Inhibition of Rejuvenation Liquid on Trees in XLPE Cables under Switching Impulse Voltages

Abstract

:1. Introduction

- (1)

- Comparing electrical tree initiation and water trees growth between two groups of cable samples after the cable-accelerated aging experiment.

- (2)

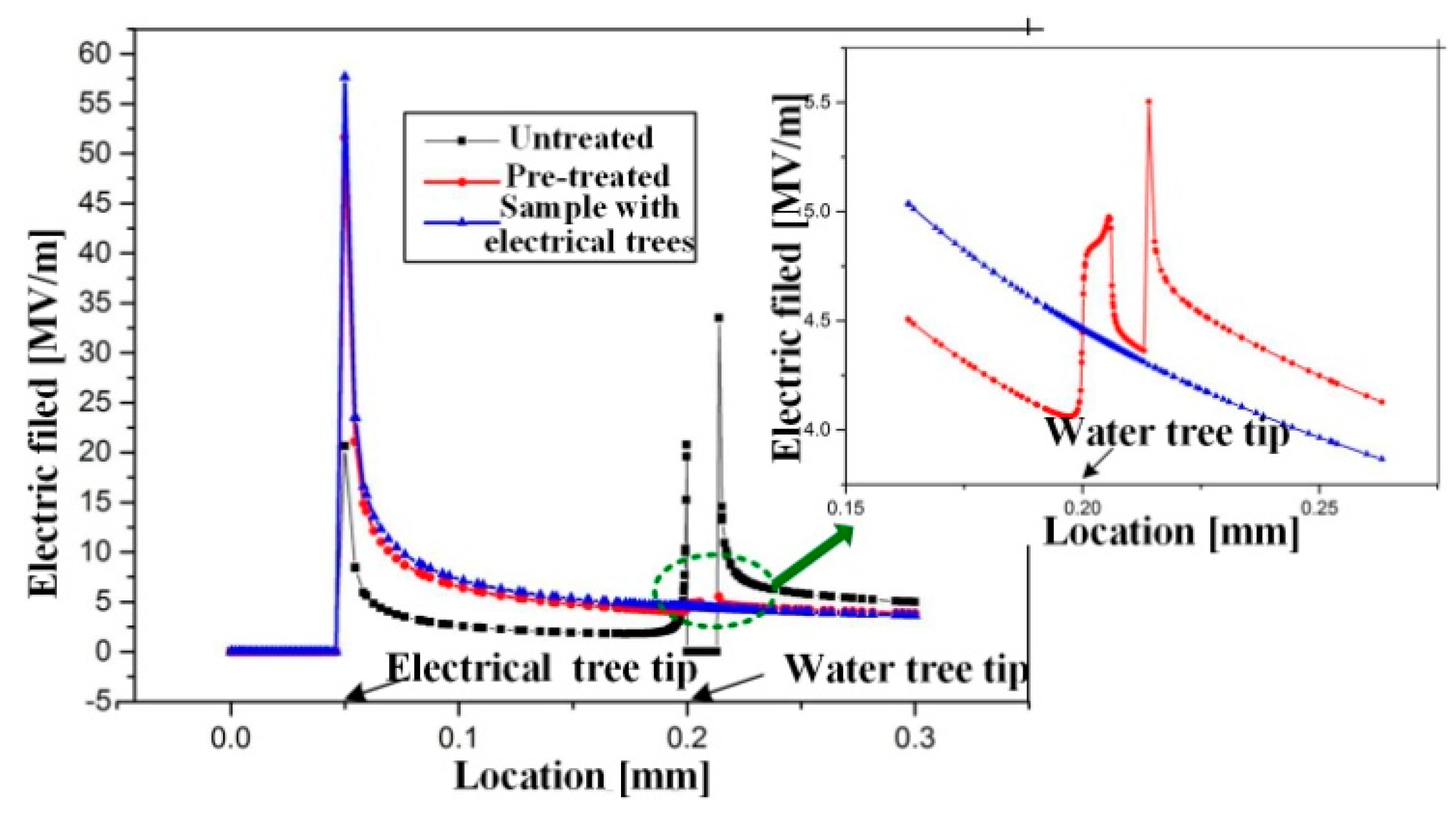

- Constructing a cable model that includes a water tree body by means of COMSOL software. Before simulation, the dielectrophoretic force of rejuvenation liquid particles is analyzed and considered by the model parameters. The electrical tree initiation mechanism is described by referring to the simulated electric field distribution of the cable.

- (3)

- Understanding the inhibition mechanism of water tree growth by analyzing the Maxwell stress of XLPE molecular chains. The local electric field at a water tree tip is referenced.

