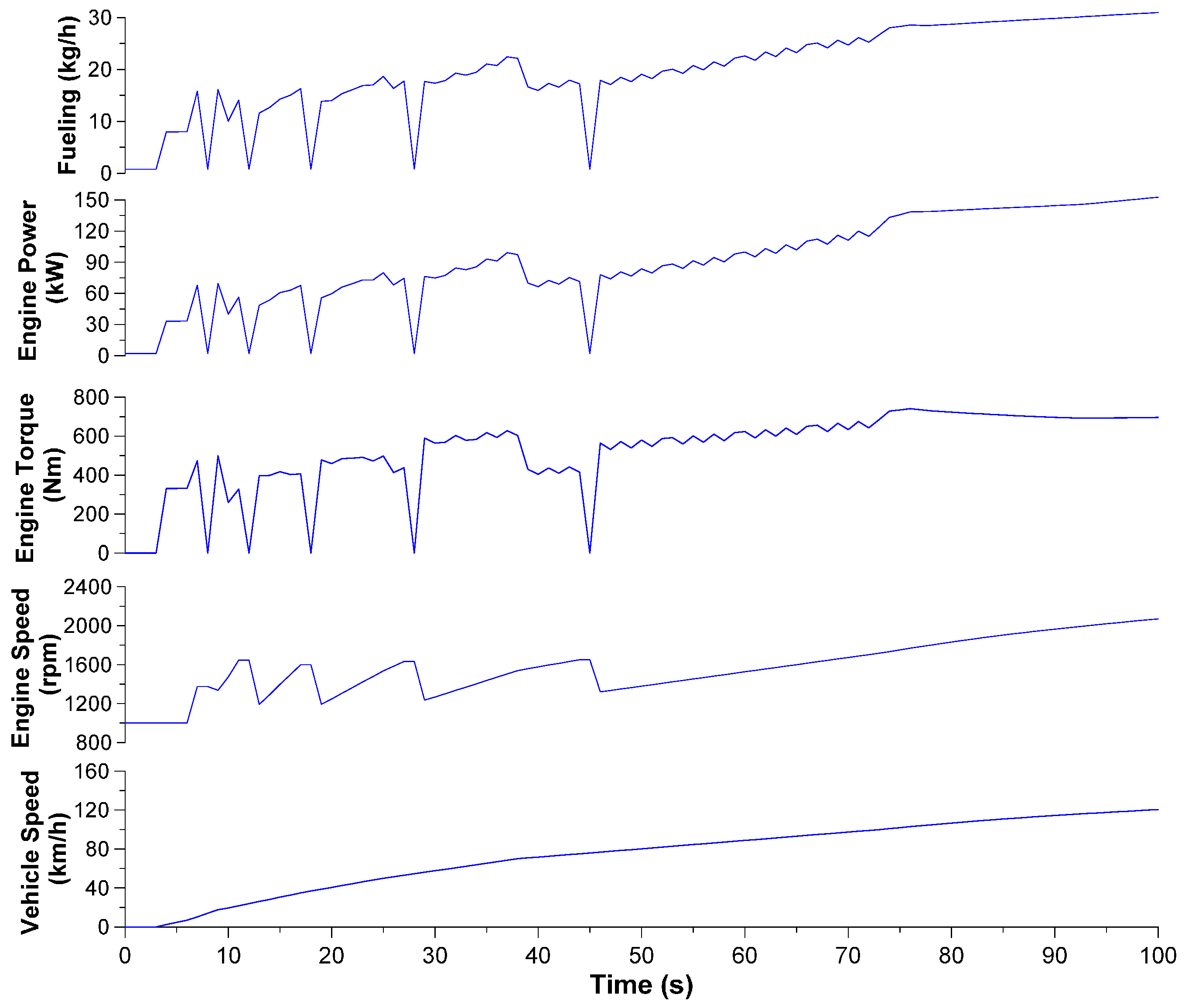

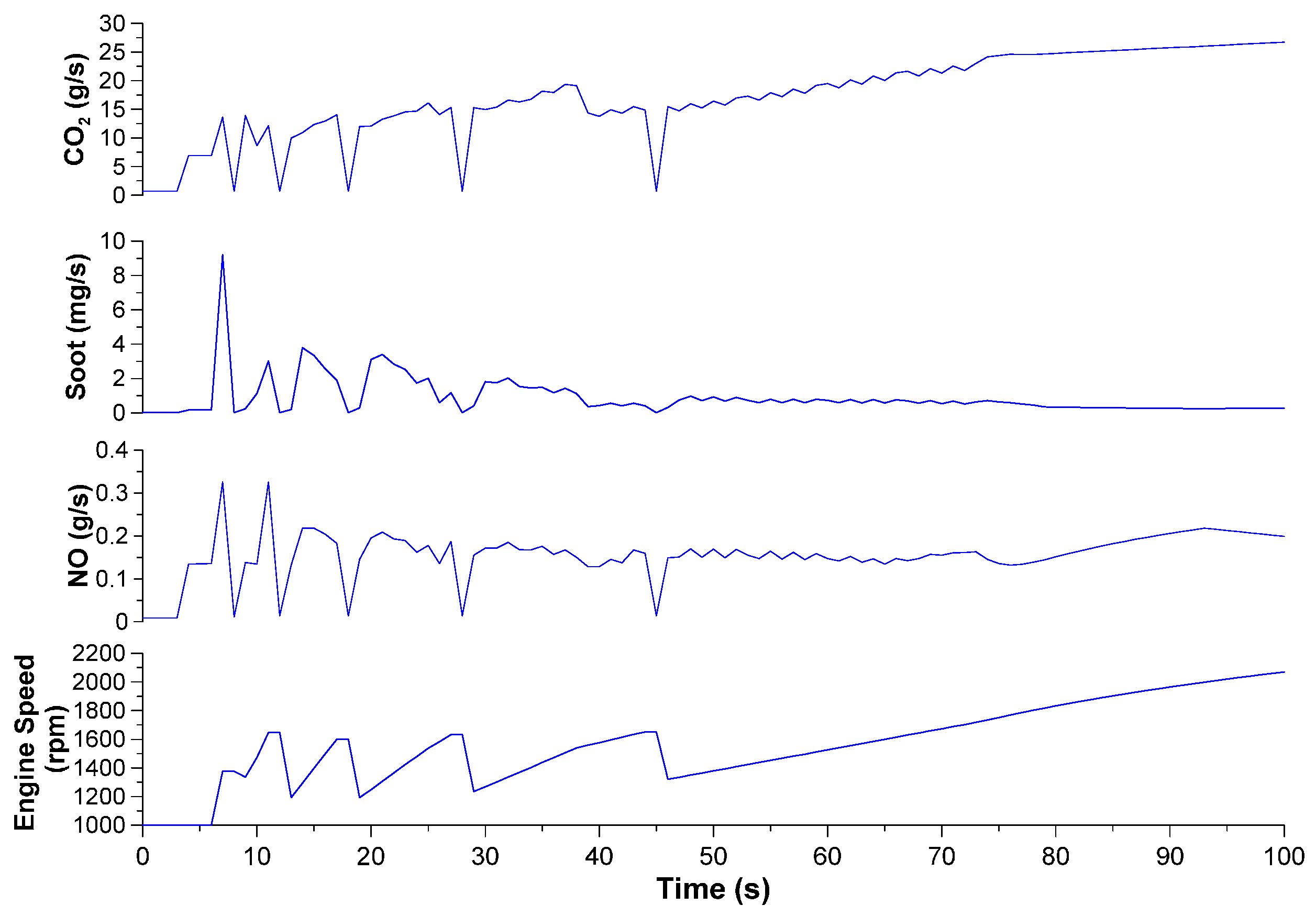

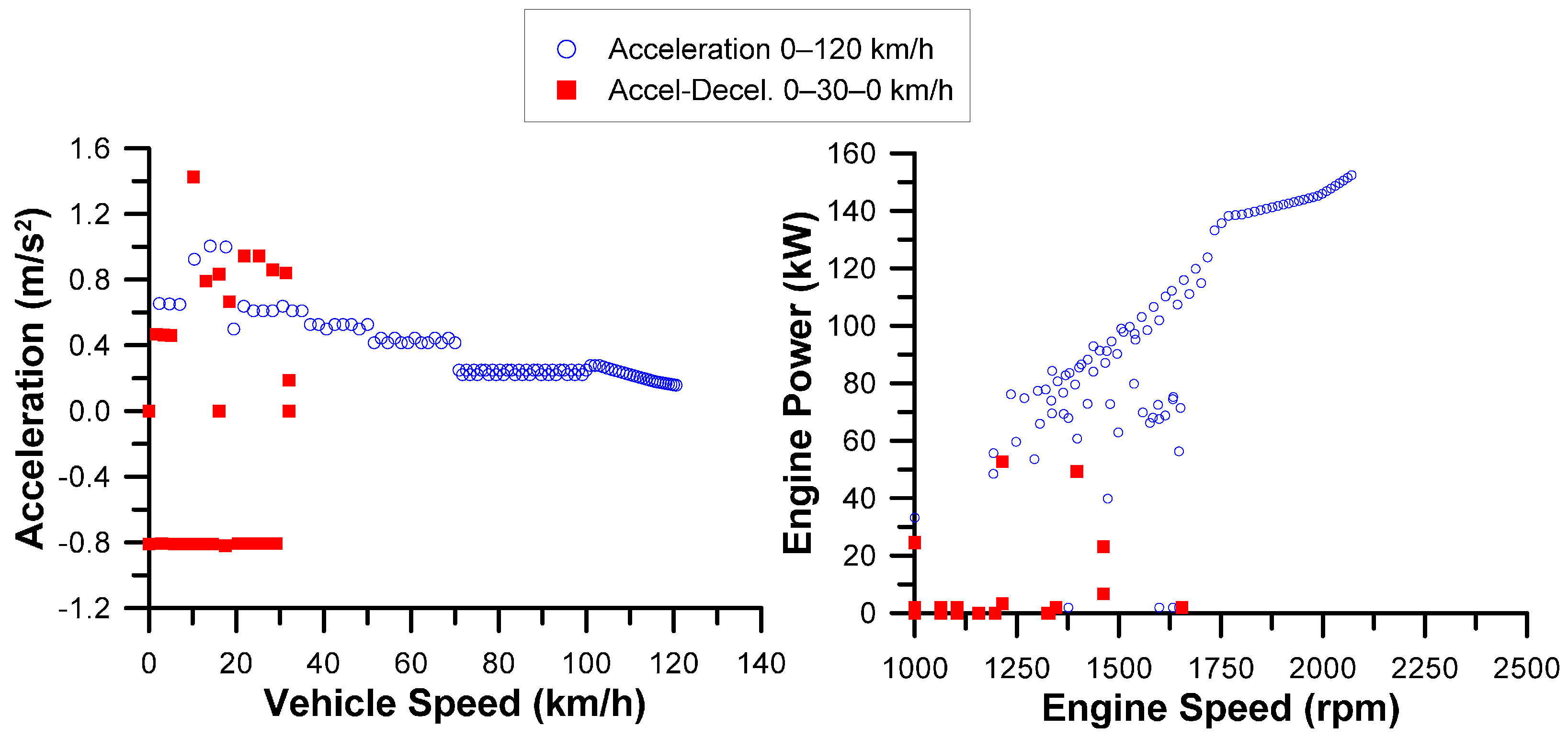

3.1. Continuous Acceleration Schedule

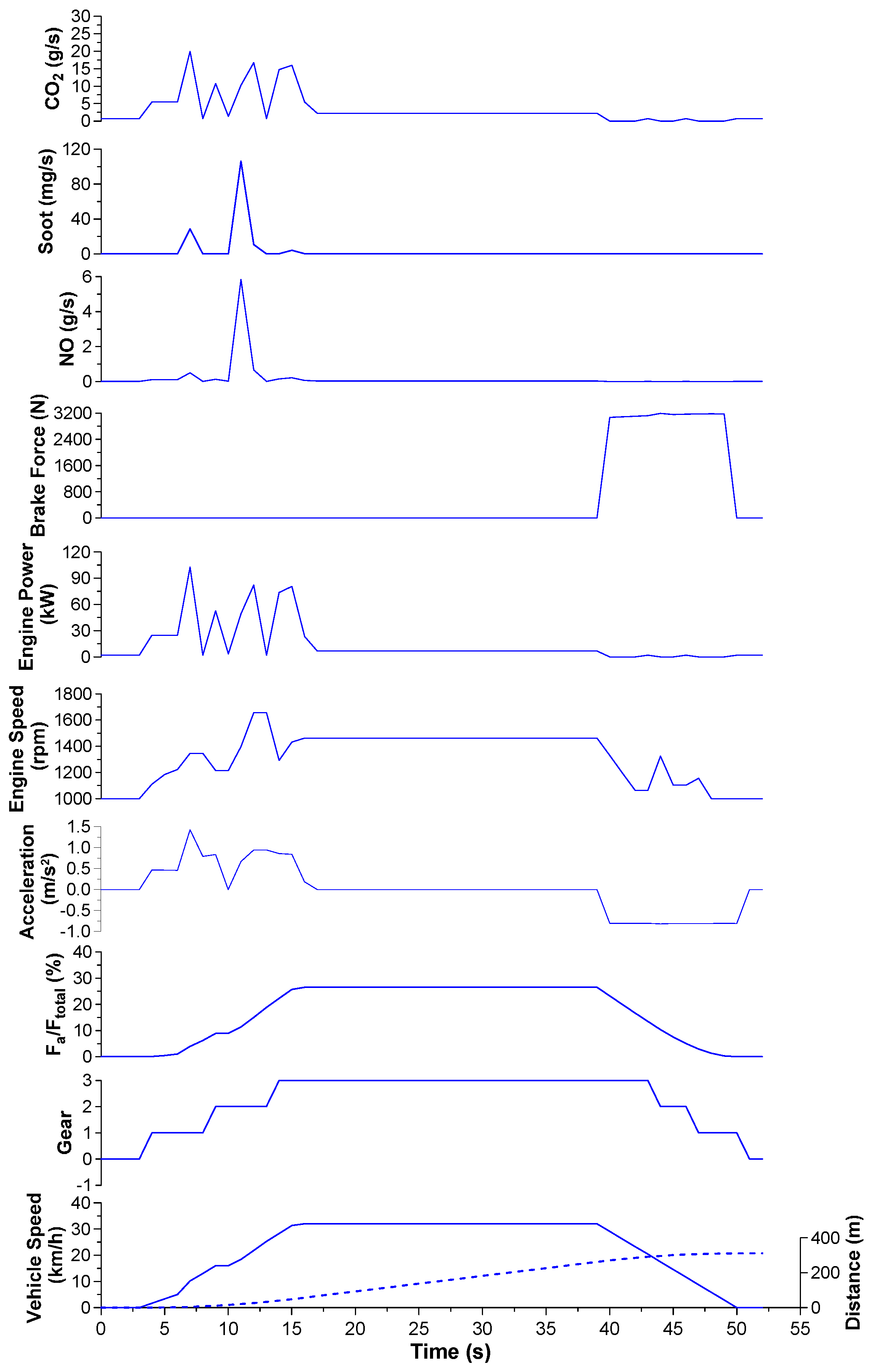

3.2. Low-Speed, Urban Schedule

4. Parametric Study

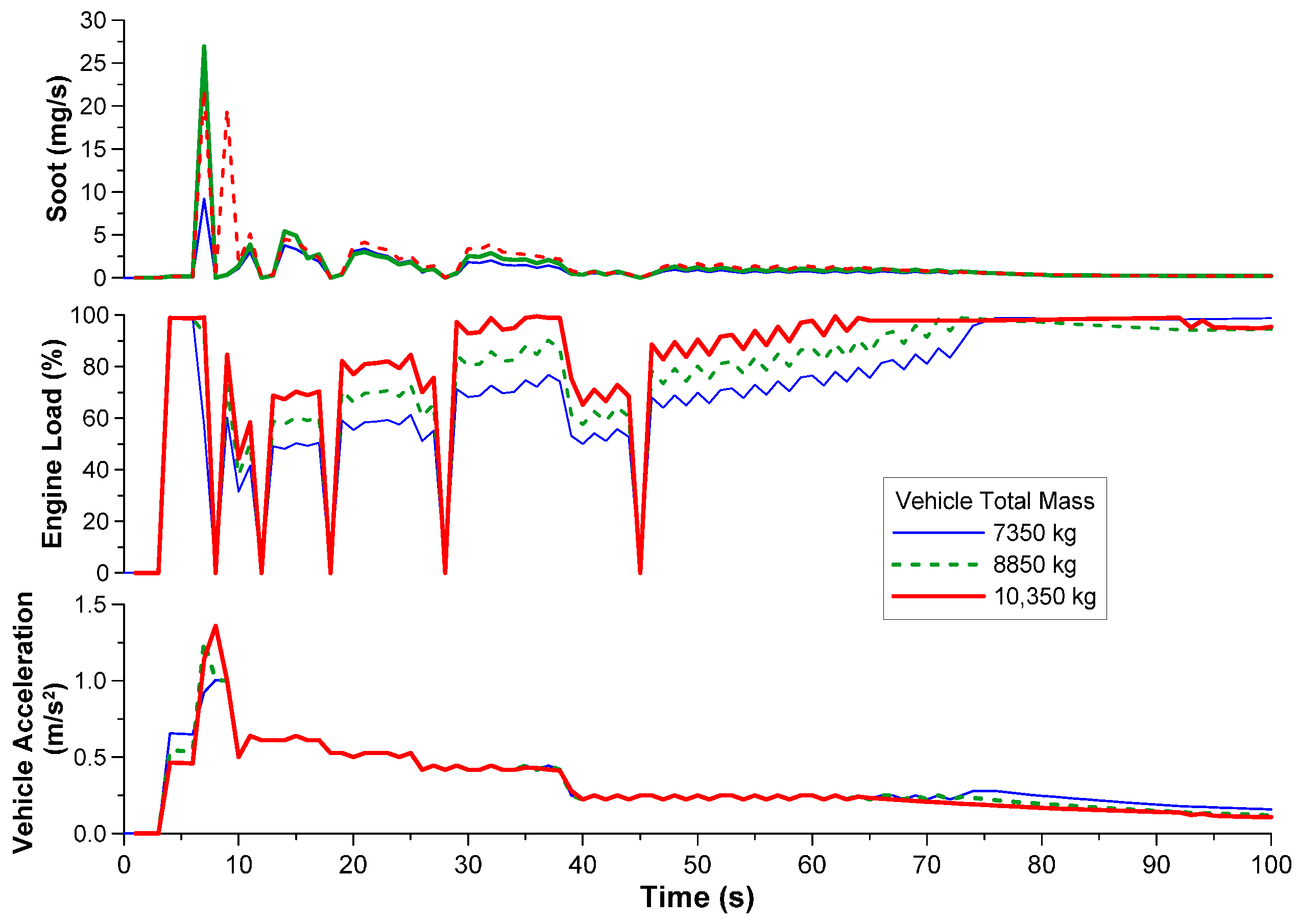

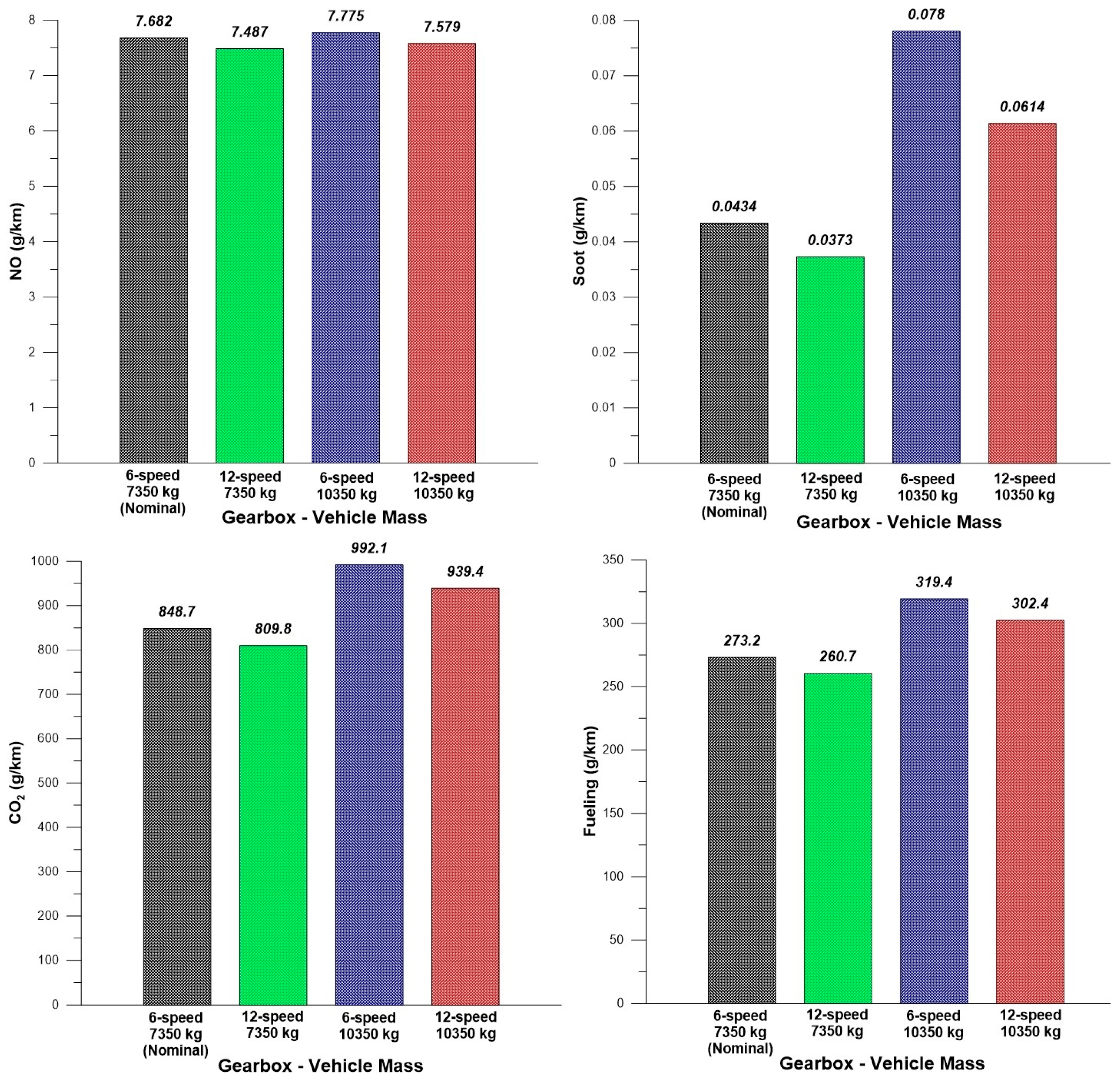

4.1. Effect of Vehicle Attributes (Mass and Gearbox)

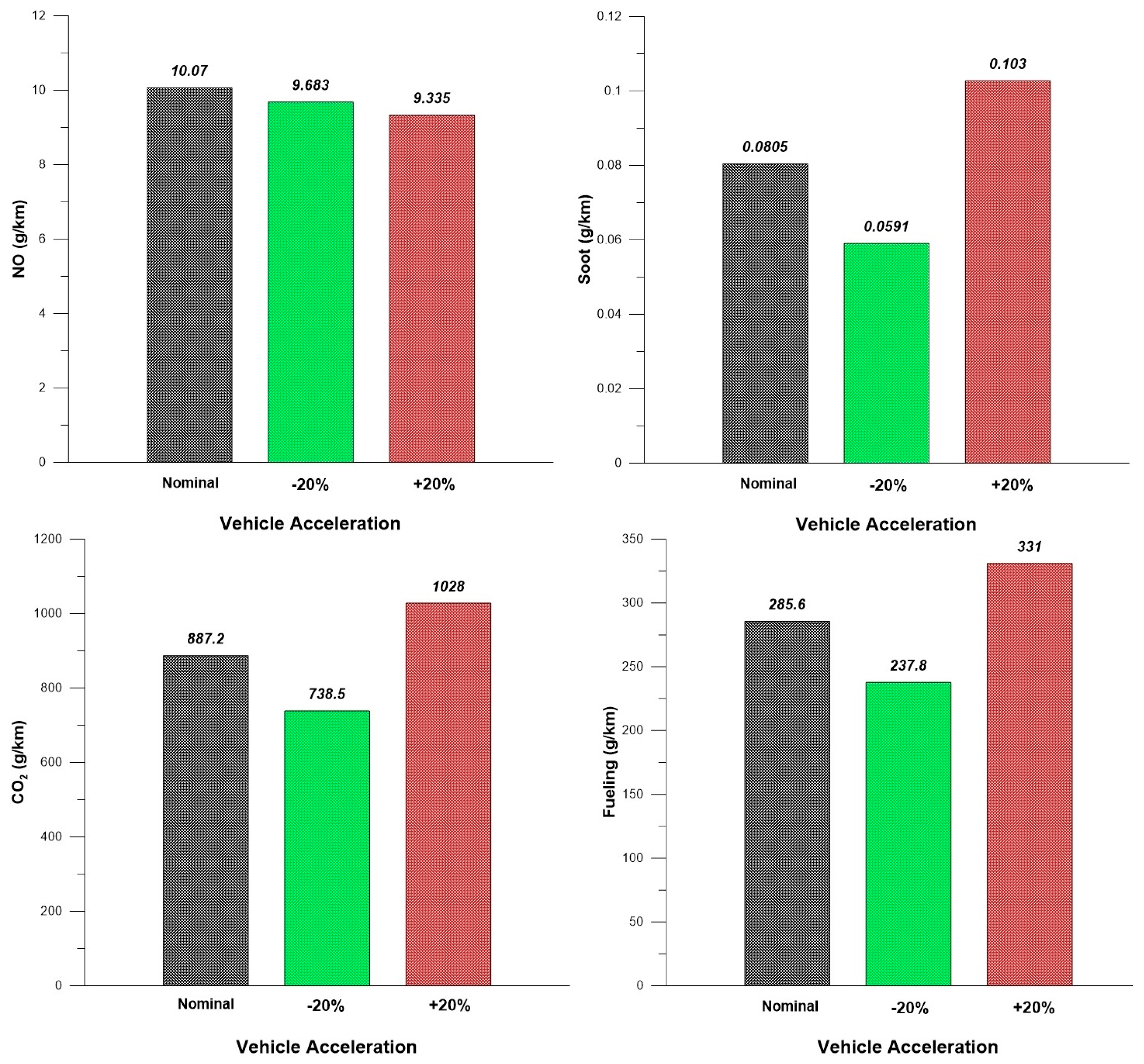

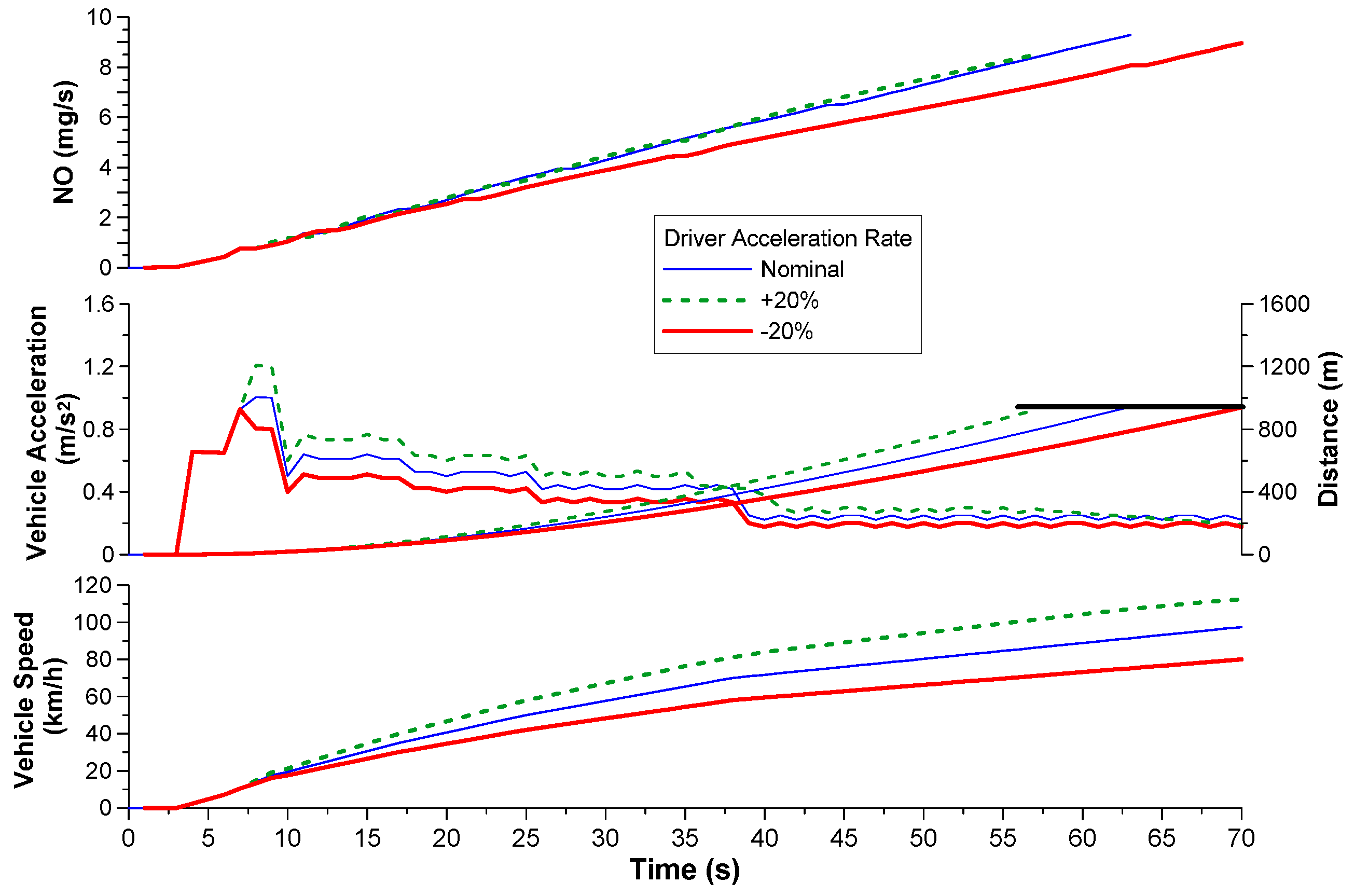

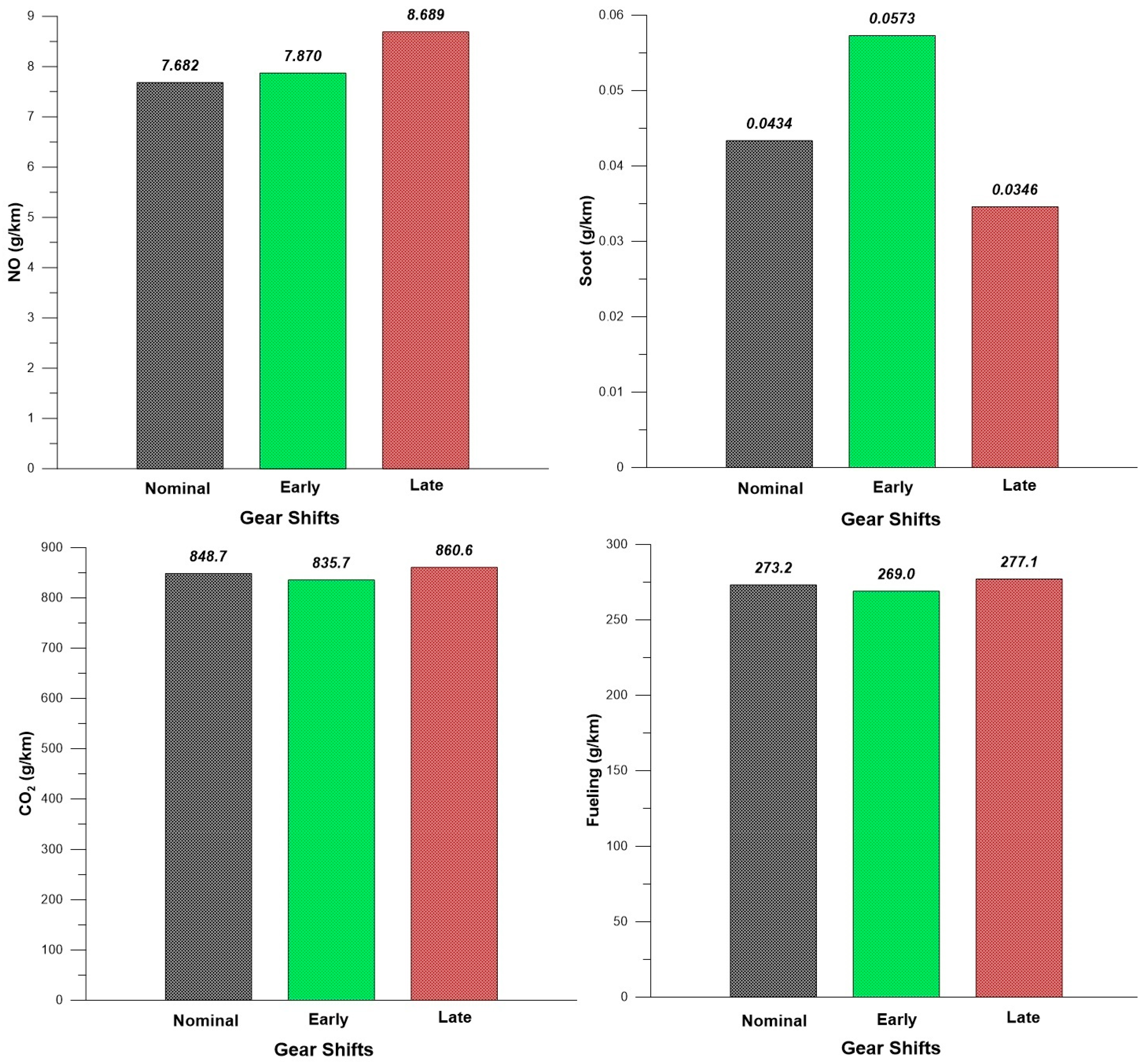

