1. Introduction

Ground improvement using stone columns, also known as granular piles or aggregate piers, is one of the most popular techniques to improve soft soils for the foundation of embankments or structures. These are vertical boreholes in the ground, filled upwards with gravel compacted by means of a vibrator.

The idea of improving soft soils for foundation purposes using granular inclusions is relatively old. It is documented [

1] that in 1839 in Bayonne (France), the French colonel Burbach used for the first time sand piles as deep foundations instead of the classical wood piles that rapidly degrade with fluctuations of the ground water level. However, it was not until the 50 s of the last century when stone columns started to be used. The ground improvement technique started as an extension of traditional vibro-compaction (deep compaction) to non-granular soils, whose low permeability and cohesion do not allow for a quick rearranging of soil particles in a denser configuration.

Stone columns act mainly as inclusions with a higher stiffness, shear strength and permeability than the natural soil. Consequently, they improve the following aspects:

The reduction of the liquefaction potential is beyond the scope of the present paper. Please refer to [

2,

3] for further information on that topic. The present paper focuses on the other four improvements, particularly, the settlement reduction. The modeling strategy for stone columns should be chosen depending on which of the previous improvements is to be analyzed.

In extremely soft soils, stone columns are not suitable because their continuity, stability, geometric shape, etc. cannot be guaranteed. The undrained shear strength (

) of natural soft soil is generally used as the limiting parameter for stone column feasibility. A limiting value around 5–15 kPa [

4] may be adopted. To improve the lateral confinement of stone columns in those extremely soft soils, encasing the columns with geotextiles or other geosynthetics, such as geogrids, has proven to be a successful technique in recent times (e.g., [

5]). Rigid or semi-rigid inclusions (e.g., adding lime or cement) is another common alternative (e.g., [

6,

7]). Han [

8] summarizes different ground column technologies.

Ground improvement using stone columns, either ordinary or encased stone columns, requires a considerable amount of columns or, at least, a group of columns. This implies a complex modeling process of the real geometry. This paper provides some guidelines for obtaining these simplified geometrical models. Some other features related with column modeling are also briefly presented, such as the critical length of the column and the influence of column installation. Additionally, some guidance and recommendations are provided on parameter selection to study stone columns. Here, the word “modeling” is understood in a broad sense, covering geometrical, mechanical, geotechnical and installation features of stone columns.

The increase in computer power and the availability of finite element codes makes numerical analyses very appealing in geotechnical design. They usually lead to more detailed studies but require a clear conception of the modeling techniques. Ground improvement techniques, such as stone columns, are more and more popular due to the increasing occupation of natural soft soils and environmental concerns [

9,

10]. Within these current trends, the review of the modeling techniques for stone columns seems interesting and useful. Besides, in some instances, there is some confusion about geometrical models and their application. For example, the results for an isolated column under concentrated load just on top of the column cannot be directly extrapolated for a large group of columns under distributed uniform load.

2. Geometrical Models

To simplify the real geometry of the problem that usually involves a considerable amount of columns (e.g.,

Figure 1a) and to be able to deal with the problem, the following simplified geometrical models are usually adopted:

The two latter cases, namely “unit cell” under triaxial conditions and isolated column, do not usually appear in real problems, but they have been used for laboratory tests (e.g., [

11,

12,

13]). The case of an isolated column is widely used for field tests (usually plate load tests) for the sake of simplicity (e.g., [

14]).

As a simple introductory comparison between the different geometrical models,

Table 1 summarizes the suitability of some of these models to study the improvements achieved with a stone column treatment for the foundation of an embankment.

All the geometrical models listed above are valid for non-encased stone columns. However, for encased stone columns, there is not yet any satisfactory way to convert the cylindrical encasement (geosynthetic) that surrounds the column for the cases of longitudinal gravel trenches and cylindrical rings of gravel.

3. Unit Cell

The unit cell model is the most widely used for theoretical analyses and it is reviewed in detail, for example, in [

15]. The basis for the simplified model is the usage of a great number of columns, uniformly distributed in a wide area under a uniform load. This is the case, for example, in the central part of an embankment on soft ground improved with stone columns. In these situations, the behavior of all the columns is the same and then, it is enough to study the behavior of just one column with the corresponding surrounding soil (tributary area). Due to symmetry conditions, at the external lateral boundary of the unit cell, only vertical displacements and only vertical water seepage are allowed.

