Novel Concept of an Installation for Sustainable Thermal Utilization of Sewage Sludge

Abstract

:1. Introduction

1.1. Introduction

- (A)

- Upgrade sewage sludge into a fuel with better fuel properties and increased energy density. Enabling the possibility of further removal of pathogens would be a significant gain from the health and safety perspective.

- (B)

- Utilize sewage sludge using a thermal process that can potentially make inorganic residues easier to handle (turn it into a useful by-product or at least allow storage at a regular landfill).

1.2. Novelty and Relevance Aspects of the Proposed Installation along with the Scope of Work

2. State of the Art—the Foundations of the Proposed Concept

2.1. Dewatering and Drying of Sewage Sludge

- -

- Free water that is not bound, in any way, by the particles of the sludge

- -

- Interstitial water, trapped by the flocs of solids or existing in capillaries

- -

- Surface water, held by adhesion and adsorption

- -

- Intracellular and chemically bound water

2.2. Dry and Wet Torrefaction and Pyrolysis of Sewage Sludge

2.3. Slagging Gasifier as a Feasible Tool for Gasification and Inertization of Solid Residues

2.4. Plasma Gasification of the Sewage Sludge

2.5. State of the Art—Summary

3. Materials and Methods

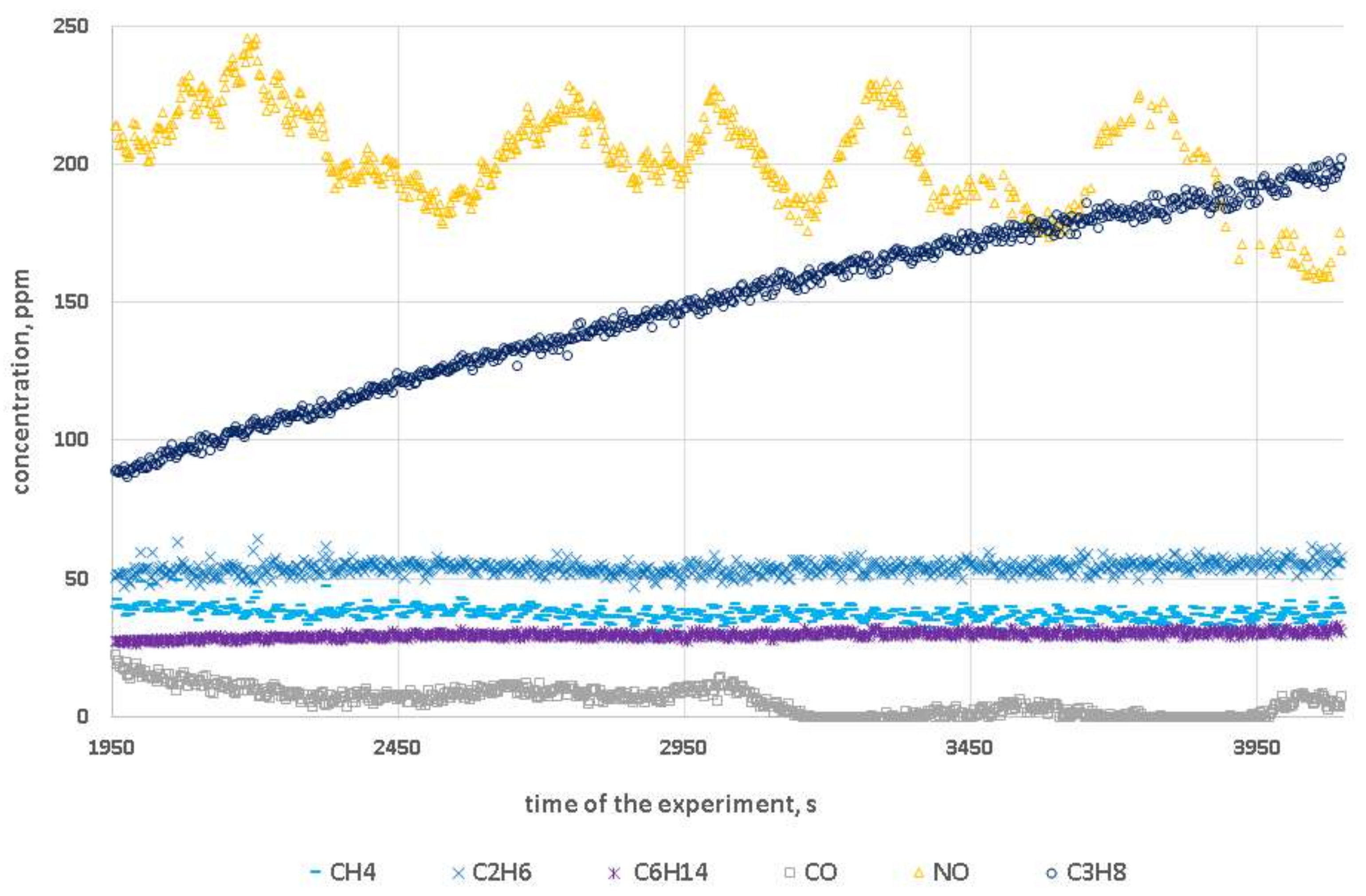

4. Results

5. Discussion

5.1. Discussion of the Obtained Results

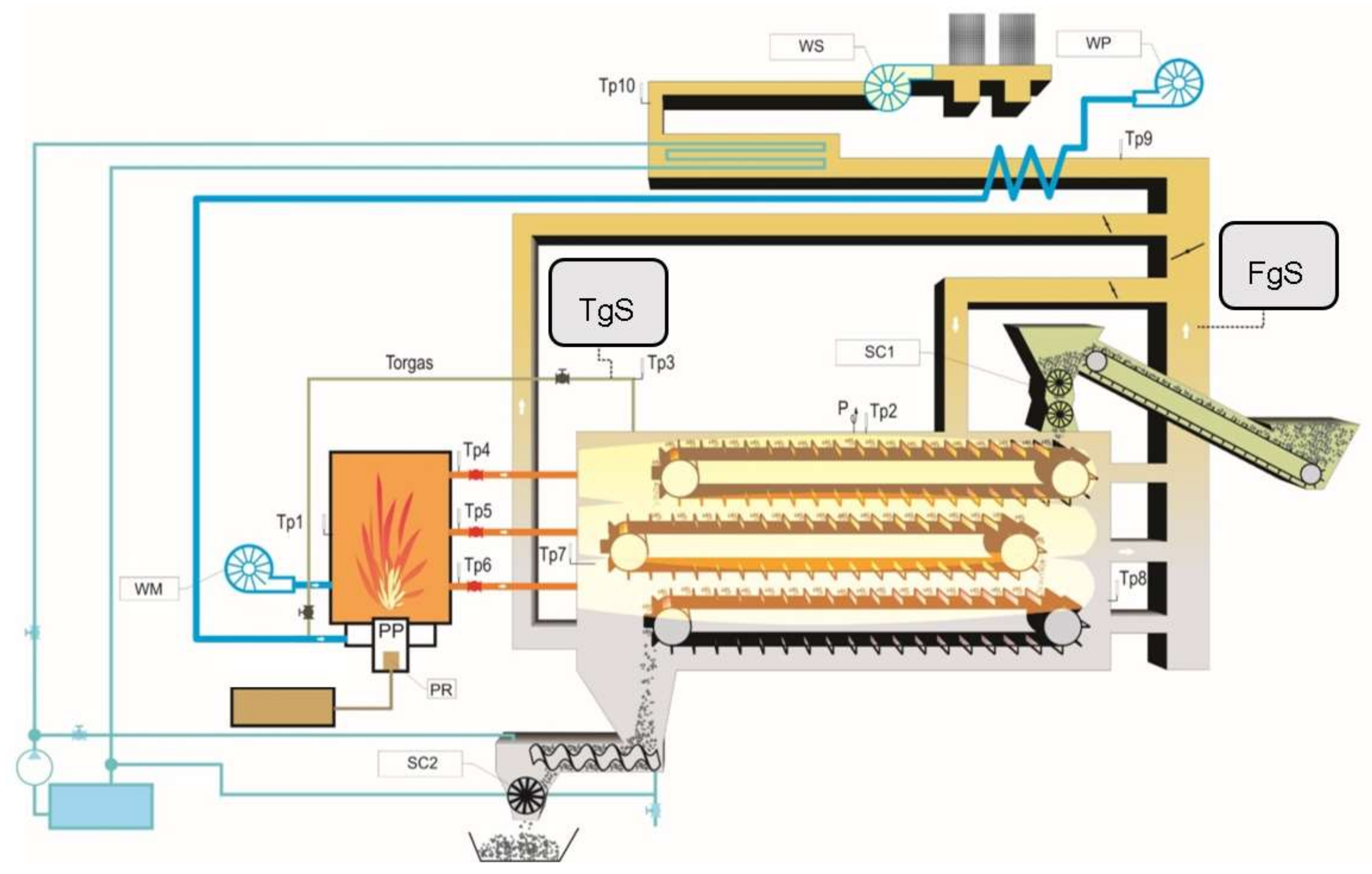

5.2. A Concept of the Sustainable Installation for Utilization of Sewage Sludge

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References and Note

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Lee, L.H.; Wu, T.Y.; Shak, K.P.Y.; Lim, S.L.; Ng, K.Y.; Nguyen, M.N.; Teoh, W.H. Sustainable approach to biotransform industrial sludge into organic fertilizer via vermicomposting: A mini-review. J. Chem. Technol. Biotechnol. 2018, 93, 925–935. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of sewage sludge management: Standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Andersen, A. Disposal and Recycling Routes for Sewage Sludge Part 4: Economic Report; Office for Official Publications of the European Communities: Luxembourg, 2002. [Google Scholar]

- Andersen, A. Disposal and Recycling Routes for Sewage Sludge: Part 1–Sludge use acceptance; Office for Official Publications of the European Communities: Luxembourg, 2001. [Google Scholar]

