Composition Optimization and Mechanical Properties of Mg-Al-Sn-Mn Alloys by Orthogonal Design

Abstract

:1. Introduction

2. Materials and Methods

3. Results

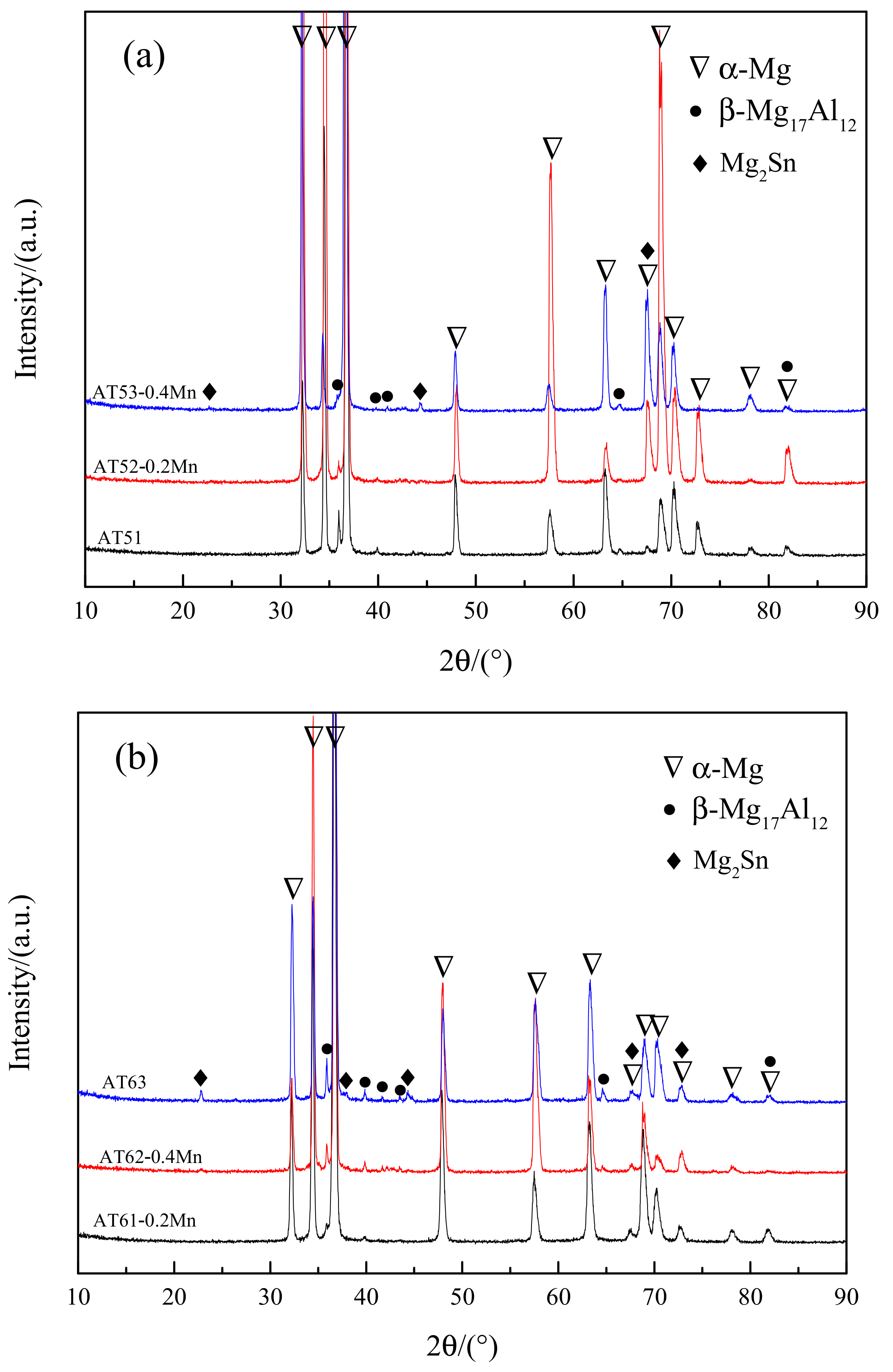

3.1. Microstructures of As-Cast Mg-Al-Sn-Mn Magnesium Alloys

3.2. Microstructure of Extruded Mg-Al-Sn-Mn Magnesium Alloys

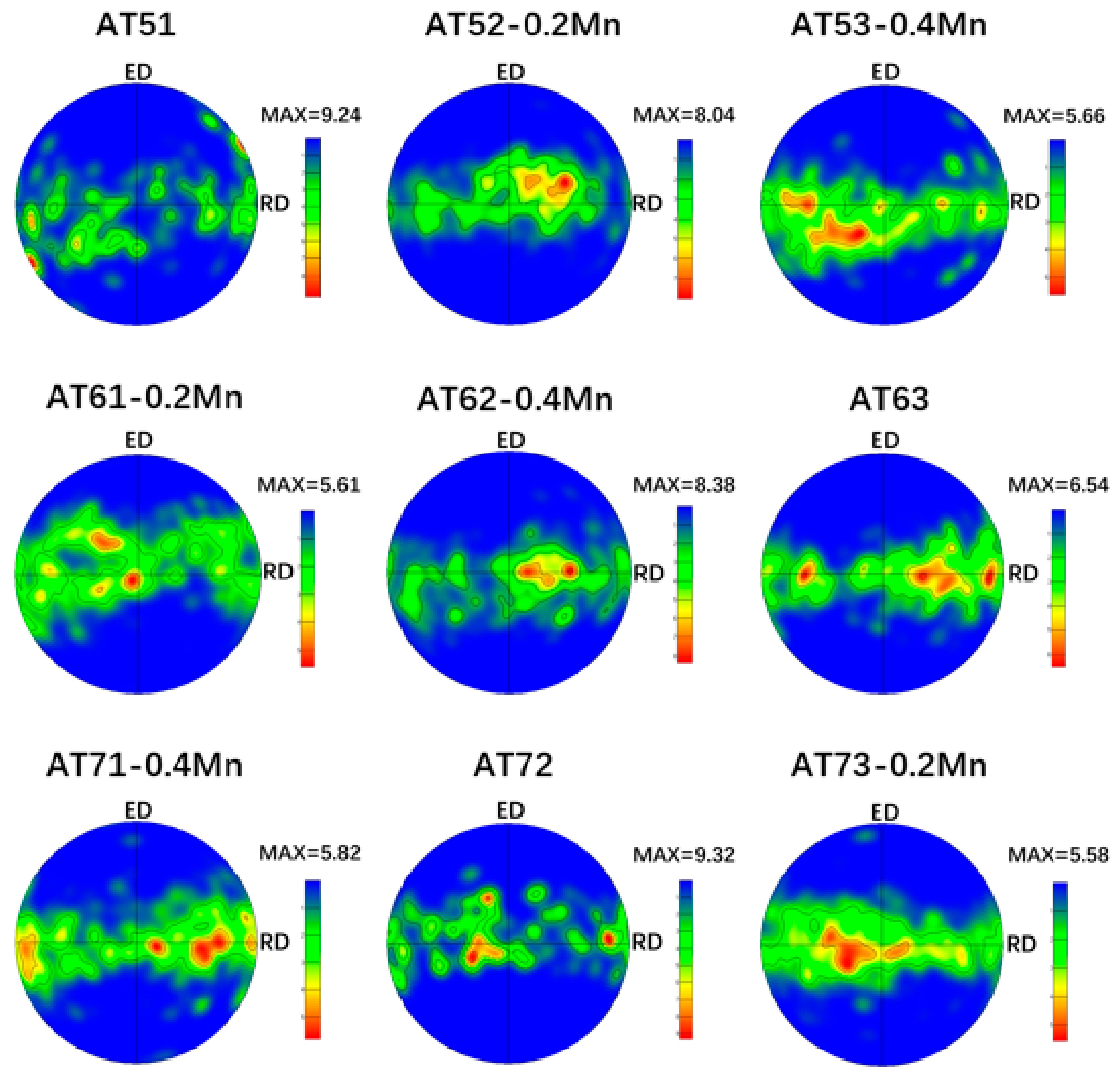

3.3. Textures of Extruded Mg-Al-Sn-Mn Magnesium Alloy

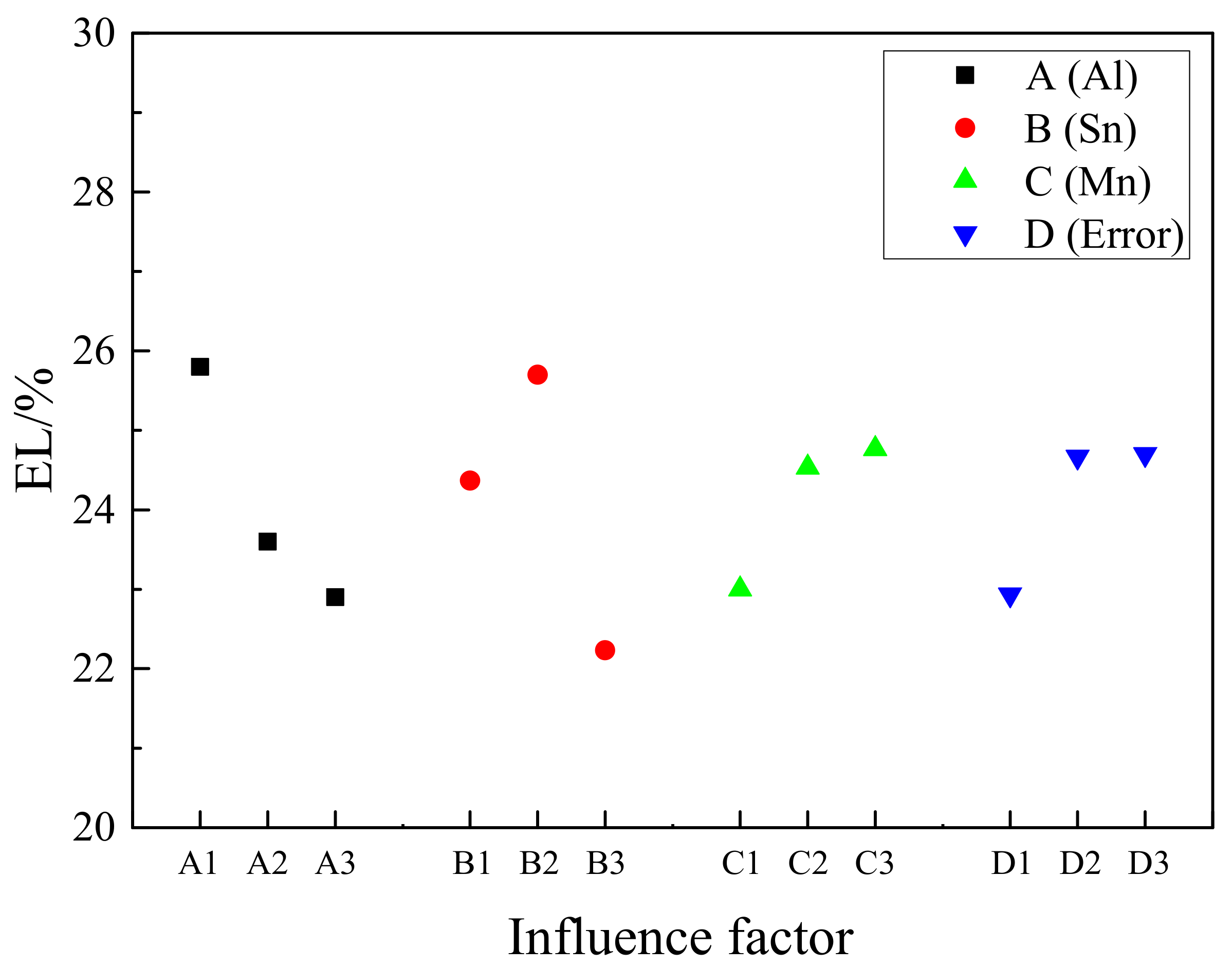

3.4. Mechanical Properties of Extruded Mg-Al-Sn-Mn Magnesium Alloys at Room Temperature

4. Conclusions

- The influence of three alloy elements on the grain size is in order of Mn, Sn, Al. The AT63-0.2Mn alloy has the minimum grain size in theory. It is not included in the designed nine kinds of alloys yet. The AT61-0.2Mn and AT73-0.2Mn alloys have the smallest grain size in the nine alloys (6.8 μm).

