Effect of Location, Clone, and Measurement Season on the Propagation Velocity of Poplar Trees Using the Akaike Information Criterion for Arrival Time Determination

Abstract

:1. Introduction

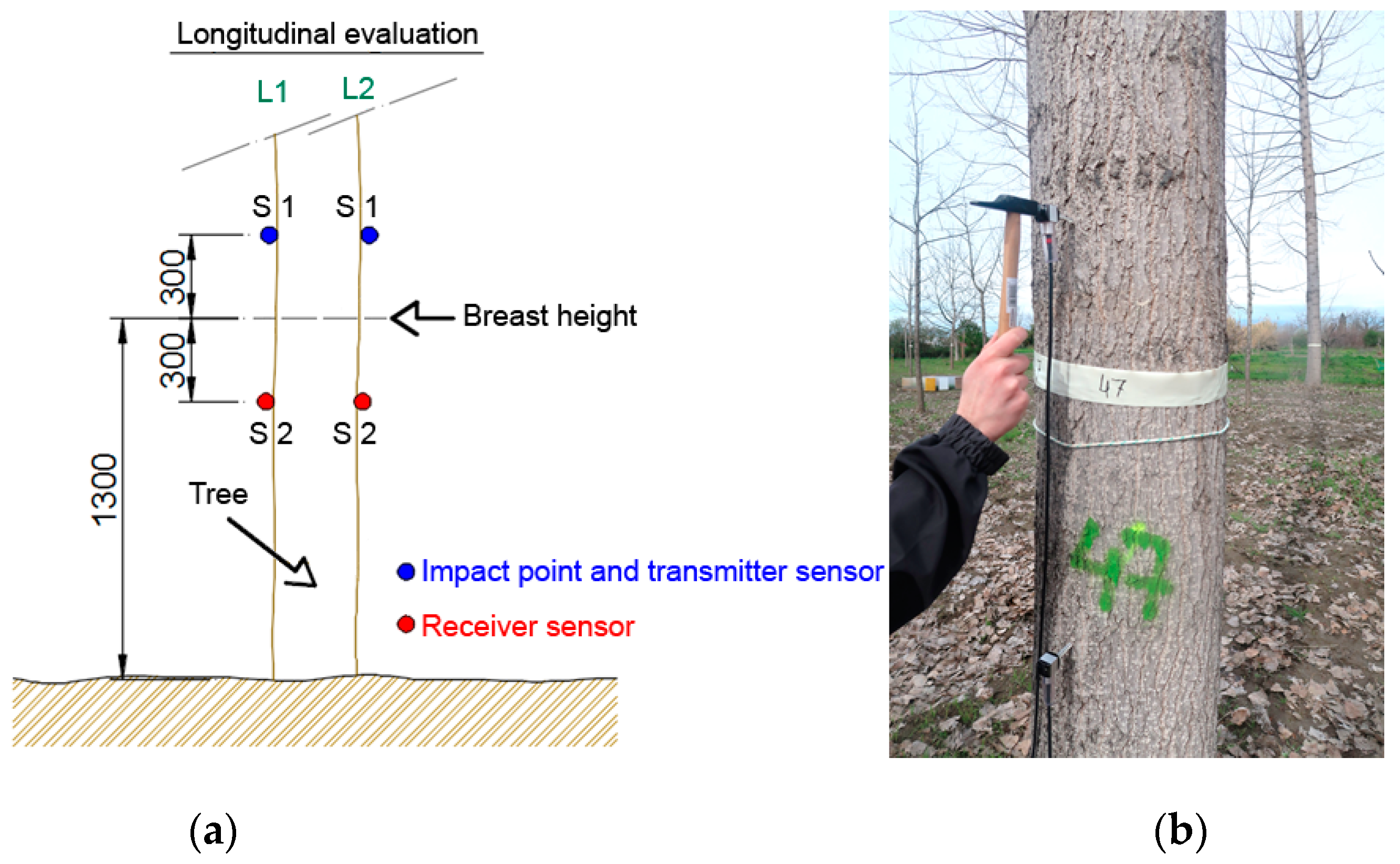

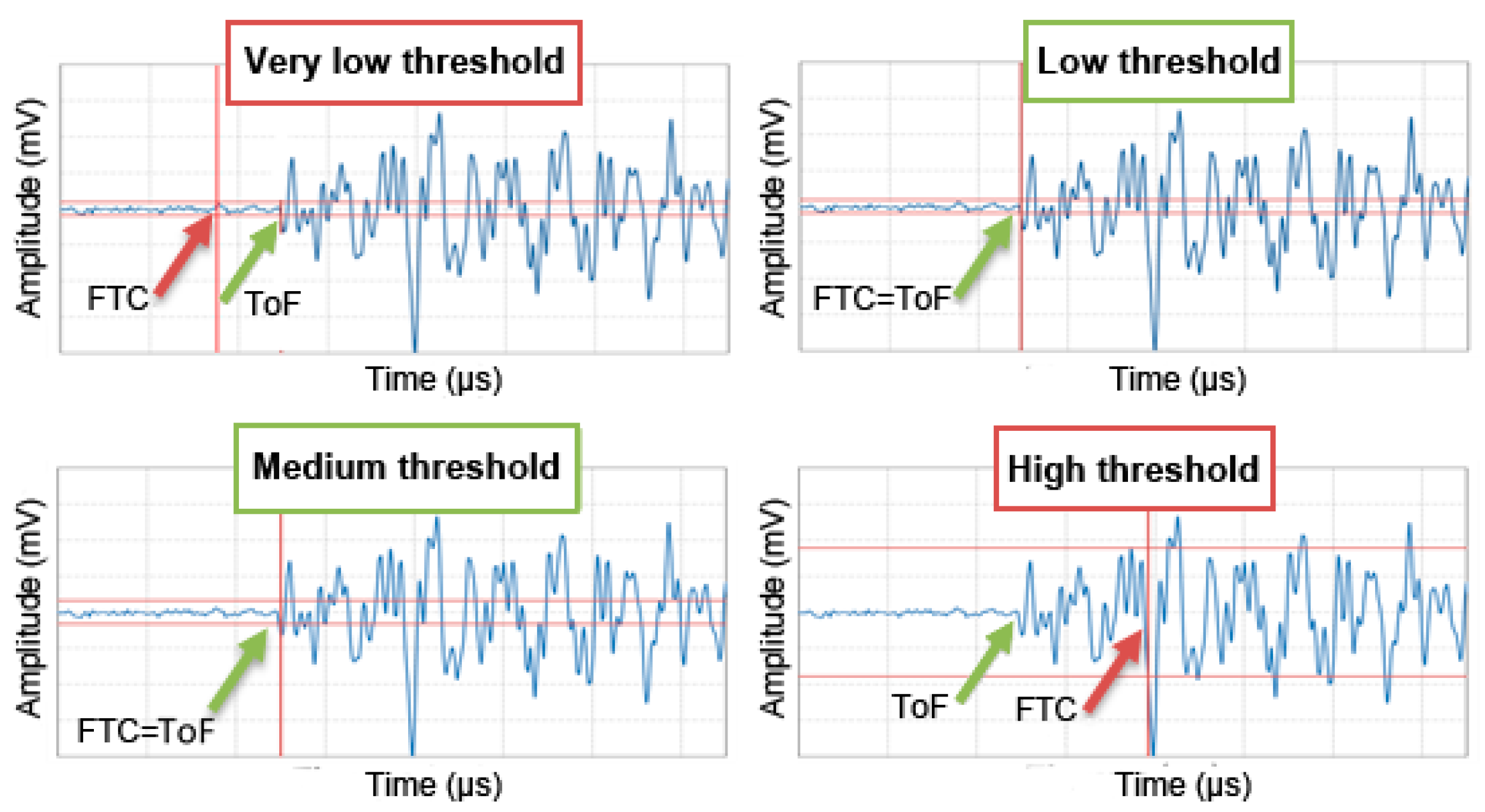

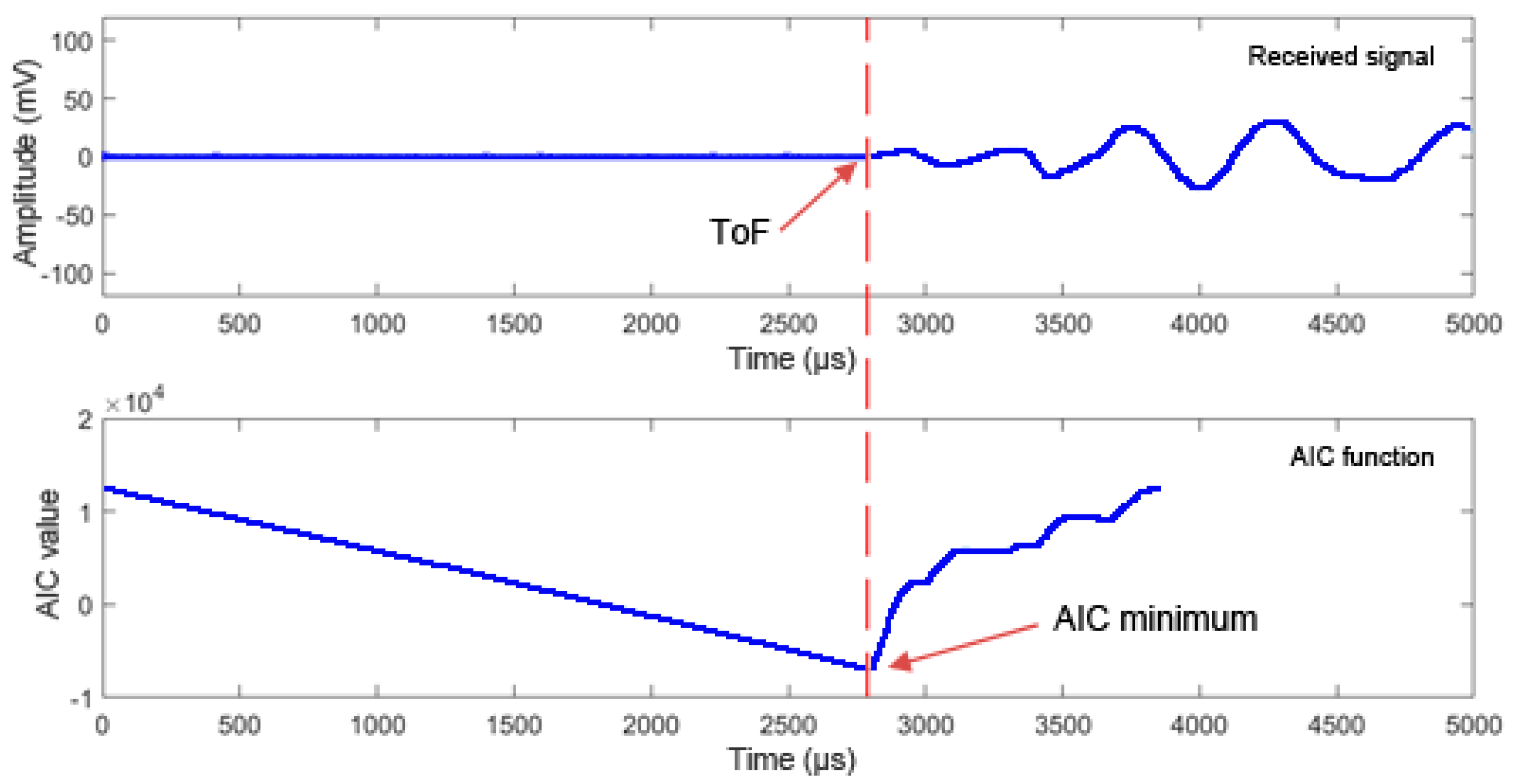

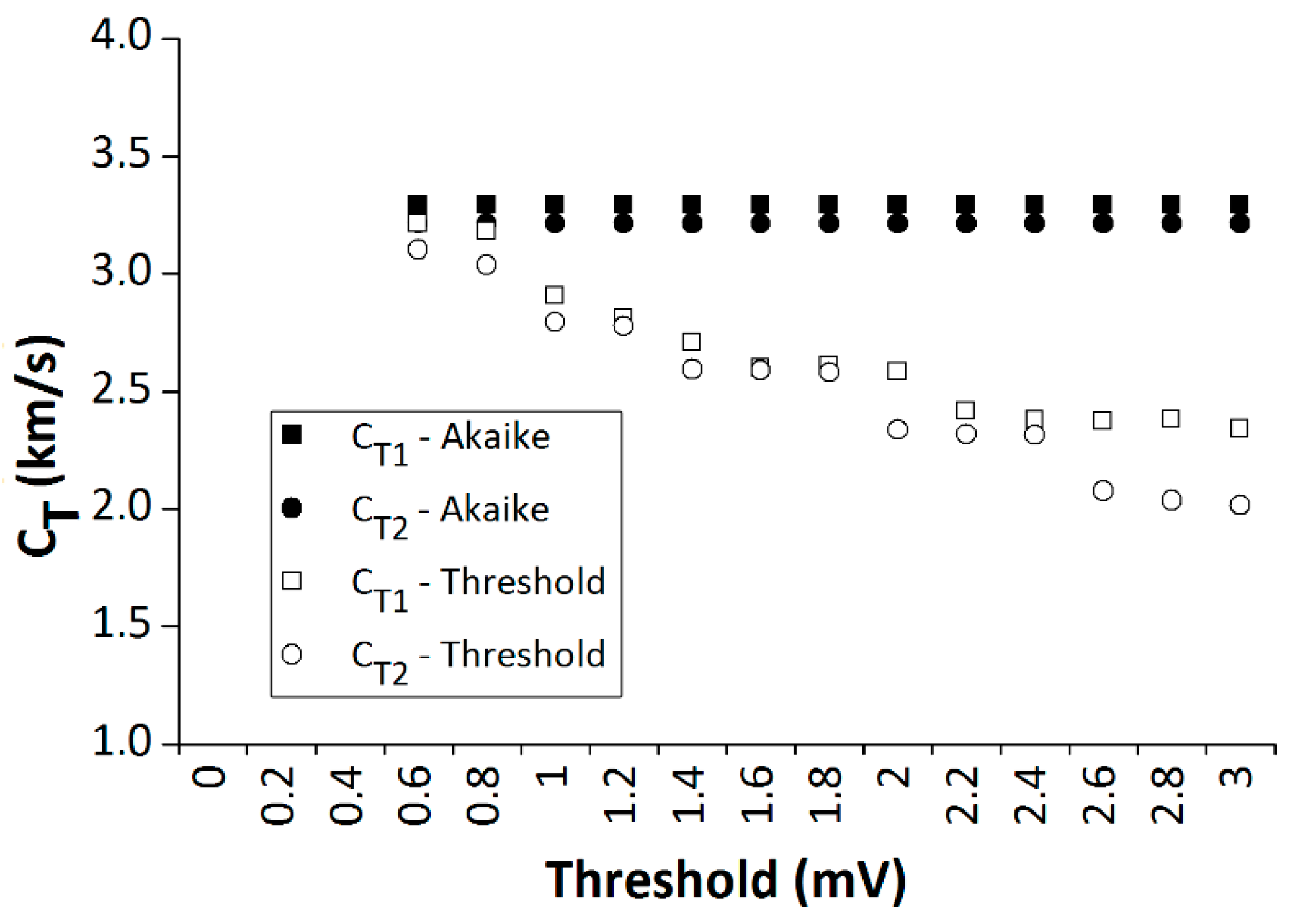

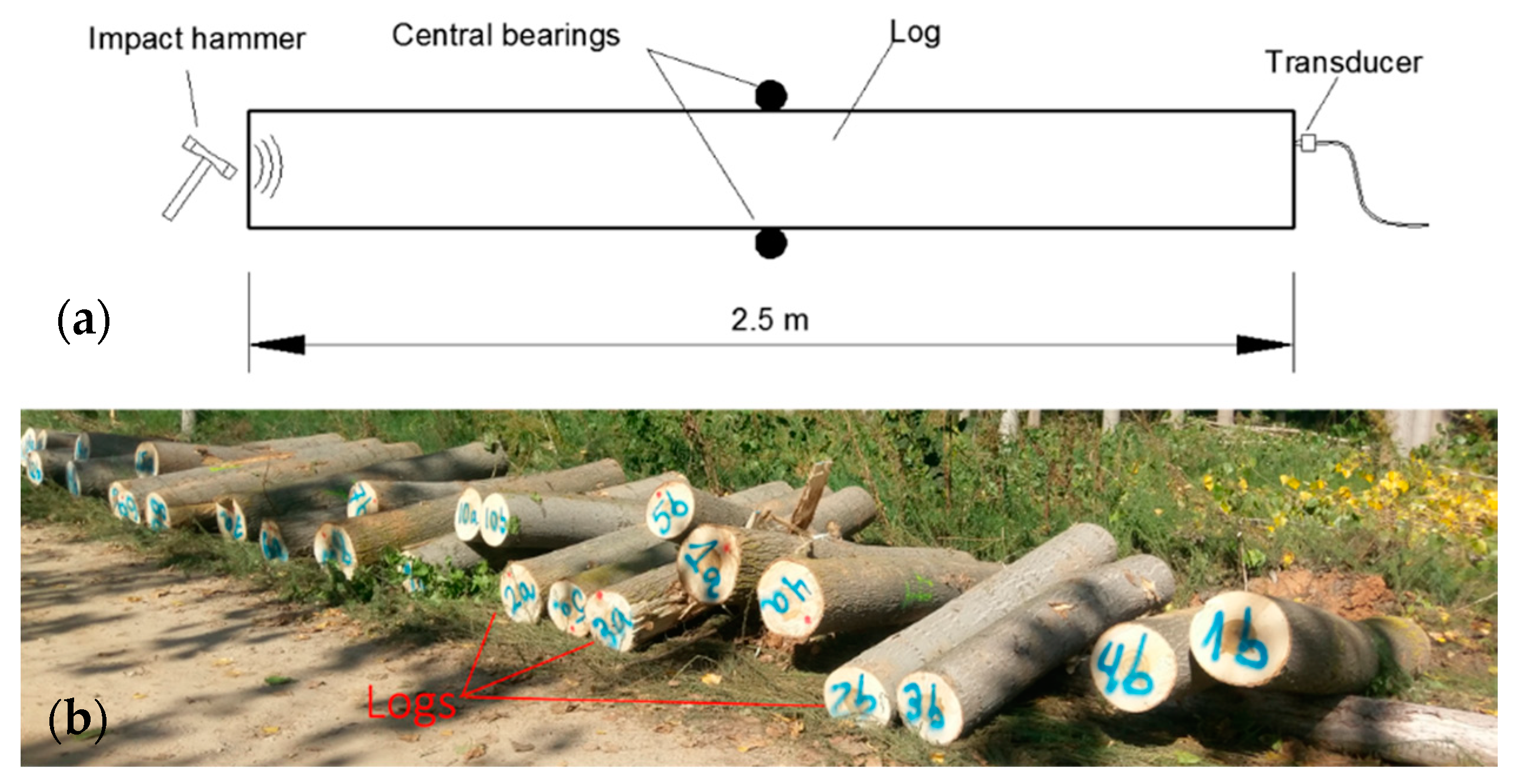

2. Methods and Materials

