From Fibrils to Toughness: Multi-Scale Mechanics of Fibrillating Interfaces in Stretchable Electronics

Abstract

:1. Introduction

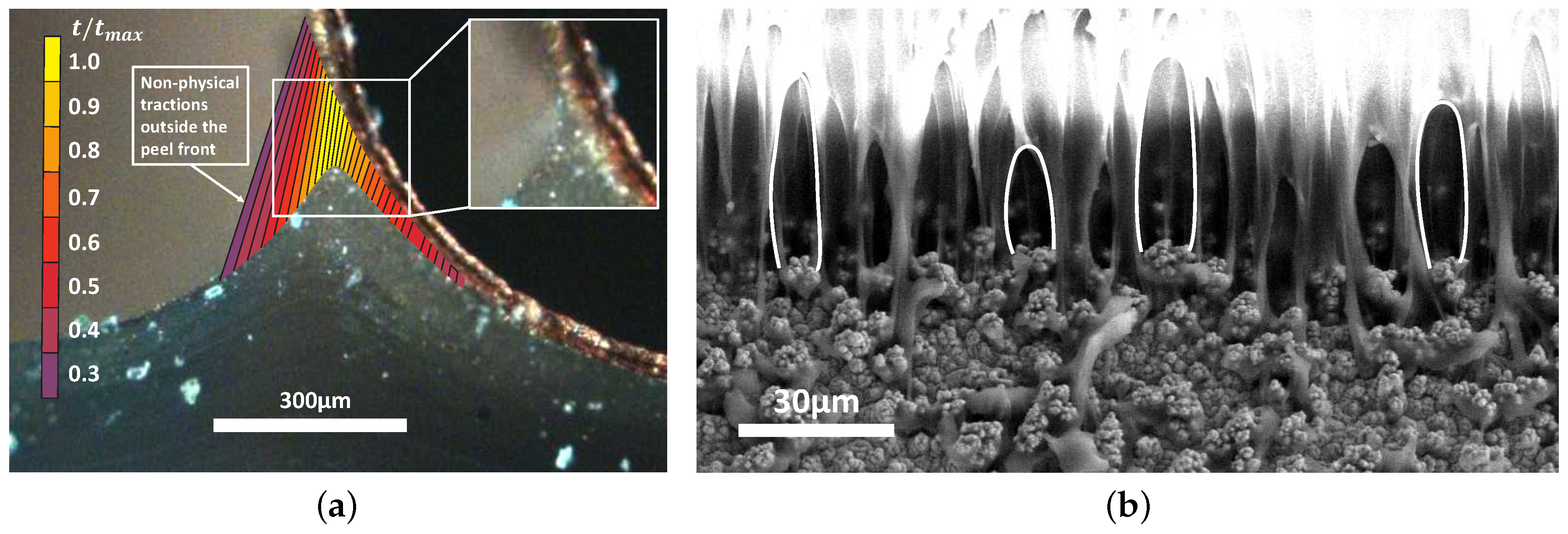

2. The Peel Test Experiments

3. The Peel Test Simulation Model