- The influence of three alloy elements on the maximum texture intensity is in the order of Sn, Mn, Al. The AT63-0.2Mn alloy has the minimum maximum texture intensity in theory. It is not included in the designed nine kinds of alloys, yet. AT61-0.2Mn alloy has the smallest maximum texture intensity in the 9 alloys (5.58).

- The influence of three alloy elements on the UTS and TYS are in the order of Al, Sn, Mn and Al, Mn, Sn, respectively. The AT73-0.2Mn alloy has the maximum UTS and TYS in theory. Its UTS and TYS are 322 MPa and 202 MPa, respectively.

- The influence of three alloy elements on the elongation is in the order of Sn, Al, Mn. The AT52-0.4Mn alloy has the highest elongation in theory. It is not included in the designed nine kinds of alloys yet. AT52-0.2Mn alloy has the highest elongation in the nine alloys (28.4%).

Author Contributions

Funding

Conflicts of Interest

References

- Park, S.H.; Kim, S.-H.; Kim, H.S.; Yoon, J.; You, B.S. High-speed indirect extrusion of Mg-Sn-Al-Zn alloy and its influence on microstructure and mechanical properties. J. Alloys Compd. 2016, 667, 170–177. [Google Scholar] [CrossRef]

- Huang, X.; Chino, Y.; Yuasa, M.; Ueda, H.; Inoue, M.; Kido, F.; Matsumoto, T. Microstructure and mechanical properties of AZX912 magnesium alloy extruded at different temperatures. Mater. Sci. Eng. A 2017, 679, 162–171. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, C.; Meng, W.; Pan, F.; Zhou, J. Microstructure, mechanical and corrosion properties of Mg-4Al-2Sn-xY-0.4Mn alloys. J. Alloys Compd. 2017, 727, 491–500. [Google Scholar] [CrossRef]

