A Comparison Study of Ag Composites Prepared by Spark Plasma Sintering and Hot Pressing with Silver-Coated CNTs as the Reinforcements

Abstract

:1. Introduction

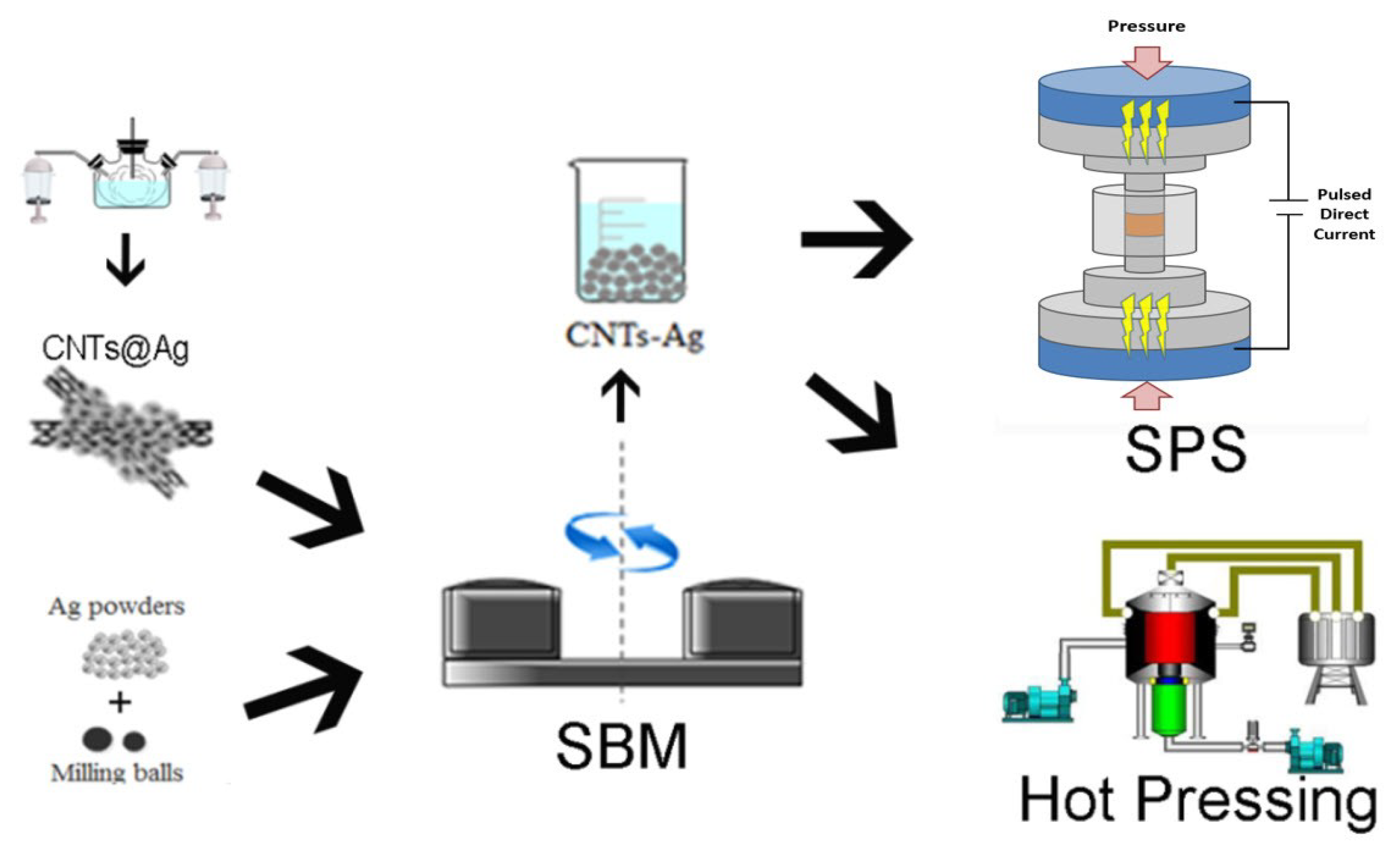

2. Experimental Section

2.1. Synthesis of Ag@CNTs

2.2. Spark Plasma Sintering and Hot Pressing of Composites

2.3. Characterization

3. Results and Discussion

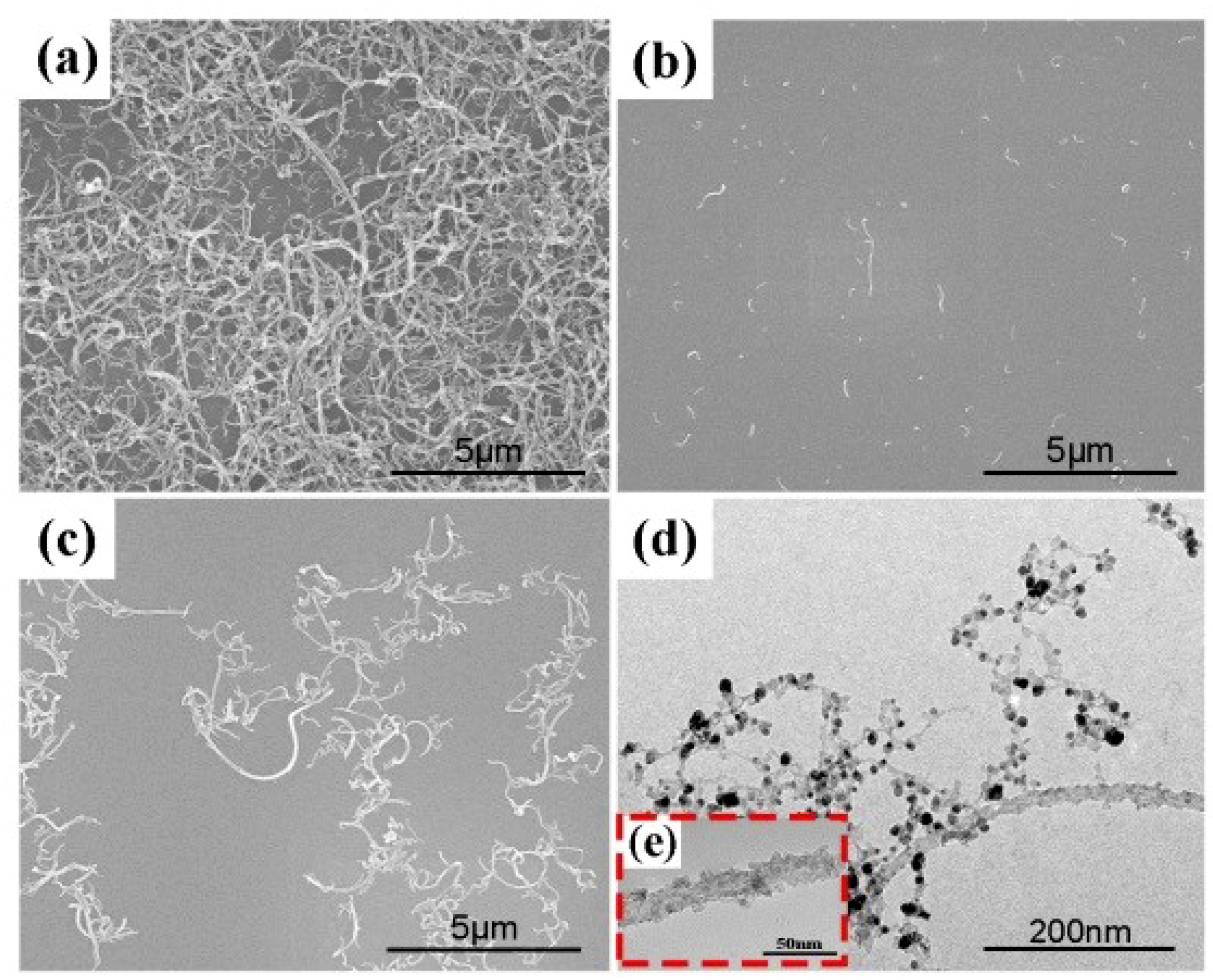

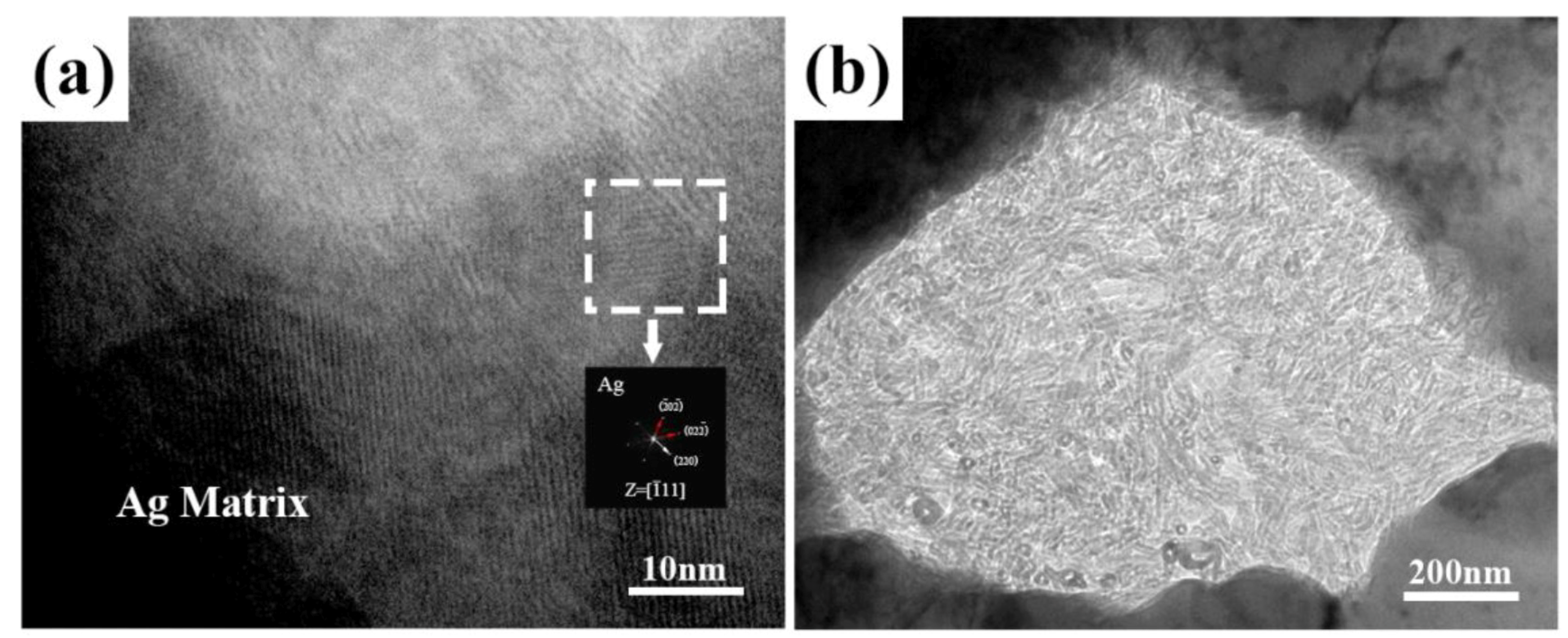

3.1. Microstructure of Ag@CNTs

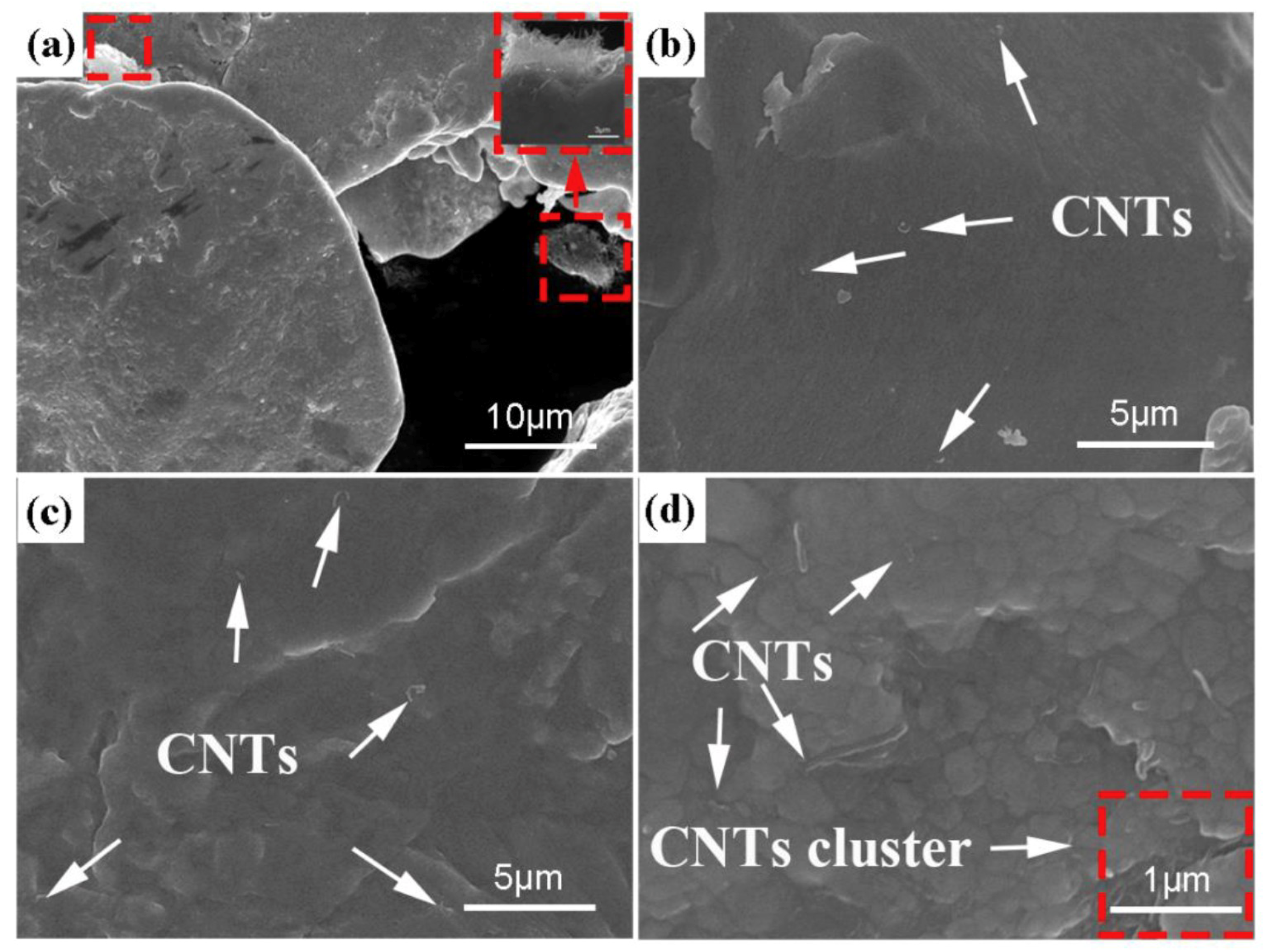

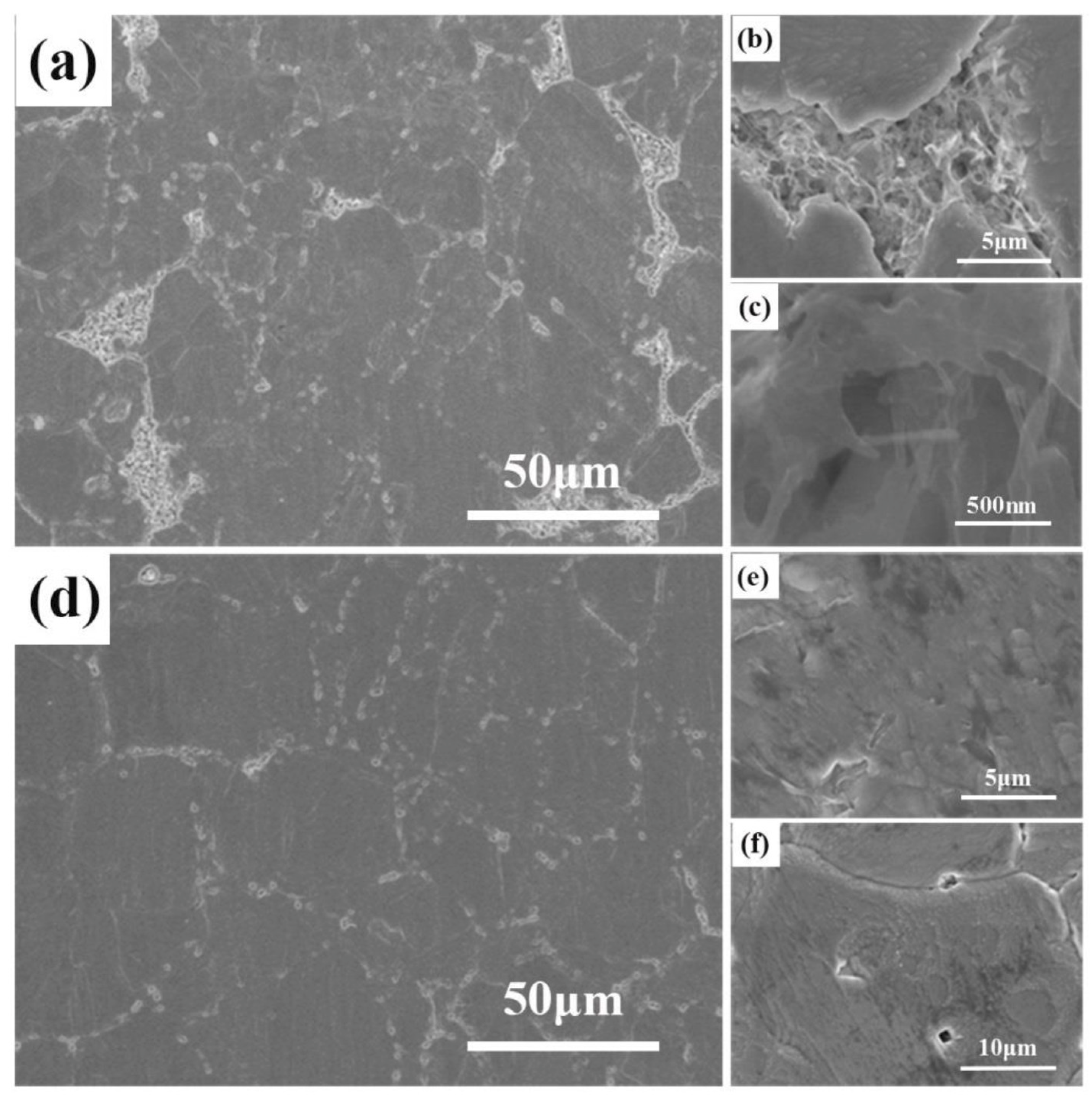

3.2. Microstructure of the Powders and Composites

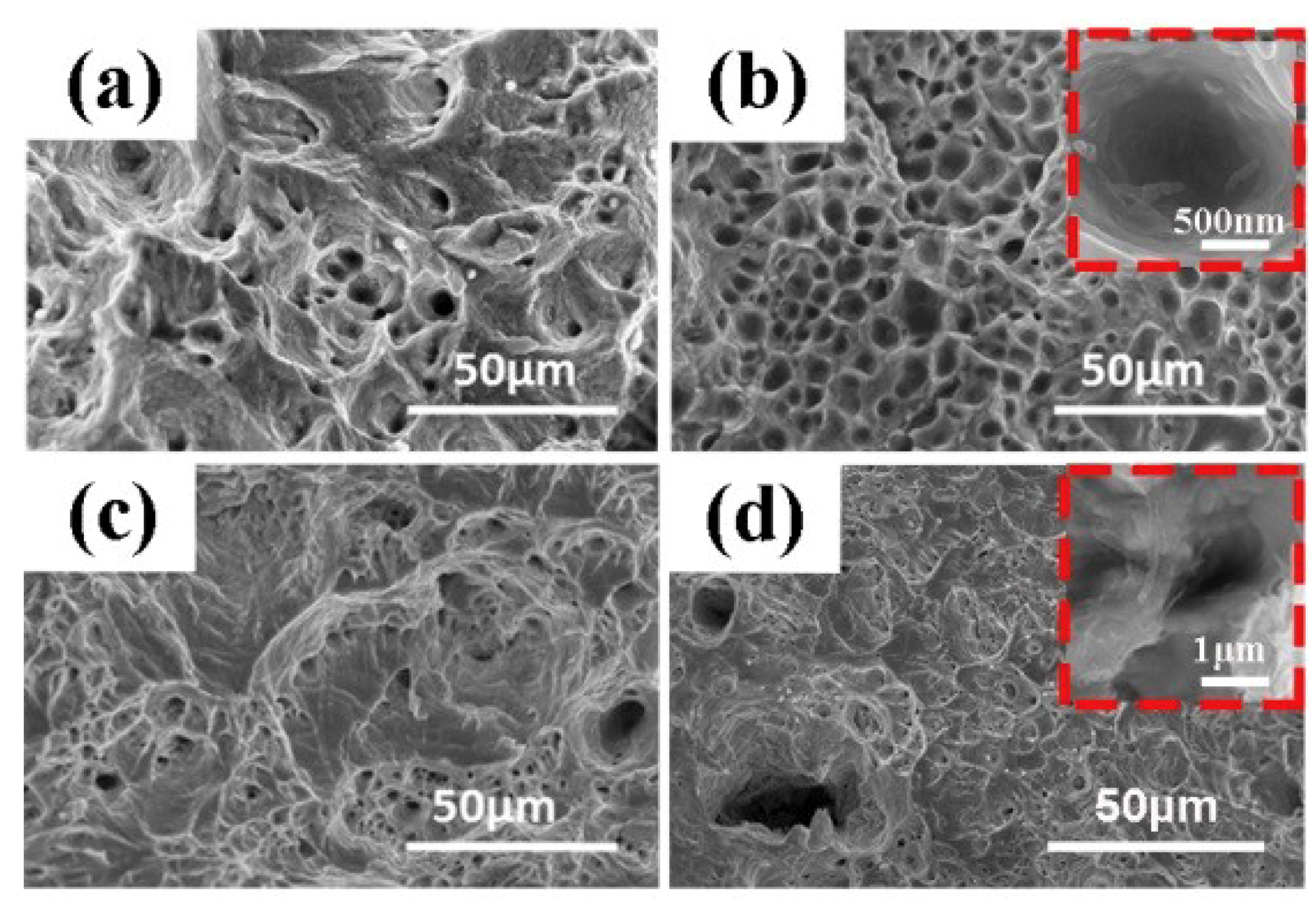

3.3. Mechanical Properties of the Composites

