Enhanced Sensing and Data Processing System for Continuous Profiling of Pavement Deflection

Abstract

:1. Introduction

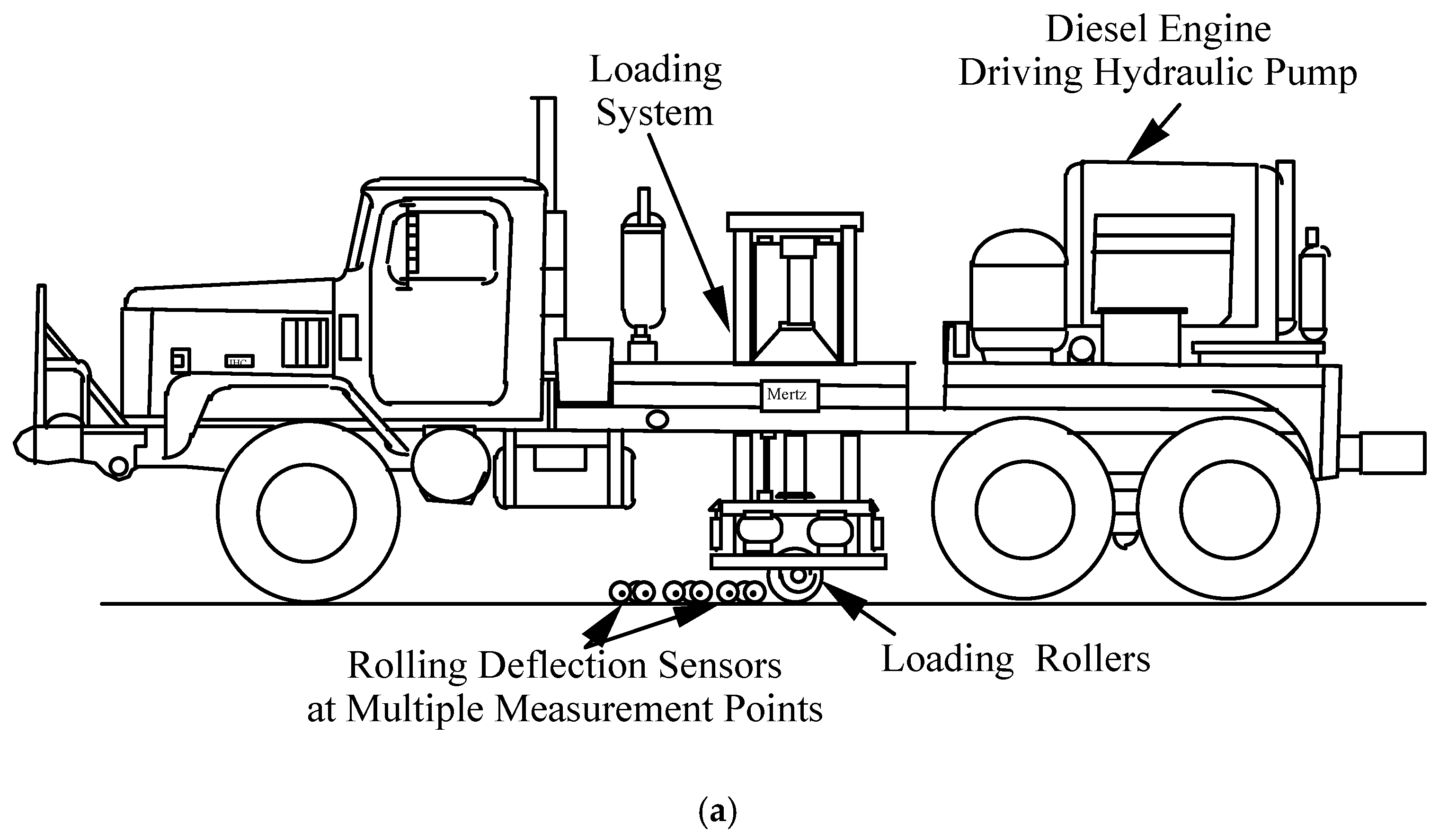

2. Background on the RDD

2.1. The RDD

2.2. RDD Signal Processing

3. Speed-Improved Rolling Sensor

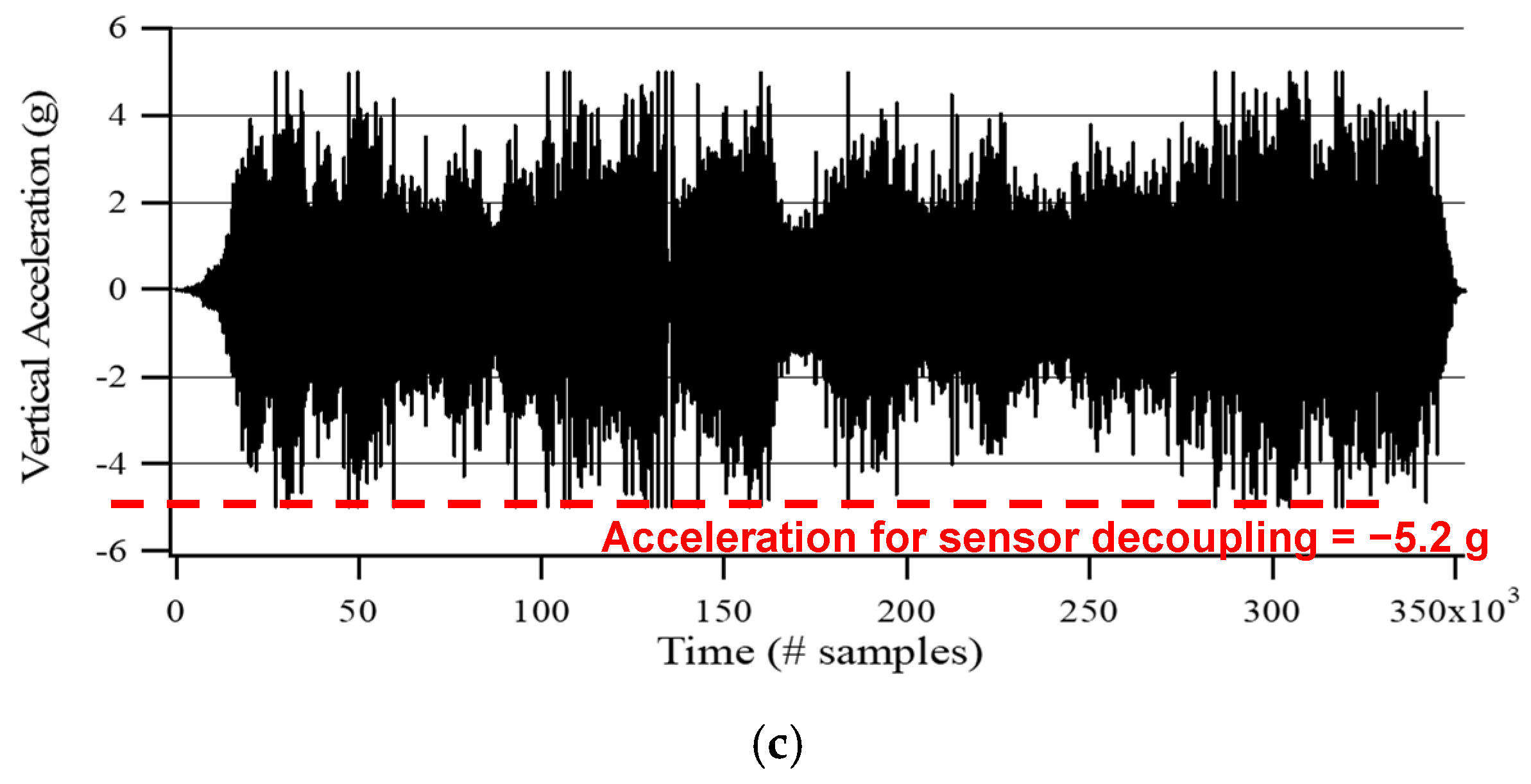

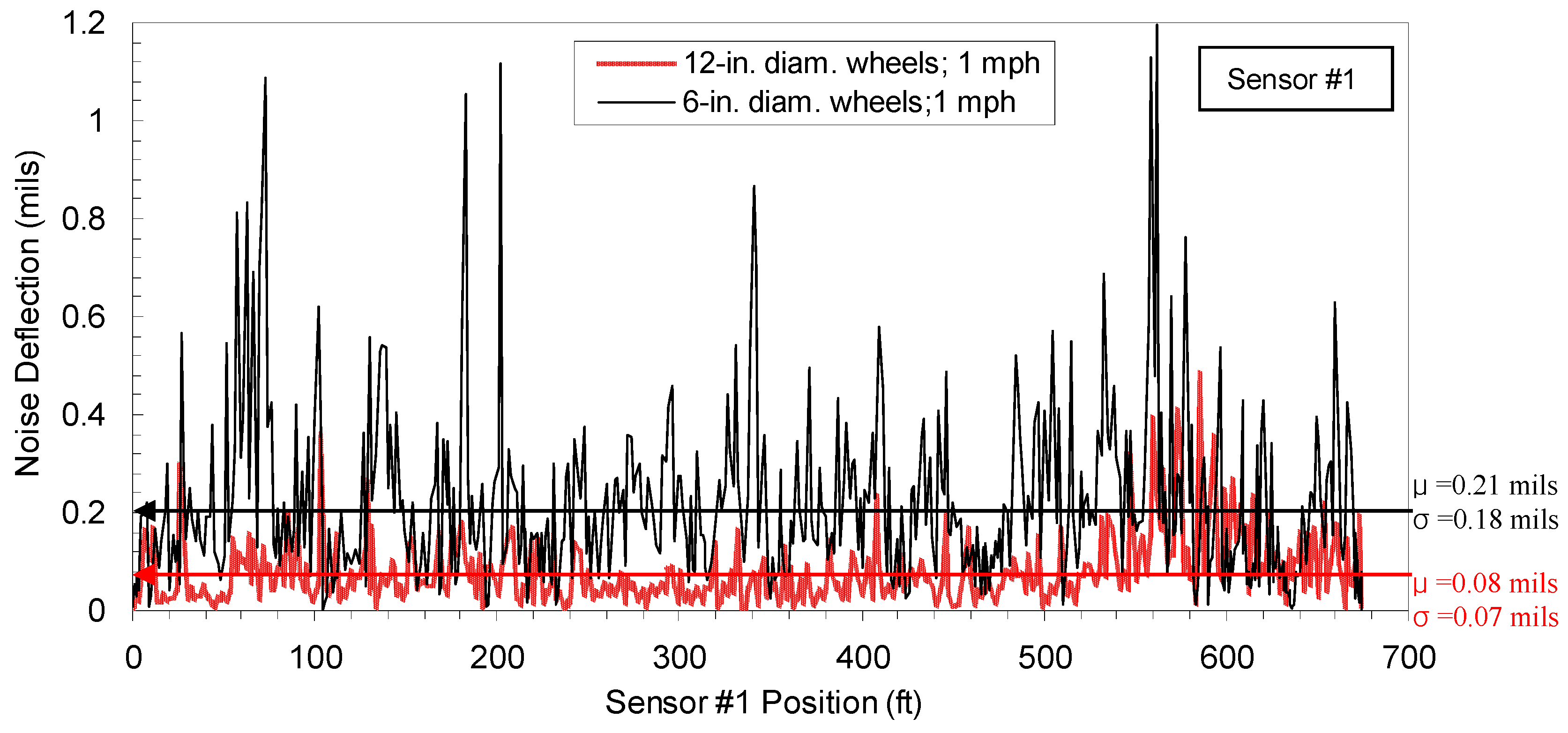

3.1. Sensor Design

3.2. Evaluation of Sensor Design Parameters

4. Enhanced RDD Data Processing

4.1. Effect of the Filter Design Parameters

4.2. New Data Processing Scheme