- Hu, Y.-B.; Deng, J.; Zhao, C.; Pan, F.-S.; Peng, J. Microstructure and mechanical properties of Mg-Gd-Zr alloys with low gadolinium contents. J. Mater. Sci. 2011, 46, 5838–5846. [Google Scholar] [CrossRef]

- Furuya, H.; Kogiso, N.; Matunaga, S.; Senda, K. Applications of magnesium alloys for aerospace structure systems. Mater. Sci. Forum 2000, 350–351, 341–348. [Google Scholar] [CrossRef]

- Lentz, M.; Risse, M.; Schaefer, N.; Reimers, W.; Beyerlein, I.J. Strength and ductility with {1011}—{1012} double twinning in a magnesium alloy. Nat. Commun. 2016, 7, 11068. [Google Scholar] [CrossRef] [PubMed]

- Zheng, T.; Hu, Y.; Zhang, Y.; Yang, S.; Pan, F. Composition optimization and electrochemical properties of Mg-Al-Sn-Mn alloy anode for Mg-air batteries. Mater. Des. 2018, 137, 245–255. [Google Scholar] [CrossRef]

- Zheng, T.; Hu, Y.; Yang, S. Effect of grain size on the electrochemical behavior of pure magnesium anode. J. Magnes. Alloys 2017, 5, 404–411. [Google Scholar] [CrossRef]

- Zheng, T.; Hu, Y.; Zhang, Y.; Pan, F. Formation of a hydrophobic and corrosion resistant coating on magnesium alloy via a one-step hydrothermal method. J. Colloid Interface Sci. 2017, 505, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Jiang, M.G.; Xu, C.; Nakata, T.; Yan, H.; Chen, R.S.; Kamado, S. Development of dilute Mg-Zn-Ca-Mn alloy with high performance via extrusion. J. Alloys Compd. 2016, 668, 13–21. [Google Scholar] [CrossRef]

- Swetha, C.V.; Dumpala, R.; Anand, K.S.; Kondaiah, V.V.; Ratna, S.B. Influence of heat treatment on the machinability and corrosion behavior of AZ91 Mg alloy. J. Magnes. Alloys 2018, 6, 52–58. [Google Scholar]

- Liu, Q.; Zhou, X.; Zhou, H.; Fan, X.; Liu, K. The effect of extrusion conditions on the properties and textures of AZ31B alloy. J. Magnes. Alloys 2017, 5, 202–209. [Google Scholar] [CrossRef]

- Li-Min, M.A.; Wang, H.X.; Zhang, L.X.; Chen, W.Z. Influences of rare earth element Y on microstructure and mechanical properties of hot-extruded Mg-Zn-Y-Zr magnesium alloys. J. Netshape Form. Eng. 2018, 10, 7–12. [Google Scholar]

- He, J.H.; Jin, L.; Wang, F.H.; Dong, S.; Dong, J. Mechanical properties of Mg-8Gd-3Y-0.5Zr alloy with bimodal grain size distributions. J. Magnes. Alloys 2017, 5, 423–429. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, J.; Huang, S.; Liu, S.; Pan, F. Substitution of Ni for Zn on microstructure and mechanical properties of Mg–Gd–Y–Zn–Mn alloy. J. Magnes. Alloys 2017, 5, 355–361. [Google Scholar] [CrossRef]

- Zheng, X.; Dong, J.; Wang, S. Microstructure and mechanical properties of Mg-Nd-Zn-Zr billet prepared by direct chill casting. J. Magnes. Alloys 2018, 6, 95–99. [Google Scholar] [CrossRef]

- Lapovok, R.; Zolotoyabko, E.; Berner, A.; Skripnyuk, V.; Lakin, E.; Larianovsky, N.; Xu, C.; Rabkin, E. Hydrogenation effect on microstructure and mechanical properties of Mg-Gd-Y-Zn-Zr alloys. Mater. Sci. Eng. A 2018, 719, 73–80. [Google Scholar] [CrossRef]

- Yu, Z.; Xu, C.; Meng, J.; Kamado, S. Microstructure evolution and mechanical properties of a high strength Mg-11.7Gd-4.9Y-0.3Zr (wt %) alloy prepared by pre-deformation annealing, hot extrusion and ageing. Mater. Sci. Eng. A 2017, 703, 348–358. [Google Scholar] [CrossRef]

- Pan, H.; Qin, G.; Huang, Y.; Ren, Y.; Sha, X.; Han, X.; Liu, Z.Q.; Li, C.; Wu, X.; Chen, H. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater. 2018, 149, 350–363. [Google Scholar] [CrossRef]

