An Approach to Identify the Suitable Plant Location for Miscanthus-Based Ethanol Industry: A Case Study in Ontario, Canada

Abstract

:1. Introduction

2. Methodology

2.1. Study Area

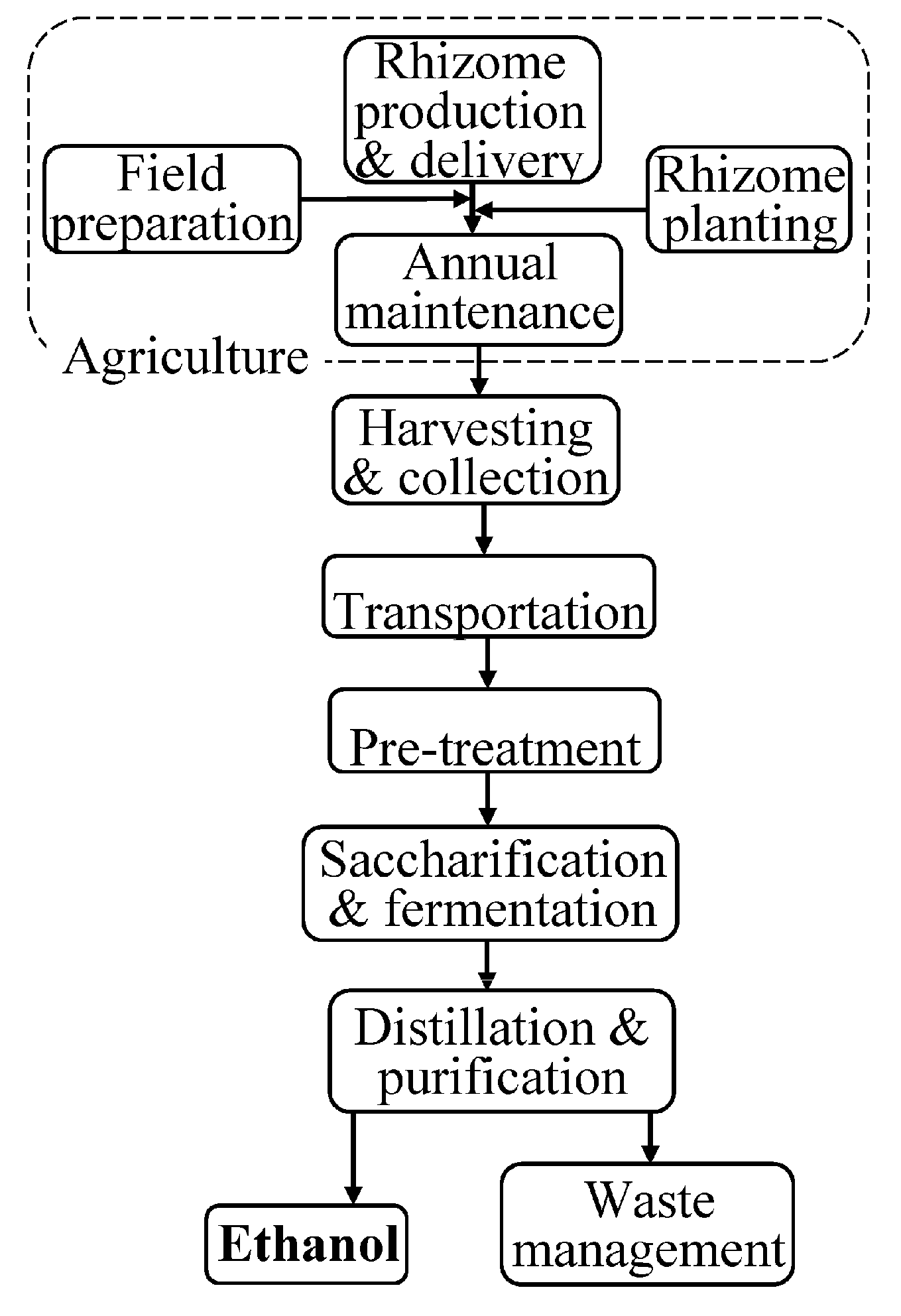

2.2. System Boundary and Assumptions

| Scenario | Land class | Soil type | Crop rotation | Yield, tDM/ha | Cost, $/tDM | * Emission, kg-CO2e/tDM |

|---|---|---|---|---|---|---|

| S1 | 1 & 2 | Silt loam-clay loom | Corn-soy rotation | 11.14 | 62.63 | −28.58 |

