Evaluating the Tensile Properties of Aluminum Foundry Alloys through Reference Castings—A Review

Abstract

:1. Introduction

2. Reference Castings for Testing Tensile Behavior

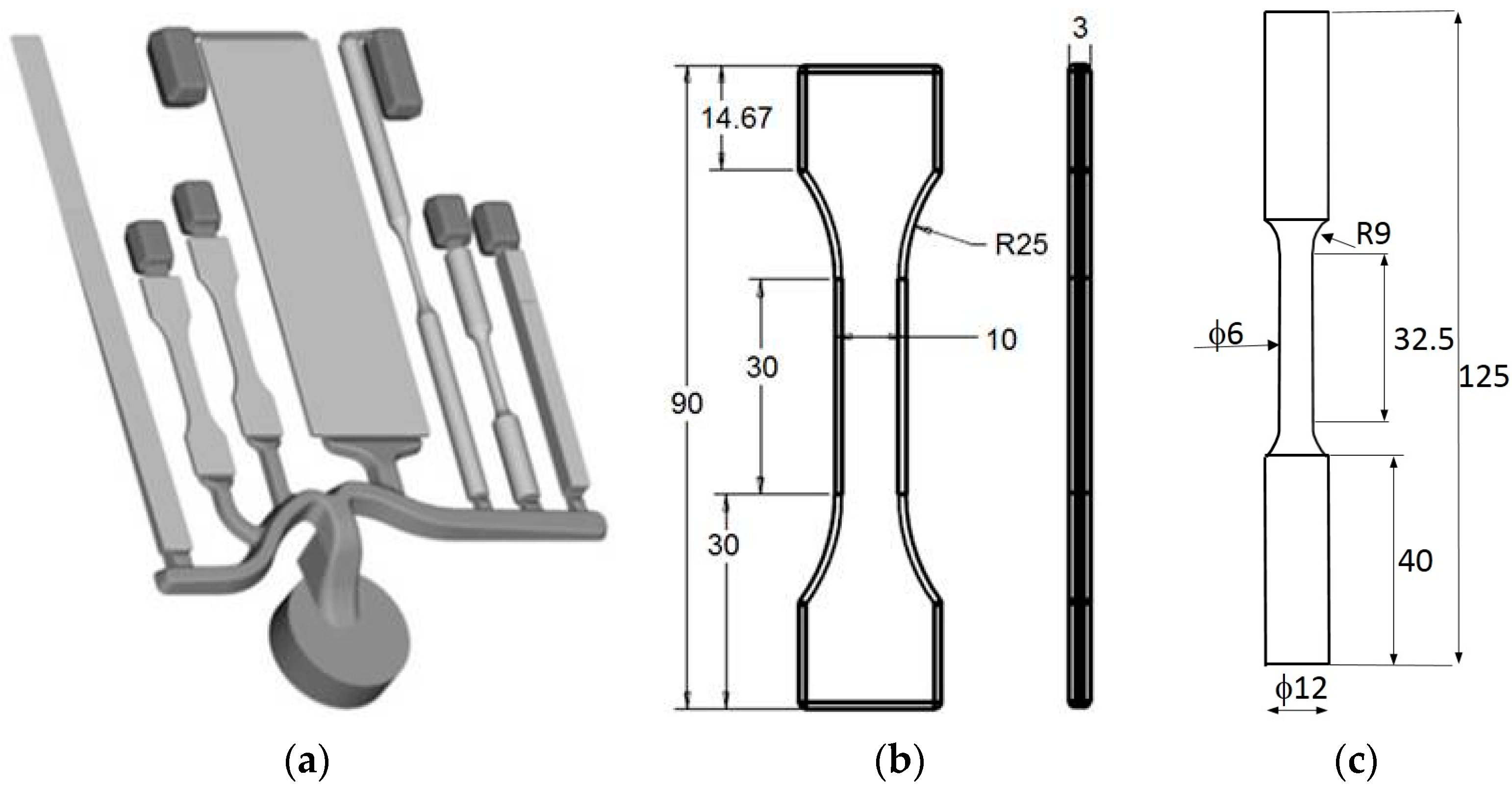

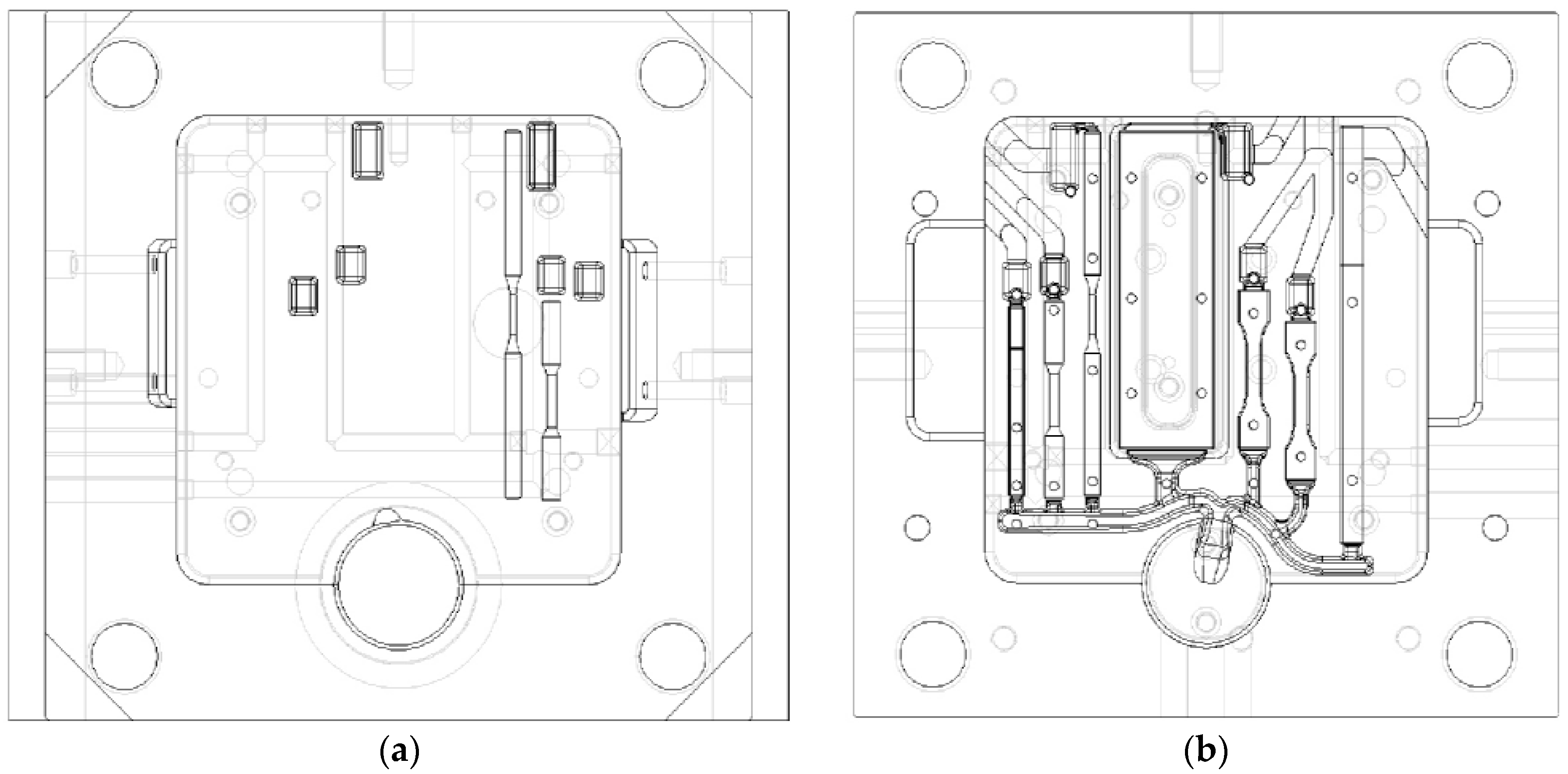

2.1. Reference Castings for High-Pressure Die-Cast Al-Si Alloys

2.2. Reference Castings for Gravity Die-Cast Al-Si Alloys

3. Results on the Expected Tensile Strength of Al-Si Alloys Cast in Permanent Mold

3.1. Expected Tensile Strength of High-Pressure Die-Cast Alloys

3.2. Expected Tensile Strength of Gravity Die-Cast Alloys

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Technical Committee CEN/TC 132. Aluminium and Aluminium Alloys. Mechanical Potential of Al-Si Alloys for High Pressure, Low Pressure and Gravity Die Casting; CEN/TR 16748; CEN: Brussels, Belgium, 2014. [Google Scholar]

- UNI EN 1706. 2010. Available online: http://www.menozzi.eu/resources/Normativa-UNI-EN-1706.pdf (accessed on 25 July 2017).

- Bonollo, F.; Fiorese, E.; Timelli, G.; Arnberg, L.; Adamane, A.R. StaCast project: From a survey of European aluminium alloys foundries to new standards on defect classification and on mechanical potential of casting alloys. In Proceedings of the 71st World Foundry Congress (WFC 2014): Advanced Sustainable Foundry, Bilbao, Spain, 19–21 May 2014. [Google Scholar]