- Wang, F.; Dong, H.; Sun, S.; Wang, Z.; Mao, P.; Liu, Z. Microstructure, tensile properties, and corrosion behavior of die-cast Mg-7Al-1Ca-xSn alloys. J. Mater. Eng. Perform. 2018, 27, 612–623. [Google Scholar] [CrossRef]

- Luo, D.; Wang, H.-Y.; Zhang, L.; Liu, G.-J.; Li, J.-B.; Jiang, Q.-C. Microstructure evolution and tensile properties of hot rolled Mg–6Al–3Sn alloy sheet at elevated temperatures. Mater. Sci. Eng. A 2015, 643, 149–155. [Google Scholar] [CrossRef]

- Kabir, A.S.H.; Sanjari, M.; Su, J.; Jung, I.H.; Yue, S. Effect of strain-induced precipitation on dynamic recrystallization in Mg-Al-Sn alloys. Mater. Sci. Eng. A 2014, 616, 252–259. [Google Scholar] [CrossRef]

- She, J.; Pan, F.; Zhang, J.; Tang, A.; Luo, S.; Yu, Z.; Song, K.; Rashad, M. Microstructure and mechanical properties of Mg-Al-Sn extruded alloys. J. Alloys Compd. 2016, 657, 893–905. [Google Scholar] [CrossRef]

- Hu, Y.; Guan, M.; Zheng, T. Microstructure, mechanical properties and yield asymmetry of Mg-4Al-2Sn-xY alloys. Mater. Sci. Technol. 2018, 34, 1–11. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, J.; Yan, H.; Su, B.; He, X.; Ran, M. Effects of artificial aging on microstructure and mechanical properties of the Mg-4.5Zn-4.5Sn-2Al alloy. J. Alloys Compd. 2014, 592, 250–257. [Google Scholar] [CrossRef]

- Wang, B.; Pan, F.; Chen, X.; Guo, W.; Mao, J. Microstructure and mechanical properties of as-extruded and as-aged Mg-Zn-Al-Sn alloys. Mater. Sci. Eng. A 2016, 656, 165–173. [Google Scholar] [CrossRef]

- Pan, H.; Qin, G.; Xu, M.; Fu, H.; Ren, Y.; Pan, F.; Gao, Z.; Zhao, C.; Yang, Q.; She, J.; et al. Enhancing mechanical properties of Mg-Sn alloys by combining addition of Ca and Zn. Mater. Des. 2015, 83, 736–744. [Google Scholar] [CrossRef]

- Kim, B.; Baek, S.-M.; Jeong, H.Y.; Lee, J.G.; Park, S.S. Grain refinement and reduced yield asymmetry of extruded Mg-5Sn-1Zn alloy by Al addition. J. Alloys Compd. 2016, 660, 304–309. [Google Scholar] [CrossRef]

- Cheng, W.; Bai, Y.; Wang, L.; Wang, H.; Bian, L.; Yu, H. Strengthening effect of extruded Mg-8Sn-2Zn-2Al Alloy: Influence of micro and nano-size Mg2Sn precipitates. Materials 2017, 10, 822. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.Y.; Zhang, N.; Wang, C.; Jiang, Q.C. First-principles study of the generalized stacking fault energy in Mg-3Al-3Sn alloy. Scr. Mater. 2011, 65, 723–726. [Google Scholar] [CrossRef]

- Luo, D.; Wang, H.Y.; Chen, L.; Liu, G.J.; Wang, J.G.; Jiang, Q.C. Strong strain hardening ability in an as-cast Mg-3Sn-1Zn alloy. Mater. Lett. 2013, 94, 51–54. [Google Scholar] [CrossRef]

- Chen, C.; Chen, J.; Yan, H.; Su, B.; Song, M.; Zhu, S. Dynamic precipitation, microstructure and mechanical properties of Mg-5Zn-1Mn alloy sheets prepared by high strain-rate rolling. Mater. Des. 2016, 100, 58–66. [Google Scholar] [CrossRef]

- Khan, S.A.; Miyashita, Y.; Mutoh, Y.; Sajuri, Z.B. Influence of Mn content on mechanical properties and fatigue behavior of extruded Mg alloys. Mater. Sci. Eng. A 2006, 420, 315–321. [Google Scholar] [CrossRef]

- Tong, L.B.; Zheng, M.Y.; Xu, S.W.; Kamado, S.; Du, Y.Z.; Hu, X.S.; Wu, K.; Gan, W.M.; Brokmeier, H.G.; Wang, G.J. Effect of Mn addition on microstructure, texture and mechanical properties of Mg-Zn-Ca alloy. Mater. Sci. Eng. A 2011, 528, 3741–3747. [Google Scholar] [CrossRef]