| S2 | 3 | Sandy-clay | Continuous soybean rotation | 10.03 | 65.67 | −88.77 |

| S3 | 3 | Sandy-clay | Corn-corn-forage-forage rotation | 10.03 | 65.67 | 167.47 |

| S4 | 4 & 5 | Sandy loam | Long term pasture | 8.35 | 71.50 | 167.67 |

2.3. Transportation

2.4. Ethanol Production

2.4.1. Pre-Treatment

2.4.2. Fermentation, Distillation and Purification

2.4.3. Waste Management

2.5. Cost Analysis

3. Results and Discussion

3.1. Net Energy Consumption

3.2. Greenhouse Gas (GHG) Emission (CO2e)

3.3. Production Cost

3.4. Sensitivity Analysis

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Natural Resource Canada (NRC). Energy Use Data Handbook Tables (Canada)—Transportation Sector. Available online: http://data.gc.ca/data/dataset/cec843a2-b8cb-4168-81f1-e1ced9daf5da (accessed on 28 September 2013).

- Environment Canada. Renewable Fuels Regulations. Available online: http://www.ec.gc.ca/energie-energy/default.asp?lang=En&n=0AA71ED2-1 (accessed on 2 October 2013).

- Biofuelnet. An Overview of Canadian Federal Biofuels Programs. Available online: http://www.biofuelnet.ca/2013/10/03/an-overview-of-canadian-federal-biofuels-programs/ (accessed on 21 December 2014).

- Winchester, N.; Reilly, J.M. The Contribution of Biomass to Emissions Mitigation under a Global Climate Policy; Technical Report for MIT Joint Program on the Science and Policy of Global Change: Cambridge, MA, USA, 2015. [Google Scholar]

- Liew, F.M.; Köpke, M.; Simpson, S.D. Gas fermentation for commercial biofuels production. In Liquid, Gaseous and Solid Biofuels—Conversion Techniques; Fang, Z., Ed.; InTech: Rijeka, Croatia, 2013. [Google Scholar]

- Mueller, S.A.; Anderson, J.E.; Wallington, T.J. Impact of biofuel production and other supply and demand factors on food price increases in 2008. Biomass Bioenergy 2011, 5, 1623–1632. [Google Scholar] [CrossRef]

- Hahn-Hägerdal, B.; Galbe, M.; Gorwa-Grauslund, M.F.; Lidén, G.; Zacchi, G. Bio-ethanol—The fuel of tomorrow from the residues of today. Trends Biotechnol. 2006, 24, 549–556. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, O.J.; Cardona, C.A. Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour. Technol. 2008, 99, 5270–5295. [Google Scholar] [CrossRef] [PubMed]

- Akhurst, M.; Kalas, N.; Woods, J. Meta-analysis of biomass potentials for biofuel production. Sci. Insights Biofuel Policy 2011, 2, 1–9. [Google Scholar]

- Sims, R.E. Bioenergy Options for a Cleaner Environment: In Developed and Developing Countries: in Developed and Developing Countries; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- World Energy Outlook 2010; International Energy Agency (IEA): London, UK, 2010.

- Cai, X.; Zhang, X.; Wang, D. Land availability for biofuel production. Environ. Sci. Technol. 2011, 45, 334–339. [Google Scholar] [CrossRef] [PubMed]

- Weiser, C.; Zeller, V.; Reinicke, F.; Wagner, B.; Majer, S.; Vetter, A.; Thraen, D. Integrated assessment of sustainable cereal straw potential and different straw-based energy applications in Germany. Appl. Energy 2014, 114, 749–762. [Google Scholar] [CrossRef]

- Kludze, H.; Deen, B.; Weersink, A.; van Acker, R.; Janovicek, K.; de Laporte, A. Assessment of the Availability of Agricultural Biomass for Heat and Energy Production in Ontario; Technical Report for Ontario Ministry of Agriculture, Food and Rural Affairs: Toronto, ON, Canada, 2010. [Google Scholar]

- Scown, C.D.; Nazaroff, W.W.; Mishra, U.; Strogen, B.; Lobscheid, A.B.; Masanet, E.; McKone, T.E. Lifecycle greenhouse gas implications of US national scenarios for cellulosic ethanol production. Environ. Res. Lett. 2012, 7. [Google Scholar] [CrossRef]

- Somerville, C.; Youngs, H.; Taylor, C.; Davis, S.C.; Long, S.P. Feedstocks for lignocellulosic biofuels. Science 2010, 329, 790–792. [Google Scholar] [CrossRef] [PubMed]