- Werle, S.; Wilk, R.K. A review of methods for the thermal utilization of sewage sludge: The Polish perspective. Renew. Energy 2010, 35, 1914–1919. [Google Scholar] [CrossRef]

- Chen, G.; Yue, P.L.; Mujumdar, A.S. Sludge dewatering and drying. Dry. Technol. 2002, 20, 883–916. [Google Scholar] [CrossRef]

- Tunçal, T.; Uslu, O. A Review of Dehydration of Various Industrial Sludges. Dry. Technol. 2014, 32, 1642–1654. [Google Scholar] [CrossRef]

- Peeters, B. Mechanical dewatering and thermal drying of sludge in a single apparatus. Dry. Technol. 2010, 28, 454–459. [Google Scholar] [CrossRef]

- Bennamoun, L.; Arlabosse, P.; Léonard, A. Review on fundamental aspect of application of drying process to wastewater sludge. Renew. Sustain. Energy Rev. 2013, 28, 29–43. [Google Scholar] [CrossRef]

- Ferrasse, J.H.; Arlabosse, P.; Lecomte, D. Heat, momentum, and mass transfer measurements in indirect agitated sludge dryer. Dry. Technol. 2002, 20, 749–769. [Google Scholar] [CrossRef]

- Arlabosse, P.; Chavez, S.; Lecomte, D. Method for thermal design of paddle dryers: Application to municipal sewage sludge. Dry. Technol. 2004, 22, 2375–2393. [Google Scholar] [CrossRef]

- Peeters, B.; Vernimmen, L. Challenges of Handling Filamentous and Viscouis Wastewater Sludge. Chem. Eng. 2016. [Google Scholar]