3. Results and Discussion

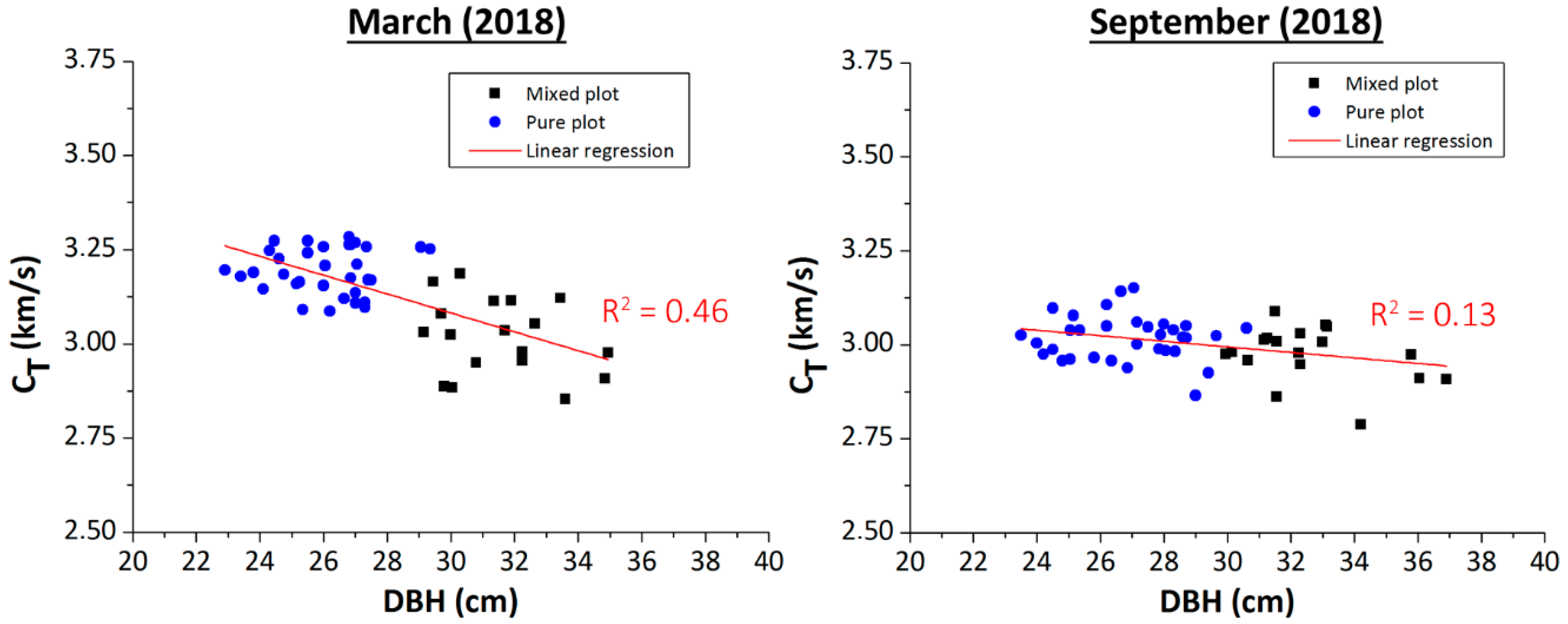

3.1. Plantation 1: Influence of the Measurement Season and Type of Crop (Pure and Mix Crop)

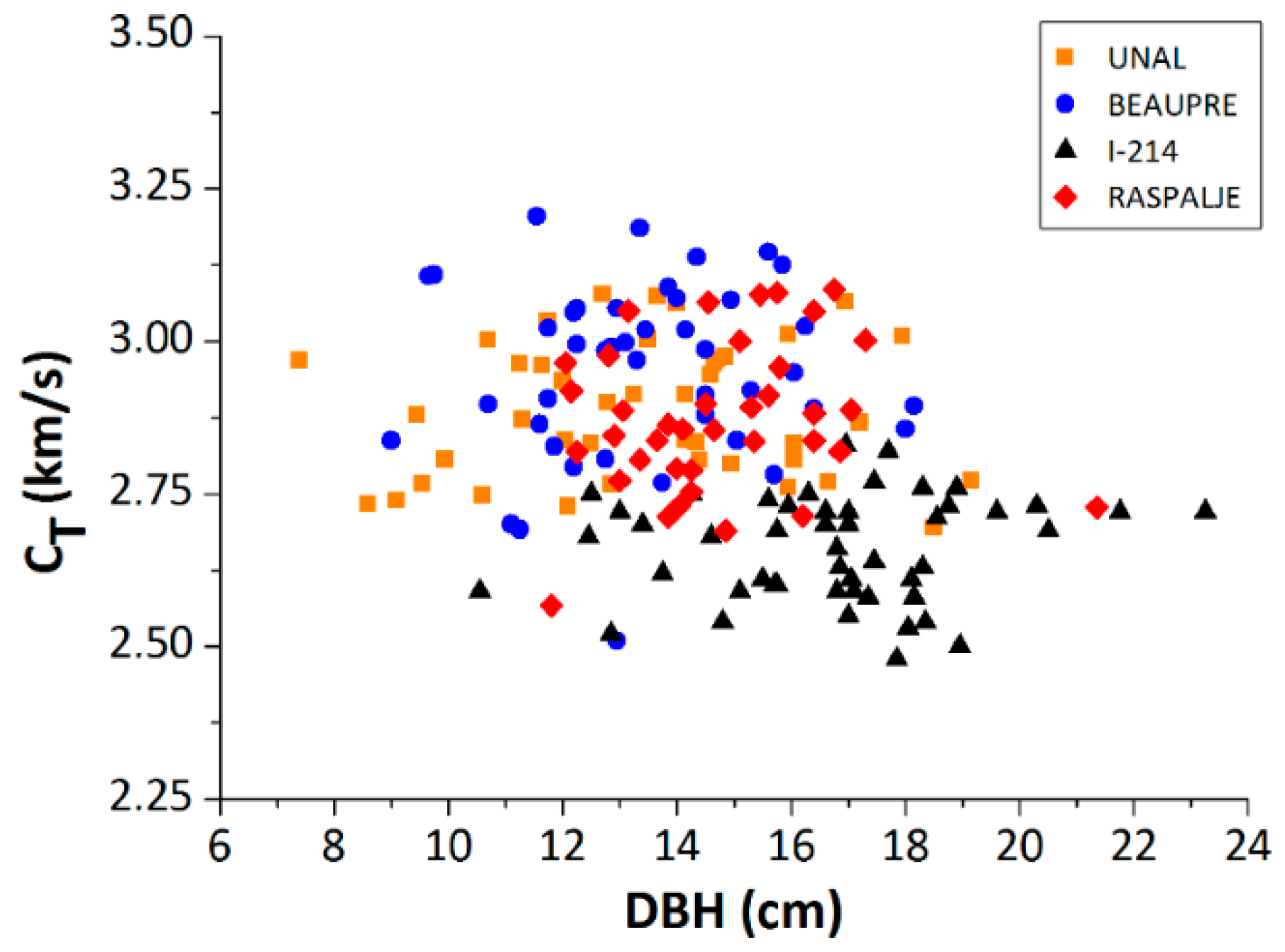

3.2. Plantation 2: Effect of the Clone

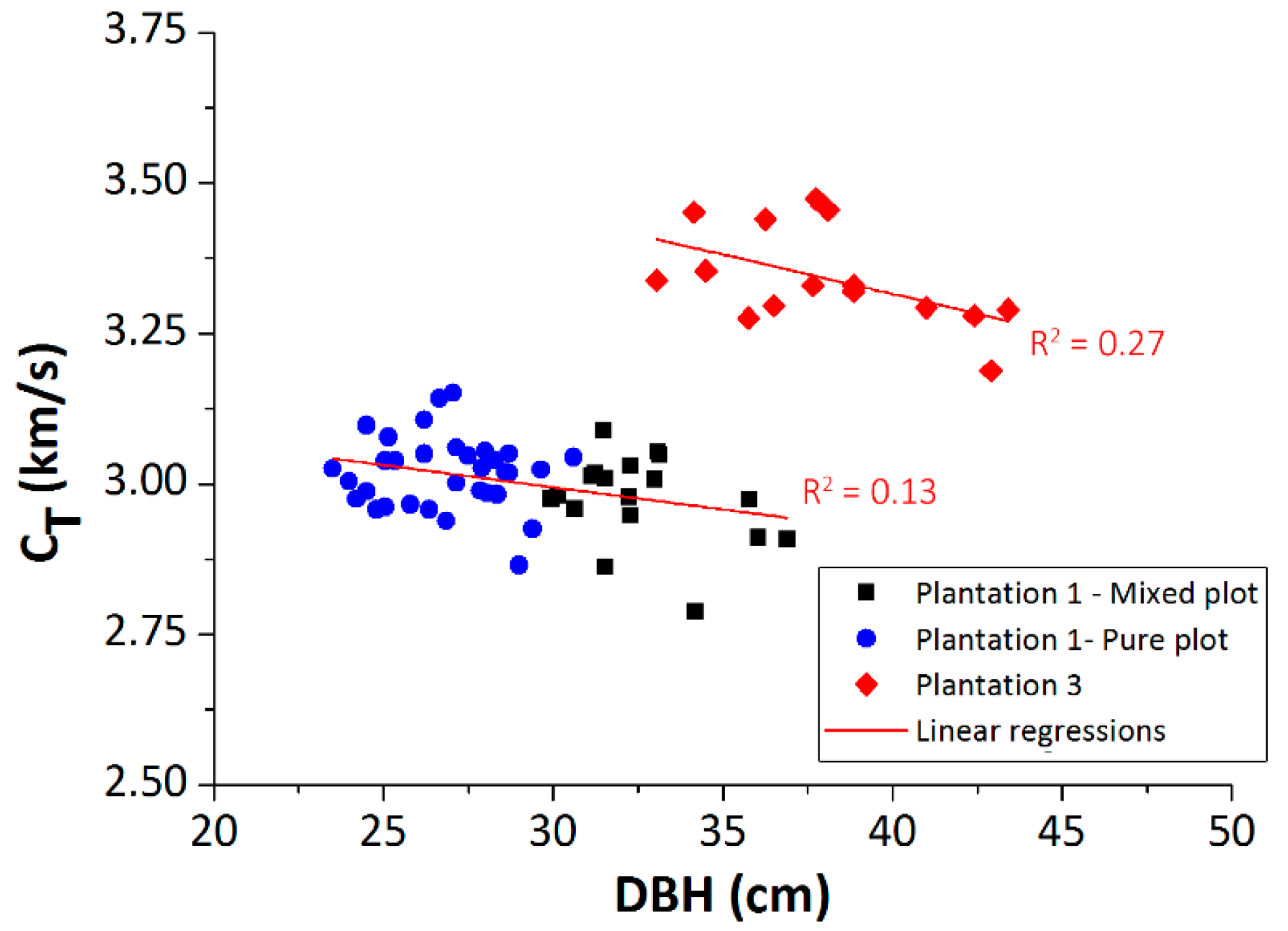

3.3. Plantation 3: Effect of the Crop Location

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Laurent, A.; van der Meer, Y.; Villeneuve, C. Comparative