Stone columns are generally uniformly distributed in triangular or square grids. Thus, the tributary area of natural soil for each column is a hexagon or a square, respectively. To allow for axial symmetry conditions, the tributary area is transformed into a circle (cylinder) of the same (cross-sectional) area. Therefore, the diameter of the unit cell is equal to

for triangular and square grids, respectively, where

is the centre-to-centre distance between columns (

Figure 2).

Figure 3 shows the unit cell model with axial symmetry that can be studied in two dimensions.

The unit cell model is used for most of the existing analytical solutions (e.g., [

16,

17]). In the analytical solutions, there is usually a further simplifying assumption for the geometry, which is to assume that the behavior of each horizontal slice is independent, i.e., the shear stresses are neglected. Numerical analyses [

17,

18] show that shear stresses are usually negligible for distributed loads. Balaam and Booker [

19] is a notable exception to the simplifying assumption of neglecting shear stresses because they study the total length of the unit cell as a whole. Nevertheless, the solution requires numerical integration, which makes the solution complex for practical purposes.

Most analytical solutions focus on the settlement reduction caused by stone columns (e.g., [

16,

17,

19]), but stone columns also act as vertical drains and, therefore, they dissipate excess pore pressures. The consolidation process may be studied independently from the settlement analysis using solutions for vertical drains [

20,

21]. Han and Ye [

22] and Castro and Sagaseta [

23] showed that the consolidation process around stone columns is slightly different because of the distribution of vertical stresses between soft soil and stone columns and they proposed specific analytical solutions to study the consolidation process around stone columns. Very recently, Pulko and Logar [

24] have developed a fully coupled solution for the consolidation process assuming the soil as a poroelastic medium and the stone column as an elastoplastic material. The solution is very accurate but requires numerical inversion of the Laplace transform.

Extending analytical solutions for ordinary stone columns to encased stone columns is quite straightforward (e.g., [

25]). Equilibrium and compatibility conditions of the geosynthetic encasement are those of a thin-walled tube, or better said, those of a flexible membrane because the encasement does not usually support compressive stresses. The internal and external pressures are here denoted as

and

, respectively (

Figure 4). Thus, the equilibrium and compatibility conditions of the geosynthetic encasement are the following, respectively:

where

is the radial displacement of the column and the encasement,

is the hoop or circumferential stiffness of the geosynthetic and

is the hoop force at the geosynthetic. The units of

and

are force per length (

F/

L) because the thickness of the geosynthetic is usually negligible. The equation that relates the radial stress of the column (

) with that of the soft soil (

) and allows the confining effect of the encasement to be included is obtained by combining Equations (1) and (2):

The unit cell model is also very useful for numerical analyses because numerical simulations allow more complex features to be studied than with the analytical solutions, such as layered ground, advance constitutive models or cyclic loads (e.g., [

26,

27,

28,

29]). Nowadays, 3D numerical codes are fairly easy to access and to use; so, there are some authors that study the unit cell as a full 3D problem, i.e., considering the hexagonal or square prism. Nevertheless, the differences between the full 3D prism and the two-dimensional (2D) model (cylinder) in axial symmetry are negligible [

30,

31]. The simplicity of the unit cell model has recently led to highly advanced numerical models, such as that presented by Indraratna et al. [

32], where the column is modelled using 2D discrete elements to represent the gravel particles. This type of numerical analysis can be regarded only as explorative and for research purposes. The unit cell model or the model of a slice of the unit cell at a specific depth are also used for small-scale laboratory studies (e.g., [

33,

34]).

The unit cell also allows floating columns to be studied, i.e., columns that do not reach a rigid substratum. In this case, the settlement due to column punching into the underlying layer and the deformation of the underlying layer should be considered [

35]. The unit cell model is only valid when the ratio between the width of the loaded area and the thickness of the soft soil layer (

) is high enough to ensure confined (oedometric) conditions. On the contrary, the applied load is distributed with depth, in a roughly trapezoidal manner, its value decreasing with depth.

Figure 5 presents some specific proposals of load distribution width depth for end-bearing and floating columns [

36,

37,

38]. The unit cell model for these cases usually overestimates the settlement because the reduction of the applied vertical stress with depth is not reproduced.

