An Experimental Study of the Crystallinity of Different Density Polyethylenes on the Breakdown Characteristics and the Conductance Mechanism Transformation under High Electric Field

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Materials

2.2. Sample Preparation

2.3. DSC Test

2.4. XRD Test

2.5. Conductivity Test

3. Experiment Results and Discussion

3.1. Polyethylene Melting Characteristics

3.2. Analysis of the Crystal Structure of Different Polyethylene

3.3. DC Breakdown Strength Test

3.4. Conductivity Test

3.4.1. Conduction Current Theory

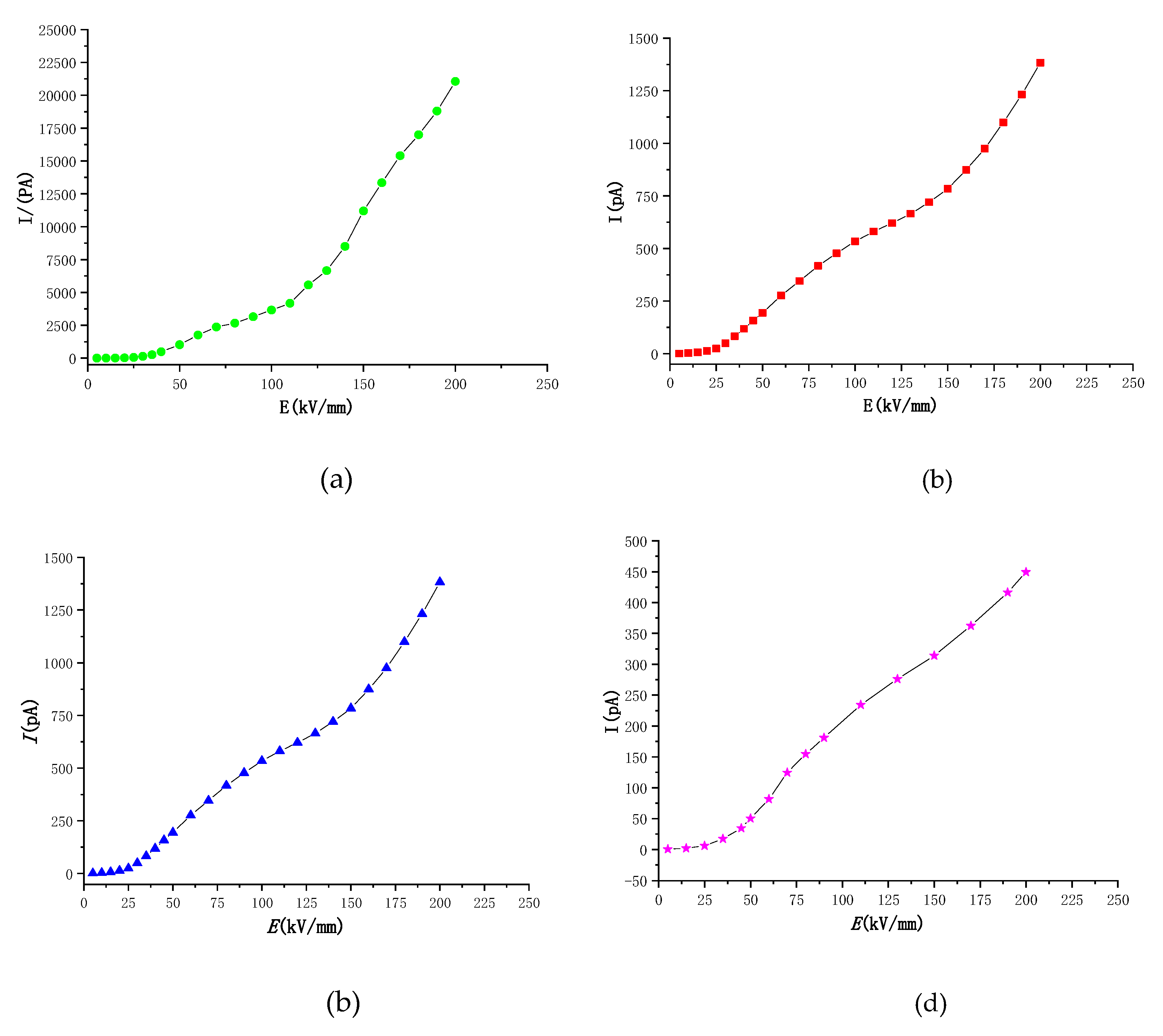

3.4.2. Test Results of Conduction Current

4. Discussion

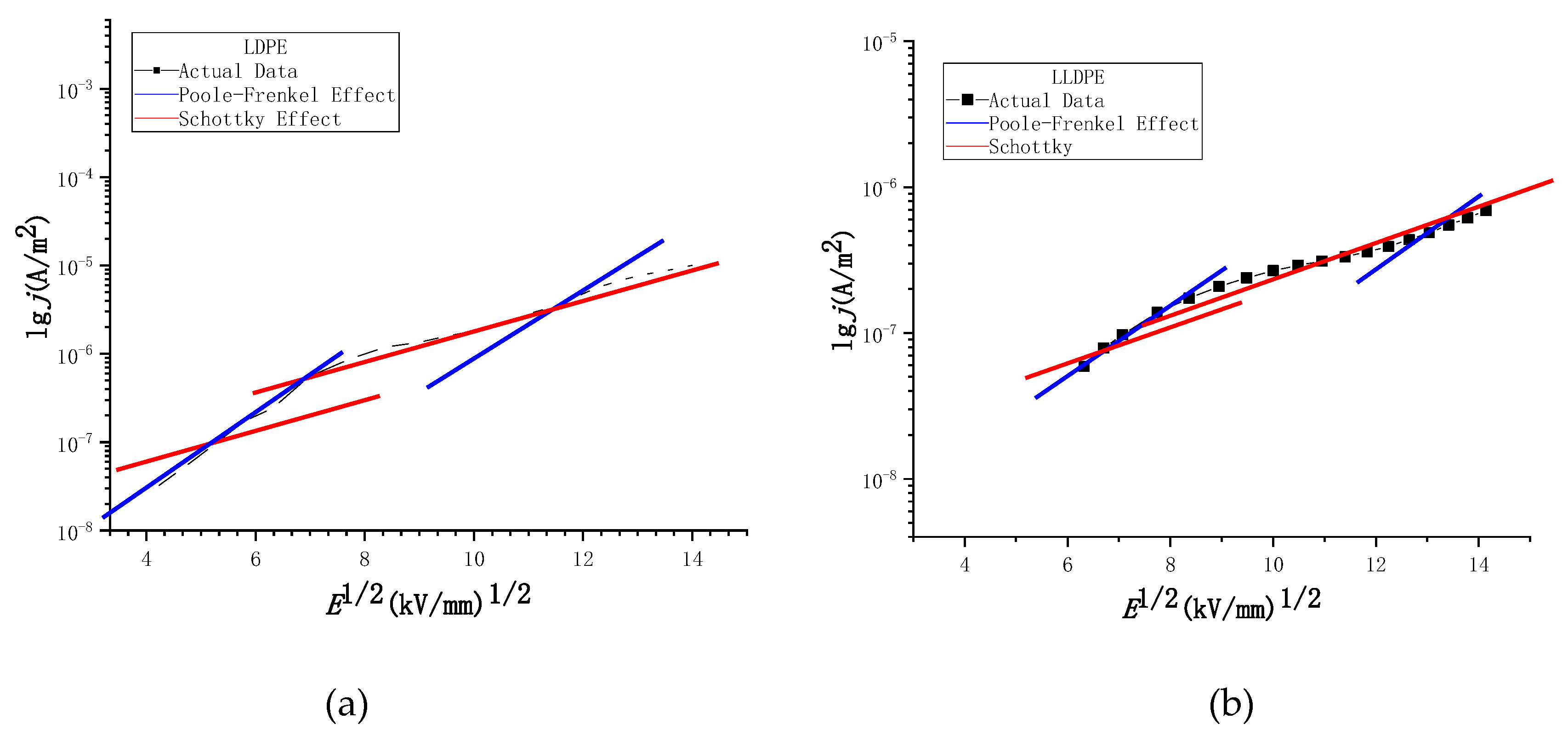

4.1. High Field Slope Change

4.2. High Field Conductance Theory

4.3. Data Segmentation Fitting Result

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ishii, R.; Cho, D.C.; Mori, T.; Mizutani, T.; Ishioka, M. Electrical Properties of Low-density Polyethylene Prepared by Different Manufacturing Process. In Proceedings of the 1999 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Austin, TX, USA, 17–20 October 1999; pp. 642–645. [Google Scholar]

- de Faria, I.P.; Martinez, M.L.B.; de Queiroz, A.A.A. Electrical Performance Evaluation of Plasticized Polyolefin Formulation Developed for Manufacturing Surge Arresters Housings. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3429–3441. [Google Scholar] [CrossRef]

