An Optimisation Study on Integrating and Incentivising Thermal Energy Storage (TES) in a Dwelling Energy System

Abstract

:1. Introduction

1.1. Background

1.2. Literature Review

1.3. Contributions of This Work

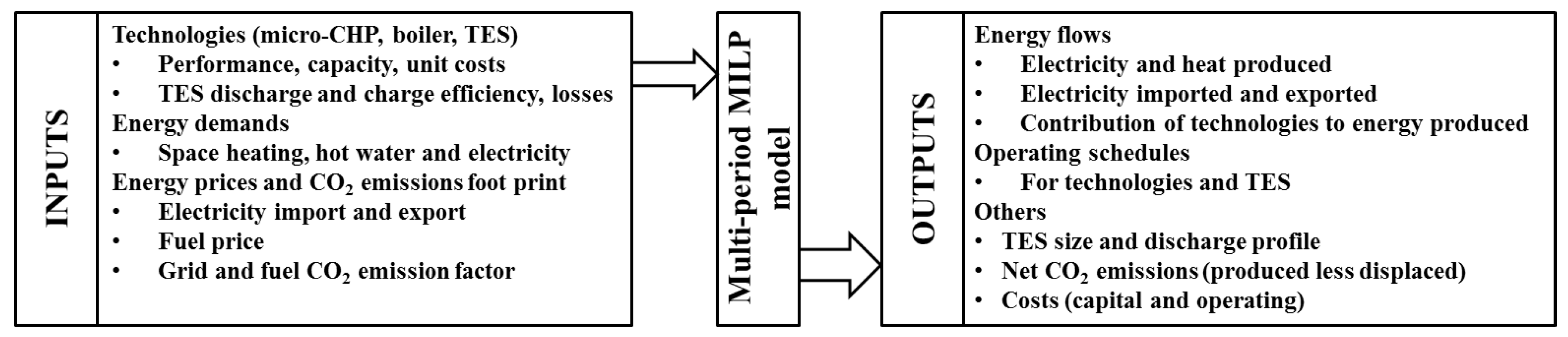

2. Methodology

2.1. Design Statement

- Given:

- ○

- Set of LZC technologies (different sizes of micro-CHP).

- ○

- The energy demands of a dwelling: space heating, hot water and electricity provided in 5 min temporal precision for all the days in a year. The electricity demand is for combined appliances, electronics and lighting.

- ○

- Energy prices (electricity and fuel), electricity tariff structure, technology costs.

- Determine:

- ○

- Optimal energy system design

- ✧

- Technologies selected, capacities and dispatch strategy

- ✧

- Contribution of technologies to heat and power provision

- ○

- Energy flows, economics and CO2 emissions

- Subject to:

- ○

- Energy (both heat and electricity) balances

- ○

- Technology capacity constraints

- In order to:

- ○

- Minimise the EAC of meeting dwelling energy demand to a residential user

2.2. Mathematical Formulation

3. Case Study

3.1. Design Problem

3.2. Results and Discussion

3.3. Limitations of This Work

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| Sets | |

| r ∈ R | Set of all time periods |

| Independent variables | |

| QCHP | Heat produced from micro-CHP (kW) |

| QBOI | Heat produced from boiler (kW) |

| QTES,IN | Heat diverted into storage, (kW) |

| QTES,OUT | Heat delivered from storage (kW) |

| SizeTES | Total storage capacity (kWh) |

| WIMP | Electricity imported to satisfy demand (kW) |

| WEXP | Electricity exported (kW) |

| Dependent variables | |

| ACC | Annualised capital cost (£/year) |

| EAC | Equivalent Annual Cost (£/year) |

| FC | Fuel cost (£/year) |

| MC | Maintenance cost (£/year) |

| WGRID,NET | Net electricity cost (£/year) |

| Binary variables | |

| YCHP | Binary variable for technology operation |

| YEI | Binary variable for export/import of electricity |

| YTES | Binary variable for charging/discharging the store |

| ZCHP | Binary variable for technology existence |

| Parameters | |

| FEF | Fuel emission factor (kg/kWh) |

| GIMP | Grid electricity import price (£/kWh) |

| GEXP | Grid electricity export price (£/kWh) |

| GEE | Grid energy efficiency (%) |

| GEF | Grid emission factor (kg/kWh) |

| ICCHP | Micro-CHP installed capital (£/kW) |

| ICTES | TES installed capital (£/kW) |

| ISH | Initial store heat (%) |

| IR | Interest rate |

| θ | Storage losses (%) |

| Lo | Lower limit |

| MCCHP | Micro-CHP maintenance cost (£/kWh) |

| MCTES | TES maintenance cost (£/kWh) |

| n | Technology lifetime (years) |

| PerfBOI | Boiler performance |

| PerfCHP | Micro-CHP performance |

| Qdemand | Heat demand (both hot water and space heating) (kW) |

| SizeCHP | Micro-CHP capacity (kW) |

| ts | Time precision |

| UEI | Upper limit for electricity export and import |

| Uo | Upper limit for micro-CHP power |

| Wdemand | Electricity demand (kW) |

| ƞcharge | TES charge efficiency (%) |

| ƞdischarge | TES discharge efficiency (%) |

Appendix A

| Technical Attributes | Natural Gas Boiler | Micro-CHP (1 kW) | Micro-CHP (2 kW) | Micro-CHP (4 kW) | Hot Water Tank |

|---|---|---|---|---|---|

| Turnkey cost (£/kW) | 163 | 3110 | 2400 | 1900 | 20 |

| Maintenance cost (£/kWh) | 0.001 | 0.01 | 0.01 | 0.01 | 0.001 |

| Performance | 0.895 | 0.9 | 0.9 | 0.9 | 2.75 |

| Charge efficiency (%) | - | - | - | - | 90 |

| Discharge efficiency (%) | - | - | - | - | 90 |

| Initial store heat (%) | - | - | - | - | 100 |

References

- International Energy Agency; Energy Technology Systems Analysis Program (ETSAP); International Renewable Energy Agency. Thermal Energy Storage, Technology Brief E17. January 2013. Available online: https://www.irena.org/DocumentDownloads/Publications/IRENA-ETSAP%20Tech%20Brief%20E17%20Thermal%20Energy%20Storage.pdf (accessed on 23 March 2017).

- Balcombe, P.; Rigby, D.; Azapagic, A. Investigating the importance of motivations and barriers related to microgeneration uptake in the UK. Appl. Energy 2014, 130, 403–418. [Google Scholar] [CrossRef]

- Cherrington, R.; Goodship, V.; Longfield, A.; Kirwan, K. The feed-in tariff in the UK: A case study focus on domestic photovoltaic systems. Renew. Energy 2013, 50, 421–426. [Google Scholar] [CrossRef]

- EASE/EERA. European Energy Storage Technology Development Roadmap Toward 2030. 2013. Available online: http://www.eera-set.eu/wp-content/uploads/148885-EASE-recommendations-Roadmap-04.pdf (accessed on 8 December 2016).

- Spataru, C.; Kok, Y.C.; Barrett, M.; Sweetnam, T. Techno-economic assessment for optimal energy storage mix. Energy Procedia 2015, 83, 515–524. [Google Scholar] [CrossRef]

- Oluleye, G.; Hawkes, A.D.; Allison, J.; Kelly, N.; Clarke, J. An optimisation study on integrating and incentivising Thermal Energy Storage (TES) in a dwelling energy system. In Proceedings of the Sustainable Development of Energy, Water and Environment Systems Conference, Dubrovnik, Croatia, 4–8 October 2017. [Google Scholar]

- Brandoni, C.; Arteconi, A.; Ciriachi, G.; Polonara, F. Assessing the impact of micro-generation technologies on local sustainability. Energy Convers. Manag. 2014, 87, 1281–1290. [Google Scholar] [CrossRef]

- Sorace, M.; Gandiglio, M.; Santarelli, M. Modelling and techno-economic analysis of the integration of a FC-based micro-CHP system for residential application with a heat pump. Energy 2015, 120, 275–2015. [Google Scholar]

- Díaz, G.; Moreno, B. Valuation under uncertain energy prices and load demands of micro-CHP plants supplemented by optimally switched thermal energy storage. Appl. Energy 2016, 177, 553–569. [Google Scholar] [CrossRef]

- Fubara, T. K.; Cecelja, F.; Yang, A. Modelling and selection of micro-CHP systems for domestic energy supply: The dimension of network-Wide primary energy consumption. Appl. Energy 2014, 114, 327–334. [Google Scholar] [CrossRef]

- Murugan, S.; Horák, B. A review of micro combined heat and power systems for residential applications. Renew. Sustain. Energy Rev. 2016, 64, 144–162. [Google Scholar] [CrossRef]