2. Experimental Steup

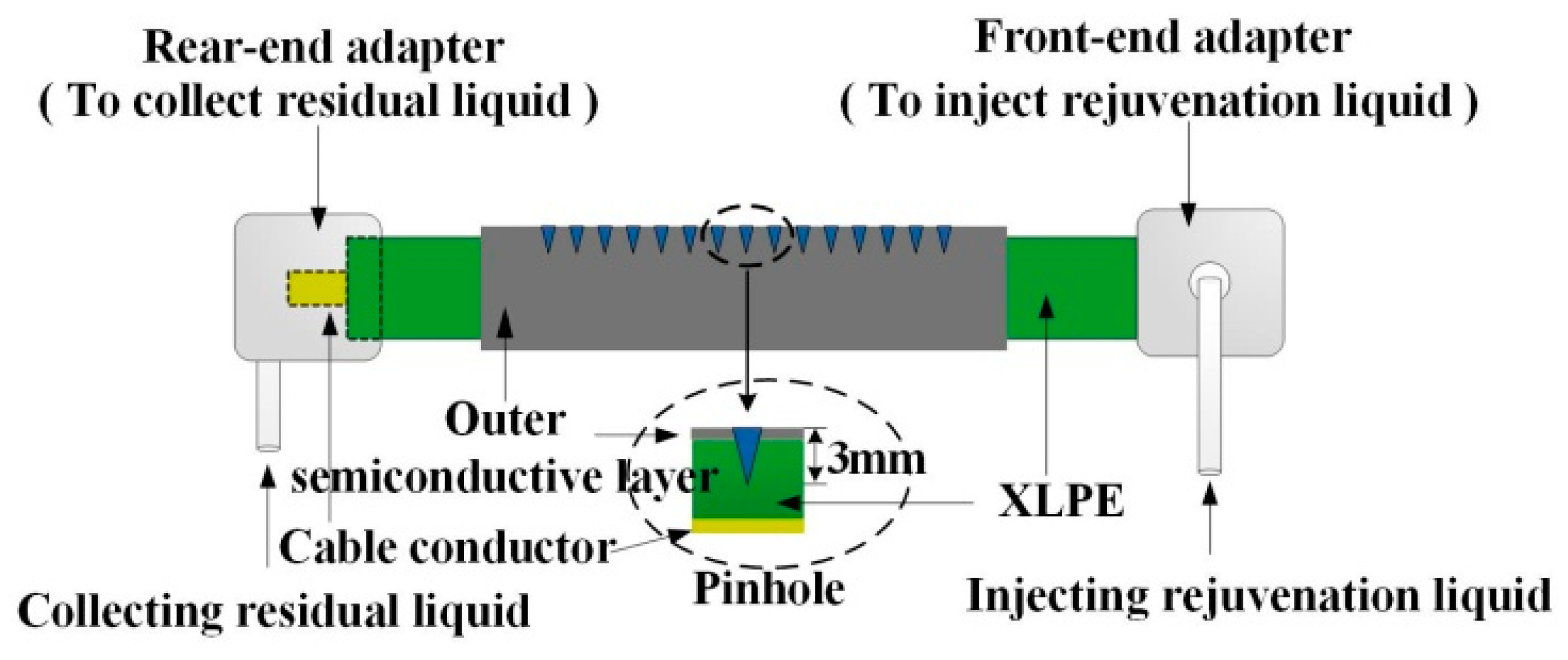

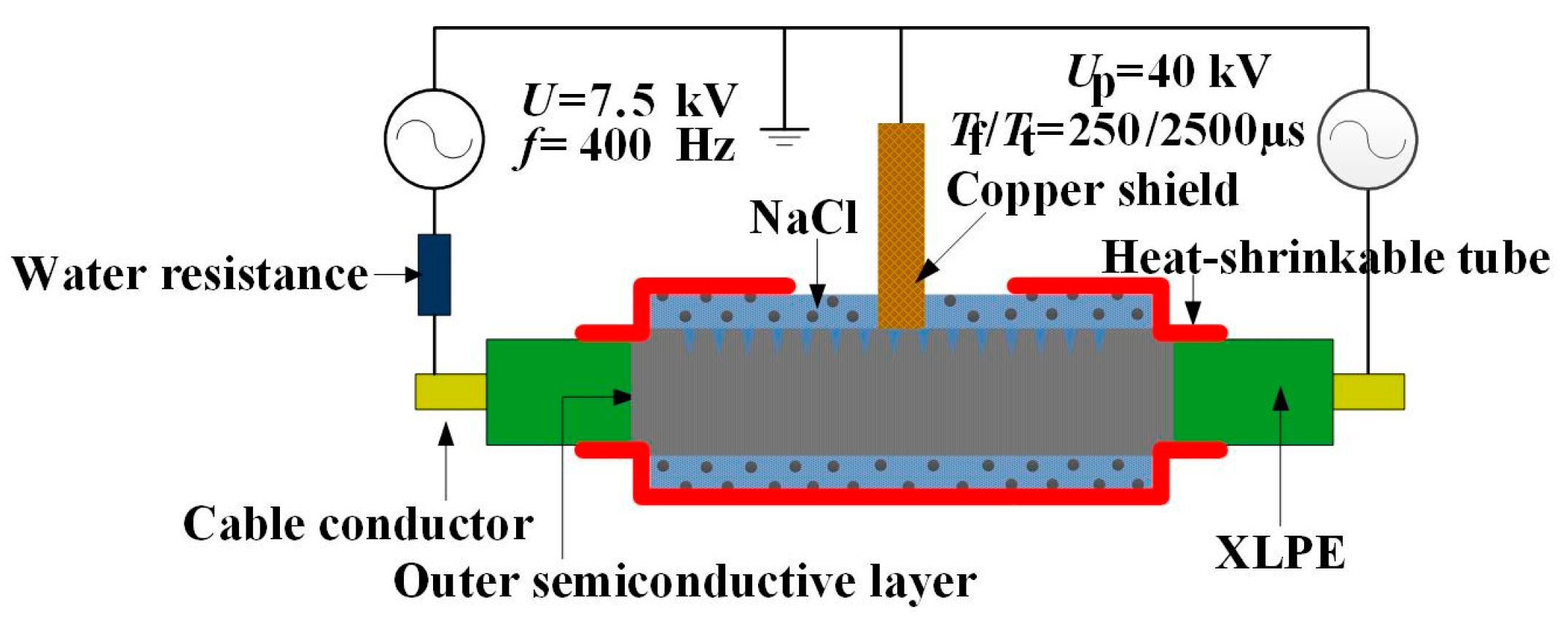

2.1. Sample Preparation

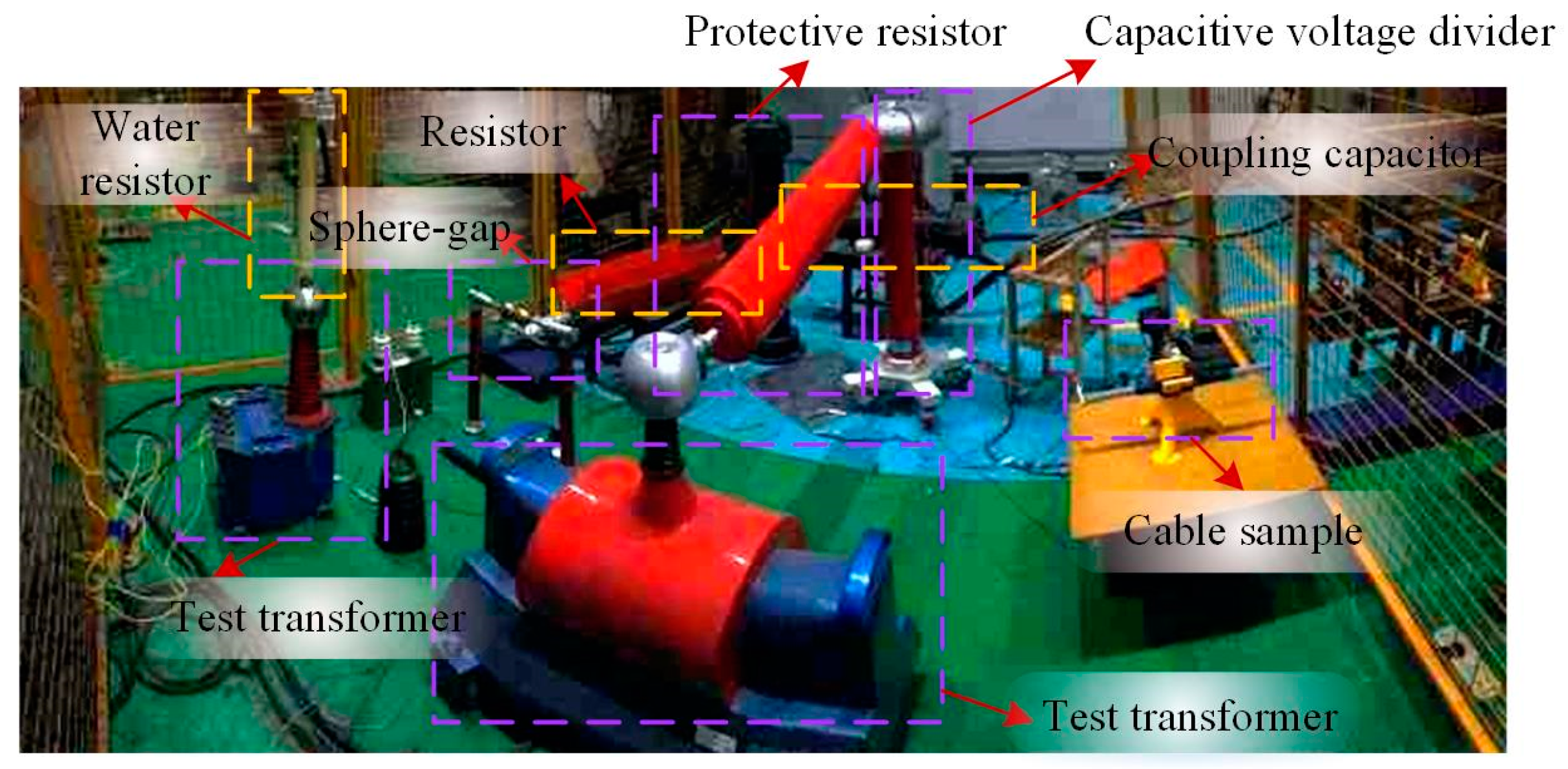

2.2. Experimental Setup

3. Results and Discussion

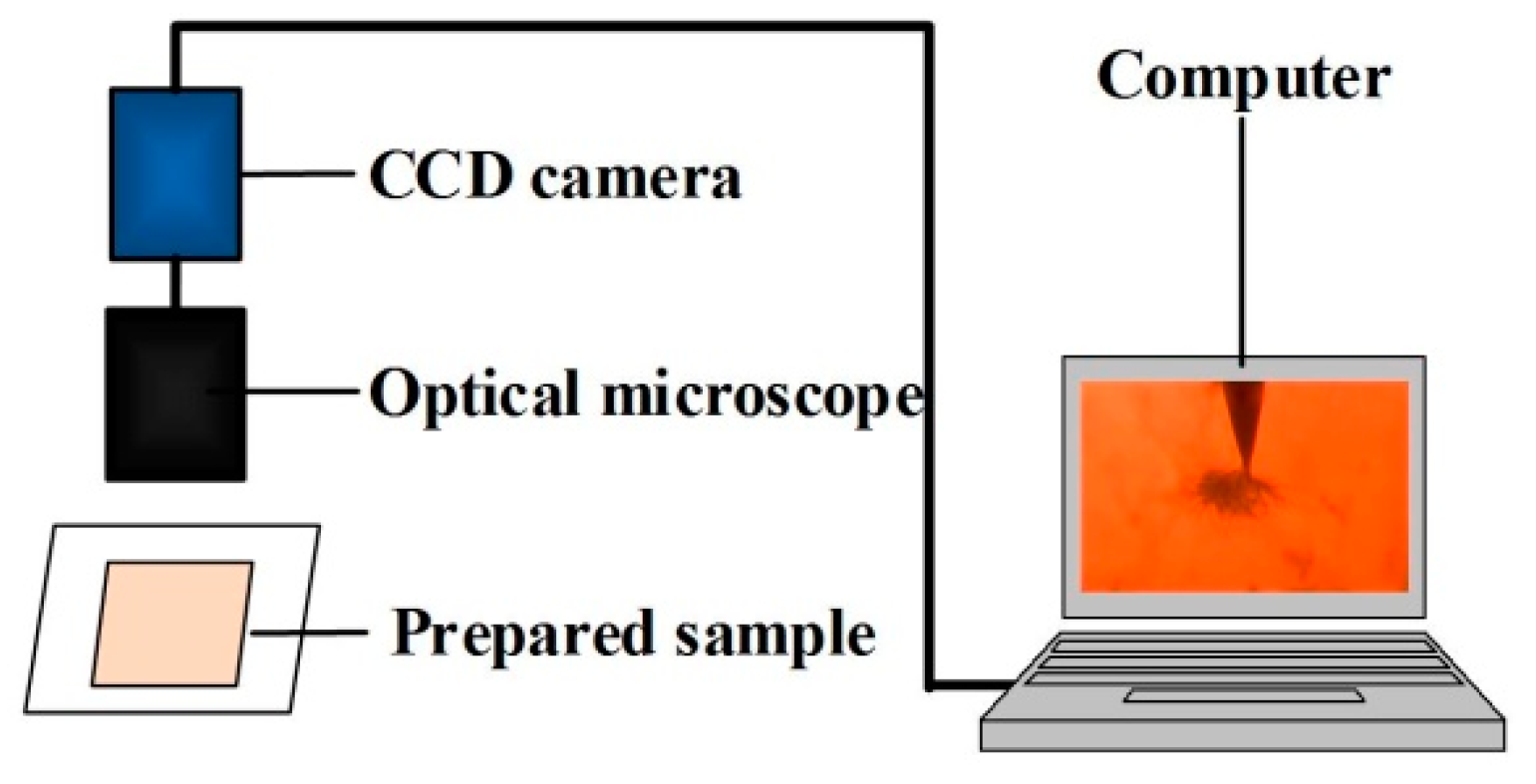

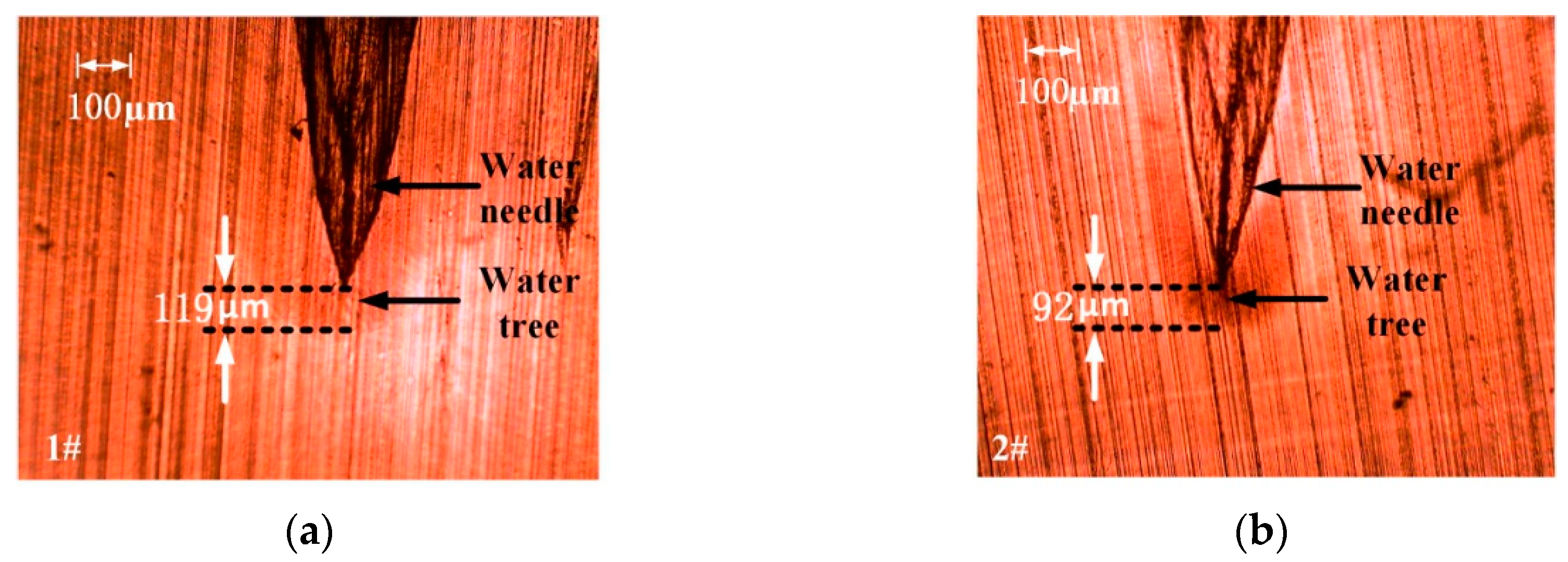

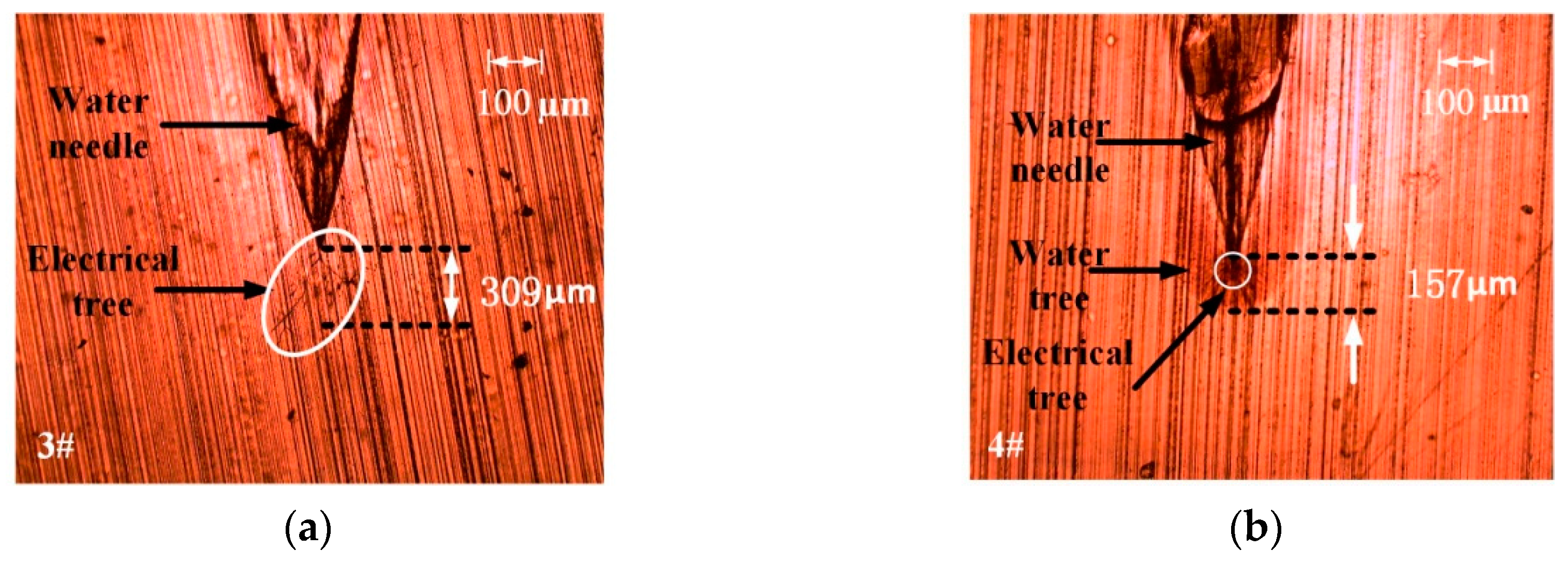

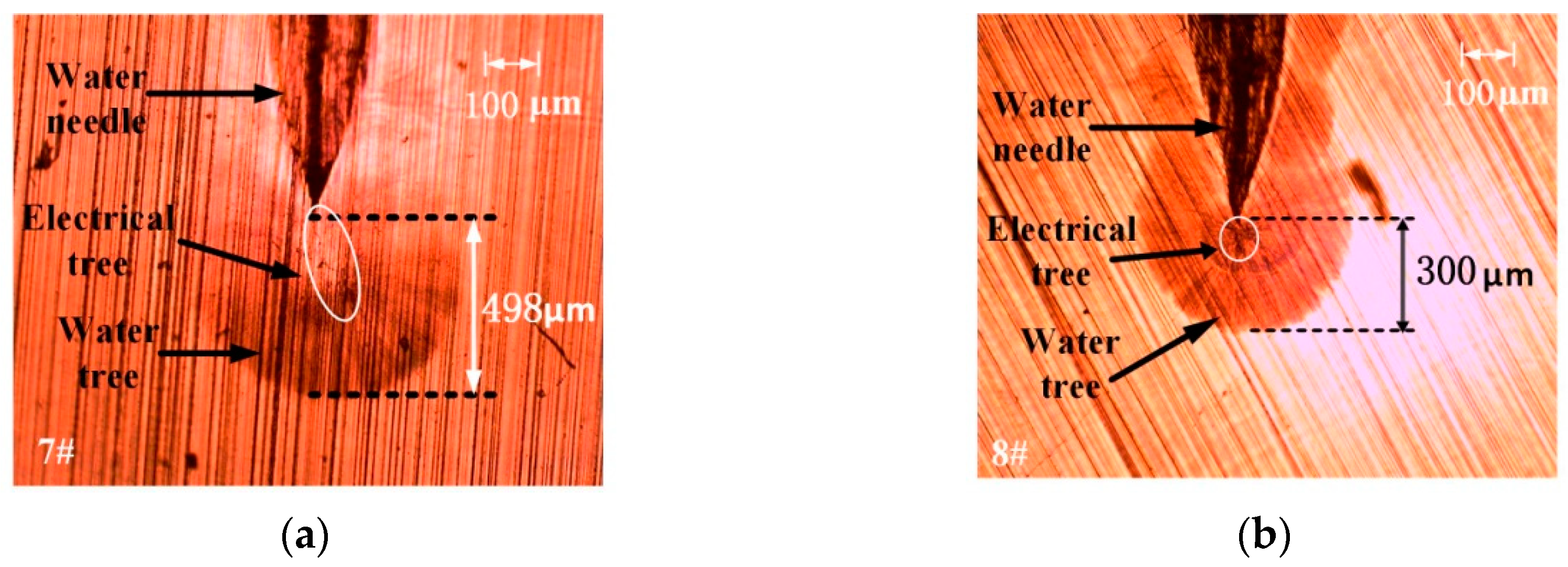

