Design Method for Constant Force Components Based on Superelastic SMA

Abstract

:1. Introduction

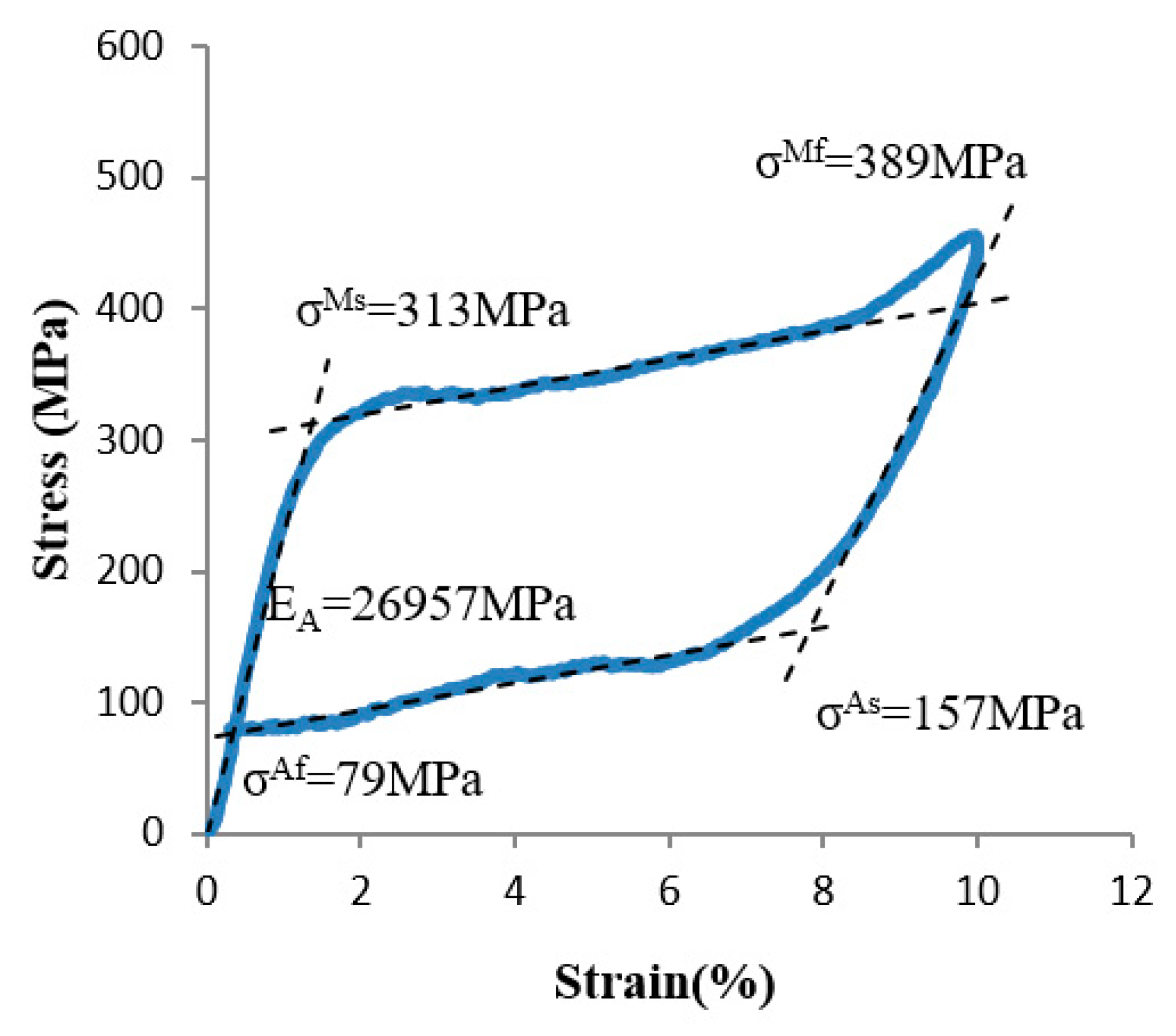

2. Materials and Method

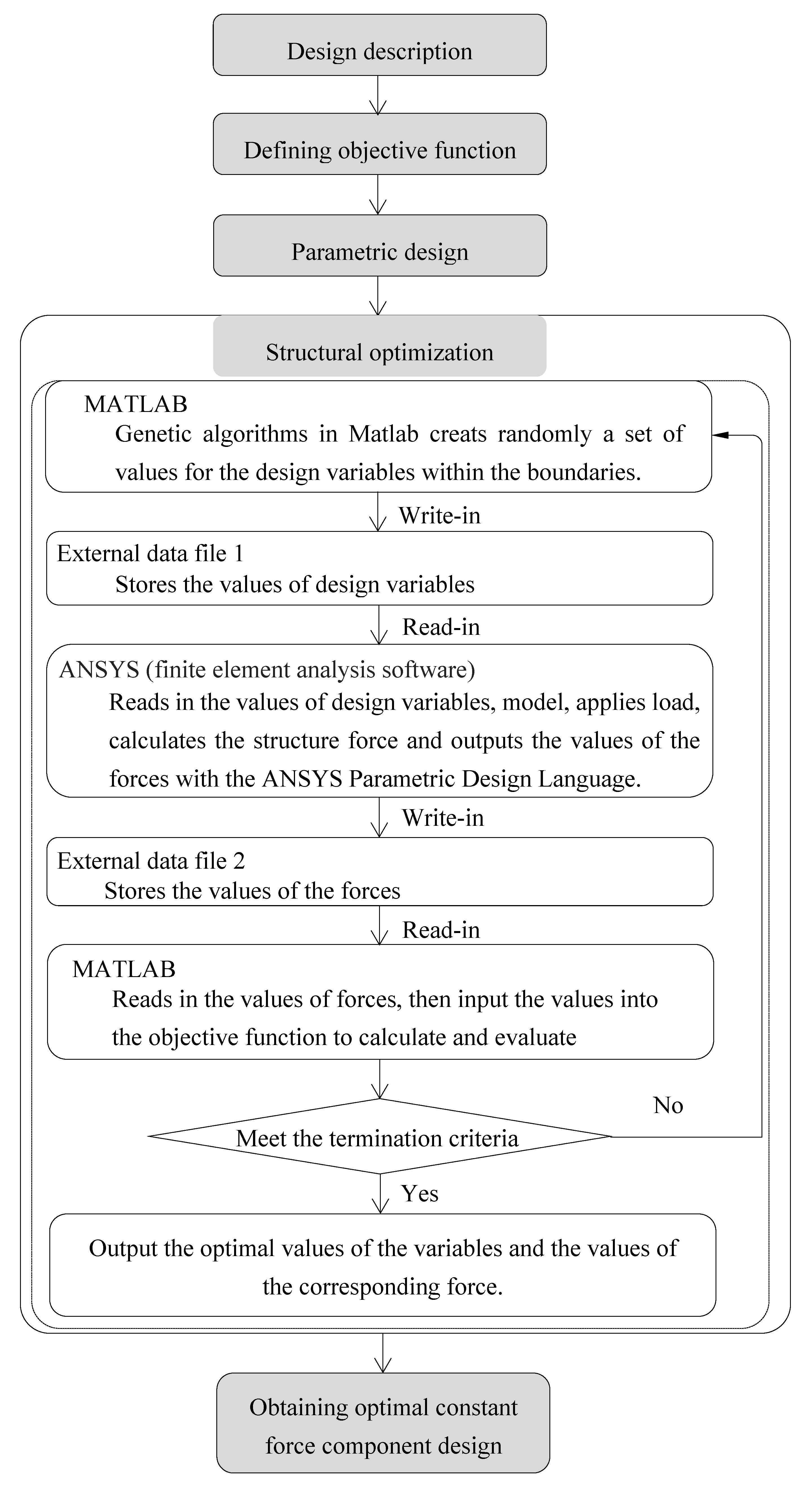

