Thermal Simulation of Close-Fitting Sportswear

Abstract

:1. Introduction

2. Methodology for Thermal Simulation

2.1. Selection of Test Person

2.2. Material and Its Characterization

2.3. Construction of Sportswear

3. Wear Trial

4. Thermal Simulation of the Test Person

- An environment of 23 °C and a 50% relative humidity with an air velocity of 0.3 m/s was defined.

- The metabolic rates were defined according to the activities (sitting, walking at 4 km/h, walking at 6 km/h) that were followed by the test person during the wear trial. The metabolic rate of the test person was calculated by the following relation [35]:where, M is the metabolic rate, W is the body weight, L is the carried load, V is the walking speed, ɳ is the nature of the terrain, and G is the walking grade. Table 5 shows the metabolic rates that were calculated based on the above mentioned equation.

- The boundary conditions for heat transfer due to convection between external environment and outer surface of the clothing/model were determined by defining the linear convection (a function of velocity).

- The view factor cavity was defined in order to consider the radiative heat flux due to longwave radiation. In this regard, radiation characteristics were also defined as well.

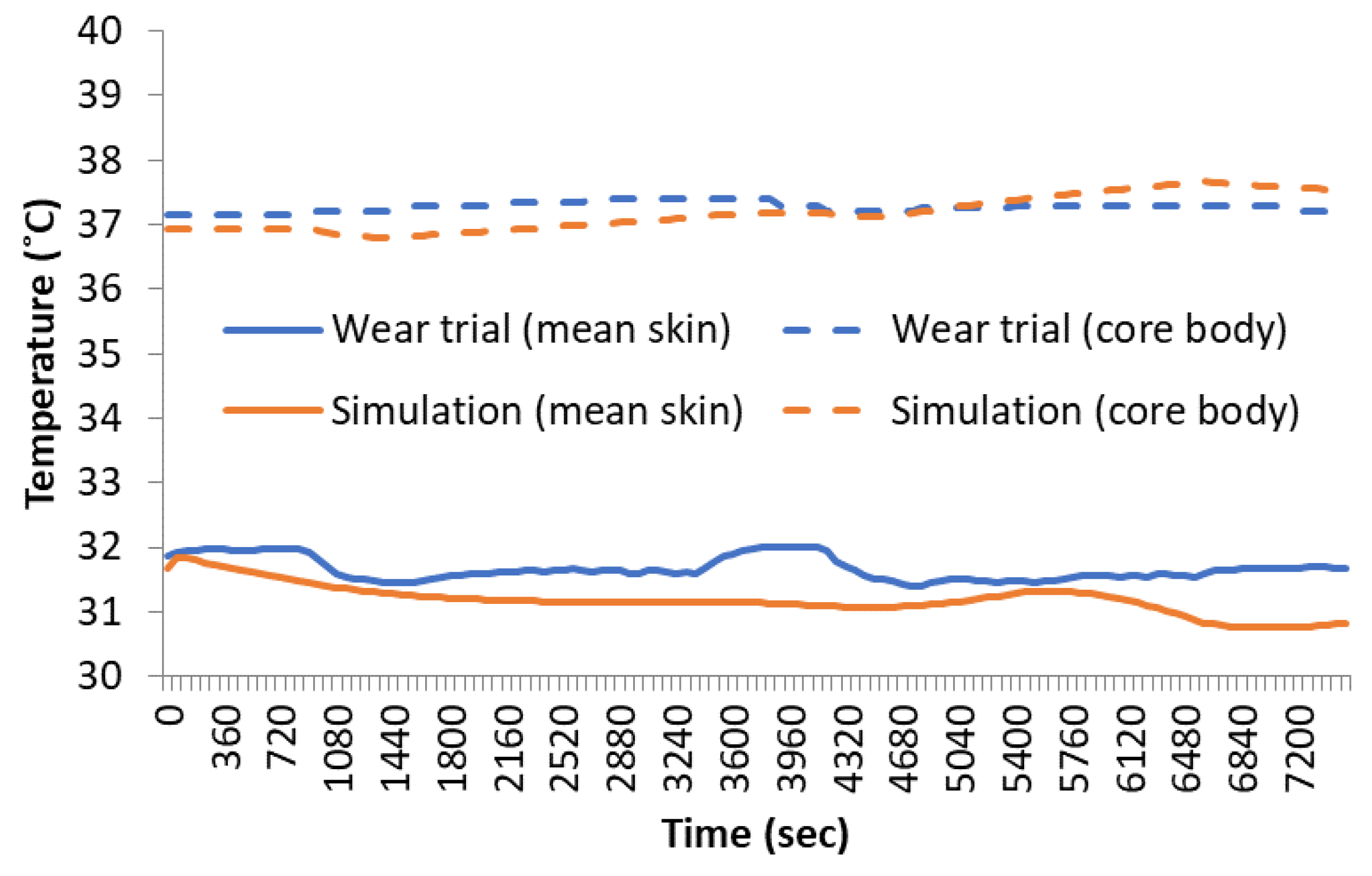

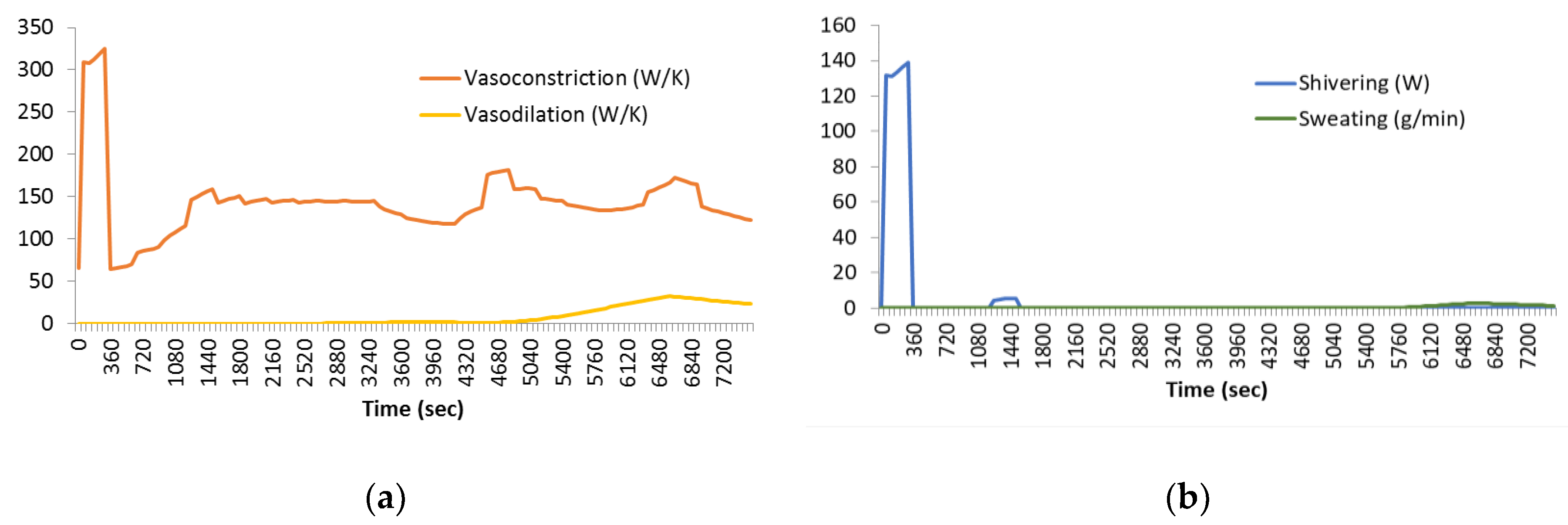

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shishoo, R. Textiles in Sport; Woodhead Publishing Limited: Sawston, UK; Cambridge, UK, 2005. [Google Scholar]

- Brotherhood, J.R. Heat stress and strain in exercise and sport. J. Sci. Med. Sport 2008, 11, 6–19. [Google Scholar] [CrossRef] [PubMed]

- Galloway, S.D.; Maughan, R.J. Effects of ambient temperature on the capacity to perform prolonged cycle exercise in man. Med. Sci. Sports Exerc. 1997, 29, 1240–1249. [Google Scholar] [CrossRef] [PubMed]

- Das, A.; Ishtiaque, S.M. Comfort Characteristics of Fabrics Containing Twist-less and Hollow Fibrous Assemblies in Weft. J. Text. Apparel. Technol. Manag. 2014, 3, 1–7. [Google Scholar]

- Havenith, G. Heat balance when wearing protective clothing. Ann. Occup. Hyg. 1999, 43, 289–296. [Google Scholar] [CrossRef] [Green Version]

- Katic, K.; Li, R.; Zeiler, W. Thermophysiological models and their applications: A review. Build. Environ. 2016, 106, 286–300. [Google Scholar] [CrossRef] [Green Version]