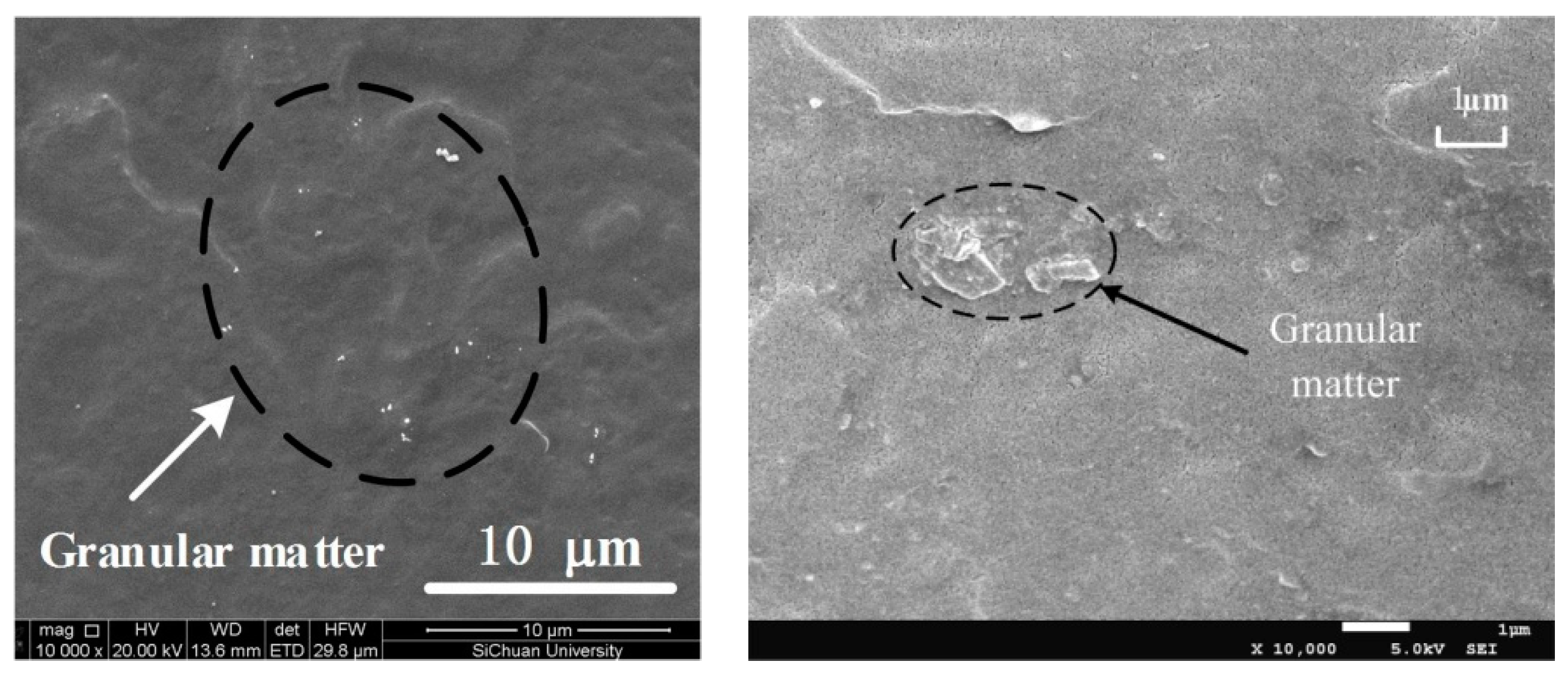

3.1. Microstructure Analysis

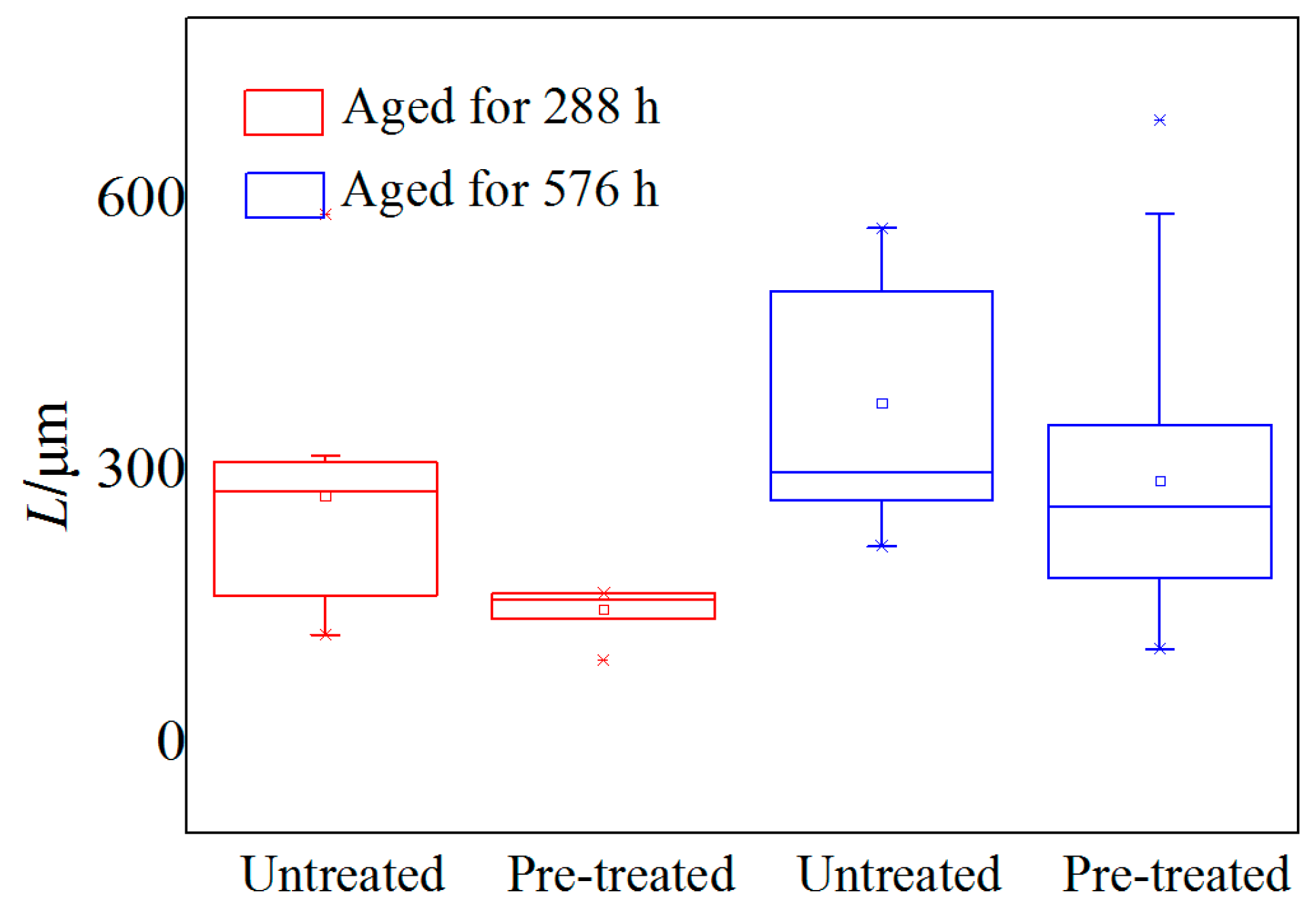

3.2. Initiation Rate of Electrical Trees and Average Tree Length

3.3. SEM and EDS Analysis

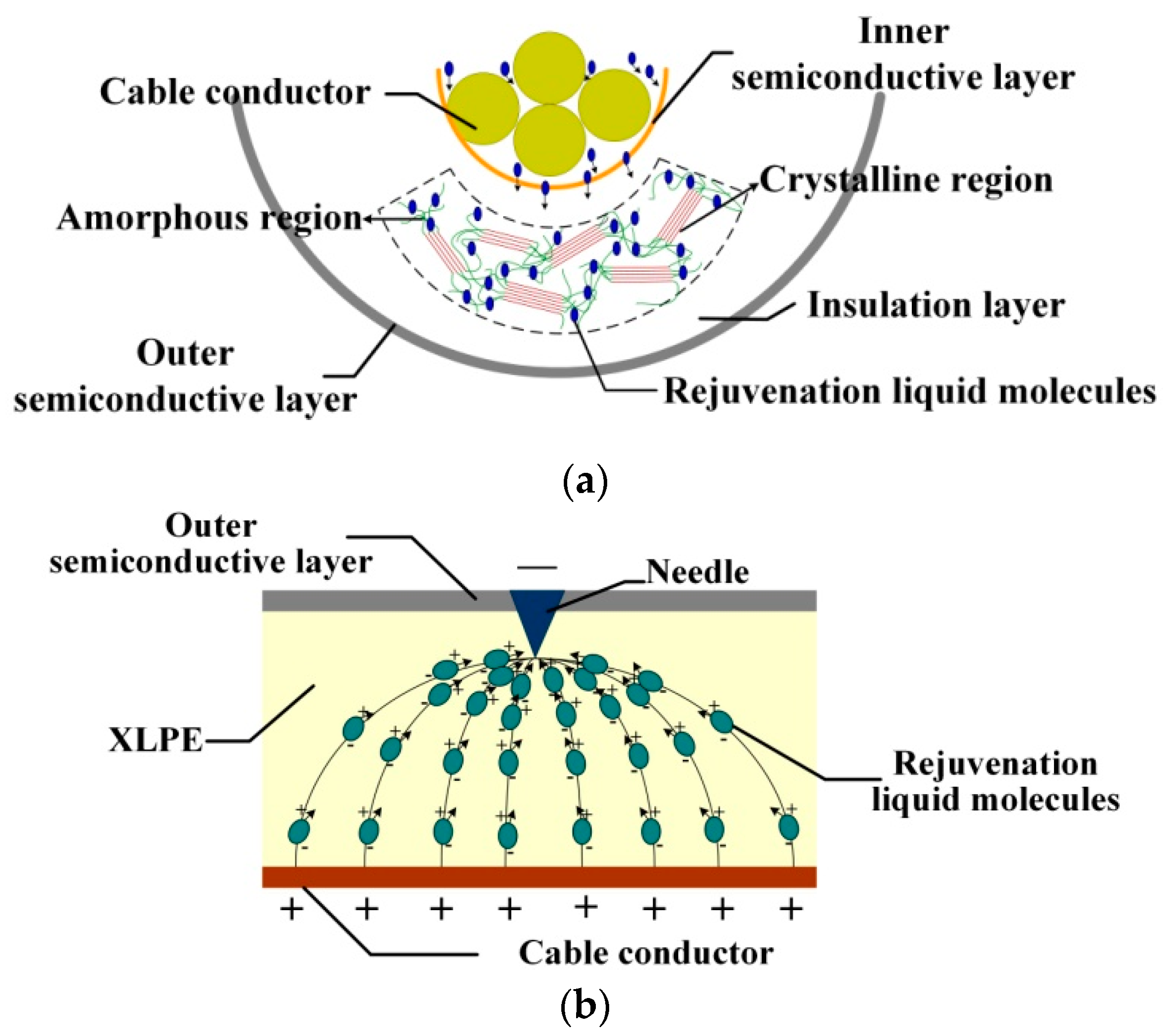

3.4. Electrical Tree and Water Tree Modeling

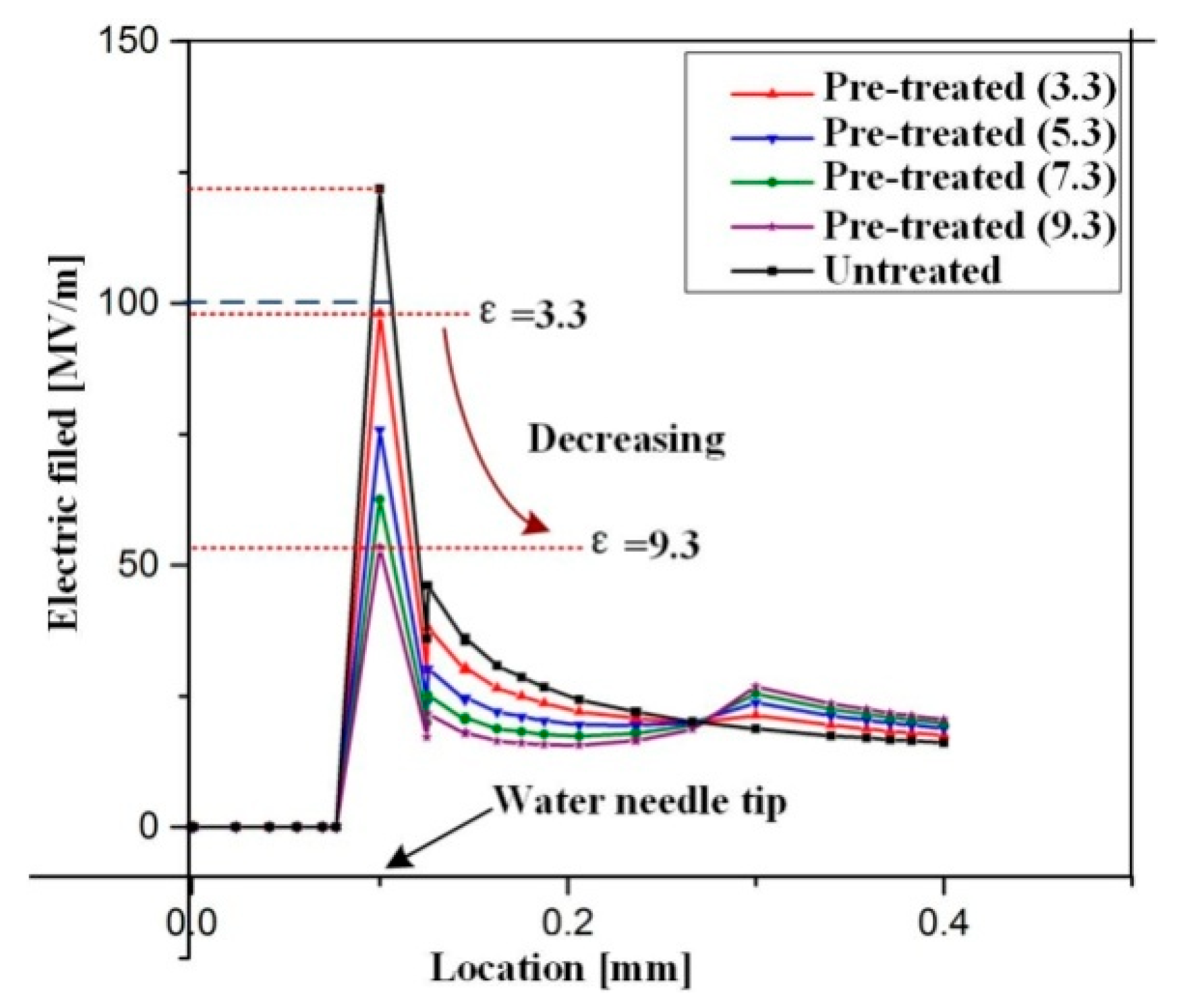

3.5. Analysis of Electrical Tree Initiation

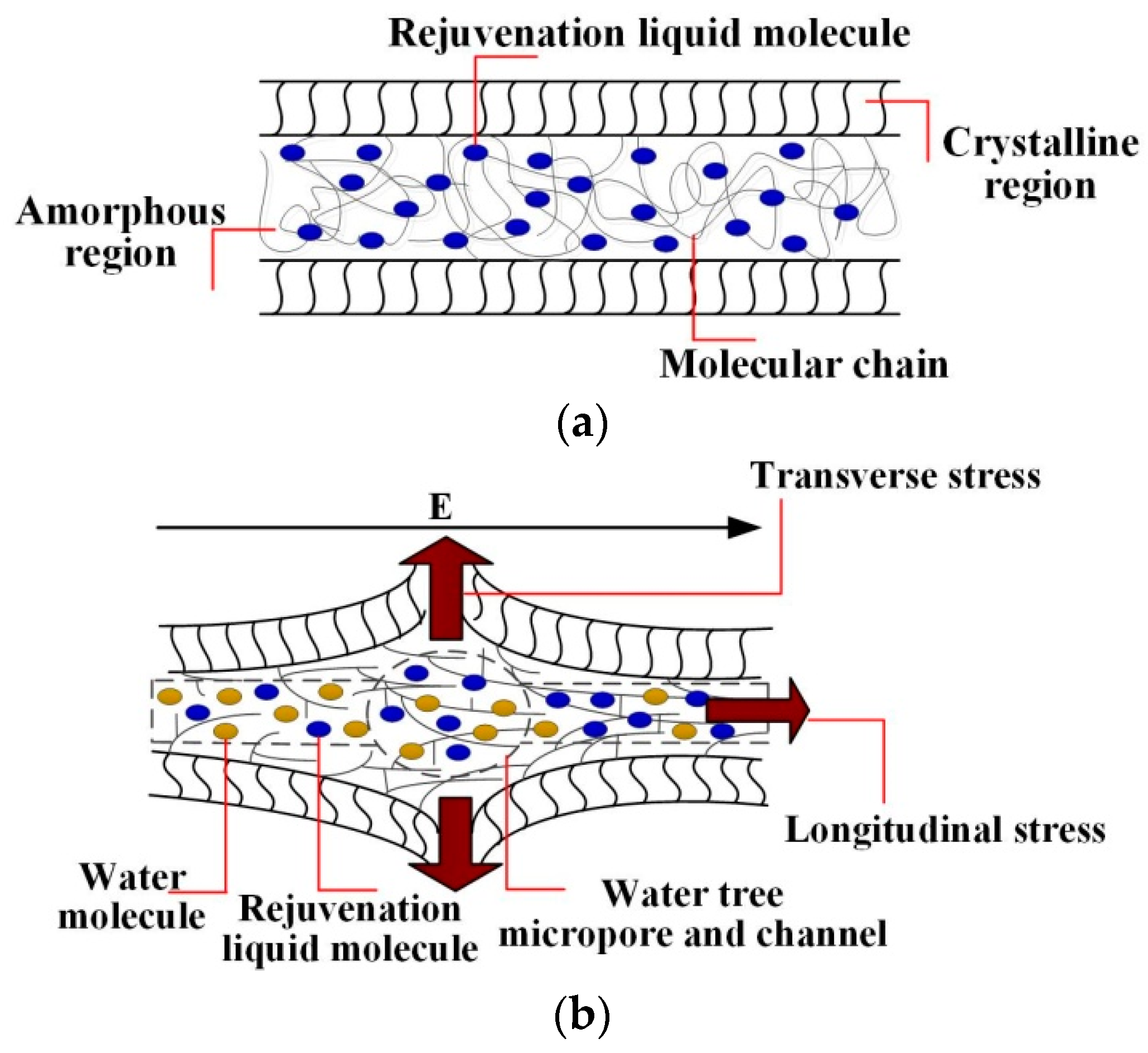