Finally, the unit cell is an appropriate simplified geometrical model to study the settlement and its evolution with time at the center of an embankment, but obviously it is not valid for studying the stability of the lateral slopes (

Table 1). For similar reasons, it does not allow the lateral spreading and the contribution of a geosynthetic reinforcement that acts as a “blanket” or “bridging layer” over the columns and soft soil foundation (geosynthetic reinforced and column supported embankments, GRCSE) to be studied [

31]. To study the lateral spreading of the embankment, the unit cell model may be improved by substituting the horizontally-fixed external lateral boundary by elastic springs [

39].

6. Gravel Rings

The idea of transforming the stone columns into gravel rings, tubes or cylindrical trenches follows the same concept as for the longitudinal gravel trenches (

Section 4) but for problems with axial symmetry rather than plane strain conditions. Thus, the model is used for problems with axial symmetry, such as circular embankments or circular storage tanks. The model implies the transformation of each group of columns into an equivalent gravel ring with the same area to keep

constant (

Figure 11). In the case of

Figure 11, the 8 neighboring columns of the central column are transformed into an equivalent ring with a thickness (

) that gives the same area. Assuming that

is small enough, its value is:

The distance of the gravel ring to the central point (

) is the weighted average of the distance of the 8 columns to the center.

For a group of only 4 columns, the weighted average is directly

[

58]. The proposal of other authors [

59] is slightly different and implies that the gravel ring surrounds the same area as that of the square formed by the 8 columns:

For practical purposes, the differences are negligible.

Mitchel and Huber [

58] seem to be the first authors to use this model. They used it in combination with the finite element method to study a field case (the foundation of a water treatment plant). Contrary to the model of the longitudinal gravel trenches, here the confining conditions of the gravel rings seem to be somehow similar to those of the stone columns and it is enough to maintain the values of

and of the drained properties of the soil and the columns to obtain satisfactory results [

60,

61]. As for the longitudinal gravel trenches, there is not yet any satisfactory way to convert the cylindrical encasement (geosynthetic) that surrounds the columns for this case.

8. Isolated Column

For the sake of simplicity, some experimental tests, either in the field or in the laboratory, are performed on an isolated or single stone column (e.g., [

63,

64]). The load is usually applied only on the column surface (

Figure 14a) or on an area slightly higher than the column. In these cases, the area replacement ratio (

) may be defined as the ratio between the area of the column and the loaded area or the footing footprint area [

61]. Thus, for isolated columns,

is usually around 100%, which is not a realistic situation because it is more efficient to increase the loaded area (

<< 100%) [

61]. Loading the surroundings of the columns is beneficial because it increases the horizontal stresses at the lateral boundaries of the columns and increases their confinement.

The results of research performed on isolated columns are sometimes directly extrapolated to other cases, leading to some confusion and non-accurate predictions. Some authors (e.g., [

15] (p. 28)) show that the column bulges (or notably expands radially) at their upper part, specifically at an upper zone with a length of two or three times the column diameter (2–3

). Hughes and Withers [

63] measured a length of 4 column diameters for the upper bulging zone for an isolated column (

= 100%) through laboratory tests. That is valid for cases with load only on the single column, i.e.,

. In the next section, it will be shown that for other cases, it is more meaningful to define the bulging zone using the footing width (

) instead of the column diameter [

61] because in those cases, the column bulging may be deeper [

3] (p. 114) [

15] (p. 28) (

Figure 14). Besides, the failure mechanism of the columns may not be bulging, for example, it may be shearing [

65].

Isolated columns are generally used to study their bearing capacity. The maximum vertical stress that a stone column may bear is usually given as:

where

is the undrained shear strength of the surrounding soft soil. Equation (9) is derived assuming that the column is in an active state with an active earth pressure coefficient of around

= 1/3 and that the radial cavity expansion factor is around 6–8 (e.g., [

63,

66]). Equation (9) is strictly valid for isolated columns with

= 100%, but when used for larger loaded areas, it is conservative because it neglects the increase in the radial stress due to vertical loading of the soil surrounding the column. Besides, Equation (9) assumes perfect undrained conditions for the soil surrounding the column and some drainage could be expected near the granular column. For common cases, Equation (9) gives a vertical load supported for each stone column of 20–50 tons [

15] (p. 6). Sometimes, field tests are performed to check the exact vertical load supported by one isolated column with

= 100%. The approach of considering the bearing capacity of a footing as the sum of the contribution of each column may usually be overconservative. For footings, an improvement for field tests (plate load tests) on an isolated column may be achieved by using a larger loaded area, so

is the same as in the footing [

3] (p. 165).