3.4. Possible Strengthening Mechanisms of CNT@Ag/Ag Composites

3.4.1. Strengthening by Grain Refinement

3.4.2. Strengthening by Load-Transfer Mechanism

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ajayan, P.M.; Vajtai, R. Properties and Applications of Carbon Nanotubes. In Carbon Filaments and Nanotubes: Common Origins, Differing Applications? Biró, L.P., Bernardo, C.A., Tibbetts, G.G., Lambin, P., Eds.; Springer: Dordrecht, The Netherlands, 2001; pp. 315–330. [Google Scholar] [CrossRef]

- Kulik, A.J.; Kis, A.; Lukic, B.; Lee, K.; Forró, L. Mechanical Properties of Carbon Nanotubes. In Fundamentals of Friction and Wear; Gnecco, E., Meyer, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 583–600. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.K.; Singh, D.P.; Vaz, A.R.; Yadav, R.R.; Rout, C.S.; Moshkalev, S.A. Synthesis of self-assembled and hierarchical palladium-CNTs-reduced graphene oxide composites for enhanced field emission properties. Mater. Des. 2017, 122, 110–117. [Google Scholar] [CrossRef]

- Mahanthesha, P.; Srinivasa, C.K.; Mohankumar, G.C. Processing and Characterization of Carbon Nanotubes Decorated with Pure Electroless Nickel and their Magnetic Properties. Procedia Mater. Sci. 2014, 5, 883–890. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Liu, F. Hydrothermal conversion of graphite to carbon nanotubes (CNTs) induced by bubble collapse. J. Phys. Chem. Solids 2016, 98, 1–9. [Google Scholar] [CrossRef]

- Guo, B.; Song, M.; Yi, J.; Ni, S.; Shen, T.; Du, Y. Improving the mechanical properties of carbon nanotubes reinforced pure aluminum matrix composites by achieving non-equilibrium interface. Mater. Des. 2017, 120, 56–65. [Google Scholar] [CrossRef]

- Daoush, W.M.; Lim, B.K.; Mo, C.B.; Nam, D.H.; Hong, S.H. Electrical and mechanical properties of carbon nanotube reinforced copper nanocomposites fabricated by electroless deposition process. Mater. Sci. Eng. A 2009, 513–514, 247–253. [Google Scholar] [CrossRef]

- Pal, H.; Sharma, V. Thermal conductivity of carbon nanotube–silver composite. Trans. Nonferr. Met. Soc. China 2015, 25, 154–161. [Google Scholar] [CrossRef]

- Yang, P.; You, X.; Yi, J.; Fang, D.; Bao, R.; Shen, T.; Liu, Y.; Tao, J.; Li, C.; Tan, S.; et al. Simultaneous achievement of high strength, excellent ductility, and good electrical conductivity in carbon nanotube/copper composites. J. Alloys Compd. 2018, 752, 431–439. [Google Scholar] [CrossRef]

- Zhang, Q.; Qin, Z.; Luo, Q.; Wu, Z.; Liu, L.; Shen, B.; Hu, W. Microstructure and nanoindentation behavior of Cu composites reinforced with graphene nanoplatelets by electroless co-deposition technique. Sci. Rep. 2017, 7, 1338. [Google Scholar] [CrossRef]

- Ma, R.; Li, W.; Huang, M.; Feng, M.; Liu, X. The reinforcing effects of dendritic short carbon fibers for rigid polyurethane composites. Compos. Sci. Technol. 2019, 170, 128–134. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, L.; Tong, Z.; Xie, M.; Yi, J. A study on the uniformity of silver coatings on nanometer SnO2 particles through chemical plating. Int. J. Mater. Product Technol. 2015, 51, 241–247. [Google Scholar] [CrossRef]

- Zhao, Q.; Tan, S.; Xie, M.; Liu, Y.; Yi, J. A study on the CNTs-Ag composites prepared based on spark plasma sintering and improved electroless plating assisted by ultrasonic spray atomization. J. Alloys Compd. 2018, 737, 31–38. [Google Scholar] [CrossRef]

