Research on Hydraulic Technology for Seam Permeability Enhancement in Underground Coal Mines in China

Abstract

:1. Introduction

2. Process of HTSPE Development

2.1. Early Experimental Stages

2.2. Popularization and Application Stages

2.3. Rapid Development Stage

3. Seam Permeability Enhancement by Water Jet

3.1. Technology and Its Application

- (1)

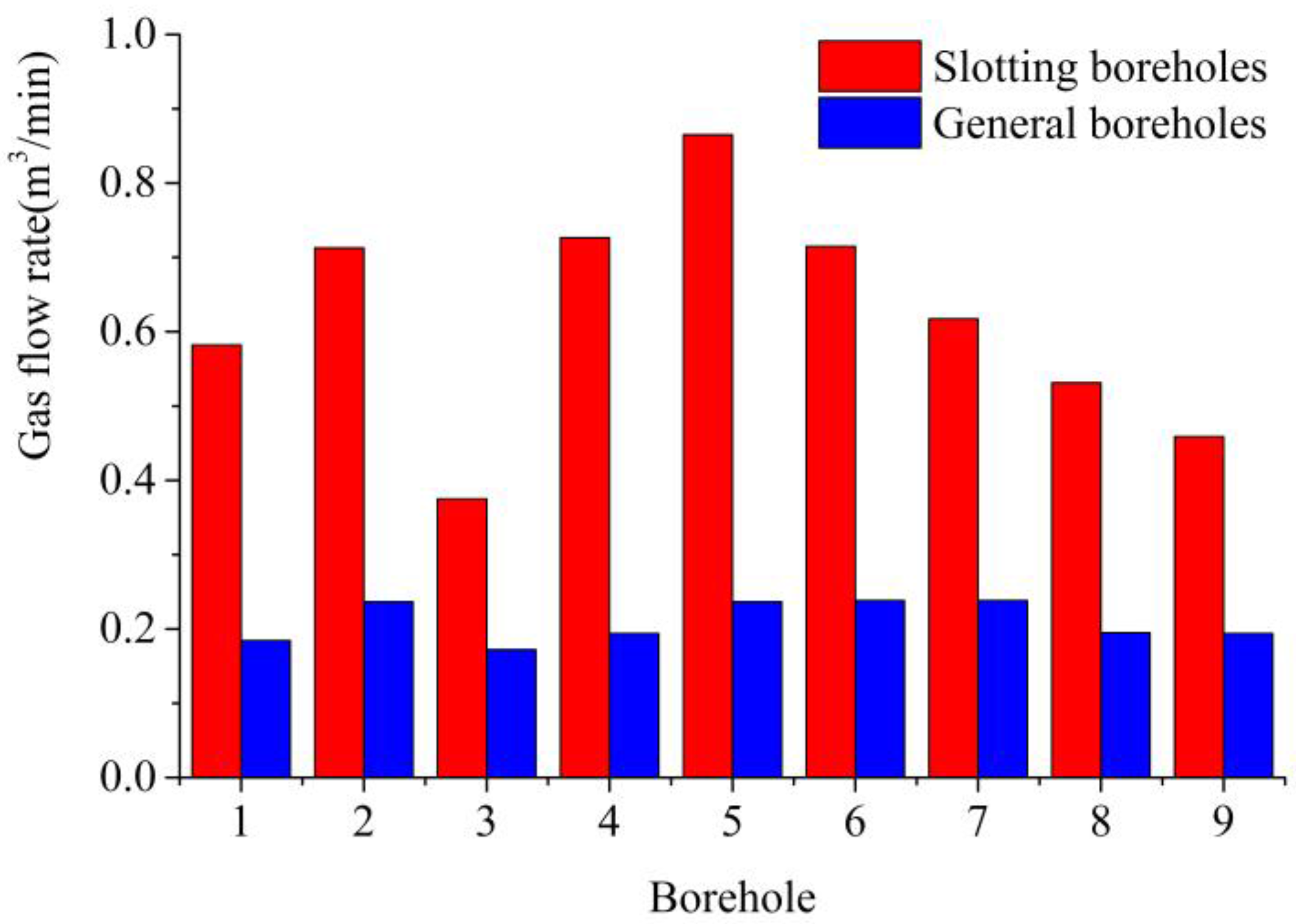

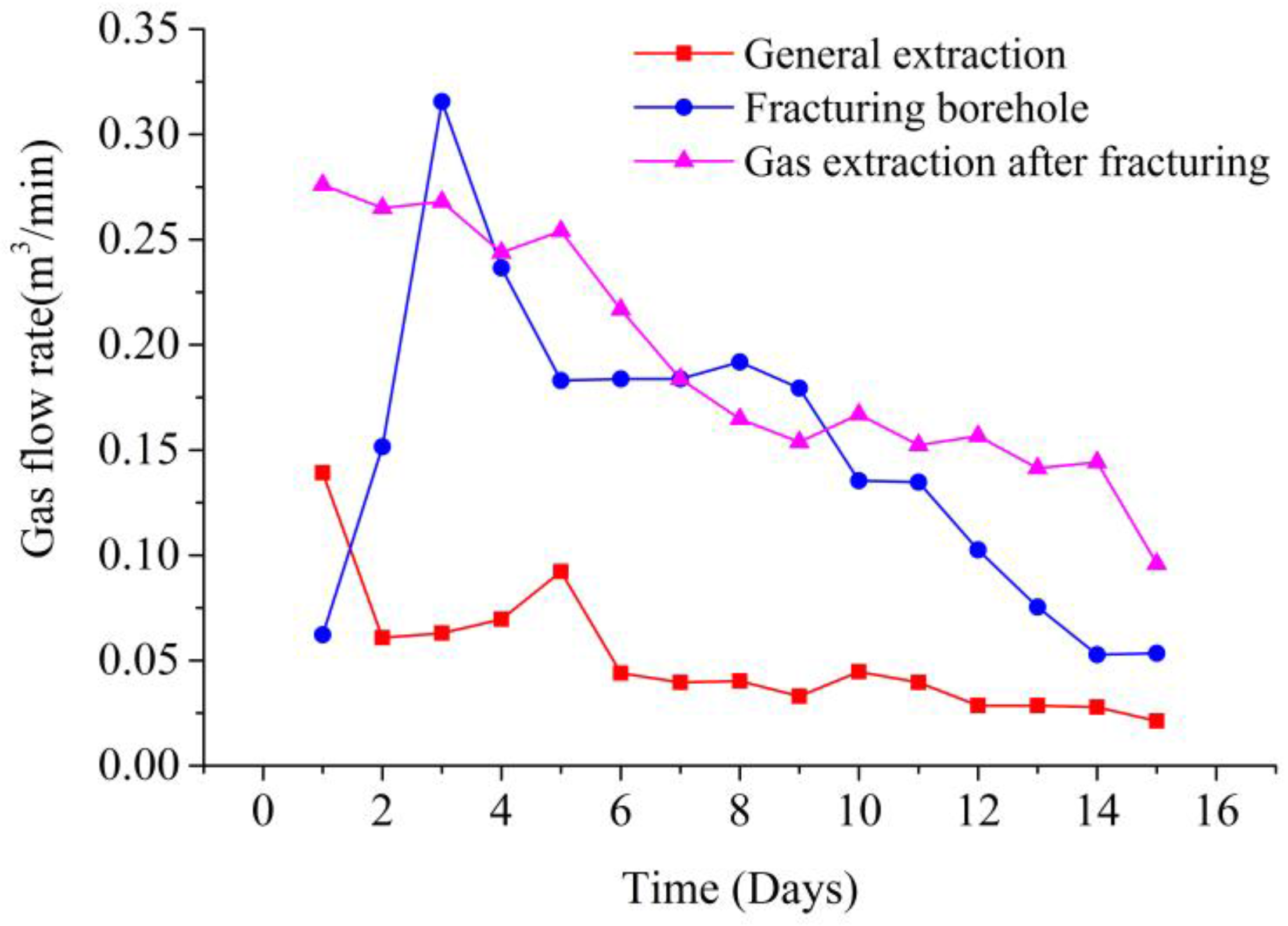

- In some instances, difficult drilling conditions and low hole drilling rates (with the depth of borehole being only 45–60 m) lead to gas extraction in soft coal seams being difficult. Figure 6 shows a novel technique of drilling in the roof or floor with a high pulse pressure water jet to improve gas extraction which has been developed and applied in the Songzao, Huainan, Yangquan, and Pingdingshan mining areas, as well as in other mining areas. As shown in Figure 7, the results indicate that borehole depths reach 120–147 m, the diameter of the slot is up to 3–4 m, and the amount of gas extraction increases more than 520% [25].

