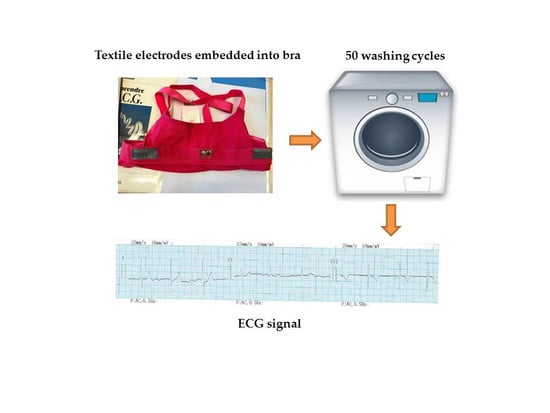

Washable and Reliable Textile Electrodes Embedded into Underwear Fabric for Electrocardiography (ECG) Monitoring

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. PEDOT:PSS Absorption

3.2. Electrical Characterization

3.3. Evaluation of Textile Electrodes in ECG Monitoring

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kolev, M.A.G.D.G. Electrical characterization of PEDOT: PSS based flexible organic optoelectronic devices. Int. J. Tech. Phys. Probl. Eng. 2016, 8, 71–76. [Google Scholar]

- Takamatsu, S.; Lonjaret, T.; Crisp, D.; Badier, J.-M.; Malliaras, G.G.; Ismailova, E. Direct patterning of organic conductors on knitted textiles for long-term electrocardiography. Sci. Rep. 2015, 5, 15003. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lang, U.; Naujoks, N.; Dual, J. Mechanical characterization of PEDOT:PSS thin films. Synth. Met. 2009, 159, 473–479. [Google Scholar] [CrossRef]

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23, 053001. [Google Scholar] [CrossRef]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.-M. Fiber-Based Wearable Electronics: A Review of Materials, Fabrication, Devices, and Applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef] [PubMed]

- Liao, C.; Zhang, M.; Yao, M.Y.; Hua, T.; Li, L.; Yan, F. Flexible Organic Electronics in Biology: Materials and Devices. Adv. Mater. 2015, 27, 7493–7527. [Google Scholar] [CrossRef] [PubMed]

- Taji, B.; Shirmohammadi, S.; Groza, V.; Batkin, I. Impact of Skin–Electrode Interface on Electrocardiogram Measurements Using Conductive Textile Electrodes. IEEE Trans. Instrum. Meas. 2014, 63, 1412–1422. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Pani, D.; Dessi, A.; Saenz-Cogollo, J.F.; Barabino, G.; Fraboni, B.; Bonfiglio, A. Fully Textile, PEDOT:PSS Based Electrodes for Wearable ECG Monitoring Systems. IEEE Trans. Biomed. Eng. 2016, 63, 540–549. [Google Scholar] [CrossRef] [PubMed]

- Tao, X.; Koncar, V.; Huang, T.H.; Shen, C.L.; Ko, Y.C.; Jou, G.T. How to Make Reliable, Washable, and Wearable Textronic Devices. Sensors (Basel) 2017, 17, 673. [Google Scholar] [CrossRef] [PubMed]

- ISO. ISO 6330:2012 Textiles—Domestic Washing and Drying Procedures for Textile Testing; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- ASTM. Standard D 257-99. Standard Test Methods for D-C Resistance or Conductance of Insulating Materials; ASTM International: West Conshohocken, PA, USA, 1999. [Google Scholar]

- IEC. 61340-5-1 Standard. Electrostatics—Part 5-1: Protection of Electronic Devices from Electrostatic Phenomena-General Requirements; The International Electrotechnical Commission: Geneva, Switzerland, 1998. [Google Scholar]

- Sensors and Cables. 12-Lead ECG Placement Guide with Illustrations Cables and Sensors. Available online: https://www.cablesandsensors.com/pages/12-lead-ecg-placement-guide-with-illustrations (accessed on 21 October 2017).

- Limb Leads—ECG Lead Placement—Normal Function of the Heart—Cardiology Teaching Package—Practice Learning—Division of Nursing—The University of Nottingham. Available online: Nottingham.ac.uk (accessed on 15 August 2009).

- Lesson 1: The Standard 12 Lead ECG. Available online: Library.med.utah.edu (accessed on 22 March 2009).

- Jin, B.E.; Wulff, H.; Widdicombe, J.H.; Zheng, J.; Bers, D.M.; Puglisi, J.L. A simple device to illustrate the Einthoven triangle. Adv. Physiol. Educ. 2012, 36, 319–324. [Google Scholar] [CrossRef] [PubMed]

- Assambo, C.; Baba, A.; Dozio, R.; Burke, M.J. Determination of the parameters of the skin-electrode impedance model for ECG measurement. In Proceedings of the 6th WSEAS International Conference on Electronics, Hardware, Wireless and Optical Communications, Corfu Island, Greece, 16–19 February 2007; pp. 90–95. [Google Scholar]

| Textile Electrodes | Percentage of Absorbed PEDOT:PSS after Drying (wt %) |

|---|---|

| Cotton | 6% |

| Polyamide | 4.4% |

| Polyester | 3.2% |

| Textile Electrodes | Surface Resistivity (kΩ) | Standard Deviation (kΩ) |

|---|---|---|

| Cotton | 21.02 | 0.64 |

| Polyamide | 34.26 | 0.74 |

| Polyester | 36.31 | 0.84 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ankhili, A.; Tao, X.; Cochrane, C.; Coulon, D.; Koncar, V. Washable and Reliable Textile Electrodes Embedded into Underwear Fabric for Electrocardiography (ECG) Monitoring. Materials 2018, 11, 256. https://doi.org/10.3390/ma11020256

Ankhili A, Tao X, Cochrane C, Coulon D, Koncar V. Washable and Reliable Textile Electrodes Embedded into Underwear Fabric for Electrocardiography (ECG) Monitoring. Materials. 2018; 11(2):256. https://doi.org/10.3390/ma11020256

Chicago/Turabian StyleAnkhili, Amale, Xuyuan Tao, Cédric Cochrane, David Coulon, and Vladan Koncar. 2018. "Washable and Reliable Textile Electrodes Embedded into Underwear Fabric for Electrocardiography (ECG) Monitoring" Materials 11, no. 2: 256. https://doi.org/10.3390/ma11020256

APA StyleAnkhili, A., Tao, X., Cochrane, C., Coulon, D., & Koncar, V. (2018). Washable and Reliable Textile Electrodes Embedded into Underwear Fabric for Electrocardiography (ECG) Monitoring. Materials, 11(2), 256. https://doi.org/10.3390/ma11020256