- Zhao, Q.; Xie, M.; Liu, Y.; Yi, J. Improved electroless plating method through ultrasonic spray atomization for depositing silver nanoparticles on multi-walled carbon nanotubes. Appl. Surf. Sci. 2017, 409, 164–168. [Google Scholar] [CrossRef]

- Feng, Y.; Yuan, H. Electroless plating of carbon nanotubes with silver. J. Mater. Sci. 2004, 39, 3241–3243. [Google Scholar] [CrossRef]

- Zheng, J.; Bao, R.; Yi, J.-H.; Yang, P. Microwave purification of multi-wall carbon nanotubes in gas phase. Diam. Relat. Mater. 2016, 68, 93–101. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Imai, H.; Umeda, J.; Takahashi, M.; Kondoh, K. Solid-state interfacial reaction and load transfer efficiency in carbon nanotubes (CNTs)-reinforced aluminum matrix composites. Carbon 2017, 114, 198–208. [Google Scholar] [CrossRef]

- Esawi, A.M.K.; Morsi, K.; Sayed, A.; Gawad, A.A.; Borah, P. Fabrication and properties of dispersed carbon nanotube–aluminum composites. Mater. Sci. Eng. A 2009, 508, 167–173. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Agarwal, A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites. Carbon 2011, 49, 533–544. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Knight, B.E.; Schuh, C.A. Six decades of the Hall–Petch effect—A survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 2016, 61, 495–512. [Google Scholar] [CrossRef]

- Oluwalowo, A.; Nguyen, N.; Zhang, S.; Park, J.G.; Liang, R. Electrical and thermal conductivity improvement of carbon nanotube and silver composites. Carbon 2019, 146, 224–231. [Google Scholar] [CrossRef]

- Chu, K.; Jia, C.C.; Li, W.S.; Wang, P. Mechanical and electrical properties of carbon-nanotube-reinforced Cu-Ti alloy matrix composites. Phys. Status Solidi A 2013, 210, 594–599. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, X.; Cen, X.; Chen, B.; Wang, X.; Song, M.; Ni, S.; Yi, J.; Shen, T.; Du, Y. Enhanced mechanical properties of aluminum based composites reinforced by chemically oxidized carbon nanotubes. Carbon 2018, 139, 459–471. [Google Scholar] [CrossRef]

- Hansen, N. The effect of grain size and strain on the tensile flow stress of aluminium at room temperature. Acta Metall. 1977, 25, 863–869. [Google Scholar] [CrossRef]

- Ryu, H.J.; Cha, S.I.; Hong, S.H. Generalized shear-lag model for load transfer in SiC/Al metal-matrix composites. J. Mater. Res. 2003, 18, 2851–2858. [Google Scholar] [CrossRef] [Green Version]

- Nam, D.H.; Cha, S.I.; Lim, B.K.; Park, H.M.; Han, D.S.; Hong, S.H. Synergistic strengthening by load transfer mechanism and grain refinement of CNT/Al-Cu composites. Carbon 2012, 50, 2417–2423. [Google Scholar] [CrossRef]

