Development of Specific Rules for the Application of Life Cycle Assessment to Carbon Capture and Storage

Abstract

:1. Introduction

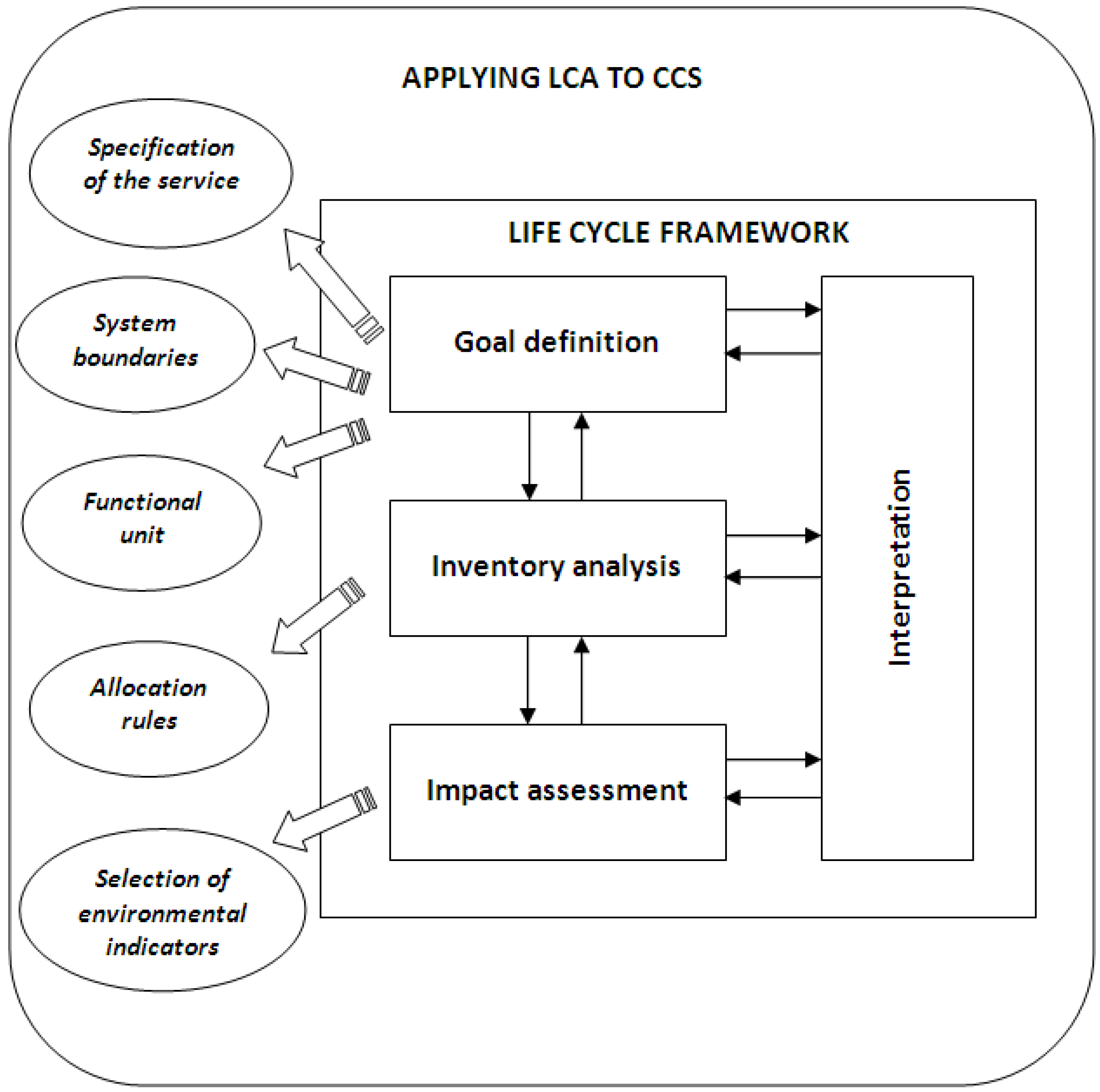

2. General Methodological Framework

2.1. Life Cycle Assessment

- (a)

- Goal and scope definition: identification of the purpose of the study (e.g., a comparative evaluation of systems that are functionally equivalent), the functional unit (i.e., a measure of the function of the studied system, that provides a reference to which the inputs and outputs can be related) and the system boundaries;

- (b)

- Inventory analysis: data collection, assessment of the procedures for the calculation of the inlet/outlet fluxes from/to the system, including the resource utilization and air emissions, waterborne effluents and solid waste;

- (c)

- Impact assessment: procedure to evaluate the effects of the compounds identified in the inventory phase on specific impact categories, such as global warming, ozone layer depletion, acidification, ground-level ozone creation, eutrophication;

- (d)

- Interpretation: combination of the results obtained in the inventory phase and in the impact assessment phase, in order to draw conclusions and formulate recommendations.