- Peeters, B.; Dewil, R.; Van Impe, J.F.; Vernimmen, L.; Smets, I.Y. Using a Shear Test-Based Lab Protocol to Map the Sticky Phase of Activated Sludge. Environ. Eng. Sci. 2011, 28, 81–85. [Google Scholar] [CrossRef]

- Peeters, B.; Dewil, R.; Vernimmen, L.; Van den Bogaert, B.; Smets, I.Y. Addition of polyaluminiumchloride (PACl) to waste activated sludge to mitigate the negative effects of its sticky phase in dewatering-drying operations. Water Res. 2013, 47, 3600–3609. [Google Scholar] [CrossRef] [PubMed]

- Deng, W.; Su, Y.; Yu, W. Theoretical Calculation of Heat Transfer Coefficient When Sludge Drying in a Nara-Type Paddle Dryer Using Different Heat Carriers. Procedia Environ. Sci. 2013, 18, 709–715. [Google Scholar] [CrossRef]

- Moscicki, K.J.; Niedzwiecki, L.; Owczarek, P.; Wnukowski, M. Commoditization of biomass: Dry torrefaction and pelletization-a review. J. Power Technol. 2014, 94, 233–249. [Google Scholar]

- Moscicki, K.J.; Niedzwiecki, L.; Owczarek, P.; Wnukowski, M. Commoditization of wet and high ash biomass : Wet torrefaction—A review. J. Power Technol. 2017, 97, 354–369. [Google Scholar]

- Wnukowski, M.; Owczarek, P.; Niedźwiecki, Ł. Wet Torrefaction of Miscanthus—Characterization of Hydrochars in View of Handling, Storage and Combustion Properties. J. Ecol. Eng. 2015, 16, 161–167. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M.; Kosturkiewicz, B. Investigation of sewage sludge preparation for combustion process. Chem. Process Eng.—Inz. Chem. Proces. 2011, 32, 299–309. [Google Scholar] [CrossRef]

- Magdziarz, A.; Werle, S. Analysis of the combustion and pyrolysis of dried sewage sludge by TGA and MS. Waste Manag. 2014, 34, 174–179. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Chang, C.C.; Yuan, M.H.; Chang, C.Y.; Wu, C.H.; Shie, J.L.; Chen, Y.H.; Chen, Y.H.; Ho, C.; Chang, W.R.; et al. Production of torrefied solid bio-fuel from pulp industry waste. Energies 2017, 10, 910. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Sung, H.-T.; Chiueh, P.-T.; Lo, S.-L. Microwave torrefaction of sewage sludge and leucaena. J. Taiwan Inst. Chem. Eng. 2017, 70, 236–243. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Sung, H.-T.; Chiueh, P.-T.; Lo, S.-L. Co-torrefaction of sewage sludge and leucaena by using microwave heating. Energy 2016, 116, 1–7. [Google Scholar] [CrossRef]

- Huang, Y.W.; Chen, M.Q.; Luo, H.F. Nonisothermal torrefaction kinetics of sewage sludge using the simplified distributed activation energy model. Chem. Eng. J. 2016, 298, 154–161. [Google Scholar] [CrossRef]

- Do, T.X.; Lim, Y.; Cho, H.; Shim, J.; Yoo, J.; Rho, K.; Choi, S.-G.; Park, B.-Y. Process modeling and energy consumption of fry-drying and torrefaction of organic solid waste. Dry. Technol. 2017, 35, 754–765. [Google Scholar] [CrossRef]

- Pulka, J.; Wiśniewski, D.; Gołaszewski, J.; Białowiec, A. Is the biochar produced from sewage sludge a good quality solid fuel? Arch. Environ. Prot. 2016, 42, 125–134. [Google Scholar] [CrossRef]

