Silver Nanowire Networks: Mechano-Electric Properties and Applications

Abstract

:1. Introduction

2. Silver Nanowire (Ag NW) Networks

2.1. Formation of Ag NW Networks

2.1.1. Drop Casting

2.1.2. Spin Coating

2.1.3. Bar Coating

2.1.4. Vacuum Filtration and Transfer (VFT)

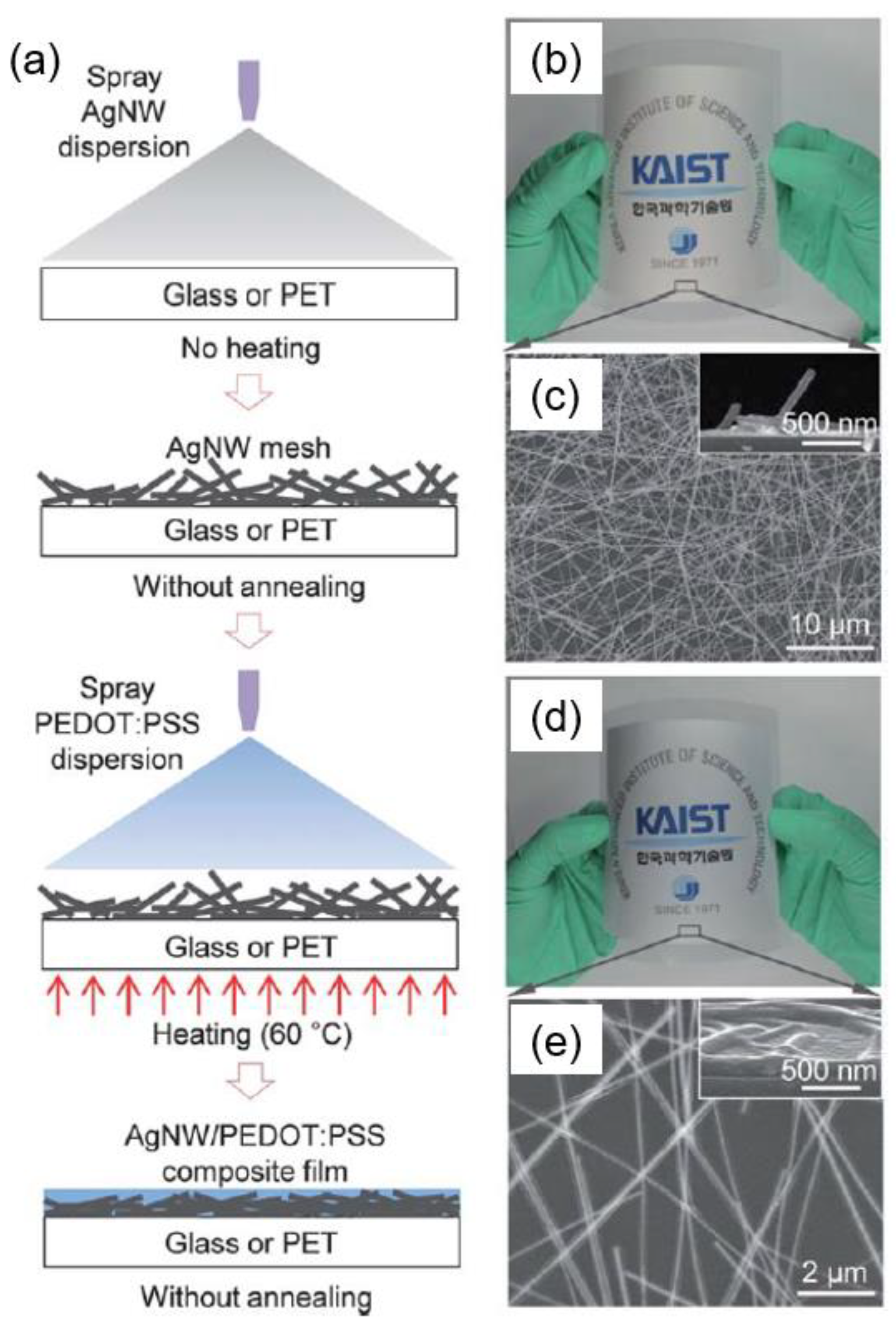

2.1.5. Spray Coating

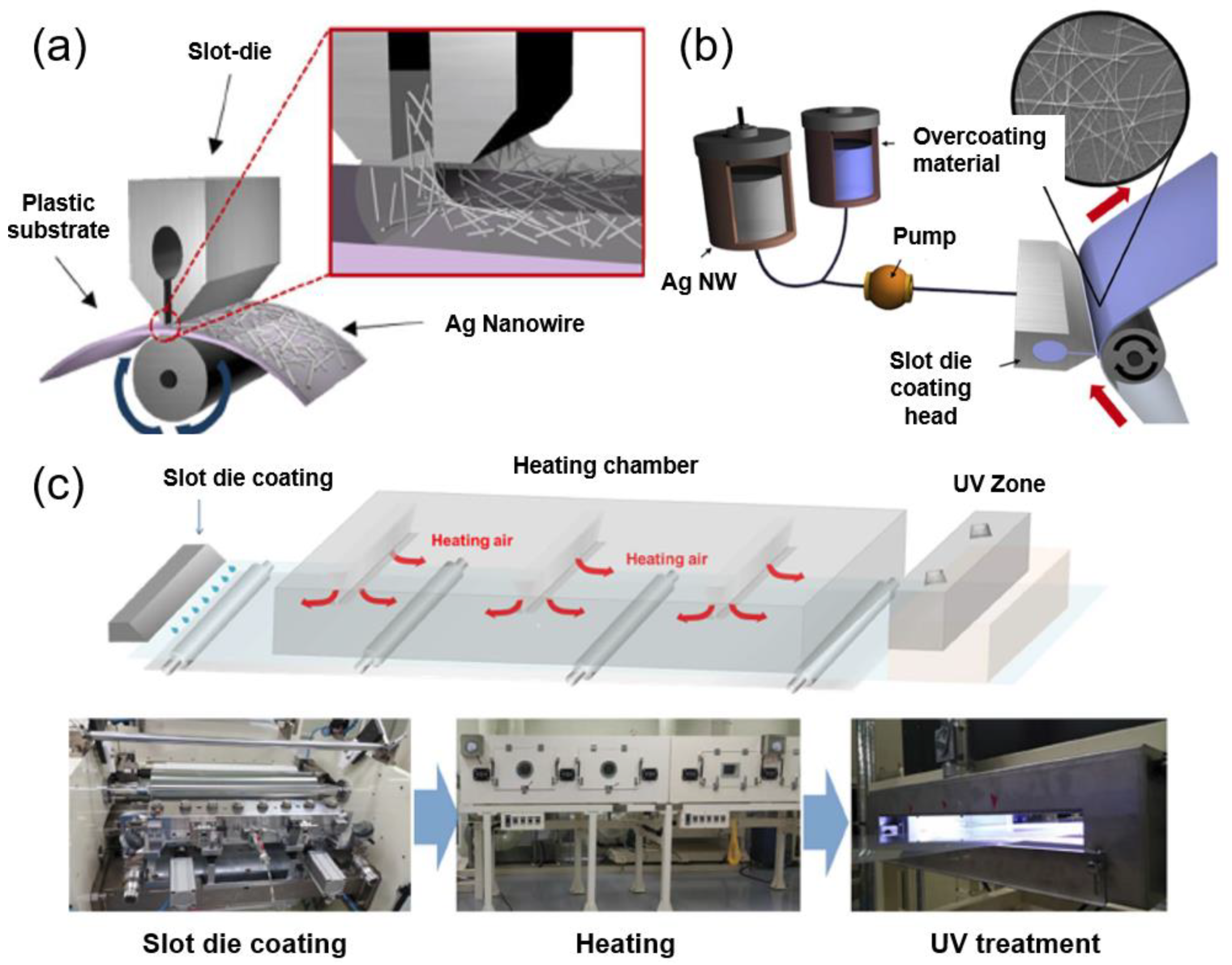

2.1.6. Slot-Die Coating

2.1.7. Printing

2.1.8. Post-Processing

2.2. Characteristics of Ag NW Networks

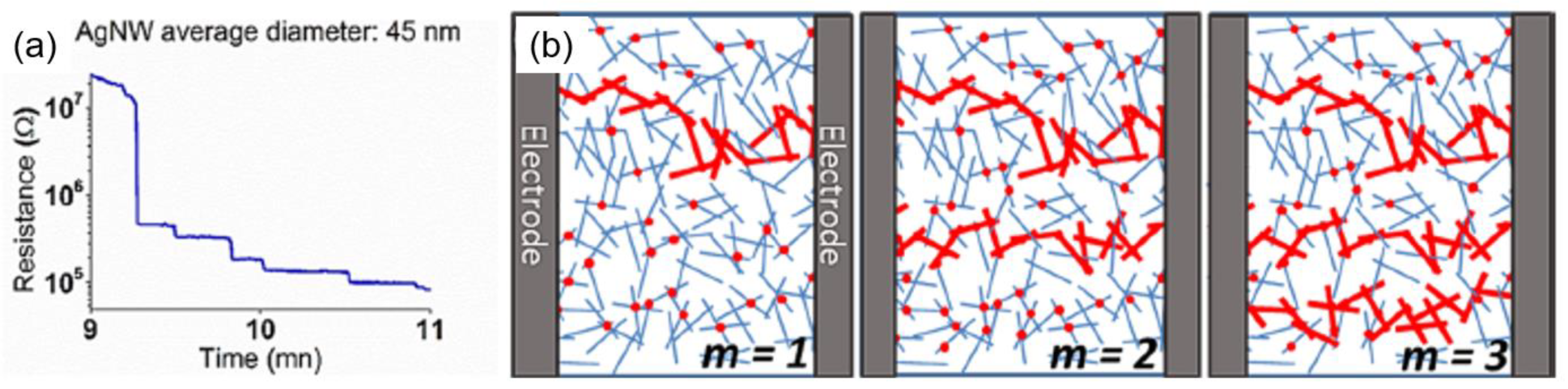

