Nonlinear Modeling and Inferential Multi-Model Predictive Control of a Pulverizing System in a Coal-Fired Power Plant Based on Moving Horizon Estimation

Abstract

:1. Introduction

- (1)

- Pulverized coal flow into the furnace should rapidly track the power plant fuel demand, allowing power generation to be adjusted in a timely way, as required by power grids.

- (2)

- The air to coal ratio (the ratio of primary air mass flow to raw coal mass flow) should be kept close to optimal to maintain coal combustion efficiency and reduce generation of nitrogen oxide pollutants [2].

- (3)

- The coal mill outlet temperature must be controlled within the safe operation region to avoid wet coal conditions and coal firing [3].

- (1)

- A first principle model of the pulverizing system was developed that explicitly considered the nonlinear dynamics of primary air, which is suitable for designing a system controller and soft sensor.

- (2)

- An inferential multi-model predictive control scheme was established based on MHE that provided improved pulverizing system control precision and tracking performance.

2. Dynamic Model of the Pulverizing System

2.1. Pulverizing System Description

2.2. First Principle Model of the Pulverizing System

- (1)

- Raw coal grinding and pulverized coal delivery are separate processes;

- (2)

- Pulverized coal fineness is neglected, and the coal is categorized into raw and pulverized coal only;

- (3)

- The classifier operates at its designed rotating speed;

- (4)

- Primary air is regarded as an ideal gas.

2.3. Parameter Identification

2.4. Model Validation

3. Formulation of the Soft Sensor

4. Inferential Multi-Model Predictive Controller Design

4.1. Nonlinearity Analysis

4.2. Multi-Model Predictive Controller Based on Extended Input-Output State Space Model

5. Simulation Results

5.1. Soft Sensor Test

5.2. Inferential Control Strategy Test

- (1)

- The desired controlled variables are more accurately “measured” by the soft sensor, hence their control precision is significantly improved. The proposed control scheme produces fewer fluctuations around its set point for mass flowrate of primary air and pulverized coal into the furnace, which indicates that the inferential controller is less sensitive to measurement uncertainty.

- (2)

- The multi-model MPC controller can automatically handle nonlinearity, large inertia, and coupling effects of the pulverizing system. At 500 s, the power plant coal demand increased to 9 kg/s. Since the predictive controller can foresee the future outlet temperature increment, it opens the cold air baffle in advance to compensate for the excess energy input by the hot air. Hence temperature is successfully maintained around 70 °C. A similar result is observed at 1700 s, where coal demand falls to 7 kg/s. The PI controller cannot predict the influence from other control loops and handle it timely, resulting in poorly controlled outlet temperature. The PI controller can also easily result in oscillatory performance, due to the large energy balance inertia.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Flynn, D. Thermal Power Plant Simulation and Control; IET: London, UK, 2003. [Google Scholar]

- Bhatt, M.S. Effect of air ingress on the energy performance of coal fired thermal power plants. Energy Convers. Manag. 2007, 48, 2150–2160. [Google Scholar] [CrossRef]

- Agrawal, V.; Panigrahi, B.K.; Subbarao, P.M.V. Review of control and fault diagnosis methods applied to coal mills. J. Process Control 2015, 32, 138–153. [Google Scholar] [CrossRef]

- Agrawal, V.; Panigrahi, B.K.; Subbarao, P.M.V. A unified thermo-mechanical model for coal mill operation. Control Eng. Pract. 2015, 44, 157–171. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, X.; Wang, Z.; Chen, L.; Cen, K. Coal powder measurement by digital holography with expanded measurement area. Appl. Opt. 2011, 50, 22–29. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Zeng, D.; Liu, J.; Jian, Y. Optimization control of a pulverizing system on the basis of the estimation of the outlet coal powder flow of a coal mill. Control Eng. Pract. 2017, 63, 69–80. [Google Scholar] [CrossRef]

- Iii, F.J.D. Nonlinear inferential control for process applications. J. Process Control 1998, 8, 339–353. [Google Scholar]

- Niemczyk, P.; Bendtsen, J.D.; Ravn, A.P.; Andersen, P.; Pedersen, T.S. Derivation and validation of a coal mill model for control. Control Eng. Pract. 2012, 20, 519–530. [Google Scholar] [CrossRef]

- Jin, A.; Hitotumatu, S.; Sato, I. Modeling and Parameter Identification of Coal Mill. J. Power Electron. 2009, 9, 700–707. [Google Scholar]

- Zeng, D.L.; Hu, Y.; Gao, S.; Liu, J.Z. Modelling and control of pulverizing system considering coal moisture. Energy 2015, 80, 55–63. [Google Scholar] [CrossRef]