- Li, T. Structural characteristics and application development of polyethylene chemical materials. Chem. Ind. 2014, 32, 20–24. [Google Scholar]

- Ye, K.Y. Study on the Influencing Factors and Mechanism of Electric Branching of XLPE Power Cables; Chongqing University: Chongqing, China, 2008. [Google Scholar]

- Wang, X.; He, H.Q.; Tu, D.M.; Lei, C.; Du, Q.G. Dielectric properties and crystalline morphology of low density polyethylene blended with metallocene catalyzed polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 319–326. [Google Scholar] [CrossRef]

- Mazzanti, G.; Montanari, G.C.; Palmieri, F. Quantities extracted from space-charge measurements as markers for insulation aging. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 198–203. [Google Scholar] [CrossRef]

- Jiong, C.; Yi, Y.; Wei, L. Study on Pre-Electrical Stress Effect of Strong Field Conductance in Nano-SiOx/Polyethylene Composite Media. CSEE 2006, 26, 146–151. [Google Scholar]

- Nagao, M.; Takamura, N.; Kurimoto, M.; Murakami, Y.; Inoue, Y.; Murata, Y. Simultaneous Measurement of Space Charge and Conduction Current on LDPE/MgO Nanocomposite. In Proceedings of the 2012 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Montreal, QC, Canada, 14–17 October 2012; pp. 311–314. [Google Scholar]

