Structural Coloration of Polyester Fabrics Coated with Al/TiO2 Composite Films and Their Anti-Ultraviolet Properties

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of Al/TiO2 Composite Films

2.3. Microstructure and Composition of Al/TiO2 Composite Films

2.4. Structural Color and Color Fastness Test

2.5. Anti-Ultraviolet Property Test

3. Results and Discussion

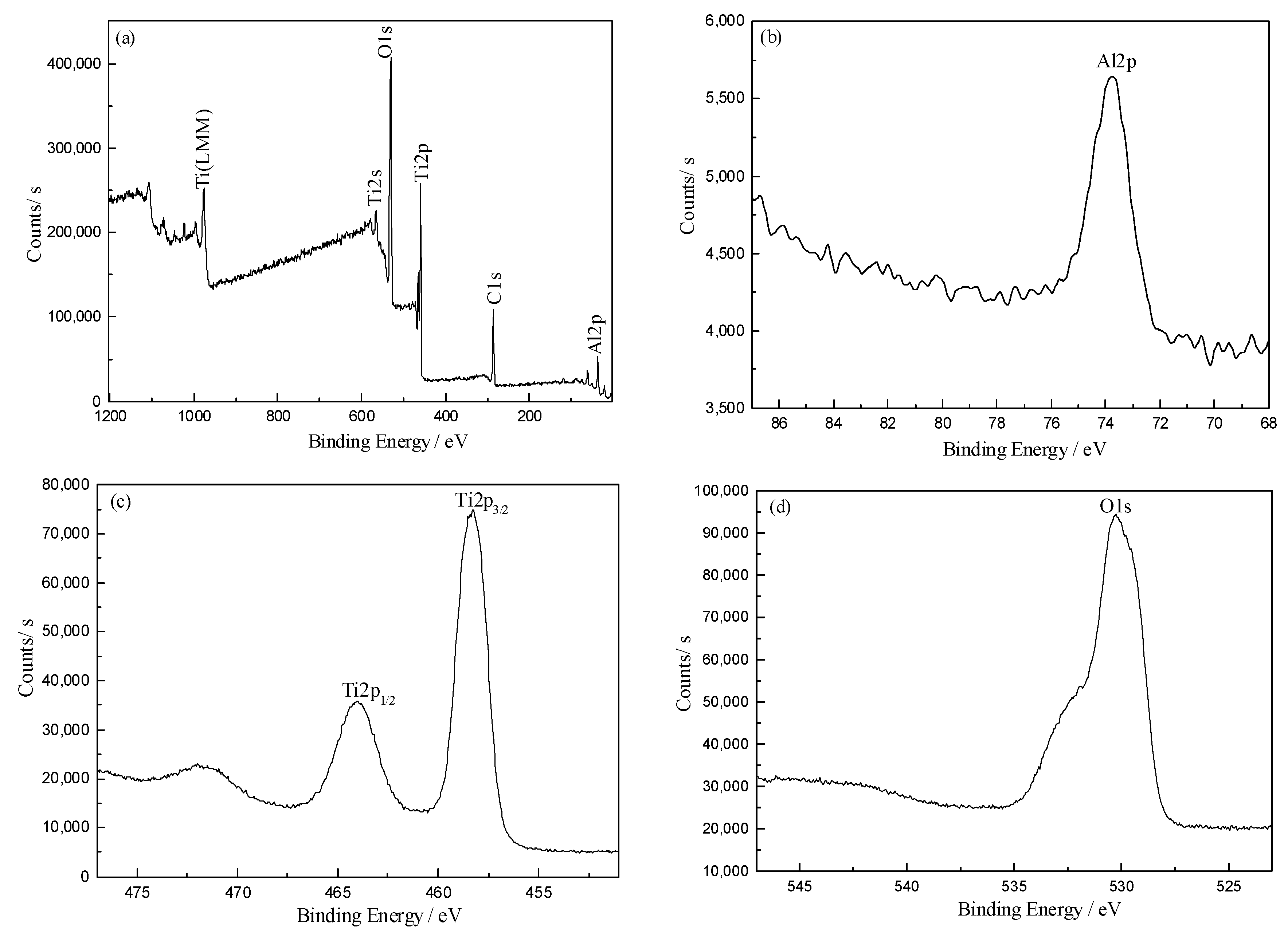