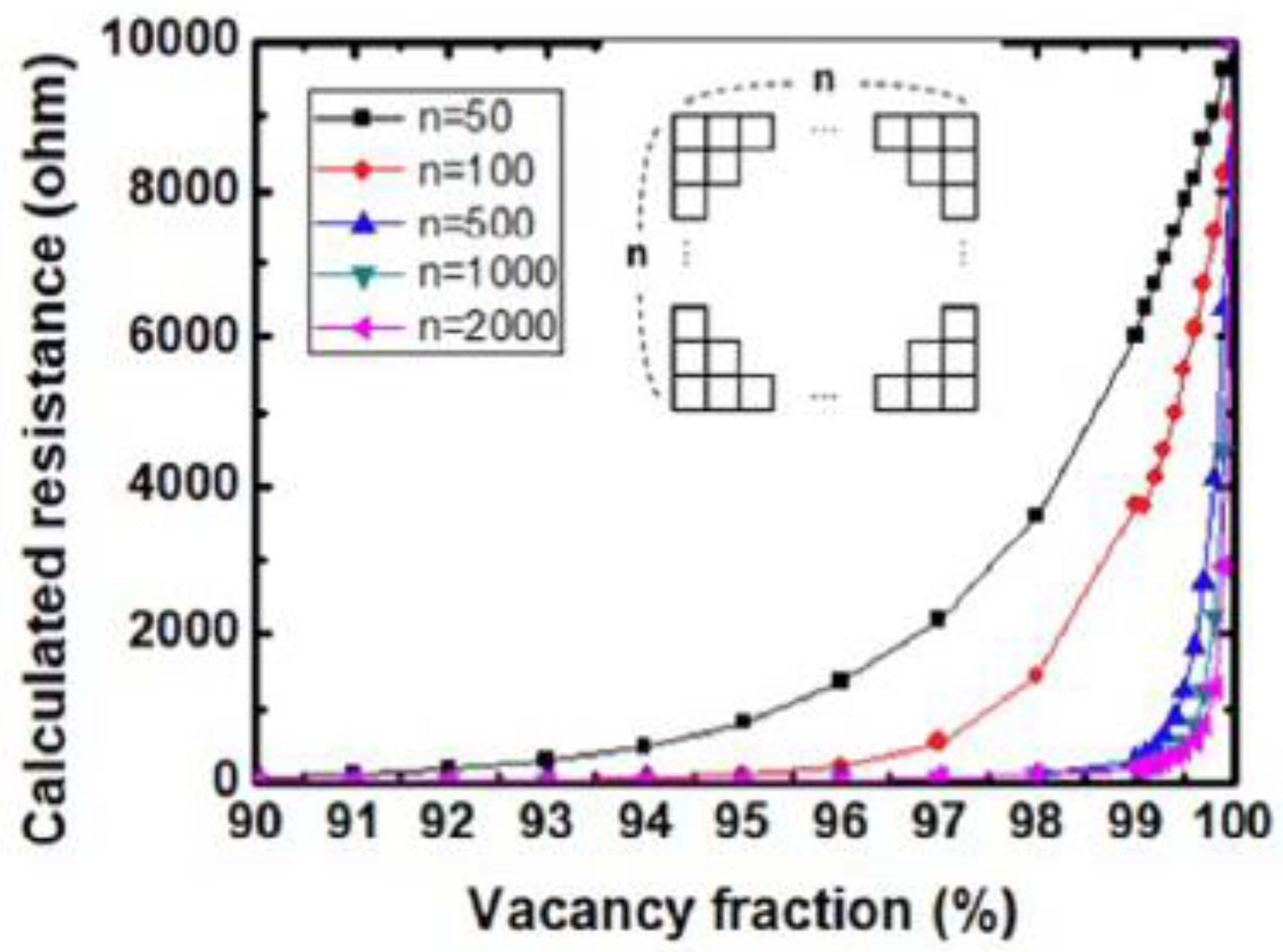

2.2.1. Electro-Optical Properties

2.2.2. Electrical Stability

3. Mechano-Electric Properties of Ag NW Network

3.1. Mechanical Property of Nanowires

3.1.1. Microstructural Size

3.1.2. Crystalline Structure

3.2. Mechano-Electric Behavior of Ag NW Networks

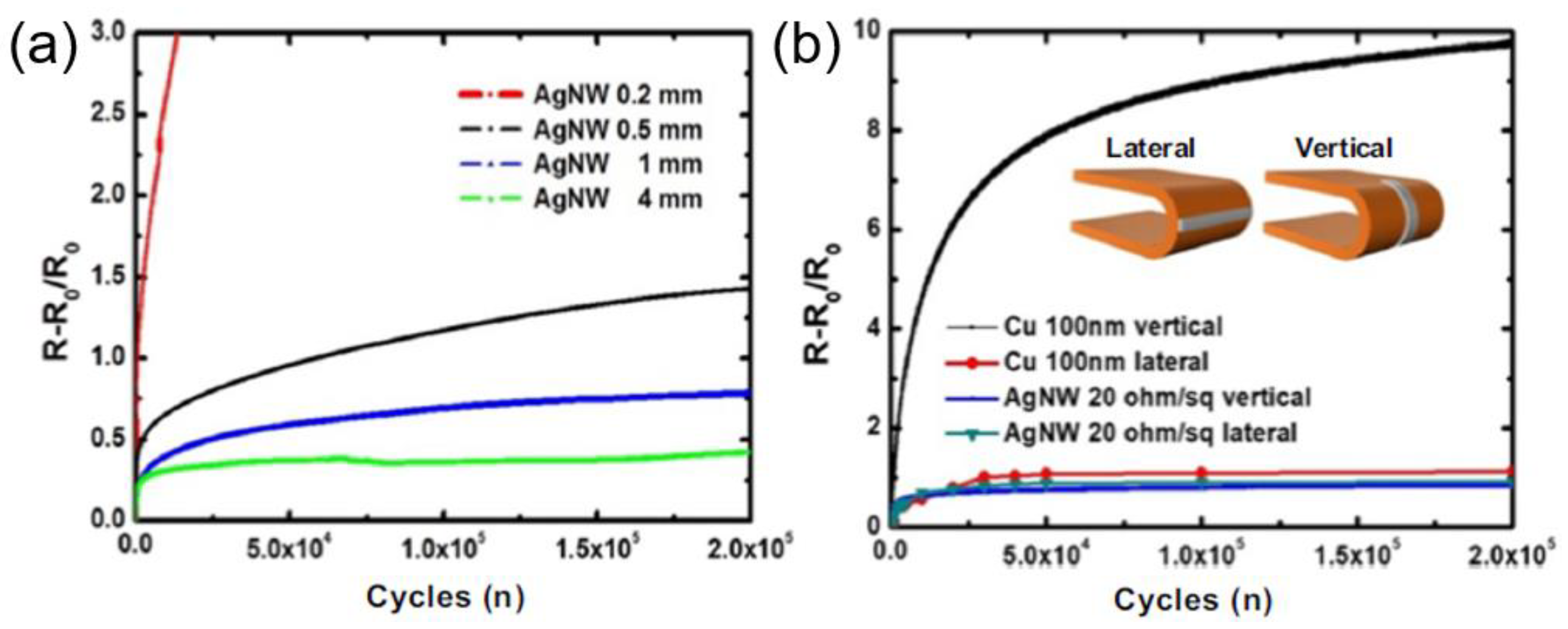

3.2.1. Dynamic Mechano-Electric Property of Ag NW Networks

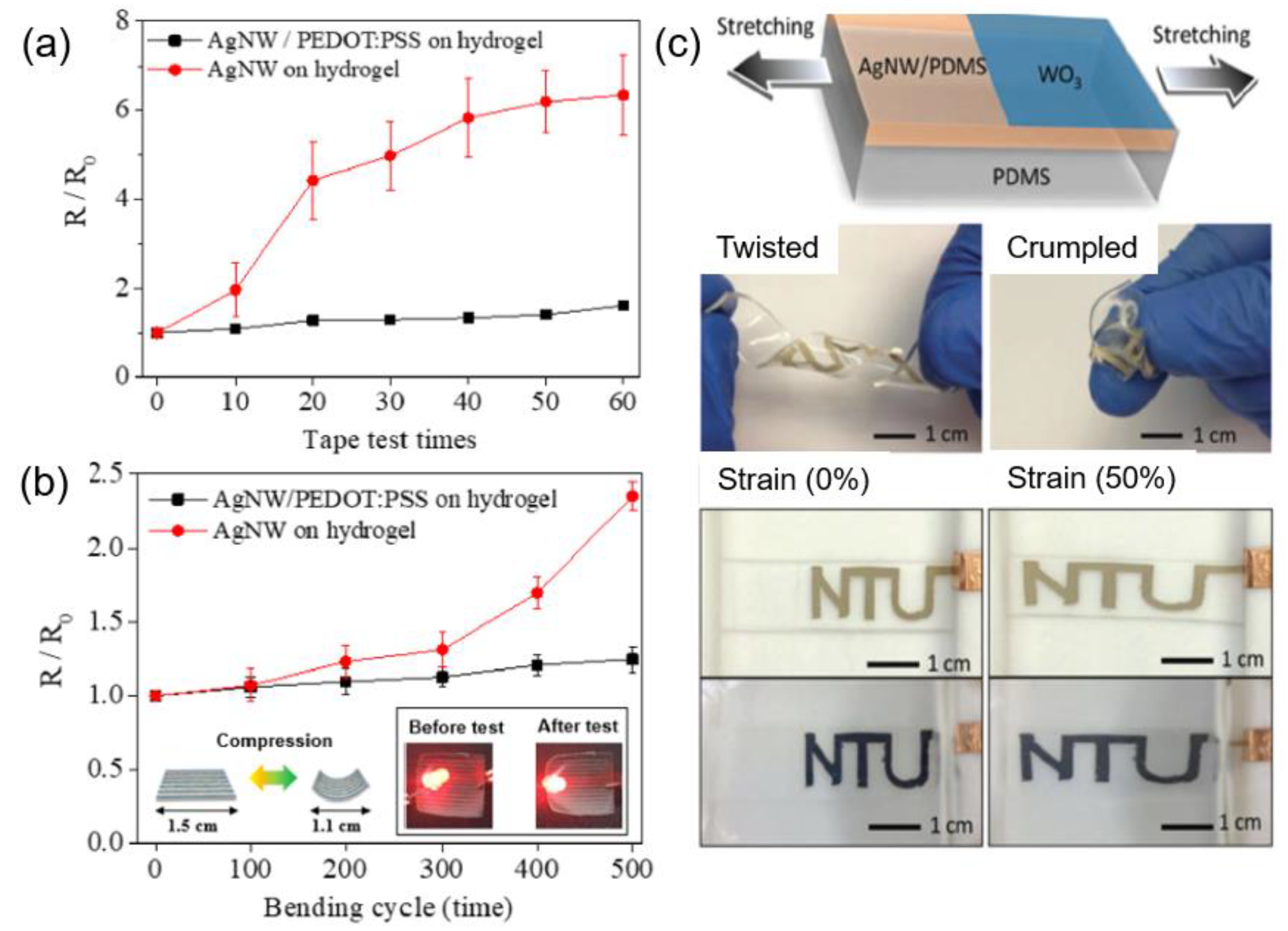

3.2.2. Enhanced Mechano-Electric Property

4. Applications of Ag NW Networks with Mechano-Electric Properties

4.1. Optoelectronic Devices

4.1.1. Transparent Conductive Electrode

4.1.2. Flexible Optoelectronic Device

4.2. Electronic Devices

4.2.1. Wearable Electronic Devices

4.2.2. Flexible Heater

4.2.3. Electromagnetic Interference Shielding

5. Summary and Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dinh, D.A.; Hui, K.N.; Hui, K.S.; Kumar, P.; Singh, J. Silver Nanowires: A Promising Transparent Conducting Electrode Material for Optoelectronic and Electronic Applications. Rev. Adv. Sci. Eng. 2013, 2, 1–22. [Google Scholar] [CrossRef]