- (2)

- When rock crosscuts are driven to uncover coal, the free surface around cross-measure boreholes is too small to lead to big density pre-drainage boreholes, which as a result leads to low gas extraction efficiency. The novel technology of cross-measure drilling with high-pressure pulsed water jets has been developed to improve gas extraction in low permeability coal seams (Figure 8). This technique has been used in the same four mining areas mentioned above (Songzao, Huainan, Yangquan, and Pingdingshan) as well as other mining areas. The results show that gas extraction increases by 293% with the number of pre-drainage boreholes needed decreased by 50% (Figure 9) [24]. In addition, the time needed to drive the rock crosscuts decreases from more than six months to about one month [24].

3.2. Theories of Hydraulic Slotting for Seam Permeability Enhancement

3.2.1. Theories of Coal Breaking by Water Jet

3.2.2. Gas Migration in a Coal Seam after Water Jetting

4. Seam Permeability Enhancement by Hydraulic Fracturing in Underground Coal Mines

- (1)

- In underground mines, hydraulic pumping pressure for fracturing is elevated empirically to fracture the largest volume of rock possible. However, as a side effect, this high pressure incurs the risk of damaging the integrity of the roof and floor of the coal seam, making the stability of roadways difficult to maintain.

- (2)

- The propagation of hydraulic fractures is influenced by the in situ stress field and is therefore mainly in the direction of the principal stress. This means there will be stress shadow zones in which the permeability will not be appreciably increased. These zones will lead to gas extraction difficulties and possibly to gas accidents.

- (3)

- The fundamental conditions of walls of the borehole used for fracturing cannot be improved, and this leads to the fractures created by the hydraulic fracturing being difficult to initiate and propagate.

4.1. Technology and Its Application

4.1.1. Sealing Technique of Hydraulic Fracturing in Underground Coal Mines

4.1.2. Fracturing Technique in Underground Coal Mines

4.2. Theories of Hydraulic Fracturing in Underground Coal Mines

4.2.1. Initiation of Hydraulic Fracturing in Underground Coal Mines

4.2.2. Propagation of Hydraulic Fracturing in Underground Coal Mines

5. Deficiencies and Prospects of HTSPE

5.1. The Deficiencies

5.1.1. Lack of Systematic Study on Seam Permeability Enhancement by Hydraulic Technology

- (1)

- When high-pressure water interacts with undisturbed coal, the gas is coupled with solid particles and with liquid. How coal fails in this three-phase coupled state is not clear.

- (2)

- There is a lack of systematic research on seam permeability enhancement by water jet slotting. Water jet slotting should be a pressure relief method for increasing seam permeability. At present, research on seam permeability enhancement by water jet slotting mainly concentrates on the mechanism of coal breaking and the stress variations around the slot. However, how to make the slots relieve pressure from the coal seam and how to change the stress state around the slots is not clear [57]. Furthermore, how the crack field around the slots change with changes in the stress state is unknown. Finally, how gas flows in and around the crack field still needs to be studied.

- (3)

- Hydraulic fracturing should also be a pressure boost method for seam permeability enhancement in underground coal mines. Most scholars think that a coal seam can be cracked and fractures can be propagated as they are in an ordinary rock. Then, the seam permeability can be increased. However, there are some essential differences:

- (a)

- Coal is a porous media and there are many pores and natural fractures in a coal seam, so the failure criteria are different from those in a rock during hydraulic fracturing.

- (b)

- Coal seams in underground mines are always between roof and floor rocks. Compared with the rocks, the coal seam is very thin. In addition, the coal’s mechanical properties are very different from rocks.

- (c)

- The roadways around coal seams in coal mines may change the stress state of the coal seam.

5.1.2. Applicable Conditions of HTSPE is Limited

5.1.3. HTSPE Equipment Improvements

5.2. Development Direction of HTSPE in the Future

5.2.1. Uniform Permeability Enhancement in the Future

5.2.2. HTSPE Theory Improvements

5.2.3. Directions for Future HTSPE Equipment Development

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Zhu, J.; Hu, K.; Lu, X.; Huang, X.; Liu, K.; Wu, X. A review of geothermal energy resources, development, and applications in China: Current status and prospects. Energy 2015, 93, 466–483. [Google Scholar] [CrossRef]

- The 13th Five Year Plan for National Energy Development; National Energy Administration of China: Beijing, China, 2016.

