Microstructure and Hot Deformation Behavior of Twin Roll Cast Mg-2Zn-1Al-0.3Ca Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

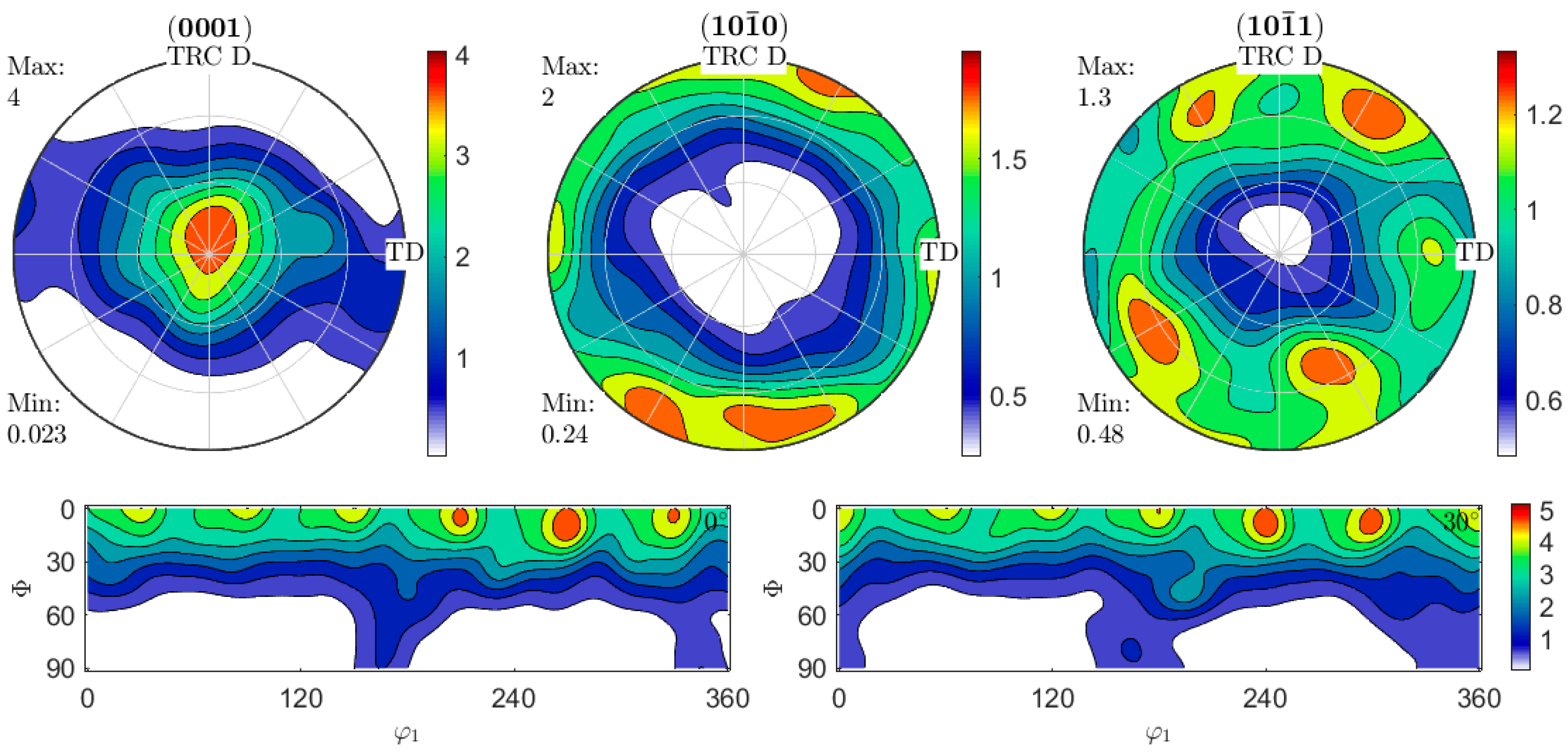

3.1. Microstructure and Texture of the Twin Roll Cast ZAX210 Alloy

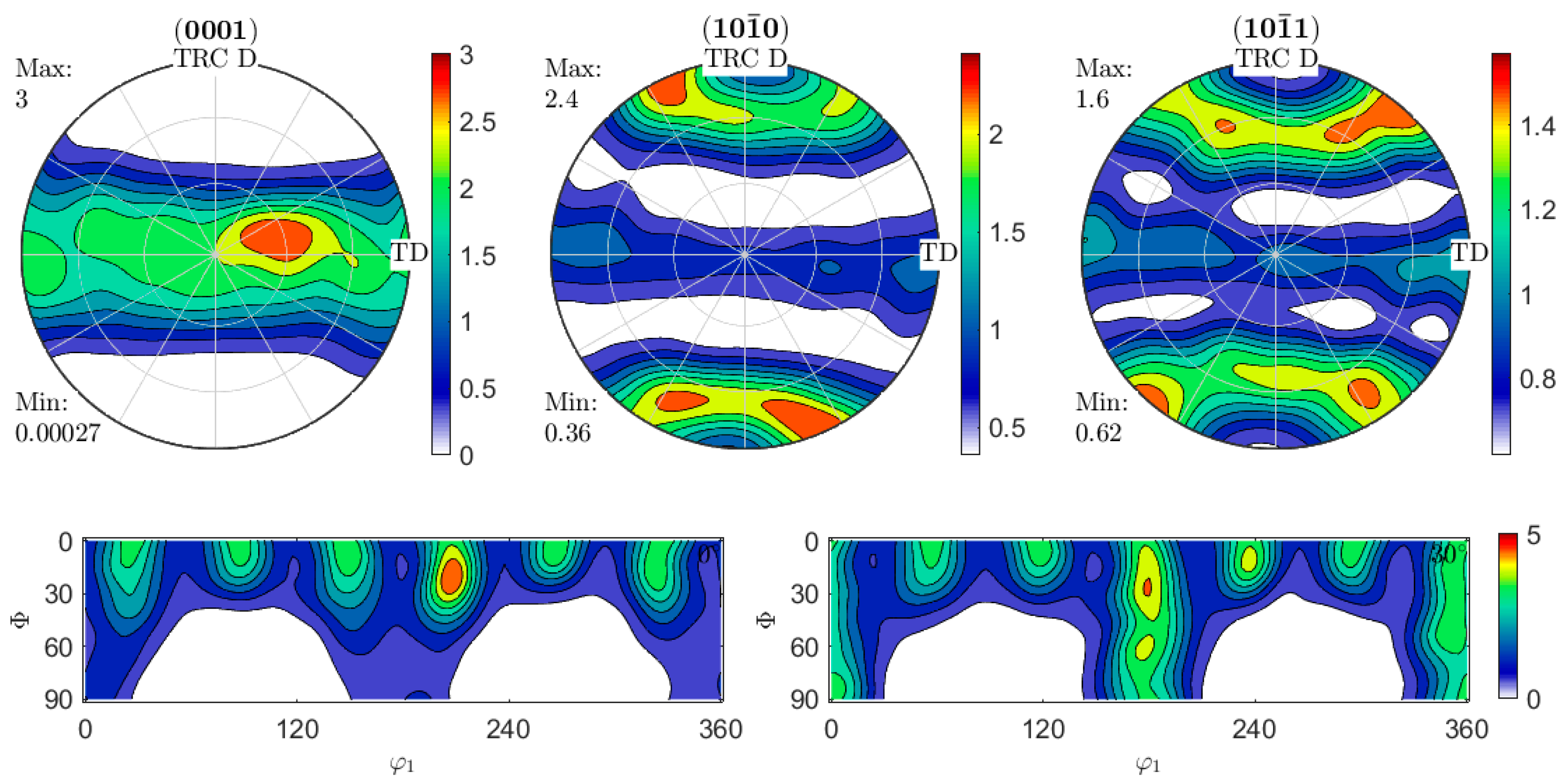

3.2. Microstructure and Texture of the Annealed ZAX210 Alloy

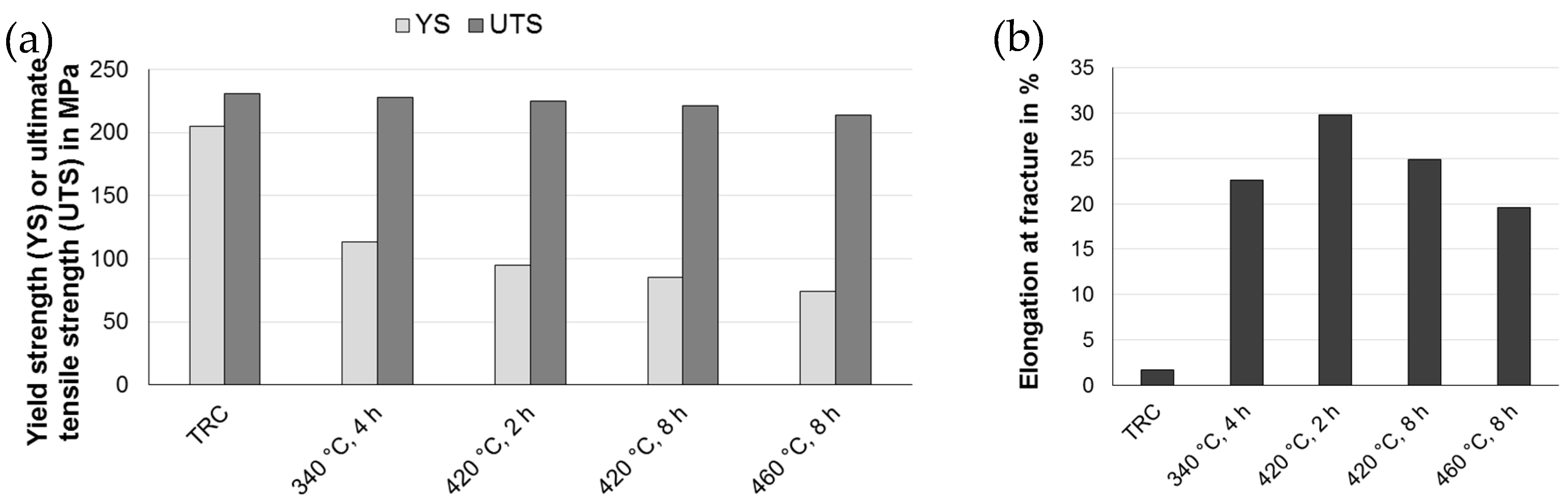

3.3. Mechanical Properties at Room Temperature

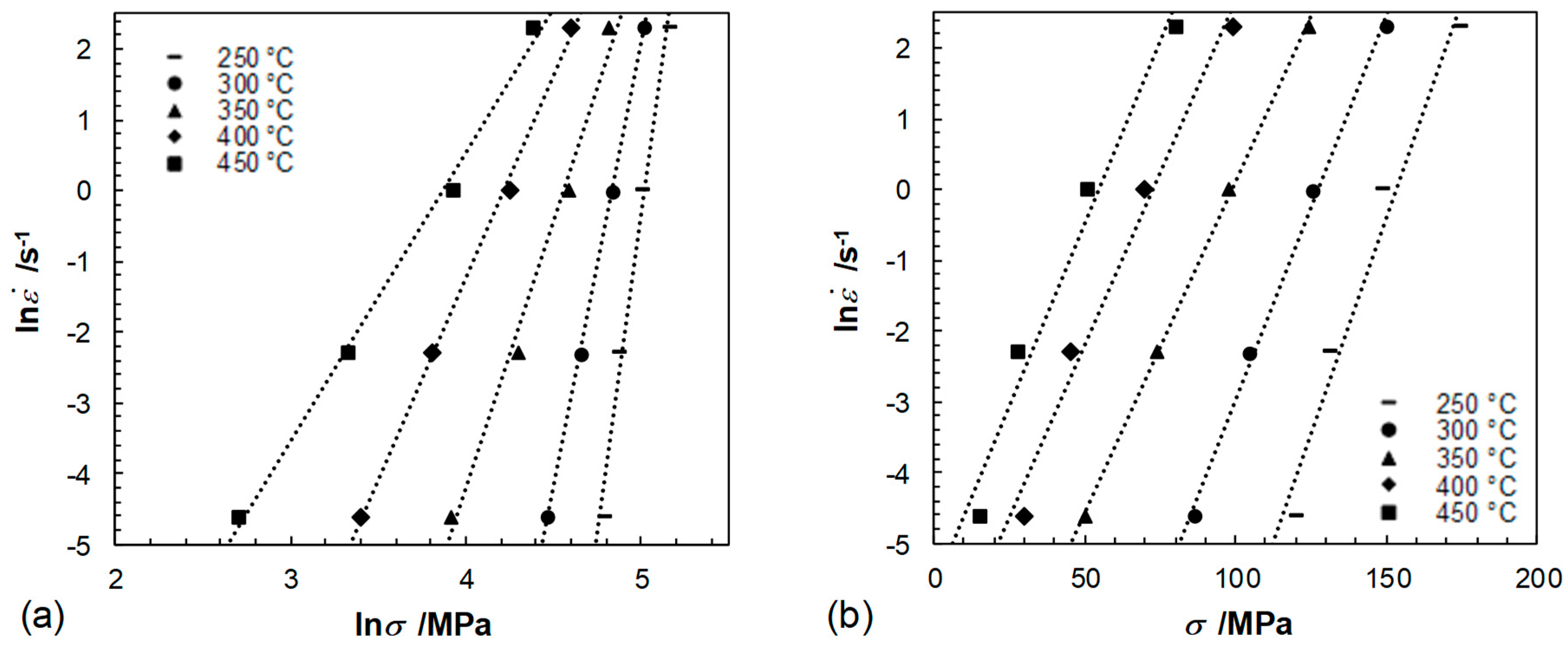

3.4. Hot forming Behavior of Twin Roll Cast and Annealed ZAX210 Alloy

