Ultrasound-Assisted Extraction as a First Step in a Biorefinery Strategy for Valorisation of Extracted Olive Pomace

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material

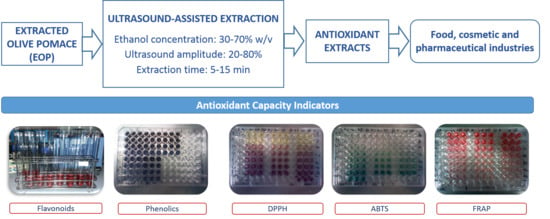

2.2. Ultrasound-Assisted Extraction (UAE) and Experimental Design

2.3. Antioxidant Capacity Indicators for EOP

3. Results and Discussion

3.1. Influence of the Factors on the UAE of EOP and Model Equations

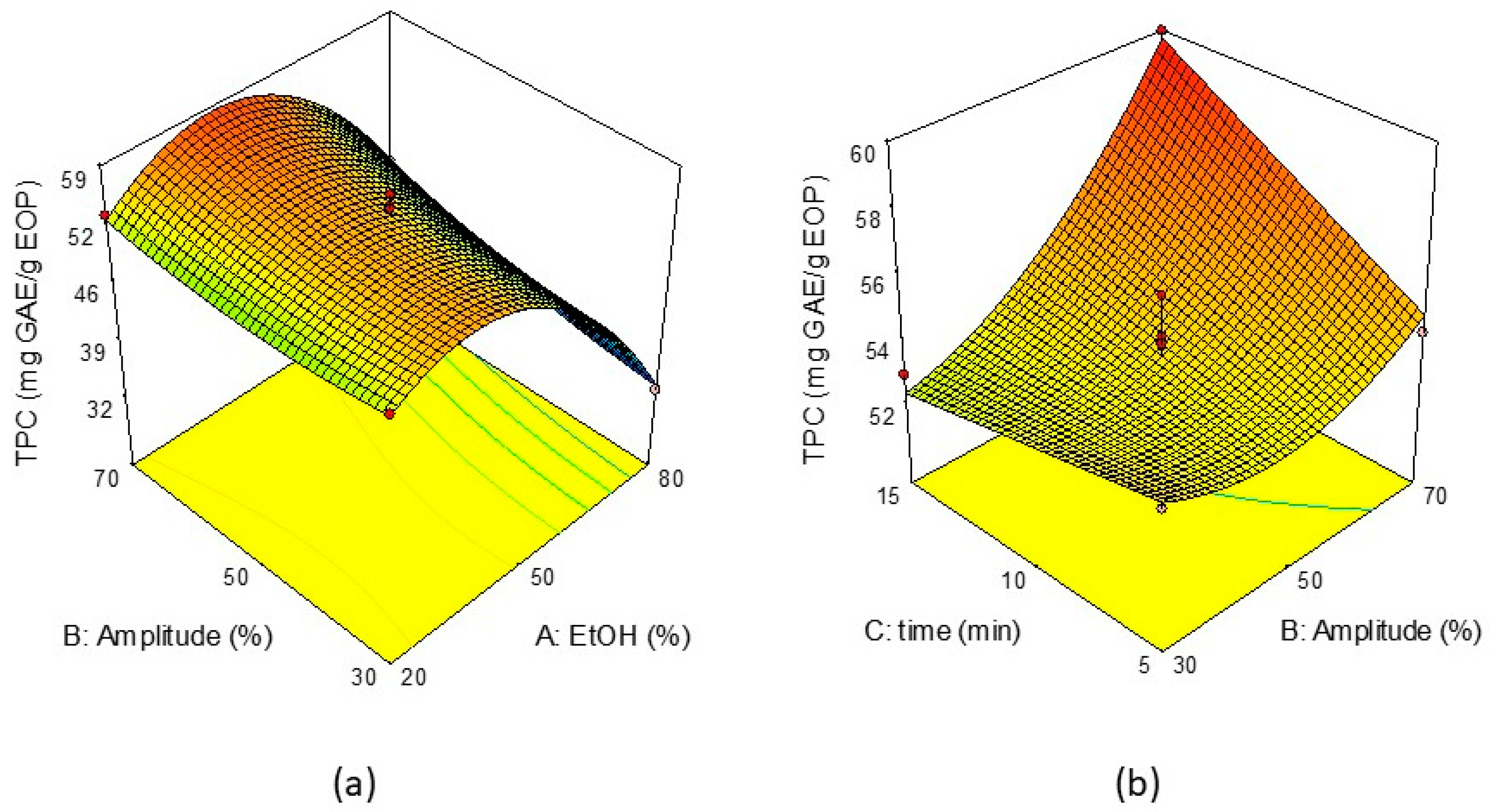

3.1.1. Total Phenolic Compounds (TPC)

3.1.2. Total Flavonoid Compounds (TFC)

3.1.3. Antioxidant Activity

3.2. Process Optimisation and Validation of the Model

3.3. Olive Pomace and Extracted Olive Pomace as Sources of Antioxidants

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Medina-Torres, N.; Ayora-Talavera, T.; Espinosa-Andrews, H.; Sánchez-Contreras, A.; Pacheco, N. Ultrasound assisted extraction for the recovery of phenolic compounds from vegetable sources. Agronomy 2017, 7, 47. [Google Scholar] [CrossRef]

- Gullón, B.; Gullón, P.; Lú-Chau, T.A.; Moreira, M.T.; Lema, J.M.; Eibes, G. Optimization of solvent extraction of antioxidants from Eucalyptus globulus leaves by response surface methodology: Characterization and assessment of their bioactive properties. Ind. Crops Prod. 2017, 108, 649–659. [Google Scholar] [CrossRef]

- Gullón, B.; Eibes, G.; Moreira, M.T.; Herrera, R.; Labidi, J.; Gullón, P. Yerba mate waste: A sustainable resource of antioxidant compounds. Ind. Crop. Prod. 2018, 113, 398–405. [Google Scholar] [CrossRef]

