Grid Integration and Power Smoothing of an Oscillating Water Column Wave Energy Converter

Abstract

:1. Introduction

2. Supercapacitor Energy Storage

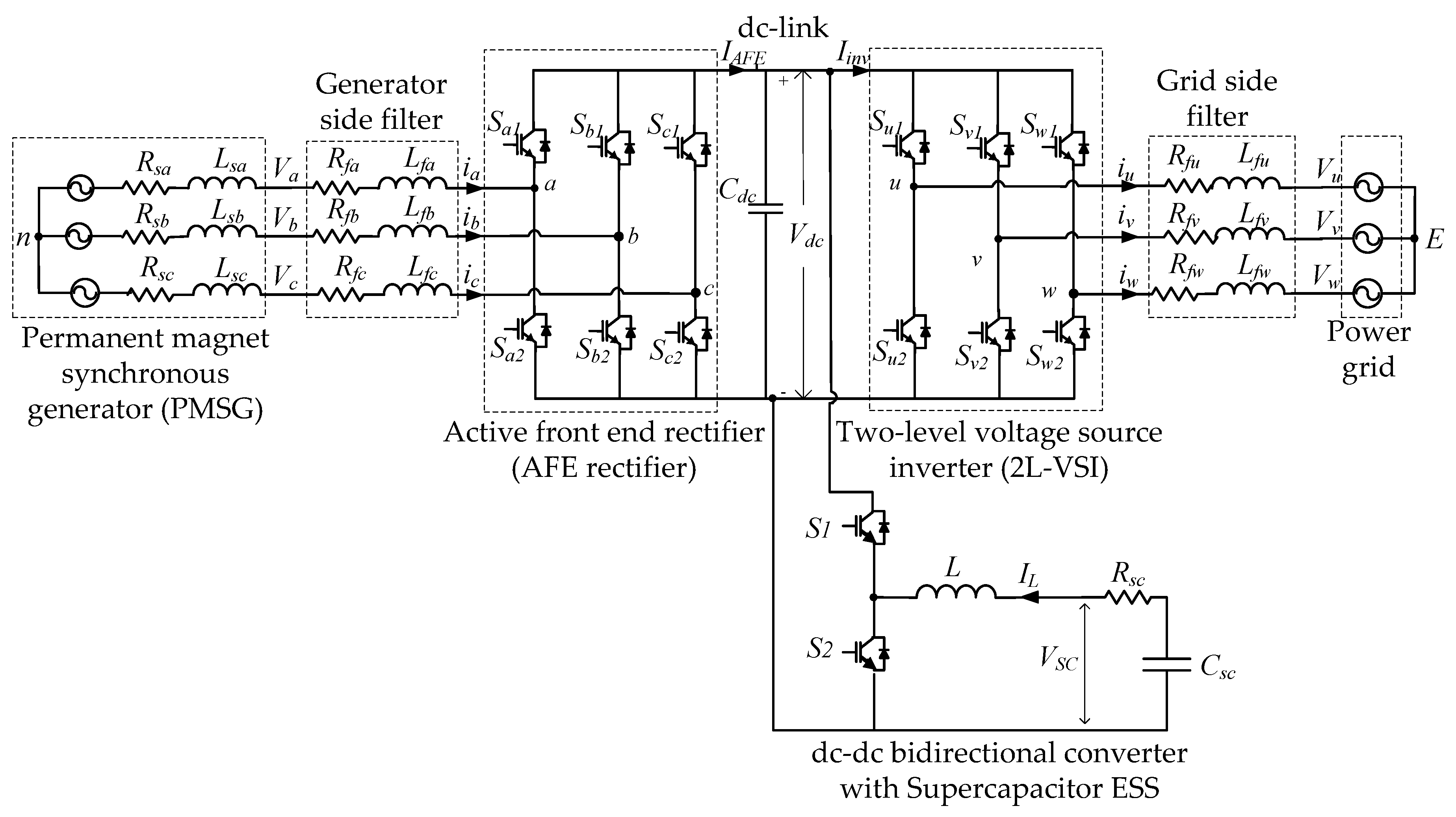

3. Model Predictive Control-Based Converter Control Strategies

3.1. Rectifier Controller

3.2. Inverter Controller

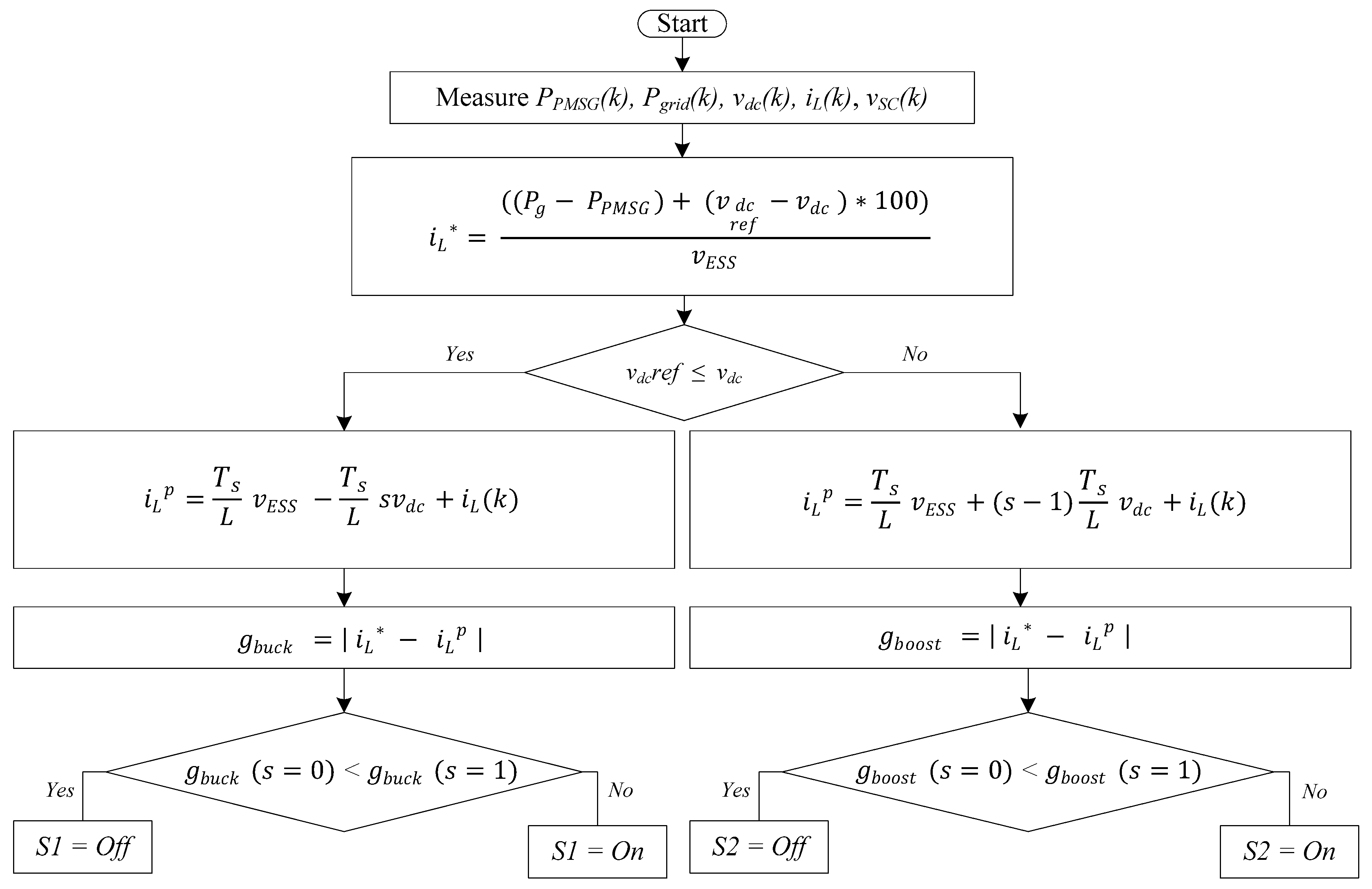

3.3. DC-DC Converter Controller

3.3.1. Space State Model of Bidirectional DC-DC Converter

3.3.2. Bidirectional DC-DC Converter in Discrete Time Domain

4. Power Management System

5. Simulation Results and Discussion

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. System Parameters Used in the Design

