Latest Developments in Industrial Hybrid Machine Tools that Combine Additive and Subtractive Operations

Abstract

1. Introduction

2. Basis of the Metal Additive Processes

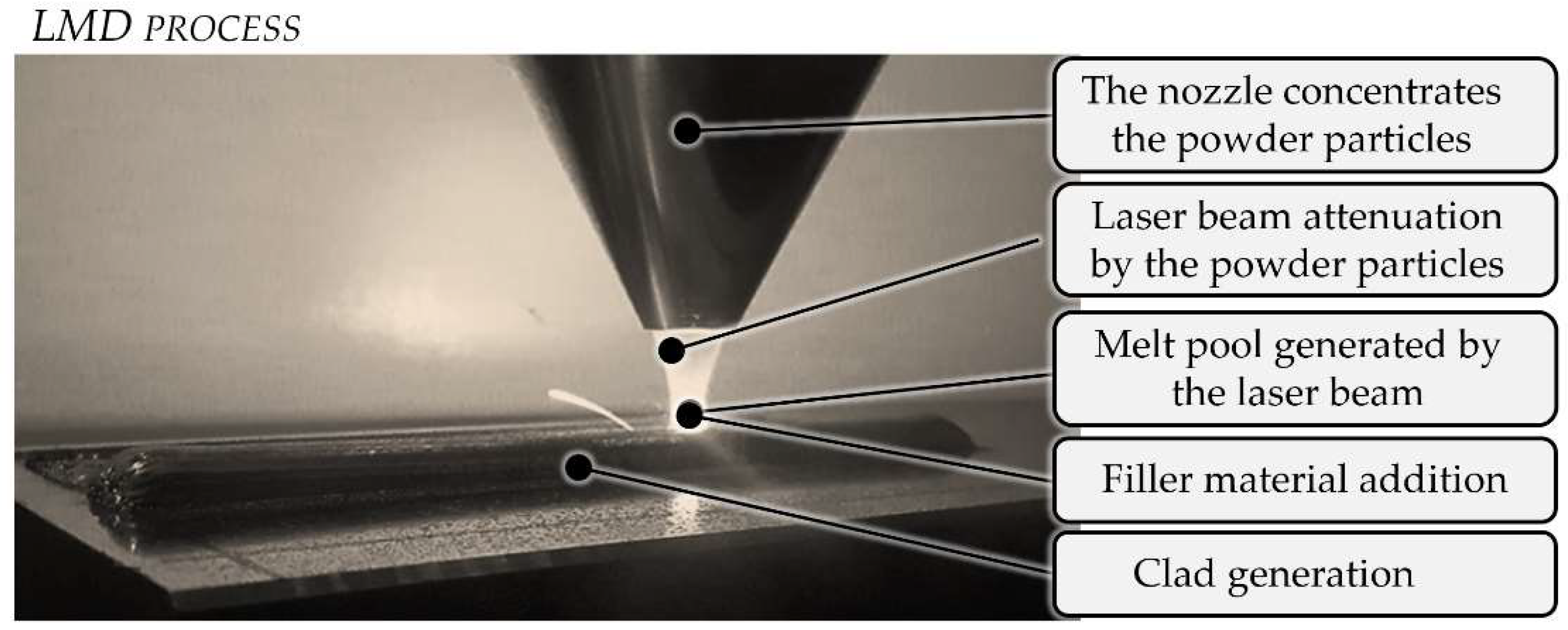

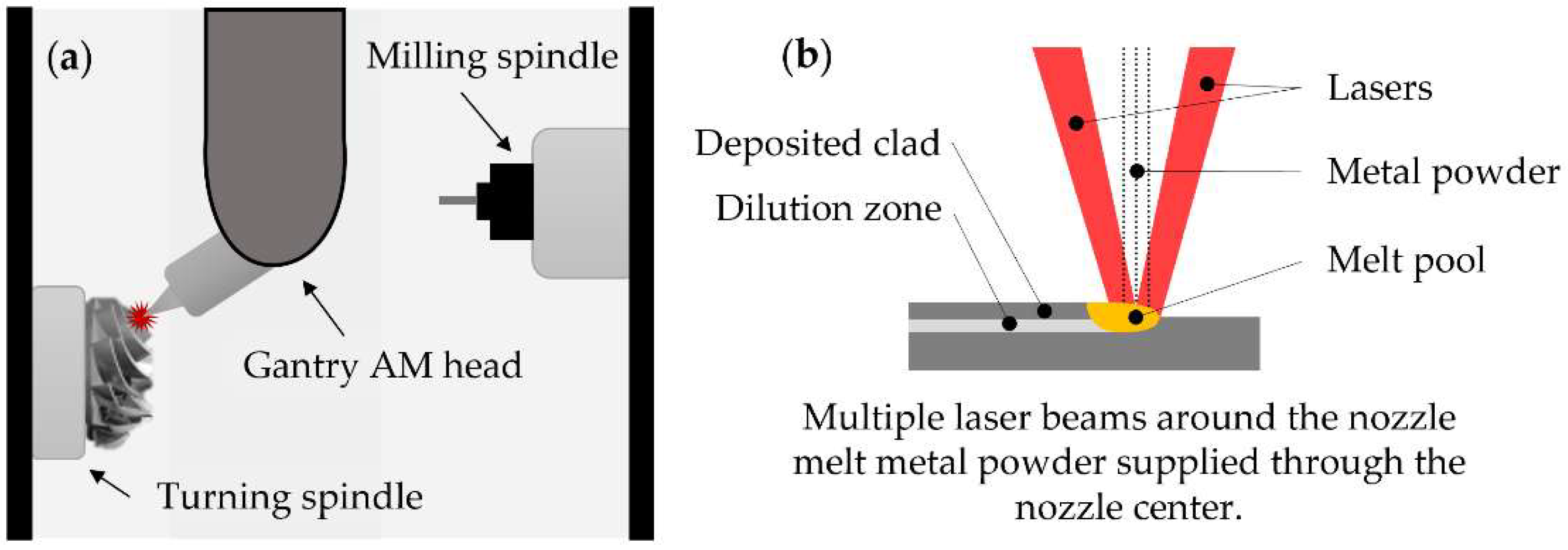

2.1. Fundamentals of the DED Process

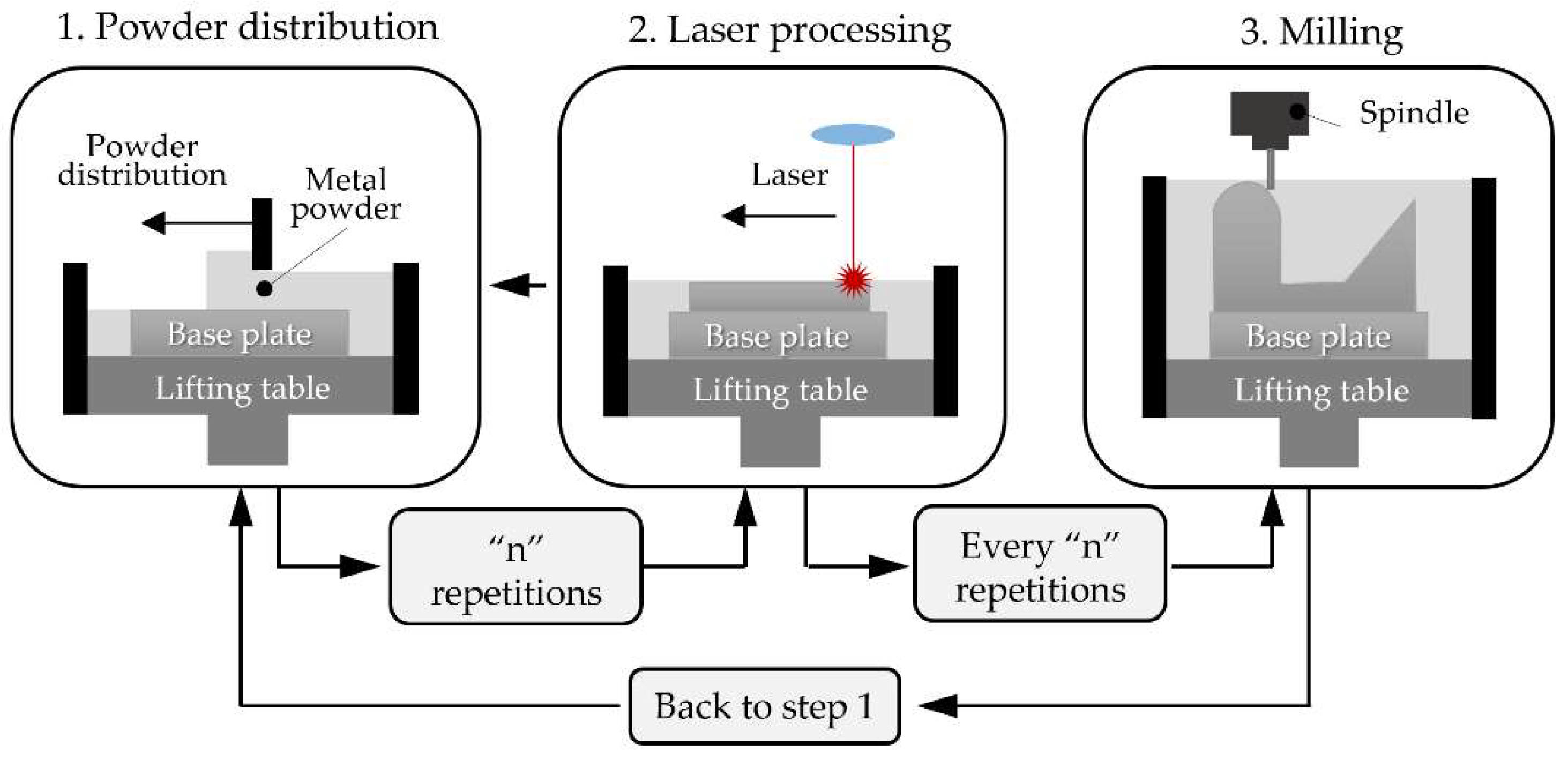

2.2. Fundamentals of the PBF Process

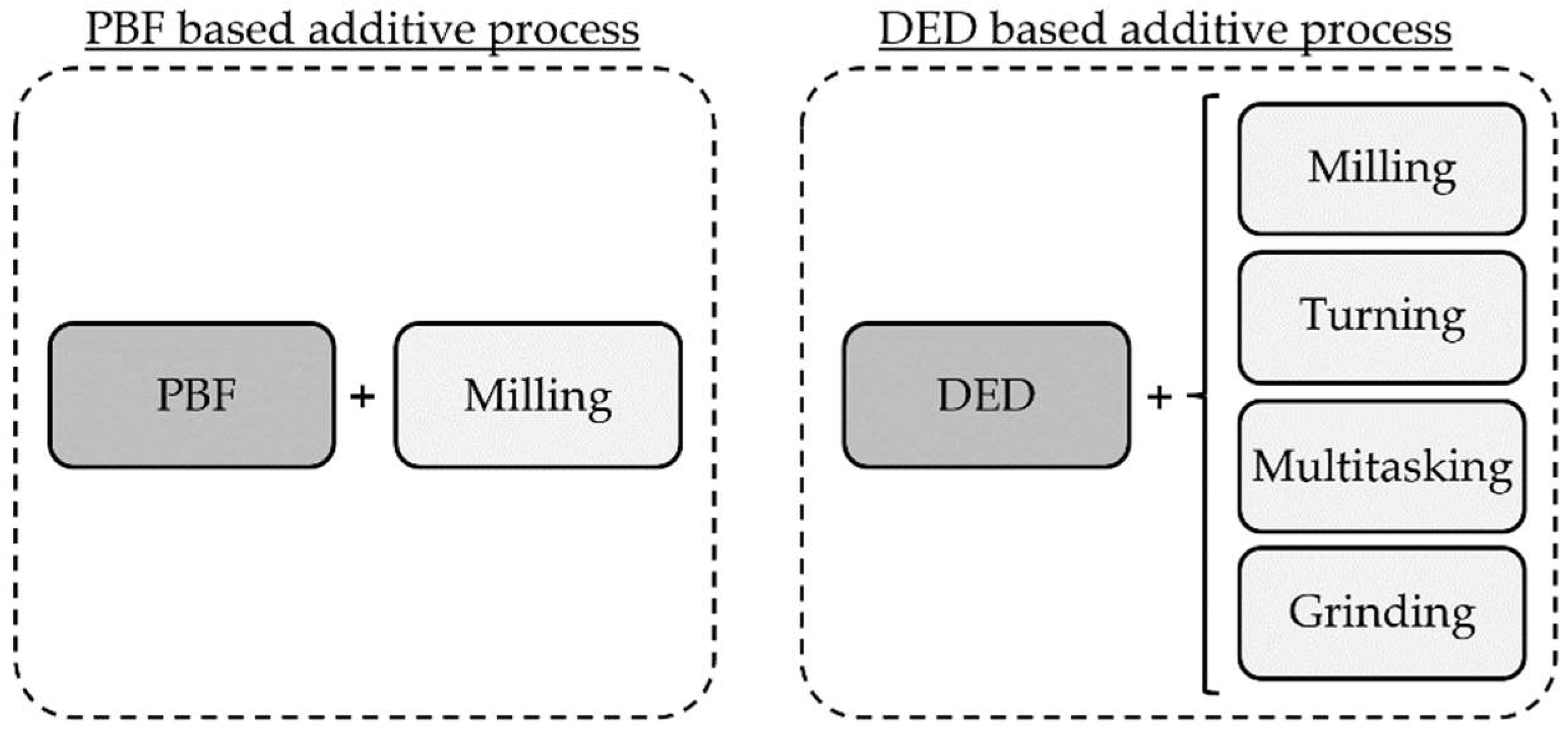

3. Configurations of Hybrid Machines

3.1. Kinematic Configurations

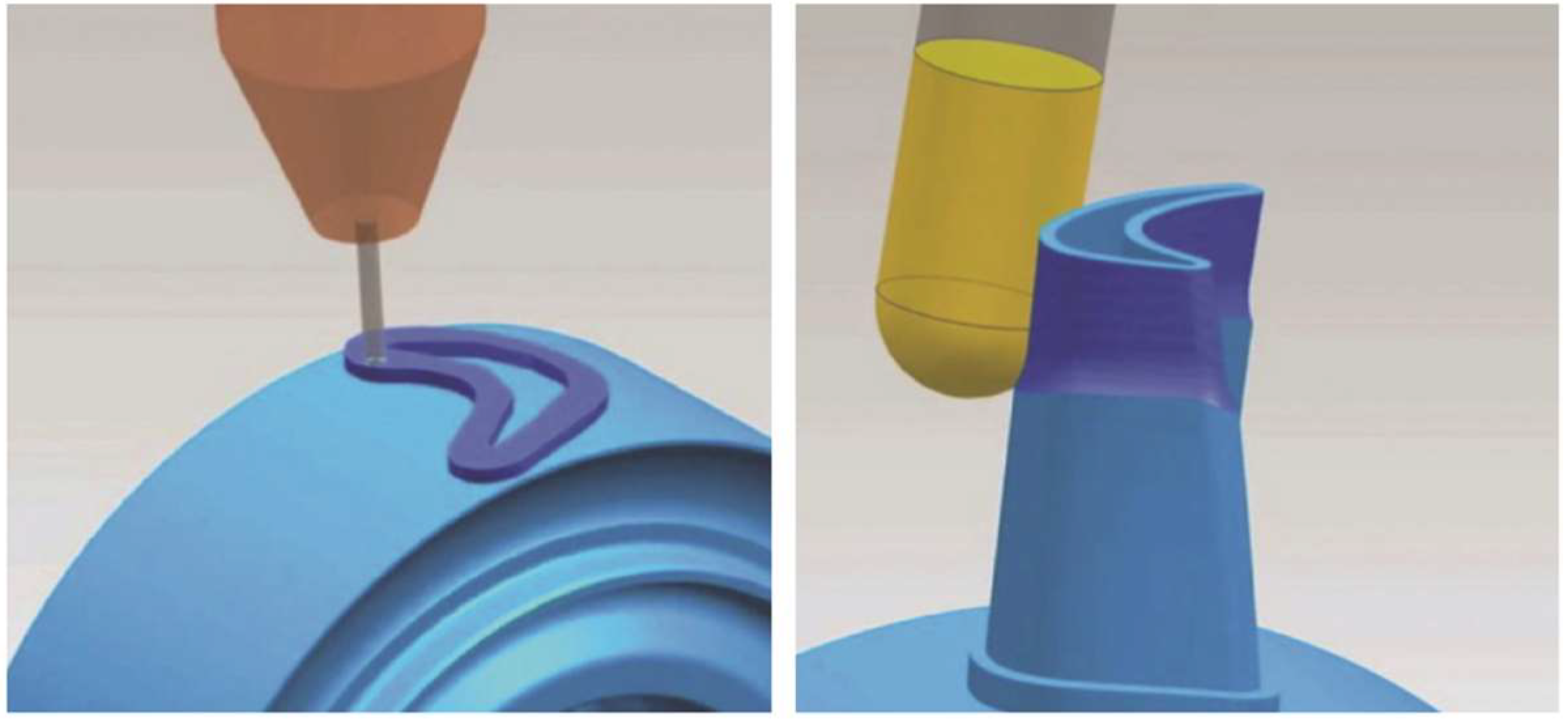

3.2. Nozzles and Strategy Restrictions

3.3. Other Features

4. Study of the Capabilities of Hybrid Machines

4.1. Potentials of Hybrid Machines

- There is no need to change part zeros during the manufacturing process. A single setup is used for both additive and subtractive operations [82]. Therefore, the part-positioning error is minimized, which results in a higher final accuracy. Furthermore, as there is only the need for a single zero-setup per part or set of parts, non-productive time due to zero making is reduced to minimum values.

