Effect of Ni Content on Microstructure and Characterization of Cu-Ni-Sn Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Mechanical Properties and X-ray Diffraction (XRD) Patterns of the Alloys

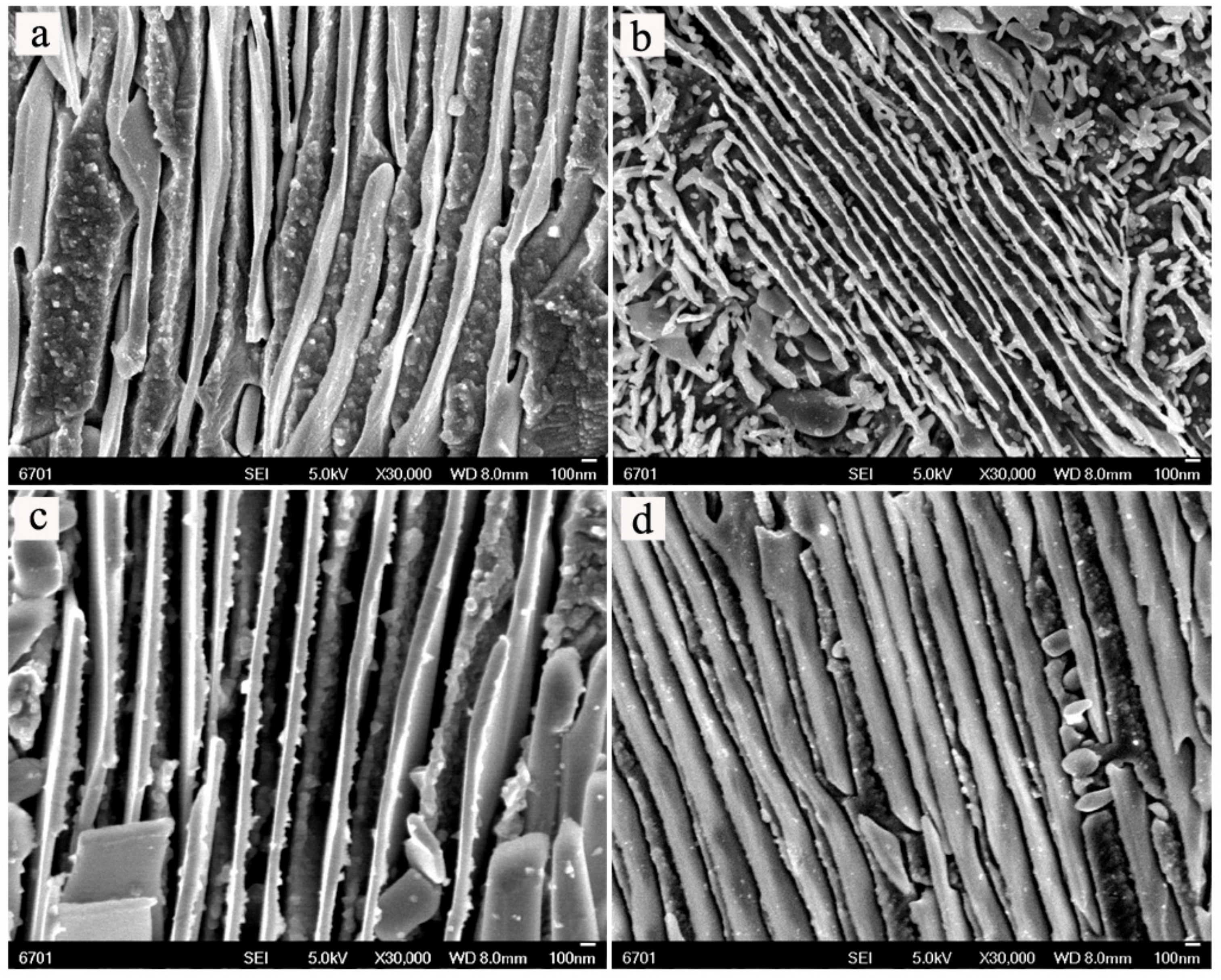

3.2. Microstructure and Morphology of the Alloys

4. Conclusions

- The hardness and yield strength of the Cu-Ni-5Sn alloys firstly increase and then decrease with the increase of Ni content, and reach up to a maximum when Ni content is 12.5 wt %.