- Pennes, H.H. Analysis of Tissue and Arterial Blood Temperatures in the Resting Human Forearm. J. Appl. Physiol. 1948, 1, 5–34. [Google Scholar] [CrossRef] [PubMed]

- Gagge, A.; Stolwijk, J.A.; Nishi, Y. An Effective Temperature Scale Based on a Simple Model of Human Physiological Regulatory Response. SHRAE Trans. 1971, 77, 247–262. [Google Scholar]

- Fanger, P. Thermal Comfort: Analysis and Applications in Environmental Engineering; Danish Technical Press: København, Denmark, 1970. [Google Scholar]

- Wissler, E.H. Mathematical simulation of human thermal behavior using whole body models. Heat Transf. Med. Biol. 1985, 1, 325–373. [Google Scholar]

- Stolwijk, J.A.; Nadel, E.R.; Wenger, C.B.; Roberts, M.F. Development and application of a mathematical model of human thermoregulation. Arch. Sci. Physiol. (Paris) 1973, 27, 303. [Google Scholar] [PubMed]

- Fiala, D.; Lomas, K.J.; Stohrer, M. A computer model of human thermoregulation for a wide range of environmental conditions: The passive system. J. Appl. Physiol. 1999, 87, 1957–1972. [Google Scholar] [CrossRef] [PubMed]

- Fiala, D.; Lomas, K.J.; Stohrer, M. Computer prediction of human thermoregulatory and temperature responses to a wide range of environmental conditions. Int. J. Biometeorol. 2001, 45, 143–159. [Google Scholar] [CrossRef] [PubMed]

- Huizenga, C.; Hui, Z.; Arens, E. A model of human physiology and comfort for assessing complex thermal environments. Build Environ. 2001, 36, 691–699. [Google Scholar] [CrossRef] [Green Version]

- Fiala, D.; Havenith, G.; Bröde, P.; Kampmann, B.; Jendritzky, G. UTCI-Fiala multi-node model of human heat transfer and temperature regulation. Int. J. Biometeorol. 2012, 56, 429–441. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Parsons, K. Human Thermal Environments, 2nd ed.; Taylor and Francis Group: London, UK; New York, NY, USA, 2003. [Google Scholar]

- Taleghani, M.; Tenpierik, M.; Kurvers, S.; van den Dobbelsteen, A. A review into thermal comfort in buildings. Renew. Sustain. Energy Rev. 2013, 26, 201–215. [Google Scholar] [CrossRef]

- Awais, M.; Wendt, E.; Krzywinski, S. Analysis of Thermal Comfort of Clothing with Different Textile Material through Thermal Simulation. In Proceedings of the 3DBODY.TECH, Lugano, Switzerland, 22–23 October 2019; pp. 127–136. [Google Scholar]

- Fojtlín, M.; Psikuta, A.; Fišer, J.; Toma, R.; Annaheim, S.; Jícha, M. Local clothing properties for thermo-physiological modelling: Comparison of methods and body positions. Build Environ. 2019, 155, 376–388. [Google Scholar] [CrossRef]

- Severens, N.M.W.; van Marken Lichtenbelt, W.D.; Frijns, A.J.H.; Van Steenhoven, A.A.; De Mol, B.A.J.M.; Sessler, D.I. A model to predict patient temperature during cardiac surgery. Phys. Med. Biol. 2007, 52, 5131–5145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Psikuta, A. Development of an ‘Artificial Human’ for Clothing Research; De Montfort University Leicester: Leicester, UK, 2009. [Google Scholar]

- Psikuta, A.; Richards, M.; Fiala, D. Single- and Multi-Sector Thermophysiological Human Simulators For Clothing Research. In Proceedings of the 7th International Thermal Manikin and Modelling Meeting, Coimbra, Portugal, 2–5 September 2018; pp. 1–5. [Google Scholar]

- Fiala, D.; Psikuta, A.; Jendritzky, G.; Paulke, S.; Nelson, D.A.; van Marken Lichtenbelt, W.D.; Frijns, A.J. Physiological modeling for technical clinical and research applications. Front. Biosci. S 2010, 2, 112. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, T.; Cropper, P.C.; Cook, M.J.; Yousaf, R.; Fiala, D. A new simulation system to predict human-environment thermal interactions in naturally ventilated buildings. In Proceedings of the 10th International Building Performance Simulation Association Conference and Exhibition (BS2007), Beijing, China, 3–6 September 2007; pp. 751–756. [Google Scholar]

- Fiala, D.; Lomas, K.J. Application of a computer model predicting human thermal responses to the design of sports stadia. In Proceedings of the CIBSE ’99, Harrogate, UK, 3–5 October 1999; pp. 492–499. [Google Scholar]

- Paulke, S.; Wagner, S. Some Considerations on Global and Local Thermal Comfort Based on Fiala ‘ S Thermal Manikin in Theseus-Fe. In Proceedings of the 6th EUROSIM Congr Model Simul, Ljubljana, Slovenia, 9–13 September 2007. [Google Scholar]

- Vitronic. Available online: https://www.vitronic.com/industrial-and-logistics-automation/sectors/3d-body-scanner.html (accessed on 10 October 2017).