- Eames, P.; Loveday, D.; Haines, V.; Romanos, P. The Future Role of Thermal Energy Storage in the UK Energy System: An Assessment of the Technical Feasibility and Factors Influencing Adoption—Research Report; REF UKERC/RR/ED/2014/001; UKERC: London, UK, 2014. [Google Scholar]

- Barbieri, E.S.; Melino, F.; Morini, M. Influence of the thermal energy storage on the profitability of micro-CHP systems for residential building applications. Appl. Energy 2012, 97, 714–722. [Google Scholar] [CrossRef]

- Arteconi, A.; Hewitt, N.; Polonara, F. State of the art of thermal storage for demand-side management. Appl. Energy 2012, 93, 371–389. [Google Scholar] [CrossRef]

- Bogdan, Z.; Kopjar, D. Improvement of the cogeneration plant economy by using heat accumulator. Energy 2006, 31, 2285–2292. [Google Scholar] [CrossRef]

- Oluleye, G.; Vasquez, L.; Smith, R.; Jobson, M. A multi-period mixed integer linear program for design of residential distributed energy centres with thermal demand data discretisation’. Sustain. Prod. Consum. 2016, 5, 16–28. [Google Scholar] [CrossRef]

- Committee on Climate Change 2013. Fourth Carbon Budget Review-Part 2: The Cost-Effective Path to the 2050 Target. Committee on Climate Change. Available online: http://www.theccc.org.uk/wp-content/uploads/2013/12/1785a-CCC_AdviceRep_Singles_1.pdf (accessed on 25 July 2017).

- Kelly, N.J.; Tuohy, P.G.; Hawkes, A.D. Performance assessment of tariff-based air source heat pump load shifting in a UK detached dwelling featuring phase change-enhanced buffering. Appl. Therm. Eng. 2014, 71, 809–820. [Google Scholar] [CrossRef] [Green Version]

- Salata, F.; Golasi, I.; Domestico, U.; Banditelli, M.; Lo Basso, G.; Nastasi, B.; de Lieto Vollaro, A. Heading towards the nZEB through CHP+HP systems. A comparison between retrofit solutions able to increase the energy performance for the heating and domestic hot water production in residential buildings. Energy Convers. Manag. 2017, 138, 61–76. [Google Scholar] [CrossRef]

- Mongibello, L.; Capezzuto, M.; Graditi, G. Technical and cost analyses of two different heat storage systems for residential micro-CHP plants. Appl. Therm. Eng. 2014, 71, 636–642. [Google Scholar] [CrossRef]

- Vögelin, P.; Koch, B.; Georges, G.; Boulouchos, K. Heuristic approach for the economic optimisation of combined heat and power (CHP) plants: Operating strategy, heat storage and power. Energy 2017, 121, 66–77. [Google Scholar] [CrossRef]

- Shaneb, O.; Coates, G.; Taylor, P. Sizing of residential μCHP systems. Energy Build. 2011, 43, 1991–2001. [Google Scholar] [CrossRef]

- Hawkes, A.; Leach, M. Modelling high level system design and unit commitment for a microgrid. Appl. Energy 2009, 86, 1253–1265. [Google Scholar] [CrossRef]

- Ren, H.; Gao, W.; Ruan, Y. Optimal Sizing for Residential CHP System. Chall. Power Eng. Environ. 2007, 73–79. [Google Scholar] [CrossRef]

- Merkel, E.; Mckenna, R.; Fichtner, W. Optimisation of the capacity and the dispatch of decentralised micro-CHP systems: A case study for the UK. Appl. Energy 2015, 140, 120–134. [Google Scholar] [CrossRef]

- Mckenna, R.; Merkel, E.; Fichtner, W. Energy autonomy in residential buildings: A techno-economic model-based analysis of the scale effects. Appl. Energy 2017, 189, 800–815. [Google Scholar] [CrossRef]

- Pruitt, K.A.; Braun, R.J.; Newman, A.M. Evaluating shortfalls in mixed-integer programming approaches for the optimal design and dispatch of distributed generation systems. Appl. Energy 2013, 102, 386–398. [Google Scholar] [CrossRef]

- Hawkes, A.; Leach, M. Impacts of temporal precision in optimisation modelling of micro-Combined Heat and Power. Energy 2005, 30, 1759–1779. [Google Scholar] [CrossRef]

- Baeten, B.; Rogiers, F.; Helsen, L. Reduction of heat pump induced peak electricity use and required generation capacity through thermal energy storage and demand response. Appl. Energy 2017, 195, 184–195. [Google Scholar] [CrossRef]