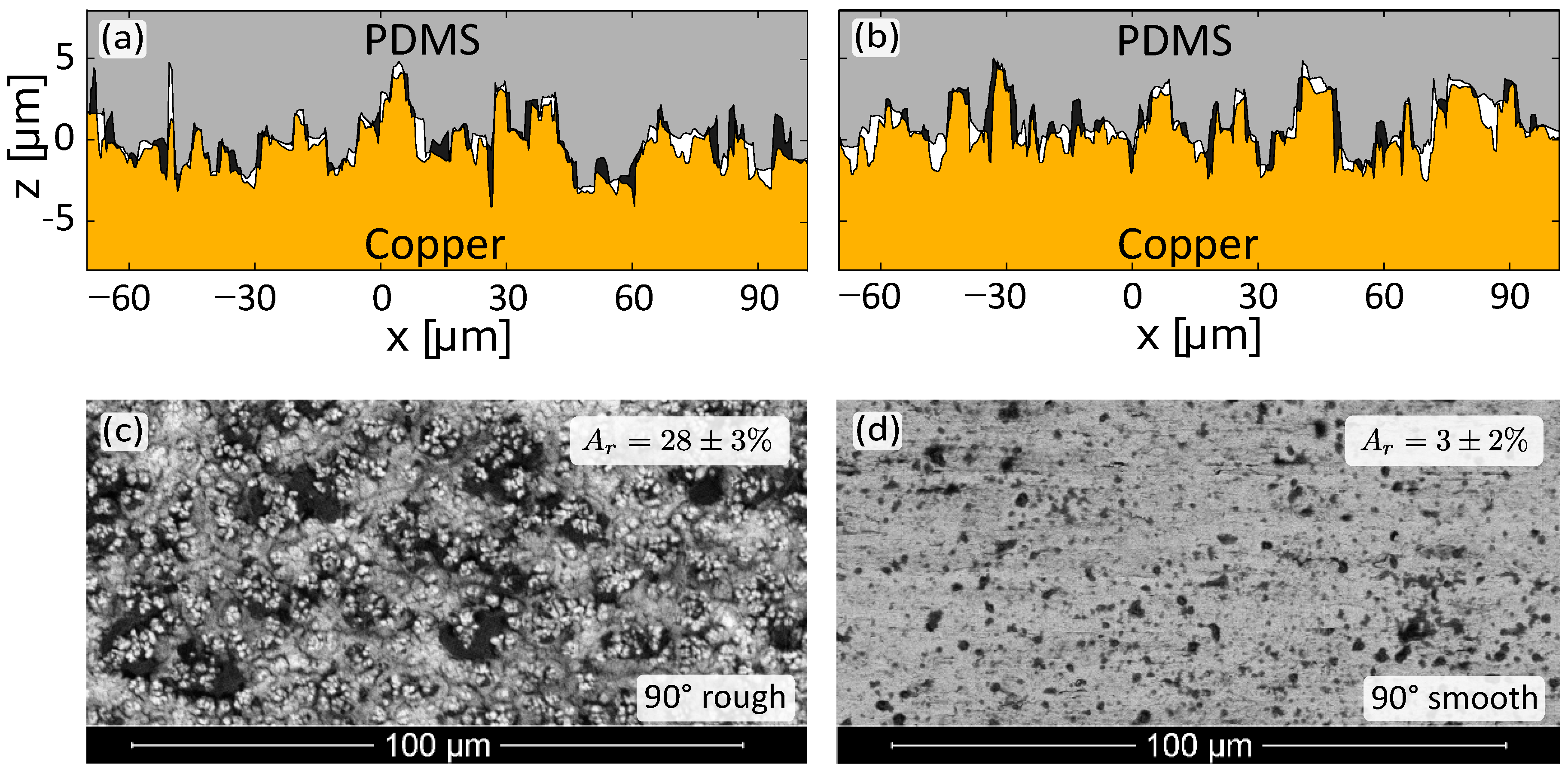

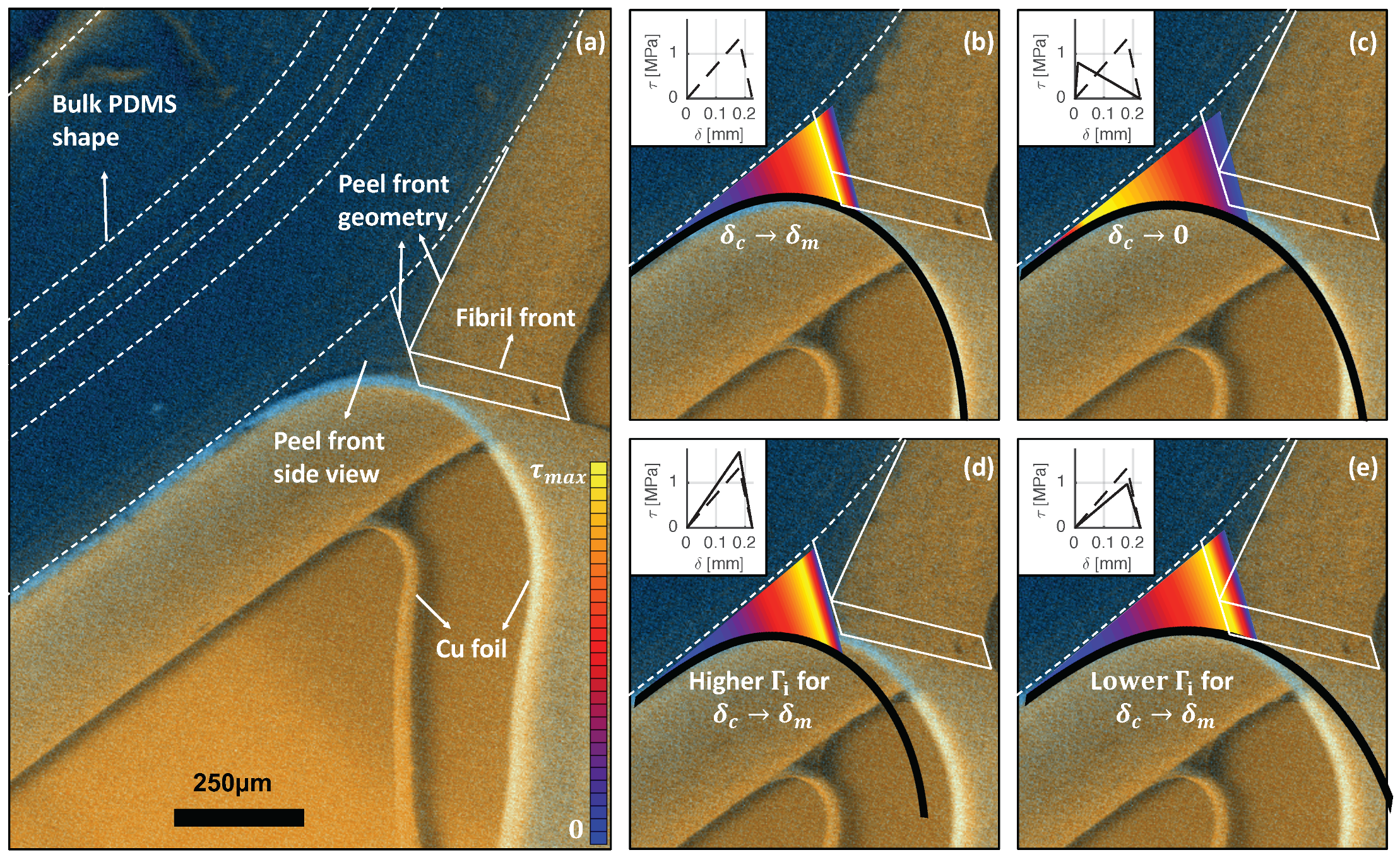

4. Experimental Analyses at the Microscopic Scale

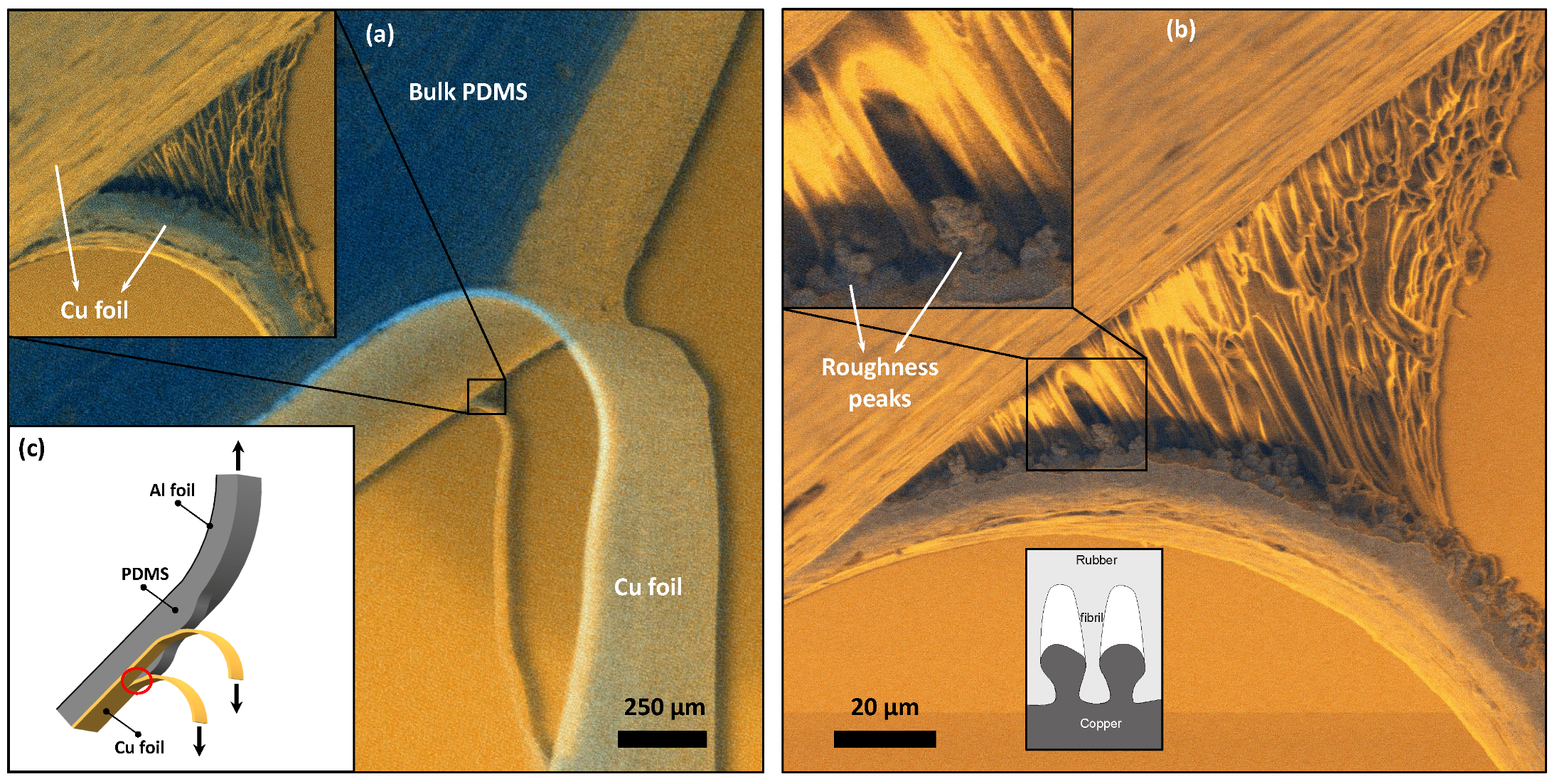

4.1. Visualization of Fibrillation

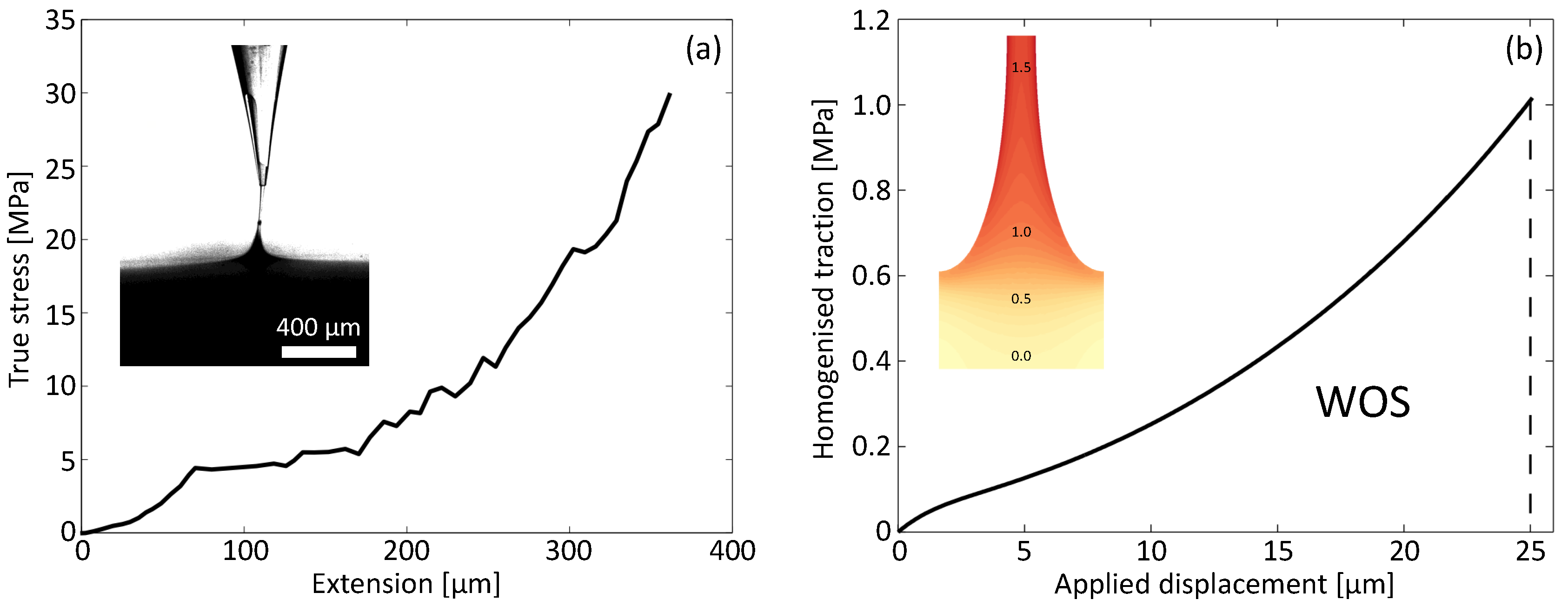

