Ultra Uniform Pb0.865La0.09(Zr0.65Ti0.35)O3 Thin Films with Tunable Optical Properties Fabricated via Pulsed Laser Deposition

Abstract

:1. Introduction

2. Methods

3. Results and Discussion

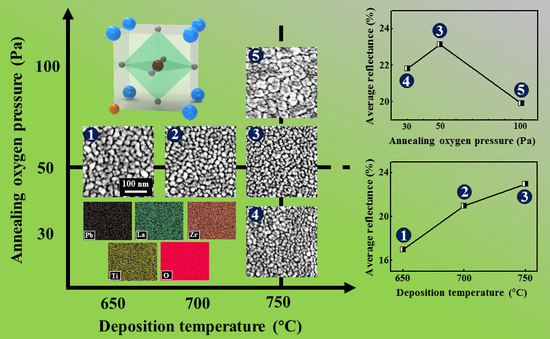

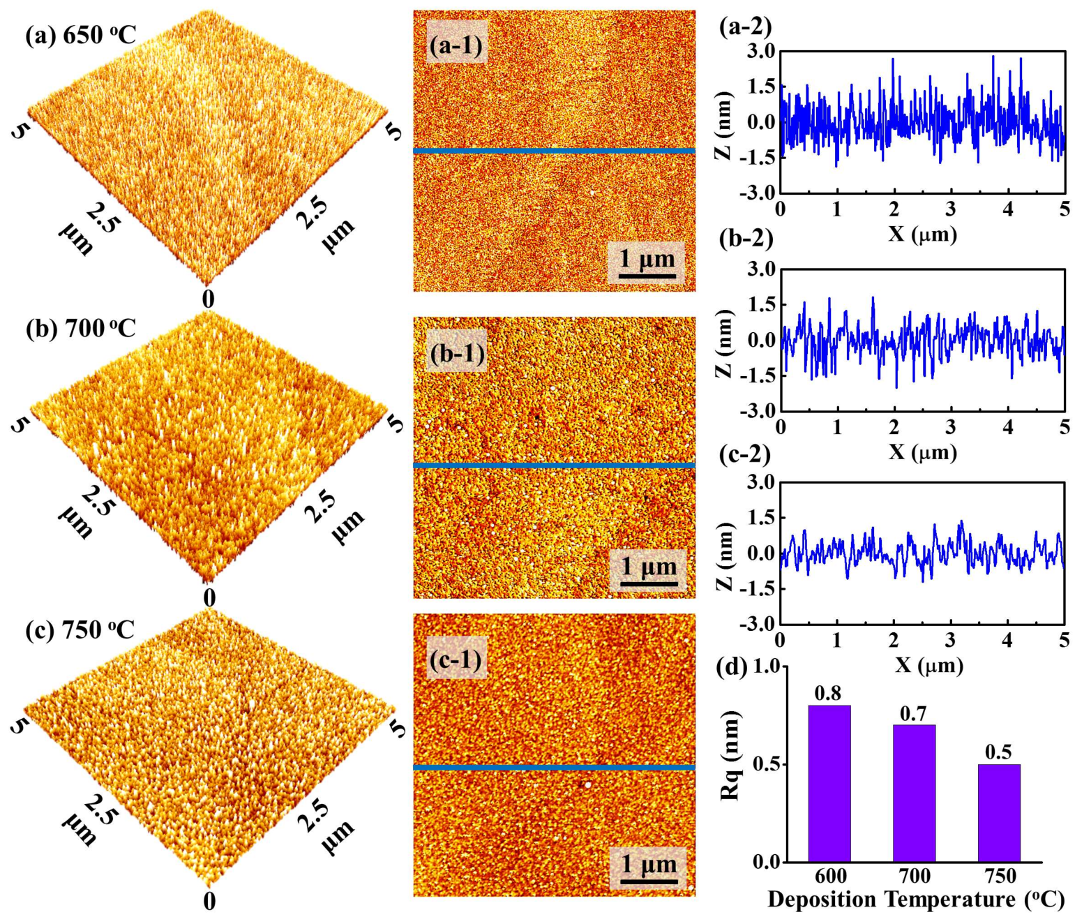

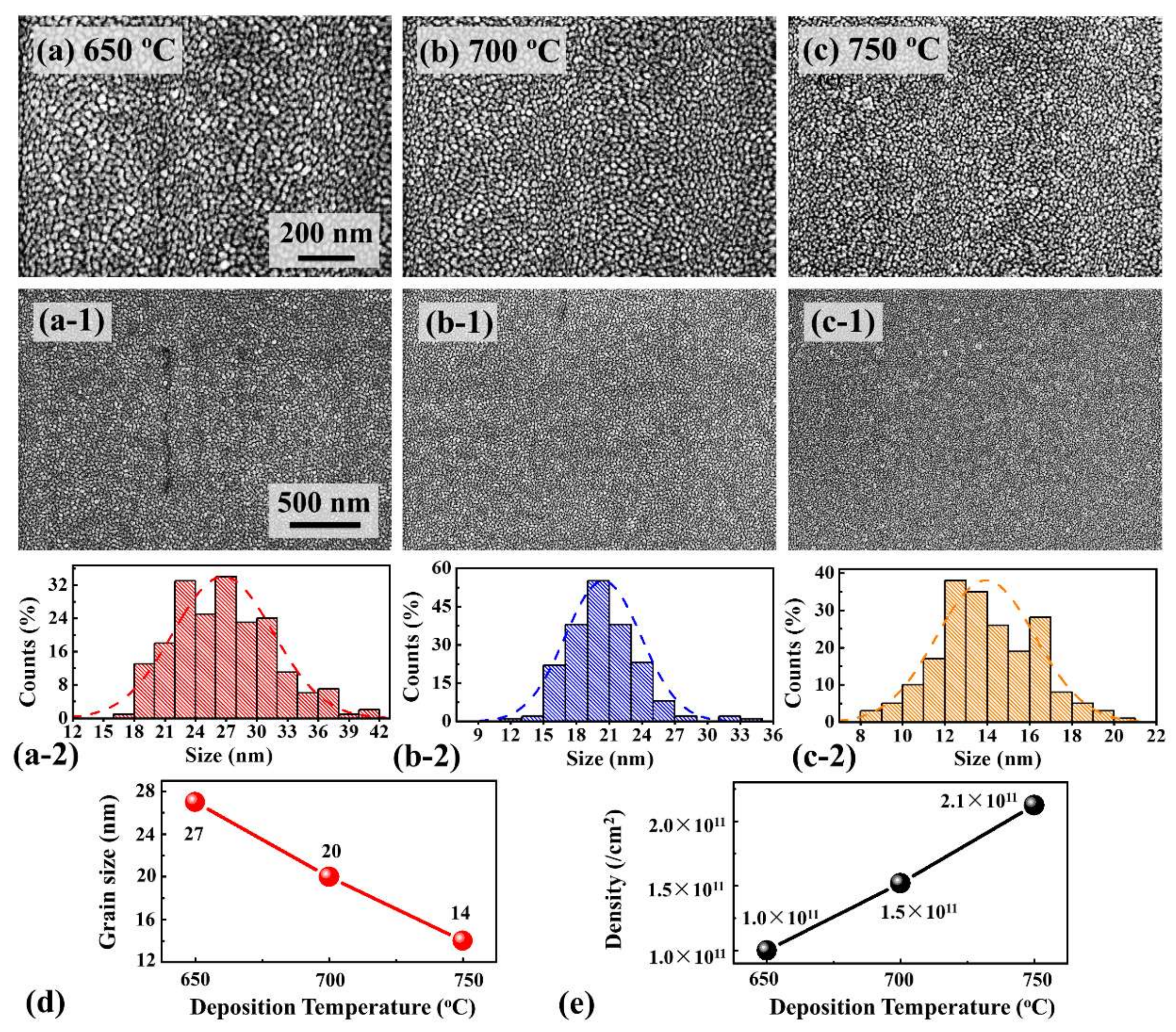

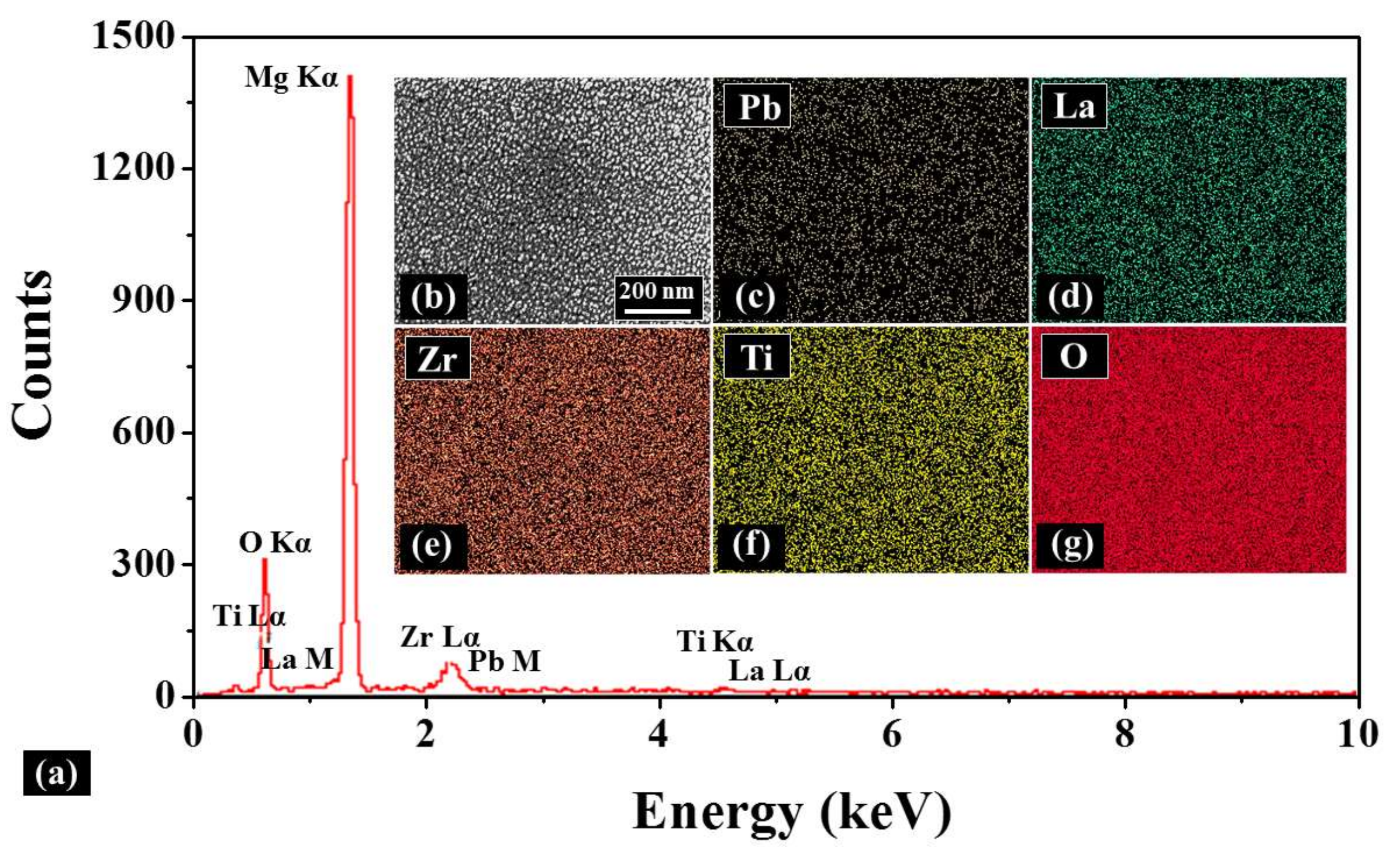

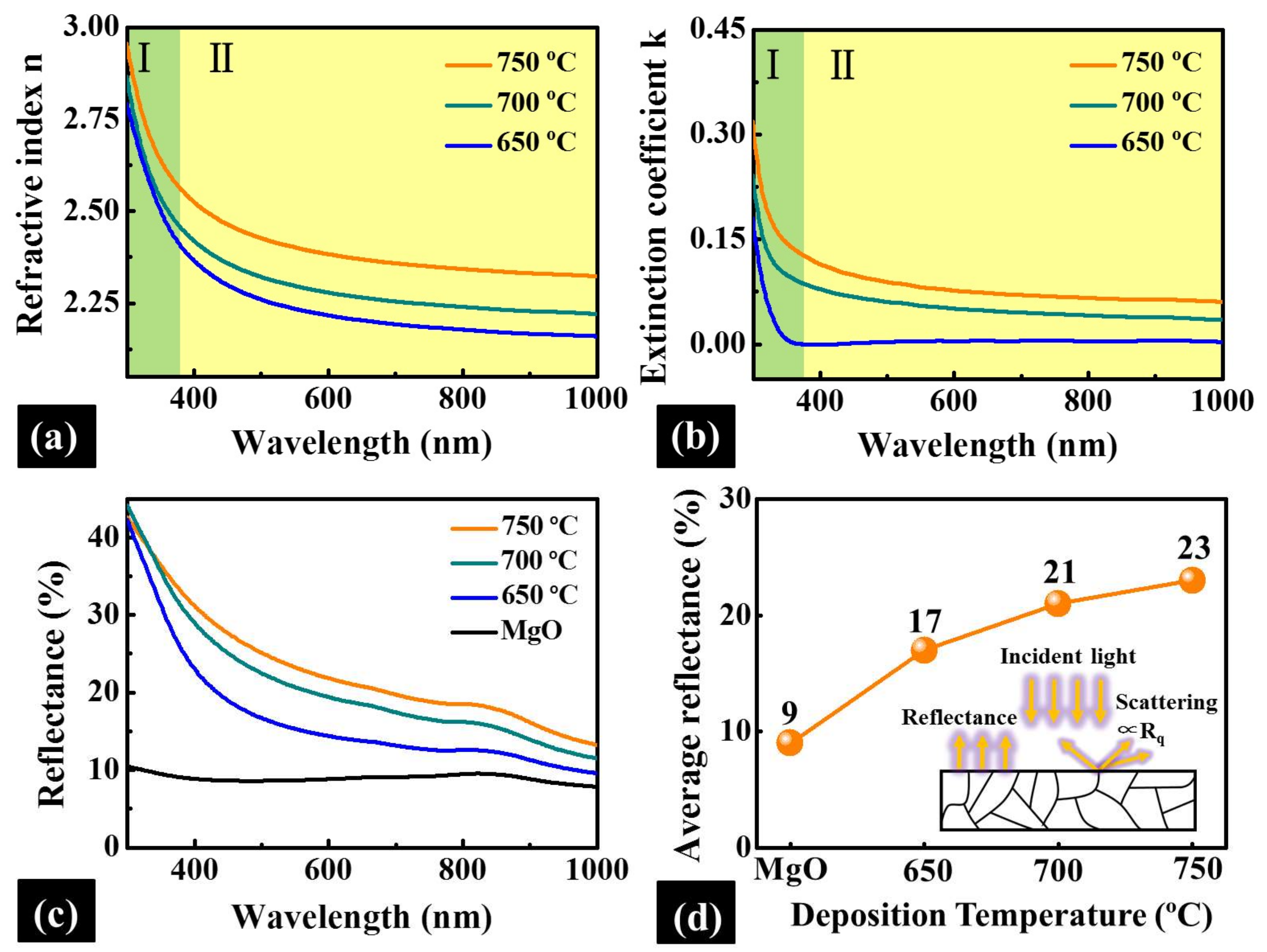

3.1. Influence of Temperature

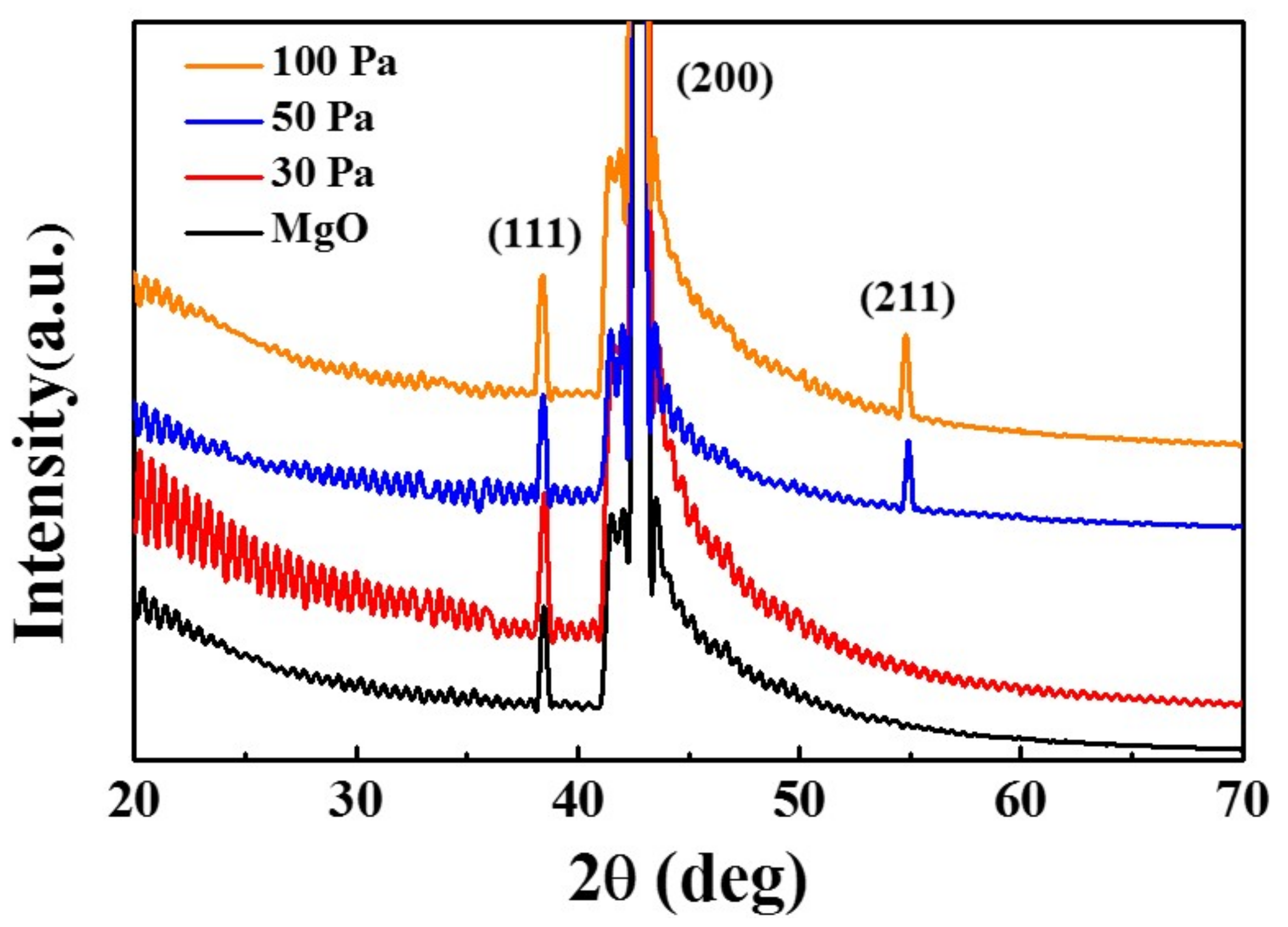

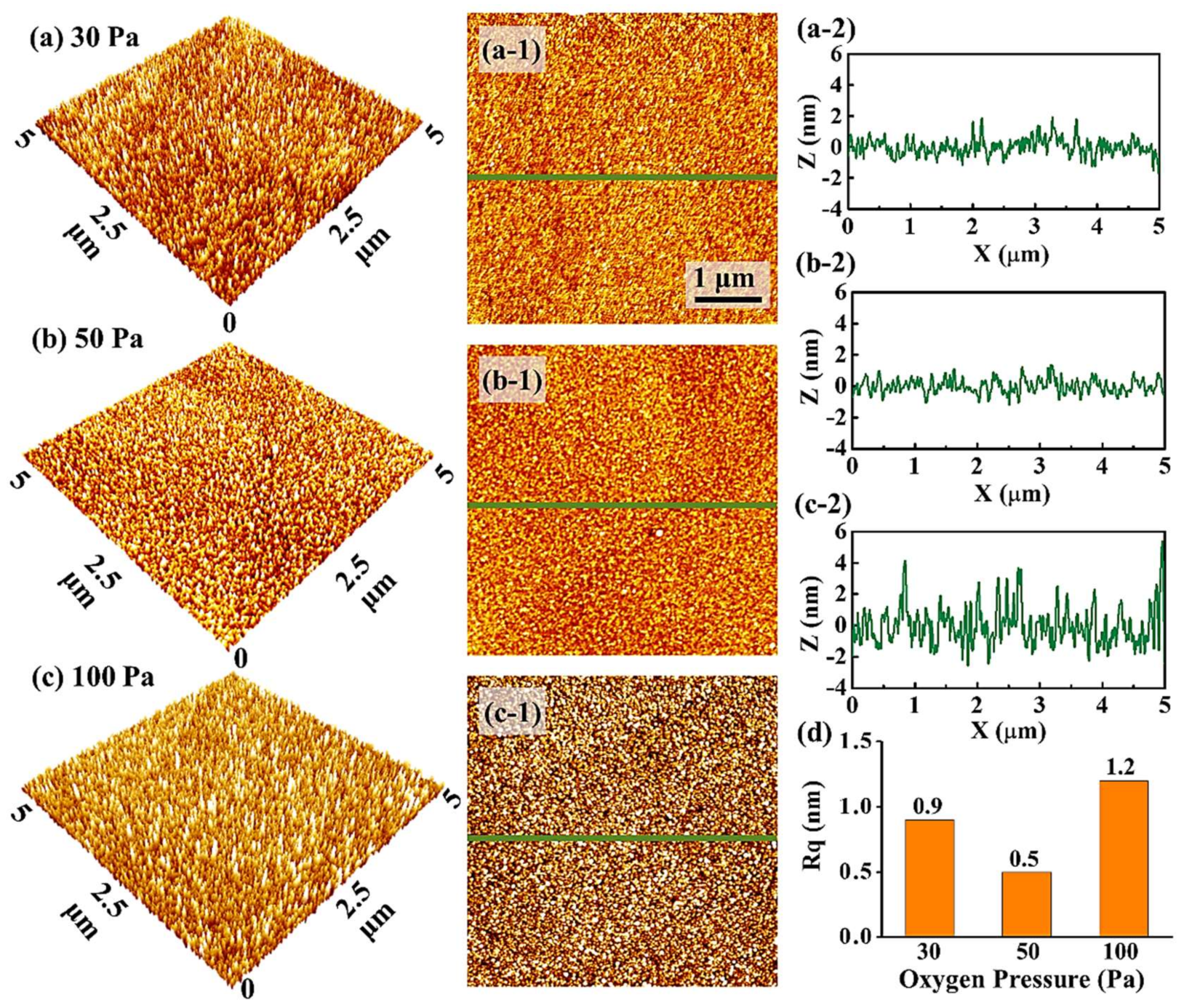

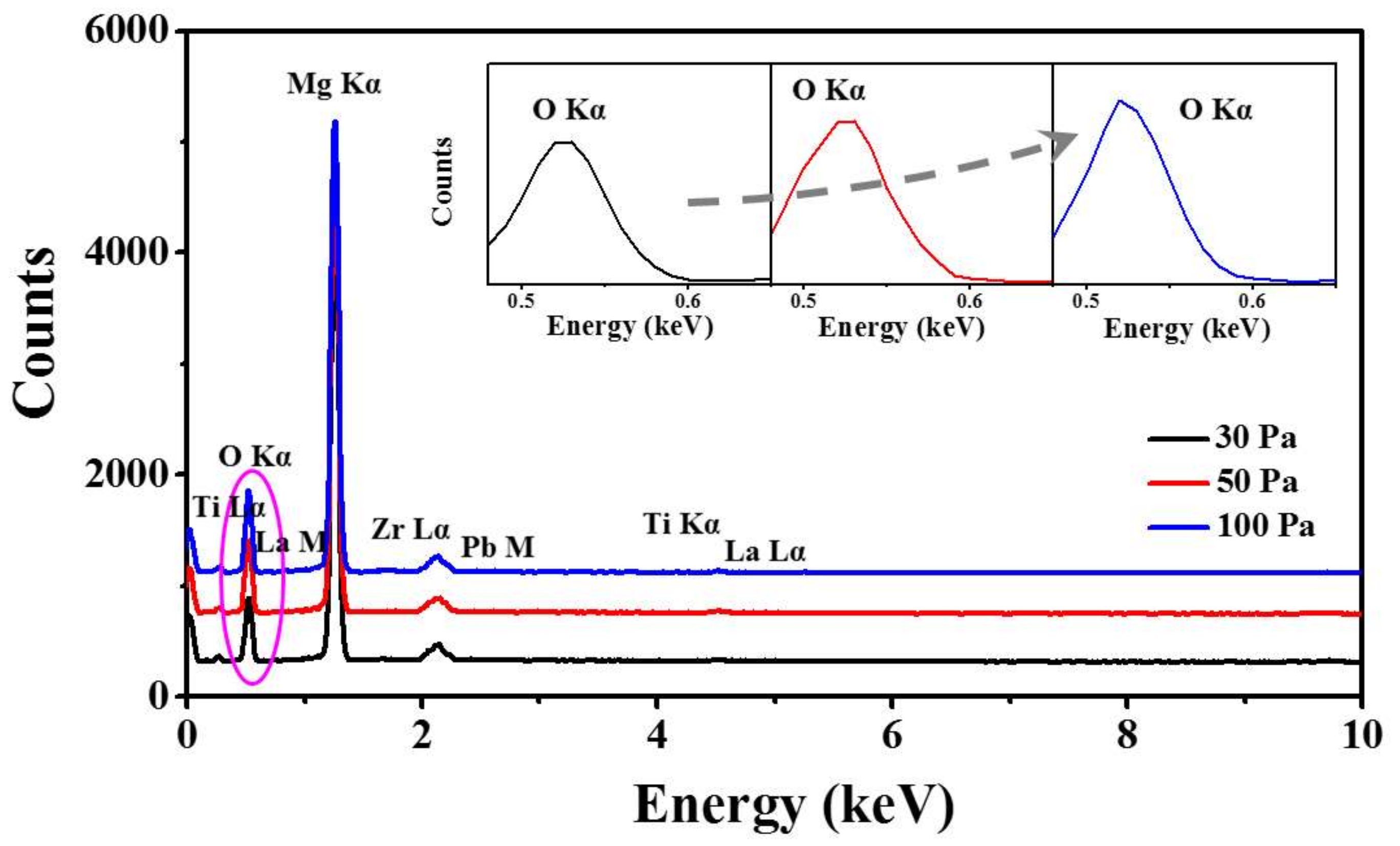

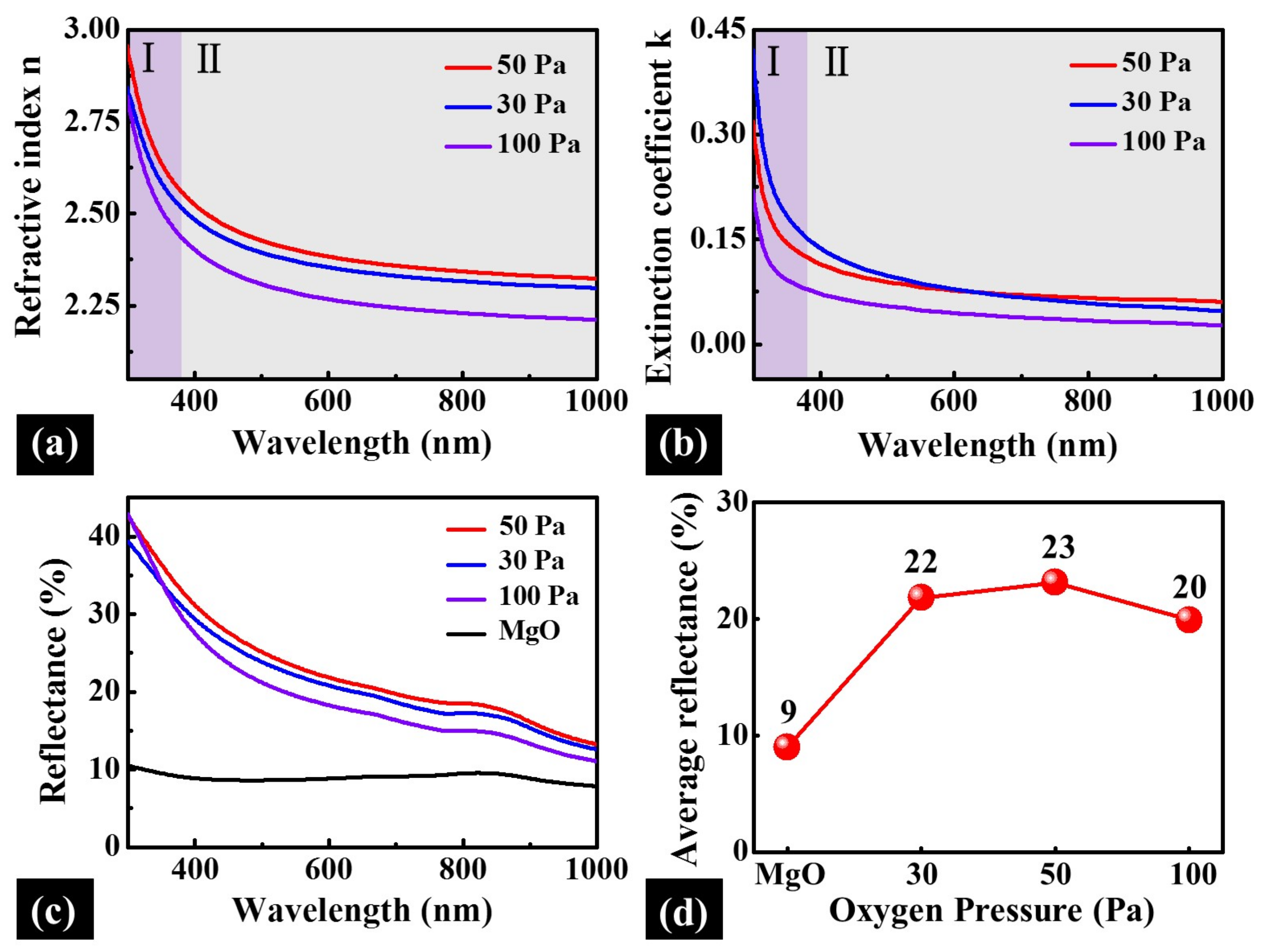

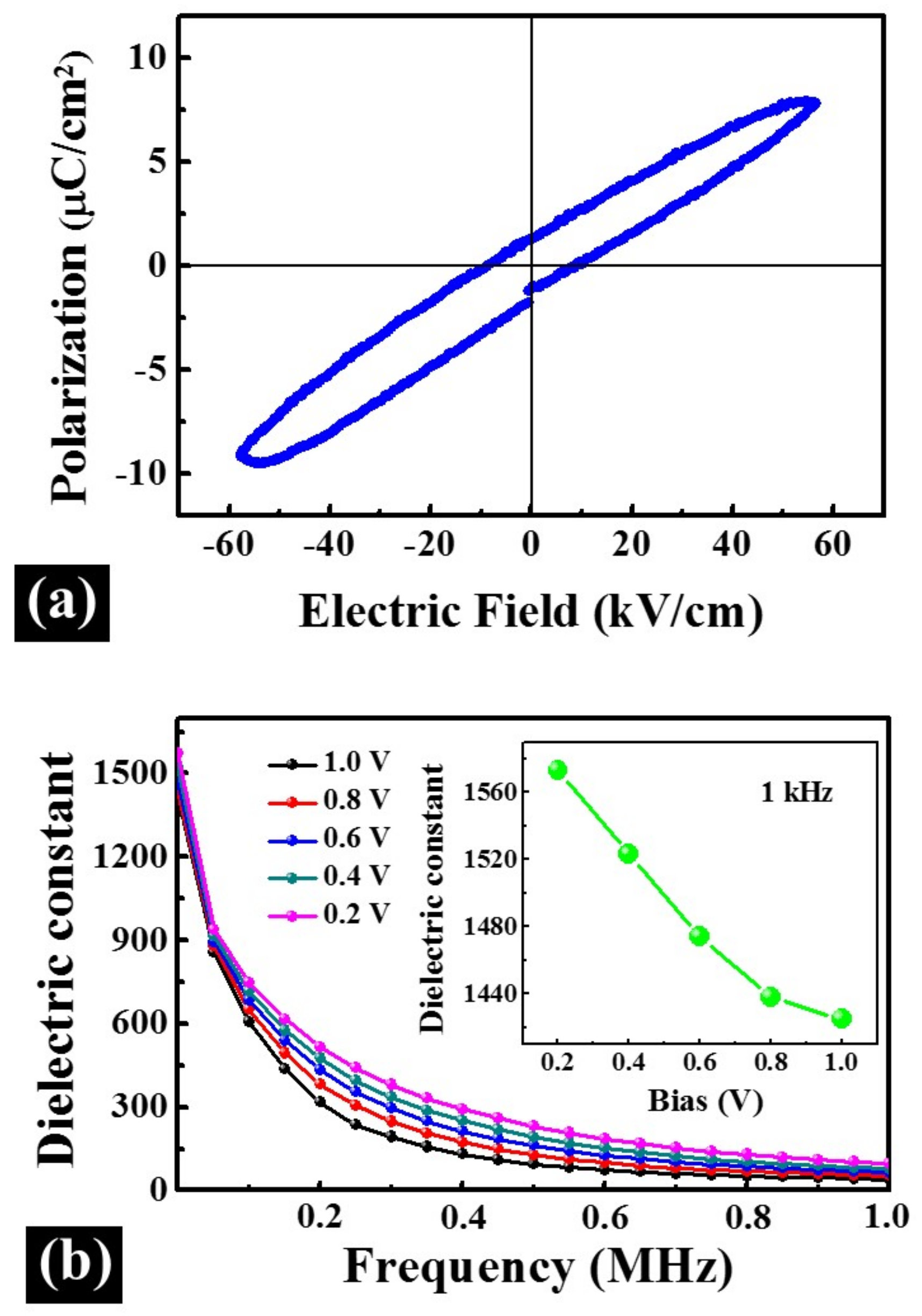

3.2. Influence of Oxygen Pressure

