Microstructural Analysis and Wear Performance of Carbon-Fiber-Reinforced SiC Composite for Brake Pads

Abstract

:1. Introduction

2. Experiments

2.1. Specimen Preparation

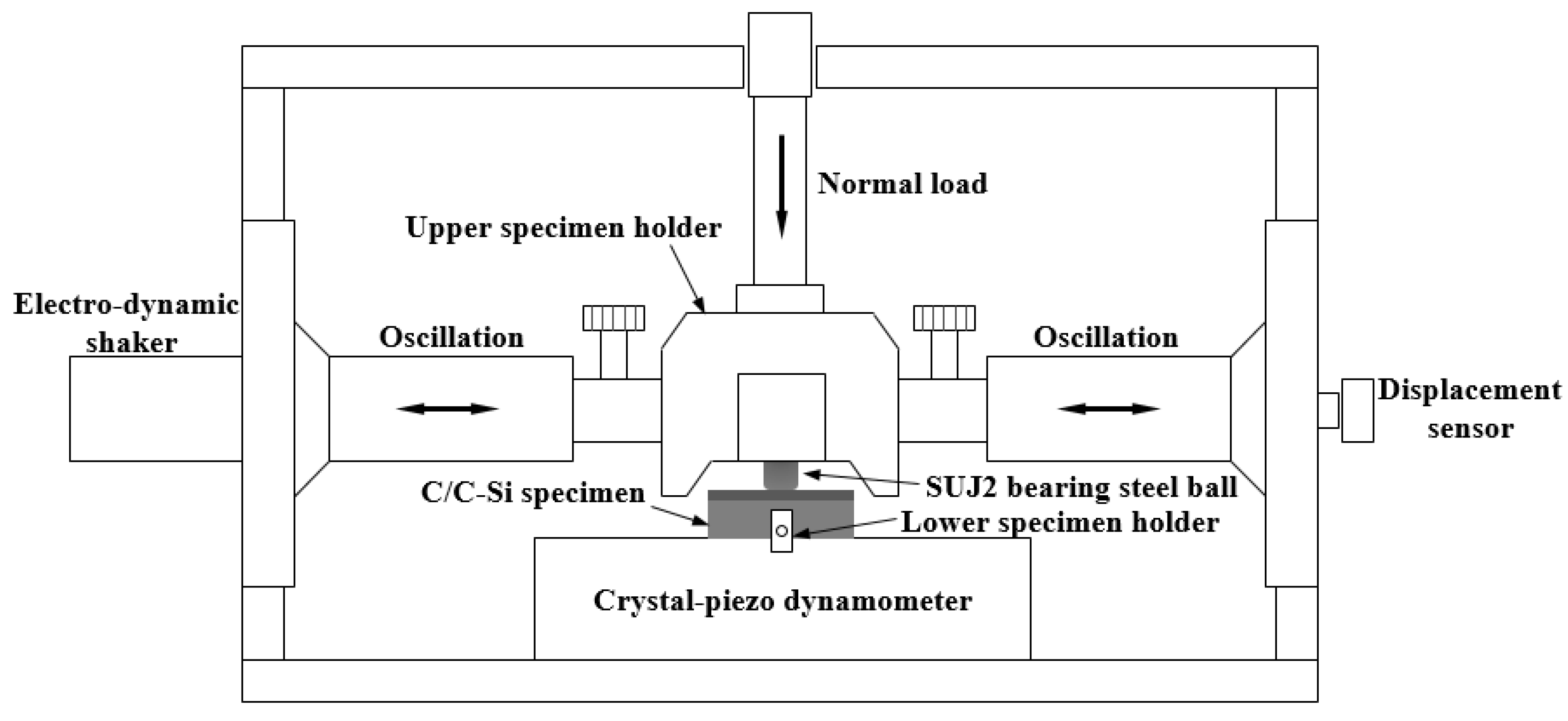

2.2. Friction and Wear Tests

