Review of Technical Design and Safety Requirements for Vehicle Chargers and Their Infrastructure According to National Swedish and Harmonized European Standards

Abstract

:1. Introduction

2. Charging Modes

3. Charging Plugs and Socket-Outlets

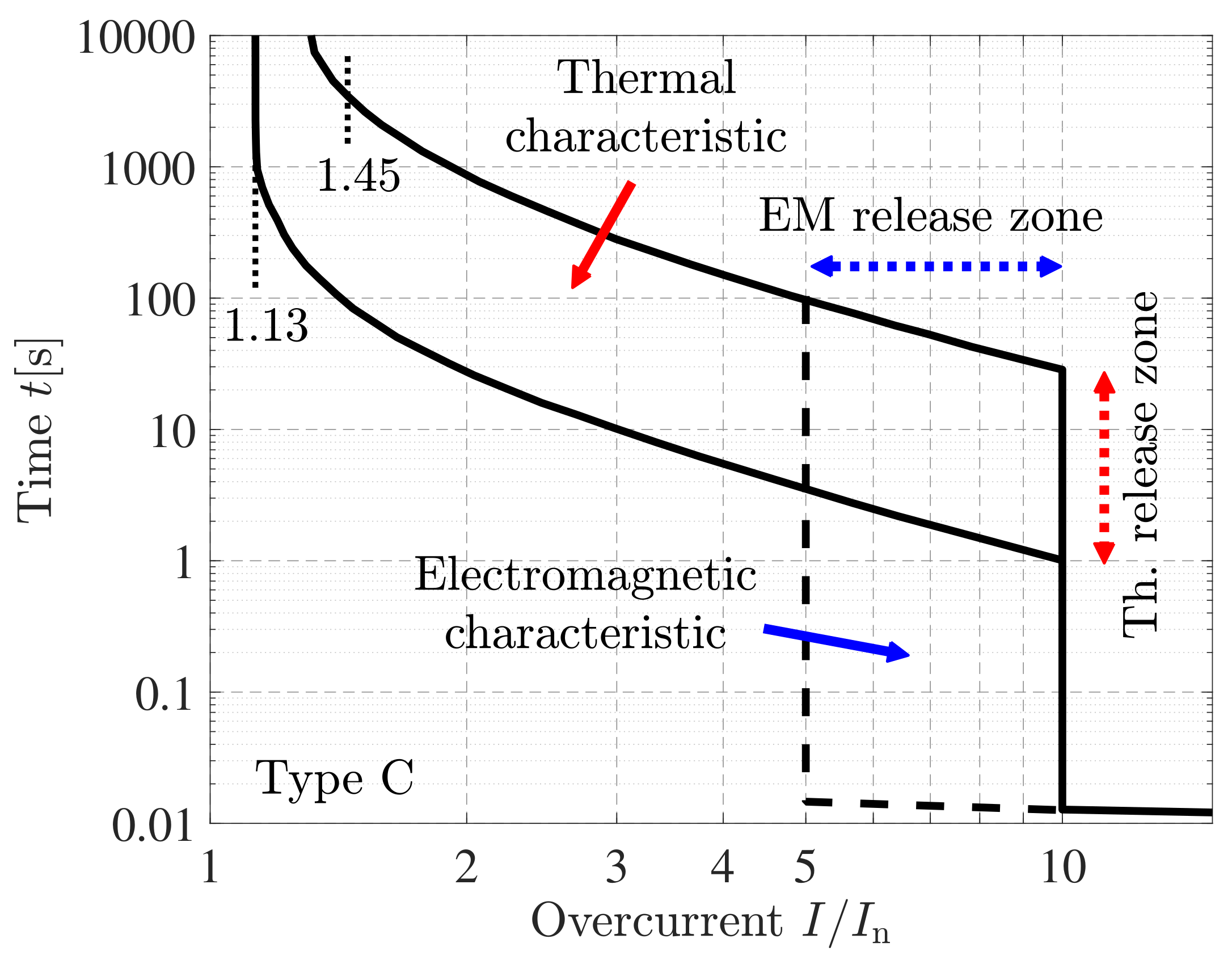

4. Overcurrent Protection and Cable Dimensioning

4.1. Selection of Overcurrent Protection Device

4.2. Placement of Overcurrent Protection Device

4.3. Permissible Voltage Drop along the Supply Line

5. Protection against Electric Shock

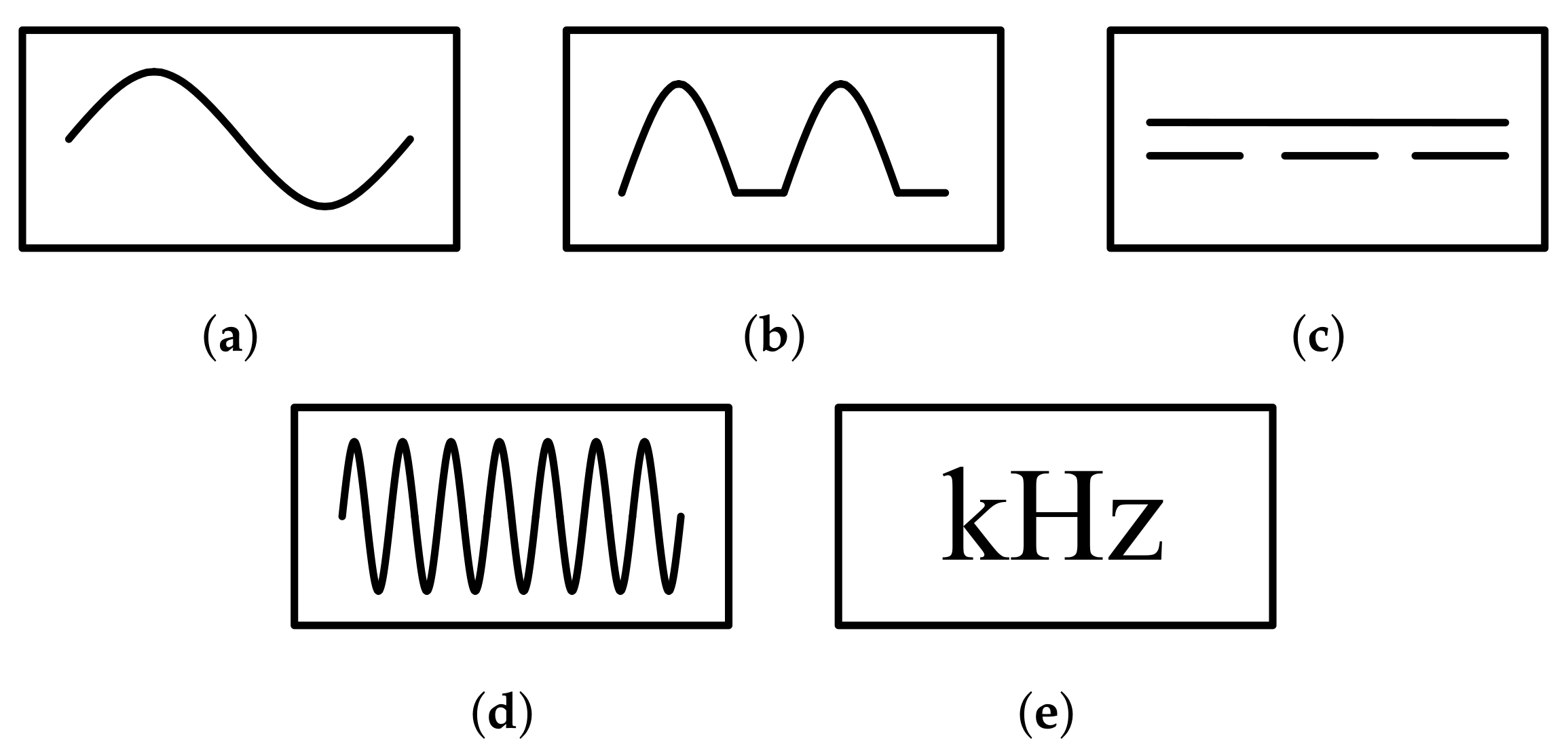

5.1. Residual Current Device

- (a)

- Detection of sinusoidal residual AC currents of 50 .

- (b)

- Detection of pulsating residual DC currents.

- (c)

- Detection of smooth residual DC currents.

- (d)

- Detection of residual currents composed of multiple frequencies from 50 up to 1 .

- (e)

- Detection of residual currents composed of multiple frequencies from 50 up to 20 .

5.2. Insulation Monitor

- Warning: If the insulation resistance has dropped below 300 −1, an optical and/or acoustical warning signal shall be activated. An ongoing charging process can be completed, but no new charging process shall be started.