- Romero-García, J.M.; Niño, L.; Martínez-Patiño, C.; Álvarez, C.; Castro, E.; Negro, M.J. Biorefinery based on olive biomass. State of the art and future trends. Bioresour. Technol. 2014, 159, 421–432. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations. FAOSTAT. 2019. Available online: http://faostat3.fao.org/ (accessed on 3 May 2019).

- Manzanares, P.; Ruiz, E.; Ballesteros, M.; Negro, M.J.; Gallego, F.J.; López-Linares, J.C.; Castro, E. Residual biomass potential in olive tree cultivation and olive oil industry in Spain: Valorization proposal in a biorefinery context. Span. J. Agric. Res. 2017, 15, 6. [Google Scholar] [CrossRef]

- Ruiz, E.; Romero-García, J.M.; Romero, I.; Manzanares, P.; Negro, M.J.; Castro, E. Olive-derived biomass as a source of energy and chemicals. Biofuel Bioprod. Biorefining 2017, 11, 1077–1094. [Google Scholar] [CrossRef]

- Berbel, J.; Posadillo, A. Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 2018, 10, 237. [Google Scholar] [CrossRef]

- Pérez-Bonilla, M.; Salido, S.; Van Beek, T.A.; Waard, P.D.; Linares-Palomino, P.J.; Sánchez, A.; Altarejos, J. Isolation of antioxidative secoiridoids from olive wood (Olea europaea L.) guided by on-line HPLC-DAD-radical scavenging detection. Food Chem. 2011, 124, 36–41. [Google Scholar] [CrossRef]

- Gullón, B.; Gullón, P.; Eibes, G.; Cara, C.; De Torres, A.; López-Linares, J.C.; Ruiz, E.; Castro, E. Valorisation of olive agro-industrial by-products as a source of bioactive compounds. Sci. Total Environ. 2018, 645, 533–542. [Google Scholar] [CrossRef]