3.1. XPS Analysis

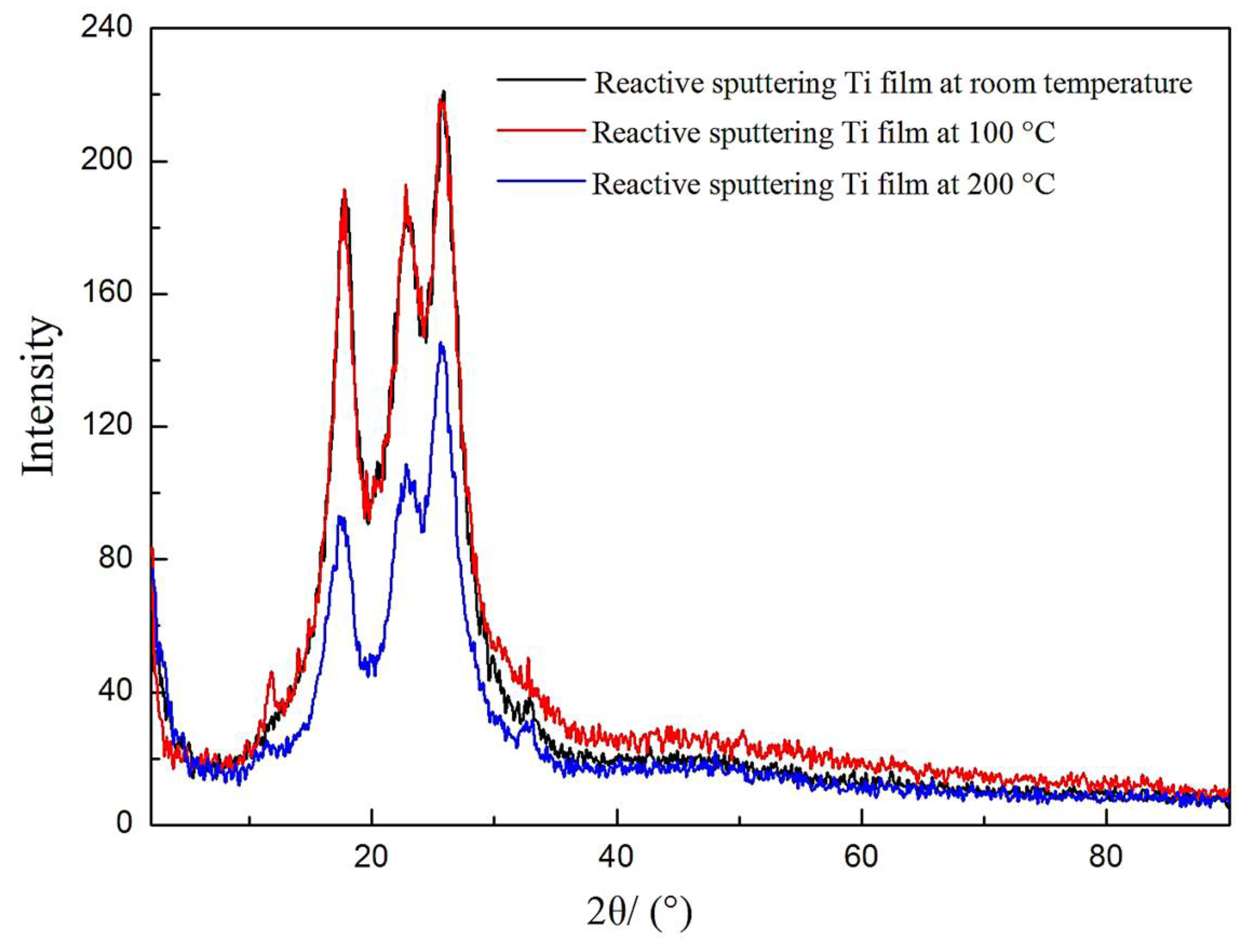

3.2. XRD Analysis

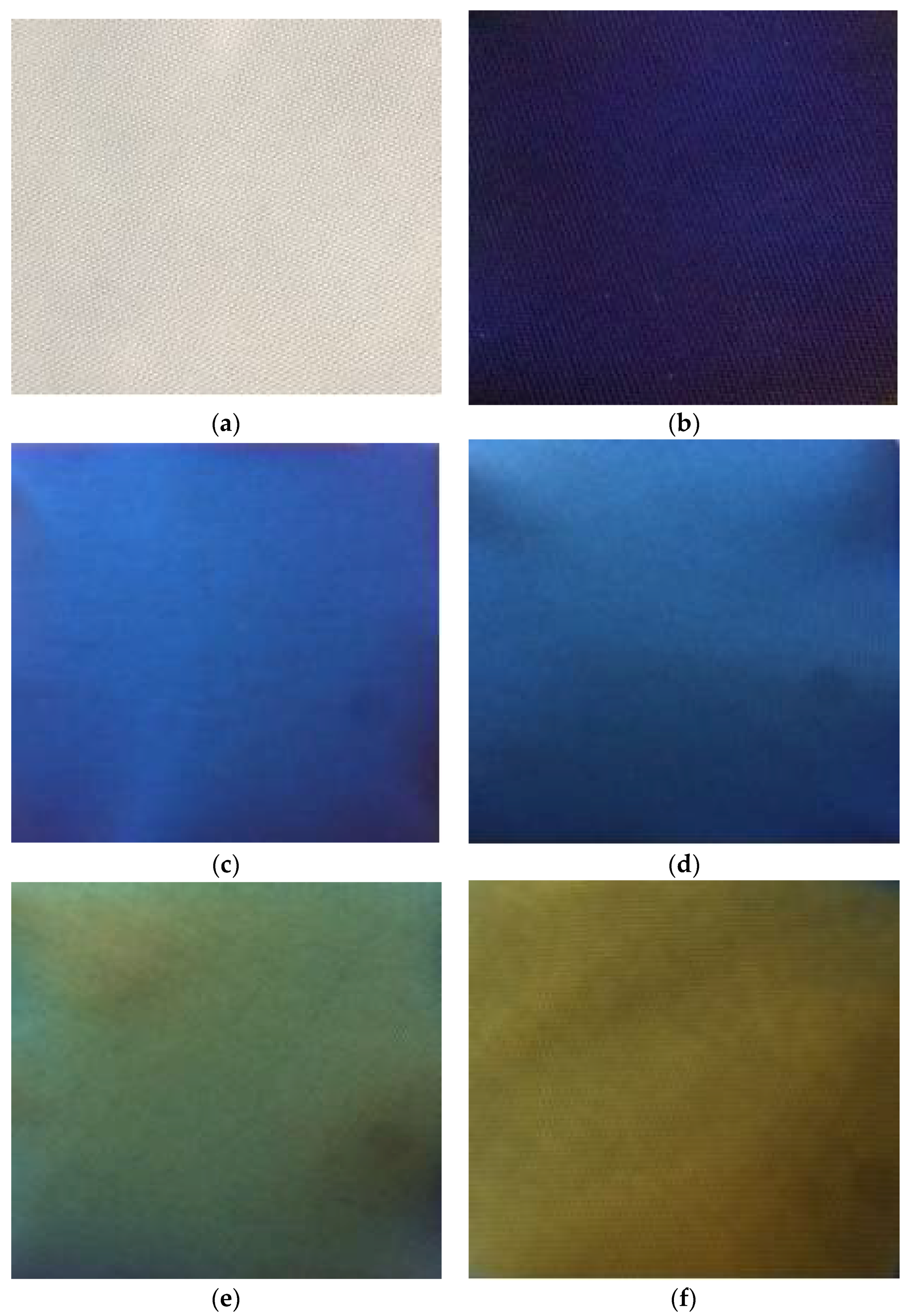

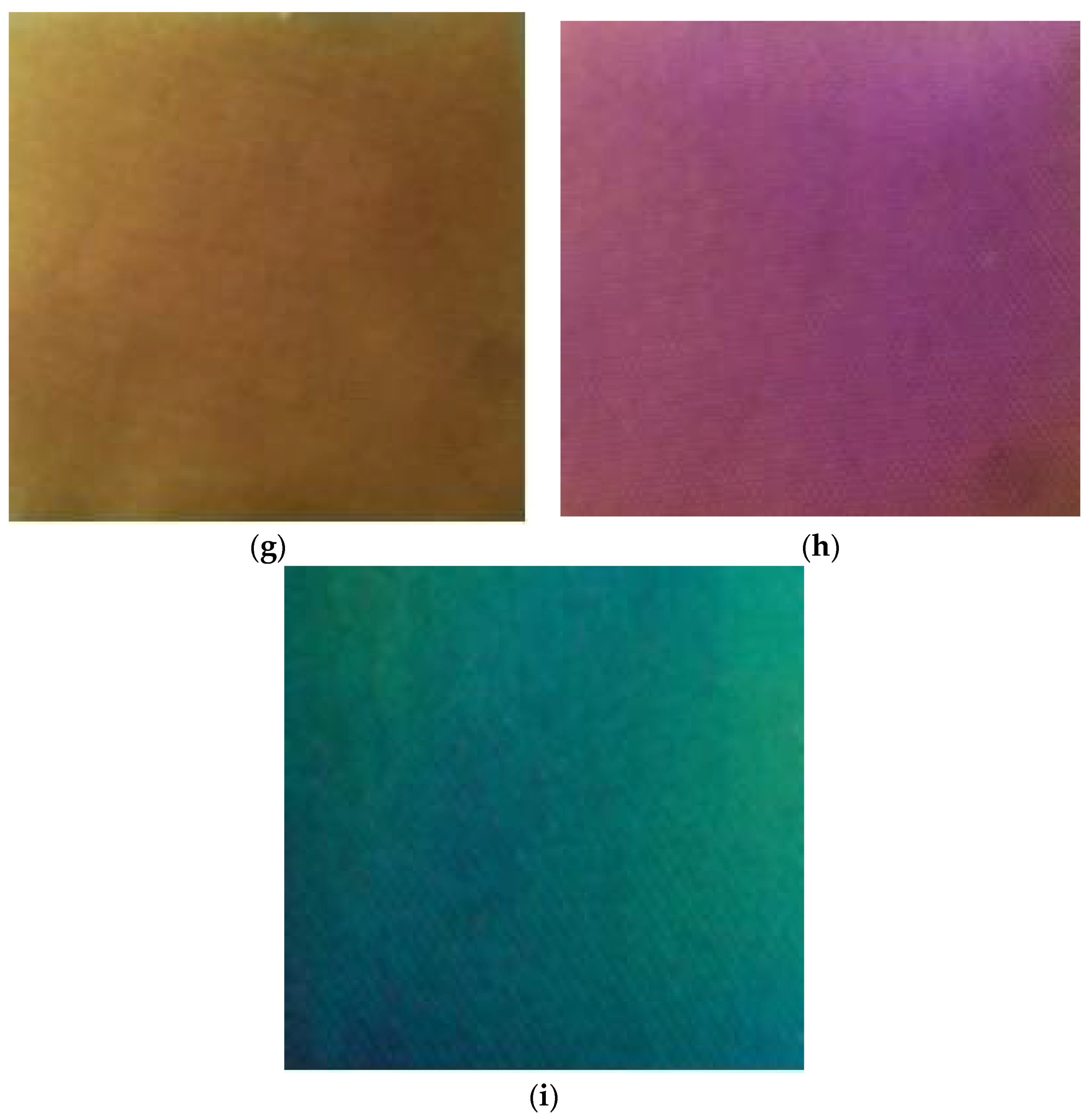

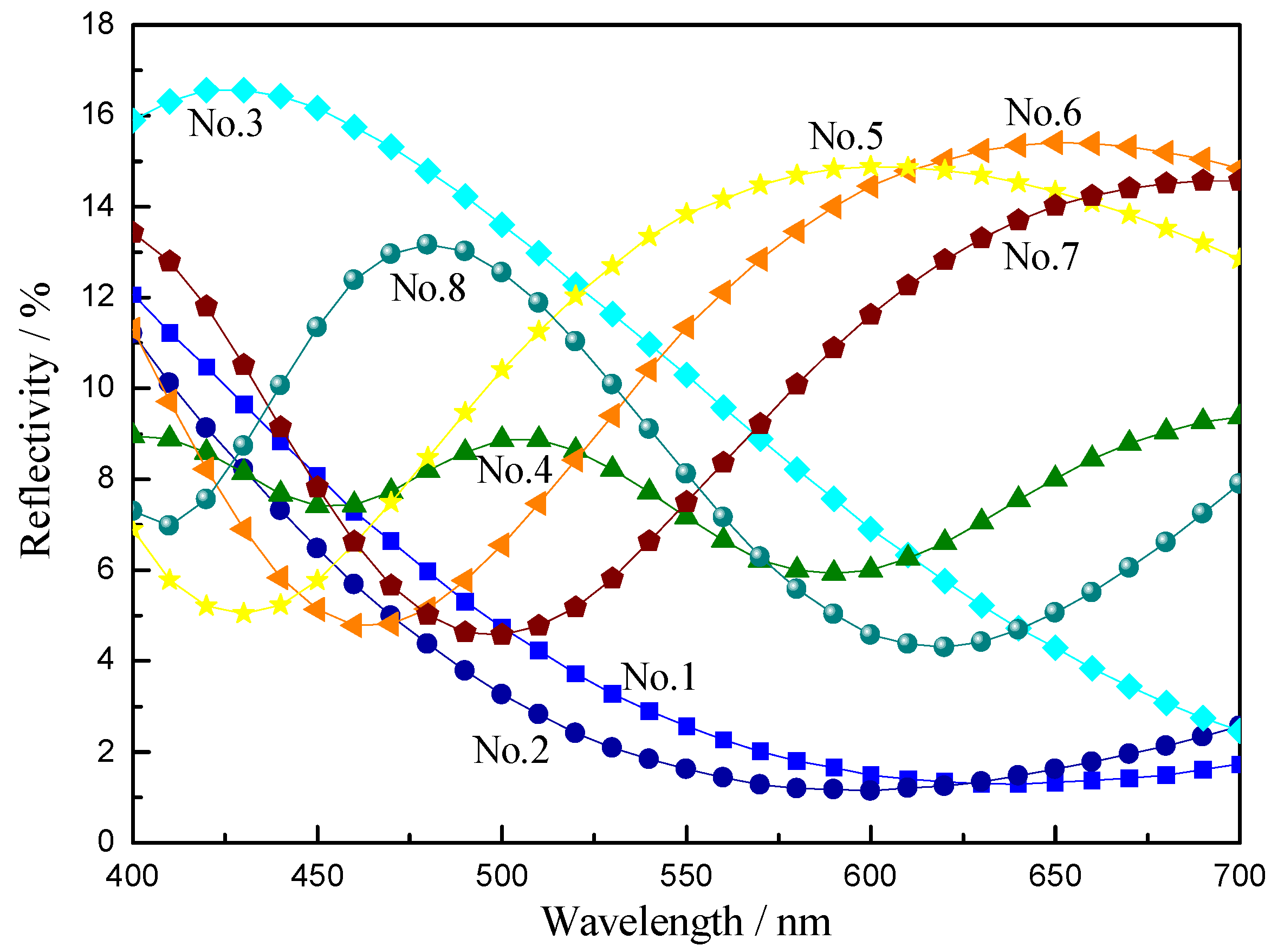

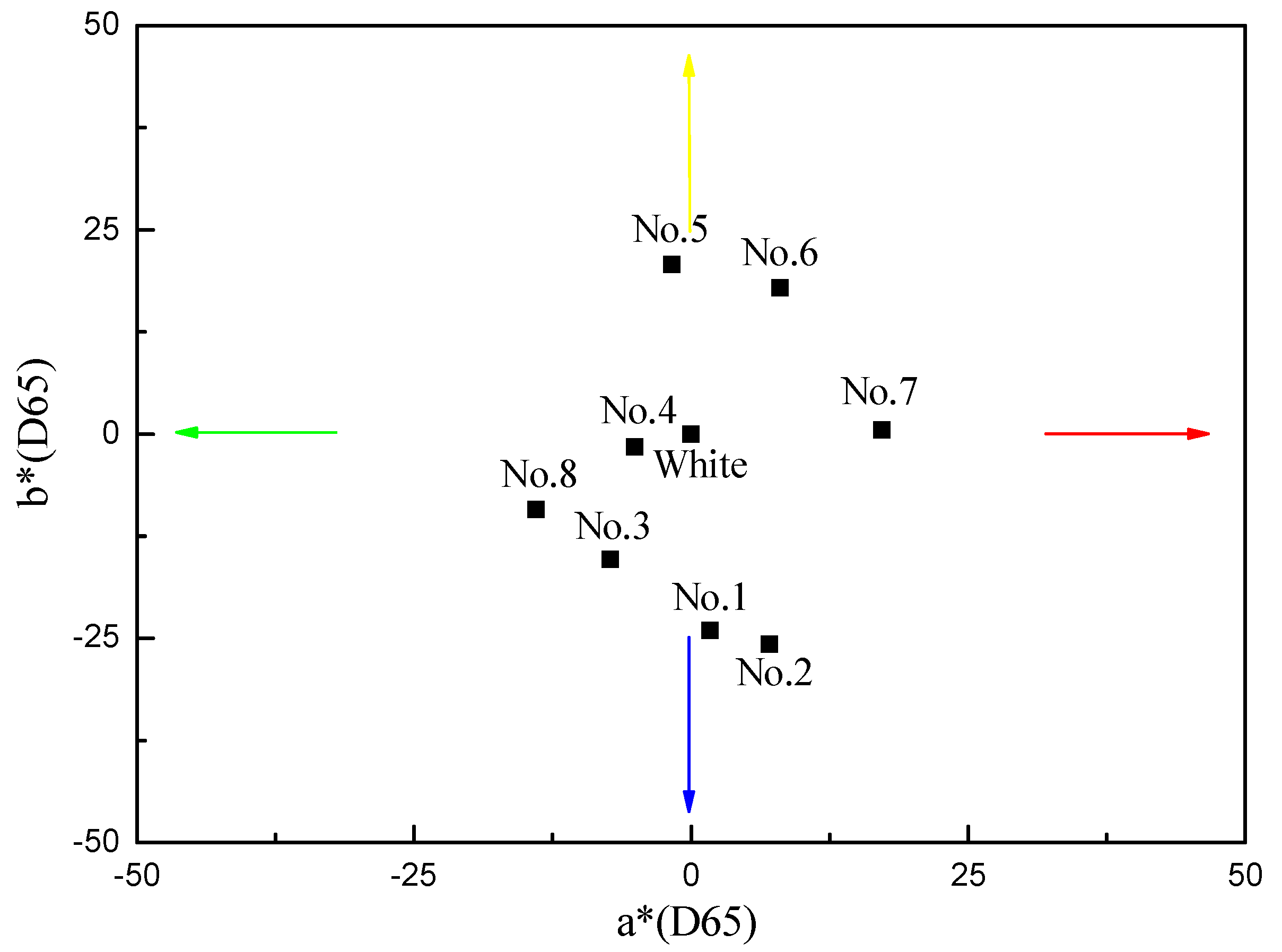

3.3. Structural Color Analysis

3.4. Anti-Ultraviolet Property Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, Z.L.; Guo, Z.G. Biomimetic superwettable materials with structural colours. Chem. Commun. 