9. Groups of Columns

Stone column treatments are traditionally used beneath large loaded areas, such as embankments, but they are also used beneath footings, when the applied loads are not high [

67]. For these cases, the homogenization technique is valid [

68]. Besides, the plane strain model using gravel trenches (

Figure 1c) is also valid for strip footings. On the other hand, when the footing could be converted into a circular footing (e.g., a square footing), the simplified geometrical model in axial symmetry that uses gravel rings is also applicable [

60,

61] (

Figure 15). For the latter case (i.e., axial symmetry conditions), the author has recently proposed an additional simplified model that assumes that all the columns may be converted into a central column with the same area (

Figure 15d), keeping

constant [

61]. The main advantages of this model are that it may be used to developed analytical solutions [

38] and that it is also applicable to encased columns. For encased columns, it is also necessary to transform the elastic properties of the encasement, so that the factor

is kept constant [

69]. The validity of this central column model for small groups of columns is based on the small influence on the footing settlement (usually less than 10%) of the number of columns and their position beneath the footing [

61]. This simplified central column is only valid to study the footing settlement and should not be used for other features, such as the consolidation process or the bending moments in the footing.

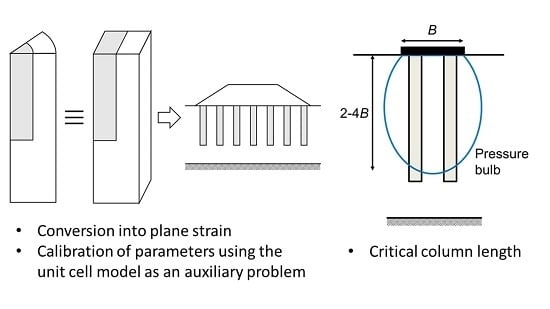

10. Critical Column Length

The concept of critical length is used for stone columns as in piles (e.g., [

65]). Thus, for columns longer than the critical length, the settlement reduction or the bearing capacity of the footing does not notably change or improve. For non-encased stone columns, the critical length of the columns for settlement reduction is around

[

61,

70]. The critical length for encased columns is usually higher, around

for common situations [

69]. The main controlling parameter of the critical column length is the extension of the load, i.e.,

, but the specific value of the critical column length also depends on other parameters, such as

and the soil and column properties [

61,

65,

69,

70].

It is worth noting that many authors (e.g., [

71,

72,

73,

74]) give critical lengths as a function of the column diameter, but the column length to diameter ratio has a minor influence by itself [

61,

69]. The origin of the misinterpretation could lie in the fact that the first proposals [

63,

64] were for the case of an isolated column with load only on the column surface, i.e.,

.

For settlement reduction, the critical column length is related to the pressure bulb that the footing generates (

Figure 16a), while for footing bearing capacity, the critical length depends on the failure mechanism (

Figure 16b). As the critical length for settlement reduction is longer, that is usually the considered value. For large loaded areas (high values of

), the critical column length is higher than the soft layer thickness, and consequently, the concept of critical or optimal length does not apply.

The mechanisms in

Figure 16 also explain the influence of additional columns outside the footing. Columns outside the footing are crossed by the slip line or failure mechanism; so, they contribute to the bearing capacity. On the contrary, they hardly influence the settlement reduction if they are outside the pressure bulb. The only minor beneficial effect for the settlement reduction is that they distribute the applied load over a slightly wider area. Therefore, when the bearing capacity is defined in terms of a critical settlement, the effect of extra columns outside the footing is only marginal [

65].

The presented analysis on critical column length is based on a homogeneous soft soil layer; for layered soils, this analysis is not directly applicable.