2.2. Methodology for Type III Environmental Declarations

3. Discussion of the Specific Methodological Choices

| Study | Year | Plant(s) | Capture technology | Functional unit | System boundaries 1 | Storage site | CO2 leakage in storage site | ||

| post-combustion | pre-combustion | oxyfuel | |||||||

| Waku et al. [16] | 1995 | Fossil fuel PP 2 | ✓ | ✓ | 1 kWh | C-T-S | geological /ocean | no | |

| Lombardi [17] | 2003 | Fossil fuel PP | ✓ | ✓ | ✓ | 1 MJ | C | n.a. | n.a. |

| Benetto et al. [18] | 2004 | Fossil fuel/ biomass PP | ✓ | 414 GJ | C | n.a | n.a. | ||

| Spath and Mann [19] | 2004 | Fossil fuel/ biomass PP | ✓ | 1 kWh | C-T | n.a. | n.a. | ||

| Khoo and Tan [20] | 2006 | Fossil fuel PP | ✓ | 1 MWh | C-S | geological /ocean | yes | ||

| Viebahn et al. [21] | 2007 | Fossil fuel PP | ✓ | ✓ | ✓ | 1 kWh | C-T-S | geological | yes |

| Hertwich et al. [22] | 2008 | Fossil fuel PP | ✓ | 1 MWh /1 m3 (oil) | C-T-S | geological | n.a. | ||

| Koorneef et al. [23] | 2008 | Fossil fuel PP | ✓ | 1 kWh | C-T-S | geological | no | ||

| Odeh and Cockerill [24] | 2008 | Fossil fuel PP | ✓ | ✓ | 1 kWh | C | n.a. | n.a. | |

| Bouvart and Prieur [25] | 2009 | Fossil fuel PP | ✓ | ✓ | 1 kWh | C-T-S | geological | no | |

| Korre et al. [26] | 2009 | Fossil fuel PP | ✓ | 1 MWh | C | n.a. | n.a. | ||

| Pehnt and Henkel [27] | 2009 | Fossil fuel PP | ✓ | ✓ | ✓ | 1 kWh | C-T-S | geological | no |

| Schreiber et al. [28] | 2009 | Fossil fuel PP | ✓ | 1 kWh | C-T-S | n.a. | n.a. | ||

| Modahl et al. [29] | 2011 | Fossil fuel PP | ✓ | 1 TWh | C-T-S | n.a. | n.a. | ||

| Nagashima et al. [30] | 2011 | Fossil fuel PP/Oil refinery/Paper mill/Ironworks | ✓ | 1 ton (CO2) | C-T-S | geological | no | ||

| Nie et al. [31] | 2011 | Fossil fuel PP | ✓ | ✓ | 1 MWh | C-T-S | geological | no | |

| Singh et al. [32] | 2011 | Fossil fuel PP | ✓ | ✓ | ✓ | 1 kWh | C-T-S | geological | no |

| Study | GWP 1 | AP 2 | ODP 3 | POCP 4 | EP 5 | Energy | Exergy | ADP 6 | Toxicity | Waste | Damage categories |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Waku et al. [16] | ✓ | ✓ | |||||||||

| Lombardi [17] | ✓ | ✓ | |||||||||

| Benetto et al. [18] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Spath and Mann [19] | ✓ | ✓ | |||||||||

| Khoo and Tan [20] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Viebahn et al. [21] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Hertwich et al. [22] | ✓ | ✓ | |||||||||

| Koorneef et al. [23] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Odeh and Cockerill [24] | ✓ | ✓ | |||||||||

| Bouvart and Prieur [25] | ✓ | ✓ | |||||||||

| Korre et al. [26] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Pehnt and Henkel [27] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Schreiber et al. [28] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Modahl et al. [29] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Nagashima et al. [30] | ✓ | ||||||||||

| Nie et al. [31] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Singh et al. [32] | ✓ | ✓ | ✓ |

3.1. Specification of the Service

- Section: 9—Community, social and personal services

- Division: 94—Sewage and waste collection, treatment and disposal and other environmental protection services

- Group: 949—Other environmental protection services n.e.c.