- Hayta, M.; Isçimen, E.M. Optimization of ultrasound-assisted antioxidant compounds extraction from germinated chickpea using response surface methodology. LWT Food Sci. Technol. 2017, 77, 208–216. [Google Scholar] [CrossRef]

- Khemakhem, I.; Ahmad-Qasem, M.H.; Catalán, E.B.; Micol, V.; García-Pérez, J.V.; Ayadi, M.A.; Bouaziz, M. Kinetic improvement of olive leaves bioactive compounds extraction by using power ultrasound in a wide temperature range. Ultrason. Sonochem. 2017, 34, 466–473. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, H.; Bolourian, S.; Yaghoubi Hamgini, E.; Ghanuni Mahababadi, E. Optimization of heat- and ultrasound-assisted extraction of polyphenols from dried rosemary leaves using response surface methodology. J. Food Process. Preserv. 2018, 42, e13778. [Google Scholar] [CrossRef]

- Tiwari, B.K. Ultrasound: A clean, green extraction technology. TrAC Trends Anal. Chem. 2015, 71, 100–109. [Google Scholar] [CrossRef]

- Bamba, B.S.B.; Shi, J.; Tranchant, C.C.; Xue, S.J.; Forney, C.F.; Lim, L.T. Influence of extraction conditions on ultrasound-assisted recovery of bioactive phenolics from blueberry pomace and their antioxidant activity. Molecules 2018, 23, 1685. [Google Scholar] [CrossRef] [PubMed]

- Singleton, V.L.; Rossi, S.A. Colorimetric of total phenolics with phosphomolibic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Martínez-Patiño, J.C.; Gullón, B.; Romero, I.; Ruiz, E.; Brncic, M.; Žlabur, J.Š.; Castro, E. Optimization of ultrasound-assisted extraction of biomass from olive trees using response surface methodology. Ultrason. Sonochem. 2019, 51, 487–495. [Google Scholar] [CrossRef]

- Kim, D.O.; Jeong, S.W.; Lee, C.Y. Antioxidant capacity of phenolic phytochemicals from various cultivars of plums. Food Chem. 2003, 81, 321–326. [Google Scholar] [CrossRef]

- Goldsmith, C.D.; Vuong, Q.V.; Stathopoulos, C.E.; Roach, P.D.; Scarlett, C.J. Ultrasound increases the aqueous extraction of phenolic compounds with high antioxidant activity from olive pomace. LWT Food Sci. Technol. 2018, 89, 284–290. [Google Scholar] [CrossRef] [Green Version]

- Zardo, I.; de Espíndola Sobczyk, A.; Marczak, L.D.F.; Sarkis, J. Optimization of Ultrasound Assisted Extraction of Phenolic Compounds from Sunflower Seed Cake Using Response Surface Methodology. Waste Biomass Valoris. 2019, 10, 33–44. [Google Scholar] [CrossRef]

- Papoutsis, K.; Pristijono, P.; Golding, J.B.; Stathopoulos, C.E.; Bowyer, M.C.; Scarlett, C.J.; Vuong, Q.V. Optimizing a sustainable ultrasound-assisted extraction method for the recovery of polyphenols from lemon by-products: Comparison with hot water and organic solvent extractions. Eur. Food Res. Technol. 2018, 244, 1353–1365. [Google Scholar] [CrossRef]

- Caballero, A.S.; Romero-García, J.M.; Castro, E.; Cardona, C.A. Supercritical fluid extraction for enhancing polyphenolic compounds production from olive waste extracts. J. Chem. Technol. Biotechnol. 2019. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/jctb.5907/ (accessed on 3 May 2019). [CrossRef]

- Chanioti, S.; Tzia, C. Extraction of phenolic compounds from olive pomace by using natural deep eutectic solvents and innovative extraction techniques. Innov. Food Sci. Emerg. Technol. 2018, 48, 228–239. [Google Scholar] [CrossRef]