- Poudel, J.; Ohm, T.I.; Lee, S.H.; Oh, S.C. A study on torrefaction of sewage sludge to enhance solid fuel qualities. Waste Manag. 2015, 40, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Poudel, J.; Karki, S.; Gu, J.H.; Lim, Y.; Oh, S.C. Effect of Co-Torrefaction on the Properties of Sewage Sludge and Waste Wood to Enhance Solid Fuel Qualities. J. Residuals Sci. Technol. 2017, 14, 23–36. [Google Scholar] [CrossRef]

- Atienza-Martínez, M.; Fonts, I.; ábrego, J.; Ceamanos, J.; Gea, G. Sewage sludge torrefaction in a fluidized bed reactor. Chem. Eng. J. 2013, 222, 534–545. [Google Scholar] [CrossRef]

- Atienza-Martínez, M.; Mastral, J.F.; Ábrego, J.; Ceamanos, J.; Gea, G. Sewage sludge torrefaction in an auger reactor. Energy Fuels 2015, 29, 160–170. [Google Scholar] [CrossRef]

- He, C.; Giannis, A.; Wang, J.Y. Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: Hydrochar fuel characteristics and combustion behavior. Appl. Energy 2013, 111, 257–266. [Google Scholar] [CrossRef]

- Danso-Boateng, E.; Shama, G.; Wheatley, A.D.; Martin, S.J.; Holdich, R.G. Hydrothermal carbonisation of sewage sludge: Effect of process conditions on product characteristics and methane production. Bioresour. Technol. 2015, 177, 318–327. [Google Scholar] [CrossRef] [PubMed]

- Danso-Boateng, E.; Holdich, R.G.; Martin, S.J.; Shama, G.; Wheatley, A.D. Process energetics for the hydrothermal carbonisation of human faecal wastes. Energy Convers. Manag. 2015, 105, 1115–1124. [Google Scholar] [CrossRef] [Green Version]

- Oh, S.Y.; Yoon, Y.M. Energy recovery efficiency of poultry slaughterhouse sludge cake by hydrothermal carbonization. Energies 2017, 10, 1876. [Google Scholar] [CrossRef]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Tomasi Morgano, M.; Leibold, H.; Richter, F.; Stapf, D.; Seifert, H. Screw pyrolysis technology for sewage sludge treatment. Waste Manag. 2018, 73, 487–495. [Google Scholar] [CrossRef] [PubMed]

- Fonts, I.; Gea, G.; Azuara, M.; Ábrego, J.; Arauzo, J. Sewage sludge pyrolysis for liquid production: A review. Renew. Sustain. Energy Rev. 2012, 16, 2781–2805. [Google Scholar] [CrossRef]

- Atienza-Martínez, M.; Ábrego, J.; Mastral, J.F.; Ceamanos, J.; Gea, G. Energy and exergy analyses of sewage sludge thermochemical treatment. Energy 2018, 144, 723–735. [Google Scholar] [CrossRef]

- Manara, P.; Zabaniotou, A. Towards sewage sludge based biofuels via thermochemical conversion—A review. Renew. Sustain. Energy Rev. 2012, 16, 2566–2582. [Google Scholar] [CrossRef]

- Pečkytė, J.; Baltrėnaitė, E. Assessment of heavy metals leaching from (bio) char obtained from industrial sewage sludge. Environ. Prot. Eng. 2015, 7, 399–406. [Google Scholar] [CrossRef]

- Council of the European Union 2003/33/EC—Council Decision establishing criteria and procedures for the acceptance of waste at landfills pursuant to Article 16 of and Annex II to Directive 1999/31/EC. Off. J. Eur. Communities 2003, L 11/27, 27–49.