- Fragaki, A.; Andersen, A.N.; Toke, D. Exploration of economical sizing of gas engine and thermal store for combined heat and power plants in the UK. Energy 2008, 33, 1659–1670. [Google Scholar] [CrossRef]

- Renaldi, R.; Kiprakis,, A.; Friedrich, D. An optimisation framework for thermal energy storage integration in a residential heat pump heating system. Appl. Energy 2017, 186, 520–529. [Google Scholar] [CrossRef]

- Hussain, A.; Bui, V.; Kim, H.; Im, Y.; Lee, J. Optimal Energy Management of Combined Cooling, Heat and Power in Different Demand Type Buildings Considering Seasonal Demand Variations. Energies 2017, 10, 789. [Google Scholar] [CrossRef]

- Bianco, V.; Scarpa, F.; Tagliafico, L. Estimation of primary energy savings by using heat pumps for heating purposes in the residential sector. Appl. Therm. Eng. 2017, 114, 938–947. [Google Scholar] [CrossRef]

- Allison, J.; Bell, K.; Clarke, J.; Cowie, A.; Elsayed, A.; Flett, G.; Oluleye, G.; Hawkes, A.; Hawker, G.; Kelly, N.; et al. Assessing domestic heat storage requirements for energy flexibility over varying timescales. Appl. Therm. Eng. 2018, 136, 602–616. [Google Scholar] [CrossRef]

- Standard European Electrical Profiles. IEA/ECBCS Annex 42 The Simulation of Building-Integrated Fuel Cell and Other Cogeneration Systems. 2006. Available online: http://www.buildup.eu/en/practices/publications/iea-ecbes-annex-42-simulation-building-integrated-fuel-cell-and-other (accessed on 19 October 2016).

- Office of Gas and Electricity Markets (Ofgem) Feed-In Tariff (FIT) Rates. 2017. Available online: https://www.ofgem.gov.uk/environmental-programmes/fit/fit-tariff-rates (accessed 10 December 2017.

- Department of Business, Energy and Industrial Strategy, Data tables 1–20 supporting the toolkit and the guidance. Available online: https://www.gov.uk/government/publications/valuation-of-energy-use-and-greenhouse-gas-emissions-for-appraisal (accessed on 15 September 2016).