2.3. Material Characterization

3. Results and Discussion

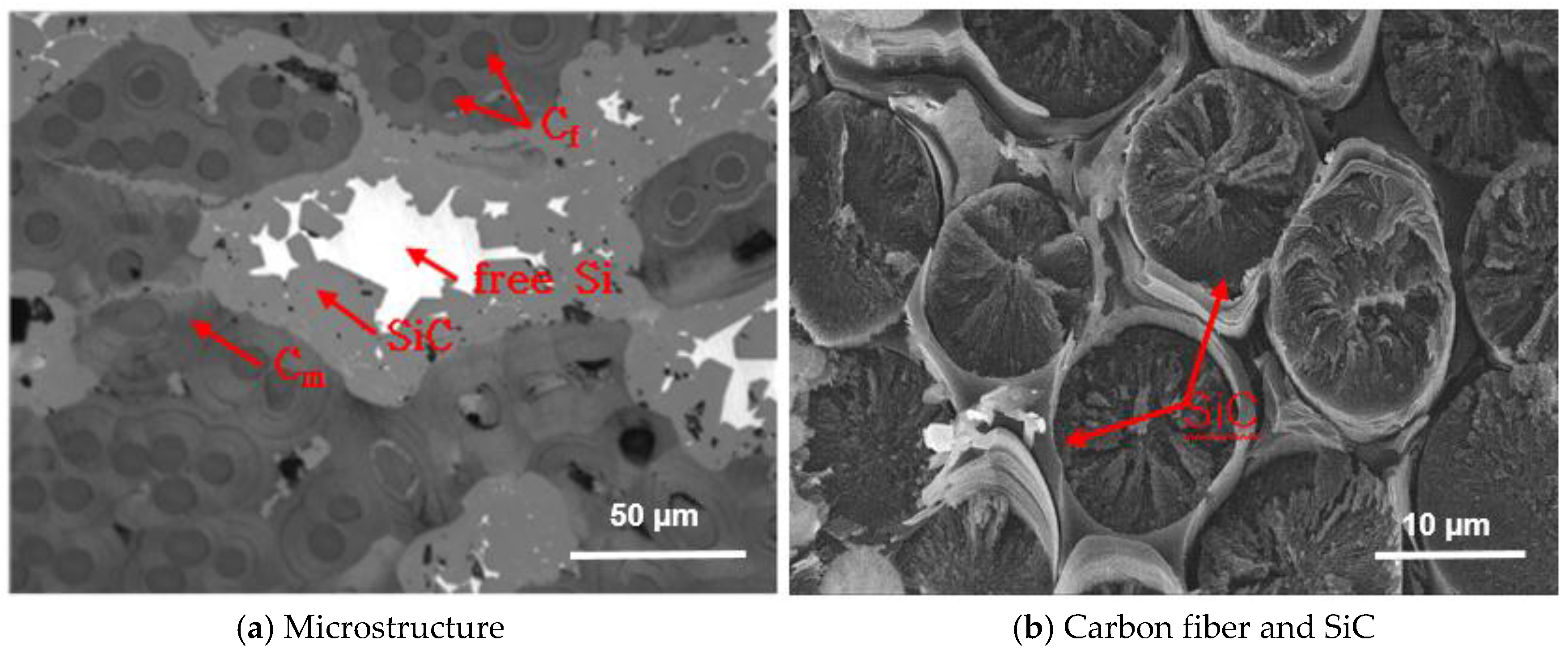

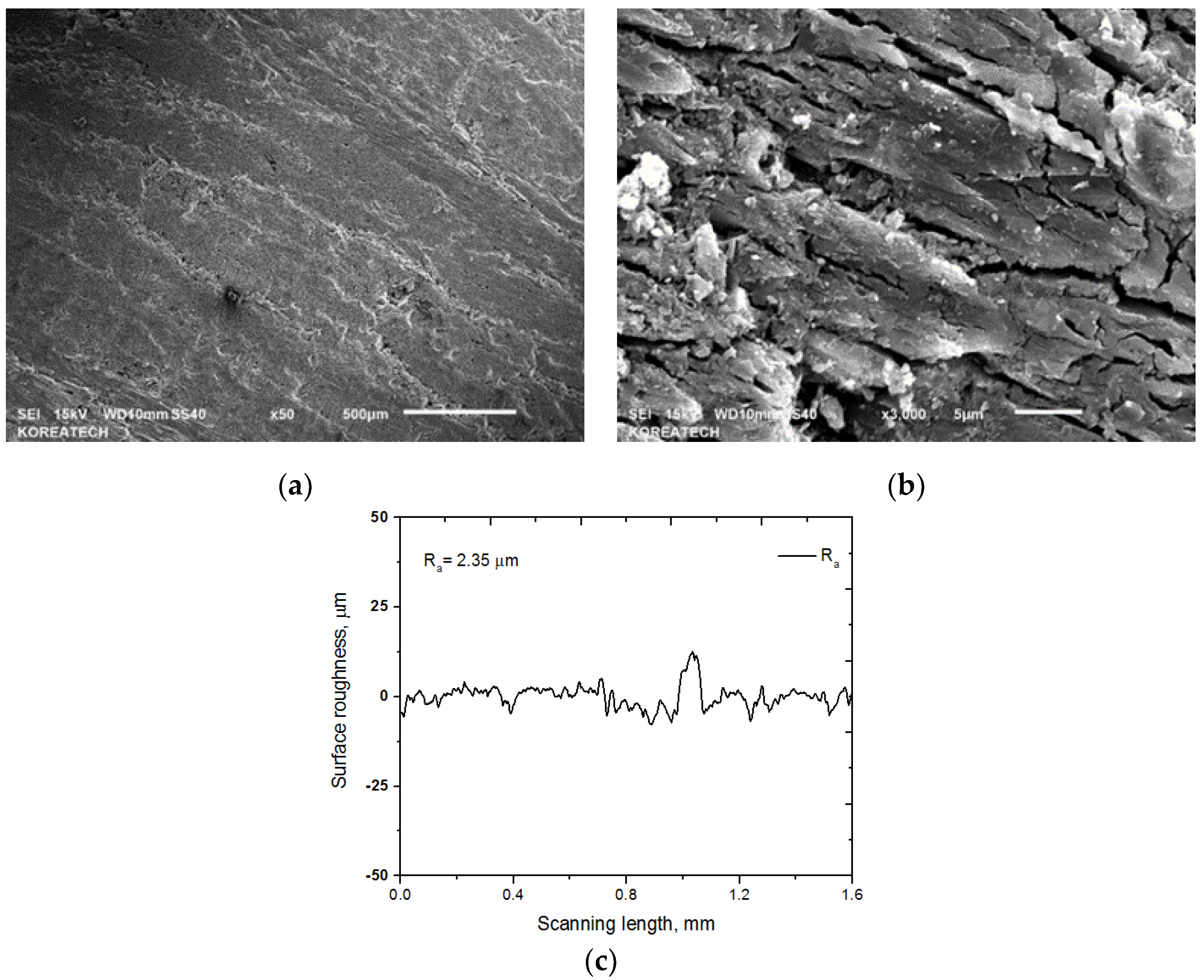

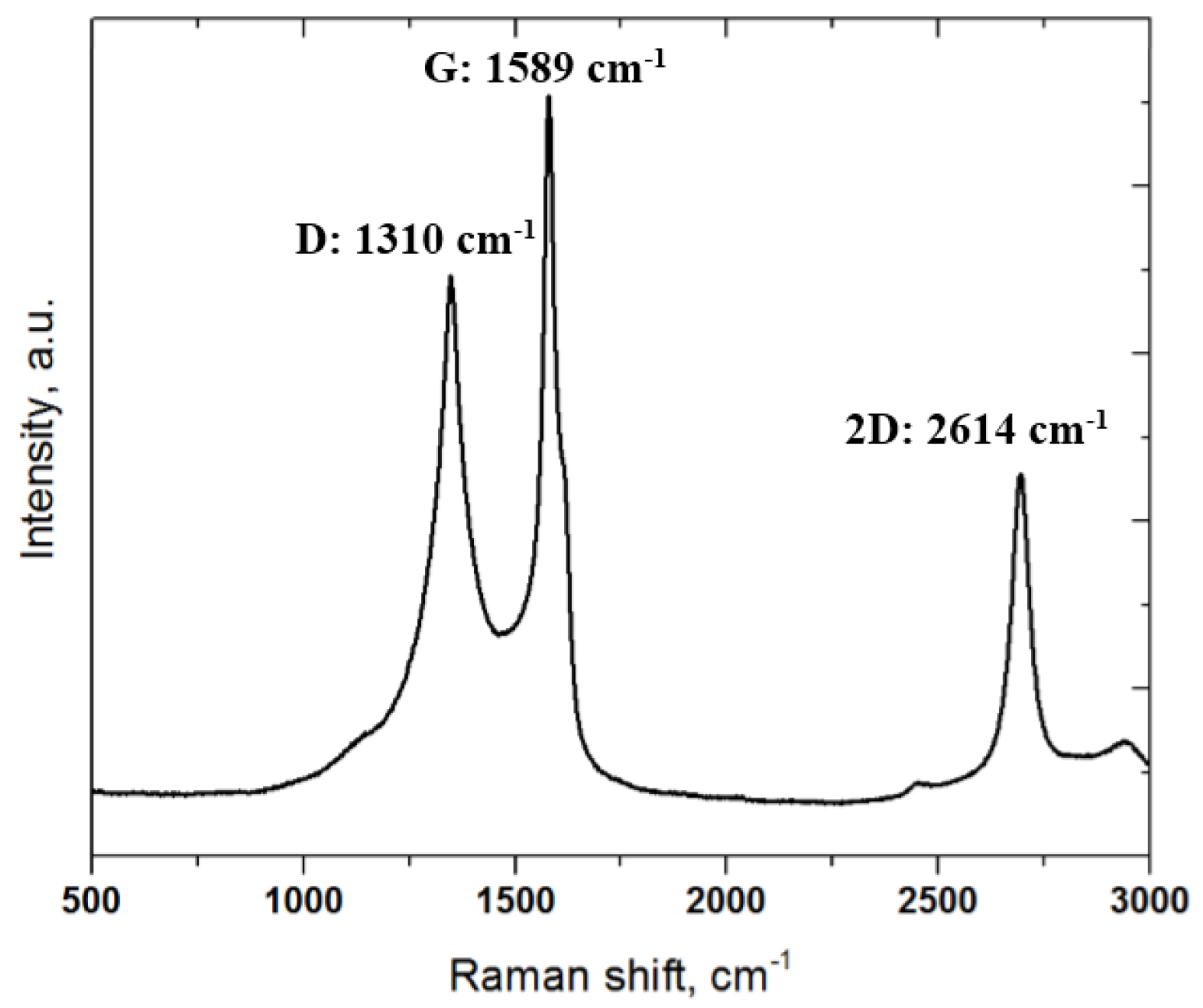

3.1. Surface Characterizations

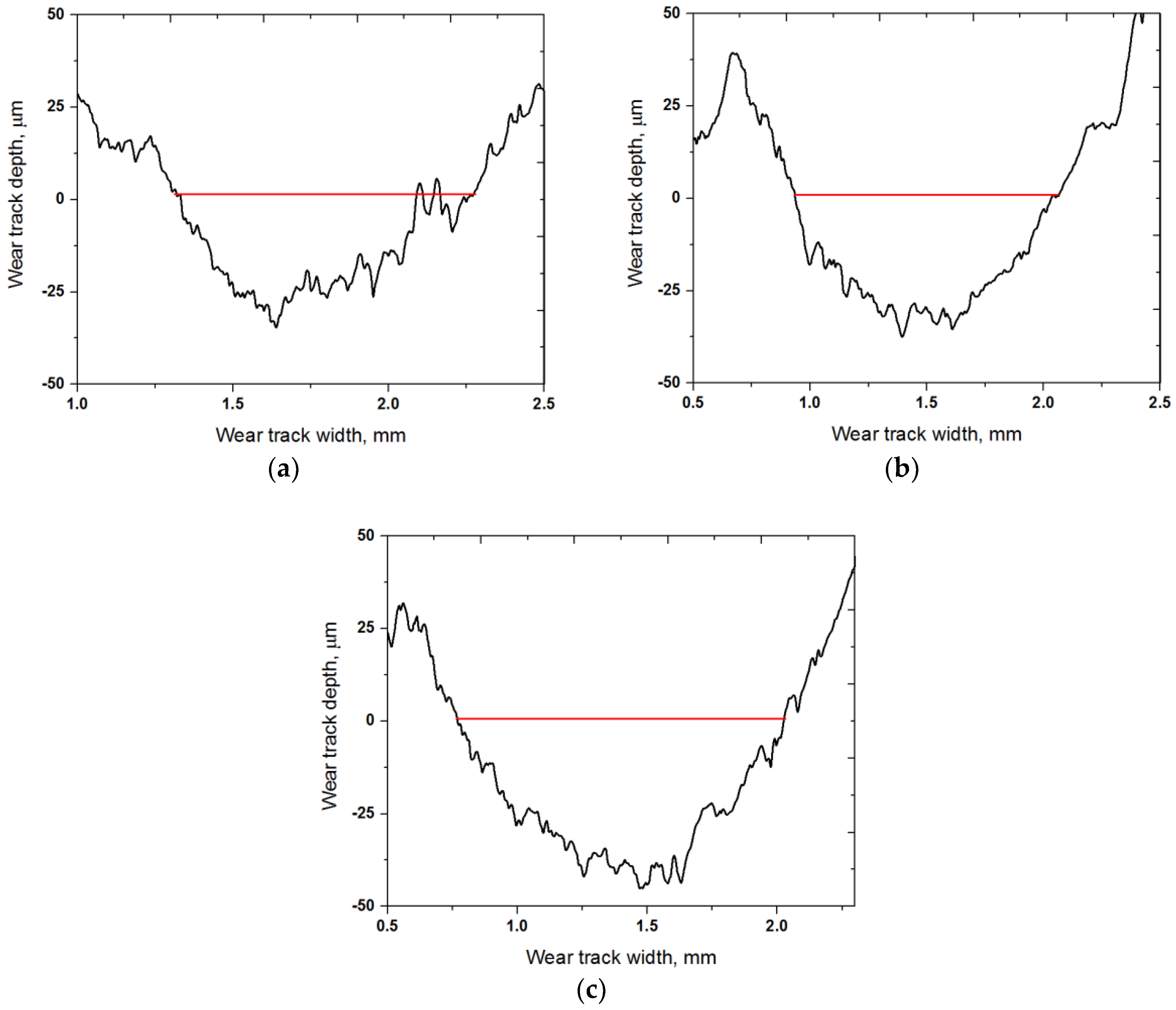

