Effects of Ca/Si Ratio, Aluminum and Magnesium on the Carbonation Behavior of Calcium Silicate Hydrate

Abstract

:1. Introduction

2. Experiments

2.1. Synthesis of C-(M)-(A)-S-H with Different Ca/Si Ratio, Al/Si Ratio and Mg/Si Ratio

2.2. Experiment of Carbonation

2.3. Polymerization of Silicon Chain

2.4. The Carbonation Products

2.5. The Content of Carbonation Products

2.5.1. The Content of Carbonation Products for C-S-H

2.5.2. The Content of Carbonation Products for C-A-S-H and C-M-S-H

3. Results and Discussion

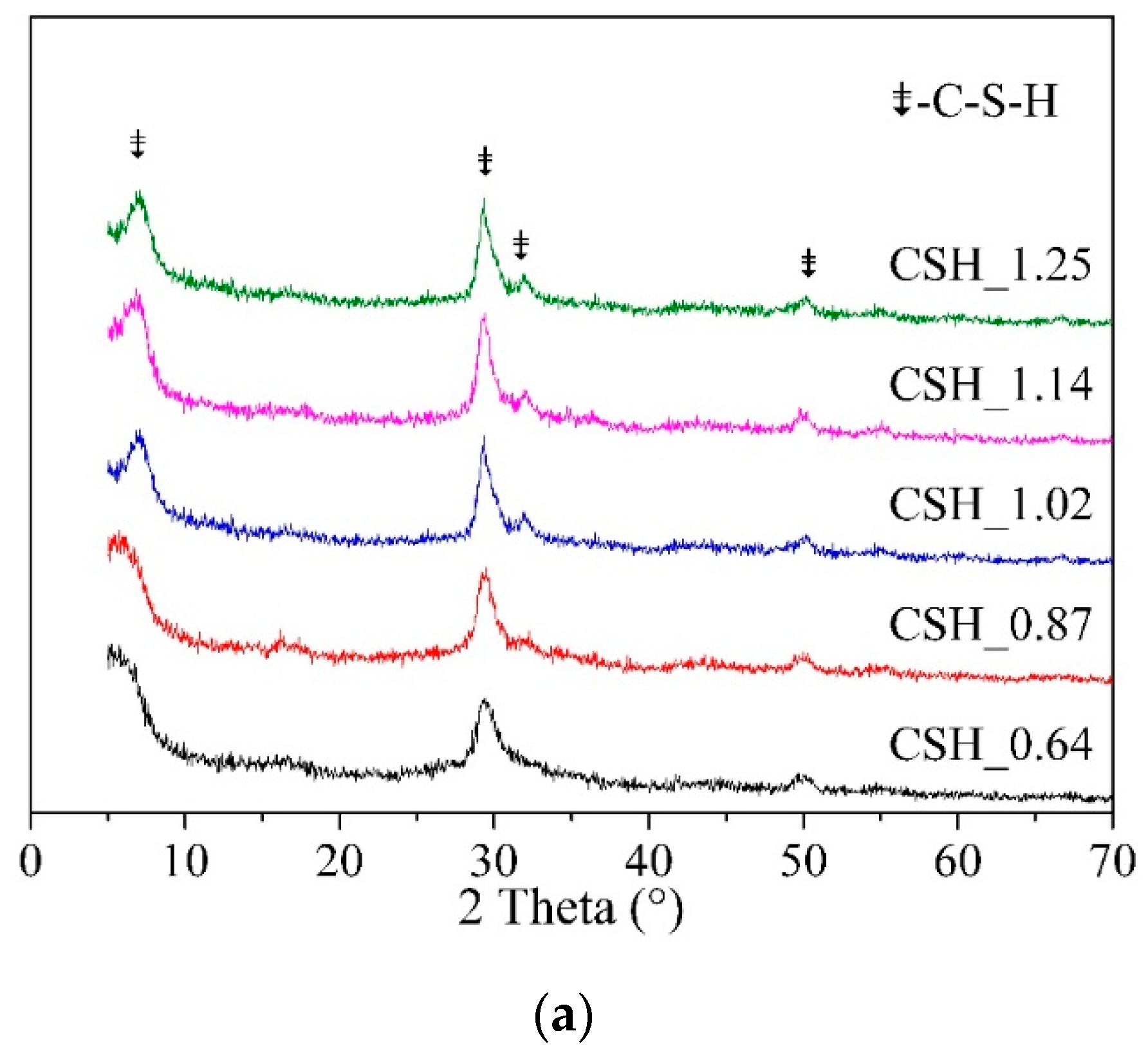

3.1. The Effects of Ca/Si, Al/Si and Mg/Si Ratios on the Structure of C-(M)-(A)-S-H

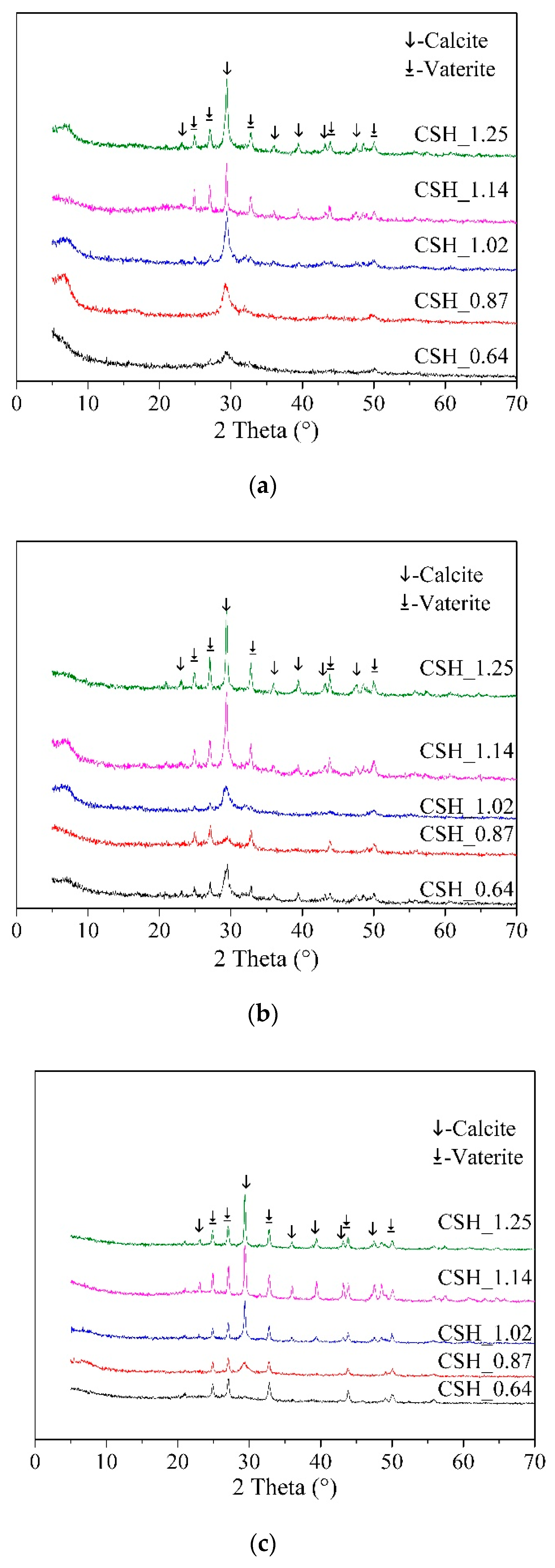

3.2. The Effect of Time on the Evolution of Carbonation Products of C-S-H with Different Ca/Si Ratio