- Kludze, H.; Deen, B.; Weersink, A.; van Acker, R.; Janovicek, K.; De Laporte, A. Impact of land classification on potential warm season grass biomass production in Ontario, Canada. Can. J. Plant Sci. 2013, 93, 249–260. [Google Scholar] [CrossRef]

- Wise, M.; Dooley, J.; Luckow, P.; Calvin, K.; Kyle, P. Agriculture, land use, energy and carbon emission impacts of global biofuel mandates to mid-century. Appl. Energy 2014, 114, 763–773. [Google Scholar] [CrossRef]

- Searchinger, T.; Heimlich, R.; Houghton, R.A.; Dong, F.; Elobeid, A.; Fabiosa, J.; Tokgoz, S.; Hayes, D.; Yu, T.H. Use of US croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef] [PubMed]

- Fazio, S.; Monti, A. Life cycle assessment of different bioenergy production systems including perennial and annual crops. Biomass Bioenergy 2011, 35, 4868–4878. [Google Scholar] [CrossRef]

- Gnansounou, E.; Dauriat, A. Techno-economic analysis of lignocellulosic ethanol: A review. Bioresour. Technol. 2010, 101, 4980–4991. [Google Scholar] [CrossRef] [PubMed]

- Roy, P.; Orikasa, T.; Tokuyasu, K.; Nakamura, N.; Shiina, T. Evaluation of the life cycle of bioethanol produced from rice straws. Bioresour. Technol. 2012, 110, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Roy, P.; Tokuyasu, K.; Orikasa, T.; Nakamura, N.; Shiina, T. A techno-economic and environmental evaluation of the life cycle of bioethanol produced from rice straw by RT-CaCCO process. Biomass Bioenergy 2012, 37, 188–195. [Google Scholar] [CrossRef]

- Roy, P.; Dutta, A. Life cycle assessment of ethanol produced from wheat straw. J. Biobased Mater. Bioenergy 2012, 6, 276–282. [Google Scholar] [CrossRef]

- Nguyen, T.L.T.; Hermansen, J.E. System expansion for handling co-products in LCA of sugar cane bio-energy systems: GHG consequences of using molasses for ethanol production. Appl. Energy 2012, 89, 254–261. [Google Scholar] [CrossRef]

- Ekman, A.; Wallberg, O.; Joelsson, E.; Börjesson, P. Possibilities for sustainable biorefineries based on agricultural residues—A case study of potential straw-based ethanol production in Sweden. Appl. Energy 2013, 102, 299–308. [Google Scholar] [CrossRef]

- Steubing, B.; Ballmer, I.; Gassner, M.; Gerber, L.; Pampuri, L.; Bischof, S.; Oliver, T.; Zah, R. Identifying environmentally and economically optimal bioenergy plant sizes and locations: A spatial model of wood-based SNG value chains. Renew. Energy 2014, 61, 57–68. [Google Scholar] [CrossRef]

- Liu, Z.; Qiu, T.; Chen, B. A study of the LCA based biofuel supply chain multi-objective optimization model with multi-conversion paths in China. Appl. Energy 2014, 126, 221–234. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B. Global warming impact assessment of a crop residue gasification project—A dynamic LCA perspective. Appl. Energy 2014, 122, 269–279. [Google Scholar] [CrossRef]

- Gasol, C.M.; Gabarrell, X.; Rigola, M.; González-García, S.; Rieradevall, J. Environmental assessment (LCA) and spatial modelling (GIS) of energy crop implementation on local scale. Biomass Bioenergy 2011, 35, 2975–2985. [Google Scholar] [CrossRef]

- Sanscartier, D.; Deen, B.; Dias, G.; MacLean, H.L.; Dadfar, H.; McDonald, I.; Kludze, H. Implications of land class and environmental factors on life cycle GHG emissions of Miscanthus as a bioenergy feedstock. GCB Bioenergy 2014, 6, 401–413. [Google Scholar] [CrossRef]

- Vyn, R.J.; Virani, T.; Deen, B. Examining the economic feasibility of miscanthus in Ontario: An application to the greenhouse industry. Energy Policy 2012, 50, 669–676. [Google Scholar] [CrossRef]

- Brosse, N.; Sannigrahi, P.; Ragauskas, A. Pretreatment of Miscanthus × giganteus using the ethanol organosolv process for ethanol production. Ind. Eng. Chem. Res. 2009, 48, 8328–8334. [Google Scholar] [CrossRef]