- Homma, T.; Nakawaki, S.; Oh-Ishi, K.; Hono, K.; Kamado, S. Unexpected influence of Mn addition on the creep properties of a cast Mg-2Al-2Ca (mass%) alloy. Acta Mater. 2011, 59, 7662–7672. [Google Scholar] [CrossRef]

- Lu, X.; Zhao, G.; Zhou, J.; Zhang, C.; Chen, L.; Tang, S. Microstructure and mechanical properties of Mg-3.0Zn-1.0Sn-0.3Mn-0.3Ca alloy extruded at different temperatures. J. Alloys Compd. 2018, 732, 257–269. [Google Scholar] [CrossRef]

- Du, W.; Liu, K.; Ma, K.; Wang, Z.; Li, S. Effects of trace Ca/Sn addition on corrosion behaviors of biodegradable Mg-4Zn-0.2Mn alloy. J. Magnes. Alloys 2018, 6, 1–14. [Google Scholar] [CrossRef]

- Peng, J.; Bin-Jiang, L.V.; Tong, X.S.; Pan, F.S. Current state and prospect of research on effects of Mn on the microstructure and properties in Mg-Zn serial magnesium alloys. Light Met. 2012, 36, 55–58. [Google Scholar]

- Wu, G.; Zhai, C.; Zeng, X.; Ding, W.; Zhu, Y. Effect of TiO2 and MnCl2 on the structure and properties of magnesium alloy waste. Acta Met. Sin. 2003, 39, 729–733. [Google Scholar]

- Wen, L.; Yu, K.; Xiong, H.; Dai, Y.; Yang, S.; Qiao, X.; Teng, F.; Fan, S. Composition optimization and electrochemical properties of Mg-Al-Pb-(Zn) alloys as anodes for seawater activated battery. Electrochim. Acta 2016, 194, 40–51. [Google Scholar] [CrossRef]

- Deng, L.; Qin, J.M.; Jia, X.P.; Guo, X. Enhanced thermoelectric performance of skutterudites via orthogonal experimental design. J. Alloys Compd. 2016, 695, 3152–3155. [Google Scholar] [CrossRef]

- Cui, W.; Li, X.; Zhou, S.; Weng, J. Investigation on process parameters of electrospinning system through orthogonal experimental design. J. Appl. Polym. Sci. 2007, 103, 3105–3112. [Google Scholar] [CrossRef]

- Tan, L.; Yang, Y. In situ phase transformation of laves phase from Chi-phase in Mo-containing Fe-Cr-Ni alloys. Mater. Lett. 2015, 158, 233–236. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, M.; Fan, Z.; Zhou, X.; Thompson, G.E. The effect of Al 8 Mn 5 intermetallic particles on grain size of as-cast Mg-Al-Zn AZ91D alloy. Intermetallics 2010, 18, 1683–1689. [Google Scholar] [CrossRef]

- Sajuri, Z.B.; Miyashita, Y.; Hosokai, Y.; Mutoh, Y. Effects of Mn content and texture on fatigue properties of as-cast and extruded AZ61 magnesium alloys. Int. J. Mech. Sci. 2006, 48, 198–209. [Google Scholar] [CrossRef]

- Jung, J.G.; Park, S.H.; You, B.S. Effect of aging prior to extrusion on the microstructure and mechanical properties of Mg-7Sn-1Al-1Zn alloy. J. Alloys Compd. 2015, 627, 324–332. [Google Scholar] [CrossRef]

- Park, S.S.; Tang, W.N.; You, B.S. Microstructure and mechanical properties of an indirect-extruded Mg-8Sn-1Al-1Zn alloy. Mater. Lett. 2010, 64, 31–34. [Google Scholar] [CrossRef]

- Kim, B.; Chan, H.P.; Kim, H.S.; You, B.S.; Park, S.S. Grain refinement and improved tensile properties of Mg-3Al-1Zn alloy processed by low-temperature indirect extrusion. Scr. Mater. 2014, 76, 21–24. [Google Scholar] [CrossRef]

- Du, Y.Z.; Zheng, M.Y.; Xu, C.; Qiao, X.G.; Wu, K.; Liu, X.D.; Wang, G.J.; Lv, X.Y. Microstructures and mechanical properties of as-cast and as-extruded Mg-4.50Zn-1.13Ca (wt %) alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 576, 6–13. [Google Scholar] [CrossRef]

- Shang, S.J.; Deng, K.K.; Nie, K.B.; Li, J.C.; Zhou, S.S.; Xu, F.J.; Fan, J.F. Microstructure and mechanical properties of SiCp/Mg-Al-Zn composites containing Mg17Al12 phases processed by low-speed extrusion. Mater. Sci. Eng. A 2014, 610, 243–249. [Google Scholar] [CrossRef]