- Chen, X.J.; Cheng, Y.P. Influence of the injected water on gas outburst disasters in coal mine. Nat. Hazards 2015, 76, 1093–1109. [Google Scholar] [CrossRef]

- Su, S.; Andrew, B.; Guo, H.; Mallett, C. An assessment of mine methane mitigation and utilization technologies. Prog. Energy Combust. 2005, 31, 123–170. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Ruiz, F.A.; Cotè, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- Cheng, Y.P.; Wang, L.; Zhao, X.L. Environmental impact of coal mine methane emissions and responding strategies in China. Int. J. Greenh. Gas Control 2011, 5, 157–166. [Google Scholar] [CrossRef]

- Li, W.; Younger, P.L.; Cheng, Y.P.; Zhang, B.; Zhou, H.; Liu, Q. Addressing the CO2 emissions of the world’s largest coal producer and consumer: Lessons from the haishiwan coalfield, China. Energy 2015, 80, 400–413. [Google Scholar] [CrossRef]

- Jiang, B.; Sun, Z.Q.; Liu, M.Q.; Jin, H.G.; Zhang, X.L. China’s energy development strategy under the low-carbon economy. Energy 2010, 35, 4257–4264. [Google Scholar] [CrossRef]

- Shen, B.H.; Liu, J.Z.; Zhang, H. The technical measures of gas control in Chinacoal mines. J. China Coal Soc. 2007, 32, 673–679. [Google Scholar]

- Yuan, L. Key technique to high efficiency and safe mining in highly gassy mining area with complex geologic condition. J. China. Coal Soc. 2006, 31, 174–178. [Google Scholar]

- Wang, H.F.; Cheng, Y.P.; Wang, W.; Xu, R. Research on comprehensive CBM extraction technology and its applications in China’s coal mines. J. Nat. Gas Sci. Eng. 2014, 20, 200–207. [Google Scholar] [CrossRef]

- Yuan, L.; Qin, Y.; Cheng, Y.P.; Meng, J.B.; Shen, J. Scenario predication for medium-long term scale of coal mine methane drainage in China. J. China Coal Soc. 2013, 38, 529–534. [Google Scholar]

- Liu, S.M.; Harpalani, S. Determination of the effective stress law for deformation in coalbed methane reservoirs. Rock Mech. Rock Eng. 2014, 47, 1809–1820. [Google Scholar] [CrossRef]

- Zhou, H.X.; Yang, Q.L.; Cheng, Y.P.; Ge, C.G.; Chen, J.X. Methane drainage and utilization in coal mines with strong coal and gas outburst dangers: A case study in Luling mine, China. J. Nat. Gas Sci. Eng. 2014, 20, 357–365. [Google Scholar] [CrossRef]

- Mazzotti, M.; Pini, R.; Storti, G. Enhanced coalbed methane recovery. J. Supercrit. Fluid 2009, 47, 619–627. [Google Scholar] [CrossRef]

- Karacan, C.Ö. Modeling and analysis of gas capture from sealed sections of abandoned coal mines. Int. J. Coal Geol. 2015, 138, 30–41. [Google Scholar] [CrossRef]

- Zhou, F.B.; Xia, T.Q.; Wang, X.X.; Zhang, Y.F.; Sun, Y.N.; Liu, J.S. Recent developments in coal mine methane extraction and utilization in China: A review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Z.G.; Shi, M.; Cai, F. Technology of gas pre-drainage with deep borehole pre-cracking blasting for gateway rapid excavation in seam with outburst. Coal Sci. Technol. 2008, 36, 45–47. [Google Scholar]

- Li, X.; Liang, W.; Zhang, Y. Application of gas drainage technology of dense boreholes along low permeability coal seam. Coal Technol. 2017, 36, 190–192. [Google Scholar]

- Zhao, B.; Wang, H. Different technologies of permeability enhancement of single coal seam in china and new technique of high pressure gas shock. Blasting 2014, 31, 32–41. [Google Scholar]

- Liu, M.J.; Kong, L.; Hao, F.C.; Xin, X.P.; Wei, G.Y.; Liu, Y.W. Application of hydraulic flushing technology in severe outburst coal. J. China Coal Soc. 2005, 30, 451–454. [Google Scholar]

