Impact and Post-Impact Performance of Sandwich Wall Boards with GFRP Face Sheets and a Web-Foam Core: The Effects of Impact Location

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimens

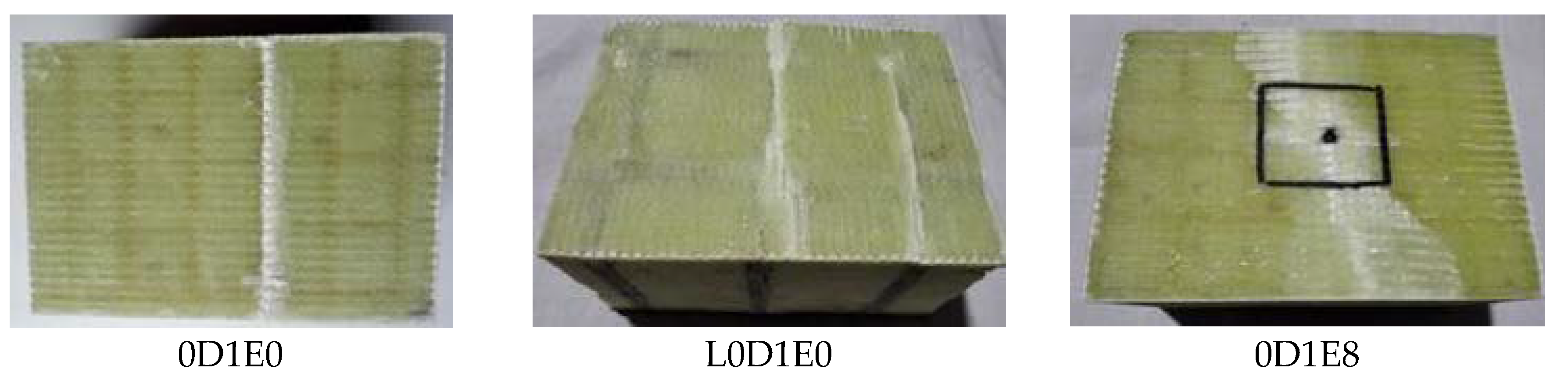

- Impact location with either skin, web, or cross of webs, designated as L0, L1, and L2, respectively, as shown in Figure 2.

- Foam density with either 40, 60, and 100 kg/m3, designated as D4, D6, and D1, respectively.

- Impact energy with either 27, 54, or 81 J, designated as E2, E5, and E8, respectively.

2.2. Material Properties

2.3. Test Set-Up for Low Velocity Impact

2.4. Test Set-Up for Compression after Impact (CAI) and Instrumentation

3. Impact Test Results and Discussion

3.1. Effects of Impact Energy

3.2. Effects of Foam Density

3.3. Effects of Impact Location

4. CAI Testing Program

4.1. Intact Wall Board Compression

4.2. Damaged Wall Panel Compression

4.3. CAI Test Results and Discussion

5. Conclusions

- (1)

- For all specimens, the larger impact energy can generate a larger impact velocity and a larger contact force. For the specimens without webs, the impact damage region enlarged with increasing impact energy, and the larger impact energy can lead to the occurrence of interfacial fracture delamination. For foam-web core specimens, the impact damage region cannot be enlarged due to the restriction of GFRP webs.

- (2)

- The larger foam density can alleviate the impact damage, because the foam core can provide much more supporting resistance to the face sheets. Meanwhile, increasing the foam density can lead to a greater contact force. When the foam density was 1.5 times larger, the contact force at least increased by 19%; when impact energy was 2.5 times larger, the contact force at least increased by 84%.

- (3)

- The impact damage of web-foam core wall boards was affected by the impact locations. For location L0, the damage region usually was a square area surrounded by the webs; for location L1, the failure mode of specimens behaved in the form of dent and crack; and for location L2, the cross-shaped impact damage, as well as the skin fracture along the directions of the webs, can be found.

- (4)

- An analytical model was proposed to predict the Young’s modulus of core material. The values of Young’s modulus of core materials were 15.17 MPa, 309.36 MPa, and 588.11 MPa when the impact locations were L0, L1, and L2, respectively. Hence, it can be concluded that the impact force of specimens with impact location of L2 was larger than those of specimens with impact locations of L0 and L1 under the same conditions of impact energy and foam density. Moreover, the duration of specimens with impact locations of L2 were fastest, while the duration of specimens without GFRP webs were longest.

- (5)

- The residual axial strength of damaged wall boards was evaluated by comparing the control wall boards. With the identical impact energy and foam density, the residual axial strength of a specimen with impact location of L2 was largest, while that of a specimen with impact location of L0 was smallest, which was only 28.9% of the residual axial strength of a specimen with impact location of L2. The reason was that the area of damage region of specimens with impact locations of L2 was smallest.

