Simultaneous Inertia Contribution and Optimal Grid Utilization with Wind Turbines

Abstract

1. Introduction

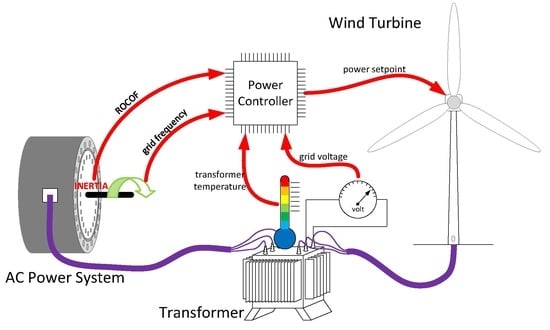

2. Case Study

3. WT Simulation Model

3.1. Power Controller

3.2. Continuous Feed-In Management Control

3.3. Continuous Inertial Response Control

3.4. Combined Control Circuit

4. Frequency Domain Analysis

4.1. Transfer Function of WT

4.2. Transfer Function of Transformer

4.3. Transfer Function of Pdem Controller

4.4. Comparison of Frequency Responses

5. Simulations and Discussion of Results

5.1. Effect of Generator–Converter Time Constant on Continuous FIM

5.2. Effect of Variable H Controller on the WT

5.3. Effect of Continuous FIM and Inertia Provision on the Grid

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bundesnetzagentur, Pressemitteilung: Bundesnetzagentur Veröffentlicht Zahlen zu Redispatch und Einspeisemanagement für 2017. 2018. Available online: https://www.bundesnetzagentur.de/SharedDocs/Downloads/DE/Allgemeines/Presse/Pressemitteilungen/2018/20180618_NetzSystemSicherheit.pdf?__blob=publicationFile&v=2 (accessed on 1 May 2019).

- Ministerium für Energiewende, Landwirtschaft, Umwelt, Natur und Digitalisierung (MELUND) Schleswig-Holstein, Kurzbericht zum Engpassmanagement in Schleswig-Holstein. 2018. Available online: https://www.schleswig-holstein.de/DE/Fachinhalte/E/erneuerbareenergien/Bericht_Einspeisemanagement.pdf;jsessionid=CAD6BCDD96E9F0CFFB6472B2DA2B6E5F?__blob=publicationFile&v=1 (accessed on 1 May 2019).

- Larscheid, P.; Maercks, M.; Dierkes, S.; Moser, A.; Patzack, S.; Vennegeerts, H.; Rolink, J.; Wieben, E. Increasing the Hosting Capacity of RES in Distribution Grids by Active Power Control. In Proceedings of the International ETG Congress, Bonn, Germany, 17–18 November 2015; Available online: https://ieeexplore.ieee.org/stamp/stamp.jsp?tp=&arnumber=7388485&tag=1 (accessed on 1 May 2019).

- Jauch, C. FH Flensburg erforscht dynamische Leistungsbereitstellung durch WEA. Ingenieurspiegel 2013, 4, 20–21. [Google Scholar]

- Jauch, C.; Gloe, A.; Hippel, S.; Thiesen, H. Increased Wind Energy Yield and Grid Utilisation with Continuous Feed-In Management. Energies 2017, 10, 870. [Google Scholar] [CrossRef]

- Jauch, C.; Gloe, A. Improved feed-in management with wind turbines. In Proceedings of the 15th Wind Integration Workshop, Vienna, Austria, 15–17 November 2016; Available online: https://www.researchgate.net/publication/311485049_Improved_Feed-in_Management_with_Wind_Turbines (accessed on 31 May 2019).