4.2. Material Behaviour of the PDMS Fibrils

4.2.1. Deformation

4.2.2. Failure

4.3. Alternative Peel Test

5. Numerical Analyses at the Microscopic Scale

5.1. The Single Fibril Model

5.2. The Multiple Fibril Model

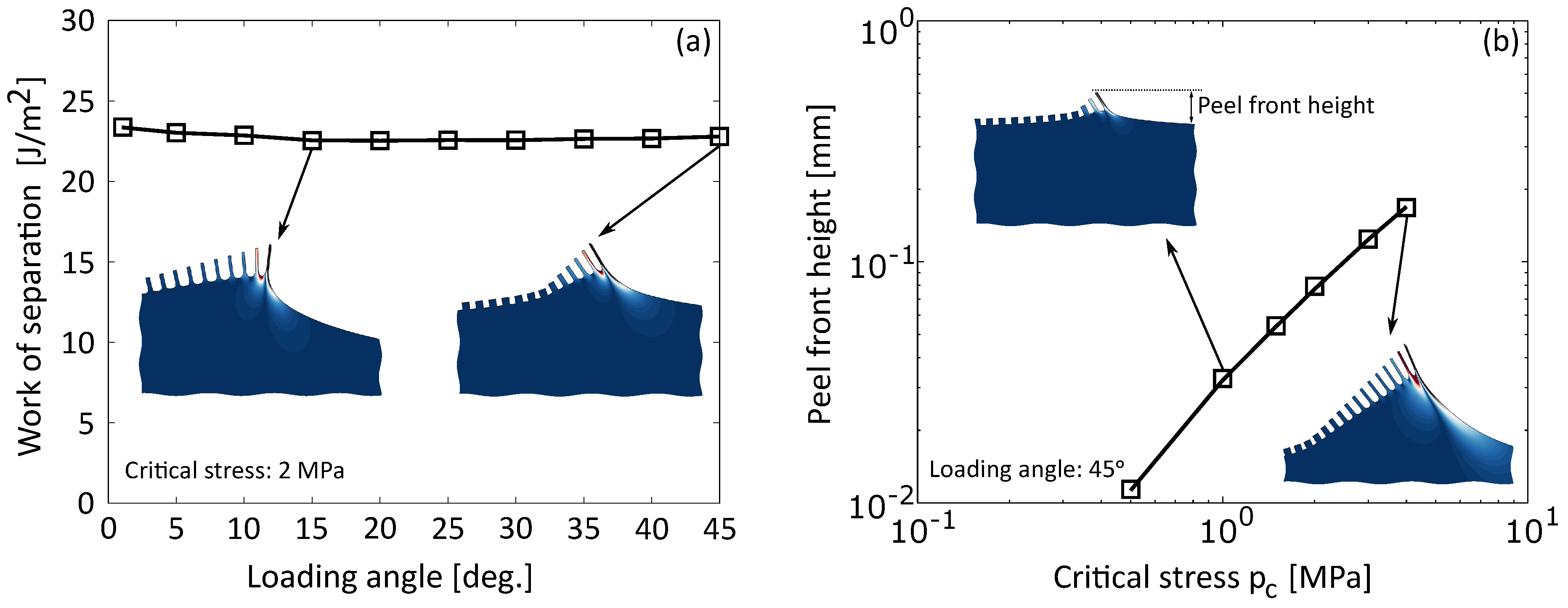

6. Macro-Scale CZ Model Revisited: A Fibril-Motivated TSL

The Pronounced Effect of the TSL Shape

7. Discussion

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| BSE | Back Scatter Electron |