3.2. Functional Unit

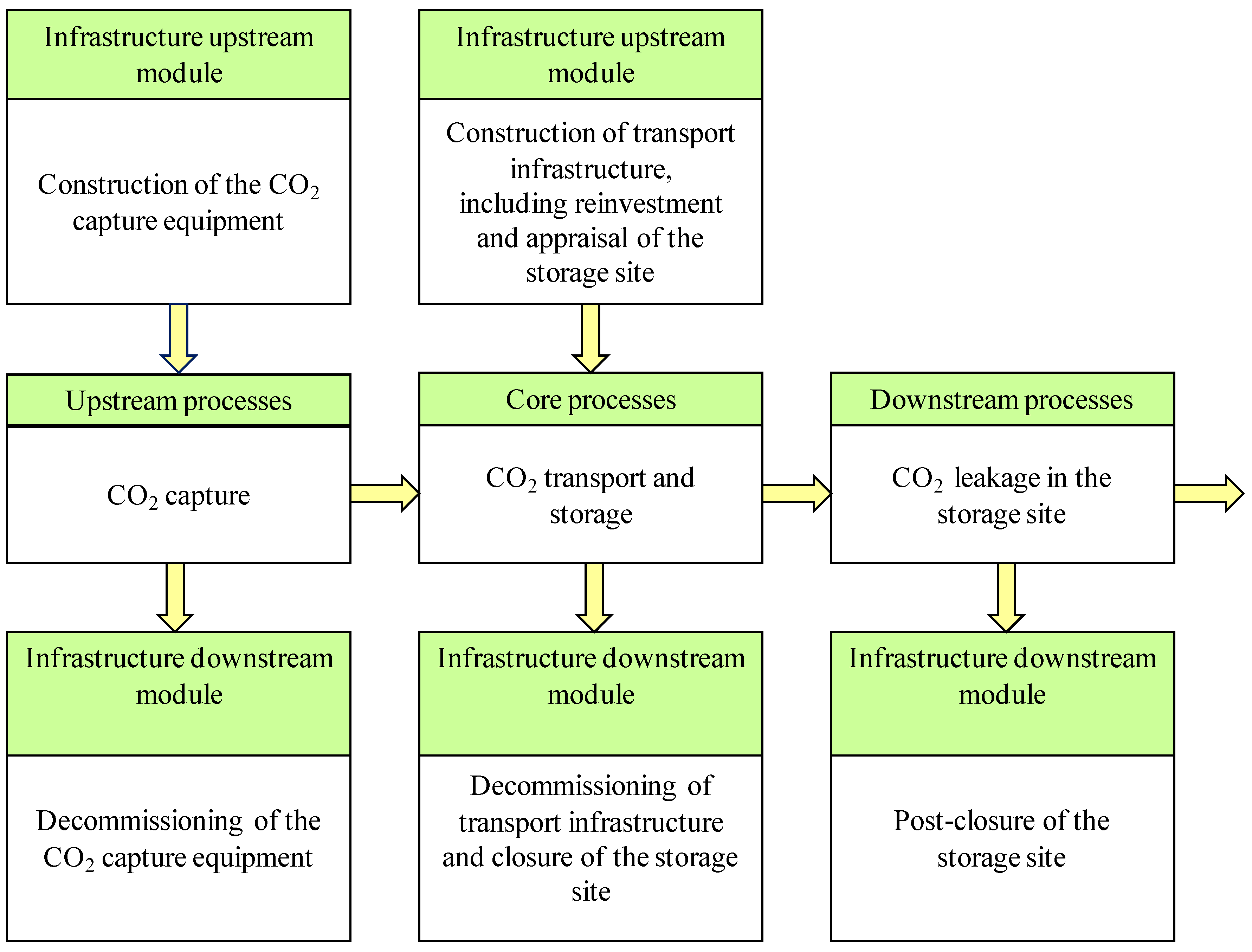

3.3. System Boundaries

3.3.1. Upstream Module

- (a)

- CO2 capture (taking into account CO2 formation and capture efficiency), e.g., by:

- Post-combustion capture technology (e.g., including CO2 separation from flue gas stream through amine-based or ammonia-based solvents, membrane separation, chemical looping and solid adsorption processes);

- Pre-combustion capture technology (e.g., including Integrated Gasification Combined Cycle (IGCC)—plants, involving the partial oxidation of solid fuel feedstock in a gasifier to produce a mixture of hydrogen and carbon monoxide, then treated in a shift converter and a physical adsorption unit);

- Oxyfuel (i.e., combusting fossil fuels in recycled flue gas enriched with oxygen).