- Sørensen, A.; Teller, P.J.; Hilstrøm, T.; Ahring, B.K. Hydrolysis of Miscanthus for bioethanol production using dilute acid presoaking combined with wet explosion pre-treatment and enzymatic treatment. Bioresour. Technol. 2008, 99, 6602–6607. [Google Scholar] [CrossRef] [PubMed]

- Murnen, H.K.; Balan, V.; Chundawat, S.P.; Bals, B.; Sousa, L.D.C.; Dale, B.E. Optimization of ammonia fiber expansion (AFEX) pretreatment and enzymatic hydrolysis of Miscanthus × giganteus to fermentable sugars. Biotechnol. Prog. 2007, 23, 846–850. [Google Scholar] [CrossRef] [PubMed]

- Han, M.; Kim, Y.; Koo, B.C.; Choi, G.W. Bioethanol production by Miscanthus as a lignocellulosic biomass: Focus on high efficiency conversion to glucose and ethanol. Bioresources 2011, 6, 1939–1953. [Google Scholar]

- Vanderghem, C.; Brostaux, Y.; Jacquet, N.; Blecker, C.; Paquot, M. Optimization of formic/acetic acid delignification of Miscanthus × giganteus for enzymatic hydrolysis using response surface methodology. Ind. Crops Prod. 2012, 35, 280–286. [Google Scholar] [CrossRef]

- Khullar, E.; Dien, B.S.; Rausch, K.D.; Tumbleson, M.E.; Singh, V. Effect of particle size on enzymatic hydrolysis of pretreated Miscanthus. Ind. Crops Prod. 2013, 44, 11–17. [Google Scholar] [CrossRef]

- Li, H.Q.; Li, C.L.; Sang, T.; Xu, J. Pretreatment on Miscanthus lutarioriparious by liquid hot water for efficient ethanol production. Biotechnol. Biofuels 2013, 6. [Google Scholar] [CrossRef] [PubMed]

- Chang, V.S.; Nagwani, M.; Kim, C.H.; Holtzapple, M.T. Oxidative lime pretreatment of high-lignin biomass. Appl. Biochem. Biotechnol. 2001, 94, 1–28. [Google Scholar] [CrossRef]

- Shiroma, R.; Park, J.Y.; Al-Haq, M.I.; Arakane, M.; Ike, M.; Tokuyasu, K. RT-CaCCO process: An improved CaCCO process for rice straw by its incorporation with a step of lime pretreatment at room temperature. Bioresour. Technol. 2011, 102, 2943–2949. [Google Scholar] [CrossRef] [PubMed]

- Junqueira, T.L.; Dias, M.O.; Maciel, M.R.; Maciel Filho, R.; Rossell, C.E.; Atala, D.I. Simulation and optimization of the continuous vacuum extractive fermentation for bioethanol production and evaluation of the influence on distillation process. Comput. Aided Chem. Eng. 2009, 26, 827–832. [Google Scholar]

- Gregg, D.J.; Saddler, J.N. Factors affecting cellulose hydrolysis and the potential of enzyme recycle to enhance the efficiency of an integrated wood to ethanol process. Biotechnol. Bioeng. 1996, 51, 375–383. [Google Scholar] [CrossRef]

- Mansfield, B.K.; Alton, A.J.; Andrews, S.H.; Bownas, J.L.; Casey, D.; Martin, S.A.; Wyrick, J.M. Breaking the Biological Barriers to Cellulosic Ethanol: A Joint Research Agenda; Technocal Report for Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2006. [Google Scholar]

- Nilsson, H. Flexibility in Wheat Bioethanol Plants—Conditions for Conversion to Lignocellulosic Feedstock. Available online: http://www.chemeng.lth.se/exjobb/E471.pdf (accessed on 12 October 2014).

- Zhang, T.; Wyman, C.E.; Jakob, K.; Yang, B. Rapid selection and identification of Miscanthus genotypes with enhanced glucan and xylan yields from hydrothermal pretreatment followed by enzymatic hydrolysis. Biotechnol. Biofuels 2012, 5. [Google Scholar] [CrossRef] [PubMed]

- Pimentel, D.; Patzek, T.W. Ethanol production using corn, switchgrass, and wood; biodiesel production using soybean and sunflower. Nat. Resour. Res. 2005, 14, 65–76. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Life cycle assessment of various cropping systems utilized for producing biofuels: Bioethanol and biodiesel. Biomass Bioenergy 2005, 29, 426–439. [Google Scholar] [CrossRef]