- Alarm: If the insulation resistance has dropped below 100 −1, an optical and/or acoustical warning signal shall be activated and within 10 any ongoing charging process shall be stopped.

6. Further Safety Requirements

- Protection against intrusion, dust, accidental contact and water: The enclosure of an outside located charging station/socket shall fulfill at least the requirements of IP code 43 according to the SS-EN 60529 [47]. IP code 43 means that the housing protects the electrical and electronic circuitry against intrusion of objects with a larger diameter of 1 and spraying water.

- Protection against external mechanical impacts: The enclosure of a charging station/socket shall protect the electrical and electronic circuitry against external mechanical impacts. Therefore, the enclosure shall fulfill at least the requirements of IK code 07 according to the SS-EN 62262 [48]. IK code 07 means that the housing protects the electrical and electronic circuitry against external mechanical impacts with an impact energy of up to 2 m.

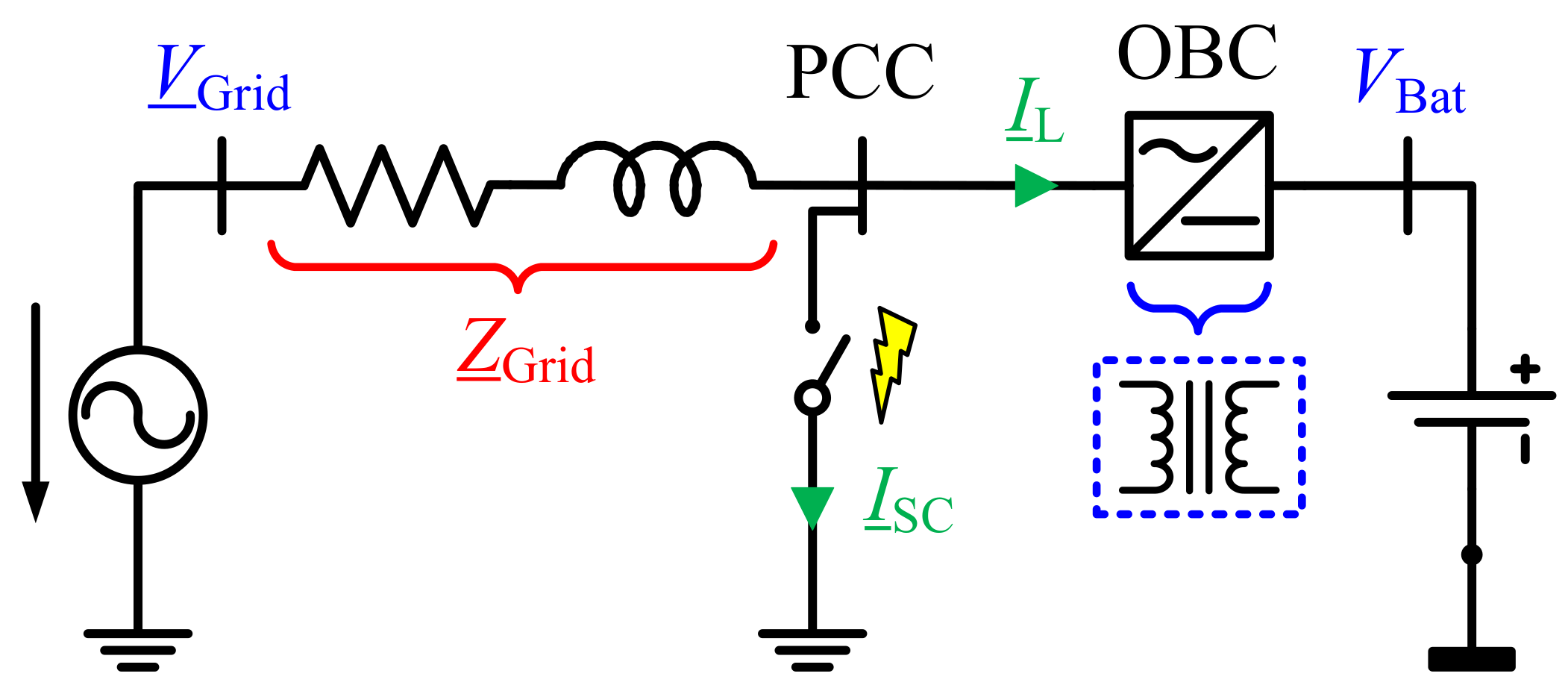

- Galvanic isolation: To avoid unwanted common mode currents, a galvanic isolation between the mains and the vehicle is required. Therefore, the vehicle’s battery shall be supplied via a permanently installed transformer in accordance with the SS-EN 61558-2-4 [49].