- Li, X.H.; Lu, Y.Y.; Zhao, Y.; Kang, Y.; Zhou, D.P. Study on improving the permeability of soft coal seam with high pressure pulsed water jet. J. China Coal Soc. 2008, 33, 1386–1390. [Google Scholar]

- Lu, Y.Y.; Ge, Z.L.; Li, X.H.; Chen, J.F.; Liu, Y. Investigation of a self-excited pulsed water jet for rock cross-cutting to uncover coal. J. China Univ. Min. Technol. 2010, 39, 55–59. [Google Scholar]

- Lu, Y.Y.; Liu, Y.; Li, X.H.; Xia, B.W. A new method of drilling long boreholes in low permeability coal by improving its permeability. Int. J. Coal Geol. 2010, 84, 94–102. [Google Scholar] [CrossRef]

- Liu, Y. A Novel Approach to Control Crack Propagation of Hydraulic Fracture in Mine and Its Mechanism of Improving Permeability; Chongqing University: Chongqing, China, 2012. [Google Scholar]

- Lu, T.K.; Yu, H.; Zhou, T.Y.; Mao, J.S.; Guo, B.H. Improvement of methane drainage in high gassy coal seam using water jet technique. Int. J. Coal Geol. 2009, 79, 40–48. [Google Scholar] [CrossRef]

- Yuan, L.; Lin, B.Q.; Yang, W. Research progress and development direction of gas control with mine hydraulic technology in China coal mine. Int. J. Coal Sci. Technol. 2015, 43, 45–49. [Google Scholar]

- Lu, T.K.; Zhao, Z.J.; Hu, H.F. Improving the gate road development rate and reducing outburst occurrences using the water jet technique in high gas content outburst-prone soft coal seam. Int. J. Rock Mech. Min. Sci. 2011, 48, 1271–1282. [Google Scholar] [CrossRef]

- Lin, B.Q.; Yan, F.Z.; Zhu, C.J.; Zhou, Y.; Zou, Q.L.; Guo, C.; Liu, T. Cross-borehole hydraulic slotting technique for preventing and controlling coal and gas outbursts during coal roadway excavation. J. Nat. Gas Sci. Eng. 2015, 56, 518–525. [Google Scholar] [CrossRef]

- Li, X.H.; Zhao, Y.; Lu, Y.Y.; Kang, Y. Improving the penetrability of soft coal seam with self-excited oscillation water jet. J. Liaoning Technol. Univ. 2009, 28, 202–205. [Google Scholar]

- Ge, Z.L.; Lu, Y.Y.; Zhou, D.P.; Zuo, W.Q.; Xia, B.W. Study on regular and mechanism of coal bed methane desorption experiment under sonic vibrating of cavitation water jets. J. China Coal Soc. 2011, 36, 1150–1155. [Google Scholar]

- Daniel, I.M. Experimental studies of water jet impact on rock and rocklike materials. In Proceedings of the 3rd International Symposium on Jet Cutting Technology, Chicago, IL, USA, May 1976; pp. 11–13. [Google Scholar]

- Lu, Y.Y.; Huang, F.; Wang, J.H.; Liu, X.C. On the failure pattern of sandstone impacted by high-velocity water jet. Int. J. Impact Eng. 2015, 76, 67–74. [Google Scholar] [CrossRef]

- Liang, Y.P. Study on the Mechanism of Coal Failure by Drilling of High Pressure Water Jetting; Shandong University of Science and Technology: Qingdao, China, 2007. [Google Scholar]

- Chang, Z.X.; Xi, B.P.; Zhao, Y.S.; Zhao, L.M. Mechanical of breaking coal by water jet. J. China Coal Soc. 2008, 33, 983–986. [Google Scholar]

- Mu, C.M.; Wu, Y.Y. Crushing strength of the coal agaist high pressure water penetration. Chin. J. Appl. Mech. 2013, 30, 451–456. [Google Scholar]

- Lu, Y.Y.; Liu, Y.; Xia, B.W.; Zhang, S. The novel technology of drilling arrangement of rock cross-cut coal uncovering basing in theoretical analysis. J. China Coal Soc. 2011, 36, 283–287. [Google Scholar]

- Liu, Y.; Lu, Y.Y.; Li, X.H.; Xia, B.W. Application of drilling in roof or floor with high pulse pressure water jet to improve gas drainage. J. China Coal Soc. 2010, 35, 1115–1119. [Google Scholar]