4. Discussion

4.1. Texture Evolution of the Twin Roll Cast and Annealed ZAX210 Alloy

4.2. Hot Deformation Behavior of Twin Roll Cast and Annealed ZAX210 Alloy

4.2.1. Analysis of Hot Compressive Deformation Behavior

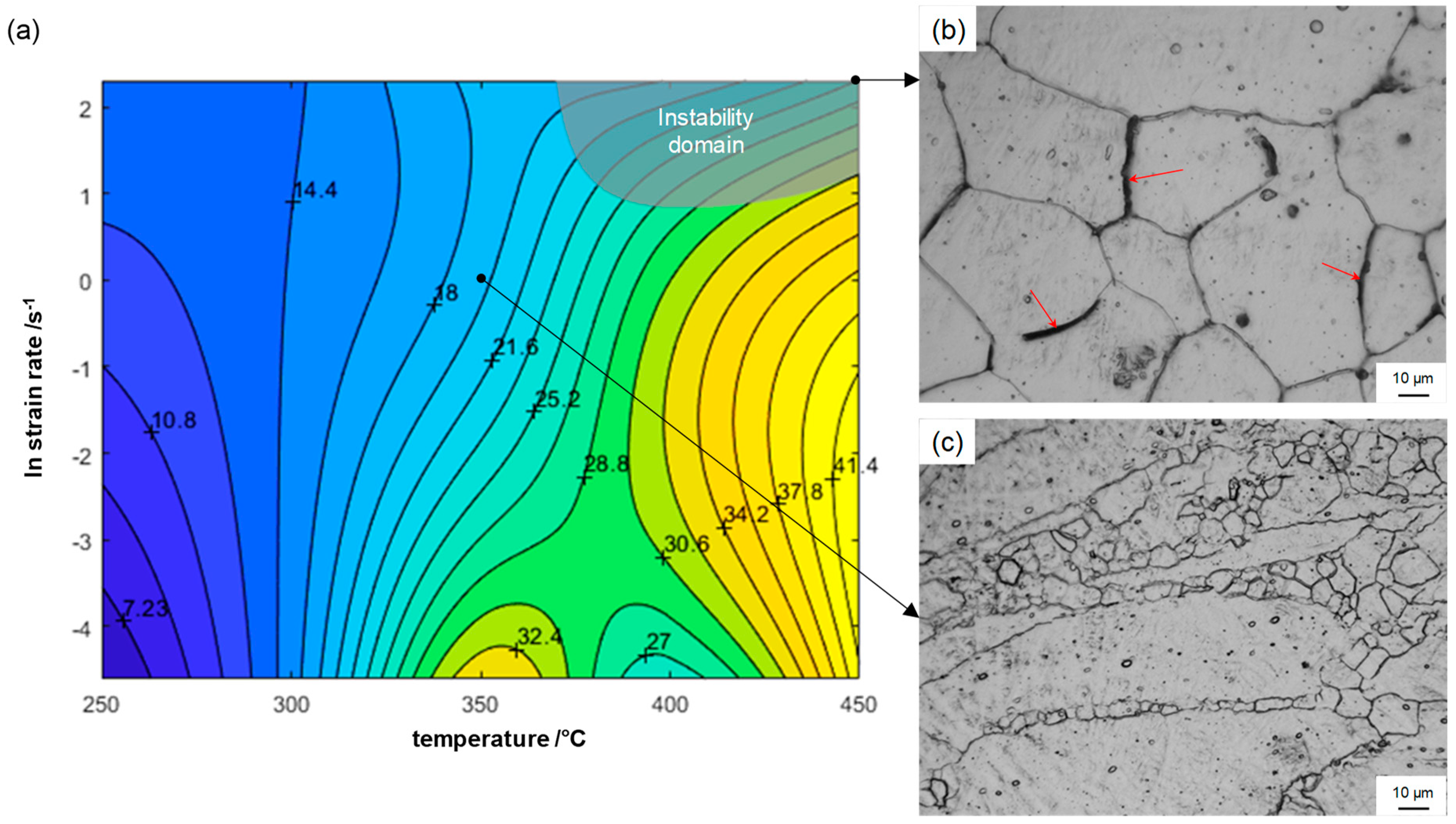

4.2.2. Processing Map

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Neh, K.; Ullmann, M.; Oswald, M.; Berge, F.; Kawalla, R. Twin roll casting and strip rolling of several magnesium alloys. Mater. Today Proc. 2015, 2S, S45–S52. [Google Scholar] [CrossRef]