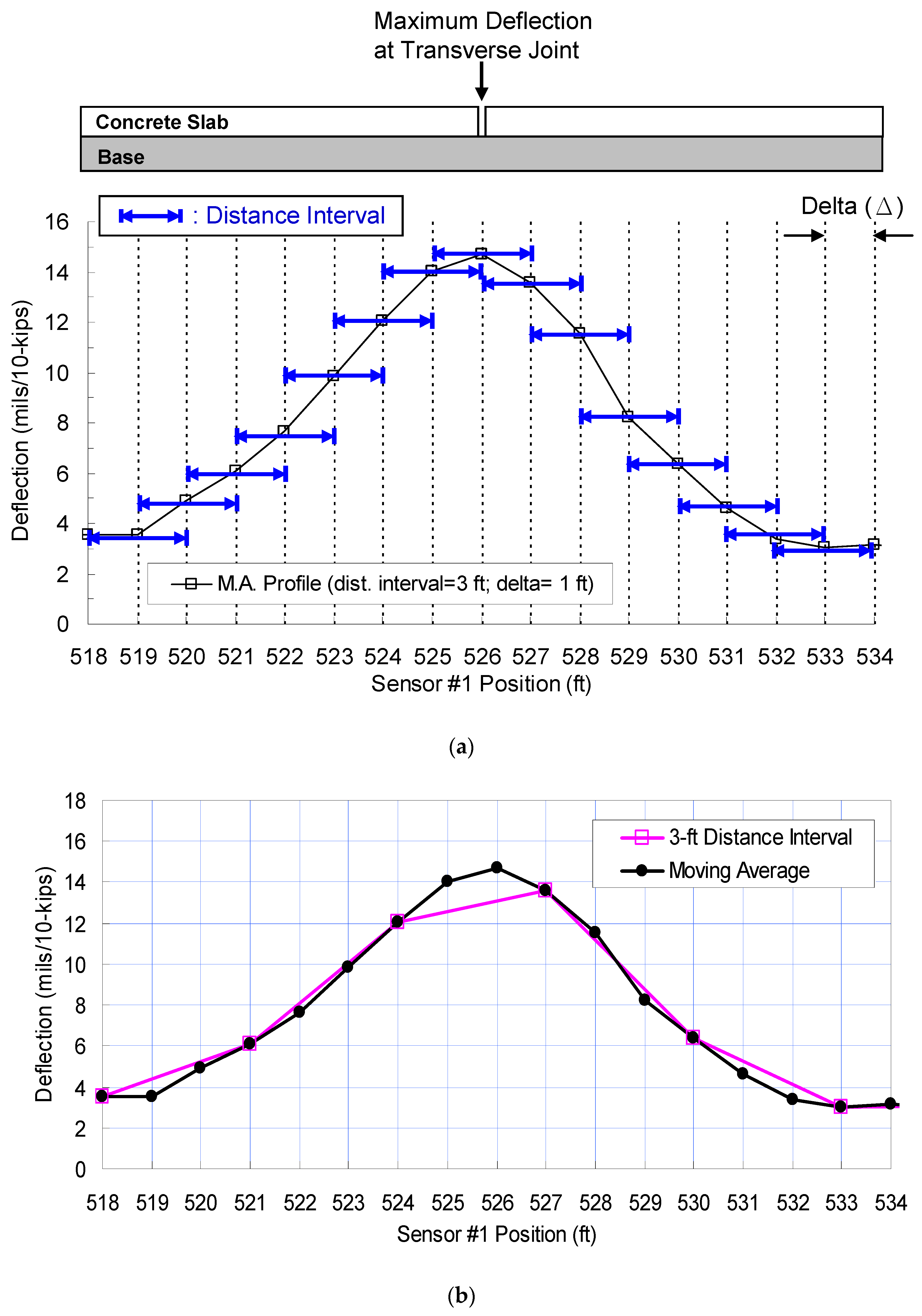

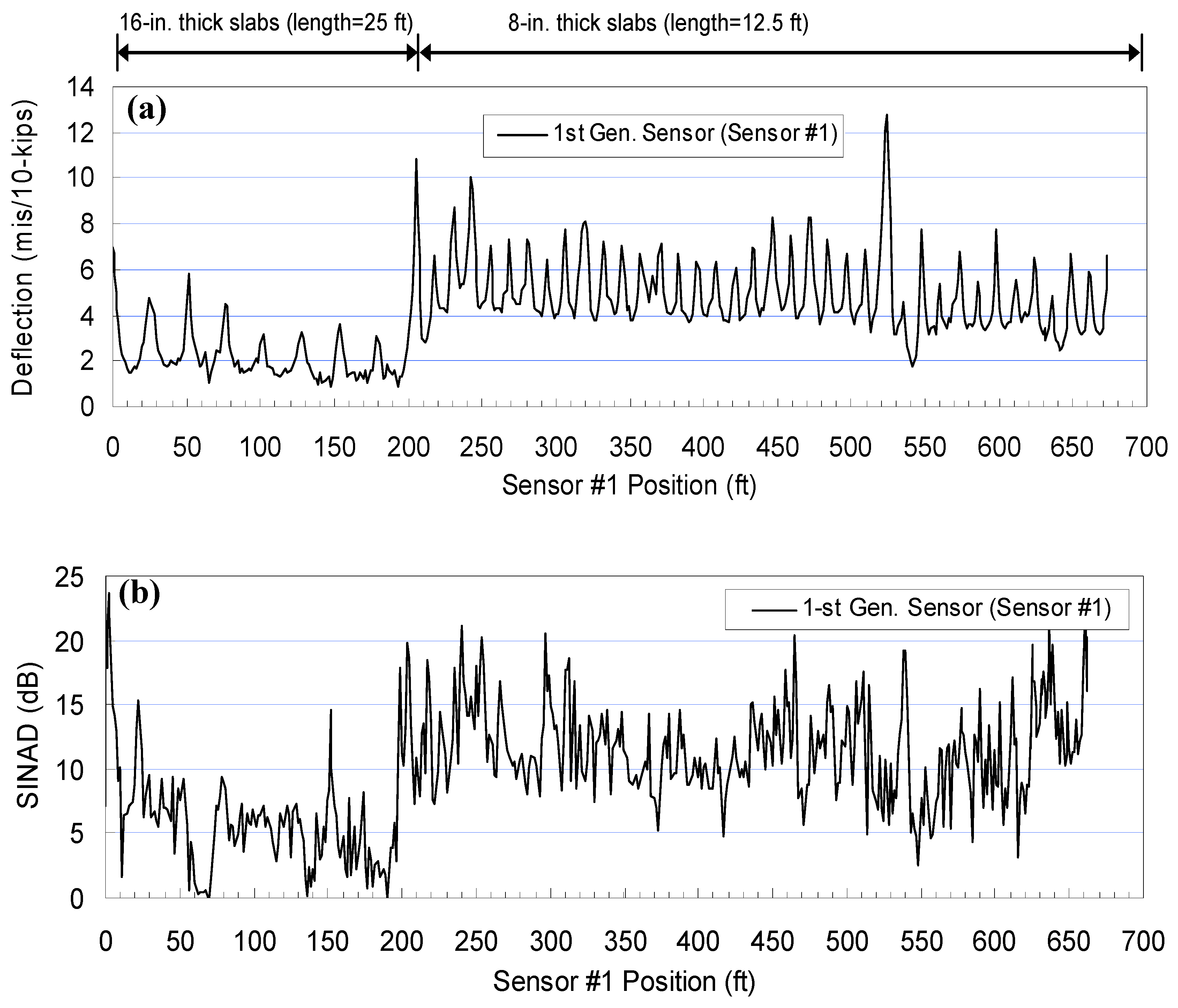

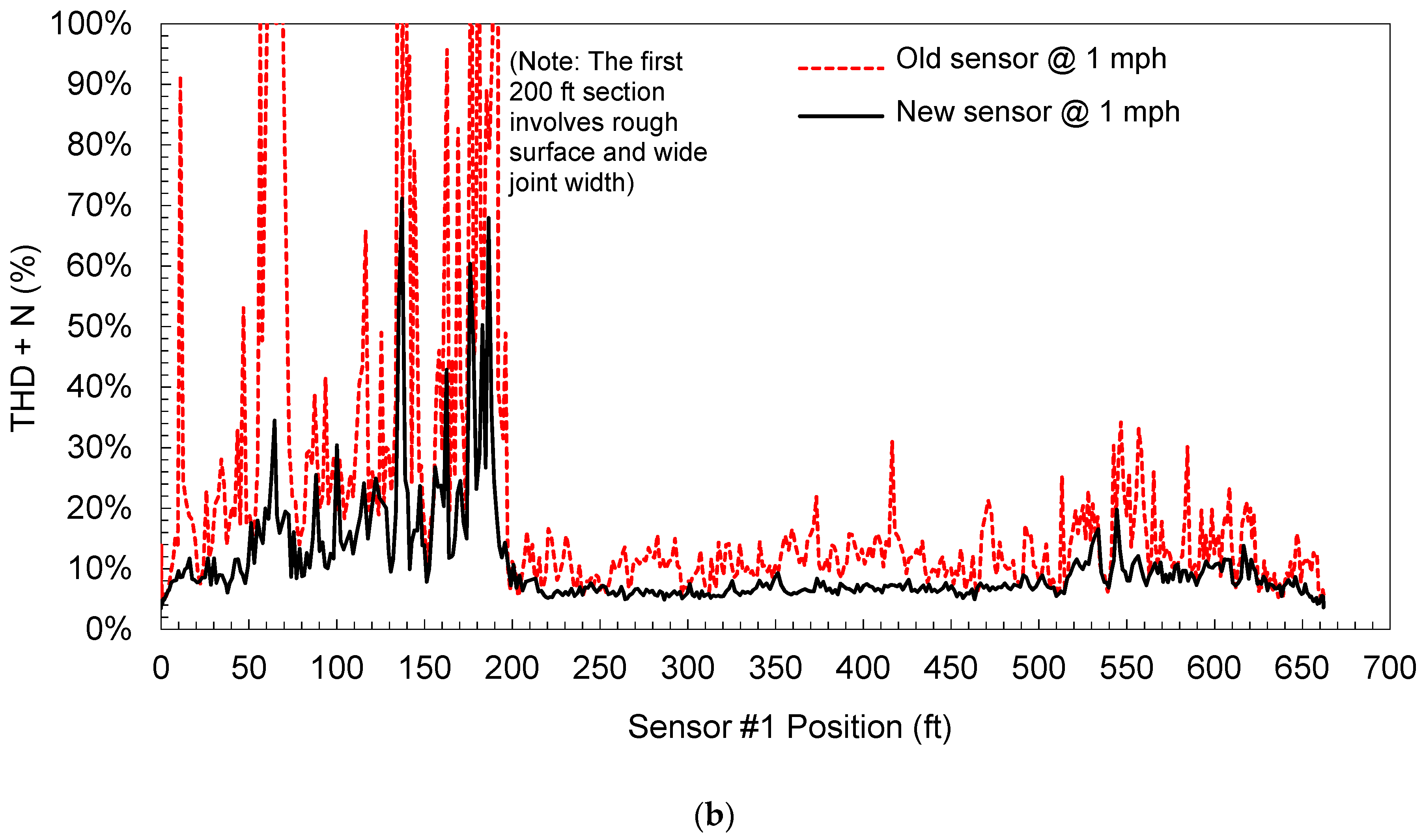

4.2.1. Distance-Based Profile

4.2.2. Moving Average Profile

4.2.3. Continuous Signal-To-Noise and Distortion Ratio (SINAD) and Noise Profiles

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hildebrand, G.; Rasmussen, S. Development of a High Speed Deflectograph. Report 117; Danish Road Institute: Copenhagen, Denmark, 2002. [Google Scholar]