Life Cycle Carbon Footprint of a Non-Residential Steel and Wooden Building Structures. Curr. Trends For. Res. 2018. [Google Scholar] [CrossRef]

- Valsta, L.; Lippke, B.; Perez-Garcia, J.; Pingoud, K.; Pohjola, J.; Solberg, B. Use of Forests and Wood Products to Mitigate Climate Change. In Managing Forest Ecosystems: The Challenge of Climate Change; Bravo, F., Jandl, R., LeMay, V., von Gadow, K., Eds.; Springer: Dordrecht, The Netherlands, 2018; Volume 17. [Google Scholar]

- Shema, A.I.; Balarabe, M.K.; Alfa, M.T. Energy efficiency in residential buildings using nano-wood composite materials. Int. J. Civ. Eng. Technol. 2018, 9, 853–864. [Google Scholar]

- Seo, J.; Wi, S.; Kim, S. Evaluation and Analysis of The Building Energy Saving Performance by Component of Wood Products Using EnergyPlus. J. Korean Wood Sci. Technol. 2016, 44, 655–663. [Google Scholar] [CrossRef] [Green Version]

- CAB International; Food and Agriculture Organization of the United Nations. Poplars and Willows: Trees for Society and the Environment; Isebrands, J.G., Richardson, J., Eds.; CAB International; FAO: Wallingford, Oxfordshire, UK, 2014. [Google Scholar]

- Van Acker, J.; Defoirdt, N.; Van del Bulcke, J. Enhanced potential of poplar and willow for engineered wood products. In Proceedings of the 2nd Conference on Engineered Wood Products Based on Poplar/Willow Wood (CEPPW2), León, Spain, 8–10 September 2016. [Google Scholar]

- Barnett, J.R.; Jeronimidis, G. (Eds.) Wood Quality and Its Biological Basis; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Gough, W.; Richards, J.; Williams, R.P. (Eds.) Vibrations and Waves, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1995. [Google Scholar]