| Cu | Copper |

| CZ | Cohesive Zone |

| DIC | Digital Image Correlation |

| ESEM | Environmental Scanning Electron Microscopy |

| FE | Finite Element |

| FPZ | Fracture Process Zone |

| GDIC | Global Digital Image Correlation |

| PDMS | Poly(dimethylsiloxane) |

| PSA | Pressure-sensitive adhesive |

| SE | Secundary Electron |

| SED | Strain energy density |

| TSL | Traction Separation Law |

| WOS | Work-of-separation |

References

- Lacour, S.P.; Jones, J.; Suo, Z.; Wagner, S. Design and performance of thin metal film interconnects for skin-like electronic circuits. IEEE Electron Device Lett. 2004, 25, 179–181. [Google Scholar] [CrossRef]

- Carta, R.; Jourand, P.; Hermans, B.; Thoné, J.; Brosteaux, D.; Vervust, T.; Bossuyt, F.; Axisa, F.; Vanfleteren, J.; Puers, R. Design and implementation of advanced systems in a flexible-stretchable technology for biomedical applications. Sens. Actuators A Phys. 2009, 156, 79–87. [Google Scholar] [CrossRef] [Green Version]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and Mechanics for Stretchable Electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef] [PubMed]

- Viventi, J.; Kim, D.H.; Moss, J.D.; Kim, Y.S.; Blanco, J.A.; Annetta, N.; Hicks, A.; Xiao, J.; Huang, Y.; Callans, D.J.; et al. A conformal, bio-interfaced class of silicon electronics for mapping cardiac electrophysiology. Sci. Transl. Med. 2010, 2, 24ra22. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Lu, N.; Ma, R.; Kim, Y.S.; Kim, R.H.; Wang, S.; Wu, J.; Won, S.M.; Tao, H.; Islam, A.; et al. Epidermal Electronics. Science 2011, 333, 838–843. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Lu, N.; Ghaffari, R.; Kim, Y.S.; Lee, S.P.; Xu, L.; Wu, J.; Kim, R.H.; Song, J.; Liu, Z.; et al. Materials for multifunctional balloon catheters with capabilities in cardiac electrophysiological mapping and ablation therapy. Nat. Mater. 2011, 10, 316–323. [Google Scholar] [CrossRef] [PubMed]

- Gutbrod, S.R.; Sulkin, M.S.; Rogers, J.A.; Efimov, I.R. Patient-specific flexible and stretchable devices for cardiac diagnostics and therapy. Prog. Biophys. Mol. Biol. 2014, 115, 244–251. [Google Scholar] [CrossRef] [PubMed]

- Quintero, A.V.; Verplancke, R.; de Smet, H.; Vanfleteren, J. Stretchable electronic platform for soft and smart contact lens applications. Adv. Mater. Technol. 2017, 2, 1700073. [Google Scholar] [CrossRef]

- An, B.W.; Shin, J.H.; Kim, S.Y.; Kim, J.; Ji, S.; Park, J.; Lee, Y.; Jang, J.; Park, Y.G.; Cho, E.; et al. Smart sensor systems for wearable electronic devices. Polymers 2017, 9, 303. [Google Scholar] [CrossRef]

- Harris, K.D.; Elias, A.L.; Chung, H.J. Flexible electronics under strain: A review of mechanical characterization and durability enhancement strategies. J. Mater. Sci. 2016, 51, 2771–2805. [Google Scholar] [CrossRef]

- Yu, X.; Mahajan, B.K.; Shou, W.; Pan, H. Materials, mechanics, and patterning techniques for elastomer-based stretchable conductors. Micromachines 2017, 8, 7. [Google Scholar] [CrossRef]

- Klein, S.A.; Aleksov, A.; Subramanian, V.; Malatkar, P.; Mahajan, R. Mechanical testing for stretchable electronics. J. Electron. Packag. 2017, 139, 020905. [Google Scholar] [CrossRef]

- Li, T.; Suo, Z.; Lacour, S.P.; Wagner, S. Compliant thin film patterns of stiff materials as platforms for stretchable electronics. J. Mater. Res. 2005, 20, 3274–3277. [Google Scholar] [CrossRef]

- Brosteaux, D.; Axisa, F.; Gonzalez, M.; Vanfleteren, J. Design and fabrication of elastic interconnections for stretchable electronic circuits. IEEE Electron Device Lett. 2007, 28, 552–554. [Google Scholar] [CrossRef]

- Gonzalez, M.; Axisa, F.; Vanden Bulcke, M.; Brosteaux, D.; Vandevelde, B.; Vanfleteren, J. Design of metal interconnects for stretchable electronic circuits. Microelectron. Reliab. 2008, 48, 825–832. [Google Scholar] [CrossRef]

- Shafqat, S.; Hoefnagels, J.P.M.; Savov, A.; Joshi, S.; Dekker, R.; Geers, M.G.D. Ultra-stretchable interconnects for high-density stretchable electronics. Micromachines 2017, 8, 277. [Google Scholar] [CrossRef]