- Protection against lightning strikes and transient overvoltages: To protect the electrical and electronic circuitry from any kind of unwanted overvoltages, a surge protection device type 2 according to the SS-EN 61643-11 [50] shall be implemented.

- Emergency stop: When an emergency stop is required, the entire load current shall be interrupted and all live conductors, including the neutral conductor, shall be disconnected via an emergency stop button.

7. Limits for Current Harmonics and Conducted Electromagnetic Emissions

7.1. Harmonic Current Emissions

7.2. Conducted Electromagnetic Emissions

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Palmer, K.; Tate, J.E.; Wadud, Z.; Nellthorp, J. Total cost of ownership and market share for hybrid and electric vehicles in the UK, US and Japan. Appl. Energy 2018, 209, 108–119. [Google Scholar] [CrossRef]

- Rietmann, N.; Hügler, B.; Lieven, T. Forecasting the trajectory of electric vehicle sales and the consequences for worldwide CO2 emissions. J. Clean. Prod. 2020, 261, 121038. [Google Scholar] [CrossRef]

- Varga, B.O.; Sagoian, A.; Mariasiu, F. Prediction of Electric Vehicle Range: A Comprehensive Review of Current Issues and Challenges. Energies 2019, 12, 946. [Google Scholar] [CrossRef] [Green Version]

- Morrissey, P.; Weldon, P.; O’Mahony, M. Future standard and fast charging infrastructure planning: An analysis of electric vehicle charging behaviour. Energy Policy 2016, 89, 257–270. [Google Scholar] [CrossRef]

- You, P.; Yang, Z.; Chow, M.; Sun, Y. Optimal Cooperative Charging Strategy for a Smart Charging Station of Electric Vehicles. IEEE Trans. Power Syst. 2016, 31, 2946–2956. [Google Scholar] [CrossRef]

- Nour, M.; Said, S.M.; Ali, A.; Farkas, C. Smart charging of electric vehicles according to electricity price. In Proceedings of the 2019 International Conference on Innovative Trends in Computer Engineering (ITCE), Aswan, Egypt, 2–4 February 2019; pp. 432–437. [Google Scholar]

- Hernández, J.C.; Sanchez-Sutil, F.; Vidal, P.; Rus-Casas, C. Primary frequency control and dynamic grid support for vehicle-to-grid in transmission systems. Int. J. Electr. Power Energy Syst. 2018, 100, 152–166. [Google Scholar] [CrossRef]

- Janjic, A.; Velimirovic, L.; Stankovic, M.; Petrusic, A. Commercial electric vehicle fleet scheduling for secondary frequency control. Electr. Power Syst. Res. 2017, 147, 31–41. [Google Scholar] [CrossRef]

- Lazzeroni, P.; Olivero, S.; Repetto, M.; Stirano, F.; Vallet, M. Optimal battery management for vehicle-to-home and vehicle-to-grid operations in a residential case study. Energy 2019, 175, 704–721. [Google Scholar] [CrossRef]

- Haghbin, S.; Lundmark, S.; Alakula, M.; Carlson, O. Grid-Connected Integrated Battery Chargers in Vehicle Applications: Review and New Solution. IEEE Trans. Ind. Electron. 2013, 60, 459–473. [Google Scholar] [CrossRef]

- Rivera, S.; Kouro, S.; Vazquez, S.; Goetz, S.M.; Lizana, R.; Romero-Cadaval, E. Electric Vehicle Charging Infrastructure—From Grid to Battery. IEEE Ind. Electron. Mag. 2021. [Google Scholar] [CrossRef]

- SS 4364000. Low-Voltage Electrical Installations—Rules for Design and Erection of Electrical Installations, 3rd ed.; SEK Svensk Elstandard: Kista, Sweden, 2017. [Google Scholar]

- Panchal, C.; Stegen, S.; Lu, J. Review of static and dynamic wireless electric vehicle charging system. Eng. Sci. Technol. Int. J. 2018, 21, 922–937. [Google Scholar] [CrossRef]

- Pehrman, D.; Liu, Y. Design and Stray Field Evaluation of Inductive Power Transfer in Electric Vehicle Charging. In Proceedings of the 2019 Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 8–10 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- SS-EN 61851-1. Electric Vehicle Conductive Charging System—Part 1: General Requirements, 2nd ed.; SEK Svensk Elstandard: Kista, Sweden, 2011. [Google Scholar]