2017, 53, 12990–13011. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.J.; Zhou, L.; Zhang, G.Q.; Shao, J.Z. Fabrication of patterned photonic crystals with brilliant structural colors on fabric substrates using ink-jet printing technology. Mater. Des. 2017, 114, 10–17. [Google Scholar] [CrossRef]

- Li, H.P.; Sun, X.M.; Peng, H.S. Mechanochromic Fibers with Structural Color. ChemPhysChem 2015, 16, 3761–3768. [Google Scholar] [CrossRef] [PubMed]

- Ge, D.T.; Yang, X.M.; Chen, Z.; Yang, L.L.; Wu, G.X.; Xia, Y.; Yang, S. Colloidal inks from bumpy colloidal nanoparticles for the assembly of ultrasmooth and uniform structural colors. Nanoscale 2017, 9, 17357–17363. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Lwkiri, T.; Yagi, R.; Ogata, T.; Kurihara, S. Fabrication of wide angle structural color with the patchy multi-bilayered films. Mol. Cryst. Liq. Cryst. 2017, 644, 36–43. [Google Scholar] [CrossRef]

- Fu, Y.L.; Tippets, C.A.; Doney, E.U.; Lopez, R. Structural colors: From natural to artificial systems. Wiley Interdiscip. Rev.-Nanomed. Nanobiotechnol. 2016, 8, 758–775. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, S.F.; Lutkenhaus, J.L.; Chu, L.; Tang, B.T.; Li, S.; Ma, W. All nanoparticle-based P(MMA-AA)/TiO2 one-dimensional photonic crystal films with tunable structural colors. J. Mater. Chem. C 2017, 5, 8266–8272. [Google Scholar] [CrossRef]

- Lee, K.T.; Ji, C.G.; Banerjee, D.; Guo, L.J. Angular- and polarization-independent structural colors based on 1D photonic crystals. Laser Photonics Rev. 2015, 9, 354–362. [Google Scholar] [CrossRef]