- Ferne, B.W.; Langdale, P.; Round, N.; Fairclough, R. Development of a Calibration Procedure for the U.K. Highways Agency Traffic-Speed Deflectometer. Transp. Res. Rec. J. Transp. Res. Board 2009, 2093, 111–117. [Google Scholar] [CrossRef]

- Muller, W.B.; Roberts, J. Revised approach to assessing traffic speed deflectometer data and field validation of deflection bowl predictions. Int. J. Pavement Eng. 2013, 14, 388–402. [Google Scholar] [CrossRef]

- Zofka, A.; Sudyka, J.; Maliszewski, M.; Harasim, P.; Sybilski, D. Alternative Approach for Interpreting Traffic Speed Deflectometer Results. Transp. Res. Rec. J. Transp. Res. Board 2014, 2457, 12–18. [Google Scholar] [CrossRef]

- Katicha, S.; Flintsch, G.; Ferne, B.; Bryce, J. Limits of Agreement Method for Comparing TSD and FWD Measurements. Int. J. Pavement Eng. 2014, 15, 532–541. [Google Scholar] [CrossRef]

- Jitin, A.; Tandon, V.; Nazarian, S. Continuous Deflection Testing of Highways at Traffic Speeds; Report No. FHWA/TX-06/0-4380-1; Center for Transportation Infrastructure Systems, University of Texas at El Paso: El Paso, TX, USA, 2006. [Google Scholar]

- Gedafa, D.S.; Hossain, M.; Miller, R.; Steele, D.A. Network-Level Pavement Structural Evaluation Using Rolling Wheel Deflectometer. In Proceedings of the 87th Meeting of the Transportation Research Board, Washington, DC, USA, 13–17 January 2008. [Google Scholar]

- Abdel-Khalek, A.M.; Elseifi, M.A.; Gaspard, K.; Zhang, Z.; Dasari, K. Model to Estimate Pavement Structural Number at Network Level with Rolling Wheel Deflectometer Data. Transp. Res. Rec. J. Transp. Res. Board 2012, 2304, 142–149. [Google Scholar] [CrossRef]

- Elseifi, M.A.; Gaspard, K.; Wilke, P.W.; Zhang, Z.; Hegab, A. Evaluation and Validation of a Model for Predicting Pavement Structural Number with Rolling Wheel Deflectometer Data. Transp. Res. Rec. J. Transp. Res. Board 2015, 2525, 13–19. [Google Scholar] [CrossRef]

- Rada, G.R.; Nazarian, S. The State-of-the-Technology of Moving Pavement Deflection Testing. Final Report. FHWA-DTFH61-08-D-00025; U.S. Department of Transportation: Washington, DC, USA, 2011.