- Kersten, A.; Kuder, M.; Thiringer, T. Hybrid Output Voltage Modulation (PWM-FSHE) for a Modular Battery System Based on a Cascaded H-Bridge Inverter for Electric Vehicles Reducing Drivetrain Losses and Current Ripple. Energies 2021, 14, 1424. [Google Scholar] [CrossRef]

- Vitols, K. Efficiency of LiFePO4 battery and charger with passive balancing. In Proceedings of the 2015 IEEE 3rd Workshop on Advances in Information, Electronic and Electrical Engineering (AIEEE), Riga, Latvia, 13–14 November 2015; pp. 1–4. [Google Scholar]

- The 4 Electric Vehicle Charging Modes|DazeTechnology. Available online: https://www.dazetechnology.com/charging-modes-for-ev/ (accessed on 7 March 2021).

- Hartmann, M.; Friedli, T.; Kolar, J.W. Three-phase unity power factor mains interfaces of high power EV battery charging systems. In Proceedings of the Power Electronics for Charging Electric Vehicles ECPE Workshop, Valencia, Spain, 21–22 March 2011; pp. 21–22. [Google Scholar]

- Meine Wallbox: Warum man nicht einfach an einer Steckdose laden kann. Available online: https://www.eon.de/frag-eon/themen/e-mobility/article/meine-wallbox-teil-1-oder-kann-man-nicht-einfach-an-der-stec/ (accessed on 21 May 2021).

- Directive EU. 94/EU of the European Parliament and of the Council of 22 October 2014 on the deployment of alternative fuels infrastructure. Off. J. Eur. Union L 2014, 307, 1–20. [Google Scholar]

- Haghbin, S. Design of a 300 kW Compact and Efficient Fast Charger Station Utilizing High-Power SiC Modules and Nanocrystalline Magnetic Materials. In Proceedings of the 2018 20th European Conference on Power Electronics and Applications (EPE’18 ECCE Europe), Riga, Latvia, 17–21 September 2018; pp. 1–7. [Google Scholar]

- Keyser, M.; Pesaran, A.; Li, Q.; Santhanagopalan, S.; Smith, K.; Wood, E.; Ahmed, S.; Bloom, I.; Dufek, E.; Shirk, M.; et al. Enabling fast charging–Battery thermal considerations. J. Power Sources 2017, 367, 228–236. [Google Scholar] [CrossRef]

- IEEE Std 2030. IEEE Guide for Smart Grid Interoperability of Energy Technology and Information Technology Operation with the Electric Power System (EPS), End-Use Applications, and Loads, 2011th ed.; IEEE: Piscataway, NJ, USA, 2011. [Google Scholar]

- SS 428 08 34. Plugs and Socket-Outlets for Household and Similar Purposes—Particular Requirements for Plugs and Socket-Outlets Used in Sweden, 1st ed.; SEK Svensk Elstandard: Kista, Sweden, 2018. [Google Scholar]

- SS-IEC 60884-1. Plugs and Socket-Outlets for Household and Similar Purposes—Part 1: General Requirements, 3rd ed.; SEK Svensk Elstandard: Kista, Sweden, 2013. [Google Scholar]

- SS-EN 60309-1. Plugs, Socket-Outlets and Couplers for Industrial Purposes—Part 1: General Requirements, 3rd ed.; SEK Svensk Elstandard: Kista, Sweden, 1999. [Google Scholar]

- SS-EN 60309-2. Plugs, Socket Outlets and Couplers for Industrial Purposes—Part 2: Dimensional Interchangeability Requirements for Pin and Contact-Tube Accessories, 3rd ed.; SEK Svensk Elstandard: Kista, Sweden, 1999. [Google Scholar]

- Charging Cable for BEVs with in-line EVSE—Single-Phase Charging Type 2 3.6kW 6 m. Available online: https://www.deltaco.se/sites/cdn/PublishingImages/Products/EV-1225-01.png?width=260 (accessed on 24 May 2021).