- Roy, P.; Dutta, A. Life cycle assessment of ethanol derived from sawdust. Bioresour. Technol. 2013, 150, 407–411. [Google Scholar] [CrossRef] [PubMed]

- Dutta, A.; Bain, R.L.; Biddy, M.J. Techno-economics of the production of mixed alcohols from lignocellulosic biomass via high-temperature gasification. Environ. Prog. Sustain. Energy 2010, 29, 163–174. [Google Scholar] [CrossRef]

- Klein-Marcuschamer, D.; Oleskowicz-Popiel, P.; Simmons, B.A.; Blanch, H.W. Technoeconomic analysis of biofuels: A wiki-based platform for lignocellulosic biorefineries. Biomass Bioenergy 2010, 34, 1914–1921. [Google Scholar] [CrossRef]

- Kumar, D.; Murthy, G.S. Impact of pretreatment and downstream processing technologies on economics and energy in cellulosic ethanol production. Biotechnol. Biofuels 2011, 4. [Google Scholar] [CrossRef] [PubMed]

- Barta, Z.; Reczey, K.; Zacchi, G. Techno-economic evaluation of stillage treatment with anaerobic digestion in a softwood-to-ethanol process. Biotechnol. Biofuels 2010, 3. [Google Scholar] [CrossRef] [PubMed]

- Bennett, R.; Phipps, R.; Strange, A.; Grey, P. Environmental and human health impacts of growing genetically modified herbicide-tolerant sugar beet: A life-cycle assessment. Plant Biotechnol. J. 2004, 2, 273–278. [Google Scholar] [CrossRef] [PubMed]

- Wikipedia. Available online: https://en.wikipedia.org/wiki (accessed on 14 May 2013).

- Asano, K.; Minowa, T. An Analysis of Bioethanol Production Costs and CO2 Reduction Costs in Japan. J. Jpn Inst. Energy 2007, 86, 957–963. (In Japanese) [Google Scholar]

- Wooley, R.; Ruth, M.; Sheehan, J.; Ibsen, K.; Majdeski, H.; Galvez, A. Lignocellulosic Biomass to Ethanol Process Design and Economics Utilizing Co-Current Dilute Acid Prehydrolysis and Enzymatic Hydrolysis Current and Futuristic Scenarios; Technical Report for National Renewable Energy Lab: Golden, CO, USA, 1999. [Google Scholar]

- Dias, M.O.; Junqueira, T.L.; Filho, R.; Maciel, M.R.; Rossell, C.E. Anhydrous bioethanol production using bioglycerol—Simulation of extractive distillation processes. Comput. Aided Chem. Eng. 2009, 26, 519–524. [Google Scholar]

- Mani, S.; Sokhansanj, S.; Tagore, S.; Turhollow, A.F. Techno-economic analysis of using corn stover to supply heat and power to a corn ethanol plant—Part 2: Cost of heat and power generation systems. Biomass Bioenergy 2010, 34, 356–364. [Google Scholar] [CrossRef]

- Huang, H.J.; Ramaswamy, S.; Al-Dajani, W.; Tschirner, U.; Cairncross, R.A. Effect of biomass species and plant size on cellulosic ethanol: A comparative process and economic analysis. Biomass Bioenergy 2009, 33, 234–246. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Turhollow, A.F. Baseline cost for corn stover collection. Appl. Eng. Agric. 2002, 18, 525–532. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roy, P.; Dutta, A.; Deen, B. An Approach to Identify the Suitable Plant Location for Miscanthus-Based Ethanol Industry: A Case Study in Ontario, Canada. Energies 2015, 8, 9266-9281. https://doi.org/10.3390/en8099266

Roy P, Dutta A, Deen B. An Approach to Identify the Suitable Plant Location for Miscanthus-Based Ethanol Industry: A Case Study in Ontario, Canada. Energies. 2015; 8(9):9266-9281. https://doi.org/10.3390/en8099266

Chicago/Turabian StyleRoy, Poritosh, Animesh Dutta, and Bill Deen. 2015. "An Approach to Identify the Suitable Plant Location for Miscanthus-Based Ethanol Industry: A Case Study in Ontario, Canada" Energies 8, no. 9: 9266-9281. https://doi.org/10.3390/en8099266

APA StyleRoy, P., Dutta, A., & Deen, B. (2015). An Approach to Identify the Suitable Plant Location for Miscanthus-Based Ethanol Industry: A Case Study in Ontario, Canada. Energies, 8(9), 9266-9281. https://doi.org/10.3390/en8099266