- Material movement inside the factory is reduced. Hybrid machines enable one to manufacture whole parts in the same machine, without the necessity to move the part to other machines for finishing operations [83]. Hence, intermediate warehouses are eliminated from the factory, which results in a better use of the available space. Besides, as the movement of the material is minimized, on the one hand, the workload of the equipment for material handling is reduced and, on the other hand, the chances for collisions and accidents are lowered, which results in an increase of the employees´ safety.

- Manufacture of higher complexity geometries. The hybrid machine can switch between additive and machining operations seamlessly during the manufacturing of a single part [84]. Therefore, it is feasible to machine areas that are no longer accessible once the part is finished. This results in a higher freedom and flexibility when designing the optimum geometry of the part. Besides, this point is directly related with the previously introduced issues 1 and 2, because when the manufacturing process switches between additive and subtractive operations, there is no material movement inside the factory, nor precision lost due to zero changes between different manufacturing platforms.

- Low buy-to-fly ratios. The possibility to generate near-net-shape components using additive manufacturing results in a reduction of material waste, as well as the economic costs related to the material recycle and waste treatment. Buy-to-fly ratios as low as 1.5:1 are achieved thanks to hybrid machines [52]. Consequently, the ecological footprint resulting from the process is reduced. Combining additive and subtractive operations enables to take advantage of the potential of both processes and therefore, material-efficiencies up to 97% can be achieved [85,86].

- Lower factory space is used. Thanks to the use of hybrid machines, additive and subtractive operations can be carried out within the same machine, the number of required machines for the manufacture of a certain part is reduced. Therefore, occupied space in the workshop is also reduced.

- Simplicity for the operator. The integration of both processes in a single machine under a unique interface means that the operator must only deal with one working station, which simplifies training as well as daily work.

- The overall investment is lower. Hybrid machines are more expensive than simple additive or milling machines. However, the integration of both technologies in a hybrid machine involves sharing common elements (e.g., guiding systems, machine tool structure, CNC control, user interface). Hence, the total investment required for the acquisition of a hybrid platform is considerably lower than buying two separate machines.

- Reduction of the costs of the final part. Additive manufacturing enables realization of high-performance coatings over ordinary or “cheap” materials, thus achieving a final part with enhanced properties, but at a cheaper cost.

4.2. Challenges of Hybrid Machines

- Influence of the cutting fluids on the additive process. The remains of the cutting fluids from the machining process can influence the subsequent additive process [87]. This issue has a double effect. On the one hand, powder particles mix with the fluid and generate moisture that directly influences the laser beam absorptivity and the dilution of the filler material within the substrate. On the other hand, the cutting fluid vaporizes during the additive process and results in porosity increase, as well as possible damage to the optical systems due to the contamination of the lenses [88,89].As a result, ensuring the cleanliness of the substrate is of great importance in order to avoid internal defects (e.g., porosity, cracks), guarantee a good bonding between the deposited and base materials, and therefore perform a high-quality additive operation [90]. This means that, as far as hybrid machines are concerned, an intermediate cleaning stage between machining and the subsequent additive operation is necessary. However, there is no agreement neither in the industry nor in academia about how to proceed with regard to this issue and only a few studies can be found [87,88].Problems with cutting fluids are even more critical when PBF processes and milling are combined. In this case, no cutting fluids can be used in the subtractive operation, as their mixture with the powder bed would be detrimental for the whole process, which results in lower feed rate, lower plunging depths, higher tool wear, etc. when machining.

- Abrasion problems inside the guiding system of the machine. Hybrid machines require a special protection that preserves the guiding system from the powder used in the additive operation [78,79]. The powder particles used in DED and PBF processes have diameters ranging between 45–150 µm and 10–40 µm, respectively. Therefore, if the machine is not properly sealed, powder particles might intrude and interfere with the smooth movement of the guiding system, as well as with the encoders used for determining the position in the machine.

- Geometric uncertainty of the additive process. Due to the uncertainty that additive manufacturing suffers as a consequence of the state of the art and lack of maturity of the technology, the additive stage is the weakest link within hybrid machines. For example, it is well known that additive manufacturing can produce complex internal features, but there is a lack of knowledge regarding how those features should be inspected [91].Regarding the accuracy of the additive process, especially in DED operations, it is lower than that of machining. In Table 1, a comparison between PBF and DED technologies’ dimensional accuracy and surface roughness is presented [92]. As it can be seen, DED is a less accurate process than PBF. However, in both cases, a post-processing stage is necessary depending on the final requirements of the part.The material deposition rate in the additive process is extremely sensitive to the feed rate of the machine, the volume of the substrate, the geometry of the region where the material is being deposited, the surface finish, etc., which may generate differences between the originally designed and finally manufactured part [97]. Besides, the internal stresses generated during the additive stage due to the thermal nature of the process may generate considerable geometrical distortions. Therefore, in the subsequent machining operation, the tool may encounter material over-accumulations and different geometries from those expected, which may lead to the breakage of the cutting tool.Table 1. Comparison between PBF and DED technologies.

Technology Dimensional Accuracy (mm) Surface Roughness (µm) Ref. PBF ±0.05 9–16 [93,94] DED ±0.13 ≈40 [95,96] - The requirement of a post-processing heat treatment. During the additive process, the material is subjected to heating and cooling thermal cycles, which leads to the generation of residual stresses that might be released during the subsequent machining operations. This results in distortions of the part geometry and hence the machining tool may encounter different plunging depths to those programmed [98]. Besides, the mechanical properties of the deposited material, for instance ductility, are very sensitive to the presence of internal defects and porosity [99].In order to reduce internal stresses and solve these issues, additively manufactured parts usually require a post-processing heat treatment [100]. For example, Kobryn and Semiating studied the influence of a post-processing stage on a Ti-6Al4V part produced by Laser Engineered Net Shaping (LENS) and concluded that a Hot Isostatic Pressing (HIP) operation can increase ductility from 0.8% to values of almost 12% [101]. Besides, authors like Åsberg et al. studied the influence of HIP on the yield strength of an AISI H13 tool steel and a 30% improvement was obtained with regard to the as-deposited material, reaching an average value of 1502 MPa [102].Therefore, in case the hybrid machine is not prepared for providing the required heat treatment, material movement to an external furnace is mandatory, which eliminates one of the main advantages of using a hybrid machine.

- Necessity of a paradigm shift. Design engineers need to learn not only each process independently (additive and subtractive), but also the possibilities that have arisen thanks to their combination, which may result in a change of the whole concept of designing parts. For instance, Salonitis and Zarban proposed a methodology for redesigning the geometry of a part to be additively manufactured based on a Multi-Criteria Decision Analysis (MCDA) for assisting in decision-making [103]. However, there is no standard methodology or process planning aimed at hybrid machines.Besides, Hällgren et al. stated that additive manufacturing could be approached from two points of view: design-driven and process-driven [104]. The first one focuses on improving the geometry of the manufactured part, but without considering the optimization of the manufacturing process itself, whereas the second one works the other way. However, if satisfying results are to be obtained and the full potential of hybrid manufacturing is to be exploited, a new point of view that combines both ideas is required.

- Training of operators is more complicated. Operators require a wider background knowledge to master in both processes; hence, this is directly translated into a longer training period. Moreover, due to the extensive freedom of additive manufacturing, hybrid machines usually require the use of computational frameworks in order to optimize both processes [105]. Besides, operators must be trained in safety issues, especially with regard to the powder handling and laser operating [106].