- Wu, H.J.; Lin, B.Q.; Yang, W.; Yao, Q.; Zhai, C. Numerical analysis of the pressure relief effect on slot at different initial stresses. J. Min. Saf. Eng. 2009, 26, 194–197. [Google Scholar]

- Lin, B.Q.; Yang, W.; Wu, H.J.; Meng, F.W.; Zhao, Y.X.; Zhai, C. A numeric analysis of the effects different factors have on slotted drilling. J. China Univ. Min. Technol. 2010, 39, 153–157. [Google Scholar]

- Liu, T.; Lin, B.Q.; Zou, Q.L.; Zhu, C.J.; Guo, C.; Li, J. Investigation on mechanical properties and damage evolution of coal after hydraulic slotting. J. Nat. Gas Sci. Eng. 2015, 24, 489–499. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Jia, Y.J.; Ge, Z.L.; Xia, B.W. Coupled fluid-solid model of coal bed methane its application after slotting by high-pressure water jet. J. China Univ. Min. Technol. 2014, 43, 23–29. [Google Scholar]

- Ge, Z.L.; Mei, X.D.; Jia, Y.J.; Lu, Y.Y.; Xia, B.W. Influence radius of slotted borehole drainage by high pressure water jet. J. Min. Saf. Eng. 2014, 31, 657–664. [Google Scholar]

- Ni, G.H.; Lin, B.Q.; Zhai, C.; Li, Q.G.; Li, X.Z.; Zheng, C.S. Microscopic properties of drilling sealing materials and their influence on the sealing performance of boreholes. J. Univ. Sci. Technol. Beijing 2013, 35, 572–579. [Google Scholar]

- Ge, Z.L.; Mei, X.D.; Lu, Y.Y.; Tang, J.R.; Xia, B.W. Optimization and application of sealing material and sealing length for hydraulic fracturing borehole in underground coal mines. Arab. J. Geosci. 2015, 8, 3477–3490. [Google Scholar] [CrossRef]

- Li, Q.G.; Lin, B.Q.; Zhai, C. The effect of pulse frequency on the fracture extension during hydraulic fracturing. J. Nat. Gas Sci. Eng. 2014, 21, 296–303. [Google Scholar] [CrossRef]

- Liu, Y.; Xia, B.; Liu, X. A novel method of orienting hydraulic fractures in coal mines and its mechanism of intensified conduction. J. Nat. Gas Sci. Eng. 2015, 27, 190–199. [Google Scholar] [CrossRef]

- Lv, Y.C. Application the hydraulic fracturing technology in the high pressure and low permeability mine. J. Chongqing Univ. 2010, 33, 102–107. [Google Scholar]

- Lu, Y.Y.; Cheng, L.; Ge, Z.L.; Xia, B.W.; Li, Q.; Chen, J.F. Analysis on the initial cracking parameters of cross-measure hydraulic fracture in underground coal mines. Energies 2015, 8, 6977–6994. [Google Scholar] [CrossRef]

- Lin, H.X.; Du, C.Z. Experimental research on the quasi three-axis hydraulic fracturing of coal. J. China Coal Soc. 2011, 36, 1801–1805. [Google Scholar]

- Yang, J.S.; Wang, Y.B.; Li, A.Q.; Chen, Z.H.; Chen, Y.P.; Zou, S.Y. Experimental study on propagation mechanism of complex hydraulic fracture in coal-bed. J. China Coal Soc. 2012, 37, 73–77. [Google Scholar]

- Lu, Y.Y.; Song, C.P.; Jia, Y.Z.; Xia, B.W.; Ge, Z.L.; Tang, J.R.; Li, Q. Analysis and numerical simulation of hydrofracture crack propagation in coal-rock bed. CMES-Comp. Model. Eng. 2015, 105, 69–86. [Google Scholar]

- Zhou, Z.; Lu, Y.Y.; Ge, Z.L.; Yang, F.; Zhang, X.W. Theoretical and experimental study on strength characteristics of coal under coupling effect of water and gas. J. China Coal. Soc. 2014, 39, 2418–2424. [Google Scholar]

- Massarotto, P.; Iyer, R.S.; Elma, M.; Nicholson, T. An experimental study on characterizing coal bed methane (CBM) fines production and migration of mineral matter in coal beds. Energy Fuel 2014, 28, 766–773. [Google Scholar] [CrossRef]