- Nath, R.; Kaura, T.; Perlman, M.M. Steady-state conduction in linear low-density polyethylene with poole-lowered trap depth. IEEE Trans. Electr. Insul. 1980, 25, 419–425. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Wang, N.H.; Yan, P.; Liang, X.D.; Guan, Z.C. Annealing effect on DC conduction in polyethylene films. J. Electrost. 2003, 57, 381–388. [Google Scholar] [CrossRef]

- Chen, J.; Yin, Y.; Li, Z.; Xiao, D. The Study on High Field Conduction in the Composites of Low-Density-Polyethylene Nano-SiOx; Electric Wire & Cable: Washington, MA, USA, 2009. [Google Scholar]

- Yang, J.M.; Wang, X.; Zheng, C.J.; Zhao, H.; Lei, Q.Q. DC conduction properties of Si02/LDPE nanocomposite. In Proceedings of the 10th IEEE International Conference on Properties and Applications of Dielectric Materials, Bangalore, India, 24–28 July 2012; pp. 1–4. [Google Scholar]

- Chen, J.; Yin, Y.; Li, Z.; Xiao, D. Electrical prestressing of high-electric-field conduction in composite of low-density polyethylene/nano-SiOx. Jpn. J. Appl. Phys. 2005, 44, 940–947. [Google Scholar] [CrossRef]

- Li, C.M.; Guo, W.M.; Han, B.Z.; Li, Z.H. The electrical pre-stress effect on field dependent conductivity of the polyethylene and carborundum composite. In Proceedings of the 8th IEEE International Conference on Properties and Applications of Dielectric Materials, Bali, Indonesia, 26–30 June 2006; pp. 751–754. [Google Scholar]