- Generated residues treatment. Thanks to the capability of the additive manufacturing to generate near-net-shape geometries, hybrid machines reduce the amount of generated waste material by as much as 90% [107]. However, their treatment may be far more complicated, from a logistical point of view, and economically expensive. Special attention must be paid to powder handling, recycling of the liquid wastes (e.g., lubrication oils used for the movement of the axes, cutting fluids employed in machining). Depending on the composition of the used powder particles, the residues are extremely hazardous to human health. Especially, powder with high content of nickel or cobalt are carcinogenic to our health. All this obliges the company to install special protective measures, as well as a proper protocol for treating the residues [108]. Moreover, despite the latest advances, there is a lack of knowledge and studies related to the toxicity and harmful effects related to the powder particles [109]

- Powder recovery and recycling. In laser metal additive processes, only a fraction of the fed powder is melted by the laser and added to the substrate, whereas the rest is lost. Industrial powder based DED systems have an efficiency ranging between 5 and 70% [110], while in wire-based DED and PBF much higher efficiencies are obtained, reaching values of almost 100%. However, this powder has interacted with the laser beam and consequently, the shape and composition of the particles may have changed, which is detrimental for its reutilization. Carroll et al. concluded that the reused powder reduces the hardness of the deposited material and increases the surface roughness [110]. Besides, it may have contacted with substances, such as oil, dust, other composition powders, etc., negatively affecting the process. In order to highlight the discrepancies between the different authors and the existing uncertainty in this field, some authors conclude that Inconel 718 DED powder can be reused twice [111], whereas others increase this number up to 10 reuses without major changes in the results for the Inconel 625 DED [110].

- Machine protections. Besides protecting the machine operator from collisions, the guarding of the hybrid machines needs to be capable of retaining the high-intensity light generated by the laser inside the machine and to withstand the heat generated during the additive process. Reflections of the laser beam when highly reflective materials are being processed (e.g., aluminum, copper) may result in the melting of specific areas of the guarding or other sensitive elements and, therefore, proper protection must be arranged.

5. Latest Developments from an Industrial Perspective

5.1. DED-based Hybrid Machines

5.2. PBF-based Hybrid Machines

6. Current Situation and Future Perspectives

6.1. Process Planning

6.2. Monitoring and Inspection

6.3. CAM Software Developments

7. Conclusions

- The prediction of issues, such as clad geometry, porosity, hardness, microstructure, or residual stresses, is highly important in order to build an accurate, high-quality component. For instance, the combination of thermomechanical models with CAD/CAM software is of great importance in order to be able to design adequate building strategies and guarantee there is no excessive deviation between the projected and the actual part. Nevertheless, the use of experimentally obtained databases that correlate process parameters and the obtained clad geometry is gaining wide acceptance due to their lower computational cost and faster solution.

- Process monitoring is of great relevance when ensuring the quality of additively manufactured parts. Besides, they can provide information regarding the process and the probability of defect apparition. Nevertheless, the future of monitoring cannot be limited to controlling the process instantaneously, but also to be capable of predicting defects before they occur and acting accordingly in order to avoid their appearance.

- Alternatives to the application of heat treatment in a furnace, which is commonly used for reducing residual stresses generated in the additive operation, are also required. The investigation of laser-based heat treatments inside the hybrid machine in combination with further heat treatment stages once the component is out of it could help overcome the setback of eliminating the furnace-based intermediate treatment stage.

- In addition, there is still a lack of agreement on some aspects, such as the best means to eliminate metal powder or cutting fluid from the working environment so that their mixture does not affect the additive operation. In this regard and based on experience, the authors believe that the best way to proceed would be a combination of powder blowing and laser cleaning prior to the additive process. However, the literature shows that different materials react unequally, in terms of porosity, cracking, and microstructural, to the presence of cutting fluid remnants during deposition. Thus, further research on either advancing towards dry machining or analyzing a wider range of materials is needed in order to understand and/or avoid this kind of interaction.

- Decision and process planning for hybrid solutions are major outstanding issues, where substantial progress needs to be made. The main challenge is now the development of a software tool that allows the design of an optimized process plan comprised of enhanced additive and subtractive operations that can be alternately applied. This is a complex issue, the result of which may vary depending on the geometry of interest. As a result, there is uncertainty about how to proceed in order to discern whether a feature should be manufactured by either subtractive or additive means and thus optimize the sequence of operations. This task requires an in-depth knowledge of both technologies, as well as the consideration of part inspection as a built-in functionality able to update the manufacturing strategies in the process. This might be the last step to be accomplished in order to fully utilize hybrid machines.

- The inspection of additively manufactured parts is another challenging field of research in which advancements are being made. This is because such parts present a level of complexity in geometry that is unprecedented and metrology tools and measuring procedures need to be developed or adapted to them.

- Moreover, and despite the fact that machine tool mechatronics and process integration is nearly solved, there are still key aspects that need to be improved, such as programming tools, process monitoring and powder recovery.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- El-Hofy, H. Advanced Machining Processes: Nontraditional and Hybrid Machining Processes; McGraw-Hill: New York, NY, USA, 2005. [Google Scholar]

- Karunakaran, K.; Suryakumar, S.; Pushpa, V.; Akula, S. Low cost integration of additive and subtractive processes for hybrid layered manufacturing. Robot. Comput. Integr. Manuf. 2010, 26, 490–499. [Google Scholar] [CrossRef]

- Zhu, Z.; Dhokia, V.G.; Nassehi, A.; Newman, S.T. A review of hybrid manufacturing processes—State of the art and future perspectives. Int. J. Comput. Integr. 2013, 26, 596–615. [Google Scholar] [CrossRef]

- Nassehi, A.; Newman, S.; Dhokia, V.; Zhu, Z.; Asrai, R.I. Using formal methods to model hybrid manufacturing processes. In Enabling Manufacturing Competitiveness and Economic Sustainability; ElMaraghy, H., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 52–56. [Google Scholar]

- Klocke, F.; Klink, A.; Veselovac, D.; Aspinwall, D.K.; Soo, S.L.; Schmidt, M.; Schilp, J.; Levy, G.; Kruth, J.P. Turbomachinery component manufacture by application of electrochemical, electro-physical and photonic processes. CIRP Ann.-Manuf. Technol. 2014, 63, 703–726. [Google Scholar] [CrossRef]

- Merklein, M.; Junker, D.; Schaub, A.; Neubauer, F. Hybrid additive manufacturing technologies—An analysis regarding potentials and applications. Phys. Procedia 2016, 83, 549–559. [Google Scholar] [CrossRef]

- Du, W.; Bai, Q.; Zhang, B. A Novel Method for Additive/Subtractive Hybrid Manufacturing of Metallic Parts. Procedia Manuf. 2016, 5, 1018–1030. [Google Scholar] [CrossRef]

- Flynn, J.M.; Shokrani, A.; Newman, S.T.; Dhokia, V. Hybrid additive and subtractive machine tools—Research and industrial developments. Int. J. Mach. Tools Manuf. 2016, 101, 79–101. [Google Scholar] [CrossRef]

- Chen, L.; Xu, K.; Tang, K. Optimized sequence planning for multi-axis hybrid machining of complex geometries. Comput. Graph. 2018, 70, 176–187. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2015(en). Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-1:v1:en:term:2.1.2 (accessed on 13 December 2018).

- Yamazaki, T. Development of A Hybrid Multi-tasking Machine Tool: Integration of Additive Manufacturing Technology with CNC Machining. Proc. CIRP 2016, 42, 81–86. [Google Scholar] [CrossRef]

- Hansel, A.; Mori, M.; Fujishima, M.; Oda, Y.; Hyatt, G.; Lavernia, E.; Delplanque, J.P. Study on Consistently Optimum Deposition Conditions of Typical Metal Material Using Additive/Subtractive Hybrid Machine Tool. Proc. CIRP 2016, 46, 579–582. [Google Scholar] [CrossRef]

- Sciaky Inc. Available online: http://www.sciaky.com/ (accessed on 13 December 2018).