- Wang, N.Y.; Shih, C.H.; Chiueh, P.T.; Huang, Y.F. Environmental effects of sewage sludge carbonization and other treatment alternatives. Energies 2013, 6, 871–883. [Google Scholar] [CrossRef]

- Werle, S.; Dudziak, M. Analysis of organic and inorganic contaminants in dried sewage sludge and by-products of dried sewage sludge gasification. Energies 2014, 7, 462–476. [Google Scholar] [CrossRef]

- Werle, S. Gasification of a Dried Sewage Sludge in a Laboratory Scale Fixed Bed Reactor. Phys. Procedia 2015, 66, 253–256. [Google Scholar] [CrossRef]

- Reed, T.B.; Gaur, S. A Survey of Biomass Gasification 2001: Gasifier Projects and Manufacturers Around the World; The Biomass Energy Foundation: Golden, CO, USA, 2001. [Google Scholar]

- Pigneri, A.; Asbjerg, M.; Collin, C.; Dicks, A.; Sproule, G. Gasification Technologies Review; The council of the city of Sydney: Sydney, Australia, 2014. [Google Scholar]

- Maczka, T.; Sliwka, E.; Wnukowski, M.; Niedzwiecki, L. Pilot installation for thermal plasma treatment of plastic wastes. In Finnish—Swedish Flame Days 2013; IFRF International Flame Research Foundation: Sheffield, UK, 2013. [Google Scholar]

- Willis, K.P.; Osada, S.; Willerton, K.L. Plasma Gasification: Lessons Learned at Eco-Valley WTE Facility. In Proceedings of the 18th Annual North American Waste-to-Energy Conference, Orlando, FL, USA, 11–13 May 2010; pp. 133–140. [Google Scholar]

- Mountouris, A.; Voutsas, E.; Tassios, D. Plasma gasification of sewage sludge: Process development and energy optimization. Energy Convers. Manag. 2008, 49, 2264–2271. [Google Scholar] [CrossRef]

- Fabry, F.; Rehmet, C.; Rohani, V.; Fulcheri, L. Waste gasification by thermal plasma: A review. Waste Biomass Valoriz. 2013, 4, 421–439. [Google Scholar] [CrossRef] [Green Version]

- Kordylewski, W.; Michalski, J.; Ociepa, M.; Wnukowski, M. A microwave plasma potential in producer gas cleaning—preliminary results with a gas derrived from a sewage sludge. In VI Konferencja Naukowo-Techniczna Energetyka Gazowa 2016; Silesian University of Technology: Gliwice, Poland, 2016. [Google Scholar]

- Striūgas, N.; Valinčius, V.; Pedišius, N.; Poškas, R.; Zakarauskas, K. Investigation of sewage sludge treatment using air plasma assisted gasification. Waste Manag. 2017. [Google Scholar] [CrossRef] [PubMed]

- CEN (European Comitte for Standardisation) EN 13284-1:2001 Stationary source emissions—Determination of low range mass concentration of dust—Part 1: Manual gravimetric method 2001.

- Peeters, B.; Dewil, R.; Smets, I. Challenges of drying sticky wastewater sludge. Chem. Eng. (United States) 2014, 121, 51–54. [Google Scholar]

- Pawlak-Kruczek, H.; Krochmalny, K.K.; Niedźwiecki, Ł.; Mościcki, K.J. Slow pyrolysis of the sewage sludge with additives: Calcium oxide and lignite. In The Clearwater Clean Coal Conference: Proceedings of the 42nd International Technical Conference on Clean Energy; Sakkestad, B.A., Ed.; Coal Technologies Associates: Clearwater, FL, USA, 2017. [Google Scholar]