- Johnson, R.; Rish, J. Rolling Weight Deflectometer with Thermal and Vibrational Bending Compensation. Transp. Res. Rec. J. Transp. Res. Board 1996, 1540, 77–82. [Google Scholar] [CrossRef]

- Briggs, R.; Johnson, R.; Stubstad, R.; Pierce, L. A Comparison of the Rolling Weight Deflectometer with the Falling Weight Deflectometer. In Nondestructive Testing of Pavements and Backcalculation of Moduli: Third Volume; Tayabji, S., Lukanen, E., Eds.; ASTM International: West Conshohocken, PA, USA, 2000; pp. 444–456. [Google Scholar]

- Lenngren, C.A. Some experience using a rolling weight deflectometer on airport pavements. Nondestruct. Evaluation Aging Infrastruct. 1995, 2455, 354–362. [Google Scholar]

- Andrén, P. Development and Results of the Swedish Road Deflection Tester. Licentiate Thesis, Royal Institute of Technology, Stockholm, Sweden, 2006. Available online: http://kth.diva-portal.org/smash/get/diva2:10556/FULLTEXT01. (accessed on 8 May 2019).

- Bay, J.A.; Stokoe, K.H. Development of a Rolling Dynamic Deflectometer for Continuous Deflection Testing of Pavement; Report No. FHWA/TX-99/1422-3F; Texas Department of Transportation: Austin, TX, USA, 1998.

- Dynatest®. Dynatest RAPTOR® (RAPID PAVEMENT TESTER). Available online: https://www.dynatest.com/rolling-weight-deflectometer-raptor (accessed on 8 May 2019).

- Lee, J.L.Y.; Chen, D.-H.; Stokoe, K.H.; Scullion, T. Evaluating Potential for Reflection Cracking with Rolling Dynamic Deflectometer. Transp. Res. Rec. J. Transp. Res. Board 2004, 1869, 16–24. [Google Scholar] [CrossRef]

- Chen, D.-H.; Nam, B.H.; Stokoe, K.H. Application of Rolling Dynamic Deflectometer to Forensic Studies and Pavement Rehabilitation Projects. Transp. Res. Rec. J. Transp. Res. Board 2008, 2084, 73–82. [Google Scholar] [CrossRef]

- Nam, B.H.; Scullion, T.; Stokoe, K.H.; Lee, J.-S.; Mitchell, M.R.; Link, R.E.; Nam, B.H.; Scullion, T.; Stokoe, K.H.; Lee, J.-S. Rehabilitation Assessment of Jointed Concrete Pavement Using the Rolling Dynamic Deflectometer and Ground Penetrating Radar. J. Test. Evaluation 2011, 39, 346–357. [Google Scholar]

- Nam, B.H.; Lee, L.Y.; Stokoe, K.H.; Chen, D.-H.; Lee, J.-S. Application of RDD Continuous Profiling in Maintenance and Rehabilitation of Concrete Pavements. In Proceedings of the GeoHunan International Conference 2011, Hunan, China, 9–11 June 2011; pp. 125–132. [Google Scholar]

- Lee, J.L.Y.; Stokoe, K.H.; Chen, D.-H.; Garrison, M.R.; Nam, B.H. Monitoring Pavement Changes in a Rehabilitation Project with Continuous Rolling Dynamic Deflectometer Profiles. Transp. Res. Rec. J. Transp. Res. Board 2005, 1905, 2–16. [Google Scholar] [CrossRef]

- Chen, D.-H.; Nam, B.H.; Yao, Z. Utilizing Advanced Characterization Tools to Prevent Reflective Cracking. J. Perform. Constr. Facil. 2010, 24, 390–398. [Google Scholar] [CrossRef]

- Mitchell, M.R.; Link, R.E.; Chen, D.-H. Using Rolling Dynamic Deflectometer and Overlay Tester to Determine the Reflective Cracking Potential. J. Test. Evaluation 2007, 35, 101075. [Google Scholar] [CrossRef]

- Nam, B.H. Transition of the Rolling Dynamic Deflectometer Device from a Screening Tool to an Evaluation Tool for Rigid Airfield Pavement Projects. Transp. Res. Rec. J. Transp. Res. Board 2011, 2206, 39–51. [Google Scholar] [CrossRef]

- Stokoe, K.H., II; Bay, J.A.; Rosenblad, B.L.; Murphy, M.R.; Fults, K.W.; Chen, D.C. Super-Accelerated Testing of a Flexible Pavement with the Stationary Dynamic Deflectometer (SDD). Transp. Res. Rec. J. Transp. Res. Board 2000, 1716, 98–107. [Google Scholar] [CrossRef]