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J. Clean. Prod. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- Ruiz, J.E.; González, H.; Cortina, M.; Arrizubieta, J.I.; Lamikiz, A. IBR manufacturing by hybrid combination of laser metal deposition and machining process. In Proceedings of the 26th International Conference on Advanced Nanotechnology, Moscow, Russia, 4–5 October 2018; Volume 4, pp. 62–63. [Google Scholar]

- Navrotsky, V.; Graichen, A.; Brodin, H. Industrialisation of 3D printing (additive manufacturing) for gas turbine components repair and manufacturing. VGB PowerTech 2015, 12, 48–52. [Google Scholar]

- Ren, L.; Padathu, A.P.; Ruan, J.; Sparks, T.; Liou, F.W. Three dimensional die repair using a hybrid manufacturing system. In Proceedings of the 17th Solid Freeform Fabrication Symposium, Austin, TX, USA, 14–16 August 2006; pp. 51–59. [Google Scholar]

- Goindi, G.S.; Sarkar, P. Dry machining: A step towards sustainable machining—Challenges and future directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Li, L.; Deng, X.; Zhao, J.; Zhao, F.; Sutherland, J.W. Multi-objective optimization of tool path considering efficiency, energy-saving and carbon-emission for free-form surface milling. J. Clean. Prod. 2018, 172, 3311–3322. [Google Scholar] [CrossRef]

- Zhou, L.; Li, J.; Li, F.; Meng, Q.; Li, J.; Xu, X. Energy consumption model and energy efficiency of machine tools: A comprehensive literature review. J. Clean. Prod. 2016, 112, 3721–3734. [Google Scholar] [CrossRef]

- Lin, Z.; Fu, J.; Shen, H.; Gan, W. A generic uniform scallop tool path generation method for five-axis machining of freeform surface. Comput.-Aided Des. 2015, 56, 120–132. [Google Scholar] [CrossRef]

- Beudaert, X.; Lavernhe, S.; Tournier, C. 5-axis local corner rounding of linear tool path discontinuities. Int. J. Mach. Tools Manuf. 2013, 73, 9–16. [Google Scholar] [CrossRef]

- Jin, G.Q.; Li, W.D.; Tsai, C.F.; Wang, L. Adaptive tool-path generation of rapid prototyping for complex product models. J. Manuf. Syst. 2011, 30, 154–164. [Google Scholar] [CrossRef]

- Wan, A.; Song, L.; Xu, J.; Liu, S.; Chen, K. Calibration and compensation of machine tool volumetric error using a laser tracker. Int. J. Mach. Tools Manuf. 2018, 124, 126–133. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, Z.C.; Yang, X. An accurate, efficient envelope approach to modeling the geometric deviation of the machined surface for a specific five-axis CNC machine tool. Int. J. Mach. Tools Manuf. 2015, 95, 67–77. [Google Scholar] [CrossRef]

- Zhang, S.J.; To, S.; Zhang, G.Q.; Zhu, Z.W. A review of machine-tool vibration and its influence upon surface generation in ultra-precision machining. Int. J. Mach. Tools Manuf. 2015, 91, 34–42. [Google Scholar] [CrossRef]

- Bi, G.; Sun, C.N.; Gasser, A. Study on influential factors for process monitoring and control in laser aided additive manufacturing. J. Mater. Process. Technol. 2013, 213, 463–468. [Google Scholar] [CrossRef]

- Haley, J.C.; Zheng, B.; Scipioni, U.; Alexander, B.; Dupuy, D.; Schoenung, J.M.; Lavernia, E.J. Working distance passive stability in laser directed energy deposition additive manufacturing. Mater. Des. 2019, 161, 86–94. [Google Scholar] [CrossRef]

- Phillips, T.; Fish, S.; Beaman, J. Development of an automated laser control system for improving temperature uniformity and controlling component strength in selective laser sintering. Addit. Manuf. 2018, 24, 316–322. [Google Scholar] [CrossRef]

- Andreau, O.; Koutiri, I.; Peyre, P.; Penot, J.D.; Saintier, N.; Pessard, E.; De Terris, T.; Dupuy, C.; Baudin, T. Texture control of 316L parts by modulation of the melt pool morphology in selective laser melting. J. Mater. Process. Technol. 2019, 264, 21–31. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, W.; Tang, Z.; Liu, X.; Zhang, N.; Li, M.; Zhang, H. Review on thermal analysis in laser-based additive manufacturing. Opt. Laser Technol. 2018, 106, 427–441. [Google Scholar] [CrossRef]

- Donadello, S.; Motta, M.D.; Demir, A.G.; Previtali, B. Monitoring of laser metal deposition height by means of coaxial laser triangulation. Opt. Lasers Eng. 2019, 112, 136–144. [Google Scholar] [CrossRef]

- Coeck, S.; Bisht, M.; Plas, J.; Verbist, F. Prediction of lack of fusion porosity in selective laser melting based on melt pool monitoring data. Addit. Manuf. 2019, 25, 347–356. [Google Scholar] [CrossRef]

- Cerniglia, D.; Montinaro, N. Defect Detection in Additively Manufactured Components: Laser Ultrasound and Laser Thermography Comparison. Procedia Struct. Integr. 2018, 8, 154–162. [Google Scholar] [CrossRef]

- Montinaro, N.; Cerniglia, D.; Pitarresi, G. Defect detection in additively manufactured titanium prosthesis by flying laser scanning thermography. Procedia Struct. Integr. 2018, 12, 165–172. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. Mitigation of lack of fusion defects in powder bed fusion additive manufacturing. J. Manuf. Process. 2018, 36, 442–449. [Google Scholar] [CrossRef]

- Teng, C.; Pal, D.; Gong, H.; Zeng, K.; Briggs, K.; Patil, N.; Stucker, B. A review of defect modeling in laser material processing. Addit. Manuf. 2017, 14, 137–147. [Google Scholar] [CrossRef]

- Oyelola, O.; Crawforth, P.; M’Saoubi, R.; Clare, A.T. Machining of functionally graded Ti6Al4V/ WC produced by directed energy deposition. Addit. Manuf. 2018, 24, 20–29. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S. Laser Cladding; CRC Press LLC: Boca Raton, FL, USA, 2005. [Google Scholar]

- Arrizubieta, J.I.; Klocke, F.; Klingbeil, N.; Arntz, K.; Lamikiz, A.; Martinez, S. Evaluation of efficiency and mechanical properties of Inconel 718 components built by wire and powder laser material deposition. Rapid Prototyp. J. 2017, 23, 965–972. [Google Scholar] [CrossRef]

- Gasser, A. Laser Metal Deposition. In Tailored Light 2; Poprawe, R., Ed.; RWTH Edition; Springer: Berlin/Heidelberg, Germany, 2011; pp. 216–224. [Google Scholar]

- Caiazzo, F. Laser-aided Directed Metal Deposition of Ni-based superalloy powder. Opt. Laser Technol. 2018, 103, 193–198. [Google Scholar] [CrossRef]

- Navas, C.; Conde, A.; Fernández, B.J.; Zubiri, F.; de Damborenea, J. Laser coatings to improve wear resistance of mould steel. Surf. Coat. Technol. 2005, 194, 136–142. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Li, L. Multiple-layer cladding of stainless steel using a high-powered diode laser: An experimental investigation of the process characteristics and material properties. Thin Solid Films 2004, 453–454, 471–476. [Google Scholar] [CrossRef]

- Richter, K.H.; Orban, S.; Nowotny, S. Laser cladding of the Titanium alloy Ti6242 to restore damaged blades. In Proceedings of the ICALEO: 23rd International Congress on Applications of Lasers and Electro-Optics, San Francisco, CA, USA, 4–7 October 2004. [Google Scholar]

- Kong, C.Y.; Scudamore, R.J.; Allen, J. High-rate laser metal deposition of Inconel 718 component using low heat-input approach. Phys. Procedia 2010, 5, 379–386. [Google Scholar] [CrossRef]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Lima, D.D.; Mantri, S.A.; Mikler, C.V.; Contieri, R.; Yannetta, C.J.; Campo, K.N.; Lopes, E.S.; Styles, M.J.; Borkar, T.; Caram, R.; et al. Laser additive processing of a functionally graded internal fracture fixation plate. Mater. Des. 2017, 130, 8–15. [Google Scholar] [CrossRef]

- Hwang, T.; Woo, Y.Y.; Han, S.W.; Moon, Y.H. Functionally graded properties in directed-energy-deposition titanium parts. Opt. Laser Technol. 2018, 105, 80–88. [Google Scholar] [CrossRef]

- Priarone, P.C.; Ingarao, G. Towards criteria for sustainable process selection: On the modelling of pure subtractive versus additive/subtractive integrated manufacturing approaches. J. Clean. Prod. 2017, 144, 57–68. [Google Scholar] [CrossRef]

- Allen, J. An Investigation into the Comparative Costs of Additive Manufacture vs. Machine from Solid for Aero Engine Parts; Rolls-Royce PLC Derby: Derbyshire, UK, 2006. [Google Scholar]

- Caiazzo, F.; Alfieri, V.; Corrado, G.; Argenio, P.; Barbieri, G.; Acerra, F.; Innaro, V. Laser Beam Welding of a Ti–6Al–4V Support Flange for Buy-to-Fly Reduction. Metals 2017, 7, 183. [Google Scholar] [CrossRef]