- (b)

- CO2 purification/separation.

- (c)

- CO2 compression to high-pressure supercritical conditions (when performed).

3.3.2. Core Module

- CO2 transport through pipelines or mobile transport facilities;

- Operation stage (including CO2 injection, site monitoring, CO2 reaction with metal oxides);

- Handling/treatment/storage of process-related emissions and waste (including CO2 leakage during transport and operation stage).

- Construction of new and dedicated infrastructure such as CO2 pipelines systems, road, railways or modification of existing infrastructure, such as oil and gas pipeline (including main transports and reinvestment). As mobile transport facilities are often used not only for the purpose of CO2 transport, the construction of the means of transport might be negligible with respect to resource use during the lifecycle and shall be included only if they are exclusively dedicated to CO2 transport;

- Storage site appraisal (e.g., well drilling and completion);

- Construction of injection station or other facilities such as platforms, etc.;

- Dismantling of dedicated transport infrastructure (dedicated CO2 pipelines, roads, railways); Dismantling of transport facilities shall be included only if they are exclusively dedicated to CO2 transport;

- Site closure (including infrastructure removing, wells plugging and main transports).

3.3.3. Downstream Module

- Site post-closure (including site management, remediation and main transports);

- Data about CO2 leakage.

3.4. Allocation Rules

3.5. Environmental Performance Indicators

- LCI emissions of CO2 captured;

- LCI emissions of CO2 leakage;

- Ratio between the CO2 permanently stored and the CO2 emitted from the considered source.

- Soil pollution;

- Impacts on biodiversity;

- Risk and safety assessment.

4. Conclusions

Acknowledgments

References

- Global Carbon Capture and Storage Institute. The Global Status of CCS; Global Carbon Capture and Storage Institute Ltd.: Canberra, Australia, 2011. [Google Scholar]

- International Energy Agency (IEA). Energy Technology Perspectives 2010. Part 1: Technology and the Global Energy Economy to 2050; OECD/IEA: Paris, France, 2010. [Google Scholar]

- International Energy Agency (IEA). Energy Technology Perspectives 2010. Part 2: The Transition from Present to 2050; OECD/IEA: Paris, France, 2010. [Google Scholar]

- International Energy Agency (IEA). CCS Model Regulatory Framework; OECD/IEA: Paris, France, 2010. [Google Scholar]

- Koornneef, J.; Ramírez, A.; Turkenburg, W.; Faaij, A. The environmental impact and risk assessment of CO2 capture, transport and storage—An evaluation of the knowledge base. Prog. Energy Combust. 2012, 38, 62–86. [Google Scholar] [CrossRef]

- Marx, J.; Schreiber, A.; Zapp, P.; Haines, M.; Hake, J.F.; Gale, J. Environmental evaluation of CCS using life cycle assessment—A synthesis report. Energy Procedia 2011, 4, 2448–2456. [Google Scholar] [CrossRef]

- Sathre, R.; Chester, M.; Cain, J.; Masanet, E. A framework for environmental assessment of CO2 capture and storage systems. Energy 2012, 37, 540–548. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Environmental Labels and Declarations, Type III Environmental Declarations, Principles and Procedures; ISO: Genève, Switzerland, 2006; European Standard ISO 14025. [Google Scholar]

- International Organization for Standardization (ISO). Environmental Management, Life Cycle Assessment; ISO: Genève, Switzerland, 2006; European Standard ISO14040. [Google Scholar]

- Commission of the European Communities. Integrated Product Policy—Building on Environmental Life-Cycle Thinking; Communication from the Commission to the Council and the European Parliament, No. COM (2003) 302 final; Office for Official Publications of the European Communities: Brussels, Belgium, 2003. [Google Scholar]

- Eco-innovation Action Plan. Available online: http://ec.europa.eu/environment/etap/ (accessed on 26 January 2012).