- Pawlak-Kruczek, H.; Zgóra, J.M.; Krochmalny, K.K. Characterization of torrefied biomass depends on process condition. In Proceedings of the 40th International Technical Conference on Clean Coal & Fuel Systems, Clearwater, FL, USA, 31 May–4 June 2015. [Google Scholar]

| Test | Symbol | Value | Unit | Standard Procedure |

|---|---|---|---|---|

| Moisture content 1 | MC | 83.90 | % | EN ISO 18134-2:2015 |

| Volatile matter content | VM d | 62.40 | % | EN 15148:2009 |

| Ash content | A d | 33.40 | % | EN ISO 1822:2015 |

| Higher heating value | HHV | 16,100 | kJ/kg | EN 14918:2009 |

| Lower heating value 2 | LHV | 661.1 | kJ/kg | EN 14918:2009 |

| Carbon content | C d | 38.05 | % | EN ISO 16948:2015 |

| Hydrogen content | H d | 3.85 | % | EN ISO 16948:2015 |

| Nitrogen content | N d | 5.55 | % | EN ISO 16948:2015 |

| Sulfur content | S d | 0.95 | % | EN ISO 16994:2016 |

| Oxygen content | O d | 18.20 | % | EN ISO 16993:2015 |

| Test | Symbol | Test 1 | Test 2 | Test 3 | Unit |

|---|---|---|---|---|---|

| Moisture content of the feedstock 1 | MCin | 83.90 | 53.47 | 32.13 | % |

| Moisture content of the dried sewage sludge 1 | MCout | 53.47 | 32.13 | 4.02 | % |

| Residence time | tres | 75 | 55 | 60 | min |

| Average temperature of the thermal oil 2 | Toil | 178.7 | 177.2 | 183.3 | °C |

| Relative humidity of the air at the outlet of the dryer | RH | 60 | 62 | 58 | % |

| Mass of dried sludge | mwet | 966 | 329 | 227 | kg |

| Mass of removed water | mvap | 637 | 102 | 66 | kg |

| Result | Symbol | Test 1 | Test 2 | Test 3 | Unit |

|---|---|---|---|---|---|

| Average consumption of the heat | Eth | 4141 | 6300 | 7203 | kJ/kgH2O |

| Average consumption of the electricity | Eel | 301 | 643 | 413 | kJ/kgH2O |

| Average total energy consumption | Etot | 4441 | 6976 | 7615 | kJ/kgH2O |

| Test | Symbol | Value | Unit | Standard Procedure |

|---|---|---|---|---|

| Moisture content 1 | MC | 1.00 | % | EN ISO 18134-2:2015 |

| Volatile matter content | VM d | 41.50 | % | EN 15148:2009 |

| Ash content | A d | 48.00 | % | EN ISO 1822:2015 |

| Higher heating value | HHV | 15,700 | kJ/kg | EN 14918:2009 |

| Lower heating value 2 | LHV | 15,515 | kJ/kg | EN 14918:20093 |

| Carbon content | C d | 34.58 | % | EN ISO 16948:2015 |

| Hydrogen content | H d | 2.73 | % | EN ISO 16948:2015 |

| Nitrogen content | N d | 5.09 | % | EN ISO 16948:2015 |

| Sulfur content | S d | 0.76 | % | EN ISO 16994:2016 |

| Oxygen content | O d | 8.83 | % | EN ISO 16993:2015 |

| Result | Symbol | Value | Unit |

|---|---|---|---|

| Concentration of CO2 in torgas | UCO2 | 2.11 | %vol |

| Concentration of condensable compounds in torgas | Dtars | 63.83 | g/mSTP3 |

| Compound | Boiling Point | Molecular Mass | Area of the Peak | Relative Area of the Peak 2 |