- Li, T.; Suo, Z. Ductility of thin metal films on polymer substrates modulated by interfacial adhesion. Int. J. Solids Struct. 2007, 44, 1696–1705. [Google Scholar] [CrossRef]

- Lu, N.; Wang, X.; Suo, Z.; Vlassak, J. Metal films on polymer substrates stretched beyond 50%. Appl. Phys. Lett. 2007, 91, 221909. [Google Scholar] [CrossRef]

- Hsu, Y.Y.; Gonzalez, M.; Bossuyt, F.; Axisa, F.; Vanfleteren, J.; De Wolf, I. The effect of pitch on deformation behavior and the stretching-induced failure of a polymer-encapsulated stretchable circuit. J. Micromech. Microeng. 2010, 20, 075036. [Google Scholar] [CrossRef]

- Xu, F.; Zhu, Y. Highly conductive and stretchable silver nanowire conductors. Adv. Mater. 2012, 24, 5117–5122. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Lee, H.; Lee, J.; Kwon, J.; Han, S.; Suh, Y.D.; Cho, H.; Shin, J.; Yeo, J.; Ko, S.H. Highly stretchable and transparent metal nanowire heater for wearable electronics applications. Adv. Mater. 2015, 27, 4744–4751. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Kim, J.; Kim, K.; Kim, S.Y.; Cheong, W.H.; Park, K.; Song, J.H.; Namgoong, G.; Kim, J.J.; Heo, J.; et al. Wearable, wireless gas sensors using highly stretchable and transparent structures of nanowires and graphene. Nanoscale 2016, 8, 10591–10597. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, M.; Lee, M.S.; Kim, K.; Ji, S.; Kim, Y.T.; Park, J.; Na, K.; Bae, K.H.; Kim, H.K.; et al. Wearable smart sensor systems integrated on soft contact lenses for wireless ocular diagnostics. Nat. Commun. 2017, 8, 14997. [Google Scholar] [CrossRef] [PubMed]

- Hsu, Y.Y.; Gonzalez, M.; Bossuyt, F.; Axisa, F.; Vanfleteren, J.; de Wolf, I. In situ observations on deformation behavior and stretching-induced failure of fine pitch stretchable interconnect. J. Mater. Res. 2009, 24, 3573–3582. [Google Scholar] [CrossRef]

- Hoefnagels, J.P.M.; Neggers, J.; Timmermans, P.H.M.; van der Sluis, O.; Geers, M.G.D. Copper-Rubber Interface Delamination in Stretchable Electronics. Scr. Mater. 2010, 63, 875–878. [Google Scholar] [CrossRef]

- Van der Sluis, O.; Hsu, Y.Y.; Timmermans, P.H.M.; Gonzalez, M.; Hoefnagels, J.P.M. Stretching induced interconnect delamination in stretchable electronic circuits. J. Phys. D Appl. Phys. 2011, 44, 034008. [Google Scholar] [CrossRef]

- Neggers, J.; Hoefnagels, J.P.M.; van der Sluis, O.; Geers, M.G.D. Multi-scale experimental analysis of rate dependent metal-elastomer interface mechanics. J. Mech. Phys. Solids 2015, 80, 26–36. [Google Scholar] [CrossRef]

- Neggers, J.; Hoefnagels, J.P.M.; van der Sluis, O.; Sedaghat, O.; Geers, M.G.D. Analysis of the dissipative mechanisms in metal-elastomer interfaces. Eng. Fract. Mech. 2015, 149, 412–424. [Google Scholar] [CrossRef]

- Creton, C.; Kramer, E.J.; Hui, C.Y.; Brown, H.R. Failure mechanisms of polymer interfaces reinforced with block copolymers. Macromolecules 1992, 25, 3075–3088. [Google Scholar] [CrossRef]

- Crosby, A.J.; Shull, K.R.; Lakrout, H.; Creton, C. Deformation and failure modes of adhesively bonded elastic layers. J. Appl. Phys. 2000, 88, 2956–2966. [Google Scholar] [CrossRef]

- Jagota, A.; Bennison, S.J. Mechanics of adhesion through a fibrillar microstructure. Integr. Comp. Biol. 2002, 42, 1140–1145. [Google Scholar] [CrossRef] [PubMed]

- Jagota, A.; Hui, C.Y. Adhesion, friction, and compliance of bio-mimetic and bio-inspired structured interfaces. Mater. Sci. Eng. R Rep. 2011, 72, 253–292. [Google Scholar] [CrossRef]

- Hui, C.Y.; Glassmaker, N.J.; Tang, T.; Jagota, A. Design of biomimetic fibrillar interfaces: 2. Mechanics of enhanced adhesion. J. R. Soc. Interface 2004, 1, 35–48. [Google Scholar] [CrossRef] [PubMed]

- Glassmaker, N.J.; Himeno, T.; Hui, C.Y.; Kim, J. Design of biomimetic fibrillar interfaces: 1. Making contact. J. R. Soc. Interface 2004, 1, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Glassmaker, N.J.; Jagota, A.; Hui, C.Y. Adhesion enhancement in a biomimetic fibrillar interface. Acta Biomater. 2005, 1, 367–375. [Google Scholar] [CrossRef] [PubMed]