- The sandwich structures and needle-like phase are observed by FESEM, and the grain boundary and intragranular precipitates are rich in both Ni and Sn.

- The formation of the inerratic and suitable lamellar precipitates in a sandwich structure and needle-like phase can be responsible for the good mechanical properties of the Cu-12.5Ni-5Sn alloy after aging treatment.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Plewes, J.T. High-strength Cu-Ni-Sn alloys by thermomechanical processing. Metall. Trans. A 1975, 6, 537–544. [Google Scholar] [CrossRef]

- Zhao, J.C.; Notis, M.R. Microstructure and precipitation in a Cu-7.5Ni-5Sn alloy. Scr. Mater. 1998, 39, 1509–1516. [Google Scholar] [CrossRef]

- Sadi, F.; Servant, C. Phase transformations and phase diagram at equilibrium in the Cu-Ni-Sn system. J. Therm. Anal. Calorim. 2007, 90, 319–323. [Google Scholar] [CrossRef]

- Hermann, P.H.; Morris, D.G. Relationship between microstructure and mechanical properties of a spinodally decomposing Cu-15Ni-8Sn alloy prepared by spray deposition. Metall. Mater. Trans. A 1994, 25, 1403–1412. [Google Scholar] [CrossRef]

- Singh, J.B.; Cai, W.; Bellon, P. Dry sliding of Cu–15 wt % Ni–8 wt % Sn bronze: Wear behaviour and microstructures. Wear 2007, 263, 830–841. [Google Scholar] [CrossRef]

- Lefevre, B.G.; D’Annessa, A.T.; Kalish, D. Age hardening in Cu-15Ni-8Sn alloy. Metall. Trans. A 1978, 9, 577–586. [Google Scholar] [CrossRef]

- Spooner, S.; Lefevre, B.G. The effect of prior deformation on spinodal age hardening in Cu-15 Ni-8 Sn alloy. Metall. Trans. A 1980, 11, 1085–1093. [Google Scholar] [CrossRef]

- Rhu, J.C.; Kim, S.S.; Jung, Y.C.; Han, S.Z.; Kim, C.J. Tensile strength of thermomechanically processed Cu-9Ni-6Sn alloys. Metal. Mater. Trans. A 1999, 30, 2649–2657. [Google Scholar] [CrossRef]

- Kim, S.S.; Rhu, J.C.; Jung, Y.C.; Han, S.Z.; Kim, C.J. Aging characteristics of thermomechanically processed Cu-9Ni-6Sn alloy. Scr. Mater. 1999, 40, 1–6. [Google Scholar] [CrossRef]

- Diánez, M.J.; Donoso, E.; Sayagués, M.J.; Perejón, A.; Sánchez-Jiménez, P.E.; Pérez-Maqueda, L.A.; Criado, J.M. The calorimetric analysis as a tool for studying the aging hardening mechanism of a Cu-10wt %Ni-5.5wt %Sn alloy. J. Alloys Compd. 2016, 688, 288–294. [Google Scholar] [CrossRef]

- Zhao, J.C.; Notis, M.R. Spinodal decomposition, ordering transformation, and discontinuous precipitation in a Cu–15Ni–8Sn alloy. Acta Mater. 1998, 46, 4203–4218. [Google Scholar] [CrossRef]

- Peng, G.; Gan, X.; Jiang, Y.; Li, Z.; Zhou, K. Effect of dynamic strain aging on the deformation behavior and microstructure of Cu-15Ni-8Sn alloy. J. Alloys Compd. 2017, 718, 182–187. [Google Scholar] [CrossRef]

- Hui, Z.; Yizhu, H.; Xiaomin, Y.; Ye, P. Microstructure and age characterization of Cu-15Ni-8Sn alloy coatings by laser cladding. Appl. Surf. Sci. 2010, 256, 5837–5842. [Google Scholar] [CrossRef]

- Virtanen, P.; Tiainen, T.; Lepistö, T. Precipitation at faceting grain boundaries of Cu–Ni–Sn alloys. Mater. Sci. Eng. A 1998, 251, 269–275. [Google Scholar] [CrossRef]