- Park, S.J.; Jung, H.C.; Shin, K.S. Deformation behaviors of twin roll cast Mg-Zn-X-Ca alloys for enhanced room-temperature formability. Mater. Sci. Eng. A 2017, 679, 329–339. [Google Scholar] [CrossRef]

- Luo, X.; Fang, D.; Liu, B. Thermo-Mechanical Treatment on Microstructure and Mechanical Properties of Mg-5.0Sn-1.0Mn-0.4Zr alloy. Adv. Mater. Phys. Chem. 2018, 8, 44–50. [Google Scholar] [CrossRef]

- Yamamoto, A.; Ikeda, M.; Tsubakino, H. Grain Refinement in AZ91E Magnesium Alloy by Thermo-mechanical Treatments. Mater. Sci. Forum 2005, 475–479, 493–496. [Google Scholar] [CrossRef]

- Agnew, S.R.; Mehrotra, P.; Lillo, T.M.; Stoica, G.M.; Liaw, P.K. Crystalligraphic texture evolution of three wrought magnesium alloys during equal channel angular extrusion. Mater. Sci. Eng. A 2005, 408, 72–78. [Google Scholar] [CrossRef]

- Gong, X.; Kang, S.B.; Cho, J.H.; Li, S. Effect of annealing on microstructure and mechanical properties of ZK60 magnesium alloy sheets processed by twin-roll cast and differential speed rolling. Mater. Charact. 2014, 97, 183–188. [Google Scholar] [CrossRef]

- Catorceno, L.L.C.; de Abreu, H.F.G.; Padilha, A.F. Effects of cold and warm cross-rolling on microstructure and texture evolution of AZ31B magnesium alloy sheet. J. Mag. Alloys 2018, 6, 121–133. [Google Scholar] [CrossRef]

- Sabat, R.K.; Mishra, R.K.; Sachdev, A.K.; Suwas, S. The deciding role of texture on ductility in a Ce containing Mg alloy. Mater. Lett. 2015, 153, 158–161. [Google Scholar] [CrossRef]

- Bohlen, J.; Nürnberg, M.R.; Senn, J.W.; Letzig, D.; Agnew, S.R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets. Acta Mater. 2007, 55, 2101–2112. [Google Scholar] [CrossRef]