- SS-EN 62196-1. Plugs, Socket-Outlets, Vehicle Connectors and Vehicle Inlets—Conductive Charging of Electric Vehicles—Part 1: General Requirements, 3rd ed.; SEK Svensk Elstandard: Kista, Sweden, 2015. [Google Scholar]

- SS-EN 62196-2. Plugs, Socket-Outlets, Vehicle Connectors and Vehicle Inlets—Conductive Charging of Electric Vehicles—Part 2: Dimensional Compatibility and Interchangeability Requirements for a.c. pin and Contact-Tube Accessories, 2nd ed.; SEK Svensk Elstandard: Kista, Sweden, 2017. [Google Scholar]

- SS-EN 62196-3. Plugs, Socket-Outlets, Vehicle Connectors and Vehicle Inlets—Conductive Charging of Electric Vehicles—Part 3: Dimensional Compatibility and Interchangeability Requirements for d.c. and a.c./d.c. pin and Contact-Tube Vehicle Couplers, 1st ed.; SEK Svensk Elstandard: Kista, Sweden, 2015. [Google Scholar]

- SS-EN ISO 15118-1:2019. Road Vehicles—Vehicle to Grid Communication Interface—Part 1: General Information and Use-Case Definition (ISO 15118-1:2019), 2nd ed.; SEK Svensk Elstandard: Kista, Sweden, 2019. [Google Scholar]

- IEEE Std 1547. IEEE Standard for Interconnection and Interoperability of Distributed Energy Resources with Associated Electric Power Systems Interfaces, 2018th ed.; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Hamdaoui, Y.; Maach, A. Smart islanding in smart grids. In Proceedings of the 2016 IEEE Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 21–24 August 2016; pp. 175–180. [Google Scholar] [CrossRef]

- SAE-J3068. Electric Vehicle Power Transfer System Using a Three-Phase Capable Coupler; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Combo2 and Type2 Charging Connectors Side by Side—Type 2 Connector—Wikipedia. Available online: https://en.wikipedia.org/wiki/Type_2_connector#/media/File:Iec-type2-ccs-combo2-and-iec-type2-charging-connectors-side-by-side.jpg (accessed on 29 April 2021).

- Combo—CCS Socket According to IEC 62196-3 from Khons Technology. Available online: https://ae01.alicdn.com/kf/HTB1BujKainrK1RjSsziq6xptpXaR/EVSE-Combo-2-CCS-Type-2-Socket-IEC-62196-3-Electric-Car-Vehicle-Charging-DC150A-850V.jpg_50x50.jpg_.webp (accessed on 21 May 2021).

- Chandra Mouli, G.R.; Schijffelen, J.; van den Heuvel, M.; Kardolus, M.; Bauer, P. A 10 kW Solar-Powered Bidirectional EV Charger Compatible With Chademo and COMBO. IEEE Trans. Power Electron. 2019, 34, 1082–1098. [Google Scholar] [CrossRef] [Green Version]

- Jampeethong, P.; Khomfoi, S. An EV quick charger based on CHAdeMO standard with grid-support function. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems (ICEMS), Pattaya City, Thailand, 25–28 October 2015; pp. 531–536. [Google Scholar] [CrossRef]

- SS-EN 60898-1. Circuit-Breakers for Overcurrent Protection for Household and Similar installations—Part 1: Circuit-Breakers for a.c. Operation, 2nd ed.; SEK Svensk Elstandard: Kista, Sweden, 2019. [Google Scholar]

- Kersten, A.; Liu, Y.; Pehrman, D.; Thiringer, T. Rotor Design of Line-Start Synchronous Reluctance Machine With Round Bars. IEEE Trans. Ind. Appl. 2019, 55, 3685–3696. [Google Scholar] [CrossRef]

- SS-EN 50160. Voltage Characteristics of Electricity Supplied by Public Distribution Systems, 3rd ed.; SEK Svensk Elstandard: Kista, Sweden, 2008. [Google Scholar]

- Kondo, R.; Schülting, P.; Wienhausen, A.H.; De Doncker, R.W. An Automated Component-Based Hardware Design of a Three-Phase Dual-Active Bridge Converter for a Bidirectional On-Board Charger. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 850–857. [Google Scholar] [CrossRef]

- Schülting, P.; Winter, C.; De Doncker, R.W. Design of a High-Frequency Dual-Active Bridge Converter with GaN Devices for an Output Power of 3.7 kW. In Proceedings of the 2018 International Power Electronics Conference (IPEC-Niigata 2018-ECCE Asia), Niigata, Japan, 20–24 May 2018; pp. 388–395. [Google Scholar] [CrossRef]