- Wei, J.L.; Wang, J.; Wu, Q.H. Development of a Multisegment Coal Mill Model Using an Evolutionary Computation Technique. IEEE Trans. Energy Convers. 2007, 22, 718–727. [Google Scholar] [CrossRef]

- Lu, J.; Chen, L.; Shen, J.; Wu, Y.; Lu, F. A study of control strategy for the bin system with tube mill in the coal fired power station. ISA Trans. 2002, 41, 215–224. [Google Scholar] [CrossRef]

- Fei, M.; Zhang, J. Robust Fuzzy Tracking Control Simulation of Medium-speed Pulverizer. In Systems Modeling and Simulation; Springer: Heidelberg, Germany, 2007. [Google Scholar]

- Cortinovis, A.; Mercangöz, M.; Mathur, T.; Poland, J.; Blaumann, M. Nonlinear coal mill modeling and its application to model predictive control. Control Eng. Pract. 2013, 21, 308–320. [Google Scholar] [CrossRef]

- Song, G.L.; Zhou, J.H.; Weng, W.G. Experimental Research on Cold Aerodynamic Field of 75t/h Boiler with Tangential Firing. Power Syst. Eng. 2005, 21, 14–16. [Google Scholar]

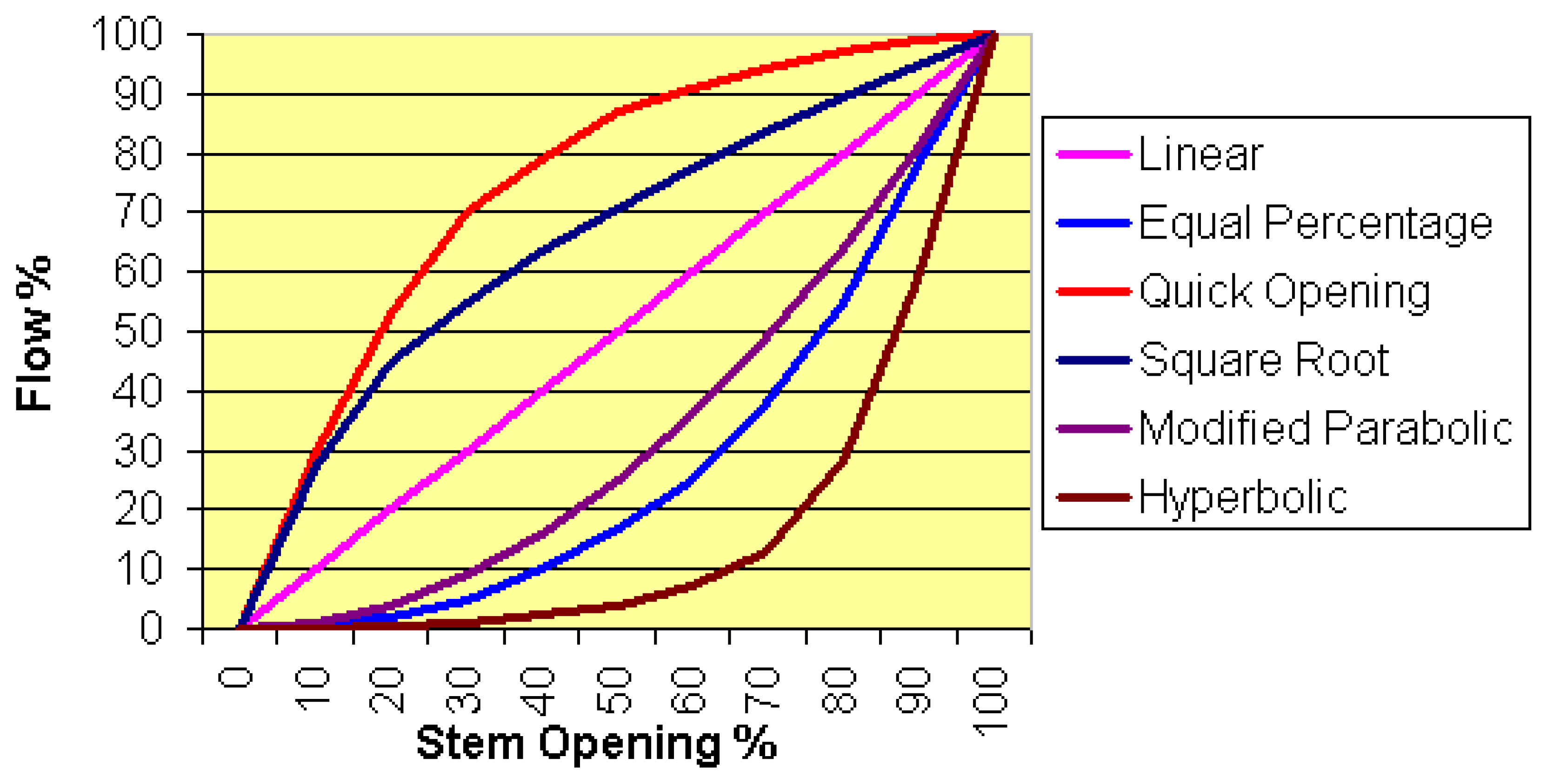

- The Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/control-valves-flow-characteristics-d_485.html (accessed on 23 January 2018).

- Kachitvichyanukul, V. Comparison of three evolutionary algorithms: GA, PSO, and DE. Ind. Eng. Manag. Syst. 2012, 11, 215–223. [Google Scholar] [CrossRef]

- Rashtchi, V.; Rahimpour, E.; Rezapour, E.M. Using a genetic algorithm for parameter identification of transformer RLCM model. Electr. Eng. 2006, 88, 417–422. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Daw, N.; Wu, Q. Identification of pneumatic cylinder friction parameters using genetic algorithms. IEEE/ASME Trans. Mechatron. 2004, 9, 100–107. [Google Scholar] [CrossRef]

- Zhang, Y.G.; Wu, Q.H.; Wang, J.; Oluwande, G. Coal Mill Modeling by Machine Learning Based on on-Site Measurements. IEEE Trans. Energy Convers. 2002, 17, 549–555. [Google Scholar] [CrossRef]

- Ghosh, A. Evolutionary Computation in Data Mining; Springer: Heidelburg, Germany, 2004. [Google Scholar]

- Pachauri, N.; Singh, V.; Rani, A. Two degree of freedom PID based inferential control of continuous bioreactor for ethanol production. ISA Trans. 2017, 68, 235–250. [Google Scholar] [CrossRef] [PubMed]

