Tuning of Schottky Barrier Height at NiSi/Si Contact by Combining Dual Implantation of Boron and Aluminum and Microwave Annealing

Abstract

:1. Introduction

2. Materials and Methods

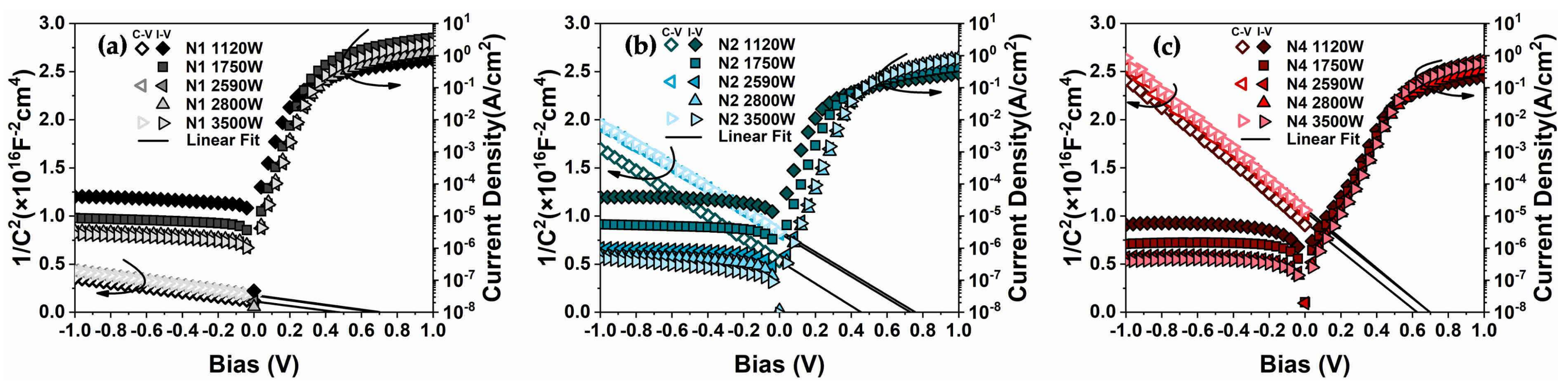

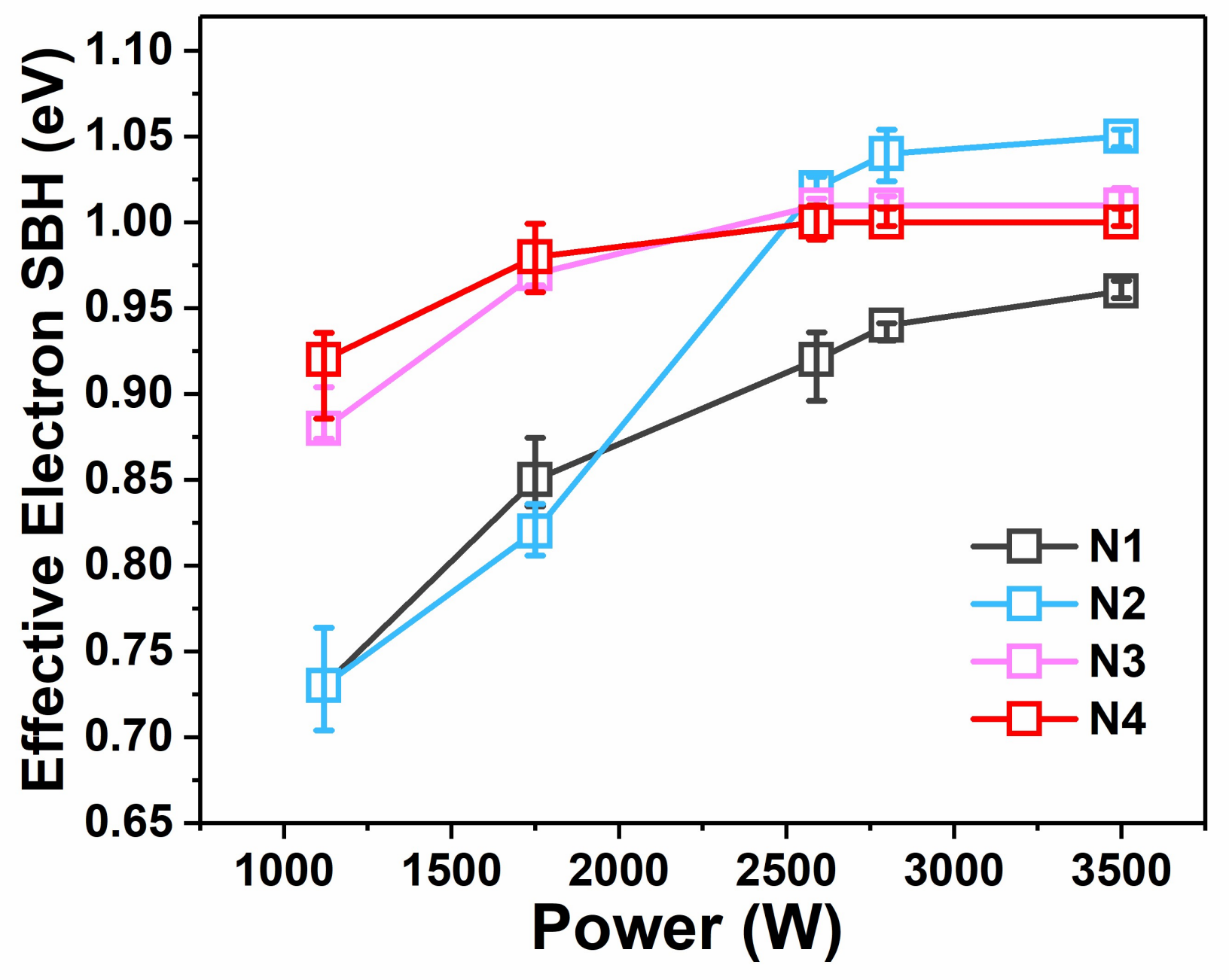

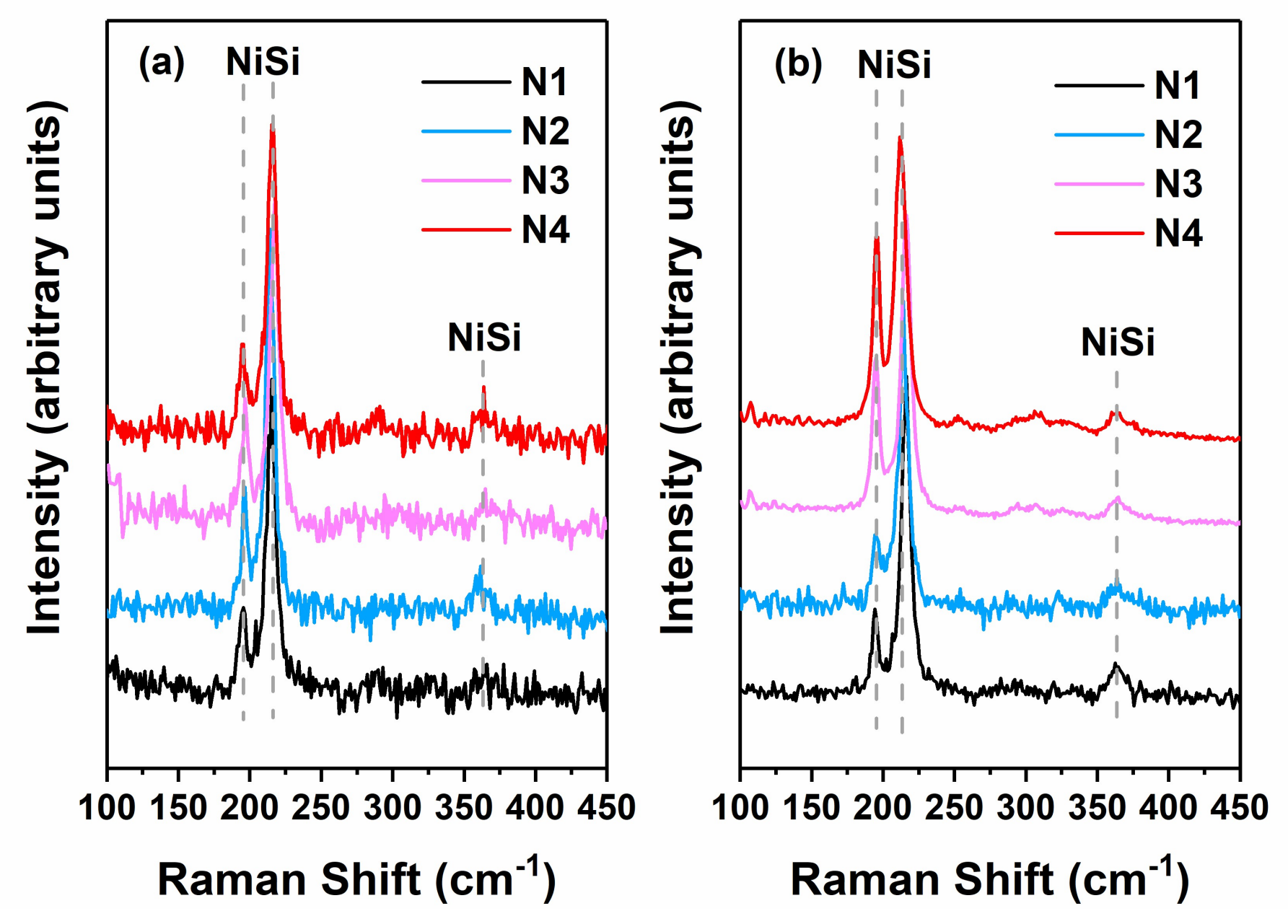

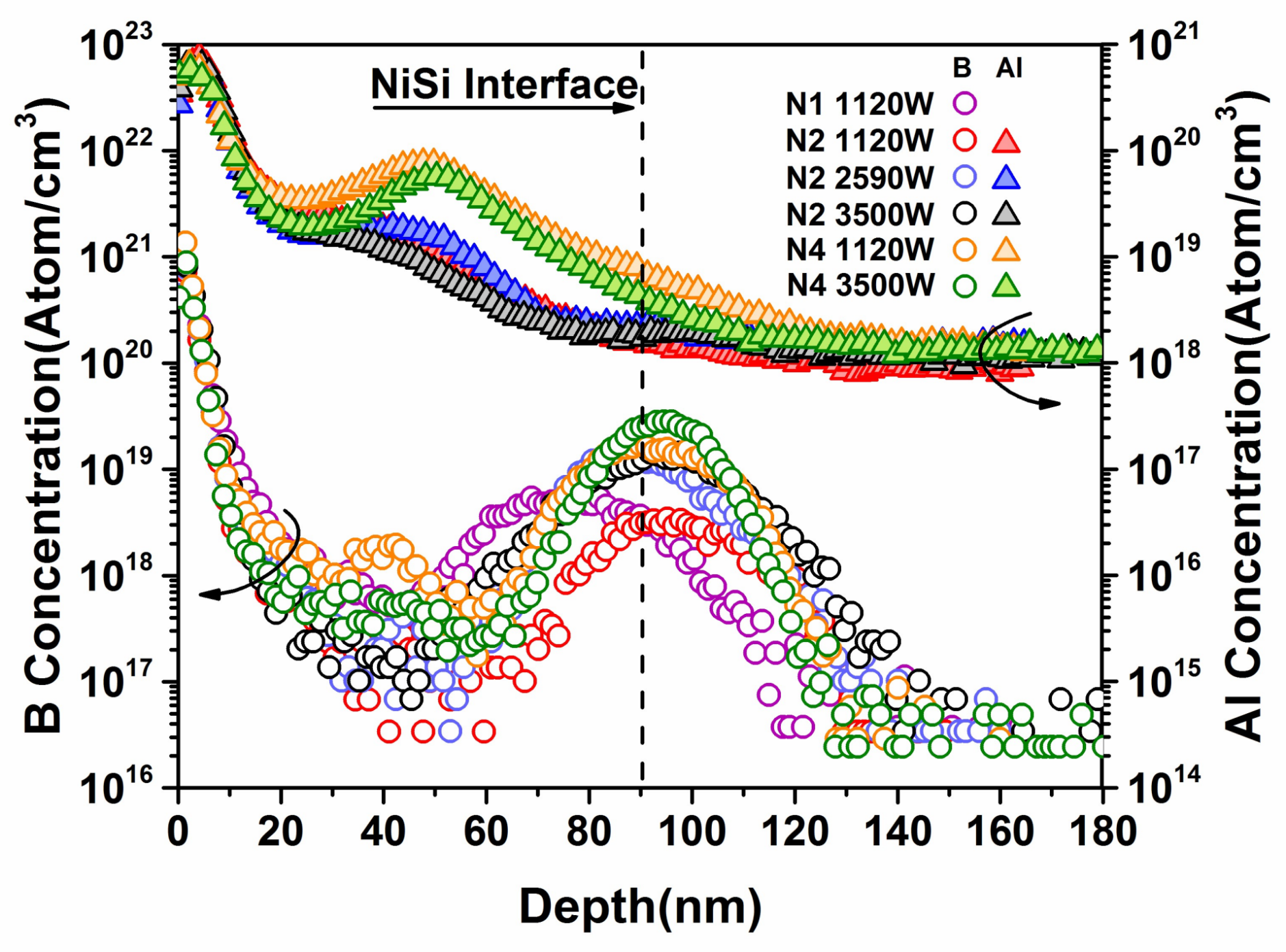

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Larson, J.M.; Snyder, J.P. Overview and Status of Metal Source/Drain Schottky Barrier MOSFET Technology. IEEE Trans. Electron Devices 2006, 53, 1048–1058. [Google Scholar] [CrossRef]