- Serebryany, V.N.; Popov, M.V.; Gordeev, A.S.; Timofeev, V.N.; Rokhlin, L.L.; Estrin, Y.; Dobatkin, S.V. Effect of Texture and Microstructure on Ductility of a Mg-Al-Ca Alloy Processed by Equal Channel Angular Pressing. Mater. Sci. Forum 2008, 584–586, 375–379. [Google Scholar] [CrossRef]

- Kyeong, J.S.; Kim, J.K.; Lee, M.J.; Park, Y.B.; Kim, W.T.; Kim, D.H. Texture Modification by Addition of Ca in Mg-Zn-Y Alloy. Mater. Trans. 2012, 53, 991–994. [Google Scholar] [CrossRef]

- Wang, T.; Jiang, L.; Mishra, R.K.; Jonas, J.J. Effect of Ca Addition on the Intensity of the Rare Earth Texture Component in Extruded Magnesium Alloys. Metall. Mater. Trans. A 2014, 45, 4698–4709. [Google Scholar] [CrossRef]

- Borkar, H.; Pekguleryuz, M. Microstructure and texture evolution in Mg-1%Mn-Sr alloys during extrusion. J. Mater. Sci. 2013, 48, 1436–1447. [Google Scholar] [CrossRef]

- Borkar, H.; Hoseini, M.; Pekguleryuz, M. Effect of strontium on texture and mechanical properties of extruded Mg-2%Mn alloys. Mater. Sci. Eng. A 2012, 549, 168–175. [Google Scholar] [CrossRef]

- Liu, W.; Liu, X.; Tang, C.; Yao, W.; Xiao, Y.; Liu, X. Microstructure and texture evolution in LZ91 magnesium alloy during cold rolling. J. Mag. Alloys 2018, 6, 77–82. [Google Scholar] [CrossRef]

- Chang, T.; Wang, J.; Chu, C.; Lee, S. Mechanical properties and microstructures of various Mg-Li alloys. Mater. Lett. 2006, 60, 3272–3276. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, S.B.; Cho, J. Microstructure and mechanical properties of Mg-Al-Mn-Ca alloy sheet produced by twin roll casting and sequential warm rolling. J. Alloys Compd. 2011, 509, 704–711. [Google Scholar] [CrossRef]

- Tong, L.B.; Zheng, M.Y.; Zhang, D.P.; Gan, W.M.; Brokmeier, H.G.; Meng, J.; Zhang, H.J. Compressive deformation behavior of Mg–Zn–Ca alloy at elevated temperature. Mater. Sci. Eng. A 2013, 586, 71–77. [Google Scholar] [CrossRef]

- Kulyasova, O.B.; Islamgaliev, R.K.; Zhao, Y.; Valiev, R.Z. Enhancement of the Mechanical Properties of an Mg–Zn–Ca Alloy Using High-Pressure Torsion. Adv. Eng. Mater. 2015, 17, 1738–1741. [Google Scholar] [CrossRef]

- Qi, J.; Du, Y.; Jiang, B.; Shen, M. Hot deformation behavior and microstructural evolution of Mg–Zn–Ca–La alloys. J. Mater. Res. 2018, 33, 2817–2826. [Google Scholar] [CrossRef]

- Neh, K.; Ullmann, M.; Kawalla, R. Substitution of Rare Earth Elements in Hot Rolled Magnesium Alloys with Improved Mechanical Properties. Mater. Sci. Forum 2016, 854, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Kurz, G.; Petersen, T.; Gonzales, I.P.; Hoppe, R.; Bohlen, J.; Letzig, D. Substitution of Rare Earth Elements in Magnesium Alloys for the Sheet Production Via Twin Roll Casting. Mag. Technol. 2016, 377–382. [Google Scholar] [CrossRef]

- Hoppe, R.; Kurz, G.; Letzig, D. Substitution of Rare Earths in Magnesium Alloys. Mater. Sci. Forum 2016, 854, 51–56. [Google Scholar] [CrossRef] [Green Version]

- Letzig, D.; Bohlen, J.; Kurz, G.; Victoria-Hernandez, J.; Hoppe, R.; Yi, S. Development of Magnesium Sheets. Mag. Technol. 2018, 355–360. [Google Scholar] [CrossRef]