- Timelli, G.; Bonollo, F. Aluminium Alloy Castings: The EU StaCast Guide to Defects Classification, Mechanical Potential and Design Issues; Assomet ServiziSrl, AIM—AssociazioneItaliana di Metallurgia: Milano, Italy, 2014; ISBN 978-88-98990-00-9. [Google Scholar]

- Adamane, A.R.; Arnberg, L.; Fiorese, E.; Timelli, G.; Bonollo, F. Influence of injection parameters on the porosity and tensile properties of high-pressure die cast Al-Si alloys: A review. Int. J. Metalcast. 2015, 9, 43–53. [Google Scholar] [CrossRef]

- Adamane, A.R.; Fiorese, E.; Timelli, G.; Bonollo, F.; Arnberg, L. Reference dies for the evaluation of tensile properties of gravity cast Al-Si alloys: An overview. Mater. Sci. Forum 2014, 794–796, 71–76. [Google Scholar] [CrossRef]

- Khan, M.A.; Sheikh, A.K. Simulation tools in enhancing metal casting productivity and quality: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1799–1817. [Google Scholar] [CrossRef]

- Timelli, G.; Ferraro, S.; Grosselle, F.; Bonollo, F.; Voltazza, F.; Capra, L. Mechanical and microstructural characterization of diecast Aluminium alloys. Metall. Ital. 2011, 103, 5–17. [Google Scholar]