- SS-EN 61557-9. Electrical Safety in Low-Voltage Distribution Systems up to 1 kV a.c. and 1,5 kV d.c.—Equipment for Testing, Measuring or Monitoring of Protective Measures—Part 9: Equipment for Insulation Fault Location in IT Systems, 2nd ed.; SEK Svensk Elstandard: Kista, Sweden, 2009. [Google Scholar]

- SS-EN 60529. Degrees of Protection Provided by Enclosures (IP Code); SEK Svensk Elstandard: Kista, Sweden, 2014. [Google Scholar]

- SS-EN 62262. Degrees of Protection Provided by Enclosures for Electrical Equipment Against External Mechanical Impacts (IK Code), 1st ed.; SEK Svensk Elstandard: Kista, Sweden, 2008. [Google Scholar]

- SS-EN 61558-2-4. Safety of Transformers, Reactors, Power Supply Units and Similar Products For Supply Voltages up to 1100 V—Part 2-4: Particular Requirements and Tests for Isolating Transformers and Power Supply Units Incorporating Isolating Transformers, 2nd ed.; SEK Svensk Elstandard: Kista, Sweden, 2009. [Google Scholar]

- SS-EN 61643-11. Low-Voltage Surge Protective Devices—Part 11: Surge Protective Devices Connected to Low-Voltage Power Systems—Requirements And Test Methods, 2nd ed.; SEK Svensk Elstandard: Kista, Sweden, 2013. [Google Scholar]

- Meyer, J.; Blanco, A.; Domagk, M.; Schegner, P. Assessment of Prevailing Harmonic Current Emission in Public Low-Voltage Networks. IEEE Trans. Power Deliv. 2017, 32, 962–970. [Google Scholar] [CrossRef]

- Noshahr, J.B.; Meykhosh, M.H.; Kermani, M. Current harmonic losses resulting from first and second generation LED lights replacement with sodium vapor lights in a LV feeder. In Proceedings of the 2017 IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I CPS Europe), Milan, Italy, 6–9 June 2017; pp. 1–5. [Google Scholar] [CrossRef]

- IEEE Std 519. IEEE Recommended Practice and Requirements for Harmonic Control in Electric Power Systems, 2014th ed.; IEEE: Piscataway, NJ, USA, 2014. [Google Scholar]

- Oberdieck, K.; Gossmann, J.; Bubert, A.; De Doncker, R.W. Common- and Differential-Mode Separators Including the FM-Broadcasting Band. In Proceedings of the PCIM Europe 2018, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 5–7 June 2018; pp. 1–8. [Google Scholar]

- Oberdieck, K.; de Doncker, R.W.; Heberling, D. Measurement and Mitigation of Electromagnetic Emissions of Propulsion Inverters for Electric Vehicles; Technical Report; Lehrstuhl und Institut für Stromrichtertechnik und Elektrische Antriebe: Aachen, Germany, 2020. [Google Scholar]

- Youssef, M.; Roudet, J.; Marechal, Y. Near-field characterisation of power electronics circuits for radiation prediction. In Proceedings of the PESC97, Record 28th Annual IEEE Power Electronics Specialists Conference, Formerly Power Conditioning Specialists Conference 1970-71, Power Processing and Electronic Specialists Conference 1972, St. Louis, MO, USA, 27 June 1997; Volume 2, pp. 1529–1534. [Google Scholar]

- Rodriguez, V. Automotive component EMC testing: CISPR 25, ISO 11452–2 and equivalent standards. IEEE Electromagn. Compat. Mag. 2012, 1, 83–90. [Google Scholar] [CrossRef]

- CISPR 14-1:2020. Electromagnetic Compatibility—Requirements for Household Appliances, Electric Tools and Similar Apparatus—Part 1: Emission, 7th ed.; Standard, IEC Test; IEC Geneva Office: Geneva, Switzerland, 2020. [Google Scholar]

- CISPR 25:2016. Vehicles, Boats and Internal Combustion Engines—Radio Disturbance Characteristics—Limits and Methods of Measurement for the Protection of On-Board Receivers, 4th ed.; Standard, IEC Test; IEC Geneva Office: Geneva, Switzerland, 2016. [Google Scholar]

- SS-EN 55014-1. Electromagnetic Compatibility—Requirements for Household Appliances, Electric Tools and Similar Apparatus—Part 1: Emission, 4th ed.; SEK Svensk Elstandard: Kista, Sweden, 2017. [Google Scholar]