- The International EPD Cooperation (IEC). General Programme Instructions for Environmental Product Declarations; IEC: Stockholm, Sweden, 2008. [Google Scholar]

- The International EPD Cooperation (IEC). Introduction, Intended Uses and Key Programme Elements for Environmental Product Declarations; IEC: Stockholm, Sweden, 2008. [Google Scholar]

- Grahl, B.; Schmincke, E. The part of LCA in ISO type III environmental declarations. Int. J. Life Cycle Assess. 2007, 12, 38–45. [Google Scholar]

- Fet, A.M.; Skaar, C. Eco-labeling, product category rules and certification procedures based on ISO 14025 requirements. Int. J. Life Cycle Assess. 2006, 11, 49–54. [Google Scholar] [CrossRef]

- Waku, H.; Tamura, I.; Inoue, M.; Akai, M. Life cycle analysis of fossil power plant with CO2 recovery and sequestering system. Energy Convers. Manag. 1995, 36, 877–880. [Google Scholar] [CrossRef]

- Lombardi, L. Life cycle assessment comparison of technical solutions for CO2 emissions reduction in power generation. Energy Convers. Manag. 2003, 44, 93–108. [Google Scholar] [CrossRef]

- Benetto, E.; Popovici, E.C.; Rousseaux, P.; Blondin, J. Life cycle assessment of fossil CO2 emissions reduction scenarios in coal-biomass based electricity production. Energy Convers. Manag. 2004, 45, 3053–3074. [Google Scholar] [CrossRef]

- Spath, P.; Mann, M. Biomass Power and Conventional Fossil Systems with and without CO2 Sequestration Comparing the Energy Balance, Greenhouse Gas Emissions and Economics; Report No. BB04.4010; National Renewable Energy Laboratory: Golden, CO, USA, 2004. [Google Scholar]

- Khoo, H.H.; Tan, R.B.H. Life cycle investigation of CO2 recovery and sequestration. Environ. Sci. Technol. 2006, 40, 4016–4024. [Google Scholar] [CrossRef] [PubMed]

- Viebahn, P.; Nitsch, J.; Fischedick, M.; Esken, A.; Schuwer, D.; Nikolaus, S.; Zuberbuhler, U.; Edenhofer, O. Comparison of carbon capture and storage with renewable energy technologies regarding structural, economic, and ecological aspects. Int. J. Greenh. Gas Control 2007, 1, 121–133. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Aaberg, M.; Singh, B.; Strømman, A.H. Life-cycle assessment of carbon dioxide capture for enhanced oil recovery. Chinese J. Chem. Eng. 2008, 16, 343–353. [Google Scholar] [CrossRef]

- Koornneef, J.; van Keulen, T.; Faaij, A.; Turkenburg, W. Life cycle assessment of a pulverized coal power plant with post-combustion capture, transport and storage of CO2. Int. J. Greenh. Gas Control 2008, 2, 448–467. [Google Scholar] [CrossRef]

- Odeh, N.A.; Cockerill, T.T. Life cycle GHG assessment of fossil fuel power plants with carbon capture and storage. Energy Policy 2008, 36, 367–380. [Google Scholar] [CrossRef]

- Bouvart, F.; Prieur, A. Comparison of life cycle GHG emissions and energy consumption of combined electricity and H2 production pathways with CCS: Selection of technologies with natural gas, coal and lignite as fuel for the European HYPOGEN Programme. Energy Procedia 2009, 1, 3779–3786. [Google Scholar] [CrossRef]

- Korre, A.; Nie, Z.; Durucan, S. Life cycle modelling of fossil fuel power generation with post combustion. Energy Procedia 2009, 1, 3771–3778. [Google Scholar] [CrossRef]

- Pehnt, M.; Henkel, J. Life cycle assessment of carbon dioxide capture and storage from lignite power plants. Int. J. Greenh. Gas Control 2009, 3, 49–66. [Google Scholar] [CrossRef]

- Schreiber, A.; Zapp, P.; Kuckshinrichs, W. Environmental assessment of German electricity production from coal-fired power plants with amine-based carbon capture. Int. J. Life Cycle Assess. 2009, 14, 547–559. [Google Scholar] [CrossRef]

- Modahl, I.S.; Nyland, C.A.; Raadal, H.L.; Kårstad, O.; Torp, T.A.; Hagemann, R. Life cycle assessment of gas power with CCS—A study showing the environmental benefits of system integration. Energy Procedia 2011, 4, 2470–2477. [Google Scholar] [CrossRef]

- Nagashima, S.; Miyagawa, T.; Matsumoto, M.; Suzuki, S.; Komaki, H.; Takagi, M.; Murai, S. Life cycle assessment performed on a CCS model case in Japan and evaluation of improvement facilitated by heat integration. Energy Procedia 2011, 4, 2457–2464. [Google Scholar] [CrossRef]