- Kwon, J.; Suh, Y.D.; Lee, J.; Lee, P.; Han, S.; Hong, S.; Yeo, J.; Lee, H.; Ko, S.H. Recent Progress in Silver Nanowire based Flexible/Wearable Optoelectronics. J. Mater. Chem. C 2018, 6, 7445–7461. [Google Scholar] [CrossRef]

- Yi, P.; Zhu, Y.; Deng, Y. Fabrication and Applications of Flexible Transparent Electrodes Based on Silver Nanowires. Flex. Electron. 2018. [Google Scholar] [CrossRef] [Green Version]

- Available online: http://www.gunze.co.jp/denzai/en/newproducts (accessed on 20 October 2014).

- Sohn, H.; Shin, W.; Woo, Y.S. Electrical Conductors and Electronic Devices including the Same. U.S. Patent Application No. US 9892821 B2, 13 February 2018. [Google Scholar]

- Langley, D.; Giusti, G.; Mayousse, C.; Celle, C.; Bellet, D.; Simonato, J.-P. Flexible Transparent Conductive Materials based on Silver Nanowire Networks: A Review. Nanotechnology 2013, 24, 452001. [Google Scholar] [CrossRef] [PubMed]

- Tokuno, T.; Nogi, M.; Jiu, J.; Sugahara, T.; Suganuma, K. Transparent Electrodes Fabricated via the Self-Assembly of Silver Nanowires Using a Bubble Template. Langmuir 2012, 28, 9298–9302. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zhang, S.; Li, L.; Chen, W. Research Progress on Large-Area Perovskite Thin Films and Solar Modules. J. Mater. 2017, 3, 231–244. [Google Scholar] [CrossRef]

- Wang, J.-L.; Hassan, M.; Liu, J.-W.; Yu, S.-H. Nanowire Assemblies for Flexible Electronic Devices: Recent Advances and Perspectives. Adv. Mater. 2018. [Google Scholar] [CrossRef]

- Naghdi, S.; Rhee, K.Y.; Hui, D.; Park, S.J. A Review of Conductive Metal Nanomaterials as Conductive, Transparent, and Flexible Coatings, Thin Films, and Conductive Fillers: Different Deposition Methods and Applications. Coatings 2018, 8, 278. [Google Scholar] [CrossRef]

- Guo, X.; Liu, X.; Luo, J.; Gan, Z.; Meng, Z.; Zhang, N. Silver Nanowire/Polyimide Composite Transparent Electrodes for Reliable Flexible Polymer Solar Cells Operating at High and Ultra-Low Temperature. RSC Adv. 2015, 5, 24953–24959. [Google Scholar] [CrossRef]

- Liu, R.; Tana, M.; Zhang, X.; Xu, L.; Chen, J.; Chen, Y.; Tang, X.; Wan, L. Solution-Processed Composite Electrodes Composed of Silver Nanowires and Aluminum-doped Zinc Oxide Nanoparticles for Thin-Film Solar Cells Applications. Sol. Energy Mater. Sol. Cells 2018, 174, 584–592. [Google Scholar] [CrossRef]

- Kim, A.; Lee, H.; Kwon, H.-C.; Jung, H.S.; Park, N.-G.; Jeong, S.; Moon, J. Fully Solution-Processed Transparent Electrodes based on Silver Nanowire Composites for Perovskite Solar Cells. Nanoscale 2016, 8, 6308–6316. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.G.; Lee, D.; Yoo, J.S.; Lee, S.; Jung, H.S. Effective passivation of Ag Nanowire-based flexible transparent conducting electrode by TiO2 Nanoshell. Nano Converg. 2016, 3, 20. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liang, J.; Jian, X.; Hu, W.; Li, J.; Pei, Q. A Flexible and Transparent Thin Film Heater Based on a Silver Nanowire/Heat-resistant Polymer Composite. Macromol. Mater. Eng. 2014, 299, 1403–1409. [Google Scholar] [CrossRef]

- Joo, Y.; Byun, J.; Seong, N.; Ha, J.; Kim, H.; Kim, S.; Kim, T.; Im, H.; Kim, D.; Hong, Y. Silver Nanowire-embedded PDMS with a Multiscale Structure for a Highly Sensitive and Robust Flexible Pressure Sensor. Nanoscale 2015, 7, 6208–6215. [Google Scholar] [CrossRef] [PubMed]

- Catenacci, M.J.; Reyes, C.; Cruz, M.A.; Wiley, B.J. Stretchable Conductive Composites from Cu-Ag Nanowire Felt. ACS Nano 2018, 12, 3689–3698. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Lee, P.; Lee, H.; Lee, D.; Lee, S.S.; Ko, S.H. Very Long Ag Nanowire Synthesis and Its Application in a Highly Transparent, Conductive and Flexible Metal Electrode Touch Panel. Nanoscale 2012, 4, 6408–6414. [Google Scholar] [CrossRef] [PubMed]

- Choi, D.Y.; Kang, H.W.; Sung, H.J.; Kim, S.S. Annealing-free, Flexible Silver Nanowire–Polymer Composite Electrodes via a Continuous Two-Step Spray-Coating Method. Nanoscale 2013, 5, 977–983. [Google Scholar] [CrossRef] [PubMed]

- Akter, T.; Kim, W.S. Reversibly Stretchable Transparent Conductive Coatings of Spray-Deposited Silver Nanowires. ACS Appl. Mater. Interfaces 2012, 4, 1855–1859. [Google Scholar] [CrossRef] [PubMed]

- Madaria, A.R.; Kumar, A.; Zhou, C. Large Scale, Highly Conductive and Patterned Transparent Films of Silver Nanowires on Arbitrary Substrates and Their Application in Touch Screens. Nanotechnology 2011, 22, 245201–245207. [Google Scholar] [CrossRef] [PubMed]

- Seok, H.-J.; Kim, J.-K.; Kim, H.-K. Effective Passivation of Ag Nanowire Network by Transparent Tetrahedral Amorphous Carbon Film for Flexible and Transparent Thin Film Heaters. Sci. Rep. 2018, 8, 13521. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-J.; Shin, H.-I.; Ko, E.-H.; Kim, K.-H.; Kim, T.-W.; Kim, H.-K. Roll-to-Roll Slot-die Coating of 400 mm wide, Flexible, Transparent Ag Nanowire Films for Flexible Touch Screen Panels. Sci. Rep. 2016, 6, 34322. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Hwang, J. Fabrication of a Flexible Ag-grid Transparent Electrode Using AC based Electrohydrodynamic Jet Printing. J. Phys. D Appl. Phys. 2014, 47, 405102–405108. [Google Scholar] [CrossRef]