- Tang, T.; Hui, C.Y.; Glassmaker, N.J. Can a fibrillar interface be stronger and tougher than a non-fibrillar one? J. R. Soc. Interface 2005, 2, 505–516. [Google Scholar] [CrossRef] [PubMed]

- Shen, S.; Soh, A.K. Tuning the geometrical parameters of biomimetic fibrillar structures to enhance adhesion. J. R. Soc. Interface 2008, 5, 373–382. [Google Scholar]

- Guidoni, G.M.; Schillo, D.; Hangen, U.; Castellanos, G.; Arzt, E.; McMeeking, R.M.; Bennewitz, R. Discrete contact mechanics of a fibrillar surface with backing layer interactions. J. Mech. Phys. Solids 2010, 58, 1571–1581. [Google Scholar] [CrossRef]

- Zhao, X. Multi-scale multi-mechanism design of tough hydrogels: Building dissipation into stretchy networks. Soft Matter 2014, 10, 672–687. [Google Scholar] [CrossRef] [PubMed]

- Yuk, H.; Zhang, T.; Lin, S.; Parada, G.; Zhao, X. Tough bonding of hydrogels to diverse non-porous surfaces. Nat. Mater. 2016, 15, 190–196. [Google Scholar] [CrossRef] [PubMed]

- Bauer, C.T.; Kroner, E.; Fleck, N.A.; Arzt, E. Hierarchical macroscopic fibrillar adhesives: In situ study of buckling and adhesion mechanisms on wavy substrates. Bioinspir. Biomim. 2015, 10, 066002. [Google Scholar] [CrossRef] [PubMed]

- Creton, C. Pressure-Sensitive Adhesives: An Introductory Course. MRS Bull. 2003, 28, 434–439. [Google Scholar] [CrossRef]

- Brown, K.; Hooker, J.C.; Creton, C. Micromechanisms of tack of soft adhesives based on styrenic block copolymers. Macromol. Mater. Eng. 2002, 287, 163–179. [Google Scholar] [CrossRef]

- Lakrout, H.; Sergot, P.; Creton, C. Direct observation of cavitation and fibrillation in a probe tack experiment on model acrylic pressure-sensitive-adhesives. J. Adhes. 1999, 69, 307–359. [Google Scholar] [CrossRef]

- Shull, K.R.; Creton, C. Deformation behavior of thin, compliant layers under tensile loading conditions. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 4023–4043. [Google Scholar] [CrossRef]

- Volinsky, A.; Moody, N.; Gerberich, W. Interfacial toughness measurements for thin films on substrates. Acta Mater. 2002, 50, 441–466. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S. Approaches to investigate delamination and interfacial toughness in coated systems: An overview. J. Phys. D Appl. Phys. 2011, 44, 034001. [Google Scholar] [CrossRef]

- Fedorov, A.; van Tijum, R.; Vellinga, W.; De Hosson, J. Degradation and recovery of adhesion properties of deformed metal-polymer interfaces studied by laser induced delamination. Prog. Organ. Coat. 2007, 58, 180–186. [Google Scholar] [CrossRef]

- Van Tijum, R.; Vellinga, W.; De Hosson, J. Adhesion along metal-polymer interfaces during plastic deformation. J. Mater. Sci. 2007, 42, 3529–3536. [Google Scholar] [CrossRef]

- Van den Bosch, M.J.; Schreurs, P.J.G.; Geers, M.G.D. Identification and characterization of delamination in polymer coated metal sheet. J. Mech. Phys. Solids 2008, 56, 3259–3276. [Google Scholar] [CrossRef]

- Kendall, K. Thin-film peeling—The elastic term. J. Phys. D Appl. Phys. 1975, 8, 1449–1452. [Google Scholar] [CrossRef]

- Thouless, M.D.; Jensen, H.M. Elastic fracture mechanics of the peel-test geometry. J. Adhes. 1992, 38, 185–197. [Google Scholar] [CrossRef]

- Kim, K.S.; Aravas, N. Elastoplastic analysis of the peel test. Int. J. Solids Struct. 1988, 24, 417–435. [Google Scholar] [CrossRef]

- van den Bosch, M.J.; Schreurs, P.J.G.; Geers, M.G.D. A cohesive zone model with a large displacement formulation accounting for interfacial fibrilation. Eur. J. Mech. A Solids 2007, 26, 1–19. [Google Scholar] [CrossRef]

- Vossen, B.G.; van der Sluis, O.; Schreurs, P.J.G.; Geers, M.G.D. On the role of fibril mechanics in the work of separation of fibrillating interfaces. Mech. Mater. 2015, 88, 1–11. [Google Scholar] [CrossRef]

- Neggers, J.; Hoefnagels, J.P.M.; Hild, F.; Roux, S.; Geers, M.G.D. Direct stress-strain measurements from bulged membranes using topography image correlation. Exp. Mech. 2014, 54, 717–727. [Google Scholar] [CrossRef]

- Maas, S.A.; Ellis, B.J.; Ateshian, G.A.; Weiss, J.A. FEBio: Finite elements for biomechanics. J. Biomech. Eng. 2012, 134, 011005. [Google Scholar] [CrossRef] [PubMed]

- Vossen, B.G.; Schreurs, P.J.G.; van der Sluis, O.; Geers, M.G.D. Multiscale modelling of delamination through fibrillation. J. Mech. Phys. Solids 2014, 6, 117–132. [Google Scholar] [CrossRef]