- Dubois, E.; Larrieu, G. Measurement of low Schottky barrier heights applied to metallic source/drain metal–oxide–semiconductor field effect transistors. J. Appl. Phys. 2004, 96, 729–737. [Google Scholar] [CrossRef]

- Fritze, M.; Chen, C.L.; Calawa, S.; Yost, D.; Wheeler, B.; Wyatt, P.; Keast, C.L.; Snyder, J.; Larson, J. High-speed Schottky-barrier pMOSFET with fT = 280 GHz. IEEE Electron Device Lett. 2004, 25, 220–222. [Google Scholar] [CrossRef]

- Larrieu, G.; Dubois, E.; Valentin, R.; Breil, N.; Danneville, F.; Dambrine, G.; Raskin, J.-P.; Pesant, J.C. Low temperature implementation of dopant-segregated band-edge metallic S/D junctions in thin-body SOI p-MOSFETs. In Proceedings of the IEEE International Electron Devices Meeting, Washington, DC, USA, 10–12 December 2007; pp. 147–150. [Google Scholar]

- Xiong, S.; King, T.J.; Bokor, J. A comparison study of symmetric ultrathin-body double-gate devices with metal source/drain and doped source/drain. IEEE Trans. Electron Devices 2005, 52, 1859–1867. [Google Scholar] [CrossRef]

- Knoch, J.; Zhang, M.; Mantl, S.; Appenzeller, J. On the performance of single-gated ultrathin-body SOI Schottky-barrier MOSFETs. IEEE Trans. Electron Devices 2006, 53, 1669–1674. [Google Scholar] [CrossRef] [Green Version]

- Qiu, Z.; Zhang, Z.; Östling, M.; Zhang, S. A Comparative Study of Two Different Schemes to Dopant Segregation at NiSi/Si and PtSi/Si Interfaces for Schottky Barrier Height Lowering. IEEE Trans. Electron Devices 2008, 55, 396–403. [Google Scholar] [CrossRef]

- Kinoshita, A.; Tsuchiya, Y.; Yagishita, A.; Uchida, K.; Koga, J. Solution for high-performance Schottky-source/drain MOSFETs: Schottky barrier height engineering with dopant segregation technique. In Proceedings of the Symposium on VLSI Technology, Honolulu, HI, USA, 15–17 June 2004; pp. 168–169. [Google Scholar] [CrossRef]