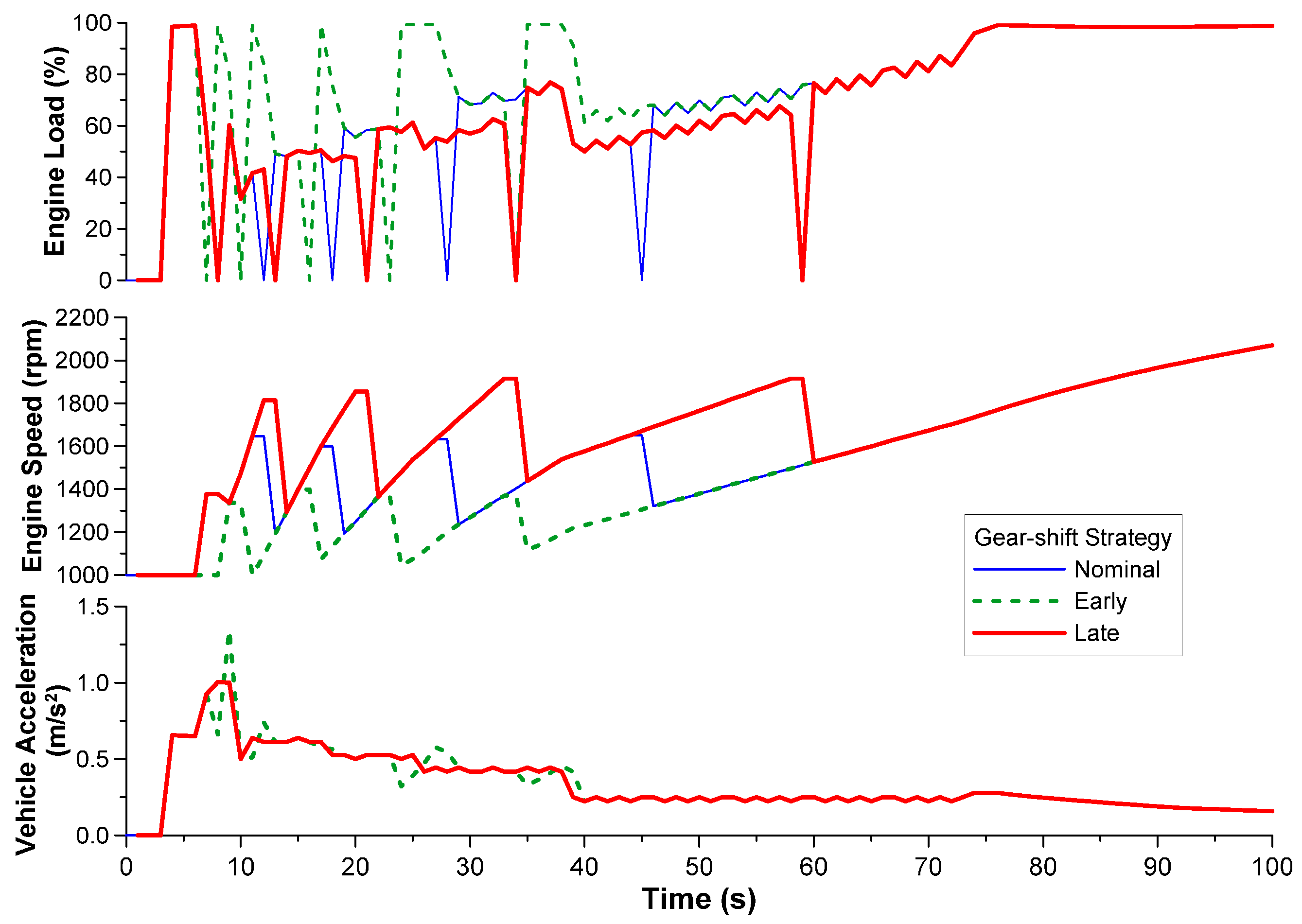

4.2. Effect of Driving Attributes (Driver ‘Aggressiveness’ and Gear-Shift Schedule)

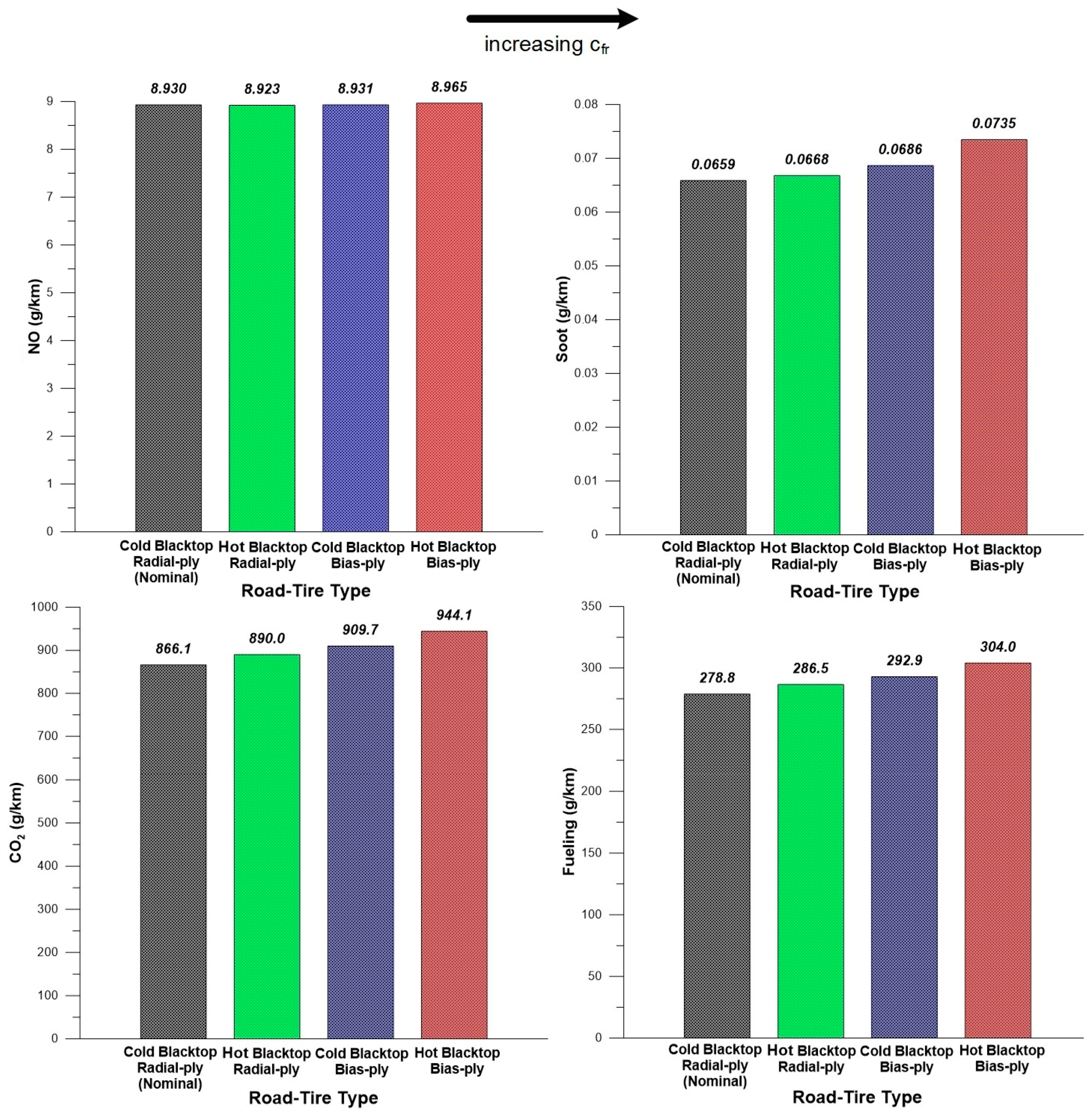

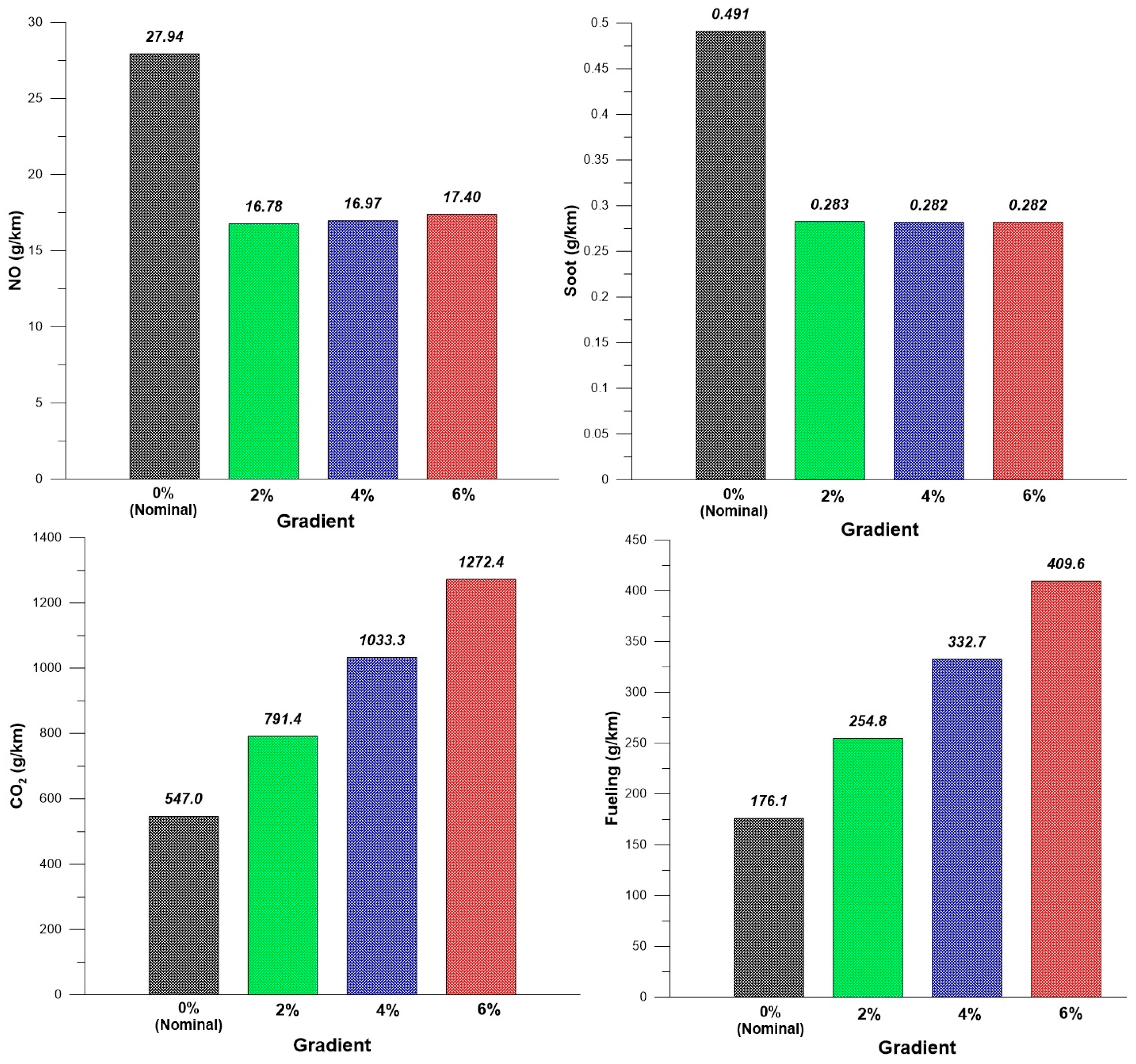

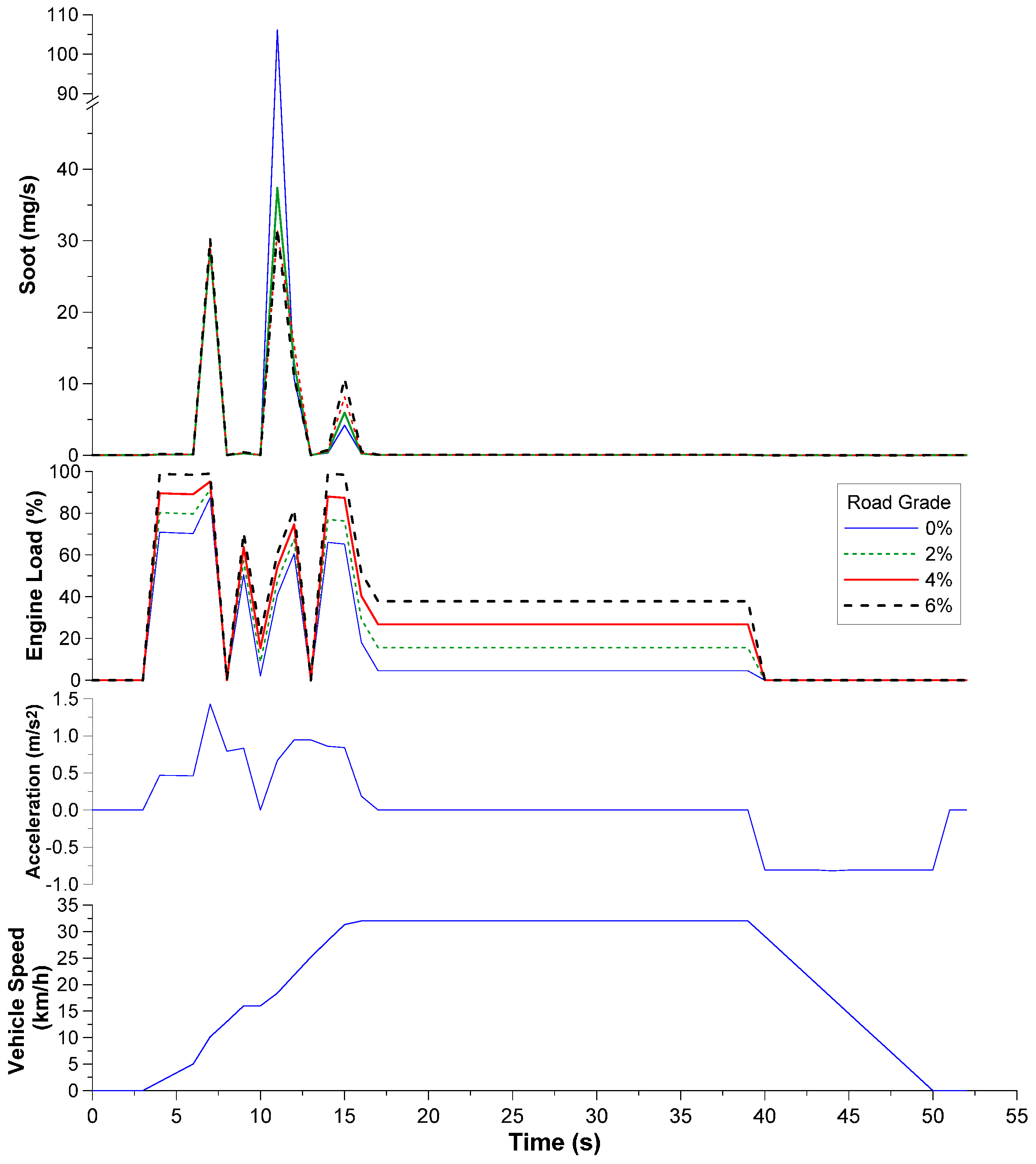

4.3. Effect of Road Characteristics (Road-Type and Gradient)

5. Summary and Conclusions

- Vehicle speed was identified as the most critical property influencing performance and practically all vehicle parameters. In this respect, low-speed (‘urban’) and