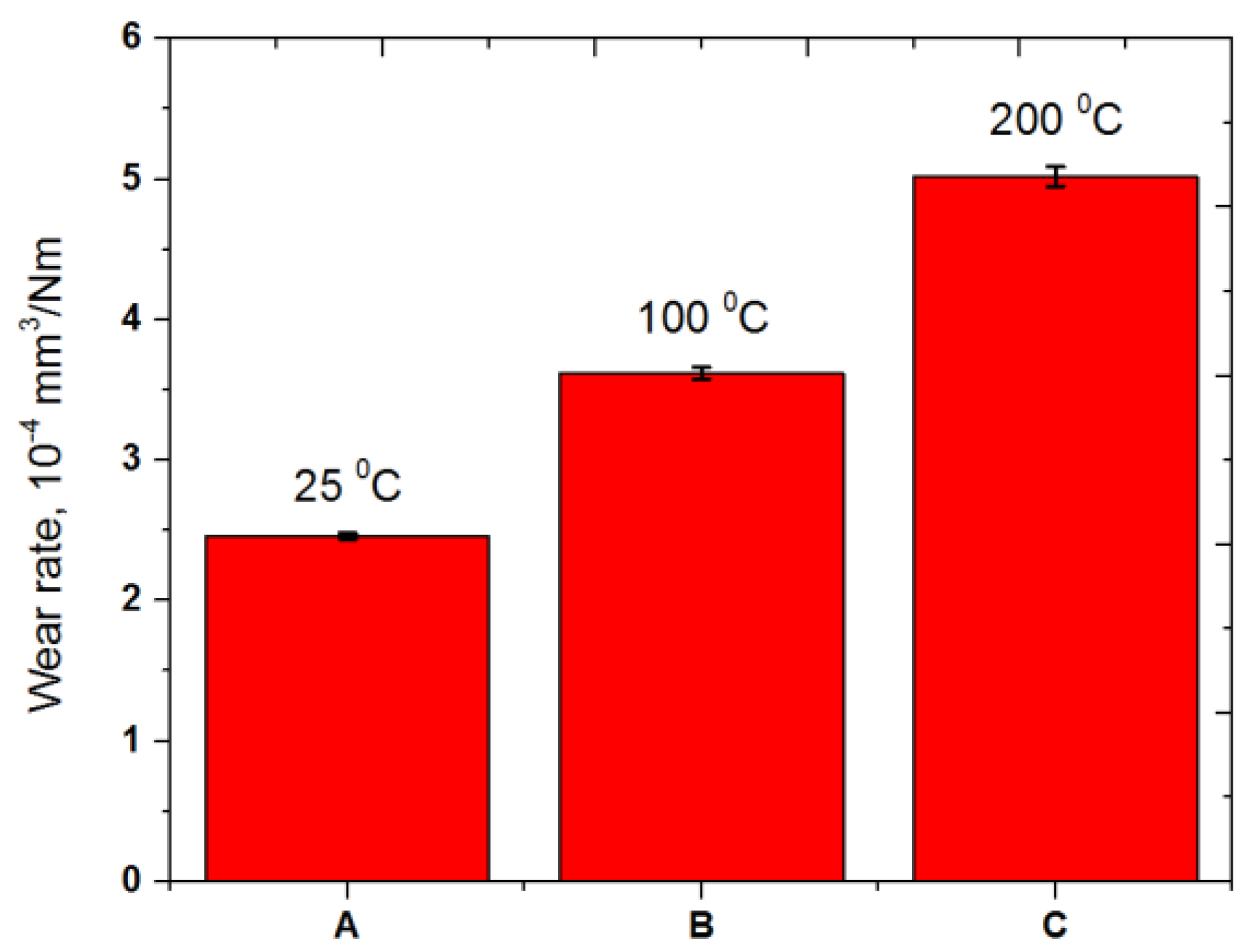

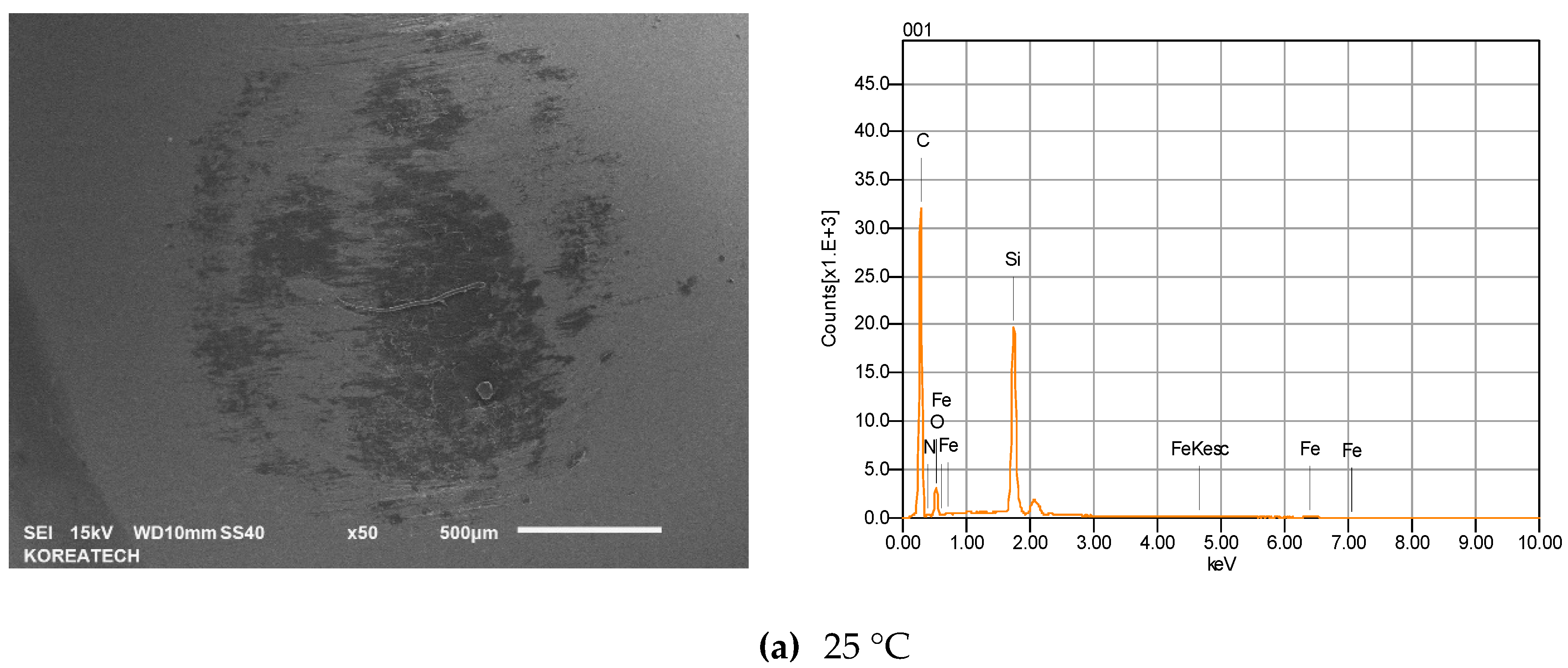

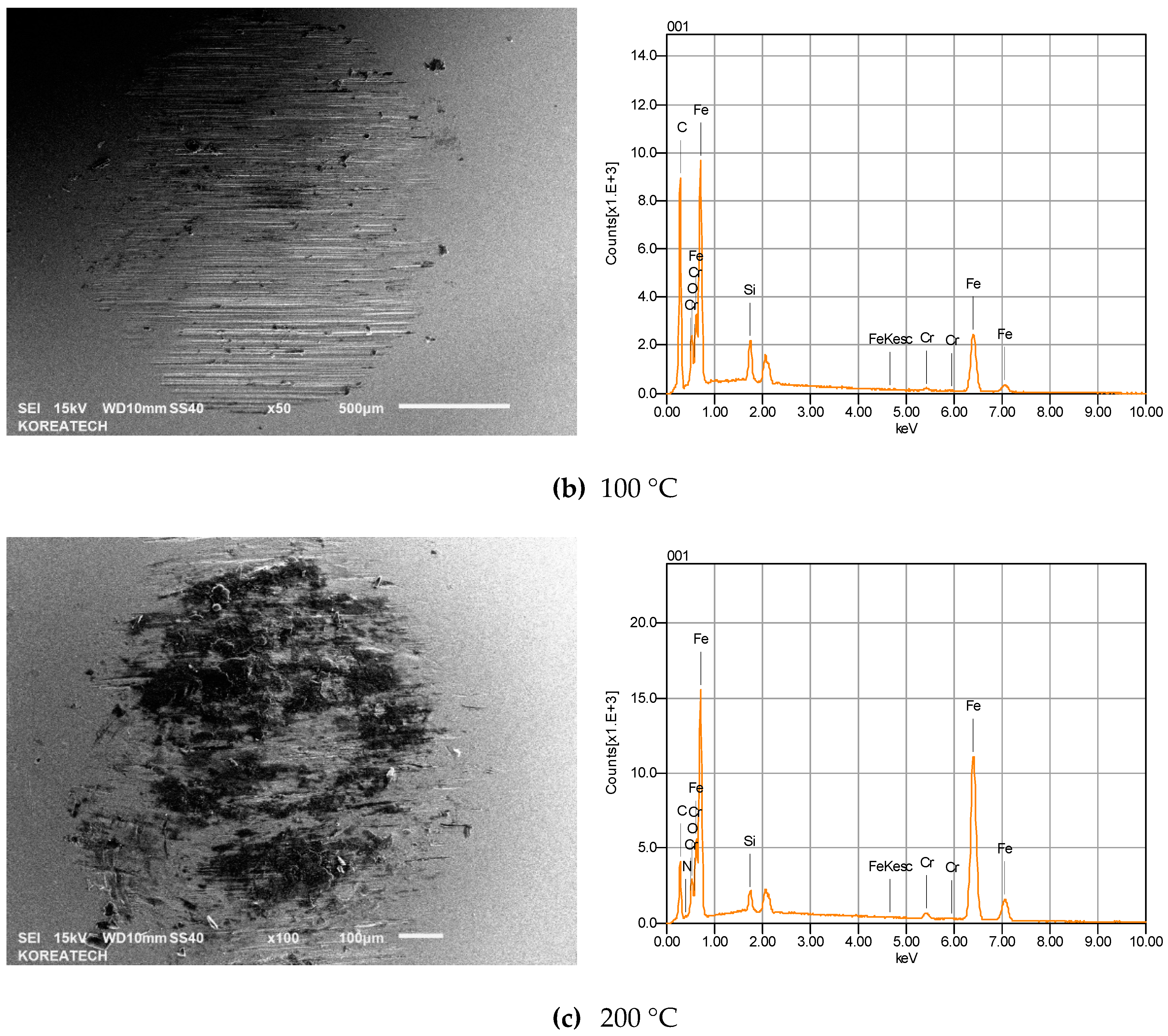

3.2. Friction and Wear Behavior

4. Conclusions

- -

- The average surface roughness of the C/C-SiC specimen before friction and wear tests was found to be 2.35 µm, while the surface hardness was found to be 156 HV. However, it should be noted that the surface roughness values highly depends on the location of the composite due to the presence of pores on the surface.