2.1. The Generalized Design Method for Generating Constant Force Components

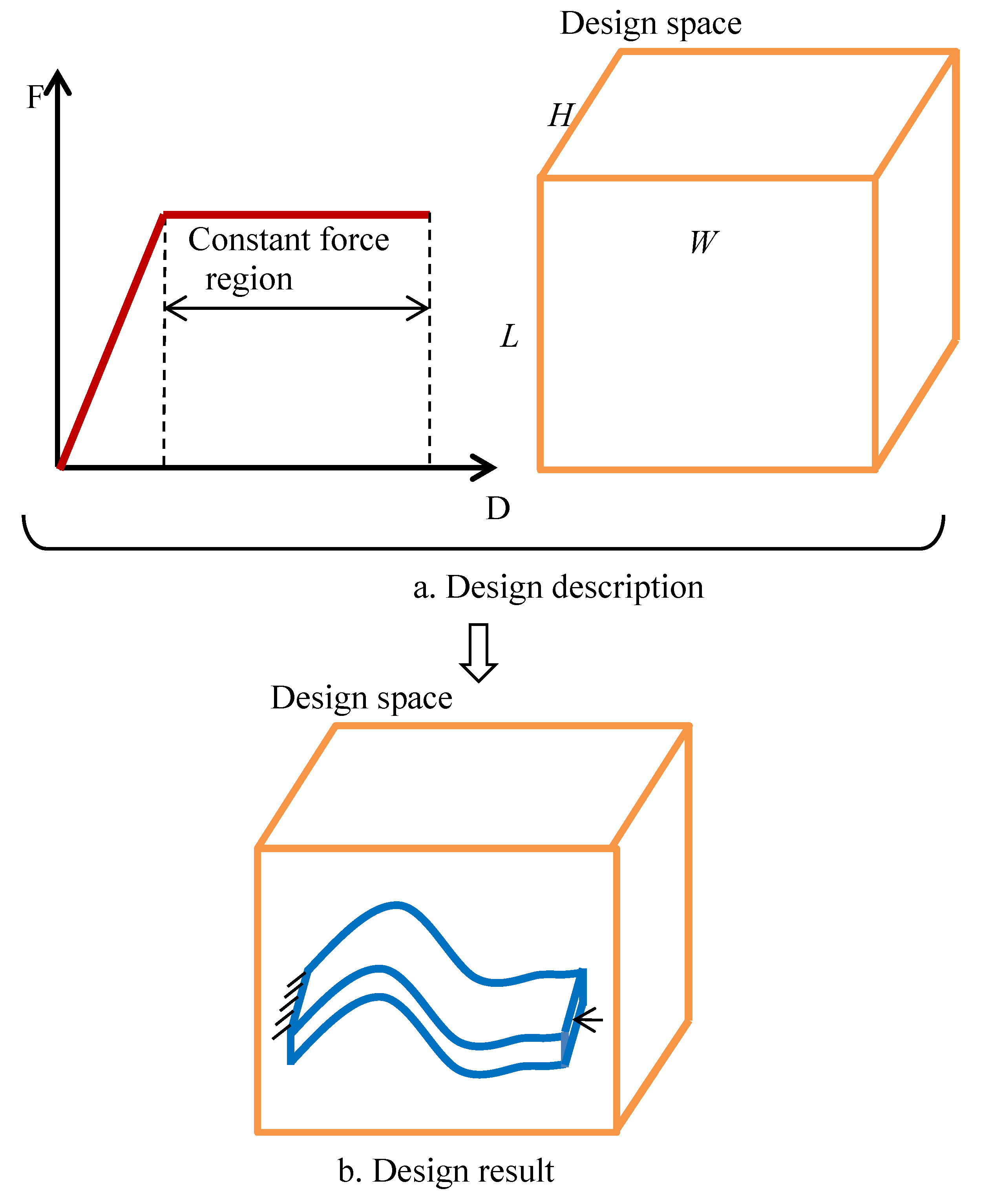

2.1.1. Design Description

2.1.2. Defining Objective Function of Constant Force Component

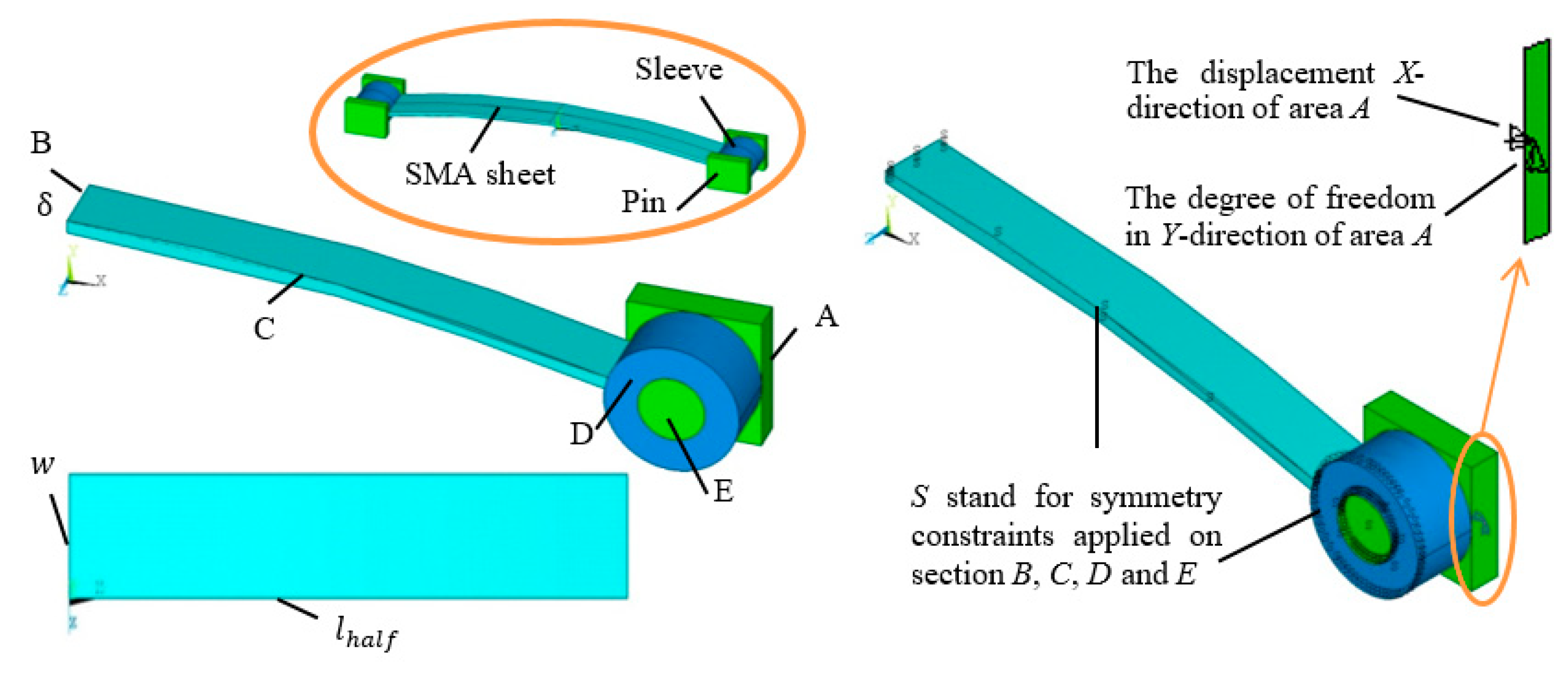