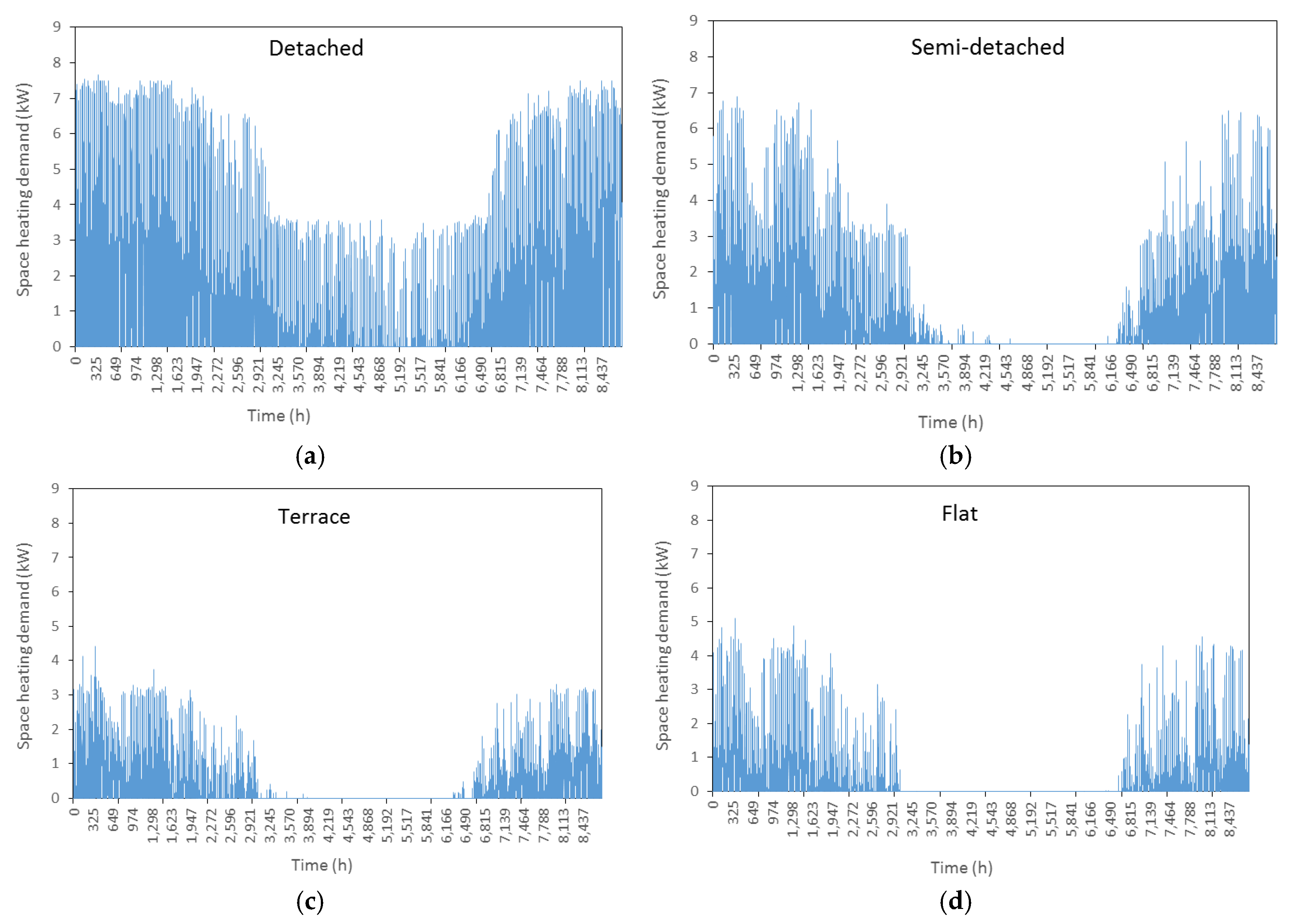

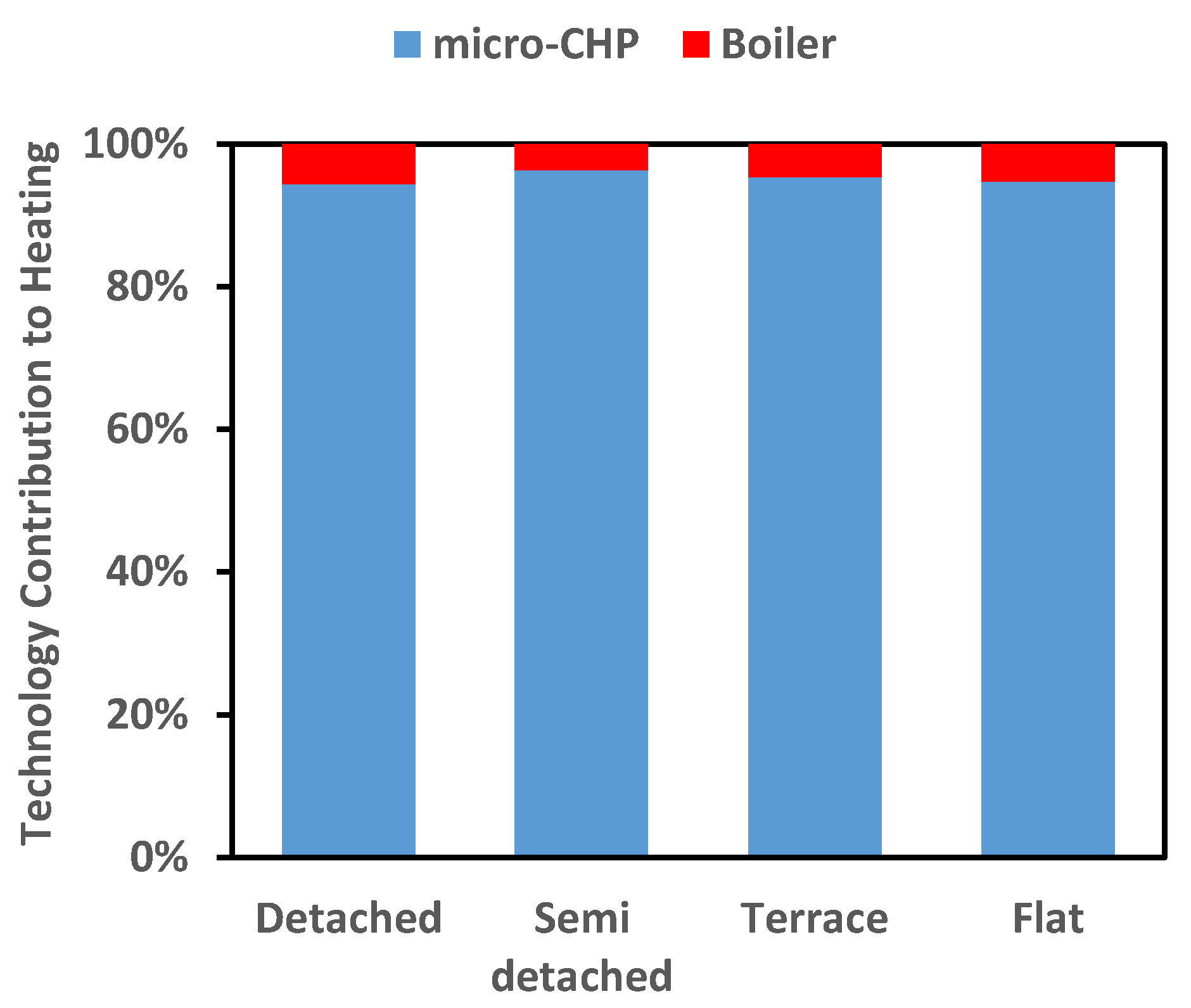

| Detached | Semi-Detached | Terrace | Flat | ||

|---|---|---|---|---|---|

| Peak demand (kW) | Space heating | 7.65 | 6.89 | 4.42 | 5.11 |

| Hot water | 27.2 | 34.9 | 34.6 | 34.7 | |

| Total demand (kWh/year) | Space heating | 9904 | 5400 | 2480 | 1940 |

| Hot water | 1712 | 1590 | 1351 | 1304 | |

| Floor area (m2) | - | 121–152 | 74–93 | 66–83 | 45–57 |

| Detached | Semi-Detached | Terrace | Flat | ||

|---|---|---|---|---|---|

| EAI (£/year) | Design with TES | 100.9 | −19.2 | −133.84 | −132.48 |

| Design without TES | 41.22 | −52.5 | −138.5 | −156 | |

| System payback (year) | Design with TES | 14 | 20 | 36 | 36 |

| Design without TES | 16 | 24 | 43 | 51 | |

| System NPV (£) | Design with TES | −1348 | −2680 | −3860 | −3830 |

| Design without TES | −1716 | −2690 | −3580 | −3760 | |

| NTCO2 (kg/year) | Design with TES | 6233 | 5416 | 4967 | 4876 |

| Design without TES | 6379 | 5514 | 4984 | 4889 | |

| TDE (kWh/year) | Design with TES | 29,286 | 25,609 | 23,640 | 23,242 |

| Design without TES | 30,078 | 26,161 | 23,788 | 23,367 | |

| TES size | - | 26 | 34 | 34 | 32 |

| Detached | Semi-Detached | Terrace | Flat | ||

|---|---|---|---|---|---|

| EAI (£/year) | Design with TES | 751 | 414 | 125 | 91 |