- Cui, Z.; Han, Y.; Huang, Q.; Dong, J.; Zhu, Y. Electrohydrodynamic Printing of Silver Nanowires for Flexible and Stretchable Electronics. Nanoscale 2018, 10, 6806–6811. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, S.; Zhang, Y.; Li, J.; Miao, J.; Wang, Q.; Yu, Z.; Wang, C. Direct Printing for Additive Patterning of Silver Nanowires for Stretchable Sensor and Display Applications. Adv. Mater. Technol. 2018, 3, 1700232. [Google Scholar] [CrossRef]

- Liang, F.-C.; Chang, Y.-W.; Kuo, C.-C.; Cho, C.-J.; Jiang, D.-H.; Jhuang, F.-C.; Rwei, S.-P.; Borsali, R. A mechanically Robust Silver Nanowire-Polydimethylsiloxane Electrode based on Facile Transfer Printing Techniques for Wearable Displays. Nanoscale 2019, 11, 1520–1530. [Google Scholar] [CrossRef] [PubMed]

- Cardenas, J.A.; Catenacci, M.J.; Andrews, J.B.; Williams, N.X.; Wiley, B.J.; Franklin, A.D. In-Place Printing of Carbon Nanotube Transistors at Low Temperature. ACS Appl. Nano Mater. 2018, 1, 1863–1869. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, Y.; Yi, P.; Peng, L.; Lai, X. Fabrication of Flexible Silver Nanowire Conductive Films and Transmittance Improvement based on Moth-eye Nanostructure Array. J. Micromech. Microeng. 2017, 27, 75010–75018. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, M.; Song, X.; Yan, G.; Ding, Y.; Bai, J. High-Performance ZnO/Ag Nanowire/ZnO Composite Film UV Photodetectors with Large Area and Low Operating Voltage. J. Mater. Chem. C 2014, 2, 4312–4319. [Google Scholar] [CrossRef]

- Chung, C.-H.; Song, T.-B.; Bob, B.; Zhu, R.; Yang, Y. Solution-Processed Flexible Transparent Conductors Composed of Silver Nanowire Networks Embedded in Indium Tin Oxide Nanoparticle Matrices. Nano Res. 2012, 5, 805–814. [Google Scholar] [CrossRef]

- Kim, A.; Won, Y.; Woo, K.; Jeong, S.; Moon, J. All-Solution-Processed Indium-Free Transparent Composite Electrodes based on Ag Nanowire and Metal Oxide for Thin-Film Solar Cells. Adv. Funct. Mater. 2014, 24, 2462–2471. [Google Scholar] [CrossRef]

- Lee, H.-J.; Oh, S.; Cho, K.-Y.; Jeong, W.-L.; Lee, D.-S.; Park, S.-J. Spontaneous and Selective Nanowelding of Silver Nanowires by Electrochemical Ostwald Ripening and High Electrostatic Potential at the Junctions for High-Performance Stretchable Transparent Electrodes. ACS Appl. Mater. Interfaces 2018, 10, 14124–14131. [Google Scholar] [CrossRef] [PubMed]

- Lagrange, M.; Langley, D.P.; Giusti, G.; Jiménez, C.; Bréchete, Y.; Bellet, D. Optimization of Silver Nanowire-based Transparent Electrodes: Effects of Density, Size and Thermal Annealing. Nanoscale 2015, 7, 17410–17423. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Engholm, M. Recent Progress on the Fabrication and Properties of Silver Nanowire-Based Transparent Electrodes. Nanomaterials 2018, 8, 628. [Google Scholar] [CrossRef] [PubMed]

- Sofiah, A.G.N.; Samykano, M.; Kadirgama, K.; Mohan, R.V.; Lah, N.A.C. Metallic Nanowires: Mechanical Properties—Theory and Experiment. Appl. Mater. Today 2018, 11, 320–337. [Google Scholar] [CrossRef]

- Alam, M.F.; Rahman, M.S. Fracture Mechanism of Single and Polycrystal Silver Nanowire: Computational Study. Inter. J. Math. Trends Tech. (IJMTT) 2018, 54, 471–476. [Google Scholar] [CrossRef]

- Pike, G.E.; Seager, C.H. Percolation and Conductivity: A Computer Study. I. Phys. Rev. B 1974, 10, 1421. [Google Scholar] [CrossRef]

- Seager, C.H.; Pike, G.E. Percolation and conductivity: A computer study. II. Phys. Rev. B 1974, 10, 1435. [Google Scholar] [CrossRef]

- Sannicolo, T.; Muñoz-Rojas, D.; Nguyen, N.D.; Moreau, S.; Celle, C.; Simonato, J.-P.; Bréchet, Y.; Bellet, D. Direct Imaging of the Onset of Electrical Conduction in Silver Nanowire Networks by Infrared Thermography: Evidence of Geometrical Quantized Percolation. Nano Lett. 2016, 16, 7046–7053. [Google Scholar] [CrossRef]

- De, S.; King, P.J.; Lyons, P.E.; Khan, U.; Coleman, J.N. Size Effects and the Problem with Percolation in Nanostructured Transparent Conductors. ACS Nano 2010, 4, 7064–7072. [Google Scholar] [CrossRef]

- Langley, D. Silver Nanowire Networks: Effects of Percolation and Thermal Annealing on Physical Properties. Ph.D. Thesis, Université de Grenoble, Grenoble, France, 2014. (In English). [Google Scholar]

- De, S.; Coleman, J.N. The effects of Percolation in Nanostructured Transparent Conductors. MRS Bull. 2011, 36, 774–781. [Google Scholar] [CrossRef]

- Langley, D.P.; Lagrange, M.; Giusti, G.; Jiménez, C.; Bréchet, Y.; Nguyen, N.D.; Bellet, D. Metallic Nanowire Networks: Effects of Thermal Annealing on Electrical Resistance. Nanoscale 2014, 6, 13535–13543. [Google Scholar] [CrossRef]

- Huang, G.-W.; Xiao, H.-M.; Fu, S.-Y. Wearable Electronics of Silver-Nanowire/Poly(dimethylsiloxane) Nanocomposite for Smart Clothing. Sci. Rep. 2015, 5, 13971. [Google Scholar] [CrossRef] [PubMed]

- Song, T.-B.; Chen, Y.; Chung, C.-H.; Yang, Y.M.; Bob, B.; Duan, H.-S.; Li, G.; Tu, K.-N.; Huang, Y.; Yang, Y. Nanoscale Joule Heating and Electromigration Enhanced Ripening of Silver Nanowire Contacts. ACS Nano 2014, 8, 2804–2811. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Sellers, M.S.; Basaran, C.; Schultz, A.J.; Kofke, D.A. Lattice Strain Due to an Atomic Vacancy. Int. J. Mol. Sci. 2009, 10, 2798–2808. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.; An, X.; Liao, X. Mechanical Behaviors of Nanowires. Appl. Phys. Rev. 2017, 4, 031104. [Google Scholar] [CrossRef]

- Park, M.; Kim, W.; Hwang, B.; Han, S.M. Effect of Varying the Density of Ag Nanowire Networks on Their Reliability during Bending Fatigue. Scr. Mater. 2019, 161, 70–73. [Google Scholar] [CrossRef]