Author Contributions

Funding

Conflicts of Interest

References

- Hollaway, L. A review of the present and future utilization of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Azzam, A.; Zhou, B.; Md, H.; Wang, Q.; Akampumuza, O.; Li, W. Experimental study on the effects of stacking sequence on low velocity impact and quasi-static response of foam sandwich composite structures. Adv. Struct. Eng. 2015, 18, 1789–1805. [Google Scholar]

- Shawkat, W.; Honickman, H.; Fam, A. Investigation of a novel composite cladding wall panel in flexure. J. Compos. Mater. 2008, 42, 315–330. [Google Scholar] [CrossRef]

- Ugale, V.; Singh, K.; Mishra, N.; Kumar, P. Experimental studies on thin sandwich panels under impact and static loading. J. Reinf. Plast. Comp. 2013, 32, 420–434. [Google Scholar] [CrossRef]

- Sharma, S. Low-Velocity Impact Response of Polyurethane Foam Composite Sandwich Structures. J. Reinf. Plast. Comp. 2004, 23, 1869–1882. [Google Scholar] [CrossRef]

- Borsellino, C.; Calabrese, L.; Valenza, A. Experimental and numerical evaluation of sandwich composite structures. Compos. Sci. Technol. 2004, 64, 1709–1715. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, Z.; Yu, J.; Yang, J. Indentation of composite sandwich panels with aluminum foam core: An experimental parametric study. J. Reinf. Plast. Comp. 2014, 33, 1671–1681. [Google Scholar] [CrossRef]

- Zangani, D.; Robinson, M.; Gibson, A. Energy absorption characteristics of web-core sandwich composite panels subjected to drop-weight impact. Appl. Compos. Mater. 2008, 15, 139–156. [Google Scholar] [CrossRef]

- Jamshid, F.; Maryam, A. Multiobjective crashworthiness optimization of multi-layer honeycomb energy absorber panels under axial impact. Thin Wall Struct. 2016, 107, 197–206. [Google Scholar]

- Umar, F.; Peter, M. Finite element simulation of damage and failure predictions of relatively thick carbon fibre-reinforced laminated composite panels subjected to flat and round noses low velocity drop-weight impact. Thin Wall Struct. 2016, 104, 82–105. [Google Scholar]

- Shipsha, A.; Zenkert, D. Compression-after-impact strength of sandwich panels with core crushing damage. Appl. Compos. Mater. 2015, 12, 149–164. [Google Scholar] [CrossRef]

- Zhao, W.; Xie, Z.; Li, X.; Yue, X.; Sun, J. Compression after impact behavior of titanium honeycomb sandwich structures. J. Sandw. Struct. Mater. 2018, 20, 639–657. [Google Scholar] [CrossRef]

- Vaidya, A.; Uddin, N.; Vaidya, U. Structural characterization of composite structural insulated panels for exterior wall applications. J. Compos. Constr. 2010, 14, 464–469. [Google Scholar] [CrossRef]

- Schubel, P.; Luo, J.; Daniel, I. Impact and post impact behavior of composite sandwich panels. Compos. Part A–Appl. 2007, 38, 1051–1057. [Google Scholar] [CrossRef]

- Kenny, J.; Torre, L. Impact testing and simulation of sandwich structures. In Proceedings of the Evolving and Revolutionary Technologies for the New Millennium, Long Beach, CA, USA, 1999; pp. 2368–2381. [Google Scholar]

- Wang, L.; Liu, W.; Wan, L.; Fang, H.; Hui, D. Mechanical performance of foam-filled lattice composite panels in four-point bending: Experimental investigation and analytical modeling. Compos. Part B–Eng. 2014, 67, 270–279. [Google Scholar] [CrossRef]

- Wang, L.; Liu, W.; Fang, H.; Wan, L. Behavior of sandwich wall panels with GFRP face sheets and a foam-GFRP web core loaded under four-point bending. J. Compos. Mater. 2015, 49, 2765–2778. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, W.; Wang, L.; Fang, H.; Hui, D. Theoretical and experimental study of foam-filled lattice composite panels under quasi-static compression loading. Compos. Part B–Eng. 2014, 60, 329–340. [Google Scholar] [CrossRef]

- Li, N.; Chen, P. Experimental investigation on edge impact damage and compression after impact (CAI) behavior of stiffened composite panels. Compos. Struct. 2016, 138, 134–150. [Google Scholar] [CrossRef]

- American Society for Testing and Materials D3039/D303039M-08. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM international: West Conshohocken, PA, USA, 2008. [Google Scholar]

- American Society for Testing and Materials D695-10. Standard Test Method for Compressive Properties of Rigid Plastics; ASTM international: West Conshohocken, PA, USA, 2010. [Google Scholar]