| Design without TES | 610 | 296 | 51 | 4 | |

| System Payback (year) | Design with TES | 4.9 | 7.4 | 12.8 | 14.0 |

| Design without TES | 5.5 | 8.7 | 15.8 | 18.7 | |

| System NPV (£) | Design with TES | 5525 | 2019 | −928 | −1266 |

| Design without TES | 4186 | 933 | −1616 | −2103 | |

| NTCO2 (kg/year) | Design with TES | 6009 | 5407 | 4954 | 4864 |

| Design without TES | 5966 | 5308 | 4881 | 4802 | |

| TDE (kWh/year) | Design with TES | 28,169 | 25,551 | 23,579 | 23,191 |

| Design without TES | 28,025 | 25,138 | 23,275 | 22,933 | |

| TES size | - | 13 | 13 | 9 | 7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oluleye, G.; Allison, J.; Kelly, N.; Hawkes, A.D. An Optimisation Study on Integrating and Incentivising Thermal Energy Storage (TES) in a Dwelling Energy System. Energies 2018, 11, 1095. https://doi.org/10.3390/en11051095

Oluleye G, Allison J, Kelly N, Hawkes AD. An Optimisation Study on Integrating and Incentivising Thermal Energy Storage (TES) in a Dwelling Energy System. Energies. 2018; 11(5):1095. https://doi.org/10.3390/en11051095

Chicago/Turabian StyleOluleye, Gbemi, John Allison, Nicolas Kelly, and Adam D. Hawkes. 2018. "An Optimisation Study on Integrating and Incentivising Thermal Energy Storage (TES) in a Dwelling Energy System" Energies 11, no. 5: 1095. https://doi.org/10.3390/en11051095