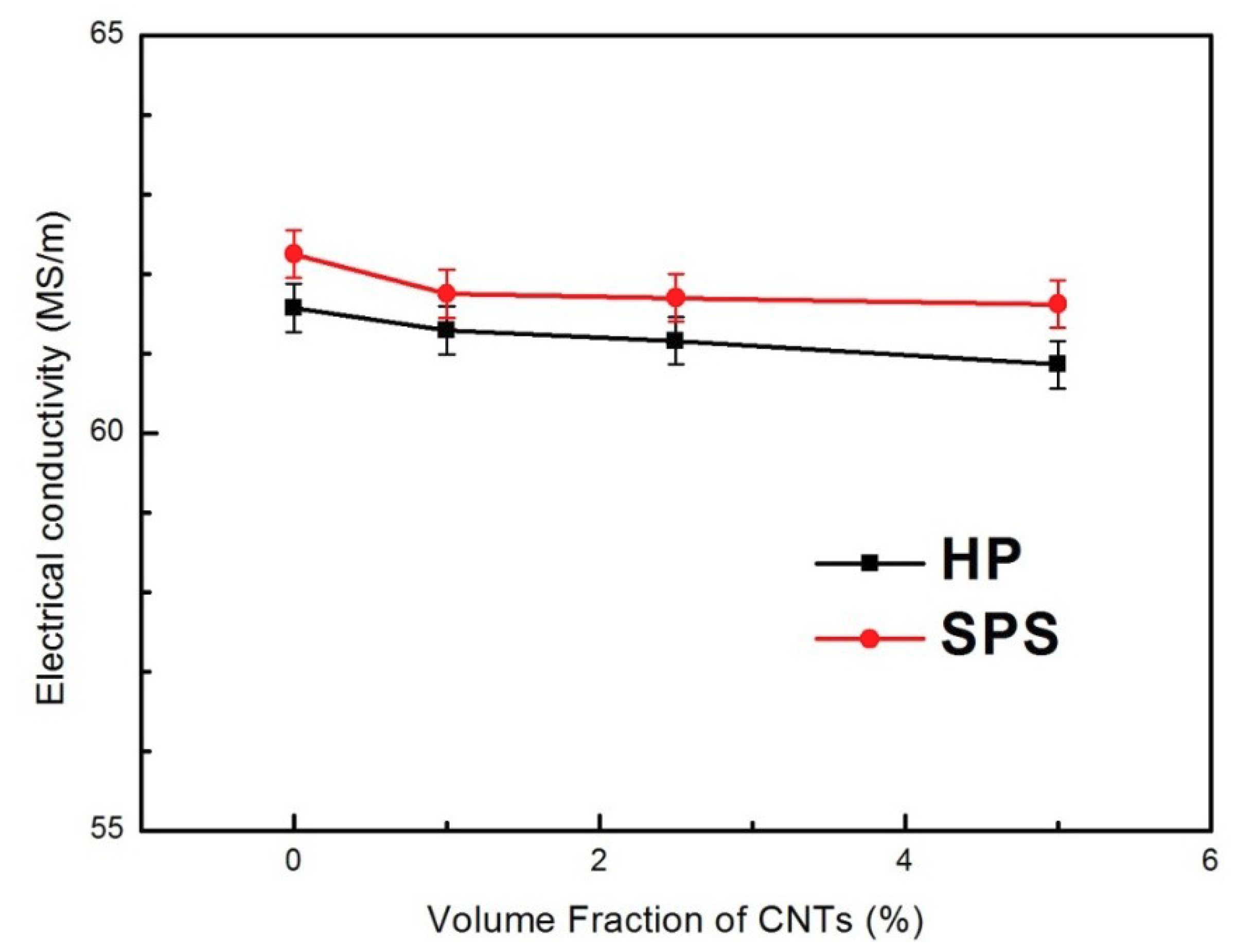

| Sample | Relative Density (%) | Hardness (HV) | Electrical Conductivity (MS/m) | Ultimate Strength (MPa) | Yield Strength (MPa) | Elongation (%) | |

|---|---|---|---|---|---|---|---|

| SPS (vol.%) | 0 | 98.93 | 55 | 62.25 | 114 | 65 | 38.7 |

| 1 | 98.13 | 65 | 61.75 | 218 | 112 | 39.8 | |

| 2.5 | 97.81 | 73 | 61.70 | 221 | 121 | 41.6 | |

| 5 | 96.17 | 92 | 61.62 | 116 | 68 | 32.1 | |

| HP (vol.%) | 0 | 97.96 | 44 | 61.57 | 113 | 62 | 41.5 |

| 1 | 96.74 | 54 | 61.29 | 156 | 81 | 37.8 | |

| 2.5 | 96.65 | 69 | 61.16 | 173 | 89 | 37.7 | |

| 5 | 95.51 | 75 | 60.86 | 122 | 72 | 38.4 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, D.; Ma, J.; Gan, X.; Tao, J.; Xie, M.; Yi, J.; Liu, Y. A Comparison Study of Ag Composites Prepared by Spark Plasma Sintering and Hot Pressing with Silver-Coated CNTs as the Reinforcements. Materials 2019, 12, 1949. https://doi.org/10.3390/ma12121949

Jia D, Ma J, Gan X, Tao J, Xie M, Yi J, Liu Y. A Comparison Study of Ag Composites Prepared by Spark Plasma Sintering and Hot Pressing with Silver-Coated CNTs as the Reinforcements. Materials. 2019; 12(12):1949. https://doi.org/10.3390/ma12121949

Chicago/Turabian StyleJia, Dongming, Junbing Ma, Xueping Gan, Jingmei Tao, Ming Xie, Jianhong Yi, and Yichun Liu. 2019. "A Comparison Study of Ag Composites Prepared by Spark Plasma Sintering and Hot Pressing with Silver-Coated CNTs as the Reinforcements" Materials 12, no. 12: 1949. https://doi.org/10.3390/ma12121949