- Caris, J.; Varadarajan, R.; Stephens, J.J., Jr.; Lewandowski, J.J. Microstructural effects on tension and fatigue behavior of Cu–15Ni–8Sn sheet. Mater. Sci. Eng. A 2008, 491, 137–146. [Google Scholar] [CrossRef]

- Alili, B.; Bradai, D.; Zieba, P. On the discontinuous precipitation reaction and solute redistribution in a Cu-15%Ni-8%Sn alloy. Mater. Charact. 2008, 59, 1526–1530. [Google Scholar] [CrossRef]

- Caris, J.; Li, D.; Stephens, J.J., Jr.; Lewandowski, J.J. Microstructural effects on tension behavior of Cu–15Ni–8Sn sheet. Mater. Sci. Eng. A 2010, 527, 137–781. [Google Scholar] [CrossRef]

- Das, A.; Verma, V.; Basak, C.B. Elucidating microstructure of spinodal copper alloy through annealing. Mater. Charact. 2016, 120, 152–158. [Google Scholar] [CrossRef]

- Sahu, P.; Pradhan, S.K.; De, M. X-ray diffraction studies of the decomposition and microstructural characterization of cold-worked powders of Cu-15Ni-Sn alloys by Rietveld analysis. J. Alloys Compd. 2004, 377, 103–116. [Google Scholar] [CrossRef]

- Shankar, K.V.; Sellamuthu, R. Determination of the Effect of Nickel Content on Hardness, Optimum Aging Temperature and Aging Time for Spinodal Bronze Alloys Cast in Metal Mould. Appl. Mech. Mater. 2015, 813/814, 597–602. [Google Scholar] [CrossRef]

- Shankar, K.V.; Sellamuthu, R. Determination on the effect of tin content on microstructure, hardness, optimum aging temperature and aging time for spinodal bronze alloys cast in metal mold. Int. J. Metalcast. 2017, 11, 189–194. [Google Scholar] [CrossRef]

| Sample | Nominally Chemical Composition (wt %) | Theoretical Density (g/cm3) | Measured Density (g/cm3) | ||

|---|---|---|---|---|---|

| Cu | Ni | Sn | |||

| C7.5NS | 87.5 | 7.5 | 5 | 8.85 | 7.63 |

| C10NS | 85 | 10 | 5 | 8.85 | 7.79 |

| C12.5NS | 82.5 | 12.5 | 5 | 8.85 | 7.82 |

| C15NS | 80 | 15 | 5 | 8.85 | 7.90 |

| C17.5NS | 77.5 | 17.5 | 5 | 8.85 | 7.92 |

| Element | 1 | 2 | 3 |

|---|---|---|---|

| Cu | 83.62 ± 0.86 | 44.54 ± 9.95 | 66.48 ± 4.41 |

| Ni | 10.52 ± 0.31 | 25.43 ± 4.15 | 18.13 ± 2.16 |

| Sn | 5.87 ± 1.14 | 25.84 ± 5.80 | 15.39 ± 2.33 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, S.; Wang, X.; Li, Z.; Yang, Z.; Wang, J. Effect of Ni Content on Microstructure and Characterization of Cu-Ni-Sn Alloys. Materials 2018, 11, 1108. https://doi.org/10.3390/ma11071108

Du S, Wang X, Li Z, Yang Z, Wang J. Effect of Ni Content on Microstructure and Characterization of Cu-Ni-Sn Alloys. Materials. 2018; 11(7):1108. https://doi.org/10.3390/ma11071108

Chicago/Turabian StyleDu, Sanming, Xiaochao Wang, Zhen Li, Zhenghai Yang, and Jingbo Wang. 2018. "Effect of Ni Content on Microstructure and Characterization of Cu-Ni-Sn Alloys" Materials 11, no. 7: 1108. https://doi.org/10.3390/ma11071108

APA StyleDu, S., Wang, X., Li, Z., Yang, Z., & Wang, J. (2018). Effect of Ni Content on Microstructure and Characterization of Cu-Ni-Sn Alloys. Materials, 11(7), 1108. https://doi.org/10.3390/ma11071108