- Zhang, Z.; Qiu, Z.; Liu, R.; Östling, M.; Zhang, S.L. Schottky-barrier height tuning by means of ion implantation into preformed silicide films followed by drive-in anneal. IEEE Electron Device Lett. 2007, 28, 565–568. [Google Scholar] [CrossRef]

- Luo, J.; Qiu, Z.J.; Zhang, D.W.; Hellstrom, P.E.; Östling, M.; Zhang, S.L. Effects of carbon on schottky barrier heights of NiSi modified by dopant segregation. IEEE Electron Device Lett. 2009, 30, 608–610. [Google Scholar] [CrossRef]

- Fu, C.; Zhou, X.; Wang, Y.; Xu, P.; Xu, M.; Wu, D.; Luo, J.; Zhao, C.; Zhang, S.-L. Schottky Barrier Height Tuning via the Dopant Segregation Technique through Low-Temperature Microwave Annealing. Materials 2016, 9, 315. [Google Scholar] [CrossRef] [PubMed]

- Deng, J.; Liu, Q.; Zhao, C.; Li, J.; Wang, W.; Chen, D.; Ye, T.; Luo, J. A modified scheme to tune the Schottky Barrier Height of NiSi by means of dopant segregation technique. Vacuum 2014, 99, 225–227. [Google Scholar] [CrossRef]

- Wong, H.; Chan, L.; Samudra, G.; Yeo, Y. Effective Schottky Barrier Height Reduction Using Sulfur or Selenium at the NiSi/n-Si (100) Interface for Low Resistance Contacts. Interface 2007, 28, 2007–2009. [Google Scholar] [CrossRef]

- Wong, H.S.; Chan, L.; Samudra, G.; Yeo, Y.C. Low Schottky barrier height for silicides on n-type Si (100) by interfacial selenium segregation during silicidation. Appl. Phys. Lett. 2008, 93, 2006–2009. [Google Scholar] [CrossRef]

- Wong, H.-S.; Chan, L.; Samudra, G.; Yeo, Y.-C. Sub-0.1-eV effective Schottky-barrier height for NiSi on n-type Si (100) using antimony segregation. IEEE Electron Device Lett. 2007, 28, 703–705. [Google Scholar] [CrossRef]

- Sinha, M.; Chor, E.F.; Yeo, Y.-C. Tuning the Schottky barrier height of nickel silicide on p-silicon by aluminum segregation. Appl. Phys. Lett. 2008, 92, 222114. [Google Scholar] [CrossRef]

- Sinha, M.; Member, S.; Tek, R.; Lee, P. Aluminum Implant and Segregation for Strained p-FinFETs With Silicon—Germanium Source/Drain. IEEE Trans. Electron Devices 2010, 57, 1279–1286. [Google Scholar] [CrossRef]

- Koh, S.M.; Wang, X.; Thanigaivelan, T.; Henry, T.; Erokhin, Y.; Samudra, G.S.; Yeo, Y.C. Schottky barrier height tuning of silicides on p-type Si (100) by aluminum implantation and pulsed excimer laser anneal. J. Appl. Phys. 2011, 110. [Google Scholar] [CrossRef]

- Alptekin, E.; Ozturk, M.C. Tuning of the nickel silicide schottky barrier height on p-type silicon by indium implantation. IEEE Electron Device Lett. 2009, 30, 1272–1274. [Google Scholar] [CrossRef]

- Shannon, J.M. Control of Schottky barrier height using highly doped surface layers. Solid State Electron. 1976, 19, 537–543. [Google Scholar] [CrossRef]

- Kitchen, H.J.; Vallance, S.R.; Kennedy, J.L.; Tapia-Ruiz, N.; Carassiti, L.; Harrison, A.; Whittaker, A.G.; Drysdale, T.D.; Kingman, S.W.; Gregory, D.H. Modern microwave methods in solid-state inorganic materials chemistry: From fundamentals to manufacturing. Chem. Rev. 2013, 114, 1170–1206. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Fu, C.; Hu, C.; Zhang, D.W.; Wu, D.; Luo, J.; Zhao, C.; Zhang, Z.B.; Zhang, S.L. Ultra-shallow junctions formed using microwave annealing. Appl. Phys. Lett. 2013, 102, 1–5. [Google Scholar] [CrossRef]