- Ruiz, J.E.; Gonzalez, H.; Cortina, M.; Arrizubieta, J.I.; Lamikiz, A. Desarrollo de estrategia y sensorizacion en proceso de LMD para reparacion de geometrias tipo blisk. Revista Iberoamericana de Ingenieria Mecanica 2018, 22, 13–18. [Google Scholar]

- Abdulrahman, K.O. Laser metal deposition technique: Sustainability and environmental impact. Procedia Manuf. 2018, 21, 109–116. [Google Scholar] [CrossRef]

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing—Enabling Circular Economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Kumar, L.J. Laser metal deposition repair applications for Inconel 718 alloy. Mater. Today Proc. 2017, 4, 11068–11077. [Google Scholar] [CrossRef]

- Jhavar, S. Causes of failure and repairing options for dies and molds: A review. Eng. Fail. Anal. 2013, 34, 519–535. [Google Scholar] [CrossRef]

- Mazumder, J. Laser assisted surface coatings. In Metallurgical and Ceramic Protective Coatings; Stern, K.H., Ed.; Springer: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Mazumder, J. Laser-aided direct metal deposition of metals and alloys. In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 21–53. [Google Scholar]

- McAndrew, A.R.; Alvarez Rosales, M.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of Ti-6Al-4V wire + arc additively manufactured features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Hejripour, F.; Valentine, D.T.; Aidun, D.K. Study of mass transport in cold wire deposition for Wire Arc Additive Manufacturing. Int. J. Heat Mass Transf. 2018, 125, 471–484. [Google Scholar] [CrossRef]

- Cunningham, C.R.; Flynn, J.M.; Shokrani, A.; Dhokia, V.; Newman, S.T. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Tabernero, I.; Paskual, A.; Álvarez, P.; Suárez, A. Study on Arc Welding Processes for High Deposition Rate Additive Manufacturing. Proc. CIRP 2018, 68, 358–362. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Materialia 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Qin, S.; Dunbar, A.; Michaleris, P.; Beese, A.M. Characterization of the strength of support structures used in powder bed fusion additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2017, 14, 60–68. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2016; ISBN 978-1-4939-4455-2. [Google Scholar]

- Wally, Z.J.; Haque, A.M.; Feteira, A.; Claeyssens, F.; Goodall, R.; Reilly, G.C. Selective laser melting processed Ti6Al4V lattices with graded porosities for dental applications. J. Mech. Behav. Biomed. Mater. 2019, 90, 20–29. [Google Scholar] [CrossRef] [PubMed]

- Ataee, A.; Li, Y.; Brandt, M.; Wen, C. Ultrahigh-strength titanium gyroid scaffolds manufactured by selective laser melting (SLM) for bone implant applications. Acta Materialia 2018, 158, 354–368. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace applications of laser additive manufacturing. In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 351–371. [Google Scholar]

- Morgan, D.; Agba, E.; Hill, C. Support Structure Development and Initial Results for Metal Powder Bed Fusion Additive Manufacturing. Procedia Manuf. 2017, 10, 819–830. [Google Scholar] [CrossRef]

- Zekovic, S.; Dwivedi, R.; Kovacevic, R. Numerical simulation and experimental investigation of gas–powder flow from radially symmetrical nozzles in laser-based direct metal deposition. Int. J. Mach. Tools Manuf. 2007, 47, 112–123. [Google Scholar] [CrossRef]

- Weisheit, A.; Backes, G.; Stromeyer, R.; Gasser, A.; Wissenbach, K.; Poprawe, R. Powder Injection: The Key to Reconditioning and Generating Components Using Laser Cladding. In Proceedings of the Materials Week, Munich, Germany, 1–4 October 2001. [Google Scholar]

- Arrizubieta, J.I.; Ruiz, J.E.; Martinez, S.; Ukar, E.; Lamikiz, A. Intelligent nozzle design for the Laser Metal Deposition process in the Industry 4.0. Procedia Manuf. 2017, 13, 1237–1244. [Google Scholar] [CrossRef]

- Nagulin, K.Y.; Iskhakov, F.R.; Shpilev, A.I.; Gilmutdinov, A.K. Optical diagnostics and optimization of the gas-powder flow in the nozzles for laser cladding. Opt. Laser Technol. 2018, 108, 310–320. [Google Scholar] [CrossRef]

- Zelinski, P. Okuma Engineer Offers Safety Tips for Hybrid Machine Tools. Additive Manufacturing Magazine. 2018. Available online: https://www.additivemanufacturing.media/blog/post/okuma-engineer-offers-safety-tips-for-hybrid-machine-tools (accessed on 13 December 2018).

- Zelinski, P. Integrating Additive without Inhibiting Machining. Additive Manufacturing Magazine. 2016. Available online: https://www.additivemanufacturing.media/blog/post/integrating-additive-without-inhibiting-machining (accessed on 13 December 2018).

- Gorman, L. New “hybrid” Additive/Subtractive Machining System Unveiled at IMTS 2016. Lasers Today. 2016. Available online: https://www.laserstoday.com/2016/12/new-hybrid-additivesubtractive-machining-system-unveiled-at-imts-2016/ (accessed on 13 December 2018).

- Skarzynski, J. Tech Tuesday—Is a Powder Stream Additive Process Right for You? Techsolve. 2018. Available online: https://www.techsolve.org/blog/manufacturing-blog/tech-tuesday-powder-stream-additive-process-right-you-check-out-these-4-key (accessed on 13 December 2018).

- Manogharan, G.; Wysk, R.; Harrysson, O.; Aman, R. AIMS—A Metal Additive-Hybrid Manufacturing System: System Architecture and Attributes. Procedia Manuf. 2015, 1, 273–286. [Google Scholar] [CrossRef]

- Li, L.; Haghighi, A.; Yang, Y. A novel 6-axis hybrid additive-subtractive manufacturing process: Design and case studies. J. Manuf. Process. 2018, 33, 150–160. [Google Scholar] [CrossRef]

- Soshi, M.; Ring, J.; Young, C.; Oda, Y.; Mori, M. Innovative grid molding and cooling using an additive and subtractive hybrid CNC machine tool. CIRP Ann. 2017, 66, 401–404. [Google Scholar] [CrossRef]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Achillas, C.; Aidonis, D.; Iakovou, E.; Thymianidis, M.; Tzetzis, D. A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory. J. Manuf. Syst. 2015, 37, 328–339. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, Y.; Newkirk, J.W.; Liou, F.; Thomas, E.; Baker, A. Investigation of machining coolant residue cleaning methods for Ti6Al4V part fabrication through hybrid manufacturing process. Manuf. Lett. 2018, 16, 10–13. [Google Scholar] [CrossRef]

- Cortina, M.; Arrizubieta, J.I.; Ukar, E.; Lamikiz, A. Analysis of the Influence of the Use of Cutting Fluid in Hybrid Processes of Machining and Laser Metal Deposition (LMD). Coatings 2018, 8, 61. [Google Scholar] [CrossRef]

- Cortina, M.; Arrizubieta, J.I.; Ruiz, J.E.; Ukar, E.; Lamikiz, A. Análisis de la influencia del uso de fluido de corte en procesos híbridos de mecanizado y aporte por láser. Revista Iberoamericana de Ingenieria Mecanica 2018, 22, 33–39. [Google Scholar]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S. Material efficiency of laser metal deposited Ti6Al4V: Effect of laser power. Eng. Lett. 2013, 21, 18–22. [Google Scholar]

- Zelinski, P. Panel Discusses Promise and Challenges of Both Additive and Hybrid Machines. Additive Manufacturing Magazine. 2015. Available online: https://www.additivemanufacturing.media/blog/post/panel-discusses-promise-and-challenges-of-both-additive-and-hybrid-machines- (accessed on 13 December 2018).