3.6. Analysis of Water Tree Growth

4. Conclusions

- (1)

- The preinjected rejuvenation liquid has an inhibitory effect on electrical tree initiation and water tree propagation. This inhibitory effect is related to the concentration of the residual rejuvenation liquid. The inhibitory effect weakens as the amount of rejuvenation liquid is reduced.

- (2)

- In the pretreated cable sample, the dielectrophoretic force of the rejuvenation liquid molecules drives them to centralize around the needle tip. In addition, the relative dielectric constant of the insulation layer increases. The electric field distortion around the needle tip in the pretreated cable is weakened, and the electric field at the water tree tip is lower than that in the untreated cable. The preinjected rejuvenation liquid strongly contributes to reducing tree growth in cables.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Eichhorn, R.M. Treeing in solid extruded electrical insulation. IEEE Trans. Dielectr. Electr. Insul. 1977, 1, 2–18. [Google Scholar] [CrossRef]

- Ross, R. Inception and propagation mechanisms of water treeing. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 660–680. [Google Scholar] [CrossRef]

- Ross, R. Effect of ageing conditions on the type of water treeing (power cables). IEEE Electr. Insul. Mag. 1993, 9, 7–13. [Google Scholar] [CrossRef]

- Ross, R.; Smit, J.J. Composition and growth of water trees in XLPE. IEEE Trans. Dielectr. Electr. Insul. 1992, 27, 519–531. [Google Scholar] [CrossRef]

- Zeller, H.R. Thermodynamics of Water Treeing. IEEE Trans. Dielectr. Electr. Insul. 1987, 22, 677–681. [Google Scholar] [CrossRef]