- Mughrabi, H. Fatigue Life and Cyclic Stress–Strain Behavior. In Encyclopedia of Materials: Science and Technology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 2917–2931. [Google Scholar]

- Hwang, B.; Kim, T.; Han, S.M. Compression and Tension Bending Fatigue Behavior of Ag Nanowire Network. Extrem. Mech. Lett. 2016, 8, 266–272. [Google Scholar] [CrossRef]

- Hwang, B.; Seol, J.G.; An, C.-H.; Kim, S.H. Bending Fatigue Behavior of Silver Nanowire Networks with Different Densities. Thin Solid Films 2017, 625, 1–5. [Google Scholar] [CrossRef]

- Chang, T.-H.; Cheng, G.; Li, C.; Zhu, Y. On the Size-Dependent Elasticity of Penta-Twinned Silver Nanowires. Extrem. Mech. Lett. 2016, 8, 177–183. [Google Scholar] [CrossRef]

- Niekiel, F.; Spiecker, E.; Bitzek, E. Influence of Anisotropic Elasticity on the Mechanical Properties of Fivefold Twinned Nanowires. J. Mech. Phys. Solids 2015, 84, 358–379. [Google Scholar] [CrossRef]

- Akinwande, D.; Brennan, C.J.; Bunch, J.S.; Egberts, P.; Felts, J.R.; Gao, H.; Huang, R.; Kim, J.-S.; Li, T.; Li, Y.; et al. A review on Mechanics and Mechanical Properties of 2D Materials–Graphene and Beyond. Extreme Mech. Lett. 2017, 13, 42–77. [Google Scholar] [CrossRef]

- Taloni, A.; Vodret, M.; Costantini, G.; Zapperi, S. Size Effects on the Fracture of Microscale and Nanoscale Materials. Nat. Rev. Mater. 2018, 3, 211–224. [Google Scholar] [CrossRef]

- Cao, K.; Han, Y.; Zhang, H.; Gao, L.; Yang, H.; Chen, J.; Li, Y.; Lu, Y. Size-Dependent Fracture Behavior of Silver Nanowires. Nanotechnology 2018, 29, 295703–295709. [Google Scholar] [CrossRef] [PubMed]

- Sansoz, F.; Deng, C. Size-Dependent Plasticity in Twinned Metal Nanowires. In Proceedings of the International Conference on Fracture (ICF), Ottawa, ON, Canada, 4–9 December 2009. [Google Scholar]

- Park, N.-Y.; Nam, H.-S.; Cha, P.-R.; Lee, S.-C. Size-Dependent Transition of the Deformation Behavior of Au Nanowires. Nano Res. 2015, 8, 941–947. [Google Scholar] [CrossRef]

- Deng, C.; Sansoz, F. Size-Dependent Yield Stress in Twinned Gold Nanowires Mediated by Site-Specific Surface Dislocation Emission. Appl. Phys. Lett. 2009, 95, 091914. [Google Scholar] [CrossRef]

- Wang, S.; Shan, Z.; Huang, H. The Mechanical Properties of Nanowires. Adv. Sci. 2017, 4, 1600332. [Google Scholar] [CrossRef] [PubMed]

- Lah, N.A.C.; Trigueros, S. Synthesis and Modelling of the Mechanical Properties of Ag, Au and Cu Nanowires. Sci. Technol. Adv. Mater. 2019, 20, 225–261. [Google Scholar] [CrossRef] [PubMed]

- Park, J.S.; Rezaei, M.; Kim, W.S. Sustained Percolation in Stretched Silver Nanowire Networks for Stretchable Inter-Connection Applications. Adv. Eng. Mater. 2014, 16, 905–908. [Google Scholar] [CrossRef]

- Hwang, B.; Shin, H.-A.-S.; Kim, T.; Joo, Y.-C.; Han, S.M. Highly Reliable Ag Nanowire Flexible Transparent Electrode with Mechanically Welded Junctions. Small 2014, 10, 3397–3404. [Google Scholar] [CrossRef]

- Kim, Y.; Jun, S.; Ju, B.-K.; Kim, J.-W. Heterogeneous Configuration of a Ag Nanowire/Polymer Composite Structure for Selectively Stretchable Transparent Electrodes. ACS Appl. Mater. Interfaces 2017, 9, 7505–7514. [Google Scholar] [CrossRef]

- Hwang, J.; Sohn, H.; Lee, S.H. Computational Characterization and Control of Electrical Conductivity of Nanowire Composite Network under Mechanical Deformation. Sci. Rep. 2018, 8, 16617. [Google Scholar] [CrossRef] [PubMed]

- Xiong, W.; Liu, H.; Chen, Y.; Zheng, M.; Zhao, Y.; Kong, X.; Wang, Y.; Zhang, X.; Kong, X.; Wang, P.; et al. Highly Conductive, Air-Stable Silver Nanowire@Iongel Composite Films toward Flexible Transparent Electrodes. Adv. Mater. 2016, 28, 7167–7172. [Google Scholar] [CrossRef] [PubMed]

- Deignan, G.; Goldthorpe, I.A. The Dependence of Silver Nanowire Stability on Network Composition and Processing Parameters. RSC Adv. 2017, 7, 35590–35597. [Google Scholar] [CrossRef]

- Giusti, G.; Langley, D.P.; Lagrange, M.; Collins, R.; Jimenez, C.; Bréchet, Y.; Bellet, D. Thermal Annealing Effects on Silver Nanowire Networks. Int. J. Nanotechnol. 2014, 11, 785–795. [Google Scholar] [CrossRef]

- Park, J.-Y.; Hong, S.; Jang, J.; Kim, H.-K. Blue Laser Annealing of Ag Nanowire Electrodes for Flexible Thin Film Heaters. ECS J. Solid State Sci. Technol. 2017, 6, P746–P751. [Google Scholar] [CrossRef]

- Lee, P.; Kwon, J.; Lee, J.; Lee, H.; Suh, Y.D.; Hong, S.; Yeo, J. Rapid and Effective Electrical Conductivity Improvement of the Ag NW-Based Conductor by Using the Laser-Induced Nano-Welding Process. Micromachines 2017, 8, 164. [Google Scholar] [CrossRef]

- Weiß, N.; Muller-Meskamp, L.; Selzer, F.; Bormann, L.; Eychmuller, A.; Leo, K.; Gaponik, N. Humidity Assisted Annealing Technique for Transparent Conductive Silver Nanowire Networks. RSC Adv. 2015, 5, 19659–19665. [Google Scholar] [CrossRef]

- Li, R.-Z.; Hu, A.; Zhang, T.; Oakes, K.D. Direct Writing on Paper of Foldable Capacitive Touch Pads with Silver Nanowire Inks. ACS Appl. Mater. Interfaces 2014, 6, 21721–21729. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Hwang, G.-T.; Kim, S.; Seo, J.; Park, H.-J.; Yu, K.; Kim, T.-S.; Lee, K.J. Flash-Induced Self-Limited Plasmonic Welding of Silver Nanowire Network for Transparent Flexible Energy Harvester. Adv. Mater. 2017, 29, 1603473. [Google Scholar] [CrossRef]