- Eriksson, R.; Modig, N.; Elkington, K. Synthetic inertia versus fast frequency response: A definition. IET Renew. Power Gener. 2018, 12, 507–514. [Google Scholar] [CrossRef]

- Fleming, P.A.; Aho, J.; Buckspan, A.; Ela, E.; Zhang, Y.; Gevorgian, V.; Scholbrock, A.; Pao, L.; Damiani, R. Effects of power reserve control on wind turbine structural loading. Wind Energy 2015, 19, 453–469. [Google Scholar] [CrossRef]

- Gloe, A.; Jauch, C.; Thiesen, H.; Viebeg, J. Inertial Response Controller Design for a Variable Speed Wind Turbine. WETI Flensbg. Univ. Appl. Sci. 2018. [Google Scholar] [CrossRef]

- Kundur, P. Power System Stability and Control; McGraw-Hill: New York, NY, USA, 1994. [Google Scholar]

- Bird, L.; Lew, D.; Milligan, M.; Carlini, E.M.; Estanqueiro, A.; Flynn, D.; Gomez-Lazaro, E.; Holttinen, H.; Menemenlis, N.; Orths, A.; et al. Wind and solar energy curtailment: A review of international experience. Renew. Sustain. Energy Rev. 2016, 65, 577–586. [Google Scholar] [CrossRef]

- Ulbig, A.; Borsche, T.S.; Andersson, G. Impact of low rotational inertia on power system stability and operation. In Proceedings of the 19thWorld Congress of the International Federation of Automatic Control (IFAC 2014), Capetown, South Africa, 24–29 August 2014; Available online: https://reader.elsevier.com/reader/sd/pii/S1474667016427618?token=1130DA98E61ECBD9185907D2DE5A4F90E659BFC754B1D06E7CABAF20EF66856E7A2E7072C5268A2049CBF7AD6D84C5A0 (accessed on 3 May 2019).

- Tielens, P.; Hertem, D.V. The relevance of inertia in power systems. Renew. Sustain. Energy Rev. 2016, 55, 999–1009. Available online: http://www.sciencedirect.com/science/article/pii/S136403211501268X (accessed on 3 May 2019).

- Gonzalez-Longatt, F.M. Activation schemes of synthetic inertia controller on full converter wind turbine (type4). In Proceedings of the IEEE Power and Energy Society General Meeting, Denver, CO, USA, 26–30 July 2015; Available online: https://ieeexplore.ieee.org/stamp/stamp.jsp?tp=&arnumber=7286430 (accessed on 2 May 2019).

- EirGrid; Soni, All Island TSO Facilitation of Renewables Studies. 2010. Available online: http://www.eirgridgroup.com/site-files/library/EirGrid/Facilitation-of-Renewables-Report.pdf (accessed on 2 May 2019).

- Hydro Québec TransÉnergie. Technical Requirements for the Connection of Generation Facilities to the Hydro-Québec Transmission System. Supplementary Requirements for Wind Generation. 2005. Available online: http://www.hydroquebec.com/transenergie/fr/commerce/pdf/eolienne_transport_en.pdf (accessed on 2 May 2019).

- Red Electrica. Technical Requirement for Wind Power and Photovoltaic Installations and Any Generating Facilities Whose Technology Does Not Consist on a Synchronous Generator Directly Connected to the Grid. Available online: http://joaocarvalhosa.weebly.com/uploads/6/6/1/5/6615139/espanha.pdff (accessed on 3 May 2019).

- Salehi Dobakhshari, A.; Azizi, S.; Ranjbar, A.M. Control of Microgrids: Aspects and Prospects. In Proceedings of the IEEE International Conference on Networking, Sensing and Control, Delft, The Netherlands, 11–13 April 2011; Available online: https://ieeexplore.ieee.org/stamp/stamp.jsp?tp=&arnumber=5874892 (accessed on 2 May 2019).

- Gloe, A.; Jauch, C.; Craciun, B.; Winkelmann, J. Continuous provision of synthetic inertia with wind turbines: Implications for the wind turbine and for the grid. IET Renew. Power Gener. 2019, 13, 668–675. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development. Available online: http://pop.h-cdn.co/assets/cm/15/06/54d150362c903_-_38060.pdf (accessed on 3 May 2019).