- -

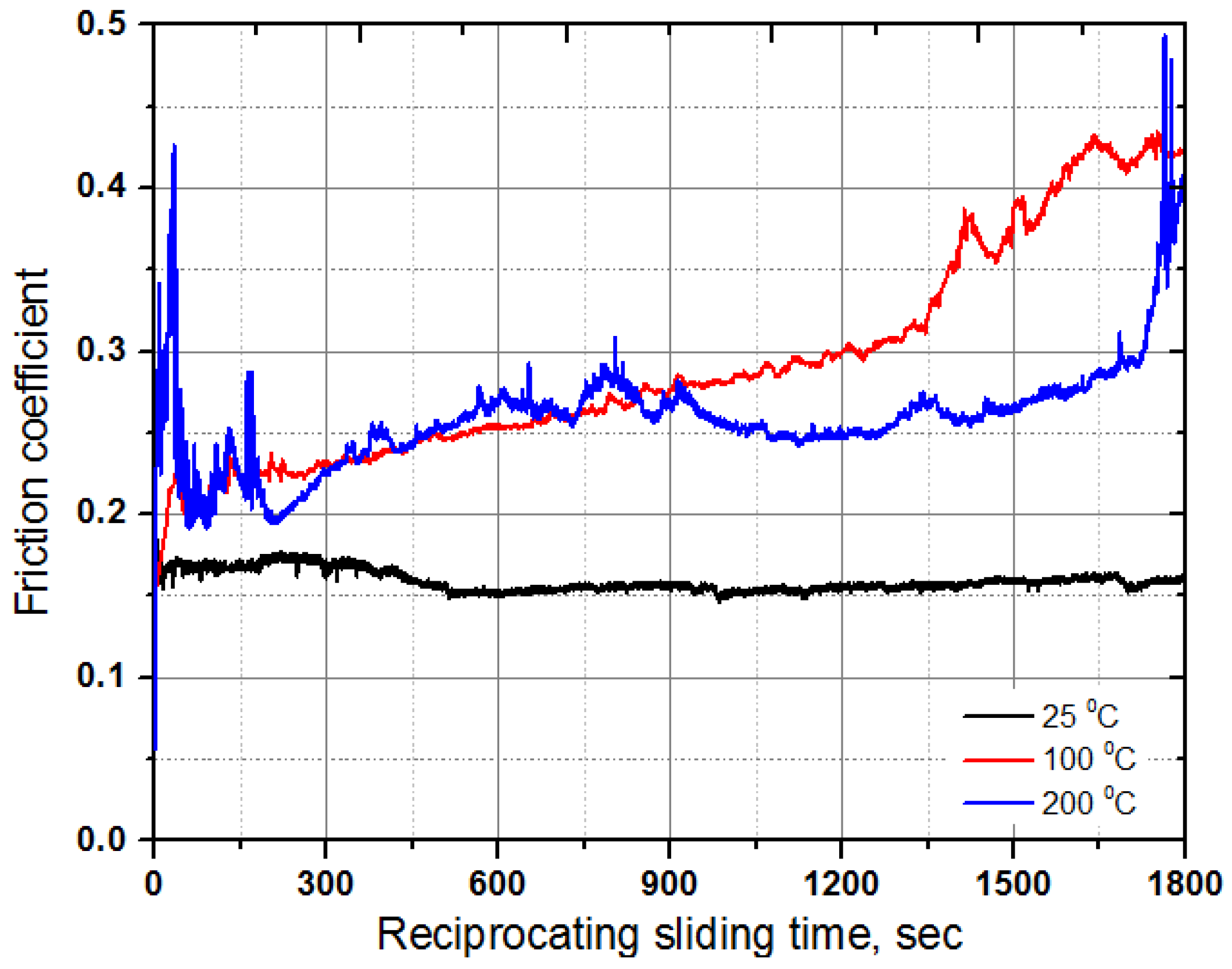

- The friction coefficient of the C/C-SiC specimen at 25 °C was very stable with a value of about 0.16, while the friction coefficients at 100 and 200 °C were unstable. The friction coefficient increased with an increasing temperature in the early period of the test, but after some sliding the friction coefficient at 200 °C was lower than that at 100 °C.