- Zhu, S.; Gao, Y.; Hu, B.; Li, J.; Su, J.; Fan, Z.; Zhou, J. Transferable Self-Welding Silver Nanowire Network as High Performance Transparent Flexible Electrode. Nanotechnology 2013, 24, 335202. [Google Scholar] [CrossRef]

- Kim, A.; Won, Y.; Woo, K.; Kim, C.-H.; Moon, J. Highly Transparent Low Resistance ZnO/Ag Nanowire/ZnO Composite Electrode for Thin Film Solar Cells. ACS Nano 2013, 7, 1081–1091. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Nguyen, V.H.; Muñoz-Rojas, D.; Aghazadehchors, S.; Jiménez, C.; Duy Nguyen, N.; Bellet, D. Stability Enhancement of Silver Nanowire Networks with Conformal ZnO Coatings Deposited by Atmospheric Pressure Spatial Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2018, 10, 19208–19217. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Kim, T.; Cho, S.; Lee, Y.; Choe, A.; Walker, B.; Ko, S.-J.; Kim, J.Y.; Ko, H. Capillary Printing of Highly Aligned Silver Nanowire Transparent Electrodes for High-Performance Optoelectronic Devices. Nano Lett. 2015, 15, 7933–7942. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; An, K.; Won, P.; Ka, Y.; Hwang, H.; Moon, H.; Kwon, Y.; Hong, S.; Kim, C.; Lee, C.; et al. A dual-scale metal nanowire network transparent conductor for highly efficient and flexible organic light emitting diodes. Nanoscale 2017, 9, 1978–1985. [Google Scholar] [CrossRef] [PubMed]

- Sohn, H.; Kim, S.; Shin, W.; Lee, J.M.; Lee, H.; Yun, D.-J.; Moon, K.-S.; Han, I.T.; Kwak, C.; Hwang, S.-J. Novel Flexible Transparent Conductive Films with Enhanced Chemical and Electro-Mechanical Sustainability: TiO2 Nanosheet-Ag Nanowire Hybrid. ACS Appl. Mater. Interfaces 2018, 10, 2688–2700. [Google Scholar] [CrossRef] [PubMed]

- Hwang, B.; Park, M.; Kim, T.; Han, S.M. Effect of RGO Deposition on Chemical and Mechanical Reliability of Ag Nanowire Flexible Transparent Electrode. RSC Adv. 2016, 6, 67389–67395. [Google Scholar] [CrossRef]

- Lee, H.; Kim, I.; Kim, M.; Lee, H. Moving Beyond Flexible to Stretchable Conductive Electrodes Using Metal Nanowires and Graphenes. Nanoscale 2016, 8, 1789–1822. [Google Scholar] [CrossRef]

- Lee, M.-S.; Kim, J.; Park, J.; Park, J.-U. Studies on the Mechanical Stretchability of Transparent Conductive Film based on Graphene-Metal Nanowire Structures. Nano. Res. Lett. 2015, 10, 27–35. [Google Scholar] [CrossRef]

- Cho, E.H.; Kim, M.J.; Sohn, H.; Shin, W.H.; Won, J.Y.; Kim, Y.; Kwak, C.; Lee, C.S.; Woo, Y.S. A Graphene Mesh as a Hybrid Electrode for Foldable Devices. Nanoscale 2018, 10, 628–638. [Google Scholar] [CrossRef]

- Sohn, H.; Woo, Y.S.; Shin, W.-H.; Yun, D.-J.; Lee, T.; Kim, F.S.; Hwang, J. Novel Transparent Conductor with Enhanced Conductivity: Hybrid of Silver Nanowires and Dual-Doped Graphene. Appl. Surf. Sci. 2017, 419, 63–69. [Google Scholar] [CrossRef]

- Yeh, M.-H.; Chen, P.-H.; Yang, Y.-C.; Chen, G.-H.; Chen, H.-S. Investigation of Ag-TiO2 Interfacial Reaction of Highly Stable Ag Nanowire Transparent Conductive Film with Conformal TiO2 Coating by Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2017, 9, 10788–10797. [Google Scholar] [CrossRef] [PubMed]

- Song, T.-B.; Rim, Y.S.; Liu, F.; Bob, B.; Ye, S.; Hsieh, Y.-T.; Yang, Y. Highly Robust Silver Nanowire Network for Transparent Electrode. ACS Appl. Mater. Interfaces 2015, 7, 24601–24607. [Google Scholar] [CrossRef] [PubMed]

- Hwang, B.; An, Y.; Lee, H.; Lee, E.; Becker, S.; Kim, Y.-H.; Kim, H. Highly Flexible and Transparent Ag Nanowire Electrode Encapsulated with Ultra-Thin Al2O3: Thermal, Ambient, and Mechanical Stabilities. Sci. Rep. 2017, 7, 41336. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Ko, Y.; Kim, W.; Kim, D.; You, J. Highly Efficient Silver Nanowire/PEDPT:PSS Composite Microelectrodes via Poly(ethylene glycol) Photolithography. Opt. Mater. Exp. 2017, 7, 2272–2279. [Google Scholar] [CrossRef]

- Ko, Y.; Kim, J.; Kim, D.; Yamauchi, Y.; Kim, J.H.; You, J. A Simple Silver Nanowire Patterning Method Based on Poly(Ethylene Glycol) Photolithography and Its Application for Soft Electronics. Sci. Rep. 2017, 7, 2282. [Google Scholar] [CrossRef]

- Yan, C.; Kang, W.; Wang, J.; Cui, M.; Wang, X.; Foo, C.Y.; Chee, K.J.; Lee, P.S. Stretchable and Wearable Electrochromic Devices. ACS Nano 2014, 8, 316–322. [Google Scholar] [CrossRef]

- Hwang, B.; Lim, S. PEDOT:PSS Overcoating Layer for Mechanically and Chemically Stable Ag Nanowire Flexible Transparent Electrode. J. Nanomater. 2017, 2017, 1489186. [Google Scholar] [CrossRef]

- Liang, J.; Tong, K.; Pei, Q. A Water-Based Silver-Nanowire Screen-Print Ink for the Fabrication of Stretchable Conductors and Wearable Thin-Film Transistors. Adv. Mater. 2016, 28, 5986–5996. [Google Scholar] [CrossRef]

- Narayanan, S.; Hajzus, J.R.; Treacy, C.E.; Bockstaller, M.R.; Porter, L.M. Polymer Embedded Silver-Nanowire Network Structures–A Platform for the Facile Fabrication of Flexible Transparent Conductors. ECS J. Solid State Sci. Technol. 2014, 3, P363–P369. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, Z.; Yu, H.; Huang, X.; Chen, M. Effect of Trifluoroacetic Acid Treatment of PEDOT:PSS layers on the Performance and Stability of Organic Solar Cells. J. Mater. Sci. Mater. Electron. 2018, 29, 6607–6618. [Google Scholar] [CrossRef]