- Gu, D. Laser Additive Manufacturing (AM): Classification, Processing Philosophy, and Metallurgical Mechanisms. In Laser Additive Manufacturing of High-Performance Materials; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Zhu, H.H.; Lu, L.; Fuh, J.Y.H. Development and characterisation of direct laser sintering Cu-based metal powder. J. Mater. Process. Technol. 2003, 140, 314–317. [Google Scholar] [CrossRef]

- Mumtaz, K.; Hopkinson, N. Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid Prototyp. J. 2009, 15, 96–103. [Google Scholar] [CrossRef]

- Mazumder, J.; Dutta, D.; Kikuchi, N. Closed loop direct metal deposition: Art to part. Opt. Laser Eng. 2000, 34, 397–414. [Google Scholar] [CrossRef]

- Milewski, J.O.; Lewis, G.K.; Thoma, D.J.; Keel, G.I.; Nemec, R.B.; Reinert, R.A. Directed light fabrication of a solid metal hemisphere using 5-axis powder deposition. J. Mater. Process. Technol. 1998, 75, 165–172. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Ruiz, J.E.; Cortina, M.; Ukar, E.; Lamikiz, A. Evaluación de la sobreacumulación de material en los cambios de dirección durante el proceso de aporte por láser mediante un modelo integral. Revista Iberoamericana de Ingenieria Mecanica 2018, 22, 3–12. [Google Scholar]

- Heigel, J.C.; Phan, T.Q.; Fox, J.C.; Gnaupel-Herold, T.H. Experimental Investigation of Residual Stress and its Impact on Machining in Hybrid Additive/Subtractive Manufacturing. Procedia Manuf. 2018, 26, 929–940. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Nicastro, L.; Kent, D.; Chen, Y.; Dargusch, M.S. Optimising the mechanical properties of Ti-6Al-4V components produced by wire + arc additive manufacturing with post-process heat treatments. J. Alloys Compd. 2018, 753, 247–255. [Google Scholar] [CrossRef]

- Oyelola, O.; Crawforth, P.; M’Saoubi, R.; Clare, A.T. On the machinability of directed energy deposited Ti6Al4V. Addit. Manuf. 2018, 19, 39–50. [Google Scholar] [CrossRef]

- Kobryn, P.; Semiatin, S. Mechanical properties of laser-deposited Ti-6Al-4V. In Proceedings of the Solid Freeform Fabrication, Austin, TX, USA, 6–8 August 2001; pp. 179–186. [Google Scholar]

- Åsberg, M.; Fredriksson, G.; Hatami, S.; Fredriksson, W.; Krakhmalev, P. Influence of post treatment on microstructure, porosity and mechanical properties of additive manufactured H13 tool steel. Mater. Sci. Eng. A 2019, 742, 584–589. [Google Scholar] [CrossRef]

- Salonitis, K.; Zarban, S.A. Redesign Optimization for Manufacturing Using Additive Layer Techniques. Proc. CIRP 2015, 36, 193–198. [Google Scholar] [CrossRef]

- Hällgren, S.; Pejryd, L.; Ekengren, J. (Re)Design for Additive Manufacturing. Proc. CIRP 2016, 50, 246–251. [Google Scholar] [CrossRef]

- Jared, B.H.; Aguilo, M.A.; Beghini, L.L.; Boyce, B.L.; Clark, B.W.; Cook, A.; Kaehr, B.J.; Robbins, J. Additive manufacturing: Toward holistic design. Scripta Materialia 2017, 135, 141–147. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P.; Papacharalampopoulos, A.; Bikas, H. Addressing the challenges for the industrial application of additive manufacturing: Towards a hybrid solution. Int. J. Lightw. Mater. Manuf. 2018, 1, 157–168. [Google Scholar] [CrossRef]

- Markillie, P. A Third Industrial Revolution. The Economist. 2013. Available online: http://www.economist.com/node/21552901 (accessed on 13 December 2018).

- Walter, J.; Baumgärtel, A.; Hustedt, M.; Hebisch, R.; Kaierle, S. Inhalation exposure to hazardous substances during powder-bed processes. Proc. CIRP 2018, 74, 295–299. [Google Scholar] [CrossRef]

- Drizo, A.; Pegna, J. Environmental impacts of rapid prototyping: An overview of research to date. Rapid Prototyp. J. 2006, 12, 64–71. [Google Scholar] [CrossRef]

- Carroll, P.A.; Brown, P.; Ng, G.; Scudamore, R.; Pinkerton, A.J.; Syed, W.; Sezer, H.; Li, L.; Allen, J. The Effect of Powder Recycling in Direct Metal Laser Deposition on Powder and Manufactured Part Characteristics. In Proceedings of the AVT-139 Specialists Meeting on Cost Effective Manufacture via Net Shape Processing, NATO Research and Technology Organisation, Neuilly-sur-Seine, France, 18 May 2006; Paper 18. Available online: http://eprints.lancs.ac.uk/59645/1/MP_AVT_139_18.pdf (accessed on 13 December 2018).

- Renderos, M.; Torregaray, A.; Gutierrez-Orrantia, M.E.; Lamikiz, A.; Saintier, N.; Girot, F. Microstructure characterization of recycled IN718 powder and resulting laser clad material. Mater. Charact. 2017, 134, 103–113. [Google Scholar] [CrossRef]

- Lasertec 65 3D Hybrid. DMG Mori. Available online: https://en.dmgmori.com/products/machines/advanced-technology/additive-manufacturing/powder-nozzle/lasertec-65-3d-hybrid (accessed on 13 December 2018).

- Lasertec 4300 3D Hybrid. DMG Mori. Available online: https://en.dmgmori.com/products/machines/advanced-technology/additive-manufacturing/powder-nozzle/lasertec-4300-3d-hybrid (accessed on 13 December 2018).

- Integrex i-400AM. Mazak. Available online: https://www.mazakusa.com/machines/integrex-i-400am/ (accessed on 13 December 2018).

- Integrex VC-500 AM. Mazak. Available online: https://www.mazakusa.com/machines/vc-500-am/ (accessed on 13 December 2018).

- Mazatrol Smooth CNC. Mazak. Available online: https://english.mazak.jp/machines/process/cnc-software/CNC/#high-quality (accessed on 13 December 2018).

- Integrex i-200s AM. Mazak. Available online: https://english.mazak.jp/news-events/press-releases/integrex-i-200s-am/ (accessed on 13 December 2018).

- Hybrid Multi-Tasking Machine—AM. Mazak. Available online: https://www.mazakeu.co.uk/machines-technology/technology/hybrid-multi-tasking-machine/ (accessed on 13 December 2018).

- Variaxis j-600AM. Mazak. Available online: https://www.mazakusa.com/news-events/news-releases/new-variaxis-j-600am-grows-the-mazak-additive-series/ (accessed on 13 December 2018).

- MU-5000V Laser EX. Okuma. Available online: https://www.okuma.eu/products/multitasking-machines/maschinenpark/baureihe/detail/laser-ex-series/mu-5000v-laser-ex/ (accessed on 13 December 2018).

- Multus U3000 Laser EX. Okuma. Available online: https://www.okuma.eu/products/multitasking-machines/maschinenpark/baureihe/detail/laser-ex-series/multus-u3000-laser-ex/ (accessed on 13 December 2018).

- Additive Manufacturing. WFL. Available online: https://www.wfl.at/en/technologies/additive-manufacturing (accessed on 13 December 2018).

- ZVH 45/L1600 Add&Process—Ibarmia. EMO 2015 Booklet. Available online: https://www.automation.siemens.com/machine-booklet/Booklet/554b7a0d3cb6e12b08e5338c/en/Machine/55d2ebeb3278301a748a9497 (accessed on 13 December 2018).

- Scott, C. Mitsui Seiki USA to Introduce the Vertex 55X-H, a New Hybrid CNC Machine and 3D Printer. 3DPrint. 2016. Available online: https://3dprint.com/141841/mitsui-seiki-cnc-3d-printer/ (accessed on 13 December 2018).

- World’s First Hybrid Grinding and Additive Manufacturing Machine Unveiled. TCT Magazine. 2015. Available online: https://www.tctmagazine.com/3d-printing-news/worlds-first-hybrid-grinding-and-additive-manufacturing-machine/ (accessed on 13 December 2018).

- OPM 250L. Sodick. Available online: https://www.sodick.com/products/metal-3d-printing/opm250l (accessed on 13 December 2018).

- OPM 350L. Sodick. Available online: https://www.sodick.org/products/additive-manufacturing/opm350l.html (accessed on 13 December 2018).

- Lumex. Matsuura. Available online: http://www.lumex-matsuura.com/english/ (accessed on 13 December 2018).

- Lumex Avance 25. Maquinser. Available online: https://www.maquinser.com/en/product/lumex_avance_25/ (accessed on 13 December 2018).

- Lumex Avance 60. Maquinser. Available online: https://www.maquinser.com/producto/lumex-avance-60/ (accessed on 13 December 2018).

- Lumex Series. Matsuura. Available online: http://www.lumex-matsuura.com/english/contents/lumex03.html (accessed on 13 December 2018).