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nayek, P.; Li, G.Q. Superior electro-optic response in multiferroic bismuth ferrite nanoparticle doped nematic liquid crystal device. Sci. Rep. 2015, 5, 10845. [Google Scholar] [CrossRef] [PubMed]

- Xiong, C.; Pernice, W.H.P.; Ngai, J.H.; Reiner, J.H.; Kumah, D.; Walker, F.J.; Ahn, C.H.; Tang, H.X. Active silicon integrated nanophotonics: Ferroelectric BaTiO3 devices. Nano Lett. 2014, 14, 1419–1425. [Google Scholar] [CrossRef] [PubMed]

- Abel, S.; Stöferle, T.; Marchiori, C.; Rossel, C.; Rossell, M.D.; Erni, R.; Caimi, D.; Sousa, M.; Chelnokov, A.; Offrein, B.J.; et al. A strong electro-optically active lead-free ferroelectric integrated on silicon. Nat. Commun. 2013, 4, 1671. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.Z.; Jiang, S.L.; Zeng, Y.K.; Zhang, Y.Y.; Zhang, Q.F.; Yu, Y. The Modified Model of the Dielectric Characteristics for Porous Ba0.6Sr0.4TiO3 Ceramics. J. Appl. Phys. 2009, 106, 034110. [Google Scholar] [CrossRef]

- Zeng, X.; He, X.Y.; Cheng, W.X.; Qiu, P.S.; Xia, B. Effect of Dy substitution on ferroelectric, optical and electro-optic properties of transparent Pb0.90La0.10(Zr0.65Ti0.35)O3 ceramics. Ceram. Int. 2014, 40, 6197–6202. [Google Scholar] [CrossRef]

- Hu, G.; Qi, Z.P.; Yun, B.F.; Zhang, R.H.; Wang, Z.Y.; Cui, Y.P. High performance ridge type PLZT optical switch with offset upper electrode. IEEE Photonics Technol. Lett. 2015, 27, 2257–2259. [Google Scholar] [CrossRef]

- Zhang, F.; Chou, H.H.; Crossland, W.A. PLZT-based shutters for free-space optical fiber switching. IEEE Photonics J. 2016, 8, 7800512. [Google Scholar] [CrossRef]