2.1.3. Parametric Design

2.1.4. The Method of Structural Optimization

2.2. An Example for Generating Constant Force Components Using the Generalized Design Method

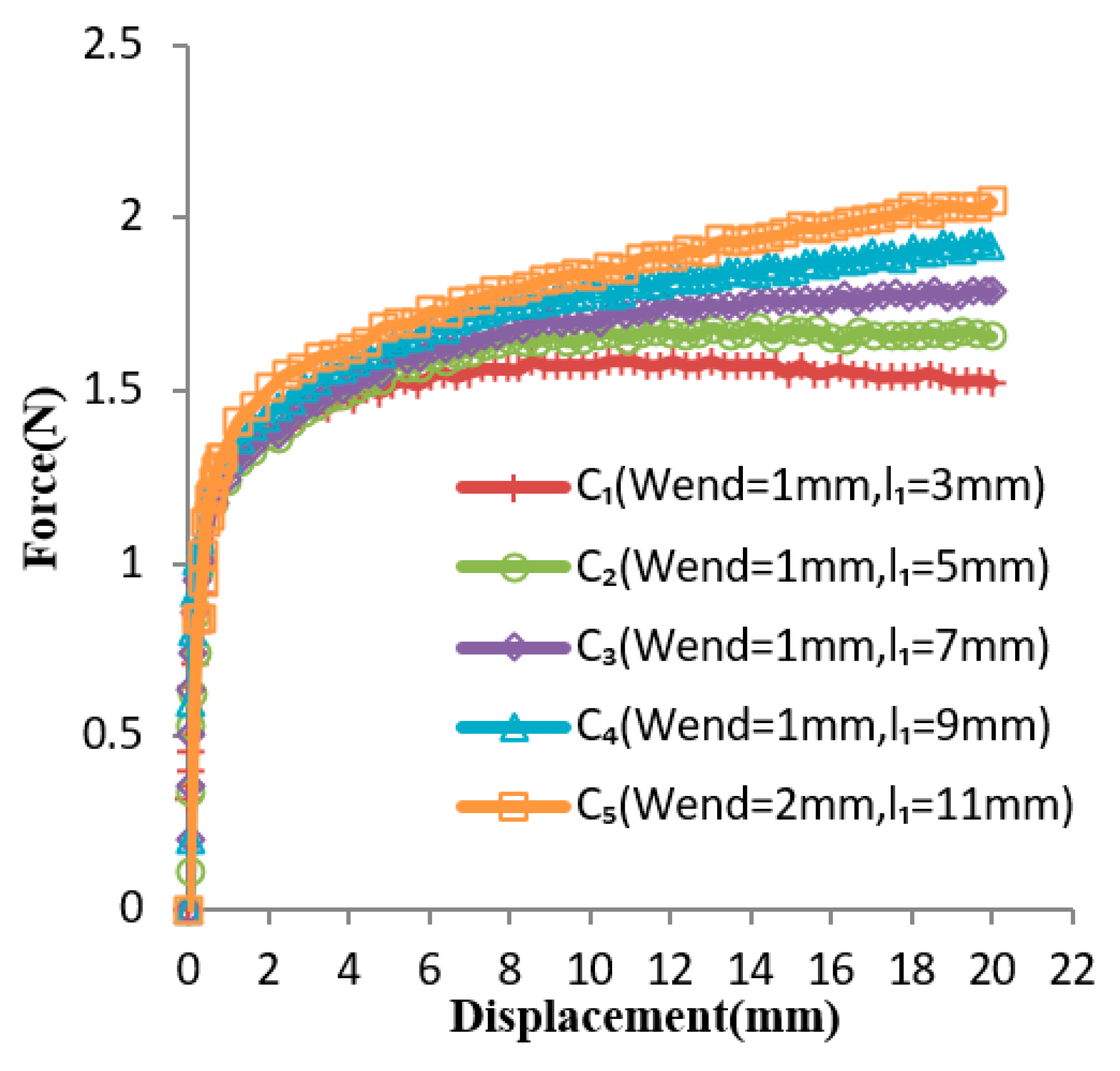

- Case 1: The width, w, is set to be 1 mm, is defined as the design variable, and its lower and upper bounds are 4 and 15, as shown in Figure 5.

- Case 2: The value of is set to be 11 mm—namely, the C-shaped curve equation of the SMA sheet is fixed as y = (−1/121) x2+ 1. The width at the middle of sheet wmid is set to be 2 mm, and wend and l1 are as the design variables. The section width of the sheet is changed linearly along its longitudinal direction, as shown in Figure 6.