- Darko, S.I.; Nikola, J.; Nikola, P.; Velimir, O. Soft sensor for real-time cement fineness estimation. ISA Trans. 2015, 55, 250–259. [Google Scholar]

- Rani, A.; Singh, V.; Gupta, J.R. Development of soft sensor for neural network based control of distillation column. ISA Trans. 2013, 52, 438–449. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.J.; Yu, D.L.; Qian, K.J.; Lee, S.; Theera-Umpon, N. A Soft Sensor-Based Fault-Tolerant Control on the Air Fuel Ratio of Spark-Ignition Engines. Energies 2017, 10, 131. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, G.; Zhao, W.; Miao, P.; Jiang, Y.; Zhou, H. A Neural Network Combined Inverse Controller for a Two-Rear-Wheel Independently Driven Electric Vehicle. Energies 2014, 7, 4614–4628. [Google Scholar] [CrossRef]

- Rao, C.V.; Rawlings, J.B.; Lee, J.H. Constrained linear state estimation—A moving horizon approach. Automatica 2001, 37, 1619–1628. [Google Scholar] [CrossRef]

- Rao, C.V.; Rawlings, J.B.; Mayne, D.Q. Constrained state estimation for nonlinear discrete-time systems: Stability and moving horizon approximations. IEEE Trans. Autom. Control 2003, 48, 246–258. [Google Scholar] [CrossRef]

- Lopez-Negrete, R.; Patwardhan, S.C.; Biegler, L.T. Constrained particle filter approach to approximate the arrival cost in moving horizon estimation. J. Process Control 2011, 21, 909–919. [Google Scholar] [CrossRef]

- Kühl, P.; Diehl, M.; Kraus, T.; Schlöder, J.P.; Bock, H.G. A real-time algorithm for moving horizon state and parameter estimation. Comput. Chem. Eng. 2011, 35, 71–83. [Google Scholar] [CrossRef]

- Du, J.; Song, C.; Yao, Y.; Li, P. Multilinear model decomposition of MIMO nonlinear systems and its implication for multilinear model-based control. J. Process Control 2013, 23, 271–281. [Google Scholar] [CrossRef]

- Zhang, R.; Xue, A.; Wang, S.; Ren, Z. An improved model predictive control approach based on extended non-minimal state space formulation. J. Process Control 2011, 21, 1183–1192. [Google Scholar] [CrossRef]

- Wang, L.; Young, P.C. An improved structure for model predictive control using non-minimal state space realisation. J. Process Control 2006, 16, 355–371. [Google Scholar] [CrossRef]