- Timelli, G.; Grosselle, F.; Voltazza, F.; Della Corte, E. A new reference die for mechanical properties evaluation in die-casting. In Proceedings of the 4th International Conference High Tech Die Casting, Montichiari, Italy, 9–10 April 2008; p. 35. [Google Scholar]

- Timelli, G.; Fabrizi, A. The Effects of Microstructure Heterogeneities and Casting Defects on the Mechanical Properties of High-Pressure Die-Cast AlSi9Cu3(Fe) Alloys. Metall. Mater. Trans. A 2014, 45, 5486–5498. [Google Scholar] [CrossRef]

- Timelli, G.; Bonollo, F. The influence of Cr content on the microstructure and mechanical properties of AlSi9Cu3(Fe) die-casting alloys. Mater. Sci. Eng. A 2010, 528, 273–282. [Google Scholar] [CrossRef]

- Fiorese, E.; Richiedei, D.; Bonollo, F. Improving the quality of die castings through optimal plunger motion planning: Analytical computation and experimental validation. Int. J. Adv. Manuf. Technol. 2017, 88, 1475–1484. [Google Scholar] [CrossRef]

- Fiorese, E.; Richiedei, D.; Bonollo, F. Analytical computation and experimental assessment of the effect of the plunger speed on tensile properties in high-pressure die casting. Int. J. Adv. Manuf. Technol. 2016, 91, 463–476. [Google Scholar] [CrossRef]