high-speed (‘motorway’) segments were found to affect vehicle operation in a different way. For the engine, it was the speed fluctuations (due to gear changes) that affected mostly the emissions and performance.

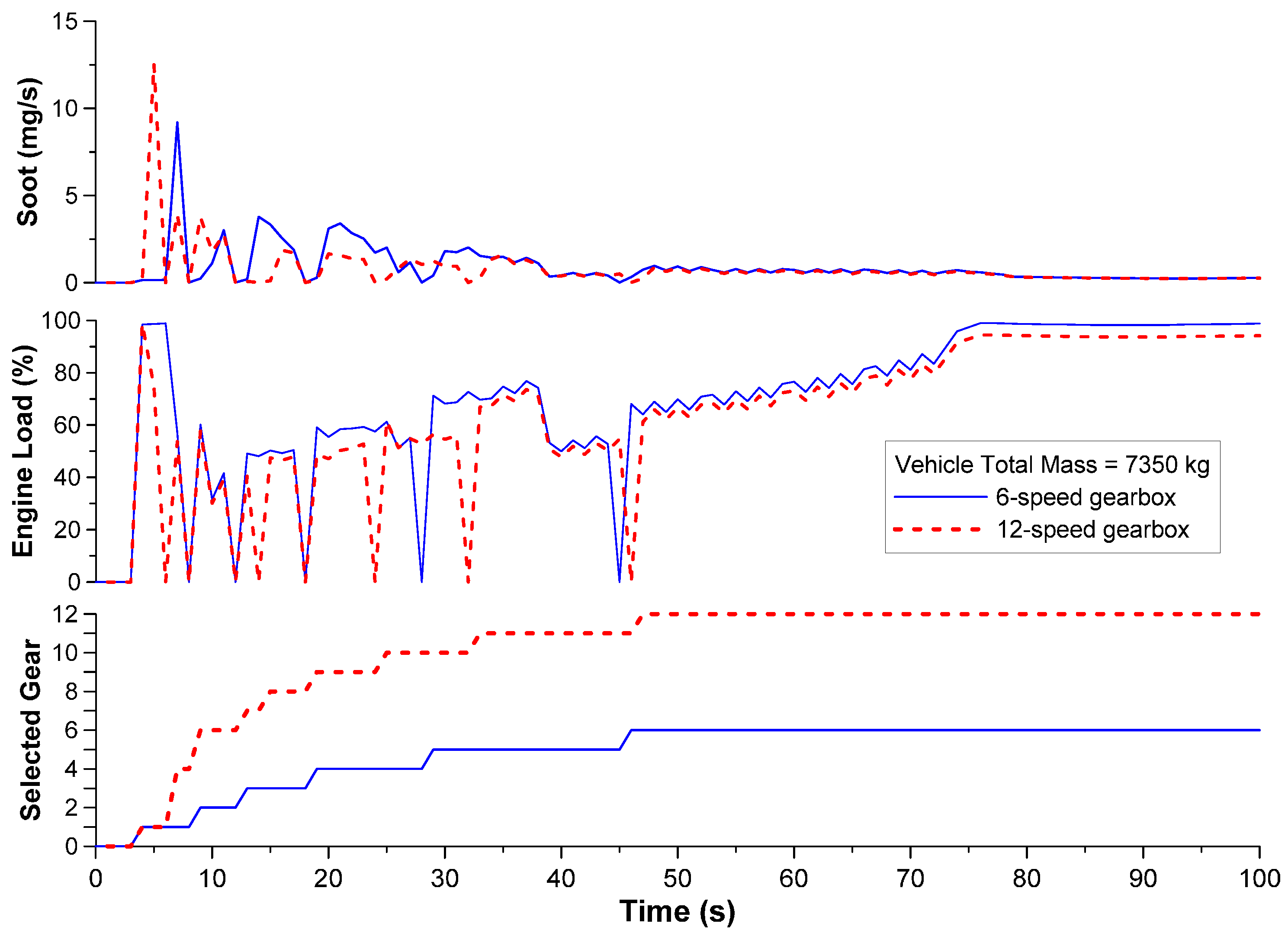

- At each step in the transient schedule where a steep vehicle velocity increase was experienced, a peak in engine-out emissions (particularly soot) was noticed as well owing to turbocharger lag. This was more pronounced during the first examined transient