- Albahari, P.; Jug, M.; Radic, K.; Jurmanovic, S.; Brncic, M.; Brncic, S.R.; Vitali Cepo, D. Characterization of olive pomace extract obtained by cyclodextrin-enhanced pulsed ultrasound assisted extraction. LWT Food Sci. Technol. 2018, 92, 22–31. [Google Scholar] [CrossRef]

- Xie, P.; Huang, L.; Zhang, C.; Deng, Y.; Wang, X.; Cheng, J. Enhanced extraction of hydroxytyrosol, maslinic acid and oleanolic acid from olive pomace: Process parameters, kinetics and thermodynamics, and greenness assessment. Food Chem. 2019, 276, 662–674. [Google Scholar] [CrossRef] [PubMed]

- Antónia Nunes, M.; Pawlowski, S.; Costa, A.S.G.; Alves, R.C.; Oliveira, M.B.P.P.; Velizarov, S. Valorization of olive pomace by a green integrated approach applying sustainable extraction and membrane-assisted concentration. Sci. Total Environ. 2019, 652, 40–47. [Google Scholar] [CrossRef] [PubMed]

- Alu’datt, M.H.; Alli, I.; Ereifej, K.; Alhamad, M.; Al-Tawaha, A.R.; Rababah, T. Optimisation, characterisation and quantification of phenolic compounds in olive cake. Food Chem. 2010, 123, 117–122. [Google Scholar] [CrossRef]

- Seçmeler, Ö.; Güçlü Üstündag, Ö.; Fernández-Bolaños, J.; Rodríguez-Gutiérrez, G. Effect of subcritical water and steam explosion pretreatments on the recovery of sterols, phenols and oil from olive pomace. Food Chem. 2018, 265, 298–307. [Google Scholar] [CrossRef] [Green Version]

- Moudache, M.; Colon, M.; Nerín, C.; Zaidi, F. Phenolic content and antioxidant activity of olive by-products and antioxidant film containing olive leaf extract. Food Chem. 2016, 212, 521–527. [Google Scholar] [CrossRef] [PubMed]

- Rubio-Senent, F.; Fernández-Bolaños, J.; García-Borrego, A.; Lama-Muñoz, A.; Rodríguez-Gutiérrez, G. Influence of pH on the antioxidant phenols solubilised from hydrothermally treated olive oil by-product (alperujo). Food Chem. 2017, 219, 339–345. [Google Scholar] [CrossRef]

- Uribe, E.; Pasten, A.; Lemus-Mondaca, R.; Vega-Gálvez, A.; Quispe-Fuentes, I.; Ortiz, J.; Di Scala, K. Comparison of Chemical Composition, Bioactive Compounds and Antioxidant Activity of Three Olive-Waste Cakes. J. Food Biochem. 2015, 39, 189–198. [Google Scholar] [CrossRef]

| Independent Variable | Nomenclature | Units | Value | ||

|---|---|---|---|---|---|

| (−1) | 0 | (+1) | |||

| Ethanol concentration | EtOH | %v/v | 20 | 50 | 80 |

| Amplitude | Amp | % | 30 | 50 | 70 |

| Extraction time | t | min | 5 | 10 | 15 |

| Exp. | EtOH (%v/v) | Amp (%) | Time (min) | T (°C) | TPC (mg GAE/g EOP) | TFC (mg RE/g EOP) | DPPH (mg TE/g EOP) | ABTS (mg TE/g EOP) | FRAP (mg TE/g EOP) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 50 | 50 | 10 | 59 | 55.8 | 119.7 | 53.6 | 126.0 | 58.9 |