- Laser, T.; Hartig, C.; Nürnberg, M.R.; Letzig, D.; Bormann, R. The influence of calcium and cerium mischmetal on the microstructural evolution of Mg-3Al-1Zn during extrusion and resulting mechanical properties. Acta Mater. 2008, 56, 2791–2798. [Google Scholar] [CrossRef]

- Jain, J.; Poole, W.J.; Sinclair, C.W.; Gharghouri, M.A. Reducing the tension–compression yield asymmetry in a Mg-8Al-0.5Zn alloy via precipitation. Scr. Mater. 2010, 62, 301–304. [Google Scholar] [CrossRef]

- Borkar, H.; Gauvin, R.; Pekguleryuz, M. Effect of extrusion temperature on texture evolution and recrystallization in extruded Mg-1% Mn and Mg-1% Mn-1.6% Sr alloys. J. Alloys Compd. 2013, 555, 219–224. [Google Scholar] [CrossRef]

| Number | Factor | Index | |||

|---|---|---|---|---|---|

| Al (A) | Sn (B) | Mn (C) | Null (D) | Grain Size (μm) | |

| 1(AT51) | 1 | 1 | 1 | 1 | 14.4 ± 2.5 |

| 2(AT52-0.2Mn) | 1 | 2 | 2 | 2 | 8.0 ± 1.6 |

| 3(AT53-0.4Mn) | 1 | 3 | 3 | 3 | 7.4 ± 1.3 |

| 4(AT61-0.2Mn) | 2 | 1 | 2 | 3 | 6.8 ± 1.2 |

| 5(AT62-0.4Mn) | 2 | 2 | 3 | 1 | 8.4 ± 1.5 |

| 6(AT63) | 2 | 3 | 1 | 2 | 10.2 ± 1.8 |

| 7(AT71-0.4Mn) | 3 | 1 | 3 | 2 | 8.3 ± 1.5 |

| 8(AT72) | 3 | 2 | 1 | 3 | 16.3 ± 2.6 |

| 9(AT73-0.4Mn) | 3 | 3 | 2 | 1 | 6.8 ± 1.2 |

| K1 | 29.8 | 29.5 | 40.9 | 29.6 | |

| K2 | 25.4 | 32.7 | 21.6 | 26.5 | |

| K3 | 31.4 | 24.4 | 24.1 | 30.5 | |

| R | 2 | 2.77 | 6.43 | 1.33 | |

| Number | Factor | Index | |||

|---|---|---|---|---|---|

| Al (A) | Sn (B) | Mn (C) | Null (D) | Max Intensity | |

| 1(AT51) | 1 | 1 | 1 | 1 | 9.24 |

| 2(AT52-0.2Mn) | 1 | 2 | 2 | 2 | 8.04 |

| 3(AT53-0.4Mn) | 1 | 3 | 3 | 3 | 5.66 |

| 4(AT61-0.2Mn) | 2 | 1 | 2 | 3 | 5.61 |

| 5(AT62-0.4Mn) | 2 | 2 | 3 | 1 | 8.38 |

| 6(AT63) | 2 | 3 | 1 | 2 | 6.54 |

| 7(AT71-0.4Mn) | 3 | 1 | 3 | 2 | 5.82 |

| 8(AT72) | 3 | 2 | 1 | 3 | 9.32 |

| 9(AT73-0.4Mn) | 3 | 3 | 2 | 1 | 5.58 |

| K1 | 22.94 | 20.67 | 25.10 | 23.20 | |

| K2 | 20.53 | 25.74 | 19.23 | 20.40 | |

| K3 | 20.72 | 17.78 | 19.86 | 20.59 | |

| R | 0.80 | 2.65 | 1.96 | 0.93 | |

| Number | Alloy | YS/MPa | UTS/MPa | EL% |

|---|---|---|---|---|

| 1 | AT51 | 160 ± 4 | 266 ± 4 | 23.8 ± 1.6 |

| 2 | AT52-0.2Mn | 176 ± 2 | 293 ± 3 | 28.4 ± 2.0 |

| 3 | AT53-0.4Mn | 169 ± 2 | 291 ± 1 | 25.2 ± 1.8 |

| 4 | AT61-0.2Mn | 173 ± 3 | 284 ± 4 | 24.9 ± 1.3 |

| 5 | AT62-0.4Mn | 176 ± 5 | 301 ± 2 | 24.7 ± 1.2 |

| 6 | AT63 | 178 ± 4 | 298 ± 2 | 21.2 ± 1.5 |

| 7 | AT71-0.4Mn | 186 ± 2 | 305 ± 3 | 24.4 ± 1.2 |

| 8 | AT72 | 179 ± 1 | 300 ± 2 | 24.0 ± 0.9 |

| 9 | AT73-0.2Mn | 202 ± 3 | 322 ± 3 | 20.3 ± 1.3 |

| Number | Factor | Index | |||

|---|---|---|---|---|---|

| A (Al) | B (Sn) | C (Mn) | D (null) | UTS/MPa | |