- Nam, B.H.; Suh, C.; Won, M. Fatigue-Life Prediction of Full-Scale Concrete Pavement Overlay over Flexible Pavement Using Super-Accelerated Pavement Testing. ACI Mater. J. 2013, 110, 1–10. [Google Scholar]

- Bay, J.A. Development of a Rolling Dynamic Deflectometer. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, May 1997. [Google Scholar]

- Bracewell, R.N. The Fourier Transform and Its Applications; McGraw-Hill Book Co.: New York, NY, USA, 1986. [Google Scholar]

- Ifeachor, E.C.; Jervis, B.W. Digital Signal Processing, A Practical Approach; Addison-Wesley Publishing Co.: Wokingham, UK, 1993. [Google Scholar]

- Nam, B.; Stokoe, K.H. Improved Rolling Dynamic Deflectometer for Continuous Pavement Deflection Measurements. J. Test. Evaluation 2014, 42, 20120262. [Google Scholar] [CrossRef]

| Testing Methods | Loading/Sensing Types | Testing Speed (mph) | Sensor Accuracy (mils) | Applied Loading (kips) | Data Spatial Resolution (ft) | Manufacturer | Updated References |

|---|---|---|---|---|---|---|---|

| Traffic Speed Deflectograph (TSD) | Moving load/ non-contact (laser doppler sensor) | 45 | ±4 mils/s | 11 | 33 | Greenwood Engineering | [1,2,3,4,5,6] |

| Rolling Wheel Deflectometer (RWD) | Moving load/ non-contact (laser displacement sensor) | 55 | ±2.75 mils | 18 (fixed) | 100 to 500 | Applied Research Associates | [6,7,8,9,10] |

| Airfield Rolling Weight Deflectometer (ARWD) | Moving load/ non-contact (laser displacement sensor) | 20 | 0.8 mils | 9 | 90 | Dynatest Consulting and Quest Integrated | [6,11,12] |

| Rolling Deflection Tester (RDT) | Moving load/ non-contact (laser displacement sensor) | 36 | ±10 mils | 8 to 14 | 66 | Swedish National Road Administration and VTI * | [13,14] |

| Rolling Dynamic Deflectometer (RDD) | Sinusoidal load/ Contact (geophone) | 1 to 3 | 0.05 mils | 10 kips static ±5 kips dynamic | 1.5 to 3 | The University of Texas at Austin | [15,17,18,19,20,21,22,23,24,25,26] |

| Speed | Mean Noise Deflection, μ | Standard Deviation, σ |

|---|---|---|

| 1 mph | 0.07 mils (2 μm) | 0.08 mils (2 μm) |

| 2 mph | 0.29 mils (7 μm) | 0.21 mils (5 μm) |

| 3 mph | 0.50 mils (13 μm) | 0.43 mils (11 μm) |

| 4 mph | 0.75 mils (19 μm) | 0.84 mils (21 μm) |

| 5 mph | 1.09 mils (28 μm) | 1.19 mils (30 μm) |

| Additional Hold-Down Pressure (psi) | Additional Hold-Down Force (lbs) | Maximum Allowable Acceleration (g) |

|---|---|---|

| 0 | 0 | −1 |

| 1 (6.9 kPa) | 19 (8.6 kg) | −1.8 |

| 2 (13.8 kPa) | 38 (17.2 kg) | −2.7 |

| 3 (20.7 kPa) | 57 (25.8 kg) | −3.5 |

| 4 (27.6 kPa) | 76 (34.5 kg) | −4.4 |

| 5 (34.5 kPa) | 95 (43.1 kg) | −5.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nam, B.H.; Stokoe, K.H., II; Youn, H. Enhanced Sensing and Data Processing System for Continuous Profiling of Pavement Deflection. Materials 2019, 12, 1653. https://doi.org/10.3390/ma12101653

Nam BH, Stokoe KH II, Youn H. Enhanced Sensing and Data Processing System for Continuous Profiling of Pavement Deflection. Materials. 2019; 12(10):1653. https://doi.org/10.3390/ma12101653

Chicago/Turabian StyleNam, Boo Hyun, Kenneth H. Stokoe, II, and Heejung Youn. 2019. "Enhanced Sensing and Data Processing System for Continuous Profiling of Pavement Deflection" Materials 12, no. 10: 1653. https://doi.org/10.3390/ma12101653