- American Society for Testing and Materials D1621-10. Standard Test Method for Compressive Properties of Rigid Cellular Plastics; ASTM international: West Conshohocken, PA, USA, 2010. [Google Scholar]

| Group | Specimen | Foam Density (kg/m3) | Impact Location | Impact Energy (J) |

|---|---|---|---|---|

| A | 0D1E0 | 100 | - | 0 |

| 0D1E2 | 100 | - | 27 | |

| 0D1E5 | 100 | - | 54 | |

| 0D1E8 | 100 | - | 81 | |

| 0D4E8 | 40 | - | 81 | |

| 0D6E8 | 60 | - | 81 | |

| 0D1E8 | 100 | - | 81 | |

| B | L0D4E8 | 40 | L0 | 81 |

| L0D6E8 | 60 | L0 | 81 | |

| L0D1E0 | 100 | - | 0 | |

| L0D1E2 | 100 | L0 | 27 | |

| L0D1E5 | 100 | L0 | 54 | |

| L0D1E8 | 100 | L0 | 81 | |

| C | L1D1E2 | 100 | L1 | 27 |

| L1D1E5 | 100 | L1 | 54 | |

| L1D1E8 | 100 | L1 | 81 | |

| D | L2D1E2 | 100 | L2 | 27 |

| L2D1E5 | 100 | L2 | 54 | |

| L2D1E8 | 100 | L2 | 81 |

| Face Sheet | Web | |

|---|---|---|

| Compressive strength (MPa) | 162.8 | 165.7 |

| Compressive modulus (GPa) | 6.26 | 6.13 |

| Compressive modulus (GPa) | 301.5 | 322.3 |

| (GPa)Tensile modulus (GPa) | 6.61 | 6.57 |

| Foam Density (ρ) (kg/m3) | Yield Strength (fy) (MPa) | Young’s Modulus (Ef) (MPa) |

|---|---|---|

| 40 | 0.171 | 5.02 |

| 60 | 0.366 | 9.87 |

| 100 | 0.637 | 15.17 |

| Group | Specimen | Velocity (m/s) | Max. Contact Force (kN) |

|---|---|---|---|

| A | 0D1E0 | - | - |

| 0D1E2 | 2.91 | 3.77 | |

| 0D1E5 | 4.20 | 5.32 | |

| 0D4E8 | 5.24 | 3.23 | |

| 0D6E8 | 5.21 | 3.84 | |

| 0D1E8 | 5.19 | 6.51 | |

| B | L0D4E8 | 5.22 | 5.73 |

| L0D6E8 | 5.22 | 7.86 | |

| L0D1E0 | - | - | |

| L0D1E2 | 2.86 | 7.84 | |

| L0D1E5 | 4.23 | 9.40 | |

| L0D1E8 | 5.23 | 10.54 | |

| C | L1D1E2 | 2.89 | 11.35 |

| L1D1E5 | 4.21 | 12.15 | |

| L1D1E8 | 5.23 | 14.40 | |

| D | L2D1E2 | 2.88 | 15.62 |

| L2D1E5 | 4.20 | 17.65 | |

| L2D1E8 | 5.20 | 20.83 |

| Specimen Number | Impact Energy (J) | Impact Location | Maximum Contact Force (kN) |

|---|---|---|---|

| 0D1E0 | 0 | None | 48.62 |

| L0D1E0 | 0 | None | 103.92 |

| 0D1E8 | 81 | - | 25.77 |

| L0D1E8 | 81 | L0 | 64.83 |

| L1D1E8 | 81 | L1 | 77.64 |

| L2D1E8 | 81 | L2 | 89.28 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Y.; Li, X.; Peng, Y.; Lai, M.; Wang, L. Impact and Post-Impact Performance of Sandwich Wall Boards with GFRP Face Sheets and a Web-Foam Core: The Effects of Impact Location. Materials 2018, 11, 1714. https://doi.org/10.3390/ma11091714

Xia Y, Li X, Peng Y, Lai M, Wang L. Impact and Post-Impact Performance of Sandwich Wall Boards with GFRP Face Sheets and a Web-Foam Core: The Effects of Impact Location. Materials. 2018; 11(9):1714. https://doi.org/10.3390/ma11091714

Chicago/Turabian StyleXia, Yiwei, Xiaoping Li, Yu Peng, Mianheng Lai, and Lu Wang. 2018. "Impact and Post-Impact Performance of Sandwich Wall Boards with GFRP Face Sheets and a Web-Foam Core: The Effects of Impact Location" Materials 11, no. 9: 1714. https://doi.org/10.3390/ma11091714

APA StyleXia, Y., Li, X., Peng, Y., Lai, M., & Wang, L. (2018). Impact and Post-Impact Performance of Sandwich Wall Boards with GFRP Face Sheets and a Web-Foam Core: The Effects of Impact Location. Materials, 11(9), 1714. https://doi.org/10.3390/ma11091714