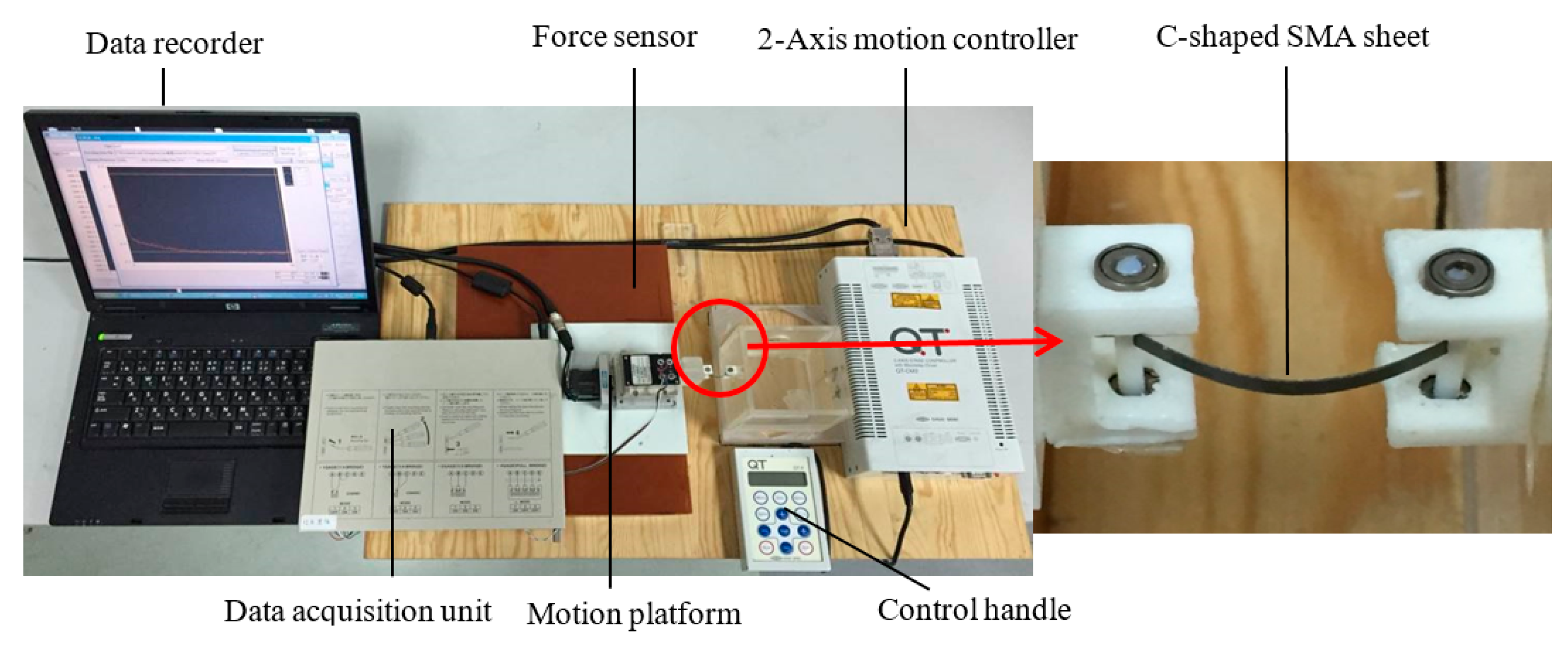

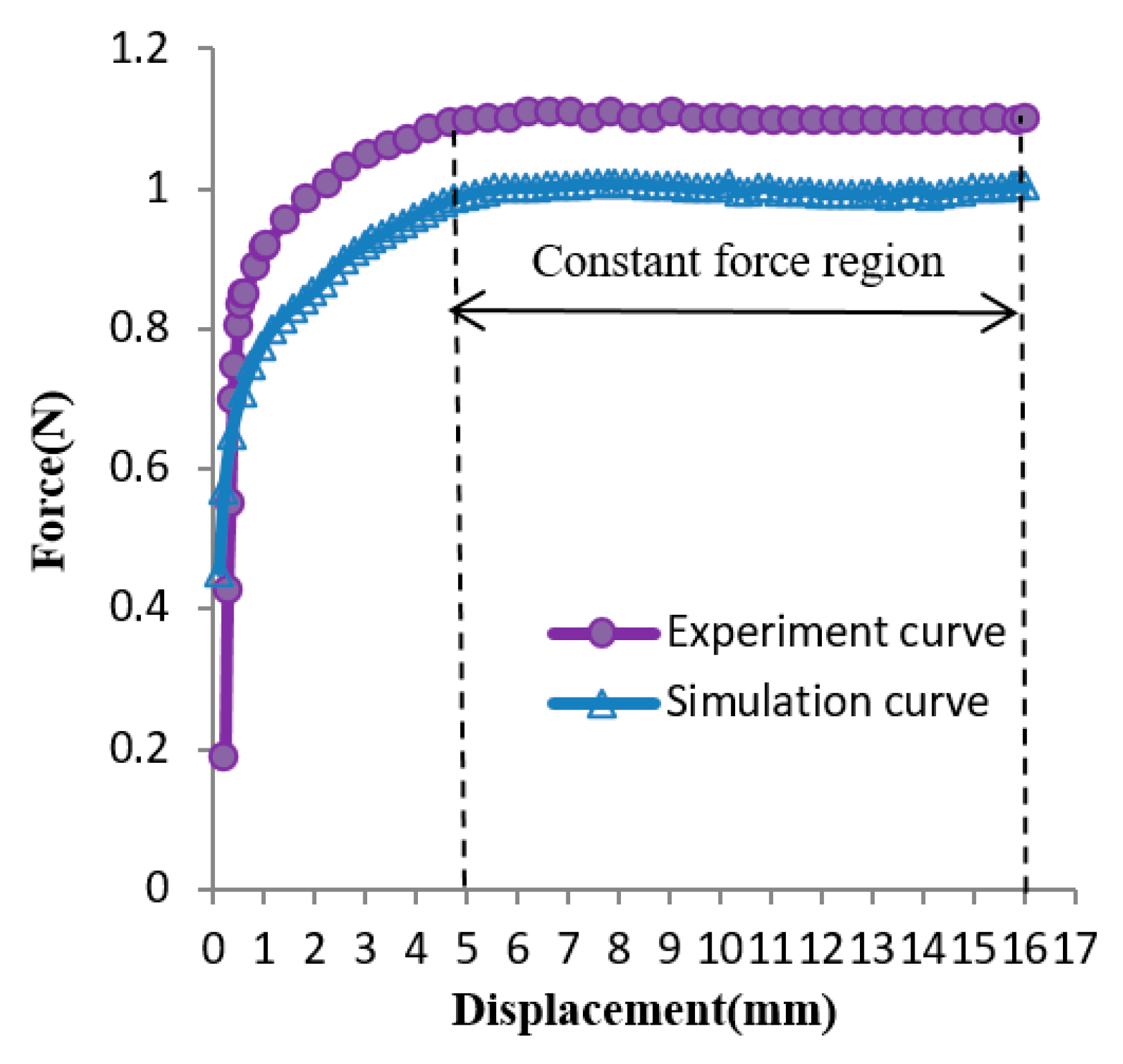

2.3. The Experiment Verification for the Generalized Design Method

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yoshikai, M.; Itoh, T.; Kamohara, K.; Yunoki, J.; Fumoto, H. Intimal injury of ultrasonically skeletonized internal thoracic artery by a vessel clamp: Morphological analysis. Interact. Cardiovasc. Thorac. Surg. 2007, 6, 331–334. [Google Scholar] [CrossRef] [PubMed]

- Harvey, J.G.; Gough, M.H. A comparison of the traumatic effects of vascular clamps. Br. J. Surg. 2010, 68, 267–272. [Google Scholar] [CrossRef] [PubMed]

- Slayback, J.B.; Bowen, W.W.; Hinshaw, D.B. Intimal injury from arterial clamps. Am. J. Surg. 1976, 132, 183–188. [Google Scholar] [CrossRef]

- Hajivassiliou, C. A review of the complications and results of implantation of the AMS artificial urinary sphincter. Eur. Urol. 1999, 35, 36–44. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Lu, J.; Li, X. Study of a pneumatic constant force tracking system. In Proceedings of the International Conference on Electronic & Mechanical Engineering & Information Technology, Harbin, China, 12–14 August 2011. [Google Scholar]