- -

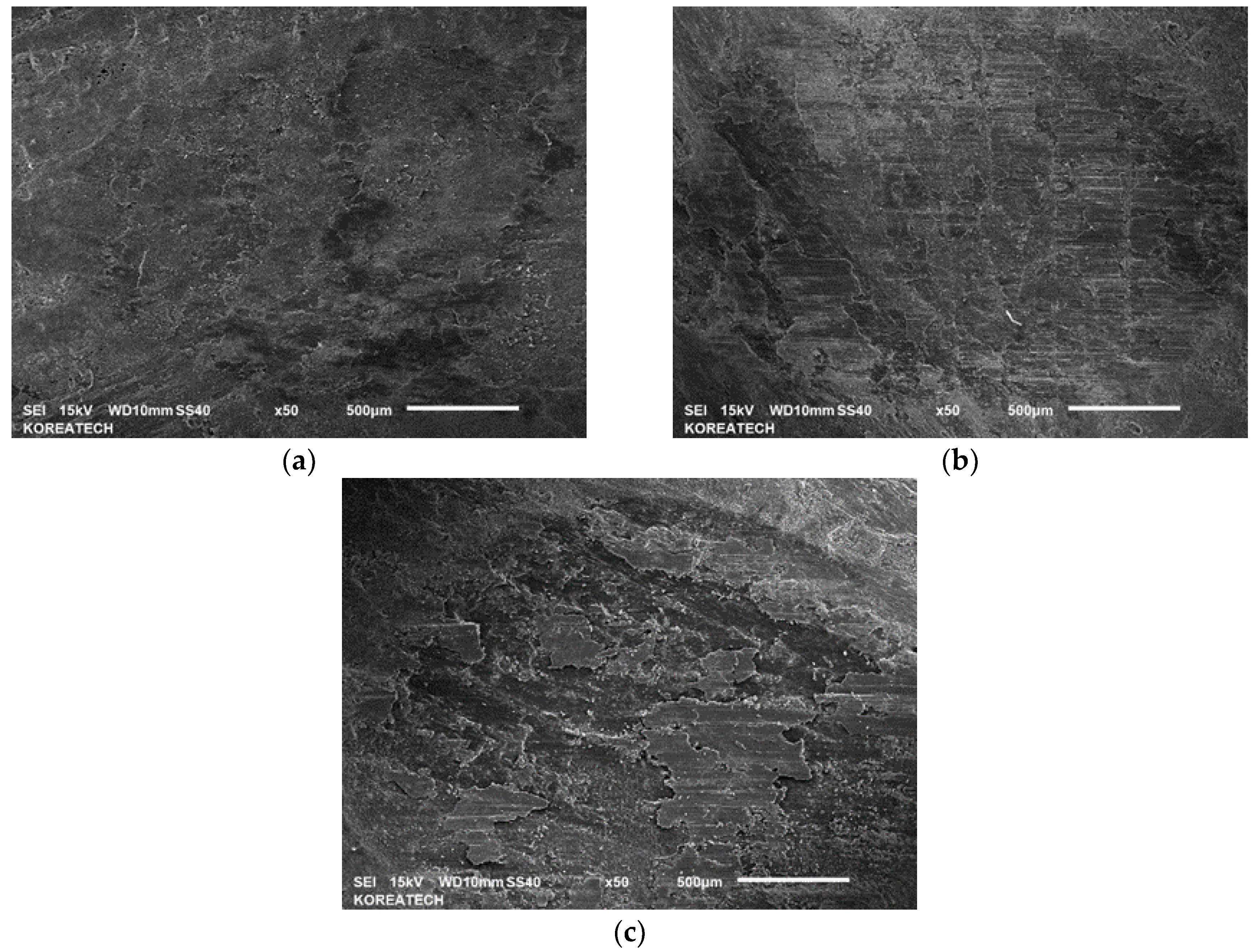

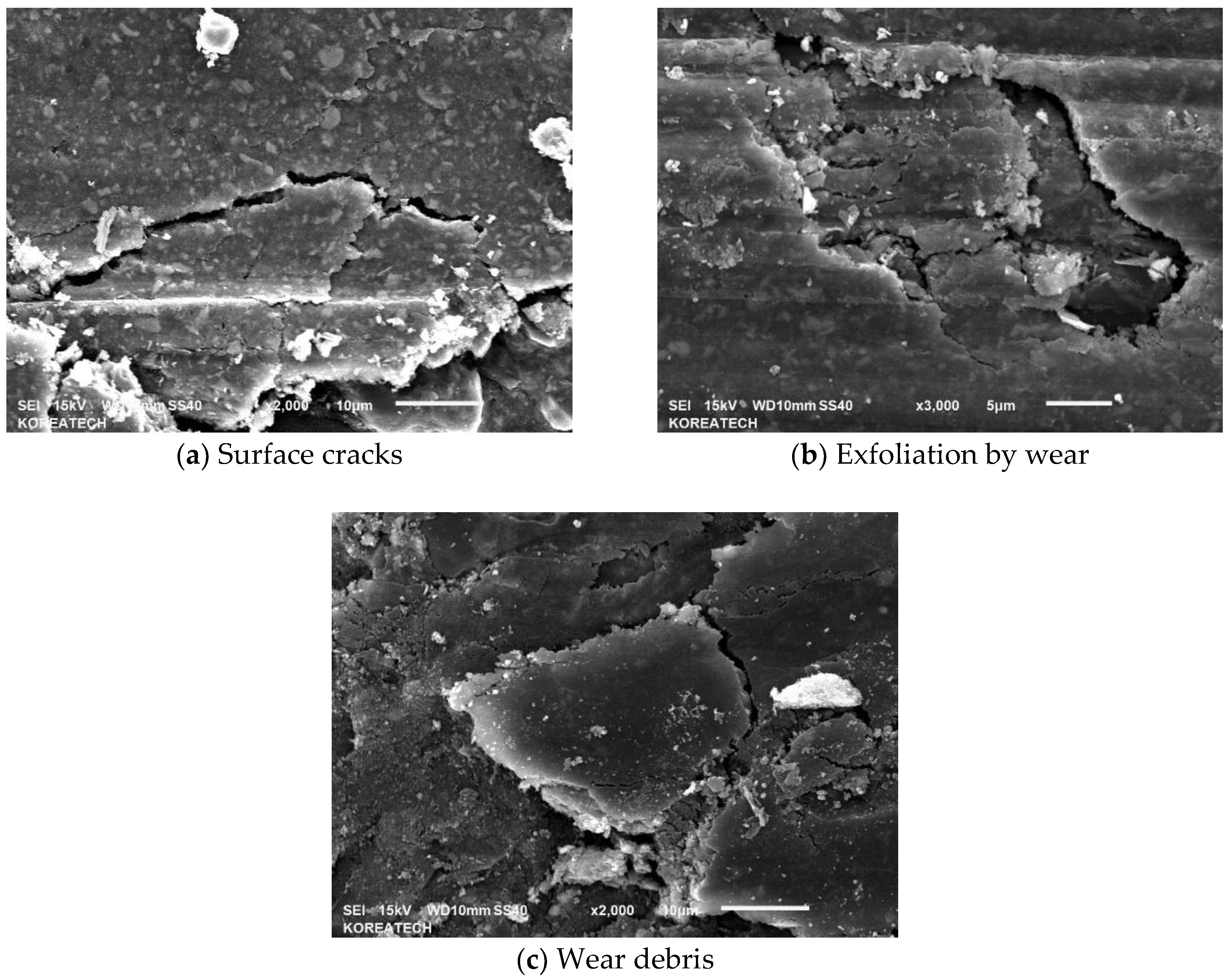

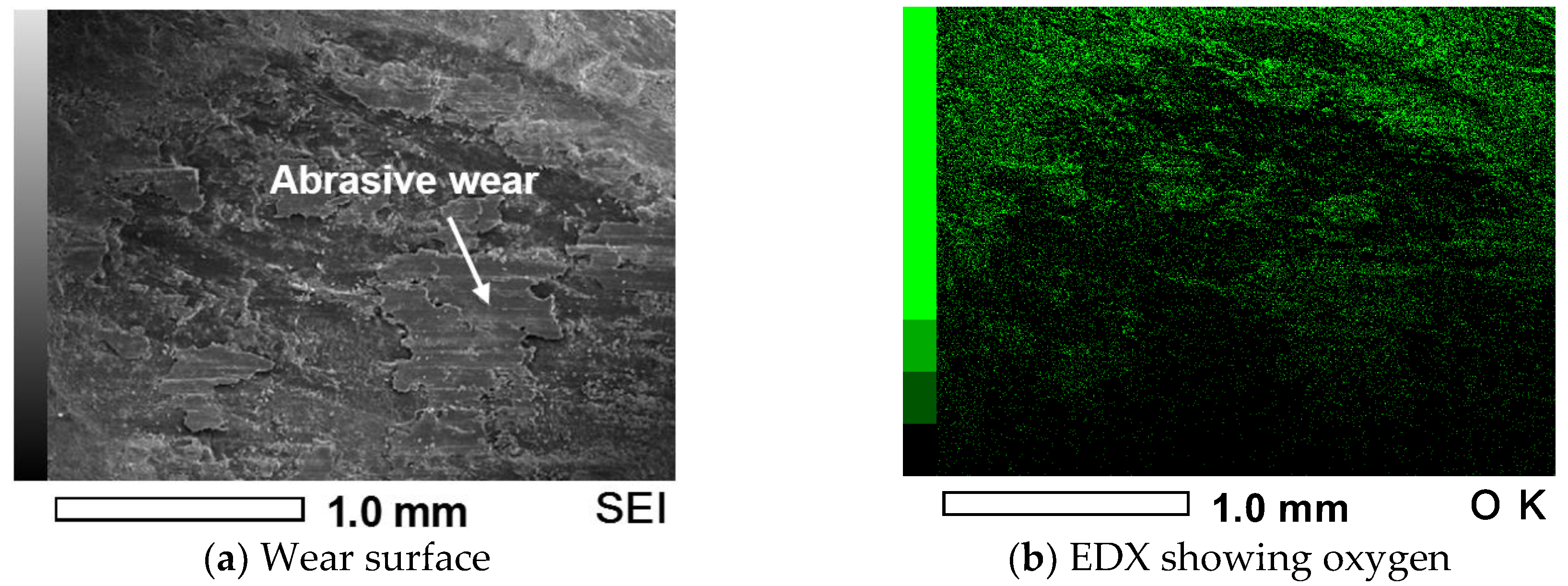

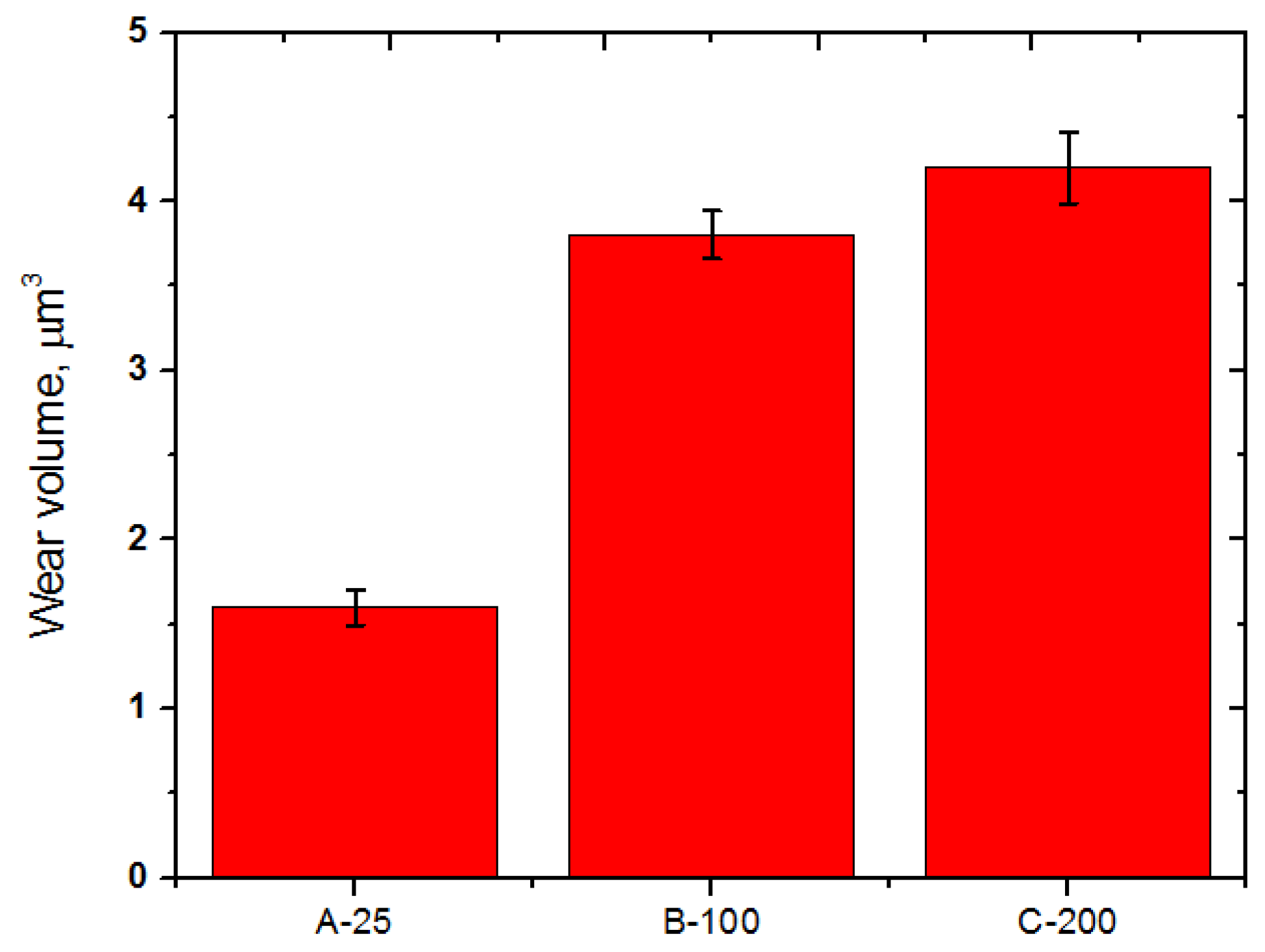

- The wear resistance decreased with an increasing temperature. The wear mechanism of C/C-SiC against SAE52100 steel was revealed to be abrasive mode.