- GF Enters Strategic Partnership with Leading 3D Printing Manufacturer. GF Machining Solutions. Available online: https://www.gfms.com/com/en/about-gf-machining-solutions/press-room/press-releases/2018/gf-enters-strategic-partnership-with-leading-3d-printing-manufac.html (accessed on 13 December 2018).

- +GF+ DMP Factory 500. GF Machining Solutions. Available online: https://www.gfms.com/content/dam/gfac/proddb/advanced-manufacturing/en/brochure-dmp-factory-500-en.pdf (accessed on 13 December 2018).

- 3D Systems and GF Machining Solutions Announce DMP Factory 500—Integrating the Best of Additive and Subtractive to Transform Manufacturing. PR Newswire. Available online: https://www.prnewswire.com/news-releases/3d-systems-and-gf-machining-solutions-announce-dmp-factory-500---integrating-the-best-of-additive-and-subtractive-to-transform-manufacturing-300708474.html (accessed on 13 December 2018).

- Kerbrat, O.; Mognol, P.; Hascoët, J.Y. A new DFM approach to combine machining and additive manufacturing. Comput. Ind. 2011, 62, 684–692. [Google Scholar] [CrossRef]

- Le, V.T.; Paris, H.; Mandil, G. The development of a strategy for direct part reuse using additive and subtractive manufacturing technologies. Addit. Manuf. 2018, 22, 687–699. [Google Scholar] [CrossRef]

- Le, V.T.; Paris, H.; Mandil, G. Process planning for combined additive and subtractive manufacturing technologies in a remanufacturing context. J. Manuf. Syst. 2017, 44, 243–254. [Google Scholar] [CrossRef]

- Behandish, M.; Nelaturi, S.; de Kleer, J. Automated process planning for hybrid manufacturing. Comput.-Aided Des. 2018, 102, 115–127. [Google Scholar] [CrossRef]

- Tapia, G.; Elwany, A. A review on process monitoring and control in metal- based additive manufacturing. J. Manuf. Sci. Eng. 2014, 136, 060801. [Google Scholar] [CrossRef]

- Purtonen, T.; Kalliosaari, A.; Salminen, A. Monitoring and adaptive control of laser processes. Phys. Procedia 2014, 56, 1218–1231. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Kim, H.; Lin, Y.; Tseng, T.L.B. A review on quality control in additive manufacturing. Rapid Prototyp. J. 2018, 24, 645–669. [Google Scholar] [CrossRef]

- Yang Chua, Z.; Ahn, I.H.; Moon, S.K. Process Monitoring and Inspection Systems in Metal Additive Manufacturing: Status and Applications. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 235–245. [Google Scholar] [CrossRef]

- Colodrón, P.; Fariña, J.; Rodríguez-Andina, J.J.; Vidal, F.; Mato, J.L.; Montealegre, M.Á. Performance Improvement of a Laser Cladding System through FPGA-Based Control. In Proceedings of the 37th Annual Conference on IEEE Industrial Electronics Society, Melbourne, VIC, Australia, 7–10 November 2011; pp. 2814–2819. [Google Scholar]

- Araújo, J.R.; Rodríguez-Andina, J.J.; Farina, J.; Vidal, F.; Mato, J.L.; Montealegre, M.Á. FPGA-Based Laser Cladding System with Increased Robustness to Optical Defects. In Proceedings of the 38th Annual Conference on IEEE Industrial Electronics Society, Monteral, QC, Canada, 25–28 October 2012; pp. 4688–4693. [Google Scholar]

- Hofman, J.; Pathiraj, B.; Van Dijk, J.; De Lange, D.; Meijer, J. A Camera Based Feedback Control Strategy for the Laser Cladding Process. J. Mater. Process. Technol. 2012, 212, 2455–2462. [Google Scholar] [CrossRef]

- Mozaffari, A.; Fathi, A.; Khajepour, A.; Toyserkani, E. Optimal Design of Laser Solid Freeform Fabrication System and Real-Time Prediction of Melt Pool Geometry Using Intelligent Evolutionary Algorithms. Appl. Soft Comput. 2013, 13, 1505–1519. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepouhor, A.; Gerlich, A. Real-time monitoring and prediction of martensite formation and hardening depth during laser heat treatment. Surf. Coat. Technol. 2017, 315, 326–334. [Google Scholar] [CrossRef]

- Campbell, R.I.; Martorelli, M.; Lee, H.S. Surface roughness visualisation for rapid prototyping models. Comput.-Aided Des. 2002, 34, 717–725. [Google Scholar] [CrossRef]

- Mandić, M.; Galeta, T.; Raos, P.; Jugović, V. Dimensional accuracy of camera casing models 3D printed on Mcor IRIS: A case study. Adv. Prod. Eng. Manag. 2016, 11, 324–332. [Google Scholar] [CrossRef]

- Newton, L.; Gomez, C.; Helmli, F.; Blunt, L.; Senin, N.; Danzl, R.; Leach, R. A real topography measurement of metal additive surfaces using focus variation microscopy. Addit. Manuf. 2018, 25, 365–389. [Google Scholar] [CrossRef]

- Townsend, A.; Racasan, R.; Leach, R.; Senin, N.; Thompson, A.; Ramsey, A.; Bate, D.; Woolliams, P.; Brown, S.; Blunt, L. An interlaboratory comparison of X-ray computed tomography measurement for texture and dimensional characterisation of additively manufactured parts. Addit. Manuf. 2018, 23, 422–432. [Google Scholar] [CrossRef]

- Liu, Y.; Bobek, T.; Klocke, F. Laser path calculation method on triangulated mesh for repair process on turbine parts. Comput.-Aided Des. 2015, 66, 73–81. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Li, L. The significance of deposition point standoff variations in multiple-layer coaxial laser cladding (coaxial cladding standoff effects). Int. J. Mach. Tools Manuf. 2004, 44, 573–584. [Google Scholar] [CrossRef]

- Zhu, G.; Li, D.; Zhang, A.; Pi, G.; Tang, Y. The influence of laser and powder defocusing characteristics on the surface quality in laser direct metal deposition. Opt. Laser Technol. 2012, 44, 349–356. [Google Scholar] [CrossRef]

- Quality Inspection for 3D Printing. Siemens PLM. Available online: https://www.plm.automation.siemens.com/global/en/products/manufacturing-planning/quality-inspection-3d-printing.html (accessed on 13 December 2018).

- New CAM system for laser material deposition. Met. Powder Rep. 2013, 68, 36. [CrossRef]

- Elser, A.; Königs, M.; Verl, A.; Servos, M. On achieving accuracy and efficiency in Additive Manufacturing: Requirements on a hybrid CAM system. Proc. CIRP 2018, 72, 1512–1517. [Google Scholar] [CrossRef]

- Additive & Hybrid Manufacturing. Siemens PLM. Available online: https://community.plm.automation.siemens.com/t5/News-NX-Manufacturing/Additive-amp-Hybrid-Manufacturing-The-Future-of-3D-Printing-is/ba-p/309426 (accessed on 13 December 2018).

- NX for Manufacturing. Siemens PLM. Available online: http://www.plm.automation.siemens.com/en_us/products/nx/for-manufacturing/cam/hybrid-additive-manufacturing.shtml (accessed on 13 December 2018).

- NX CAM Hybrid Manufacturing. Siemens PLM Software. Available online: https://www.flickr.com/photos/31274959@N08/albums/72157653490811501/with/18100938796/ (accessed on 13 December 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cortina, M.; Arrizubieta, J.I.; Ruiz, J.E.; Ukar, E.; Lamikiz, A. Latest Developments in Industrial Hybrid Machine Tools that Combine Additive and Subtractive Operations. Materials 2018, 11, 2583. https://doi.org/10.3390/ma11122583

Cortina M, Arrizubieta JI, Ruiz JE, Ukar E, Lamikiz A. Latest Developments in Industrial Hybrid Machine Tools that Combine Additive and Subtractive Operations. Materials. 2018; 11(12):2583. https://doi.org/10.3390/ma11122583

Chicago/Turabian StyleCortina, Magdalena, Jon Iñaki Arrizubieta, Jose Exequiel Ruiz, Eneko Ukar, and Aitzol Lamikiz. 2018. "Latest Developments in Industrial Hybrid Machine Tools that Combine Additive and Subtractive Operations" Materials 11, no. 12: 2583. https://doi.org/10.3390/ma11122583

APA StyleCortina, M., Arrizubieta, J. I., Ruiz, J. E., Ukar, E., & Lamikiz, A. (2018). Latest Developments in Industrial Hybrid Machine Tools that Combine Additive and Subtractive Operations. Materials, 11(12), 2583. https://doi.org/10.3390/ma11122583