- Nie, Z.; Korre, A.; Durucan, S. Life cycle modelling and comparative assessment of the environmental impacts of oxy-fuel and post-combustion CO2 capture, transport and injection processes. Energy Procedia 2011, 4, 2510–2517. [Google Scholar] [CrossRef]

- Singh, B.; Strømman, A.H.; Hertwich, E.G. Comparative life cycle environmental assessment of CCS technologies. Int. J. Greenh. Gas Control 2011, 5, 911–921. [Google Scholar] [CrossRef]

- The International EPD® system. Product Category Rules CPC 171 Electrical energy and CPC 173 Steam and hot water; PCR 2007:08. Version 2.01. Available online: http://www.environdec.com/en/Product-Category-Rules/Detail/?Pcr=5802 (accessed on 26 January 2012).

- United Nations Statistic Division Homepage. Available online: http://unstats.un.org/unsd/default.htm (accessed on 26 November 2011).

- EUROPA: the official web site of the European Union. Directive 2009/31/EC of the European parliament and of the council of 23 April 2009. Available online: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:140:0114:0135: EN:PDF (accessed on 26 January 2012).

- Authenticated U.S. Government Information GPO; Environmental Protection Agency. Federal Requirements under the Underground Injection Control (UIC) Program for Carbon Dioxide (CO2) Geologic Sequestration (GS) Wells; Final Rule,75 Fed. Reg. 77230; 10 December 2010. Available online: http://www.gpo.gov/fdsys/pkg/FR-2010–12–10/pdf/2010–29954.pdf (accessed on 26 January 2012).

- Authenticated U.S. Government Information GPO; Environmental Protection Agency. Mandatory Reporting of Greenhouse Gases: Injection and Geologic Sequestration of Carbon Dioxide; Final Rule,75 Fed. Reg. 75060; 1 December 2010. Available online: http://www.gpo.gov/fdsys/pkg/FR-2010–12–01/pdf/2010–29934.pdf (accessed on 26 January 2012).

- Metz, B.; Davidson, O.; de Coninck, H.C.; Loos, M.; Meyer, L.A. IPCC Special Report on Carbon Dioxide Capture and Storage; Prepared by Working Group III of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2005. [Google Scholar]

- Del Borghi, A. Analisi del ciclo di vita applicata ai rifiuti: Uno strumento per la progettazione ecosostenibile. In Quaderno di Ingegneria Ambientale; C.I.P.A. S.R.L. (Centro Italiano Prodotti Artistici): Milano, Italy, 2003; Volume 37, pp. 9–61. [Google Scholar]

- Del Borghi, A.; Gallo, M.; Del Borghi, M. A survey of life-cycle thinking integrated into waste management. Int. J. Life Cycle Assess. 2009, 14, 597–610. [Google Scholar] [CrossRef]

- The International EPD Cooperation (IEC). Supporting Annexes for Environmental Product Declarations; IEC: Stockholm, Sweden, 2008. [Google Scholar]

- Organisation for Economic Co-Operation and Development (OECD). Recommendation of the Council on Guiding Principles Concerning International Economic Aspects of Environmental Policies. Recommendation C(72)128. Adopted May 26, 1972. Available online: http://acts.oecd.org/Instruments/ShowInstrumentView.aspx?InstrumentID=4&InstrumentPID=255&Lang=en&Book=False (accessed on 26 November 2011).

- Pennington, D.W.; Potting, J.; Finnveden, G.; Lindeijer, E.; Jolliet, O.; Rydberg, T.; Rebitzer, G. Life cycle assessment Part 2: Current impact assessment practice. Environ. Int. 2004, 30, 721–739. [Google Scholar] [CrossRef] [PubMed]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Strazza, C.; Del Borghi, A.; Gallo, M. Development of Specific Rules for the Application of Life Cycle Assessment to Carbon Capture and Storage. Energies 2013, 6, 1250-1265. https://doi.org/10.3390/en6031250

Strazza C, Del Borghi A, Gallo M. Development of Specific Rules for the Application of Life Cycle Assessment to Carbon Capture and Storage. Energies. 2013; 6(3):1250-1265. https://doi.org/10.3390/en6031250

Chicago/Turabian StyleStrazza, Carlo, Adriana Del Borghi, and Michela Gallo. 2013. "Development of Specific Rules for the Application of Life Cycle Assessment to Carbon Capture and Storage" Energies 6, no. 3: 1250-1265. https://doi.org/10.3390/en6031250