- Wang, X.; Ross, R.J.; McClellan, M.; Barbour, R.J.; Erickson, J.R.; Forsman, J.W.; McGinnis, G.D. Nondestructive evaluation of standing trees with a stress wave method. For. Prod. Lab. 2001, 33, 523–533. [Google Scholar]

- Carter, P.; Briggs, D.; Ross, R.J.; Wang, X. Acoustic testing to enhance western forest values and meet customer wood quality needs. In Productivity of Western Forest: A Forest Products Focus; Harrington, C.A., Schoenholtz, S.H., Eds.; U.S. Department of Agriculture, Forest Service, Pacific Northwest Research Station: Portland, OR, USA, 2005; pp. 121–129. [Google Scholar]

- Chauhan, S.S.; Walker, J.C.F. Variations in acoustic velocity and density with age, and their interrelationships in radiata pine. For. Ecol. Manag. 2006, 229, 388–394. [Google Scholar] [CrossRef]

- Laserre, J.P.; Mson, E.G.; Watt, M.S. Asessing corewood acoustic velocity and modulus of elasticity with two impact based instruments in 11-year-old trees from a clonal-spacing experiment of Pinus Radiata D. Don. For. Ecol. Manag. 2007, 239, 217–221. [Google Scholar] [CrossRef]

- Wang, X. Acoustic measurements on trees and logs: A review and analysis. Wood Sci. Technol. 2013, 47, 965–975. [Google Scholar] [CrossRef]

- Paradis, N.; Auty, D.; Carter, P.; Achim, A. Using a standing-tree acoustic tool to identify forest stands for the production of mechanically-graded lumber. Sensors 2013, 13, 3394–3408. [Google Scholar] [CrossRef]

- Legg, M.; Bradley, S. Measurement of stiffness of standing trees and felled logs using acoustics: A review. J. Acoust. Soc. Am. 2016, 139, 588–604. [Google Scholar] [CrossRef] [Green Version]

- Newton, P.F. Acoustic-based non-destructive estimation of wood quality attributes within standing red pine trees. Forests 2017, 8, 380. [Google Scholar] [CrossRef]

- Essien, C.; Via, B.K.; Gallagher, T.; McDonald, T.; Eckhardt, L. Distance error for determining the acoustic velocity of standing tree using tree morphological, physical and anatomical properties. J. Indian Acad. Wood Sci. 2018, 15, 52–60. [Google Scholar] [CrossRef]

- Arciniegas, A.; Prieto, F.; Brancheriau, L.; Lasaygues, P. Literature review of acoustic and ultrasonic tomography in standing trees. Trees 2014, 28, 1559–1567. [Google Scholar] [CrossRef]

- Wang, X.; Ross, R.J.; Carter, P. Acoustic evaluation of standing trees—Recent research development. In Proceedings of the 14th International Symposium on Nondestructive Testing of Wood, Eberswalde, Germany, 2–4 May 2005; pp. 455–465. [Google Scholar]

- Mora, C.R.; Schimleck, R.; Isik, F.; Mahon, J.M., Jr.; Clark, A., III; Daniels, R.F. Relationships between acoustic variables and different measures of stiffness in standing Pinus taeda trees. Can. J. For. Res. 2009, 39, 1421–1429. [Google Scholar] [CrossRef]

- Baar, J.; Tippner, J.; Gryc, V. The influence of wood density on longitudinal wave velocity determined by the ultrasound method in comparison to the resonance longitudinal method. Eur. J. Wood Prod. 2012, 70, 767–769. [Google Scholar] [CrossRef]

- Grabianowski, M.; Manley, B.; Walker, J.C.F. Acoustic measurements on standing trees, logs and green lumber. Wood Sci. Technol. 2006, 40, 205–216. [Google Scholar] [CrossRef]

- Proto, A.R.; Macri, G.; Russo, D. Acoustic evaluation of wood quality with a non-destructive method in standing trees: A first survey in Italy. iForest Biogeosci. For. 2017, 10, 700–706. [Google Scholar] [CrossRef]

- Lenzen, F.; Kim, K.I.; Schafer, H.; Nair, R.; Meister, S.; Becker, F.; Garbe, C.S.; Theobalt, C. Denoising strategies for time-of-flight data. In Time-of-Flight and Depth Imaging. Sensors, Algorithms, and Applications; Grzegorzek, M., Theobalt, C., Koch, R., Kolb, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 25–45. [Google Scholar]

- Mendel, J.M. Tutorial on higher-order statistics (spectra) in signal processing and system theory: Theoretical results and some applications. Proc. IEEE 1991, 79, 278–305. [Google Scholar] [CrossRef]

- Espinosa, L.; Bacca, J.; Prieto, F.; Lasaygues, P.; Brancheriau, L. Accuracy on the Time-of-Flight Estimation for Ultrasonic Waves Applied to Non-Destructive Evaluation of Standing Trees: A Comparative Experimental Study. Acta Acust. United Acust. 2018, 104, 429–439. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Shang, X.; Morales-Esteban, A.; Wang, Z. Identifying P phase arrival of weak events: The Akaike Information Criterion picking application based on the Empirical Mode Decomposition. Comput. Geosci. 2017, 100, 57–66. [Google Scholar] [CrossRef]

- Mborah, C.; Ge, M. Enhancing manual P-phase arrival detection and automatic onset time picking in a noisy microseismic data in underground mines. Int. J. Min. Sci. Technol. 2018, 28, 691–699. [Google Scholar] [CrossRef]