- Yin, G.Z.; Jiang, C.B.; Xu, J.; Guo, L.S.; Peng, S.J.; Li, W.P. An experimental study on effect of water content on coalbed gas permeability in ground stress field. Transp. Porous Media 2012, 94, 87–99. [Google Scholar] [CrossRef]

- Palmer, I. Permeability changes in coal, analytical modeling. Int. J. Coal. Geol. 2009, 77, 119–126. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Zuo, S.J.; Ge, Z.L.; Xiao, S.Q.; Cheng, Y.G. Experimental study of crack initiation and extension induced by hydraulic fracturing in a tree-type borehole array. Energies 2016, 9, 514. [Google Scholar] [CrossRef]

| Technology | Time | Technique | Principle | Status of application |

|---|---|---|---|---|

| Water jet | 1959 | Hydraulic flushing | High-pressure water jet is used to cut a large slot in the coal at the face of the heading, then gas migration increases greatly with the pressure around the slot being relieved. | Some experiments have been conducted for coal roadway tunneling. |

| 1965 | Water jet scouring | Water jet was used to break coal on the surface before coal mining or coal roadway tunneling. | Water jet scouring has been used for rock cross-cut coal uncovering successfully. | |

| 1978 | Water jet slotting | The technique is using a jet of high-pressure water to break coal in coal seam and increase the free face area to allow for increased gas emissions. | Some experiments have been conducted to prevent coal and gas outburst. | |

| After 2003 | Water jet slotting | Water jet slotting has been widely used for coal seam permeability enhancement. | ||

| Hydraulic fracturing | 1970–1985 | Hydraulic fracturing | The principle of hydraulic fracturing is to use high pressure water to form a fracture network in the coal seam to increase the permeability of coal seam. | Hydraulic fracturing has been used for CBM development initially. |

| 1997 | Hydraulic extrusion | Hydraulic extrusion is also known as medium-pressure water injection. Medium-pressure water is injected into coal seam to make the seam loose. | Some experiments have been conducted to prevent coal and gas outburst during coal roadway tunneling. | |

| After 2009 | Hydraulic fracturing | The principle of hydraulic fracturing is to use high pressure water to form a fracture network in the coal seam to increase the permeability of coal seam. | Hydraulic fracturing has been widely used for coal seam permeability enhancement. |

| Technology | Merits | Demerits |

|---|---|---|

| Water jet slotting | 1. The operation is simple and can be controlled manually. 2. A net-like pattern of boreholes can be arranged for slotting and no blind zone will be generated. 3. Good applicability | The scope of seam permeability enhancement is small, and the number of boreholes is still very large. |

| Hydraulic fracturing | 1. The scope of seam permeability enhancement is wide and the effect is good. 2. The number of gas extraction borehole decreased after Hydraulic fracturing. | 1. Hydro-fractures tend to propagate along the direction of maximum principal stress, while few hydro-fracture can propagate along the direction of minimum principal stress. Thus, it leads to the area not being enhanced. 2. Hydraulic fracturing may destroy the coal seam roof and floor because of its high initiation pressure. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, L.; Ge, Z.; Xia, B.; Li, Q.; Tang, J.; Cheng, Y.; Zuo, S. Research on Hydraulic Technology for Seam Permeability Enhancement in Underground Coal Mines in China. Energies 2018, 11, 427. https://doi.org/10.3390/en11020427

Cheng L, Ge Z, Xia B, Li Q, Tang J, Cheng Y, Zuo S. Research on Hydraulic Technology for Seam Permeability Enhancement in Underground Coal Mines in China. Energies. 2018; 11(2):427. https://doi.org/10.3390/en11020427

Chicago/Turabian StyleCheng, Liang, Zhaolong Ge, Binwei Xia, Qian Li, Jiren Tang, Yugang Cheng, and Shaojie Zuo. 2018. "Research on Hydraulic Technology for Seam Permeability Enhancement in Underground Coal Mines in China" Energies 11, no. 2: 427. https://doi.org/10.3390/en11020427

APA StyleCheng, L., Ge, Z., Xia, B., Li, Q., Tang, J., Cheng, Y., & Zuo, S. (2018). Research on Hydraulic Technology for Seam Permeability Enhancement in Underground Coal Mines in China. Energies, 11(2), 427. https://doi.org/10.3390/en11020427