- Ullmann, M.; Kittner, K.; Henseler, T.; Stöcker, A.; Prahl, U.; Kawalla, R. Development of new alloy systems and innovative processing technologies for the production of magnesium flat products with excellent property profile. Procedia Manuf. 2019, 27, 203–208. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Sasidhara, S. Hot Working Guide: A Compendium on Processing Maps; ASM International: Metals Park, OH, USA, 1997; ISBN 0871705982. [Google Scholar]

- Klein, H.; Schwarzer, R.A. Texture analysis with MTEX—Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- Ullmann, M.; Schmidtchen, M.; Kittner, K.; Henseler, T.; Kawalla, R.; Prahl, U. Hot Deformation Behaviour and Processing Maps of an as-cast Mg-6.8Y-2.5Zn-0.4Zr Alloy. Mater. Sci. Forum 2019, 949, 57–65. [Google Scholar] [CrossRef]

- Ullmann, M.; Schmidtchen, M.; Kawalla, R. Dynamic recrystallization behaviour of twin roll cast AZ31 strips during hot deformation. Key Eng. Mater. 2014, 622–623, 569–574. [Google Scholar] [CrossRef]

- Kittner, K.; Ullmann, M.; Henseler, T.; Kawalla, R.; Prahl, U. Microstructure, texture and mechanical properties of twin roll cast Mg-2Zn-1Al-0.3Ca alloy. In Proceedings of the MSSM2018, Paisley, UK, 7–10 August 2018. [Google Scholar]

- Wang, Y.N.; Huang, J.C. Texture analysis in hexagonal materials. Mater. Chem. Phys. 2003, 81, 11–26. [Google Scholar] [CrossRef]

- Masoumi, M.; Zarandi, F.; Pekguleryuz, M. Microstructure and texture studies on twin-roll cast AZ31 (Mg-3wt%Al-1wt%Zn) alloy and the effect of thermomechanical processing. Mater. Sci. Eng. A 2011, 528, 1268–1279. [Google Scholar] [CrossRef]

- Tang, N.; Wang, M.P.; Lou, H.F.; Zhao, Y.Y.; Li, Z. Microstructure and texture of twin-roll cast Mg-3Al-1Zn-0.2Mn magnesium alloy. Mater. Chem. Phys. 2009, 116, 11–15. [Google Scholar] [CrossRef]

- Soomro, M.W. Formability of Magnesium AZ80. Ph.D. Thesis, School of Engineering, Computer and Mathematical Sciences, Auckland, New Zealand, 2016. [Google Scholar]

- Chaudry, U.M.; Kim, T.H.; Park, S.D.; Kim, Y.S.; Hamad, K.; Kim, J. On the high formability of AZ31-0.5Ca magnesium alloy. Materials 2018, 11, 2201. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Peng, J.; Li, M.; Nyberg, E.A.; Pan, F. Effects of Ca Addition on the Mechanical Properties and Corrosion Behavior of ZM21 Wrought Alloys. Acta Metall. Sin. 2017, 30, 53–65. [Google Scholar] [CrossRef]

- Zeng, Z.R.; Zhu, Y.M.; Xu, S.W.; Bian, M.Z.; Davies, C.H.J.; Birbilis, N.; Nie, J.F. Texture evolution during static recrystallization of cold-rolled magnesium alloys. Acta Mater. 2016, 105, 479–494. [Google Scholar] [CrossRef]

- Basu, I.; Al-Samman, T. Triggering rare earth texture modification in magnesium alloys by addition of zinc and zirconium. Acta Mater. 2014, 67, 116–133. [Google Scholar] [CrossRef]

- Zimina, M.; Zimina, A.; Pokova, M.; Bohlen, J.; Letzig, D.; Kurz, G.; Knapek, M.; Cieslar, M. Influence of the heat treatment on the texture of twin-roll-cast AZ31 magnesium alloy. Metal 2014. [Google Scholar] [CrossRef]

- Griffiths, D. Explaining texture weakening and improved formability in magnesium rare earth alloys. Mater. Sci. Technol. 2015, 31, 10–24. [Google Scholar] [CrossRef]