- -

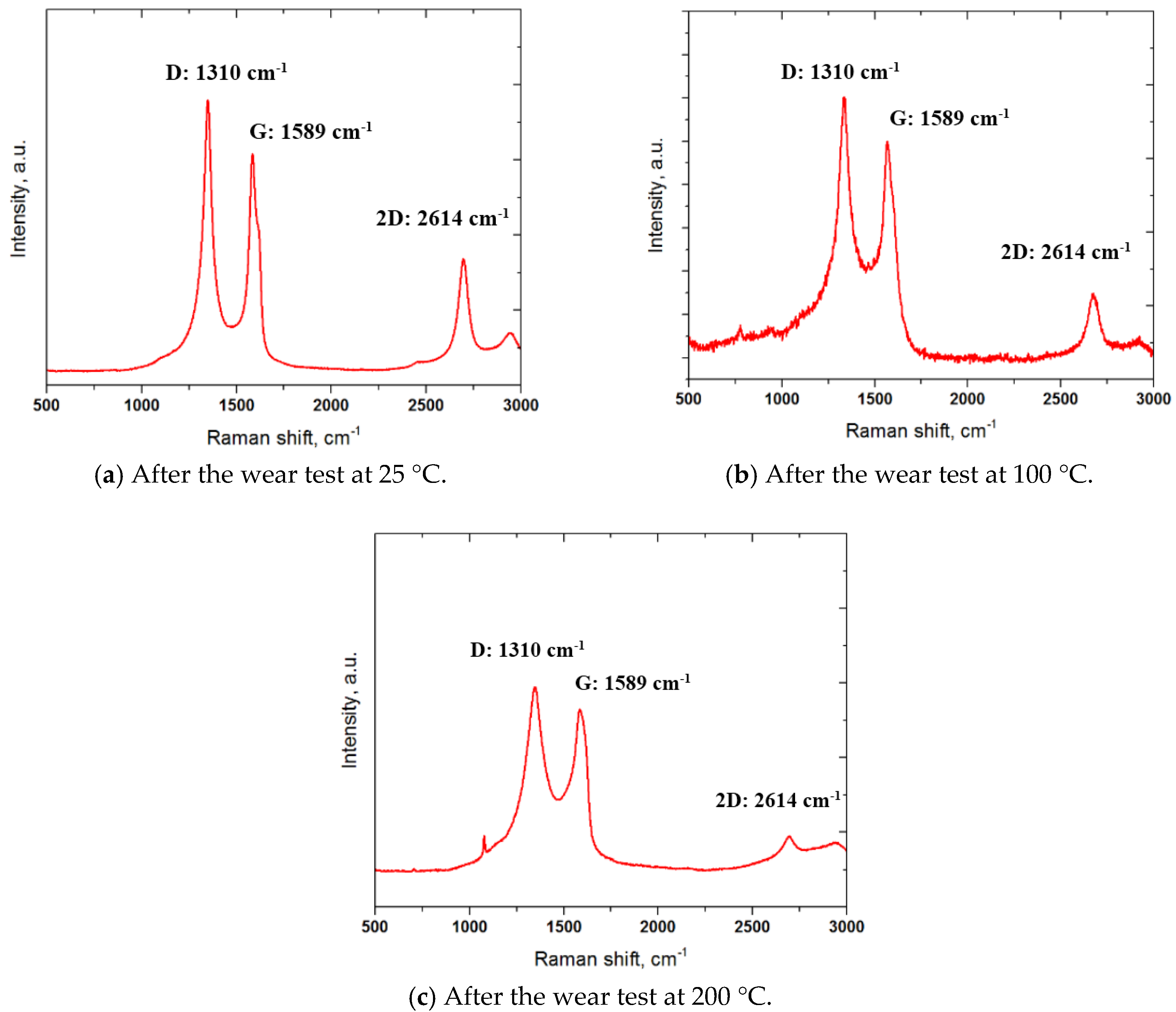

- Raman spectroscopy results revealed that the intensity of the G band was not changed significantly for all the specimens after the friction and wear tests. However, the intensity of D and 2D bands decreased with an increasing temperature.