| 1(AT51) | 1 | 1 | 1 | 1 | 266 |

| 2(AT52-0.2Mn) | 1 | 2 | 2 | 2 | 293 |

| 3(AT53-0.4Mn) | 1 | 3 | 3 | 3 | 291 |

| 4(AT61-0.2Mn) | 2 | 1 | 2 | 3 | 284 |

| 5(AT62-0.4Mn) | 2 | 2 | 3 | 1 | 301 |

| 6(AT63) | 2 | 3 | 1 | 2 | 298 |

| 7(AT71-0.4Mn) | 3 | 1 | 3 | 2 | 305 |

| 8(AT72) | 3 | 2 | 1 | 3 | 300 |

| 9(AT73-0.4Mn) | 3 | 3 | 2 | 1 | 322 |

| K1 | 850 | 855 | 864 | 889 | |

| K2 | 883 | 894 | 899 | 896 | |

| K3 | 927 | 911 | 897 | 875 | |

| R | 25.7 | 18.7 | 11.7 | 7 | |

| Number | Factor | Index | |||

|---|---|---|---|---|---|

| A (Al) | B (Sn) | C (Mn) | D (null) | TYS/MPa | |

| 1(AT51) | 1 | 1 | 1 | 1 | 160 |

| 2(AT52-0.2Mn) | 1 | 2 | 2 | 2 | 176 |

| 3(AT53-0.4Mn) | 1 | 3 | 3 | 3 | 169 |

| 4(AT61-0.2Mn) | 2 | 1 | 2 | 3 | 173 |

| 5(AT62-0.4Mn) | 2 | 2 | 3 | 1 | 176 |

| 6(AT63) | 2 | 3 | 1 | 2 | 178 |

| 7(AT71-0.4Mn) | 3 | 1 | 3 | 2 | 186 |

| 8(AT72) | 3 | 2 | 1 | 3 | 179 |

| 9(AT73-0.4Mn) | 3 | 3 | 2 | 1 | 202 |

| K1 | 505 | 519 | 517 | 538 | |

| K2 | 527 | 531 | 551 | 540 | |

| K3 | 567 | 549 | 531 | 521 | |

| R | 20.7 | 10.0 | 11.3 | 6.3 | |

| Number | Factor | Index | |||

|---|---|---|---|---|---|

| A (Al) | B (Sn) | C (Mn) | D (null) | El/% | |

| 1(AT51) | 1 | 1 | 1 | 1 | 23.8 |

| 2(AT52-0.2Mn) | 1 | 2 | 2 | 2 | 28.4 |

| 3(AT53-0.4Mn) | 1 | 3 | 3 | 3 | 25.2 |

| 4(AT61-0.2Mn) | 2 | 1 | 2 | 3 | 24.9 |

| 5(AT62-0.4Mn) | 2 | 2 | 3 | 1 | 24.7 |

| 6(AT63) | 2 | 3 | 1 | 2 | 21.2 |

| 7(AT71-0.4Mn) | 3 | 1 | 3 | 2 | 24.4 |

| 8(AT72) | 3 | 2 | 1 | 3 | 24.0 |

| 9(AT73-0.4Mn) | 3 | 3 | 2 | 1 | 20.3 |

| K1 | 77.4 | 73.1 | 69.0 | 68.8 | |

| K2 | 70.8 | 77.1 | 73.6 | 74.0 | |

| K3 | 68.7 | 66.7 | 74.3 | 74.1 | |

| R | 2.90 | 3.47 | 1.77 | 1.77 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, M.; Hu, Y.; Zheng, T.; Zhao, T.; Pan, F. Composition Optimization and Mechanical Properties of Mg-Al-Sn-Mn Alloys by Orthogonal Design. Materials 2018, 11, 1424. https://doi.org/10.3390/ma11081424

Guan M, Hu Y, Zheng T, Zhao T, Pan F. Composition Optimization and Mechanical Properties of Mg-Al-Sn-Mn Alloys by Orthogonal Design. Materials. 2018; 11(8):1424. https://doi.org/10.3390/ma11081424

Chicago/Turabian StyleGuan, Maosheng, Yaobo Hu, Tianxu Zheng, Tianshuo Zhao, and Fusheng Pan. 2018. "Composition Optimization and Mechanical Properties of Mg-Al-Sn-Mn Alloys by Orthogonal Design" Materials 11, no. 8: 1424. https://doi.org/10.3390/ma11081424

APA StyleGuan, M., Hu, Y., Zheng, T., Zhao, T., & Pan, F. (2018). Composition Optimization and Mechanical Properties of Mg-Al-Sn-Mn Alloys by Orthogonal Design. Materials, 11(8), 1424. https://doi.org/10.3390/ma11081424