- Bing, L.; Li, G.; Lin, W.; Peng, X. Design and constant force control of a parallel polishing machine. In Proceedings of the IEEE International Conference on Information Science & Technology, Shenzhen, China, 26–28 April 2014. [Google Scholar]

- Huang, H.; Dong, S.; Hao, S.; Mills, J.K. Force Sensing and Control in Robot-Assisted Suspended Cell Injection System. In Advances in Robotics and Virtual Reality; Springer: Berlin/Heidelberg, Germany, 2012; pp. 61–88. [Google Scholar]

- Wahl, A. Mechanical Springs; McGAW-HILL: New York, NY, USA, 1963. [Google Scholar]

- Nathan, R. A constant force generation mechanism. J. Mech. Transm. Autom. Des. 1985, 107, 508–512. [Google Scholar] [CrossRef]

- Liu, Y.; Li, D.J.; Yu, D.P.; Miao, J.G.; Yao, J. Design of a curved surface constant force mechanism. JSM 2017, 45, 13. [Google Scholar] [CrossRef]

- Chao-Chieh, L.; Jhe-Hong, W.; Yi-Ho, C. A compliant constant-force mechanism for adaptive robot end-effector operations. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation (ICRA), Anchorage, Alaska, USA, 3–7 May 2010; pp. 2131–2136. [Google Scholar]

- Weight, B.L. Development and Design of Constant-Force Mechanisms; Brigham Young University: Provo, UT, USA, 2002. [Google Scholar]

- Weight, B.L.; Mattson, C.A.; Magleby, S.P.; Howell, L.L. Configuration selection, modeling, and preliminary testing in support of constant force electrical connectors. J. Electron. Packag. 2007, 129, 236–246. [Google Scholar] [CrossRef]

- Mohd Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Morgan, N.B. Medical shape memory alloy applications—The market and its products. Mater. Sci. Eng. A 2004, 378, 16–23. [Google Scholar] [CrossRef]

- Auricchio, F. Shape-memory alloys: Modelling and numerical simulations of the finite-strain superelastic behavior. Comput. Methods Appl. Mech. Eng. 1997, 143, 175–194. [Google Scholar] [CrossRef]

- Auricchio, F. A robust integration-algorithm for a finite-strain shape-memory-alloy superelastic model. Int. J. Plast. 2001, 17, 971–990. [Google Scholar] [CrossRef]

- Attanasi, G.; Auricchio, F.; Urbano, M. Theoretical and Experimental Investigation on SMA Superelastic Springs. J. Mater. Eng. Perform. 2011, 20, 706–711. [Google Scholar] [CrossRef]

- Auricchio, F.; Scalet, G.; Urbano, M. A Numerical/Experimental Study of Nitinol Actuator Springs. J. Mater. Eng. Perform. 2014, 23, 2420–2428. [Google Scholar] [CrossRef]

- Troisfontaine, N.; Bidaud, P. Optimal design of micro-actuators based on SMA wires. Smart Mater. Struct. 1999, 8, 197. [Google Scholar] [CrossRef]

- Konh, B.; Honarvar, M.; Hutapea, P. Design optimization study of a shape memory alloy active needle for biomedical applications. Med. Eng. Phys. 2015, 37, 469–477. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Yu, H.; Liu, B.; Zhu, L.; Luo, Y. Design Optimization of C-Shaped Superelastic SMA Sheet with Constant Force. J. Mech. Med. Biol. 2018, 18, 1750064. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Yu, H.; Shi, P.; Meng, Q. Design Method for Constant Force Components Based on Superelastic SMA. Materials 2019, 12, 2842. https://doi.org/10.3390/ma12182842

Wang M, Yu H, Shi P, Meng Q. Design Method for Constant Force Components Based on Superelastic SMA. Materials. 2019; 12(18):2842. https://doi.org/10.3390/ma12182842

Chicago/Turabian StyleWang, Minghui, Hongliu Yu, Ping Shi, and Qiaoling Meng. 2019. "Design Method for Constant Force Components Based on Superelastic SMA" Materials 12, no. 18: 2842. https://doi.org/10.3390/ma12182842