- Gous, G.Z.; De Vaal, P.L. Using MV overshoot as a tuning metric in choosing DMC move suppression values. ISA Trans. 2012, 51, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Garriga, J.L.; Soroush, M. Model predictive control tuning methods: A review. Ind. Eng. Chem. Res. 2010, 49, 3505–3515. [Google Scholar] [CrossRef]

- And, E.L.H.; Rawlings, J.B. Critical Evaluation of Extended Kalman Filtering and Moving-Horizon Estimation. Ind. Eng. Chem. Res. 2005, 44, 2451–2460. [Google Scholar]

- Wu, X.; Shen, J.; Li, Y.; Lee, K.Y. Fuzzy modeling and stable model predictive tracking control of large-scale power plants. J. Process Control 2014, 24, 1609–1626. [Google Scholar] [CrossRef]

| Population Size | Probability of Mutation | Probability of Crossover | Termination Iterations | Generation Gap | |||||

|---|---|---|---|---|---|---|---|---|---|

| 50 | 0.3 | 0.9 | 200 | 0.8 | 2 | 1 | 1 | 1.5 | 1 |

| Parameter | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 |

|---|---|---|---|---|---|---|---|---|

| Value | 0.70 | 0.66 | 0.75 | 0.77 | 150.1 | 1.06 | 22.5 | 1.08 |

| Parameter | K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 |

| Value | 0.053 | 1.47 × 10−6 | 1423 | 10,530 | 1309 | 2398 | 1306 | 5893 |

| Parameter | K9 | K10 | K11 | K12 | K13 | K14 | K15 | K16 |

| Value | 7037 | 95 | 5.29 | 0.0095 | 10.26 | 0.114 | 0.0292 | 19.11 |

| Primary Air Temperature | Primary Air Mass Flowrate | Electric Current | Outlet Temperature | Differential Pressure |

|---|---|---|---|---|

| 664 | 1806 | 852 | 799 | 995 |

| Raw Coal Feed Rate (kg/s) | Primary Air Mass Flow (kg/s) | Primary Air Temperature (K) | Cold Air Baffle Position (%) | Hot Air Baffle Position (%) | Outlet Temperature (°C) | Mill Electric Current (A) | Mill Differential Pressure (kPa) |

|---|---|---|---|---|---|---|---|

| 3 | 10.0 | 195.6 | 10.7 | 16.5 | 70 | 26.77 | 0.5995 |

| 5 | 12.5 | 218.0 | 9.3 | 26.2 | 70 | 31.10 | 0.9646 |

| 7 | 17.5 | 224.2 | 14.3 | 46.9 | 70 | 35.00 | 1.9944 |

| 9 | 22.5 | 235.1 | 16.6 | 74.1 | 70 | 39.06 | 3.5074 |

| State Constraints | |||||||

| Value | 0.9 K/s | 0.3 kg/s | 0.5 kg/s | 0.3 kg/s | 0.2 K/s | 0.01 | 0.01 |

| Input Constraints | |||||||

| Value | 0.05 kg/s | 2%/s | 2%/s | 0.1 °C/s | 0.1 °C/s | 1.5 °C/s |

| Raw Coal Stored in the Mill | Pulverized Coal Stored in the Mill | Moisture Content | Grindability | |

|---|---|---|---|---|

| RMS of MHE | 2.8493 | 0.9084 | 0.0391 | 0.028 |

| RMS of EKF | 6.0084 | 1.8175 | 0.0417 | 0.0585 |

| Error bound of EKF | ±18.0326 | ±5.4549 | ±0.1253 | ±0.1757 |

| Error bound of MHE | ±8.5516 | ±2.7263 | ±0.1172 | ±0.0839 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, X.; Li, Y.; Wu, X.; Shen, J. Nonlinear Modeling and Inferential Multi-Model Predictive Control of a Pulverizing System in a Coal-Fired Power Plant Based on Moving Horizon Estimation. Energies 2018, 11, 589. https://doi.org/10.3390/en11030589

Liang X, Li Y, Wu X, Shen J. Nonlinear Modeling and Inferential Multi-Model Predictive Control of a Pulverizing System in a Coal-Fired Power Plant Based on Moving Horizon Estimation. Energies. 2018; 11(3):589. https://doi.org/10.3390/en11030589

Chicago/Turabian StyleLiang, Xiufan, Yiguo Li, Xiao Wu, and Jiong Shen. 2018. "Nonlinear Modeling and Inferential Multi-Model Predictive Control of a Pulverizing System in a Coal-Fired Power Plant Based on Moving Horizon Estimation" Energies 11, no. 3: 589. https://doi.org/10.3390/en11030589