| 2 | 20 | 30 | 10 | 47 | 53.0 | 113.9 | 50.7 | 121.6 | 56.9 |

| 3 | 50 | 70 | 15 | 76 | 60.4 | 125.6 | 59.9 | 140.5 | 64.4 |

| 4 | 50 | 50 | 10 | 58 | 54.5 | 118.2 | 56.6 | 128.0 | 61.0 |

| 5 | 20 | 50 | 5 | 44 | 51.1 | 105.2 | 51.8 | 103.6 | 51.6 |

| 6 | 50 | 50 | 10 | 58 | 54.2 | 117.4 | 55.8 | 124.3 | 58.3 |

| 7 | 50 | 30 | 5 | 41 | 54.1 | 113.2 | 52.3 | 116.7 | 51.8 |

| 8 | 50 | 30 | 15 | 57 | 53.3 | 116.0 | 58.3 | 128.2 | 57.5 |

| 9 | 50 | 70 | 5 | 54 | 54.7 | 114.5 | 59.3 | 122.9 | 57.7 |

| 10 | 50 | 50 | 10 | 59 | 54.3 | 119.4 | 56.1 | 125.2 | 57.5 |

| 11 | 80 | 50 | 15 | 64 | 37.3 | 91.2 | 45.3 | 84.8 | 43.2 |

| 12 | 80 | 70 | 10 | 69 | 41.3 | 88.0 | 44.0 | 90.4 | 44.2 |

| 13 | 80 | 50 | 5 | 44 | 35.7 | 81.1 | 40.5 | 72.1 | 36.6 |

| 14 | 80 | 30 | 10 | 44 | 32.8 | 83.1 | 40.8 | 74.6 | 36.1 |

| 15 | 50 | 50 | 10 | 59 | 52.5 | 118.4 | 56.1 | 128.3 | 58.8 |

| 16 | 20 | 70 | 10 | 74 | 53.5 | 110.0 | 52.7 | 119.3 | 55.6 |

| 17 | 20 | 50 | 15 | 64 | 51.3 | 113.2 | 52.1 | 116.9 | 52.8 |

| Coefficient | TPC | TFC | DPPH | ABTS | FRAP |

|---|---|---|---|---|---|

| F-value | 147.14 | 166.67 | 76.85 | 192.12 | 60.44 |

| p-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| R2 | 0.9913 | 0.9901 | 0.9835 | 0.9934 | 0.9734 |

| Adj R2 | 0.9843 | 0.9842 | 0.9707 | 0.9882 | 0.9571 |

| C.V | 1.98 | 1.61 | 2.00 | 1.96 | 3.24 |

| Lack of fit (p-value) | 0.8047 | 0.0706 | 0.6751 | 0.2425 | 0.2274 |

| Values | TPC (mg GAE/g EOP) | TFC (mg RE/g EOP) | DPPH (mg TE/g EOP) | ABTS (mg TE/g EOP) | FRAP (mg TE/g EOP) |

|---|---|---|---|---|---|

| Predicted value | 60.9 | 126.9 | 59.3 | 139.4 | 63.0 |

| Experimental value | 57.5 ± 0.3 | 139.6 ± 2.3 | 56.7 ± 1.5 | 139.1 ± 4.7 | 64.9 ± 0.6 |

| Error | 5.9% | 9.1% | 4.6% | 0.2% | 2.9% |

| Residue Ratio | TPC | TFC | DPPH | ABTS | FRAP |

|---|---|---|---|---|---|

| EOP/OTP | 1.85 | 1.88 | 1.79 | 2.09 | 1.78 |

| EOP/OML | 1.37 | 1.45 | 1.33 | 1.45 | 1.31 |

| Material | Method | Conditions | Characterization of the Extracts | Ref. |

|---|---|---|---|---|

| Olive pomace | Ultrasound assisted extraction | Water, 30 °C, 75 min | TPC: 19.7 mg GAE/g DPPH: 31.2 mg TE/g; CUPRAC: 73.5 mg TE/g | [19] |

| Orujillo (exhausted pomace) | Supercritical fluid extraction | Ethanol (60%), pressure 200, 250 and 300 bar | TPC: 14.0 mg GAE/g DPPH: 85.3 µg TE/mL | [22] |

| Olive pomace | Homogenate (HAE), microwave (MAE), ultrasound (UAE) and high hydrostatic pressure (HHPAE) assisted extraction | Natural deep eutectic solvents: | [23] | |