- Fu, C.; Wang, Y.; Xu, P.; Yue, L.; Sun, F.; Zhang, D.W.; Zhang, S.L.; Luo, J.; Zhao, C.; Wu, D. Understanding the microwave annealing of silicon. AIP Adv. 2017, 7, 1–8. [Google Scholar] [CrossRef]

- Alford, T.L.; Thompson, D.C.; Mayer, J.W.; Theodore, N.D. Dopant activation in ion implanted silicon by microwave annealing. J. Appl. Phys. 2009, 106. [Google Scholar] [CrossRef]

- Hu, C.; Xu, P.; Fu, C.; Zhu, Z.; Gao, X.; Jamshidi, A.; Noroozi, M.; Radamson, H.; Wu, D.; Zhang, S.L. Characterization of Ni(Si,Ge) films on epitaxial SiGe(100) formed by microwave annealing. Appl. Phys. Lett. 2012, 101. [Google Scholar] [CrossRef]

- Vemuri, R.N.P.; Gadre, M.J.; Theodore, N.D.; Chen, W.; Lau, S.S.; Alford, T.L. Susceptor assisted microwave annealing for recrystallization and dopant activation of arsenic-implanted silicon. J. Appl. Phys. 2011, 110, 34907. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Luongo, G.; Giubileo, F.; Funicello, N.; Niu, G.; Schroeder, T.; Lisker, M.; Lupina, G. Hybrid graphene/silicon Schottky photodiode with intrinsic gating effect. 2D Mater. 2017, 4, 25075. [Google Scholar] [CrossRef]

- Luongo, G.; Giubileo, F.; Genovese, L.; Iemmo, L.; Martucciello, N.; Di Bartolomeo, A. I-V and C-V Characterization of a High-Responsivity Graphene/Silicon Photodiode with Embedded MOS Capacitor. Nanomaterials 2017, 7, 158. [Google Scholar] [CrossRef] [PubMed]

- Cichoň, S.; MacHáč, P.; Barda, B.; MacHovič, V.; Slepička, P. Raman study of Ni and Ni silicide contacts on 4H- and 6H-SiC. Thin Solid Films 2012, 520, 4378–4388. [Google Scholar] [CrossRef]

- Jiang, Y.L.; Agarwal, A.; Ru, G.P.; Cai, G.; Li, B.Z. Nickel silicide formation on shallow junctions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2005, 237, 160–166. [Google Scholar] [CrossRef]

- Sivalingam, G.; Agarwal, N.; Madras, G. Kinetics of microwave-assisted polymerization of ϵ-caprolactone. J. Appl. Polym. Sci. 2004, 91, 1450–1456. [Google Scholar] [CrossRef]

- Richter, K.W.; Chandrasekaran, K.; Ipser, H. The Al–Ni–Si phase diagram. Part II: Phase equilibria between 33.3 and 66.7 at. % Ni. Intermetallics 2004, 12, 545–554. [Google Scholar] [CrossRef]

- Chen, L.J. Silicide Technology for Integrated Circuits; Iet: London, UK, 2004; Volume 5, ISBN 0863413528. [Google Scholar]

- Krause, O.; Ryssel, H.; Pichler, P. Determination of aluminum diffusion parameters in silicon. J. Appl. Phys. 2002, 91, 5645–5649. [Google Scholar] [CrossRef]

- Trumbore, F.A. Solid solubilities of impurity elements in germanium and silicon. Bell Labs Tech. J. 1960, 39, 205–233. [Google Scholar] [CrossRef]

- Yamauchi, T.; Nishi, Y.; Tsuchiya, Y.; Kinoshita, A.; Koga, J.; Kato, K. Novel doping technology for a 1 nm NiSi/Si junction with dipoles comforting Schottky (DCS) barrier. Tech. Dig. Int. Electron Devices Meet. IEDM 2007, 963–966. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Biersack, J.P.; Ziegler, M.D. The Stopping and Range of Ions in Matter, SRIM, 2013. Available online: http//www.srim.org (accessed on 21 March 2018).