schedule owing to its continuous up-gear shift profile. In fact, one abrupt acceleration produced more engine-out soot than many minutes of constant-speed operation.

- Increasing the vehicle mass resulted in deterioration of its performance at high velocities, hence the vehicle failed to follow the prescribed driving schedule; elevated amount of pollutants was also observed. Similar results were reached when studying the effect of road-tire friction and road grade; all the above being parameters directly affecting the vehicle resistance forces.

- The selected gearbox was a critical parameter affecting driving behavior as well as emissions and performance. More specifically, for gearboxes with high number of gears, the accelerations were in general milder (hence the amount of soot lower), although the vehicle drivability is expected to be adversely affected.

- Predictably, driving in a more aggressive way, as a result of higher average accelerations, had significant impact on all emissions and the vehicle performance in general.

- A noteworthy statistical correlation was established between pollutant emissions (NO, soot) and vehicle mass or road-tire friction, as well as between fueling/CO2 and vehicle mass, road-tire friction and road grade.

- From the range of values investigated in this paper, and for the current engine/vehicle combination, it seems that the most critical parameters for the emission of NO and soot are the vehicle mass, the driving ‘aggressiveness’ and the exact gear-change profile (the latter only for soot). Vehicle mass, driving ‘aggressiveness’ and road-grade were identified as the most influential parameters for the emission of CO2.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Watson, N.; Janota, M.S. Turbocharging the Internal Combustion Engine; McMillan: London, UK, 1982. [Google Scholar]

- Rakopoulos, C.D.; Giakoumis, E.G. Diesel Engine Transient Operation; Springer: London, UK, 2009. [Google Scholar]

- Available online: https://www.transportpolicy.net/ (accessed on 5 January 2018).