- Timelli, G.; Lohne, O.; Arnberg, L.; Laukli, H.I. Effect of solution heat treatments on the microstructure and mechanical properties of a die-cast AlSi7MgMn alloy. Metall. Mater. Trans. 2008, 39, 1747–1758. [Google Scholar] [CrossRef]

- Otarawanna, S.; Laukli, H.I.; Gourlay, C.M.; Dahle, A.K. Feeding mechanisms in high-pressure die castings. Metall. Mater. Trans. 2010, 41, 1836–1846. [Google Scholar] [CrossRef]

- Otarawanna, S.; Gourlay, C.M.; Laukli, H.I.; Dahle, A.K. Microstructure formation in AlSi4MgMn and AlMg5Si2Mn high-pressure die castings. Metall. Mater. Trans. 2009, 40, 1645–1659. [Google Scholar] [CrossRef]

- Campbell, J. Castings, 2nd ed.; Butterworth Heinemann: Oxford, UK, 2003; Volume VIII, pp. 70–95. [Google Scholar]

- ASTM B108. Standard Specification for Aluminum-Alloy Permanent Mold Castings; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Miguelucci, E. The aluminum association cast alloy test program: Interim report. AFS Trans. 1985, 93, 913–916. [Google Scholar]

- Grosselle, F.; Timelli, G.; Bonollo, F.; Tiziani, A.; Della Corte, E. Correlation between microstructure and mechanical properties of Al-Si cast alloys. Metall. Ital. 2009, 101, 25–32. [Google Scholar]

- ASTM B557-15. Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Grosselle, F.; Timelli, G.; Bonollo, F. Doe applied to microstructural and mechanical properties of Al-Si-Cu-Mg casting alloys for automotive applications. Mater. Sci. Eng. A 2010, 527, 3536–3545. [Google Scholar] [CrossRef]

- Timelli, G.; Capuzzi, S.; Bonollo, F. Optimization of a Permanent Step Mold Design for Mg Alloy Castings. Metal. Mater. Trans. B 2015, 46, 473–484. [Google Scholar] [CrossRef]

- Akhtar, S.; Dispinar, D.; Arnberg, L.; Di Sabatino, M. Effect of hydrogen content, melt cleanliness and solidification conditions on tensile properties of A356 alloy. Int. J. Cast Met. Res. 2009, 22, 22–25. [Google Scholar] [CrossRef]

- Akhtar, S.; Timelli, G.; Bonollo, F.; Arnberg, L.; Di Sabatino, M. A comparative study of defects and mechanical properties in high-pressure die-cast and gravity die-cast aluminium alloys. Foundry Trade J. Int. 2009, 61, 2–14. [Google Scholar]

- Timelli, G.; Fiorese, E. Metodi di neutralizzazione del Fe in leghe Al-Si da fonderia. Metall. Ital. 2011, 3, 9–23. [Google Scholar]

- Di Sabatino, M.; Arnberg, L.; Rørvik, S.; Prestmo, A. The influence of oxide inclusions on the fluidity of Al–7 wt.%Si alloy. Mater. Sci. Eng. A 2005, 413–414, 272–276. [Google Scholar] [CrossRef]

- Timelli, G.; Caliari, D. Effect of Superheat and Oxide Inclusions on the Fluidity of A356 Alloy. Mater. Sci. Forum 2017, 884, 71–80. [Google Scholar] [CrossRef]

- Dispinar, D.; Campbell, J. Critical assessment of reduced pressure test. Part 2: Quantification. Int. J. Cast Met. Res. 2004, 17, 287–294. [Google Scholar] [CrossRef]

- Avalle, M.; Belingardi, G.; Cavatorta, M.P.; Doglione, R. Static and fatigue strength of a die-cast Aluminium alloy under different feeding conditions. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2002, 216, 25–30. [Google Scholar] [CrossRef]

- Wang, Y.; Schwam, D.; Neff, D.V.; Chen, C.J.; Zhu, X. Improvement in Mechanical Properties of A356 Tensile Test Bars Cast in a Permanent Mold by Application of a Knife Ingate. Metall. Mater. Trans. 2012, 43, 1048–1059. [Google Scholar] [CrossRef]