- Matouš, K.; Kulkarni, M.G.; Geubelle, P.H. Multiscale cohesive failure modeling of heterogeneous adhesives. J. Mech. Phys. Solids 2008, 56, 1511–1533. [Google Scholar] [CrossRef]

- Hirschberger, C.; Ricker, S.; Steinmann, P.; Sukumar, N. Computational multiscale modeling of heterogeneous material layers. Eng. Fract. Mech. 2009, 76, 793–812. [Google Scholar] [CrossRef]

- Verhoosel, C.V.; Remmers, J.J.C.; Gutiérrez, M.A.; de Borst, R. Computational homogenization for adhesive and cohesive failure in quasi-brittle solids. Int. J. Numer. Methods Eng. 2010, 83, 1155–1179. [Google Scholar] [CrossRef]

- Cid Alvaro, M.V.; Suiker, A.S.J.; Verhoosel, C.V.; de Borst, R. Numerical homogenization of cracking processes in thin fibre-epoxy layers. Eur. J. Mech. A Solids 2010, 29, 119–131. [Google Scholar] [CrossRef]

- Krishnan, V.R.; Hui, C.Y. Large deformation of soft elastic materials in adhesive contact with a rigid cylindrical flat punch. Soft Matter 2008, 4, 1909–1915. [Google Scholar] [CrossRef]

- Vossen, B.G.; van der Sluis, O.; Schreurs, P.J.G.; Geers, M.G.D. High toughness fibrillating metal-elastomer interfaces: On the role of discrete fibrils within the fracture process zone. Eng. Fract. Mech. 2016, 164, 93–105. [Google Scholar] [CrossRef]

- Reeder, J.R.; Crews, J.R. Mixed mode bending method for delamination testing. AIAA J. 1990, 28, 1270–1276. [Google Scholar] [CrossRef]

- Hutchinson, J.W.; Suo, Z. Mixed mode cracking in layered materials. Adv. Appl. Mech. 1992, 29, 63–191. [Google Scholar]

- Chandra, N.; Li, H.; Shet, C.; Ghonem, H. Some issues in the application of cohesive zone models for metal-ceramic interfaces. Int. J. Solids Struct. 2002, 39, 2827–2855. [Google Scholar] [CrossRef]

- Alfano, G. On the influence of the shape of the interface law on the application of cohesive-zone models. Compos. Sci. Technol. 2006, 66, 723–730. [Google Scholar] [CrossRef]

- Dimitri, R.; Trullo, M.; Lorenzis, L.D.; Zavarise, G. Coupled cohesive zone models for mixed-mode fracture: A comparative study. Eng. Fract. Mech. 2015, 148, 145–179. [Google Scholar] [CrossRef]

- Li, H.; Chandra, N. Analysis of crack growth and crack-tip plasticity in ductile materials using cohesive zone models. Int. J. Plast. 2003, 19, 849–882. [Google Scholar] [CrossRef]

- Qiu, Y.; Crisfield, M.A.; Alfano, G. Interface element Formation for the simulation of delamination with buckling. Eng. Fract. Mech. 2001, 68, 1755–1776. [Google Scholar] [CrossRef]

- Noijen, S.P.M.; van der Sluis, O.; Timmermans, P.H.M.; Zhang, G.Q. A semi-analytic method for crack kinking analysis at isotropic bi-material interfaces. Eng. Fract. Mech. 2012, 83, 8–25. [Google Scholar] [CrossRef]

- Strom, J.L.; Parmigiani, J.P. Transition of crack path at bi-material interfaces. Eng. Fract. Mech. 2014, 115, 13–21. [Google Scholar] [CrossRef]

- Van der Sluis, O.; Remmers, J.J.C.; Thurlings, M.A.C.; Welling, B.J.; Noijen, S.P.M. The competition between adhesive and cohesive fracture at a micro-patterned polymer-metal interface. Key Eng. Mater. 2014, 577–578, 225–228. [Google Scholar]

- Tankasala, H.C.; Deshpande, V.S.; Fleck, N.A. Crack kinking at the tip of a mode I crack in an orthotropic solid. Int. J. Fract. 2017, 207, 181–191. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van der Sluis, O.; Vermeij, T.; Neggers, J.; Vossen, B.; Van Maris, M.; Vanfleteren, J.; Geers, M.; Hoefnagels, J. From Fibrils to Toughness: Multi-Scale Mechanics of Fibrillating Interfaces in Stretchable Electronics. Materials 2018, 11, 231. https://doi.org/10.3390/ma11020231

Van der Sluis O, Vermeij T, Neggers J, Vossen B, Van Maris M, Vanfleteren J, Geers M, Hoefnagels J. From Fibrils to Toughness: Multi-Scale Mechanics of Fibrillating Interfaces in Stretchable Electronics. Materials. 2018; 11(2):231. https://doi.org/10.3390/ma11020231

Chicago/Turabian StyleVan der Sluis, Olaf, Tijmen Vermeij, Jan Neggers, Bart Vossen, Marc Van Maris, Jan Vanfleteren, Marc Geers, and Johan Hoefnagels. 2018. "From Fibrils to Toughness: Multi-Scale Mechanics of Fibrillating Interfaces in Stretchable Electronics" Materials 11, no. 2: 231. https://doi.org/10.3390/ma11020231