- Giakoumis, E.G. Driving and Engine Cycles; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Watson, N. Eliminating Rating Effects on Turbocharged Diesel Engine Response; SAE Technical Paper 840134; SAE International: Warrendale, PA, USA, 1984. [Google Scholar]

- Horlock, J.H.; Winterbone, D.E. (Eds.) The Thermodynamics and Gas Dynamics of Internal Combustion Engines, Vol. II; Clarendon Press: Oxford, UK, 1986. [Google Scholar]

- Rakopoulos, C.D.; Giakoumis, E.G. Review of Thermodynamic Diesel Engine Simulations under Transient Operating Conditions; SAE Technical Paper 2006-01-0884; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Filipi, Z.; Wang, Y.; Assanis, D. Effect of Variable Geometry Turbine (VGT) on Diesel Engine and Vehicle System Transient Response; SAE Technical Paper 2001-01-1247; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Giakoumis, E.G.; Alysandratou, A. Performance and emissions of a heavy-duty truck during the UDDS driving cycle—Simulation analysis. J. Energy Eng. 2016, 142, E4015011. [Google Scholar] [CrossRef]

- Berglund, S. A Model of Turbocharged Engines as Dynamic Drivetrain Members; SAE Technical Paper 933050; SAE International: Warrendale, PA, USA, 1993. [Google Scholar]

- Rackmil, C.I.; Blumberg, P.N.; Becker, D.A.; Schuller, R.R.; Garvey, D.C. A dynamic model of a locomotive diesel engine and electrohydraulic governor. J. Eng. Gas Turbines Power 1988, 110, 405–414. [Google Scholar] [CrossRef]

- Jiang, Q.; Van Gerpen, J.H. Prediction of Diesel Engine Particulate Emission during Transient Cycles; SAE Technical Paper 920466; SAE International: Warrendale, PA, USA, 1992. [Google Scholar]

- Jensen, J.P.; Kristensen, A.F.; Sorensen, S.C.; Houbak, N.; Hendricks, E. Mean Value Modeling of a Small Turbocharged Diesel Engine; SAE Technical Paper 910070; SAE International: Warrendale, PA, USA, 1991. [Google Scholar]

- Ericson, C.; Westerberg, B.; Egnell, R. Transient Emission Predictions with Quasi Stationary Models; SAE Technical Paper 2005-01-3852; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Giakoumis, E.G.; Alafouzos, A.I. Study of diesel engine performance and emissions during a Transient Cycle applying an engine mapping-based methodology. Appl. Energy 2010, 87, 1358–1365. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Lioutas, S.C. Diesel-engined vehicle nitric oxide and soot emissions during the European light-duty driving cycle using a transient mapping approach. Transp. Res. Part D 2010, 15, 134–143. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Zachiotis, A.T. Investigation of a diesel-engined vehicle’s performance and emissions during the WLTC driving cycle—Comparison with the NEDC. Energies 2017, 10, 240. [Google Scholar] [CrossRef]

- Celik, V.; Arcaklioglu, E. Performance maps of a diesel engine. Appl. Energy 2005, 81, 247–259. [Google Scholar] [CrossRef]

- Bishop, J.D.K.; Stettler, M.E.J.; Molden, N.; Boies, A.M. Engine maps of fuel use and emissions from transient driving cycles. Appl. Energy 2016, 183, 202–217. [Google Scholar] [CrossRef]

- Roy, S.; Banerjee, R.; Bose, P.K. Performance and exhaust emissions prediction of a CRDI assisted single cylinder diesel engine coupled with EGR using artificial neural network. Appl. Energy 2014, 119, 330–340. [Google Scholar] [CrossRef]

- Johri, R.; Filipi, Z. Neuro-fuzzy model tree approach to virtual sensing of transient diesel soot and NOx emissions. Int. J. Engine Res. 2014, 15, 918–927. [Google Scholar] [CrossRef]

- Wang, J.; Rakha, H.A. Fuel consumption model for conventional diesel buses. Appl. Energy 2016, 170, 394–402. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, J.; Gan, H.; Jia, B.; Xia, Y. Development of a real-time two-stroke marine diesel engine model with in-cylinder pressure prediction capability. Appl. Energy 2017, 194, 55–70. [Google Scholar] [CrossRef]

- Gambarotta, A.; Lucchetti, G.; Vaja, I. Real-time modelling of transient operation of turbocharged diesel engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2001, 225, 1186–1203. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G.; Peckham, M.S. Experimental Assessment of Turbocharged Diesel Engine Transient Emissions during Acceleration, Load Change and Starting; SAE Technical Paper 2010-01-1287; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Winterbone, D.E.; Benson, R.S.; Mortimer, A.G.; Kenyon, P.; Stotter, A. Transient Response of Turbocharged Diesel Engines; SAE Technical Paper 770122; SAE International: Warrendale, PA, USA, 1977. [Google Scholar]

- Gillespie, T.D. Fundamentals of Vehicle Dynamics; SAE International: Warrendale, PA, USA, 1992. [Google Scholar]

- Assanis, D.; Bryzik, W.; Chalhoub, N.; Filipi, Z.; Henein, N.; Jung, D.; Liu, X.; Louca, L.; Moskwa, J.; Munns, S.; et al. Integration and Use of Diesel Engine, Driveline and Vehicle Dynamics Models for Heavy Duty Truck Simulation; SAE Technical Paper 1999-01-0970; SAE International: Warrendale, PA, USA, 1999. [Google Scholar]

- Lucas, G.G. Road Vehicle Performance: Methods of Measurement and Calculation; Gordon and Breach Science: New York, NY, USA, 1986. [Google Scholar]

- Cole, D. Elementary Vehicle Dynamics—Course Notes in Mechanical Engineering; University of Michigan: Ann Arbor, MI, USA, 1972. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Hountalas, D.T.; Mavropoulos, G.C.; Zannis, T.C.; Mamalis, S.D. Use of Water Emulsion and Intake Water Injection as NOx Reduction Techniques for Heavy Duty Diesel Engines; SAE Technical Paper 2006-01-1414; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Law, C.K. Combustion Physics; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Tsokolis, D.; Tsiakmakis, S.; Dimaratos, A.; Fontaras, D.; Pistikopoulos, P.; Ciuffo, B.; Samaras, Z. Fuel consumption and CO2 emissions of passenger cars over the New Worldwide Harmonized Test Protocol. Appl. Energy 2016, 179, 1152–1165. [Google Scholar] [CrossRef]

| Engine Model and Type | Six-Cylinder, Four-Stroke, Direct Injection, Turbocharged and Aftercooled Diesel Engine |

|---|---|

| Total displacement | 5958 cm3 |

| Bore/Stroke | 97.5 mm/133 mm |

| Compression ratio | 18:1 |

| Speed range | 800–2600 rpm |

| Maximum power | 177 kW @ 2600 rpm |

| Maximum torque | 840 Nm @ 1250–1500 rpm |

| Maximum turbocharger pressure | 2.50 bar |

| Fuel | Standard automotive diesel fuel |

| Nominal Mass (Refers to Unloaded Vehicle) | 7350 kg |

| Frontal area | 4.65 m2 |

| Aerodynamic resistance coefficient | 0.70 |

| Gear ratios | 1st—7.72:1 |

| 2nd—4.42:1 | |

| 3rd—2.66:1 | |

| 4th—1.79:1 | |

| 5th—1.28:1 | |

| 6th—1.00:1 | |

| Back-axle ratio | 3.70:1 |

| Wheel radius | 0.57 m |

| Longitudinal distance between center of gravity and front axle | 1.95 m |

| Longitudinal distance between center of gravity and rear axle | 1.30 m |

| Vertical distance (height) between center of gravity and ground level | 0.89 m |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giakoumis, E.G.; Triantafillou, G. Analysis of the Effect of Vehicle, Driving and Road Parameters on the Transient Performance and Emissions of a Turbocharged Truck. Energies 2018, 11, 295. https://doi.org/10.3390/en11020295

Giakoumis EG, Triantafillou G. Analysis of the Effect of Vehicle, Driving and Road Parameters on the Transient Performance and Emissions of a Turbocharged Truck. Energies. 2018; 11(2):295. https://doi.org/10.3390/en11020295

Chicago/Turabian StyleGiakoumis, Evangelos G., and George Triantafillou. 2018. "Analysis of the Effect of Vehicle, Driving and Road Parameters on the Transient Performance and Emissions of a Turbocharged Truck" Energies 11, no. 2: 295. https://doi.org/10.3390/en11020295

APA StyleGiakoumis, E. G., & Triantafillou, G. (2018). Analysis of the Effect of Vehicle, Driving and Road Parameters on the Transient Performance and Emissions of a Turbocharged Truck. Energies, 11(2), 295. https://doi.org/10.3390/en11020295