- Singworth, G.K.; Kuhn, T.A. Use of ‘Standard’ Molds to Evaluate Metal Quality and Alloy Properties’. AFS Trans. 2009, 117, 55–62. [Google Scholar]

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Pb | Sn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AlSi9Cu3(Fe) | 8.227 | 0.799 | 2.825 | 0.261 | 0.252 | 0.083 | 0.081 | 0.895 | 0.083 | 0.026 | 0.041 | bal. |

| AlSi11Cu2(Fe) | 10.895 | 0.889 | 1.746 | 0.219 | 0.224 | 0.082 | 0.084 | 1.274 | 0.089 | 0.029 | 0.047 | bal. |

| AlSi12Cu1(Fe) | 10.510 | 0.721 | 0.941 | 0.232 | 0.242 | 0.045 | 0.080 | 0.354 | 0.055 | 0.025 | 0.038 | bal. |

| Alloy | Type of Specimen | UTS (MPa) | YS (MPa) | EL (%) |

|---|---|---|---|---|

| AlSi9Cu3(Fe) | Flat | 309 ± 6 | 163 ± 1 | 3.6 ± 0.3 |

| Round | 342 ± 8 | 168 ± 6 | 5.1 ± 0.4 | |

| AlSi11Cu2(Fe) | Flat | 312 ± 2 | 153 ± 1 | 3.5 ± 0.1 |

| Round | 342 ± 7 | 158 ± 3 | 5.5 ± 0.7 | |

| AlSi12Cu1(Fe) | Flat | 283 ± 2 | 137 ± 1 | 3.5 ± 0.1 |

| Round | 315 ± 7 | 131 ± 2 | 7.1 ± 0.5 |

| Alloy | Si | Fe | Cu | Mn | Mg | Ni | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| AlSi7Mg0.3 | 6.5 | 0.1 | 0.002 | 0.007 | 0.3 | 0.003 | 0.006 | 0.1 | bal. |

| AlSi6Cu4 | 6.0 | 1.0 | 4.0 | 0.5 | 0.1 | 0.3 | 1.0 | 0.2 | bal. |

| Alloy | Step Thickness (mm) | Reference Die #3 | Reference Die #4 | ||

|---|---|---|---|---|---|

| UTS (MPa) | EL (%) | UTS (MPa) | EL (%) | ||

| AlSi7Mg0.3 | 5 | 181 | 2.3 | 194 ± 2 | 9.5 ± 1 |

| 10 | 172 | 1.7 | 182 ± 3 | 7.1 ± 0.5 | |

| 15 | 182 | 2.3 | 174 ± 1 | 5.6 ± 0.3 | |

| 20 | 167 | 1.8 | 166 ± 2 | 4.4 ± 0.2 | |

| 30 | - | - | 161 ± 3 | 3.2 ± 0.6 | |

| AlSi6Cu4 | 5 | 203 | 0.9 | - | - |

| 10 | 207 | 1.0 | - | - | |

| 15 | 194 | 0.8 | - | - | |

| 20 | 188 | 0.7 | - | - | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anilchandra, A.R.; Arnberg, L.; Bonollo, F.; Fiorese, E.; Timelli, G. Evaluating the Tensile Properties of Aluminum Foundry Alloys through Reference Castings—A Review. Materials 2017, 10, 1011. https://doi.org/10.3390/ma10091011

Anilchandra AR, Arnberg L, Bonollo F, Fiorese E, Timelli G. Evaluating the Tensile Properties of Aluminum Foundry Alloys through Reference Castings—A Review. Materials. 2017; 10(9):1011. https://doi.org/10.3390/ma10091011

Chicago/Turabian StyleAnilchandra, A.R., Lars Arnberg, Franco Bonollo, Elena Fiorese, and Giulio Timelli. 2017. "Evaluating the Tensile Properties of Aluminum Foundry Alloys through Reference Castings—A Review" Materials 10, no. 9: 1011. https://doi.org/10.3390/ma10091011