11. Column Installation Effects

Column installation alters the surrounding soil, especially when the columns are installed by vibrodisplacement. However, it is commonly accepted that in a stone column treatment, installation effects are less significance and the main improvement is caused by the inclusion of gravel. The search for more accurate designs has led to more detailed analyses of the installation effects [

75,

76,

77,

78]. Notable excess pore pressures are consistently measured in the field due to column installation [

79]. However, in most cases, these pore pressures quickly dissipate [

80]. Column installation, especially by vibrodisplacement, also leads to an increase in the horizontal stresses [

75]. This is usually quantified through the earth pressure coefficient,

[

3,

75,

76]. The increase in effective mean stress leads, in turn, to an increase in the soft soil stiffness [

3] (p. 138).

The excess pore pressures and the remolding caused by column installation lead to an instantaneous reduction of the undrained shear strength just after installation [

77,

81]. As the pore pressures dissipates and the effective mean stress increases, the value of the undrained shear strength recovers and usually increases above its initial value [

77,

81]. Special care must be taken with soil remolding in sensitive soils [

67,

77]. Poker vibration is necessary for proper column compaction, but excessive use of the poker with many repenetrations (“overworking”) may result in high excess pore pressures and disturbance of sensitive or overconsolidated soil layers, such as a dry, stiff upper crust that is common is soft soils and is beneficial for load distribution [

79].

The remolding caused by column installation also alters the permeability of the soft soil in the vicinity of the column. This zone, whose permeability is lower than the natural soft soil, is usually called the “smear” zone [

82,

83]. The properties of the smear zone, specially its size and permeability, have been largely studied for vertical drains [

84,

85,

86]. Another related problem is column clogging [

83]. Gravel compaction during column installation and the high hydraulic gradients at the soil-column interface inevitably produce a migration of clay particles into the pores of the granular column, notably reducing the permeability of an external annulus of the column. This phenomenon is normally less important in geosynthetic encased columns because the geosynthetic usually acts as a filter.

The introduction of installation effects in the numerical modeling of stone columns is a complex process. Some attempts have been made using field measurements and back-fitting the results [

75] or using previous numerical analyses that simulate column installation as a cylindrical cavity expansion [

78]. From a practical point of view, column installation may be considered altering the at-rest earth pressure coefficient of the natural soft soil. Priebe’s theoretical solution [

16] considers, for example, a value of 1. Published values [

59] vary between 0.4 and 2.5, with average values slightly above 1. Obviously, the earth pressure coefficient after column installation should depend on the initial value, the construction method and the type of soil. Finally, if the numerical model does not consider a stress-dependent constitutive model for the soft soil, its stiffness should be increased correspondingly [

76].

12. Properties of the Columns

The modeling process of the soft soil is beyond the scope of this review and it is broadly analyzed elsewhere (e.g., [

87,

88]). Some authors [

79,

89] warn about the importance of secondary compression in some soils and the limited capacity of stone columns to reduce it. Gravel properties are also well-analyzed (e.g., [

90,

91,

92]), but the properties of the gravel for stone columns are not so readily available nor are they generally measured for each project. For stone columns, the gravel should be clean, preferably crushed stone, hard, unweathered, free from organics or other deleterious materials and its degradation using the Los Angeles testing machine should be less than a 45% of loss [

15] (p. 117). Its grain size should be between 12 and 75 mm. For bottom feed columns, the maximum size is usually limited to 50 mm to avoid obstructions in the feeding tube.

The relative density of the gravel in the stone columns is not usually measured and it may vary along the length of the column, in a similar manner as the column diameter. A proper stone column construction should achieve relative densities of the gravel above 75% [

15]. Herle et al. [

93] measured values close to 100%.

The friction angle of the columns (

) has a notable influence on the results of a stone column treatment. Its value decreases with the confining pressure (

). Using samples in a dense state, Herle et al. [

93] measure values up to 60° for low confining pressures (

= 50 kPa) and values around 50° for medium confining pressures (

= 200 kPa) (

Table 2). However, when choosing a value of the friction angle to model stone columns, it is necessary to consider the following points:

The Young’s modulus of the columns is usually between 25 and 100 MPa (

Table 3) and it also varies with the confining pressure. A hyperbolic power law is sometimes used to reproduce the stress dependent stiffness of the gravel of the columns (e.g., [

58,

95,

96]). The common value of the exponent of the power law is around 0.3 (

Table 3). The unit weight of the gravel does not require further comment, except for the cases where the columns do not reach a rigid substratum and they are installed by vibrodisplacement (e.g., [

49]). In those cases, the addition of gravel and its corresponding weight may cause additional deformation in the underlying layer that is not improved with stone columns. For example, [

49] used non-realistic high values, namely

= 23.5 kN/m

3 to account for this effect.