- -

- It is believed that the developed C/C-SiC composite can be a good candidate for an eco-friendly brake pad.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bijwe, J. Composites as friction materials: Recent developments in non-asbestos fiber reinforced friction materials—A review. Polym. Compos. 1997, 18, 378–396. [Google Scholar] [CrossRef]

- Bian, G.; Wu, H. Friction performance of carbon/silicon carbide ceramic composite brakes in ambient air and water spray environment. Tribol. Int. 2015, 92, 1–11. [Google Scholar] [CrossRef]

- Krenkel, W.; Heidenreich, B.; Renz, R. C/C-SiC Composites for advanced friction systems. Adv. Eng. Mater. 2002, 4, 427–436. [Google Scholar] [CrossRef]

- Ozcan, S.; Filip, P. Wear of carbon fiber reinforced carbon matrix composites: Study of abrasive, oxidative wear and influence of humidity. Carbon 2013, 62, 240–247. [Google Scholar] [CrossRef]

- Eriksson, M.; Jakobson, S. Tribological surfaces of organic brake pads. Tribol. Int. 2000, 33, 817–827. [Google Scholar] [CrossRef]

- Schulte-Fischedick, J.; Zern, A.; Mayer, J.; Ruhle, M.; Frieß, M.; Krenkel, W.; Kochendorfer, R. The morphology of silicon carbide in C/C–SiC composites. Mater. Sci. Eng. A 2002, 332, 146–152. [Google Scholar] [CrossRef]

- Jacko, M.G.; Trang, P.H.S.; Rhee, S.K. Wear debris compaction and friction film formation of polymer composites. Wear 1989, 133, 23–38. [Google Scholar] [CrossRef]

- Morgan, P. Carbon Fibers and Their Composites; Taylor & Francis Group, CRC Press: Boca Raton, FL, USA, 2005; ISBN 9780824709839. [Google Scholar]

- Noda, T.; Fujita, M.; Araki, H.; Kohyama, A. Impurities and evaluation of induced activity of CVI SiCf/SiC composites. Fusion Eng. Design 2000, 51–52, 99–103. [Google Scholar] [CrossRef]

- Buckley, J.D.; Edie, D.D. Carbon-Carbon Materials and Composites; William Andrew: Norwich, NY, USA, 1993; ISBN 978-0-8155-1324-7. [Google Scholar]

- Krenkel, W.; Berndt, F. C/C-SiC composites for space applications and advanced friction systems. Mater. Sci. Eng. A 2005, 412, 177–181. [Google Scholar] [CrossRef]

- Krenkel, W.; Henke, T. Design of high preformance CMC brake discs. Key Eng. Mater. 1999, 164–165, 421–424. [Google Scholar] [CrossRef]

- Fan, S.; Zhang, L.; Cheng, L.; Zhang, J.; Yang, S.; Liu, H. Wear mechanisms of the C/SiC brake materials. Tribol. Int. 2011, 44, 25–28. [Google Scholar] [CrossRef]

- Goo, B.C. Development and characterization of C/C-SiC brake disc. Mater. Manuf. Process. 2016, 31, 979–988. [Google Scholar] [CrossRef]

- Jacko, M.G.; Tsang, P.H.S.; Rhee, S.K. Automotive friction materials evolution during the past decade. Wear 1984, 100, 503–515. [Google Scholar] [CrossRef]

- Maleque, M.A.; Atiqah, A.; Talib, R.J.; Zahurin, H. New natural fibre reinforced aluminium composite for automotive brake pad. Int. J. Mech. Mater. Eng. 2012, 7, 166. [Google Scholar]

- Washer, G.; Blum, F., Jr. Raman spectroscopy for the nondestructive testing of carbon fiber. Res. Lett. Mater. Sci. 2008, 693207. [Google Scholar] [CrossRef]

- Cheng, D.Q.; Wang, X.T.; Zhu, J.; Qiu, D.H.; Cheng, X.W.; Guan, Q.F. Friction and wear behavior of carbon fiber reinforced brake materials. Front. Mater. Sci. Chin. 2009, 3, 56–60. [Google Scholar] [CrossRef]

- Boutaous, A.; Peseux, B.; Gornet, L.; Belaidi, A. A new modeling of plasticity coupled with the damage and identification for carbon fibre composite laminates. Compos. Struct. 2006, 74, 1–9. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S.; Kim, J.H.; Sakai, S. The usability and preliminary effectiveness of ultrasonic nanocrystalline surface modification technique on surface properties of silicon carbide. Appl. Surf. Sci. 2014, 311, 448–460. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Y.; Cheng, L.; Zhang, L.; Lou, J.; Zhang, J. Preparation and friction behavior of carbon fiber reinforced silicon carbide matrix composites. Ceram. Int. 2007, 33, 439–445. [Google Scholar] [CrossRef]

- Xiao, P.; Li, Z.; Xiong, X. Microstructure and tribological properties of 3D needle-punched C/C-SiC brake composites. Solid State Sci. 2010, 12, 617–623. [Google Scholar] [CrossRef]

- Shi, Q.; Xiao, P. Effect of pyrolytic carbon content on microstructure and tribological properties of C/C–SiC brake composites fabricated by isothermal chemical vapor infiltration. Solid State Sci. 2012, 14, 26–34. [Google Scholar] [CrossRef]

- Tuinista, F.; Koening, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095. [Google Scholar] [CrossRef]

| Normal Load (N) | Frequency (Hz) | Stroke (mm) | Sliding Time (min) | Temperature (°C) | RH (%) |

|---|---|---|---|---|---|

| 50 | 10 | 1 | 30 | 25, 100, 200 | 60 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Byeong-Choon, G.; In-Sik, C. Microstructural Analysis and Wear Performance of Carbon-Fiber-Reinforced SiC Composite for Brake Pads. Materials 2017, 10, 701. https://doi.org/10.3390/ma10070701

Byeong-Choon G, In-Sik C. Microstructural Analysis and Wear Performance of Carbon-Fiber-Reinforced SiC Composite for Brake Pads. Materials. 2017; 10(7):701. https://doi.org/10.3390/ma10070701

Chicago/Turabian StyleByeong-Choon, Goo, and Cho In-Sik. 2017. "Microstructural Analysis and Wear Performance of Carbon-Fiber-Reinforced SiC Composite for Brake Pads" Materials 10, no. 7: 701. https://doi.org/10.3390/ma10070701

APA StyleByeong-Choon, G., & In-Sik, C. (2017). Microstructural Analysis and Wear Performance of Carbon-Fiber-Reinforced SiC Composite for Brake Pads. Materials, 10(7), 701. https://doi.org/10.3390/ma10070701