| HAE (60 °C, 30 min, 12,000 rpm) | TPC: 34 mg GAE/g; 28 g d.w/g DPPH | |||

| MAE (60 °C, 30 min, 200 W) | TPC: 29.6 mg GAE/g; 36.7 g d.w./g DPPH | |||

| UAE (60 °C, 30 min, 280 W, 60 kHz) | TPC: 20.1 mg GAE/g; 40.6 g d.w./g DPPH | |||

| HHPAE (10 min, 600 MPa) | TPC: 26 mg GAE/g; 45.7 g d.w./g DPPH | |||

| Olive pomace | Conventional solvent extraction (CSE) | CSE (Water-EtOH) | TPC: 16.9 mg GAE/g; DPPH: 0.81 g TE/L | [24] |

| Ultrasound-assisted extraction (UAE) | UAE (70 °C, 120 min) | TPC: 14.7 mg GAE/g; DPPH: 1.76 g TE/L | ||

| Cyclodextrin-enhanced pulsed UAE | Cyclodextrin-enhanced pulsed UAE | TPC: 69.6 mg GAE/g DPPH: 52.2 mg TE/kg | ||

| Olive pomace | Ultrasound-assisted extraction (UAE) | UAE (90% EtOH; 50 °C; 5 min, S/L: 30 g/mL, 135.6 W/cm, 60 kHz) | 55.1 mg HT/g; 381.2 mg MA/g; 29.8 mg OA/g | [25] |

| Olive pomace | Extraction via membrane processing | Selected membranes (NF90, NF270, BW30) | TPC: 1234.3 mg GAE/L extract TFC: 464.2 mg EE/L extract DPPH: 405.9 µg TE/L extract FRAP: 9183.3 µmol FSE/L extract | [26] |

| Olive cake | Conventional extraction | Methanol, 70 °C, 12 h, 3 cycles | TPC: 4.37 mg GAE/g DPPH: 72% inhibition | [27] |

| Olive pomace | Hydrothermal pretreatments (steam explosion (SE) and subcritical water (SCW)) | 200 °C, 5 min | SE TPC: 73.3 mg GAE/g SCW TPC: 69.7 mg GAE/g | [28] |

| Olive cake | Extraction by magnetic stirring | Ethanol and acetone (70%), 2 h | TPC: 63.7 mg GAE/g extract DPPH: 95.4% inhibition ORAC: 0.82 mg TE/g | [29] |

| Alperujo | Hydrothermal treatment | Ethyl acetate, 160 °C, 60 min (pH = 4.5) | TPC: 64.2 g GAE/100 g DPPH: 12 mg TE/mL FRAP: 1.8 mg TE/mL | [30] |

| Olive-waste cake | Soxhlet extraction | n-hexane; 60 min | TPC: 35 mg GAE/g; TFC: 13.3 mg CTE/g DPPH: 67.2 µmol TE/g FRAP: 176.7 µmol TE/g | [31] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Patiño, J.C.; Gómez-Cruz, I.; Romero, I.; Gullón, B.; Ruiz, E.; Brnčić, M.; Castro, E. Ultrasound-Assisted Extraction as a First Step in a Biorefinery Strategy for Valorisation of Extracted Olive Pomace. Energies 2019, 12, 2679. https://doi.org/10.3390/en12142679

Martínez-Patiño JC, Gómez-Cruz I, Romero I, Gullón B, Ruiz E, Brnčić M, Castro E. Ultrasound-Assisted Extraction as a First Step in a Biorefinery Strategy for Valorisation of Extracted Olive Pomace. Energies. 2019; 12(14):2679. https://doi.org/10.3390/en12142679

Chicago/Turabian StyleMartínez-Patiño, José Carlos, Irene Gómez-Cruz, Inmaculada Romero, Beatriz Gullón, Encarnación Ruiz, Mladen Brnčić, and Eulogio Castro. 2019. "Ultrasound-Assisted Extraction as a First Step in a Biorefinery Strategy for Valorisation of Extracted Olive Pomace" Energies 12, no. 14: 2679. https://doi.org/10.3390/en12142679