Regarding encased stone columns, the material used to construct them is usually sand instead of gravel. The available information is more limited, but it seems obvious to use lower values of both the friction and dilatancy angles (

Table 4).

13. Modeling the Geosynthetic Encasement

As shown in

Figure 4, the geosynthetic encasement may be modeled as a flexible membrane that does not support compressive stresses, has a negligible thickness and behaves as a linear elastic material with a modulus of

= 1000–5000 kN/m. Regarding its tensile strength, for modeling purposes, it may usually be enough to verify that it is far from being reached. The tensile strength is usually reached for circumferential strains of around 5–10%, which implies strength values of 100–300 kN/m [

5]. It is common that geosynthetic may be anisotropic and then different properties should be input for each direction.

Some other geosynthetic features, such as creep and damage during installation, are usually considered through reduction factors. Recent numerical analyses [

99] model numerically the creep behavior of geosynthetics.

In those numerical analyses where the geosynthetic is modeled as a continuum element of small thickness, it is necessary to ensure that it does not support compressive stresses, and hence, bending moments. Its Young’s modulus should be divided by its thickness.

Little attention is usually paid to the Poisson’s ratio of the geosynthetic (

), but it may have important consequences on the results [

100]. When the encasement is modeled as a membrane, it is common to study the two directions of the geosynthetic independently, without interaction between them (Equation (3)). That means

= 0.

On the other hand, when the geosynthetic is modeled as a continuum element, it is necessary to specify a value for

. In some cases (e.g., [

31]), a common value of 0.3 is input. That implies that, although the geosynthetic that surrounds the columns does not support compressive stresses in the vertical direction, it compresses vertically (vertical strains) and then, that vertical compression leads to a radial expansion of the geosynthetic (horizontal or circumferential strains) due to Poisson’s effect. Thus, the geosynthetic encasement decreases its lateral confinement to the column due to this radial expansion. Common geosynthetics for column encasement are woven geotextiles. For woven geotextiles, the two directions work nearly independently; so, it seems logical to use values of the Poisson’s ratio close to 0. Soderman and Giroud [

101] propose values of

= 0.1 for woven geotextiles and

= 0.35 for non-woven geotextiles.

14. Conclusions

This paper reviews the main modeling techniques for stone columns, both ordinary or non-encased stone columns, and geosynthetic-encased stone columns. The paper tries to encompass the more recent advances and recommendations in the topic.

There exist several simplified geometrical models. The suitability of each of them depends on the type of process to be studied, e.g., bearing capacity or settlement, and the type of analyses, e.g., analytical or numerical in 2D or 3D. For numerical analyses of a problem that fulfils plane strain conditions but for the stone column treatment, such as an embankment for a linear infrastructure, the simplified geometrical model of a three-dimensional slice of columns is recommended because it does not require any transformation of the problem parameters. For more simplified models for the stone column treatment, such as gravel trenches or homogenization, calibrating or tuning the parameters using the unit cell as an auxiliary problem is recommended. The model of an isolated column with load just on top of it may be useful for field tests, but it is not a common situation in real cases because loading the soil that surrounds the column is beneficial. The behavior of an isolated column is different from that of a column within a large group under distributed load. Those differences should be considered when extrapolating results.

For groups of columns, the critical column length depends mainly on the loading area. For non-encased columns, its value is around twice the footing width and for encased columns is slightly higher.

Some guidance is provided to consider installation effects and to model the column and the geosynthetic encasement. Column installation usually increases the horizontal stresses and that is often accounted for using a high value of the earth pressure coefficient, typically around 1. On the other hand, the relevance of the Poisson’s ratio of the geosynthetic is taken into account and an appropriate value for a woven geotextile could be close to 0, i.e., the two directions work nearly independently.

Finally, laboratory tests are not commonly performed to characterize stone column properties and some column parameters published in the literature are tabulated as a reference.