- Zeller, H.R. Breakdown and Prebreakdown Phenomena in Solid Dielectrics. IEEE Trans. Dielectr. Electr. Insul. 1987, 22, 115–122. [Google Scholar] [CrossRef]

- Opydo, W.; Dobrzycki, A. Detection of electric tree of solid dielectrics with the method of acoustic emission. Electr. Eng. 2012, 94, 37–48. [Google Scholar] [CrossRef]

- Dobrzycki, A.; Mikulski, S.; Opydo, W. Using ANN and SVM for the Detection of Acoustic Emission Signals. Accompanying Epoxy Resin Electrical Treeing. Appl. Sci. 2019, 9, 1523. [Google Scholar] [CrossRef]

- Schurch, R.; Rowland, S.M.; Bradley, R.S.; Withers, P.J. Imaging and analysis techniques for electrical trees using X-ray computed tomography. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 53–63. [Google Scholar] [CrossRef]

- Pelissou, S.; Lessard, G. Underground medium-voltage cable rejuvenation—Part I: Laboratory Tests on Cables. IEEE Trans. Power Deliv. 2011, 26, 2324–2332. [Google Scholar] [CrossRef]

- Meyer, D.F.; Vincent, G.A. Restoring Stranded Conductor Electrical Distribution Cable. U.S. Patent 4,766,011A, 23 August 1988. [Google Scholar]

- Pelissou, S.; Antoine, S.S. Underground medium-voltage cable rejuvenation—Part II: Pilot projects in the field. IEEE Trans. Power Deliv. 2011, 26, 2605–2612. [Google Scholar] [CrossRef]

- Moreau, E.; Mayoux, C.; Laurent, C.; Boudet, A. The structure characteristics of water trees in power cables and laboratory specimens. IEEE Trans. Dielectr. Electr. Insul. 1993, 28, 54–64. [Google Scholar] [CrossRef]

- Shimizu, N.; Laurent, C. Electrical tree initiation. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 651–659. [Google Scholar] [CrossRef]

- William, R.S. Cable Injection Technology. Proceedings of 2006 IEEE/PES Transmission & Distribution Conference and Exposition: Latin America, Caracas, Venezuela, 15–18 August 2006. [Google Scholar]

- Shu, W.; Boggs, S.A. Effect of cable restoration fluid on inhibiting water tree initial. IEEE Trans. Power Deliv. 2011, 26, 97–100. [Google Scholar] [CrossRef]

- Dissado, L.A. Understanding electrical trees in solids: From experiment to theory. In Proceedings of the 2001 IEEE 7th International Conference on Solid Dielectrics, Eindhoven, The Netherlands, 25–29 June 2001. [Google Scholar]

- Bahder, G.; Garrity, T.; Sosnowski, M.; Eaton, R.; Katz, C. Physical model of electric aging and breakdown of extruded polymeric insulated power cables. IEEE Trans. Power Appar. Syst. 1982, 101, 1378–1388. [Google Scholar] [CrossRef]

- Zhou, K.; Tao, X.; Wang, X.; Zhao, W.; Tao, W. Insight into the new role of titanium isopropoxide catalyst on reju-venation for water tree aged cables. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 611–618. [Google Scholar] [CrossRef]

- Elayyan, H.S.B.; Abderrazzaq, M.H. Electric Field Computation in Wet Cable Insulation Using Finite Element Approach. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 1125–1133. [Google Scholar] [CrossRef]

- Boggs, S.; Densley, J.; Kuang, J. Mechanism for Impulse Conversion of Water Trees to Electrical trees in XLPE. IEEE Trans. Power Deliv. 1998, 13, 310–315. [Google Scholar] [CrossRef]

- Radu, I.; Acedo, M.; Filippini, J.C.; Notingher, P.; Ftutos, F. The effect of water treeing on the electric field distribution of XLPE. IEEE Trans. Dielectr. Electr. Insul. 2000, 7, 860–868. [Google Scholar] [CrossRef]

- Thomas, J.; Saha, T.K. A New Dielectric Response Model for Water Tree Degraded XLPE Insulation—Part A: Model Development with Small Sample Verification. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1131–1143. [Google Scholar] [CrossRef]

- Zhou, K.; Tao, X.; Zhao, W. A cable rejuvenation method based on formation of nano-TiO2 inside water tree and its insulation enhancement mechanism. Proc. CSEE 2013, 33, 202–210. [Google Scholar]

- Peschke, E.; von Olshausen, R. Cable systems for high and extra-high voltage development, manufacture, testing, installation and operation of cables and their accessories. IEEE Electr. Insul. Mag. 2001, 175, 60. [Google Scholar]

- Wang, Z.; Marcolongo, P.; Lemberg, J.A.; Panganiban, B.; Evans, J.W.; Ritchie, R.O.; Wright, P.K. Mechanical fatigue as a mechanism of water tree growth in TR-XLPE. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 321–330. [Google Scholar] [CrossRef]

- Zhou, K.; Li, K.; He, Y.; Zhu, G. A new insight into the influence of mechanical orientation on water tree propagation in abnormal water tree shapes. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3878–3886. [Google Scholar] [CrossRef]

| Statistical Parameters | At First Stage (Aged for 288 h) | At Last Stage (Aged for 576 h) | ||

|---|---|---|---|---|

| Untreated | Pretreated | Untreated | Pretreated | |

| P (%) | m0 = 14, m = 8 | m0 = 7, m = 1 | m0 = 25, m = 5 | m0 = 15, m = 4 |

| 57.1 | 14.3 | 20 | 26.67 | |

| The root mean squared error (RMSE) of P (%) | 57.1 ± 13.2 | 14.3 ± 13.2 | 20 ± 8 | 26.67 ± 11.4 |

| L (μm) | 272 | 144 | 375 | 288 |

| Part | Parameters | |

|---|---|---|

| εr | γ (S/m) | |

| XLPE | 2.3 | 1 × 10−17 |

| Water tree body | 10 | 1 × 10−10 |

| NaCl solution | 8.5 × 107 | 2.0 |

| Polysiloxane | 2.8 | 1 × 10−11 |

| Semiconductive layer | 20 | 1 × 10−4 |

| Electrical tree | 80 | 2.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, G.; Zhou, K.; Gong, W.; He, M.; Kong, J.; Li, K. Inhibition of Rejuvenation Liquid on Trees in XLPE Cables under Switching Impulse Voltages. Energies 2019, 12, 2133. https://doi.org/10.3390/en12112133

Zhu G, Zhou K, Gong W, He M, Kong J, Li K. Inhibition of Rejuvenation Liquid on Trees in XLPE Cables under Switching Impulse Voltages. Energies. 2019; 12(11):2133. https://doi.org/10.3390/en12112133

Chicago/Turabian StyleZhu, Guangya, Kai Zhou, Wei Gong, Min He, Jiaming Kong, and Kangle Li. 2019. "Inhibition of Rejuvenation Liquid on Trees in XLPE Cables under Switching Impulse Voltages" Energies 12, no. 11: 2133. https://doi.org/10.3390/en12112133