- Moyle, B.M.; French, T.A.; Pearson, R.M.; McCarthy, B.G.; Miyake, G.M. Structural Color for Additive Manufacturing: 3D-Printed Photonic Crystals from Block Copolymers. ACS Nano 2017, 11, 3052–3058. [Google Scholar] [CrossRef] [Green Version]

- Umh, H.N.; Yu, S.J.; Kim, Y.H.; Lee, S.Y.; Yi, J.H. Tuning the Structural Color of a 2D Photonic Crystal Using a Bowl like Nanostructure. ACS Appl. Mater. Interfaces 2016, 8, 15802–15808. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.H.; Xu, W.Z.; Huang, F.L.; Chen, D.S.; Wei, Q.F. Polyester fabric coated with Ag/ZnO composite film by magnetron sputtering. Appl. Surf. Sci. 2016, 390, 863–869. [Google Scholar] [CrossRef]

- Matthews, M.B.; Kearns, S.L.; Buse, B. The accuracy of Al and Cu film thickness determination and the implications for electron probe microanalysis. Microsc. Microanal. 2016, 24, 83–92. [Google Scholar] [CrossRef] [PubMed]

- Raghu, P.; Srinatha, N.; Naveen, C.S.; Mahesh, H.M.; Basavaraj Angadi, B. Investigation on the effect of Al concentration on the structural, optical and electrical properties of spin coated Al: ZnO thin films. J. Alloys Compd. 2017, 694, 68–75. [Google Scholar] [CrossRef]

- Sobczak, N.; Stobierski, L.; Radziwill, W.; Ksiazek, M.; Warmuzek, M. Wettability and interfacial reactions in Al/TiO2. Surf. Interface Anal. 2004, 36, 1067–1070. [Google Scholar] [CrossRef]

- Zhang, D.L.; Ying, D.Y.; Munroe, P. Formation of Al2O3 during heating of an Al/TiO2 nanocomposite powder. J. Mater. Res. 2005, 20, 307–313. [Google Scholar] [CrossRef]

- GB/T 3921-2008–Textile Test for Color Fastness to Washing with Soap or Soap and Soda; Chinese Standards Association: Beijing, China, 2008.

- GB/T18830-2009–Textiles-Evaluation for Solar Ultraviolet for Solar Ultraviolet Radiation Protective Properties; Chinese Standards Association: Beijing, China, 2009.

- Moulder, J.F.; Stickle, W.F.; Sobol, P.E.; Bomben, K.D. Handbook of X-ray Photoelectron Spectroscopy; Eden Prairie: Perkin Elmer, NY, USA, 1992; pp. 213–240. [Google Scholar]

- Zhou, B.; Liu, Z.B.; Tang, B.; Rogachev, A.V. Catalytic effect of Al and AlN interlayer on the growth and properties of containing carbon films. Appl. Surf. Sci. 2015, 326, 174–180. [Google Scholar] [CrossRef]

- Quesada-Gonzalez, M.; Boscher, N.D.; Carmalt, C.J.; Parkin, I.P. Interstitial Boron-doped TiO2 thin films: The significant effect of boron on TiO2 coatings grown by atmospheric pressure chemical vapour deposition. ACS Appl. Mater. Interfaces 2016, 8, 25024–25029. [Google Scholar] [CrossRef] [PubMed]

- El Fissi, L.; Vandormael, D.; Houssiau, L.; Francis, L.A. Surface functionalization of cyclic olefin copolymer (COC) with evaporated TiO2 thin film. Appl. Surf. Sci. 2016, 363, 670–675. [Google Scholar] [CrossRef]

- Rao, Z.P.; Liu, B.W.; Li, C.B.; Xia, Y.; Wan, J. Dehydroxylation action on surface of TiO2 films restrained by nitrogen carrier gas during atomic layer deposition process. Rare Met. 2014, 33, 583–586. [Google Scholar] [CrossRef]

- Jang, J.M.; Kim, S.D.; Park, T.E.; Choe, H.C. Ultra-fine structures of Pd-Ag-HAp nanoparticle deposition on protruded TiO2 barrier layer for dental implant. Appl. Surf. Sci. 2018, 432, 285–293. [Google Scholar] [CrossRef]