| PMSG | Rated Power | 2 MW |

| Rated rotate speed | 650 rpm | |

| Rated Voltage | 690 VAC | |

| Rated current | 1673.5 A | |

| Number of pole pairs | 4 | |

| Resistance (Rs) | 0.0024 Ω | |

| Inductances (Ld = Lq) | 0.3552 mH (line-phase) | |

| Magnetic flux | 0.666 Wb | |

| Inertia (J) | 2 kgm2 | |

| Grid side Filter | Inductance | 1.6 mH |

| Resistance | 0.01 Ω | |

| Rated charge/discharge currents | 1500 A | |

| Grid | Voltage | 690 Vrms |

| Frequency | 50 Hz | |

| Generator Side Filter | Inductance | 1 mH |

| Resistance | 0.01 Ω | |

| DC-link | Total power | 265 kW |

| DC-link voltage (Vdc) | 1200 V | |

| DC-link current (Idc_max) | 1000 A | |

| Supercapacitor | Capacitance (Csc) (83F; 21 in series; 4 parallel loop) | 15.8 F |

| Resistance (Rsc) | 52.5 mΩ | |

| Voltage Initial (Vinitial) (Csc_nominal: 48 V each) | 650 V | |

| Reference Values | Active Power | 265 kW |

| Reactive Power | 0 | |

| Other | Sample time (s) (Rec./Inv./bidirectional) | 10−4/10−4/7 × 10−5 |

| Simulator run time | 20 s |

Appendix A.2. FCS-MPC for Rectifier

Appendix A.3. FCS-MPC for Inverter

Appendix A.4. FCS-MPC for dc-dc Bidirectional Converter of Energy Storage

References

- Aderinto, T.; Li, H. Ocean Wave Energy Converters: Status and Challenges. Energies 2018, 11. [Google Scholar] [CrossRef]

- Hannon, M.; Griffiths, J.; Vantoch-Wood, A.; Carcas, M.; Bradley, S.; Boud, R.; Wyatt, S. World Energy Resources; Marine Energy 2016; World Energy Council; World Energy Resources: London, UK, 2016. [Google Scholar]

- Carson, L.; Bradshaw, M.; Jaques, L. Australian Energy Resource Assessment 2014, 2nd ed.; Commonwealth of Australia (Geoscience Australia): Canberra, Australia, 2014.

- Carson, L.; Bradshaw, M.; Jaques, L.; Che, N.; Ball, A. Australian Energy Resource Assessment 2010; Commonwealth of Australia (Geoscience Australia): Canberra, Australia, 2010.

- Hughes, M.G.; Heap, A.D. National-scale wave energy resource assessment for Australia. Renew. Energy 2009, 35, 1783–1791. [Google Scholar] [CrossRef]

- Wave Swell Energy. Sustainable Elecricity from the Ocean. Available online: http://waveswellenergy.com.au/ (accessed on 27 March 2017).

- Australian Maritime College. Successful Ocean Wave Energy Converter Testing Leads to Commercialisation. Available online: http://www.amc.edu.au/about-amc/news-and-events/news-items/successful-tidal-turbine-testing-leads-to-commercialisation/ (accessed on 11 May 2017).

- PerAero Turbine Design LLC. Turbine Design Report for Wave Swell Energy Ltd.; PerAero Turbine Design LLC: Bonita Springs, FL, USA, 2017. [Google Scholar]

- Hamidi, S.A.; Lonel, D.M.; Nasiri, A. Modeling and Management of Batteries and Ultracapacitor for Renewable Energy Support in Electric Power Systems—An Overview. Electr. Power Compon. Syst. 2017, 43, 1434–1452. [Google Scholar] [CrossRef]

- Rajapakse, G.; Jayasinghe, S.G.; Fleming, A.; Shahnia, F. Model Predictive Control-based Power take-off Control of an Oscillating Water Column Wave Energy Conversion System. In Proceedings of the 2017 International Conference on Substantial Energy Engineering (ICSEE 2017), Perth, Australia, 12–14 June 2017. [Google Scholar]

- Maercos, V.M.M.; Martinez, M.A.G.; Gonzalez, F.B.; Montero, M.I.M. A Grid Connected Photovoltic Inverter with Battery-Supercapacitor Hybrid Energy Storage. Sensors 2017, 17. [Google Scholar] [CrossRef]