- Qi, Z.P.; Hu, G.H.; Liu, C.; Li, L.; Yun, B.F.; Zhang, R.H.; Cui, Y.P. Design and investigation of a novel silicon/ferroelectric hybrid electrooptical microring modulator. Opt. Commun. 2017, 385, 130–135. [Google Scholar] [CrossRef]

- Uchiyama, K.; Kasamatsu, A.; Otani, Y.; Shiosaki, T. Electro-optic properties of lanthanum-modified lead zirconate titanate thin films epitaxially grown by the advanced sol–gel method. Jpn. J. Appl. Phys. 2007, 46, 244–246. [Google Scholar] [CrossRef]

- Phan, T.T.; Miyasako, T.; Higashimine, K.; Tokumitsu, E.; Shimod, T. Surface-modified lead-zirconium-titanate system for solution-processed ferroelectric-gate thin-film transistors. Appl. Phys. A 2013, 113, 333–338. [Google Scholar] [CrossRef]

- Masuda, S.; Seki, A.; Shiota, K.; Hara, H.; Masuda, Y. Electro-optic and dielectric characterization of ferroelectric films for high-speed optical waveguide modulators. J. Appl. Phys. 2011, 109, 124108. [Google Scholar] [CrossRef]

- Ma, B.; Liu, S.S.; Tong, S.; Narayanan, M.; Balachandran, U.B. Enhanced dielectric properties of Pb0.92La0.08 Zr0.52Ti0.48O3 films with compressive stress. J. Appl. Phys. 2012, 112, 114117. [Google Scholar] [CrossRef]

- Hao, X.H.; Wang, Y.; Yang, J.C.; An, S.L.; Xu, J.B. High energy-storage performance in Pb0.91La0.09(Ti0.65Zr0.35)O3 relaxor ferroelectric thin films. J. Appl. Phys. 2012, 112, 114111. [Google Scholar] [CrossRef]

- Singh, R.; Goel, T.C.; Chandra, S. Effect of post-deposition annealing on phase formation and properties of RF magnetron sputtered PLZT thin films. Mater. Res. Bull. 2008, 43, 384–393. [Google Scholar] [CrossRef]

- Kan, D.; Shimakawa, Y. Controlled cation stoichiometry in pulsed laser deposition-grown BaTiO3 epitaxial thin films with laser fluence. Appl. Phys. Lett. 2011, 99, 081907. [Google Scholar] [CrossRef]

- Sun, L.; He, J.; Chen, Y.; Yue, F.Y.; Yang, P.X.; Chu, J.H. Comparative study on Cu2ZnSnS4 thin films deposited by sputtering and pulsed laser deposition from a single quaternary sulfide target. J. Cryst. Growth 2012, 361, 147–151. [Google Scholar] [CrossRef]

- Droubay, T.C.; Qiao, L.; Kaspar, T.C.; Engelhard, M.H.; Shutthanandan, V.; Chambers, S.A. Nonstoichiometric material transfer in the pulsed laser deposition of LaAlO3. Appl. Phys. Lett. 2010, 97, 124105. [Google Scholar] [CrossRef]