- 3D Scanning, Design and Reverse Engineering Software From 3D Systems Geomagic. Available online: http://www.geomagic.com/en/ (accessed on 7 September 2016).

- Rogers, D.F. An Introduction to NURBS With Historical Perspective; Morgan Kaufmann: Burlington, MA, USA, 2001. [Google Scholar]

- Lectra. Available online: http://www.lectra.com/en (accessed on 10 June 2017).

- Girdauskaite, L. Lokale Strukturfixierung im Preformherstellungsprozess für Komplex Gekrümmte Faserkunststoffverbundbauteile; TUDpress: Dresden, Germany, 2011. [Google Scholar]

- International Standard Organization, ISO 9886 Ergonomics-Evaluation of Thermal Strain by Physiological Measurements; International Standard Organization: Geneva, Switzerland, 2004.

- Theseus, F.E. Available online: http://www.theseus-fe.com/simulation-software/human-thermal-model (accessed on 3 October 2017).

- Duncan, S.; McLellan, T.; Dickson, E.G. Improving Comfort in Clothing; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Pandolf, K.; Givoni, B.; Goldman, R. Predicting energy expenditure with loads while standing or walking very slowly. J. Appl. Physiol. 1977, 43, 577–581. [Google Scholar] [CrossRef] [PubMed]

| Properties | Instruments | Values |

|---|---|---|

| Fabric thickness [mm] | Karl Schröder KG Material tester | 0.56 |

| Average mass per unit area of the fabrics [g m−2] | GSM cutter and weighing balance | 184 |

| Thermal resistance [m2KW−1] | Skin model | 0.0059 |

| Water vapor resistance [m2PaW−1] | Skin model | 2.01 |

| Air permeability [mm s−1] | Air permeability Tester FX 3300 LABOTESTER III | 221 |

| Phase | Activity | Duration |

|---|---|---|

| 1 | Sitting | 15 min |

| 2 | Walking at 4 km/h | 40 min |

| 3 | Sitting | 15 min |

| 4 | Walking at 6 km/h | 40 min |

| 5 | Sitting | 15 min |

| No. | Positioning of the Sensors | Type of Sensors | Weight Factor (ISO 9886) |  | |

|---|---|---|---|---|---|

| 1 | Forehead | T | 0.070 | ||

| 3 | Shoulder | Right | RH, T | 0.175 | |

| 4 | Chest | Left | RH, T | 0.175 | |

| 5 | Upper arm | Right | RH, T | 0.070 | |

| 6 | Lower arm | Left | T | 0.070 | |

| 7 | Hand | Left | T | 0.050 | |

| 10 | Front of the upper thigh | Right | RH, T | 0.190 | |

| 9 | Lower back | Left | T | - | |

| 13 | Calf | Left | RH, T | 0.200 | |

| Description | Formula for Calculating the Parameters | Values [clo] |

|---|---|---|

| Icl | 0.03225 | |

| Icl/icl | 0.21306 |

| Activity | Metabolic Rate (Met) |

|---|---|

| Sitting | 1 |

| Walking at 4 km/h | 2.7 |

| Walking at 6 km/h | 4.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awais, M.; Krzywinski, S.; Wölfling, B.-M.; Classen, E. Thermal Simulation of Close-Fitting Sportswear. Energies 2020, 13, 2419. https://doi.org/10.3390/en13102419

Awais M, Krzywinski S, Wölfling B-M, Classen E. Thermal Simulation of Close-Fitting Sportswear. Energies. 2020; 13(10):2419. https://doi.org/10.3390/en13102419

Chicago/Turabian StyleAwais, Muhammad, Sybille Krzywinski, Bianca-Michaela Wölfling, and Edith Classen. 2020. "Thermal Simulation of Close-Fitting Sportswear" Energies 13, no. 10: 2419. https://doi.org/10.3390/en13102419