- Park, Y.J.; Kwon, J.H.; Sim, J.Y.; Hwang, J.N.; Seo, C.W.; Kim, J.H.; Lim, K.J. DC conduction and breakdown characteristics of Al2O3/cross-linked polyethylene nanocomposites for high voltage direct current transmission cable insulation. Jpn. J. Appl. Phys. 2014, 53, 08NL05. [Google Scholar] [CrossRef]

- Takada, T.; Hayase, Y.; Tanaka, Y. Space charge trapping in electrical potential well caused by permanent and induced dipoles for LDPE/MgO nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 152–160. [Google Scholar] [CrossRef]

- Murakami, Y.; Nemoto, M.; Okuzumi, S.; Masuda, S.; Nagao, M.; Hozumi, N.; Murata, Y. DC conduction and electrical breakdown of MgO/LDPE nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 33–39. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, L.; Sha, Y.; Tian, J. Numerical analysis of space charge characteristics in low-density polyethylene nanocomposite under external DC electric field. High Volt. Eng. 2013, 39, 1813–1820. [Google Scholar]

- Lv, Z.; Wang, X.; Wu, K.; Chen, X.; Cheng, Y.; Dissado, L.A. The dependence of charge accumulation on sample thickness in nano-SiO2 doped LDPE. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 337–345. [Google Scholar]

- Wang, X.; Lv, Z.; Wu, K.; Chen, X.; Tu, D.; Dissado, L.A. Study of the factors that suppress space charge accumulation in LDPE nano-composites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 670–1679. [Google Scholar] [CrossRef]

- Kao, K.C. Dielectric Phenomena in Solids; Elsevier Academic Press: Amsterdam, The Netherlands, 2004; pp. 460–462. [Google Scholar]

- Ahmed, T.; Mamat, O. The Development and Characterization of HDPE-silica Sand Nanoparticles Composites. In Proceedings of the 2011 IEEE Colloquium on Humanities, Science and Engineering, Penang, Malaysia, 5–6 December 2011; pp. 6–11. [Google Scholar]

- Alapati, S.; Meledath, J.T.; Karmarkar, A. Effect of Morphology on Electrical Treeing in Low Density Polyethylene Nanocomposites. IET Sci. Meas. Technol. 2014, 8, 60–68. [Google Scholar] [CrossRef]

- Lisheng, Z. Engineering Dielectric Physics and Dielectric Phenomena; Xi’an Jiaotong University Press: Xi’an, China, 2013; pp. 167–168. [Google Scholar]

- Guanzhi, G.; Wei, H. Electrical Transport in Solids; Science Press: Beijing, China, 1991; pp. 57–67. [Google Scholar]

- Jidan, C.; Ziyu, L. Dielectric Physics; China Machine Press: Beijing, China, 1982; pp. 193–234. [Google Scholar]

- LI, C.J.; Yang, J.; Chen, J. Study on DC dielectric properties of different density polyethylenes. Insul. Mater. 2017, 50, 35–38. [Google Scholar]

- Bambery, K.R.; Fleming, R.J.; Holboll, J.T. Space charge profiles in low density polyethylene samples containing a permittivity/ conductivity gradient. J. Phys. 2001, 34, 3071–3077. [Google Scholar] [CrossRef]

- Nuriziani, H.; George, C. Analysis of space charge formation in LDPE in the presence of crosslinking byproducts. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 126–133. [Google Scholar]

- Lisheng, Z.; Shengtao, L.; Chuanxiang, X. Engineering Dielectric Physics and Dielectric Phenomena; Xi’an Jiaotong University Press: Xi’an, China, 2013; pp. 138–157. [Google Scholar]

- Montanari, G.C.; Mazzanti, G.; Palmieri, F.; Motori, A.; Perego, G.; Serra, S. Spacecharge trapping and conduction in LDPE, HDPE and XLPE. J. Phys. Appl. Phys. 2001, 34, 2002. [Google Scholar] [CrossRef]