- Zhou, Q.; Koh, S.M.; Thanigaivelan, T.; Henry, T.; Yeo, Y.C. Contact resistance reduction for strained N-MOSFETs with silicon-carbon source/drain utilizing aluminum ion implant and aluminum profile engineering. IEEE Trans. Electron Devices 2013, 60, 1310–1317. [Google Scholar] [CrossRef]

- Kim, Y.H.; Cabral, C.; Gusev, E.P.; Carruthers, R.; Gignac, L.; Gribelyuk, M.; Cartier, E.; Zafar, S.; Copel, M.; Narayanan, V.; et al. Systematic study of work function engineering and scavenging effect using NiSi alloy FUSI metal gates with advanced gate stacks. In Proceedings of the IEEE IEDM Technical Digest International Electron Devices Meeting, Washington, DC, USA, 5 December 2005. [Google Scholar] [CrossRef]

- Koh, S.M.; Zhou, Q.; Thanigaivelan, T.; Henry, T.; Samudra, G.S.; Yeo, Y.C. Novel technique to engineer aluminum profile at nickel-silicide/silicon: Carbon interface for contact resistance reduction, and integration in strained N-MOSFETs with silicon-carbon stressors. In Proceedings of the IEEE International Electron Devices Meeting (IEDM), Washington, DC, USA, 5–7 December 2011; pp. 845–848. [Google Scholar] [CrossRef]

- Lee, R.T.P.; Liow, T.Y.; Tan, K.M.; Lim, A.E.J.; Koh, A.T.Y.; Zhu, M.; Lo, G.Q.; Samudra, G.S.; Chi, D.Z.; Yeo, Y.C. Achieving conduction band-edge Schottky barrier height for arsenic-segregated nickel aluminide disilicide and implementation in FinFETs with ultra-narrow fin widths. IEEE Electron Device Lett. 2008, 29, 382–385. [Google Scholar] [CrossRef]

- Koh, A.T.-Y.; Lee, R.T.-P.; Lim, A.E.-J.; Lai, D.M.-Y.; Chi, D.-Z.; Hoe, K.-M.; Balasubramanian, N.; Samudra, G.S.; Yeo, Y.-C. Nickel-Aluminum Alloy Silicides with High Aluminum Content for Contact Resistance Reduction and Integration in n-Channel Field-Effect Transistors. J. Electrochem. Soc. 2008, 155, H151. [Google Scholar] [CrossRef]