- Kolassa, S. Combining exponential smoothing forecasts using Akaike weights. Int. J. Forecast. 2011, 27, 238–251. [Google Scholar] [CrossRef]

- Hayes, M.P.; Chen, J. A portable stress wave measurement system for timber inspection. In Proceedings of the Electronics New Zealand Conference (ENZCON), Hamilton, New Zealand, 1–2 September 2003; pp. 1–6. [Google Scholar]

- Toulmin, M.J.; Raymond, C.A. Developing a sampling strategy for measuring acoustic velocity in standing Pinus Radiata using the treetap time of flight tool. N. Z. J. For. Sci. 2007, 37, 96–111. [Google Scholar]

- Emms, G.; Nanayakkara, B.; Harrington, J. A novel technique for non-damaging measurement of sound speed in seedlings. Eur. J. For. Res. 2012, 131, 1449–1459. [Google Scholar] [CrossRef]

- Yang, K.C.; Hazenberg, G. Impact of spacings on sapwood and heartwood thickness in Picea mariana (Mill.) B.S.P. and Picea glauca (Moench.) VOSS. Wood Fiber Sci. 1992, 24, 330–336. [Google Scholar]

- Mahon, J.M.; Jordan, L.; Schimleck, L.R.; Clarck, A.; Daniels, R.F. A comparison of sampling methods for a standing tree acoustic device. South J. Appl. For. 2009, 33, 62–68. [Google Scholar]

- Akaike, H. Information theory and an extension of the maximum likelihood principle. In Proceedings of the 2nd International Symposium on Information Theory, Tsahkadsor, Armenia, 2–8 September 1973; pp. 267–281. [Google Scholar]

- Bozdogan, H. Akaike’s information criterion and recent developments in information complexity. J. Math. Psychol. 2000, 44, 62–91. [Google Scholar] [CrossRef]

- Haines, D.W.; Leban, J.M.; Herbé, C. Determination of young’s modulus for spruce, fir and isotropic materials by the resonance flexure method with comparisons to static flexure and other dynamic methods. Wood Sci. Technol. 1996, 30, 253–263. [Google Scholar] [CrossRef]

| Characteristics | Plantation 1 | Plantation 2 | Plantation 3 |

|---|---|---|---|

| Location (DMS) | 37°10′01.9″N 3°36′56.5″W | 37°11′27.5″N 3°41′33.8″W | 40°45′40.1″N 3°08′55.0″W |

| Altitude (m) | 651 | 591 | 682 |

| Climate | Transition between Mediterranean and Semi-arid | Transition between Mediterranean and Semi-arid | Continental Mediterranean |

| Poplar clone | I-214 | Unal, Beaupre, I-214, and Raspalje | I-214 |

| Age (years) | 8 | 5 | 13 |

| Plantation density (m2) | 5 × 5 | 5 × 5 | 5.5 × 5.5 |

| Number of tested trees | 18 (mix plot) + 36 (pure plot) | 43, 43, 50, and 39 | 15 |

| Measurement season | March 2018 & September 2018 | September 2018 | September 2018 |

| Parameters | March (2018) | September (2018) | ||

|---|---|---|---|---|

| Pure Plot | Mixed Plot | Pure Plot | Mixed Plot | |

| Average DBH (cm) | 26.1 ± 1.5 | 31.6 ± 1.8 | 27.0 ± 1.8 | 32.6 ± 2.0 |

| Average velocity (km/s) | 3.19 ± 0.06 | 3.02 ± 0.10 | 3.02 ± 0.06 | 2.97 ± 0.07 |

| Parameters | Unal | Beaupre | I-214 | Raspalje |

|---|---|---|---|---|

| Number of trees | 43 | 45 | 50 | 42 |

| Average DBH (cm) | 13.4 ± 2.7 | 13.4 ± 2.1 | 16.8 ± 2.4 | 14.7 ± 1.9 |

| Average velocity (km/s) | 2.89 ± 0.11 | 2.95 ± 0.15 | 2.66 ± 0.08 | 2.86 ± 0.12 |

| Parameters | Plantation 1 | Plantation 3 | |

|---|---|---|---|

| Pure Plot | Mixed Plot | ||

| Average DBH (cm) | 27.0 ± 1.8 | 32.6 ± 2.0 | 38.1 ± 3.2 |

| Average velocity (km/s) | 3.02 ± 0.06 | 2.97 ± 0.07 | 3.34 ± 0.08 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rescalvo, F.J.; Ripoll, M.A.; Suarez, E.; Gallego, A. Effect of Location, Clone, and Measurement Season on the Propagation Velocity of Poplar Trees Using the Akaike Information Criterion for Arrival Time Determination. Materials 2019, 12, 356. https://doi.org/10.3390/ma12030356

Rescalvo FJ, Ripoll MA, Suarez E, Gallego A. Effect of Location, Clone, and Measurement Season on the Propagation Velocity of Poplar Trees Using the Akaike Information Criterion for Arrival Time Determination. Materials. 2019; 12(3):356. https://doi.org/10.3390/ma12030356

Chicago/Turabian StyleRescalvo, Francisco J., María A. Ripoll, Elisabet Suarez, and Antolino Gallego. 2019. "Effect of Location, Clone, and Measurement Season on the Propagation Velocity of Poplar Trees Using the Akaike Information Criterion for Arrival Time Determination" Materials 12, no. 3: 356. https://doi.org/10.3390/ma12030356