- Montanari, G.C. The electrical degradation threshold of polyethylene investigated by space charge and conduction current measure. IEEE Trans. Dielectr. Electr. Insul. 2000, 7, 309–315. [Google Scholar] [CrossRef]

- Khalil, M.S.; Henriksen, M.; Henk, P.O. Electrical conduction in plain polyethylene and polyethylene doped with an inorganic additive. In Proceedings of the Annual Report IEEE Conference on Electrical Insulation and Dielectric Phenomena, Knoxville, TN, USA, 20–23 October 1991; pp. 169–175. [Google Scholar]

- Mizutani, T.; Ieda, M. Electrical conduction in solid dielectrics. IEEE Trans. Electr. Insul. 1986, 6, 833–839. [Google Scholar] [CrossRef]

| Sample | Tm (°C) | Tc (°C) | ΔHm (J/g) | (Xc) % |

|---|---|---|---|---|

| LDPE | 108 | 94 | 113.5 | 38.73 |

| LLDPE | 121 | 107 | 115.6 | 39.45 |

| MDPE | 124 | 113 | 141.7 | 48.36 |

| HDPE | 125 | 113 | 149.9 | 51.17 |

| Material | Shape Parameter | Characteristic Breakdown Strength (kV/mm) |

|---|---|---|

| LDPE | 7.791 | 328.0 |

| LLDPE | 5.277 | 377.3 |

| MDPE | 6.654 | 421.7 |

| HDPE | 9.577 | 452.6 |

| Different Areas | T1 | T2 | T3 |

|---|---|---|---|

| LDPE | 1.16 | 3.94 | 2.13 |

| LLDPE | 1.42 | 2.93 | 1.23 |

| MDPE | 1.36 | 2.89 | 0.89 |

| HDPE | 1.15 | 2.83 | 1.12 |

| The Turning Point | LDPE | LLDPE | MDPE | HDPE |

|---|---|---|---|---|

| A | 12.76 kV/mm | 13.33 kV/mm | 15.68 kV/mm | 18.37 kV/mm |

| B | 50.88 kV/mm | 53.61 kV/mm | 65.34 kV/mm | 71.89 kV/mm |

| Temperature/(°C) | Threshold Field Strength of LDPE/(kV/mm) | Threshold Field Strength of LLDPE/(kV/mm) | Threshold Field Strength of MDPE/(kV/mm) | Threshold Field Strength of HDPE/(kV/mm) |

|---|---|---|---|---|

| 25 | 44.89 | 54.76 | 72.25 | 77.44 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Wang, X.; Zhang, Y.; Zhang, P.; Li, Z. An Experimental Study of the Crystallinity of Different Density Polyethylenes on the Breakdown Characteristics and the Conductance Mechanism Transformation under High Electric Field. Materials 2019, 12, 2657. https://doi.org/10.3390/ma12172657

Zhou L, Wang X, Zhang Y, Zhang P, Li Z. An Experimental Study of the Crystallinity of Different Density Polyethylenes on the Breakdown Characteristics and the Conductance Mechanism Transformation under High Electric Field. Materials. 2019; 12(17):2657. https://doi.org/10.3390/ma12172657

Chicago/Turabian StyleZhou, Liwei, Xuan Wang, Yongqi Zhang, Peng Zhang, and Zhi Li. 2019. "An Experimental Study of the Crystallinity of Different Density Polyethylenes on the Breakdown Characteristics and the Conductance Mechanism Transformation under High Electric Field" Materials 12, no. 17: 2657. https://doi.org/10.3390/ma12172657

APA StyleZhou, L., Wang, X., Zhang, Y., Zhang, P., & Li, Z. (2019). An Experimental Study of the Crystallinity of Different Density Polyethylenes on the Breakdown Characteristics and the Conductance Mechanism Transformation under High Electric Field. Materials, 12(17), 2657. https://doi.org/10.3390/ma12172657