- Ball, E.A.; Prangnell, P.B. Tensile-compressive yield asymmetries in high strength wrought magnesium alloys. Scr. Metall. Mater. 1994, 31, 111–116. [Google Scholar] [CrossRef]

- Sandlöbes, S.; Friak, M.; Korte-Kerzel, S.; Pei, Z.; Neugebauer, J.; Raabe, D. A rare-earth free magnesium alloy with improved intrinsic ductility. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef]

- Garofalo. Fundamentals of Creep and Creep-Rupture in Metals; McMillan Series in Materials Science; McMillan: New York, NY, USA, 1965. [Google Scholar]

- Weertman, J. Dislocation climb theory of steady-state creep. ASM Trans. Quavt. Metal. Sci. J. 1968, 61, 681–694. [Google Scholar] [CrossRef]

- Sherby, O.D.; Taleff, E.M. Influence of grain size, solute atoms and second-phase particles on creep behaviour of polycrystalline solids. Mater. Sci. Eng. A 2002, 322, 89–99. [Google Scholar] [CrossRef]

- Lesuer, D.R.; Syn, C.K.; Sherby, O.D. An evaluation of power law breakdown in metals, alloys, dispersion hardened materials, and compounds. In Deformation, Processing and Properties of Structural Materials, Proceedings of the Honorary Symposium for Professor OD Sherby, Nashville, TN, USA, 16–20 March 2000; Taleff, E.M., Syn, C.K., Lesuer, D.R., Eds.; TMS: Warrendale, PA, USA, 2000; pp. 81–194. [Google Scholar]

- Rao, K.P.; Chalasani, D.; Suresh, K.; Prasad, Y.V.R.K.; Dieringa, H.; Hort, N. Connected Process Design for Hot Working of a Creep-Resistant Mg–4Al–2Ba–2Ca Alloy (ABaX422). Metals 2018, 8, 463. [Google Scholar] [CrossRef]

- Suresh, K.; Rao, K.P.; Prasad, Y.V.R.K.; Wu, C.-M.L.; Hort, N.; Dieringa, H. Mechanism of Dynamic Recrystallization and Evolution of Texture in the Hot Working Domains of the Processing Map for Mg-4Al-2Ba-2Ca Alloy. Metals 2017, 7, 539. [Google Scholar] [CrossRef]

- Rao, K.P.; Suresh, K.; Prasad, Y.V.R.K.; Dharmendra, C.; Hort, N.; Dieringa, H. High Temperature Strength and Hot Working Technology for As-Cast Mg–1Zn–1Ca (ZX11) Alloy. Metals 2017, 7, 405. [Google Scholar] [CrossRef]

- Dharmendra, C.; Rao, K.P.; Suresh, K.; Hort, N. Hot Deformation Behavior and Processing Map of Mg-3Sn-2Ca-0.4Al-0.4Zn Alloy. Metals 2018, 8, 216. [Google Scholar] [CrossRef]

| Zn | Al | Ca | Mn | Cu | Fe | Ni | Others | Mg |

|---|---|---|---|---|---|---|---|---|

| 2.290 | 0.920 | <0.250 | 0.040 | 0.001 | 0.005 | 0.001 | <0.045 | Bal. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kittner, K.; Ullmann, M.; Henseler, T.; Kawalla, R.; Prahl, U. Microstructure and Hot Deformation Behavior of Twin Roll Cast Mg-2Zn-1Al-0.3Ca Alloy. Materials 2019, 12, 1020. https://doi.org/10.3390/ma12071020

Kittner K, Ullmann M, Henseler T, Kawalla R, Prahl U. Microstructure and Hot Deformation Behavior of Twin Roll Cast Mg-2Zn-1Al-0.3Ca Alloy. Materials. 2019; 12(7):1020. https://doi.org/10.3390/ma12071020

Chicago/Turabian StyleKittner, Kristina, Madlen Ullmann, Thorsten Henseler, Rudolf Kawalla, and Ulrich Prahl. 2019. "Microstructure and Hot Deformation Behavior of Twin Roll Cast Mg-2Zn-1Al-0.3Ca Alloy" Materials 12, no. 7: 1020. https://doi.org/10.3390/ma12071020