- Kubicek, M.; Cai, Z.H.; Ma, W.; Yildiz, B.; Hutter, H.; Fleig, J. Tensile lattice strain accelerates oxygen surface exchange and diffusion in La1-xSrxCoO3-δ thin films. ACS Nano 2013, 7, 3276–3286. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.Z.; Chen, Z.B.; Fan, B.Y.; Liu, J.G.; Chen, M.; Shen, M.; Liu, P.; Zeng, Y.K.; Jiang, S.L.; Wang, Q. Large enhancement of the electrocaloric effect in PLZT ceramics prepared by hot-pressing. APL Mater. 2016, 4, 064103. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Chen, M.; Fan, B.Y.; Liu, Y.; Li, M.Y.; Jiang, S.L.; Huang, H.B.; Liu, H.; Li, H.L.; Wang, Q. High electrocaloric effect in hot-pressed Pb0.85La0.1(Zr0.65Ti0.35)O3 ceramics with a wide operating temperature range. J. Am. Ceram. Soc. 2017, 100, 4581–4589. [Google Scholar] [CrossRef]

- Zhang, X.; Xue, D.F.; Xua, D.L.; Feng, X.Q.; Wang, J.Y. Growth of large MgO single crystals by an arc-fusion method. J. Cryst. Growth 2005, 280, 234–238. [Google Scholar] [CrossRef]

- Balakrishnan, G.; Sundari, S.T.; Ramaseshan, R.; Thirumurugesan, R.; Mohandas, E.; Sastikumar, D.; Kuppusami, P.; Kim, T.G.; Song, J.I. Effect of substrate temperature on microstructure and optical properties of nanocrystalline alumina thin films. Ceram. Int. 2013, 39, 9017–9023. [Google Scholar] [CrossRef]

- Somwan, S.; Ngamjarurojana, A. Study of aging behavior of 9/70/30 and 9/65/35 PLZT by optical interferometric technique. Ceram. Int. 2015, 41, 7536–7542. [Google Scholar] [CrossRef]

- Ramana, C.V.; Rubio, E.J.; Barraza, C.D.; Gallardo, A.M.; McPeak, S.; Kotru, S.; Grant, J.T. Chemical bonding, optical constants, and electrical resistivity of sputter-deposited gallium oxide thin films. J. Appl. Phys. 2014, 115, 043508. [Google Scholar] [CrossRef]

- Li, M.Y.; Sui, M.; Pandey, P.; Zhang, Q.Z.; Kunwar, S.; Salamo, G.J.; Lee, J. Precise control of configuration, size and density of self-assembled Au nanostructures on 4H-SiC (0001) by systematic variation of deposition amount, annealing temperature and duration. CrystEngComm 2016, 18, 3347–3357. [Google Scholar] [CrossRef]

- Li, M.Y.; Zhang, Q.Z.; Pandey, P.; Sui, M.; Kim, E.S.; Lee, J. From the Au nano-clusters to the nanoparticles on 4H-SiC (0001). Sci. Rep. 2015, 5, 13954. [Google Scholar] [CrossRef] [PubMed]

- Rmili, A.; Ouachtari, F.; Bouaoud, A.; Louardi, A.; Chtouki, T.; Elidrissi, B.; Erguig, H. Structural, optical and electrical properties of Ni-doped CdS thin films prepared by spray pyrolysis. J. Alloys Compd. 2013, 557, 53–59. [Google Scholar] [CrossRef]

- Jeyaseelan, A.A.; Dutta, S. Effect of ligand concentration on microstructure, ferroelectric and piezoelectric properties of PLZT film. Mater. Chem. Phys. 2015, 162, 487–490. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Zheng, F.; Jin, C.F.; Fei, W.D. Thickness-dependent monoclinic phases and piezoelectric properties observed in polycrystalline (Pb0.94La0.04)(Zr0.60Ti0.40)O3 thin films. J. Phys. Chem. C 2015, 119, 17487–17492. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Wang, L.D.; Li, W.L.; Li, N.; Fei, W.D. Effects of lanthanum doping on the preferred orientation, phase structure and electrical properties of sol–gel derived Pb1–3x/2Lax (Zr0.6Ti0.4)O3 thin films. J. Alloys Compd. 2011, 509, 2976–2980. [Google Scholar] [CrossRef]

- Yang, S.Y.; Man, B.Y.; Liu, M.; Chen, C.S.; Gao, X.G.; Wang, C.C.; Hu, B. Effect of substrate temperature on the morphology, structural and optical properties of Zn1−xCoxO thin films. Appl. Surf. Sci. 2011, 257, 3856–3860. [Google Scholar] [CrossRef]

- Pawar, S.M.; Moholkar, A.V.; Kim, I.K.; Shin, S.W.; Moon, J.H.; Rhee, J.I.; Kim, J.H. Effect of laser incident energy on the structural, morphological and optical properties of Cu2ZnSnS4 (CZTS) thin films. Curr. Appl. Phys. 2010, 10, 565–569. [Google Scholar] [CrossRef]

- Lazzari, R.; Jupille, J. Growth kinetics and size-dependent wetting of Ag/α-Al2O3(0001) nanoparticles studied via the plasmonic response. Nanotechnology 2012, 23, 135707. [Google Scholar] [CrossRef] [PubMed]

- Parish, C.M.; Brewer, L.N. Key parameters affecting quantitative analysis of STEM-EDS spectrum images. Microsc. Microanal. 2010, 16, 259–272. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.S.; Rubio, E.J.; Noor-A-Alam, M.; Martinez, G.; Manandhar, S.; Shutthanandan, V.; Thevuthasan, S.; Ramana, C.V. Structure, morphology, and optical properties of amorphous and nanocrystalline gallium oxide thin films. J. Phys. Chem. C 2013, 117, 4194–4200. [Google Scholar] [CrossRef]

- Shan, F.K.; Yu, Y.S. Band gap energy of pure and Al-doped ZnO thin films. J. Eur. Ceram. Soc. 2004, 24, 1869–1872. [Google Scholar] [CrossRef]

- Ramana, C.V.; Baghmar, G.; Rubio, E.J.; Hernandez, M.J. Optical constants of amorphous, transparent titanium-doped tungsten oxide thin films. ACS Appl. Mater. Interfaces 2013, 5, 4659–4666. [Google Scholar] [CrossRef] [PubMed]

- Mazilu, M.; Tigau, N.; Musat, V. Optical properties of undoped and Al-doped ZnO nanostructures grown from aqueous solution on glass substrate. Opt. Mater. 2012, 34, 1833–1838. [Google Scholar] [CrossRef]

- Song, S.S.; Sun, Y.J.; Lin, Y.D.; You, B. A facile fabrication of light diffusing film with LDP/polyacrylates composites coating for anti-glare LED application. Appl. Surf. Sci. 2013, 273, 652–660. [Google Scholar] [CrossRef]