- SS-EN 55025. Vehicles, Boats, and Internal Combustion Engines—Radio Disturbance Characteristics—Limits and Methods of Measurement for the Protection of On-Board Receivers, 3rd ed.; SEK Svensk Elstandard: Kista, Sweden, 2017. [Google Scholar]

- Hirsch, H.; Jeschke, S.; Wei, L.; Trautmann, M.; Bärenfänger, J.; Maarleveld, M.; Heyen, J.; Darrat, A. Latest development of the national and international EMC-standards for electric vehicles and their charging infrastructure. In Proceedings of the 2015 IEEE International Symposium on Electromagnetic Compatibility (EMC), Dresden, Germany, 16–22 August 2015; pp. 708–713. [Google Scholar] [CrossRef]

- CISPR 16-SER. Specification for Radio Disturbance and Immunity Measuring Apparatus and Methods. Standard, IEC Test; IEC Geneva Office: Geneva, Switzerland, 2019. [Google Scholar]

- Kersten, A.; Oberdieck, K.; Gossmann, J.; Bubert, A.; Loewenherz, R.; Neubert, M.; Thiringer, T.; Doncker, R.W.D. Measuring and Separating Conducted Three-Wire Emissions From a Fault-Tolerant, NPC Propulsion Inverter With a Split-Battery Using Hardware Separators Based on HF Transformers. IEEE Trans. Power Electron. 2021, 36, 378–390. [Google Scholar] [CrossRef]

| Charging Type | Power Rating [kW] | Charging Time [h] |

|---|---|---|

| Single-phase—10 | ||

| Single-phase—16 | ||

| Three-phase—16 | 11 | |

| Three-phase—32 | 22 | |

| Three-phase—63 | 44 | |

| DC fast charging | 50 | |

| DC fast charging | 120 |

| Charging Type a,b | A = 2.5 mm | A = 4 mm | A = 10 mm |

|---|---|---|---|

| Single-phase—16 | |||

| Single-phase—32 | — | — | |

| Three-phase—32 | — | — | |

| Three-phase—63 | — | — |

| Maximum Harmonic Current Distortion in Percent of | ||||||

|---|---|---|---|---|---|---|

| Individual Harmonic Order (Odd Harmonics) a,b | ||||||

| / | TDD | |||||

| <20 | ||||||

| >1000 | ||||||

| Service/ Band | Frequency [MHz] | Levels [dBV] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Class 1 | Class 2 | Class 3 | Class 4 | Class 5 | |||||||

| Peak | Quasi- Peak | Peak | Quasi- Peak | Peak | Quasi- Peak | Peak | Quasi- Peak | Peak | Quasi- Peak | ||

| LW –AM | 0.15–0.3 | 113 | 100 | 103 | 90 | 93 | 80 | 83 | 70 | 73 | 60 |

| MW –AM | 0.53–2.0 | 95 | 82 | 87 | 74 | 79 | 66 | 71 | 58 | 63 | 50 |

| SW –AM | 5.9–6.2 | 77 | 64 | 71 | 58 | 65 | 52 | 59 | 46 | 53 | 40 |

| VHF –FM | 30–54 | 77 | 64 | 71 | 58 | 65 | 52 | 59 | 46 | 53 | 40 |

| VHF—FM | 70–108 | 61 | 48 | 55 | 42 | 49 | 36 | 43 | 30 | 37 | 24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kersten, A.; Rodionov, A.; Kuder, M.; Hammarström, T.; Lesnicar, A.; Thiringer, T. Review of Technical Design and Safety Requirements for Vehicle Chargers and Their Infrastructure According to National Swedish and Harmonized European Standards. Energies 2021, 14, 3301. https://doi.org/10.3390/en14113301

Kersten A, Rodionov A, Kuder M, Hammarström T, Lesnicar A, Thiringer T. Review of Technical Design and Safety Requirements for Vehicle Chargers and Their Infrastructure According to National Swedish and Harmonized European Standards. Energies. 2021; 14(11):3301. https://doi.org/10.3390/en14113301

Chicago/Turabian StyleKersten, Anton, Artem Rodionov, Manuel Kuder, Thomas Hammarström, Anton Lesnicar, and Torbjörn Thiringer. 2021. "Review of Technical Design and Safety Requirements for Vehicle Chargers and Their Infrastructure According to National Swedish and Harmonized European Standards" Energies 14, no. 11: 3301. https://doi.org/10.3390/en14113301