- Nam, S.; Song, M.; Kim, D.-H.; Cho, B.; Lee, H.M.; Kwon, J.-D.; Park, S.-G.; Nam, K.-S.; Jeong, Y.; Kwon, S.-H.; et al. Ultrasmooth, Extremely Deformable and Shape Recoverable Ag Nanowire Embedded Transparent Electrode. Sci. Rep. 2014, 4, 4788. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Cao, S.; Wang, J.; Zhu, H.; Wang, J.; Yang, S.; Wang, X.; Kong, D. Bright Stretchable Electroluminescent Devices based on Silver Nanowire Electrodes and High-k Thermoplastic Elastomers. ACS Appl. Mater. Interfaces 2018, 10, 44760–44767. [Google Scholar] [CrossRef] [PubMed]

- Hauger, T.C.; Al-Rafia, S.M.I.; Buriak, J.M. Rolling Silver Nanowire Electrodes: Simultaneously Addressing Adhesion, Roughness, and Conductivity. ACS Appl. Mater. Interfaces 2013, 5, 12663–12671. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Lee, P.; Lee, H.B.; Hong, S.; Lee, I.; Yeo, J.; Lee, S.S.; Kim, T.-S.; Lee, D.; Ko, S.H. Room-Temperature Nanosoldering of a Very Long Metal Nanowire Network by Conducting-Polymer-Assisted Joining for a Flexible Touch-Panel Application. Adv. Funct. Mater. 2013, 23, 4171–4176. [Google Scholar] [CrossRef]

- Yim, J.H.; Joe, S.-Y.; Pang, C.; Lee, K.M.; Jeong, H.; Park, J.-Y.; Ahn, Y.H.; de Mello, J.C.; Lee, S. Fully Solution-Processed Semitransparent Organic Solar Cells with a Silver Nanowire Cathode and a Conducting Polymer Anode. ACS Nano 2014, 8, 2857–2863. [Google Scholar] [CrossRef] [PubMed]

- Langley, D.P.; Giusti, G.; Lagrange, M.; Collins, R.; Jiménez, C.; Bréchet, Y.; Bellet, D. Silver Nanowire Networks: Physical Properties and Potential Integration in Solar Cells. Sol. Energy Mater. Sol. Cells 2014, 125, 318–324. [Google Scholar] [CrossRef]

- Liang, J.; Li, L.; Tong, K.; Ren, Z.; Hu, W.; Niu, X.; Chen, Y.; Pei, Q. Silver Nanowire Percolation Network Soldered with Graphene Oxide at Room Temperature and Its Application for Fully Stretchable Polymer Light-Emitting Diodes. ACS Nano 2014, 8, 1590–1600. [Google Scholar] [CrossRef]

- Lian, L.; Dong, D.; Yang, S.; Wei, B.; He, G. Highly Conductive and Uniform Alginate/Silver Nanowire Composite Transparent Electrode by Room Temperature Solution Processing for Organic Light Emitting Diode. ACS Appl. Mater. Interfaces 2017, 9, 11811–11818. [Google Scholar] [CrossRef]

- Kim, D.; Ko, Y.; Kwon, G.; Kim, U.-J.; You, J. Micropatterning Silver Nanowire Networks on Cellulose Nanopaper for Transparent Paper Electronics. ACS Appl. Mater. Interfaces 2018, 10, 38517–38525. [Google Scholar] [CrossRef]

- Atwa, Y.; Maheshwari, I.A. Goldthorpe, Silver Nanowire Coated Threads for Electrically Conductive Textiles. J. Mater. Chem. C 2015, 3, 3908–3912. [Google Scholar] [CrossRef]

- Lee, J.-G.; Lee, J.-H.; An, S.; Kim, D.-Y.; Kim, T.-G.; Al-Deyab, S.S.; Yarin, A.L.; Yoon, S.S. Highly Flexible, Stretchable, Wearable, Patternable and Transparent Heaters on Complex 3D Surfaces Formed from Supersonically Sprayed Silver Nanowires. J. Mater. Chem. A 2017, 5, 6677–6685. [Google Scholar] [CrossRef]

- Hong, C.-H.; Oh, S.K.; Kim, T.K.; Cha, Y.-J.; Kwak, J.S.; Shin, J.-H.; Ju, B.-K.; Cheong, W.-S. Electron Beam Irradiated Silver Nanowires for a Highly Transparent Heater. Sci. Rep. 2015, 5, 17716. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-M.; Kim, S.H.; Lee, J.H.; Lee, S.-J.; Kim, H.-K. Hydrophobic and Stretchable Ag Nanowire Network Electrode Passivated by a Sputtered PTFE Layer for Self-Cleaning Transparent Thin Film Heaters. RSC Adv. 2018, 8, 18508–18518. [Google Scholar] [CrossRef]

- He, X.; Duan, F.; Liu, J.; Lan, Q.; Wu, J.; Yang, C.; Yang, W.; Zeng, Q.; Wang, H. Transparent Electrode Based on Silver Nanowires and Polyimide for Film Heater and Flexible Solar Cell. Materials 2017, 10, 1362. [Google Scholar] [CrossRef] [PubMed]

- Sorel, S.; Bellet, D.; Coleman, J.N. Relationship between Material Properties and Transparent Heater Performance for Both Bulk-like and Percolative Nanostructured Networks. ACS Nano 2014, 8, 4805–4814. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.; Lee, H.; Ha, I.; Cho, H.; Kim, K.K.; Kwon, J.; Won, P.; Hong, S.; Ko, S.H. Highly Stretchable and Transparent Electromagnetic Interference Shielding Film Based on Silver Nanowire Percolation Network for Wearable Electronics Applications. ACS Appl. Mater. Interfaces 2017, 9, 44609–44616. [Google Scholar] [CrossRef] [PubMed]

| Materials | ITO | TCO* | Ag NW | Graphene | CNT | Conducting Polymer | Metal Mesh | |

|---|---|---|---|---|---|---|---|---|

| Application | Flat | From Flat to Flexible | ||||||

| Player | Nitto Denko & GUNZE | Cambrios and Others | Graphene Square and Others | Eikos and Others | Heraeus | 3M | ||

| Specification | Sheet resistance (Ω/sq.) | Δ (~150) | Δ (~150) | O (~40) | Δ (~500) | Δ (~200) | Δ (>200) | O (~30) |

| Transmittance (%) | O (~90) | O (~90) | O (~90) | O (>90, monolayer) | Δ (<90) | Δ (<90) | Δ (~90) | |

| Stability** | O | O | Δ | O | <90 | O | Δ | |

| Bending stability | X | X | Δ (<5R) | O (<5R) | O (<5R) | O (<5R) | Δ (<10R) | |

| Commercialization | O | O | O | Δ | Δ | O | O | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sohn, H.; Park, C.; Oh, J.-M.; Kang, S.W.; Kim, M.-J. Silver Nanowire Networks: Mechano-Electric Properties and Applications. Materials 2019, 12, 2526. https://doi.org/10.3390/ma12162526

Sohn H, Park C, Oh J-M, Kang SW, Kim M-J. Silver Nanowire Networks: Mechano-Electric Properties and Applications. Materials. 2019; 12(16):2526. https://doi.org/10.3390/ma12162526

Chicago/Turabian StyleSohn, Hiesang, Chulhwan Park, Jong-Min Oh, Sang Wook Kang, and Mi-Jeong Kim. 2019. "Silver Nanowire Networks: Mechano-Electric Properties and Applications" Materials 12, no. 16: 2526. https://doi.org/10.3390/ma12162526