- Murray, D.; Multon, A.J.B.; Ahmed, H.B. Electrical energy storage systems. In Electrical Design for Ocean Wave and Tidal Energy Systems; Alcorn, R., O’Sullivan, V., Eds.; The Institution of Engineering and Technology (IET): Herts, UK, 2013. [Google Scholar]

- Kim, J.; Suharto, Y.; Daim, T.U. Evaluation of Electrical Energy Storage (EES) technologies for renewable energy: A case from the US Pacific Northwest. J. Energy Storage 2017, 11, 25–54. [Google Scholar] [CrossRef]

- Murray, D.B.; Hayes, J.G.; Egan, M.G.; O’Sullivan, D.L. Supercapacitor Testing for Power Smoothing in a Variable Speed Offshore Wave Energy Converter. IEEE J. Ocean. Eng. 2011, 37, 301–308. [Google Scholar] [CrossRef]

- Rajapakse, G.; Jayasinghe, S.G.; Negnevitsky, M.; Fleming, A. A Model Predictive Control-Based Power Converter System for Oscillating Water Column Wave Energy Converters. Energies 2017, 10, 1631. [Google Scholar] [CrossRef]

- Hamidi, A.; Weber, L.; Nasiri, A. EV Chargeing Station Integrating Renewable Energy and Second Life Battery. In Proceedings of the International Conference on Renewable Energy Research and Application, Madrid, Spain, 20–23 October 2013. [Google Scholar]

- Wu, F.; Zhang, X.; Ju, P. Application of the battery energy storage in wave energy conversion system. In Proceedings of the International Conference on Sustainable Generation and supply (SUPERGEN’09), Nanjing, China, 6–7 April 2009. [Google Scholar]

- Rodriguez, J.; Kazmierkowski, M.P.; Espinoza, J.R.; Zanchetta, P.; Abu-Rub, H.; Young, H.A.; Rojas, C.A. State of the Art of Finite Control Set Model Predictive Control in Power Electronics. IEEE Trans. Ind. Inform. 2013, 9, 1003–1016. [Google Scholar] [CrossRef]

- Vazquez, S.; Leon, J.I.; Franquelo, L.G.; Rodriguez, J.; Young, H.A.; Marquez, A.; Zanchetta, P. Model Predictive Control: A Review of Its Applications in Power Electronics. IEEE Ind. Electron. Mag. 2014, 8, 16–31. [Google Scholar] [CrossRef] [Green Version]

- Pirooz, A.; Noroozian, R. Model Predictive Control of Classic Bidirectional DC-DC Converter for Battery Applications. In Proceedings of the 7th Power Electronics, Drive Systems & Technologies Conference (PEDSTC 2016), Iran University of Science and Technology, Tehran, Iran, 16–18 February 2016. [Google Scholar]

- Ceballos, S.; Rea, J.; Robles, E.; Lopez, I.; Pou, J.; O’Sullivan, D.L. Control strategies for combining local energy storage with wells turbine oscillating water column devices. Renew. Energy 2015, 83, 1097–1107. [Google Scholar] [CrossRef]

- Ceballos, S.; Rea, J.; Lopez, I.; Pou, J.; Robles, E.; O’Sullivan, D.L. Efficiency optimization in low inertia wells turbine oscillating water column devices. IEEE Trans. Energy Convers. 2013, 28, 553–564. [Google Scholar] [CrossRef]

- Li, W.; Joos, G.; Abbey, C. A parallel bidirectional DC/DC converter topology for energy storage systems in wind applications. In Proceedings of the Conference Record of the 2007 IEEE Industry Applications Conference, New Orleans, LA, USA, 2007; pp. 171–185. [Google Scholar]

- Zou, Y.; Cheng, K.W.E. A Vertical Flux-Switching Permanent Magnet Based Oscillating Wave Power Generator with Energy Storage. Energies 2017, 10, 887. [Google Scholar] [CrossRef]

- Maxwell Technologies. Maxwell_Supercapacitor_48v_DN 1009365 13; Maxwell Technologies: San Diego, CA, USA, 2017. [Google Scholar]