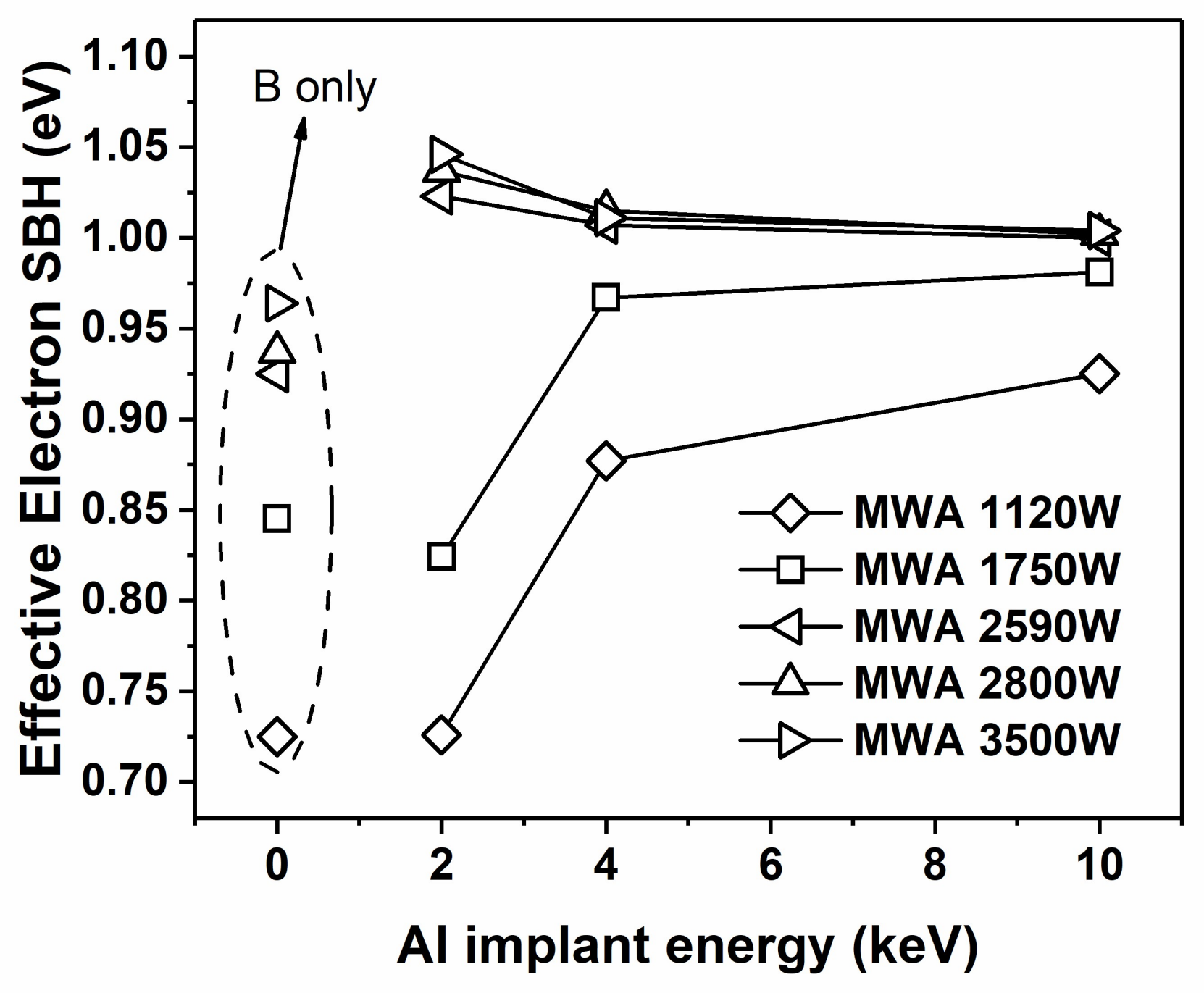

| Sample No. | Implant Species | MWA Power | |||||

|---|---|---|---|---|---|---|---|

| B | Al | 1120 W | 1750 W | 2590 W | 2800 W | 3500 W | |

| Implant Energy (keV) | φbn (eV) | ||||||

| N1 | 1 | - | 0.73 | 0.85 | 0.92 | 0.94 | 0.96 |

| N2 | 1 | 2 | 0.73 | 0.82 | 1.02 | 1.04 | 1.05 |

| N3 | 1 | 4 | 0.88 | 0.97 | 1.01 | 1.01 | 1.01 |

| N4 | 1 | 10 | 0.92 | 0.98 | 1.00 | 1.00 | 1.00 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, F.; Li, C.; Fu, C.; Zhou, X.; Luo, J.; Zou, W.; Qiu, Z.-J.; Wu, D. Tuning of Schottky Barrier Height at NiSi/Si Contact by Combining Dual Implantation of Boron and Aluminum and Microwave Annealing. Materials 2018, 11, 471. https://doi.org/10.3390/ma11040471

Sun F, Li C, Fu C, Zhou X, Luo J, Zou W, Qiu Z-J, Wu D. Tuning of Schottky Barrier Height at NiSi/Si Contact by Combining Dual Implantation of Boron and Aluminum and Microwave Annealing. Materials. 2018; 11(4):471. https://doi.org/10.3390/ma11040471

Chicago/Turabian StyleSun, Feng, Chen Li, Chaochao Fu, Xiangbiao Zhou, Jun Luo, Wei Zou, Zhi-Jun Qiu, and Dongping Wu. 2018. "Tuning of Schottky Barrier Height at NiSi/Si Contact by Combining Dual Implantation of Boron and Aluminum and Microwave Annealing" Materials 11, no. 4: 471. https://doi.org/10.3390/ma11040471