|---|---|---|---|---|

| °C | g/mol | a.u. (10−6) 1 | % | |

| Trimethylamine | 2.9 | 59.11 | 1.73 | 76.4% |

| Furan | 31.3 | 68.07 | 0.07 | 3.2% |

| Acetone | 56 | 58.08 | 1.14 | 50.5% |

| 2-Methylfuran | 63 | 82.1 | 0.47 | 20.6% |

| Methyl Alcohol | 64.7 | 32.04 | 2.19 | 100.0% |

| Acetonitrile | 82 | 41.05 | 0.54 | 23.7% |

| Dimethyl disulfide | 110 | 94.19 | 1.19 | 52.6% |

| p-Xylene | 138.4 | 106.16 | 0.20 | 9.0% |

| Pyridine | 115.6 | 79.1 | 0.57 | 25.2% |

| Pyrazine | 115 | 80.09 | 0.05 | 2.4% |

| Isocapronitrile | 155 | 97.16 | 0.01 | 0.6% |

| 2-Methylpyrazine | 135 | 94.11 | 0.25 | 11.2% |

| 4-Aminopyridine | 273 | 94.11 | 0.11 | 4.7% |

| Dimethyl trisulfide | 170 | 126.26 | 0.40 | 17.6% |

| Acetic acid | 118.1 | 60.05 | 1.66 | 73.3% |

| 1-(2-Furyl)ethanone | 173 | 110.11 | 0.05 | 2.3% |

| Pyrrole | 129 | 67.09 | 0.74 | 32.9% |

| 2-Methyl-1H-pyrrole | 148 | 81.12 | 0.07 | 3.0% |

| Acetamide | 221.2 | 59.07 | 1.29 | 57.1% |

| (E)-2-Butenoic acid | 185 | 86.09 | 0.08 | 3.4% |

| Phenol | 181.7 | 94.11 | 0.13 | 5.6% |

| Octanoic acid | 237 | 144.21 | 0.01 | 0.4% |

| p-Cresol | 201.8 | 108.13 | 0.03 | 1.2% |

| 3,4,5-Trimethylpyrazole | 170 | 110.16 | 0.11 | 4.9% |

| 3-Pyridinol | 180 | 95.1 | 0.60 | 26.5% |

| Indole | 254 | 117.15 | 0.35 | 15.4% |

| Succinimide | 288 | 99.09 | 0.04 | 1.7% |

| Dodecanoic acid | 298.9 | 200.32 | 0.06 | 2.8% |

| N-(Pyridin-3-yl)acetamide | 327 | 136.15 | 0.26 | 11.3% |

| n-Hexadecanoic acid | 351.5 | 256.43 | 0.05 | 2.3% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tic, W.J.; Guziałowska-Tic, J.; Pawlak-Kruczek, H.; Woźnikowski, E.; Zadorożny, A.; Niedźwiecki, Ł.; Wnukowski, M.; Krochmalny, K.; Czerep, M.; Ostrycharczyk, M.; et al. Novel Concept of an Installation for Sustainable Thermal Utilization of Sewage Sludge. Energies 2018, 11, 748. https://doi.org/10.3390/en11040748

Tic WJ, Guziałowska-Tic J, Pawlak-Kruczek H, Woźnikowski E, Zadorożny A, Niedźwiecki Ł, Wnukowski M, Krochmalny K, Czerep M, Ostrycharczyk M, et al. Novel Concept of an Installation for Sustainable Thermal Utilization of Sewage Sludge. Energies. 2018; 11(4):748. https://doi.org/10.3390/en11040748

Chicago/Turabian StyleTic, Wilhelm Jan, Joanna Guziałowska-Tic, Halina Pawlak-Kruczek, Eugeniusz Woźnikowski, Adam Zadorożny, Łukasz Niedźwiecki, Mateusz Wnukowski, Krystian Krochmalny, Michał Czerep, Michał Ostrycharczyk, and et al. 2018. "Novel Concept of an Installation for Sustainable Thermal Utilization of Sewage Sludge" Energies 11, no. 4: 748. https://doi.org/10.3390/en11040748

APA StyleTic, W. J., Guziałowska-Tic, J., Pawlak-Kruczek, H., Woźnikowski, E., Zadorożny, A., Niedźwiecki, Ł., Wnukowski, M., Krochmalny, K., Czerep, M., Ostrycharczyk, M., Baranowski, M., Zgóra, J., & Kowal, M. (2018). Novel Concept of an Installation for Sustainable Thermal Utilization of Sewage Sludge. Energies, 11(4), 748. https://doi.org/10.3390/en11040748