- Thounthong, P.; Sikkabut, S.; Mungporn, P.; Mobarakeh, N.; Pierfederici, S.; Davat, B. Nonlinear Control Algorithm of Supercapacitor/Li-Ion Battery Energy Storage Devices for Fuel Cell Vehicle Applications. In Proceedings of the Mecatronics-2014, Tokyo, Japan, 27–29 November 2014. [Google Scholar]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Zhi, L.; Peng, Z.; Zhifu, W.; Qiang, S.; Yinan, R. State of charge estimation for Li-ion battery based on extended Kalman filter. In Proceedings of the 8th International Conference on Applied Energy—ICAE2016, Beijing, China, 8–11 October 2016; pp. 3515–3520. [Google Scholar]

- Bernal, L.E.Z. Characterization of Double-Layer Capacitors for Power Electronics Applications. Master’s Thesis, Electrical and Computer Engineering, University of Toronto, Toronto, ON, Canada, 1997. [Google Scholar]

- Zubieta, L.; Bonert, R. Characterization of Double-Layer Capacitors for Power Electronics Applications. IEEE Trans. Ind. Appl. 2000, 36, 199–205. [Google Scholar] [CrossRef]

- Islam, M.S.; Hossain, M.B.; Hossain, M.N.; Alam, S.B.; Chowdhury, M.E.H. Modeling of a Double-Layer Capacitor with Individual Branch Response. In Proceedings of the World Congress on Engineering and Computer Science 2010, San Francisco, CA, USA, 20–22 October 2010. [Google Scholar]

- Bimbhra, P.S. Generalized Theory of Electrical Machines; Khanna Publishers: Delhi, India, 1992. [Google Scholar]

- Vilathgamuwa, M.; Nayanasiri, D.; Gamini, S.; Hudgins, J. Power Electronics for Photovoltaic Power Systems (Synthesis Lectures on Power Electroncs); Morgan & Claypool Publishers: San Rafael, CA, USA, 2015; ISBN 978-1-62705-775-2. [Google Scholar]

- Abdullah, M.A.; Yatim, A.H.M.; Tan, C.W.; Samosir, A.S. Control of a Bidirectional Converter to Interface Ultracapacitor with Renewable Energy Sources. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Cape Town, South Africa, 25–28 February 2013. [Google Scholar]

- Samosir, A.S.; Yatim, A.H.M. Implementation of Dynamic Evolution Control of Bidirectional DC–DC Converter for Interfacing Ultracapacitor Energy Storage to Fuel-Cell System. IEEE Trans. Ind. Electron. 2010, 57, 3468–3473. [Google Scholar] [CrossRef]

- Leuchter, J. Bi-Directional DC-DC Converters for Battery Buffers with Supercapacitor. In Energy Storage in the Emerging Era of Smart Grids; InTech: Rijeka, Croatia, 2011; p. 492. ISBN 978-953-307-269-2. [Google Scholar]

- Hart, D.W. Power Electronics; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Yaramasu, V.N.R. Predictive control of Multilevel Converters for MegaWatt Wind Energy Conversion Systems. Ph.D. Thesis, Electrical and Computer Engineering, Ryerson University, Toronto, ON, Canada, 2014. [Google Scholar]

- Brka, A.; Kothapalli, G.; Abdeli, Y.M. Predictive power management strategies for stand-alonehydrogen systems: Lab-scale validation. Int. J. Hydrog. Energy Publ. 2015, 40, 9907–9916. [Google Scholar] [CrossRef]

- Langella, R.; Testa, A. IEEE Recommended Practice and Requirements for Harmonic Control in Electric Power System; University of Campania “Luigi Vanvitelli”: Caserta, Italy, 2014. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajapakse, G.; Jayasinghe, S.; Fleming, A.; Negnevitsky, M. Grid Integration and Power Smoothing of an Oscillating Water Column Wave Energy Converter. Energies 2018, 11, 1871. https://doi.org/10.3390/en11071871

Rajapakse G, Jayasinghe S, Fleming A, Negnevitsky M. Grid Integration and Power Smoothing of an Oscillating Water Column Wave Energy Converter. Energies. 2018; 11(7):1871. https://doi.org/10.3390/en11071871

Chicago/Turabian StyleRajapakse, Gimara, Shantha Jayasinghe, Alan Fleming, and Michael Negnevitsky. 2018. "Grid Integration and Power Smoothing of an Oscillating Water Column Wave Energy Converter" Energies 11, no. 7: 1871. https://doi.org/10.3390/en11071871