- Jauch, C. First Eigenmode Simulation Model of a Wind Turbine—for Control Algorithm Design. WETI Flensbg. Univ. Appl. Sci. 2016. Available online: https://www.researchgate.net/publication/312935476_First_Eigenmode_Simulation_Model_of_a_Wind_Turbine_-_for_Control_Algorithm_Design (accessed on 3 May 2019). [CrossRef]

- Gloe, A.; Thiesen, H.; Jauch, C. Grid frequency analysis for assessing the stress on wind turbines. In Proceedings of the 15th Wind Integration Workshop, Vienna, Austria, 15–17 November 2016; Available online: https://www.researchgate.net/publication/311485049_Improved_Feed-in_Management_with_Wind_Turbines (accessed on 3 May 2019).

- Thiesen, H.; Jauch, C. Identifying electromagnetic illusions in grid frequency measurements for synthetic inertia provision. In Proceedings of the IEEE CPE-POWERENG 2019, 13th International Conference on Compatibility, Power Electronics and Power Engineering, Sonderborg, Denmark, 23–25 April 2019. [Google Scholar]

- Hafiz, F.; Abdennour, A. An adaptive neuro-fuzzy inertia controller for variable-speed wind turbines. Renew. Energy 2016, 92, 136–146. [Google Scholar] [CrossRef]

- Andresen, M. Simulation eines Einspeisereglers für Erzeugungsanlagen. Bachelor‘s Thesis, WSTECH GmbH, Flensburg, Germany, 2 January 2019. [Google Scholar]

- MATLAB Version: 9.4.0.813654 (R2018a). Available online: http://uk.mathworks.com/products/matlab/ (accessed on 2 May 2019).

- Jonkman, J.M.; Jonkman, B.J. FAST modularization framework for wind turbine simulation: Full-system linearization. In Proceedings of the Conference: Science of Making Torque from Wind (TORQUE 2016), Munich, Germany, 5–7 October 2016; Available online: https://www.nrel.gov/docs/fy17osti/67015.pdf (accessed on 3 May 2019).

- Nise, N.S. Control Systems Engineering, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2000; ISSN/ISBN 0-471-36601-3. [Google Scholar]

- Jauch, C.; Gloe, A. Flexible Wind Power Control for Optimal Power System Utilisation. In Proceedings of the WindAc Africa 2017, Cape Town, South Africa, 14–15 November 2017; Available online: https://www.researchgate.net/publication/321212504_Flexible_Wind_Power_Control_For_Optimal_Power_System_Utilisation (accessed on 3 May 2019).

- Stevenson, W.; Grainger, J. Power System Analysis; McGraw-Hill: New York, NY, USA, 1994. [Google Scholar]

| 5 April 2017 00:00–24:00 | 5 April 2017 00:00–12:00 | 5 April 2017 12:00–24:00 | |

|---|---|---|---|

| Hfixed = 6 s | 88.2029 kWh | 41.5384 kWh | 46.6645 kWh |

| Hvar from Hdem = 6 s | 33.0589 kWh | 4.3307 kWh | 28.7283 kWh |

| Hvar from Hdem = 12 s | 66.1327 kWh | 8.6603 kWh | 57.4724 kWh |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jauch, C.; Gloe, A. Simultaneous Inertia Contribution and Optimal Grid Utilization with Wind Turbines. Energies 2019, 12, 3013. https://doi.org/10.3390/en12153013

Jauch C, Gloe A. Simultaneous Inertia Contribution and Optimal Grid Utilization with Wind Turbines. Energies. 2019; 12(15):3013. https://doi.org/10.3390/en12153013

Chicago/Turabian StyleJauch, Clemens, and Arne Gloe. 2019. "Simultaneous Inertia Contribution and Optimal Grid Utilization with Wind Turbines" Energies 12, no. 15: 3013. https://doi.org/10.3390/en12153013

APA StyleJauch, C., & Gloe, A. (2019). Simultaneous Inertia Contribution and Optimal Grid Utilization with Wind Turbines. Energies, 12(15), 3013. https://doi.org/10.3390/en12153013