- Yang, Q.Y.; Zhang, X.A.; Bagal, A.; Guo, W.; Chang, C.H. Antireflection effects at nanostructured material interfaces and the suppression of thin-film interference. Nanotechnology 2013, 24, 235202. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Charipar, N.; Osofsky, M.; Qadri, S.B.; Piqué, A. Optimization of the semiconductor-metal transition in VO2 epitaxial thin films as a function of oxygen growth pressure. Appl. Phys. Lett. 2014, 104, 081913. [Google Scholar] [CrossRef]

- Gondoni, P.; Ghidelli, M.; Fonzo, F.D.; Russo, V.; Bruno, P.; Martí-Rujas, J.; Bottani, C.E.; Bassi, A.L.; Casari, C.S. Highly performing Al:ZnO thin films grown by pulsed laser deposition at room temperature. Nanosci. Nanotech. Lett. 2013, 5, 484–486. [Google Scholar] [CrossRef]

- Passoni, L.; Ghods, F.; Docampo, P.; Abrusci, A.; Martí-Rujas, J.; Ghidelli, M.; Divitini, G.; Ducati, C.; Binda, M.; Guarnera, S.; et al. Hyperbranched quasi-1D nanostructures for solid-state dye-sensitized solar cells. ACS Nano 2013, 7, 10023–10031. [Google Scholar] [CrossRef] [PubMed]

- Russo, V.; Ghidelli, M.; Gondoni, P.; Casari, C.S.; Li Bassi, A. Multi-wavelength raman scattering of nanostructured Al-doped zinc oxide. J. Appl. Phys. 2014, 115, 073508. [Google Scholar] [CrossRef]

- Ma, C.; Ma, B.; Mi, S.B.; Liu, M.; Wu, J. Enhanced dielectric nonlinearity in epitaxial Pb0.92La0.08Zr0.52Ti0.48O3 thin films. Appl. Phys. Lett. 2014, 104, 162902. [Google Scholar] [CrossRef]

- Ashok Kumar Reddy, Y.; Sivasankar Reddy, A.; Sreedhara Reddy, P. Effect of oxygen partial pressure on the properties of NiO–Ag composite films grown by DC reactive magnetron sputtering. J. Alloys Compd. 2014, 583, 396–403. [Google Scholar] [CrossRef]

- García, T.; de Posada, E.; Bartolo-Pérez, P.; Peña, J.L.; Diamant, R.; Calderón, F.; Pelaíz, A. Pulsed laser deposition process of PLZT thin films using an infrared Nd:YAG laser. Appl. Surf. Sci. 2006, 252, 3783–3788. [Google Scholar] [CrossRef]

- Chang, W.L.; He, J.L. XPS studies of PZT films deposited by metallic lead and ceramic PZT dual target co-sputtering. J. Electroceram. 2004, 13, 47–50. [Google Scholar] [CrossRef]

- Kim, J.N.; Shin, K.S.; Kim, D.H.; Park, B.O.; Kim, N.K.; Cho, S.H. Changes in chemical behavior of thin film lead zirconate titanate during Ar+-ion bombardment using XPS. Appl. Surf. Sci. 2003, 206, 119–128. [Google Scholar] [CrossRef]

- Kozielski, L.; Clemens, F.; Lusiola, T.; Pilch, M. Uniaxial extrusion as an enhancement method of piezoelectric properties of ceramic micro fibers. J. Alloys Compd. 2016, 687, 604–610. [Google Scholar] [CrossRef]

- Kiomarsipour, N.; Razavi, R.S. Hydrothermal synthesis of ZnO nanopigments with high UV absorption and vis/NIR reflectance. Ceram. Int. 2014, 40, 11261–11268. [Google Scholar] [CrossRef]

- Ortega, N.; Kumar, A.; Scott, J.F.; Chrisey, D.B.; Tomazawa, M.; Kumari, S.; Diestra, D.G.B.; Katiyar, R.S. Relaxor-ferroelectric superlattices: High energy density capacitors. J. Phys. Condens. Matter 2012, 24, 445901. [Google Scholar] [CrossRef] [PubMed]

- Brown, E.; Ma, C.; Acharya, J.; Ma, B.H.; Wu, J.; Li, J. Controlling dielectric and relaxor-ferroelectric properties for energy storage by tuning Pb0.92La0.08Zr0.52Ti0.48O3 film thickness. ACS Appl. Mater. Interface 2014, 6, 22417–22422. [Google Scholar] [CrossRef] [PubMed]

- Tong, S.; Ma, B.H.; Narayanan, M.; Liu, S.S.; Koritala, R.; Balachandran, U.; Shi, D.L. Lead lanthanum zirconate titanate ceramic thin films for energy storage. ACS Appl. Mater. Interface 2013, 5, 1474–1480. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Zeng, Y.; Shen, Y.; Lin, Y.H.; Nan, C.W. Thickness-dependent dielectric and energy storage properties of (Pb0.96La0.04)(Zr0.98Ti0.02)O3 antiferroelectric thin films. J. Appl. Phys. 2016, 119, 124106. [Google Scholar] [CrossRef]

- Liang, R.H.; Dong, X.L.; Chen, Y.; Cao, F.; Wang, Y.L. Effect of ZrO2 doping on the tunable and dielectric properties of Ba0.55Sr0.45TiO3/MgO composites for microwave tunable application. Mater. Res. Bull. 2006, 41, 1295–1302. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, S.; Huang, C.; Gu, H.; Liu, S.; Zhu, S.; Li, M.-Y.; Yao, L.; Wu, Y.; Zhang, G. Ultra Uniform Pb0.865La0.09(Zr0.65Ti0.35)O3 Thin Films with Tunable Optical Properties Fabricated via Pulsed Laser Deposition. Materials 2018, 11, 525. https://doi.org/10.3390/ma11040525

Jiang S, Huang C, Gu H, Liu S, Zhu S, Li M-Y, Yao L, Wu Y, Zhang G. Ultra Uniform Pb0.865La0.09(Zr0.65Ti0.35)O3 Thin Films with Tunable Optical Properties Fabricated via Pulsed Laser Deposition. Materials. 2018; 11(4):525. https://doi.org/10.3390/ma11040525

Chicago/Turabian StyleJiang, Shenglin, Chi Huang, Honggang Gu, Shiyuan Liu, Shuai Zhu, Ming-Yu Li, Lingmin Yao, Yunyi Wu, and Guangzu Zhang. 2018. "Ultra Uniform Pb0.865La0.09(Zr0.65Ti0.35)O3 Thin Films with Tunable Optical Properties Fabricated via Pulsed Laser Deposition" Materials 11, no. 4: 525. https://doi.org/10.3390/ma11040525