- Adochite, R.C.; Munteanu, D.; Torrell, M.; Cunha, L.; Alves, E.; Barradas, N.P.; Cavaleiro, A.; Riviere, J.P.; Le Bourhis, E.; Eyidi, D.; et al. The influence of annealing treatments on the properties of Ag: TiO2 nanocomposite films prepared by magnetron sputtering. Appl. Surf. Sci. 2012, 258, 4028–4034. [Google Scholar] [CrossRef]

- Liu, F.M.; Wang, T.M. Surface and optical properties of nanocrystalline anatase titania films grown by radio frequency reactive magnetron sputtering. Appl. Surf. Sci. 2002, 195, 284–290. [Google Scholar] [CrossRef]

- Kaipio, M.; Blanquart, T.; Tomczak, Y.; Niinisto, J.; Gavagnin, M.; Longo, V.; Wanzenbock, H.D.; Pallem, V.R.; Dussarrat, C.; Puukilainen, E.; et al. Atomic layer deposition, characterization, and growth mechanistic studies of TiO2 thin films. Langmuir 2014, 30, 7395–7404. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.H.; Xu, W.Z.; Huang, F.L.; Wang, Q.Q.; Wei, Q.F.; Chen, D.S. Structural colors of fabric from Ag/TiO2 composite films prepared by magnetron sputtering deposition. Int. J. Cloth. Sci. Technol. 2017, 29, 427–435. [Google Scholar] [CrossRef]

- GB/T18830-2002–Textiles-Evaluation for Solar Ultraviolet for Solar Ultraviolet Radiation Protective Properties; Chinese Standards Association: Beijing, China, 2002.

| Samples | L* | a* | b* | C* |

|---|---|---|---|---|

| No. 1 | 19.781 | 1.681 | −23.979 | 24.038 |

| No. 2 | 15.710 | 7.106 | −25.764 | 26.726 |

| No. 3 | 37.515 | −7.281 | −15.323 | 16.965 |

| No. 4 | 32.794 | −5.054 | −1.578 | 5.294 |

| No. 5 | 43.093 | −1.776 | 20.803 | 20.878 |

| No. 6 | 39.357 | 8.058 | 17.917 | 19.646 |

| No. 7 | 34.164 | 17.240 | 0.494 | 17.247 |

| No. 8 | 34.174 | −13.992 | −9.235 | 16.764 |

| Samples | T (UVA)/% | T (UVB)/% | UPF | |||

|---|---|---|---|---|---|---|

| Average Value/% | Standard Deviation/% | Average Value/% | Standard Deviation/% | Average Value | Standard Deviation | |

| No. 1 | 3.65 | 0.44 | 3.30 | 0.14 | 31.92 | 0.88 |

| No. 2 | 3.05 | 0.75 | 2.69 | 0.12 | 36.42 | 0.75 |

| No. 3 | 3.75 | 0.12 | 3.45 | 0.09 | 30.66 | 0.68 |

| No. 4 | 3.61 | 0.11 | 3.30 | 0.07 | 31.83 | 0.77 |

| No. 5 | 3.49 | 0.08 | 3.22 | 0.10 | 32.74 | 0.98 |

| No. 6 | 3.47 | 0.15 | 3.06 | 0.10 | 33.05 | 1.01 |

| No. 7 | 3.82 | 0.05 | 3.41 | 0.05 | 30.82 | 0.86 |

| No. 8 | 3.49 | 0.10 | 3.01 | 0.08 | 33.52 | 0.58 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, X.; Ye, Y.; Lian, M.; Wei, Q. Structural Coloration of Polyester Fabrics Coated with Al/TiO2 Composite Films and Their Anti-Ultraviolet Properties. Materials 2018, 11, 1011. https://doi.org/10.3390/ma11061011

Yuan X, Ye Y, Lian M, Wei Q. Structural Coloration of Polyester Fabrics Coated with Al/TiO2 Composite Films and Their Anti-Ultraviolet Properties. Materials. 2018; 11(6):1011. https://doi.org/10.3390/ma11061011

Chicago/Turabian StyleYuan, Xiaohong, Yuanjing Ye, Min Lian, and Qufu Wei. 2018. "Structural Coloration of Polyester Fabrics Coated with Al/TiO2 Composite Films and Their Anti-Ultraviolet Properties" Materials 11, no. 6: 1011. https://doi.org/10.3390/ma11061011