3.2.1. Carbonation Products

3.2.2. The Effect of Ca/Si Ratio of C-S-H on the Formation Rate of Carbonation Products

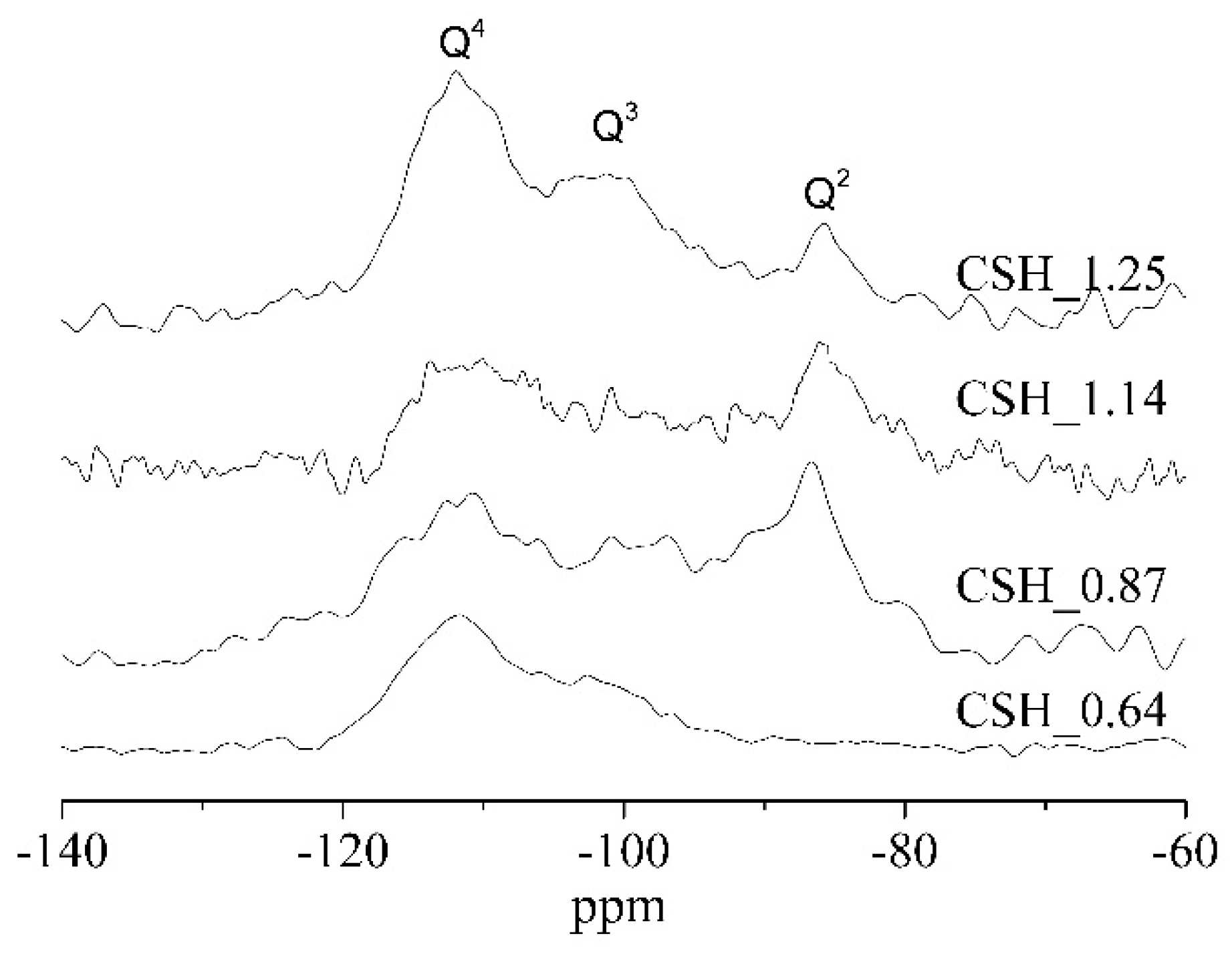

3.2.3. The Structure Change of C-S-H with Different Ca/Si Ratio after Carbonation for 28 Days

3.3. The Effects of Aluminum Uptake and Magnesium Uptake in C-S-H on the Formation Rate of Carbonation Products after Carbonation for 28 Days

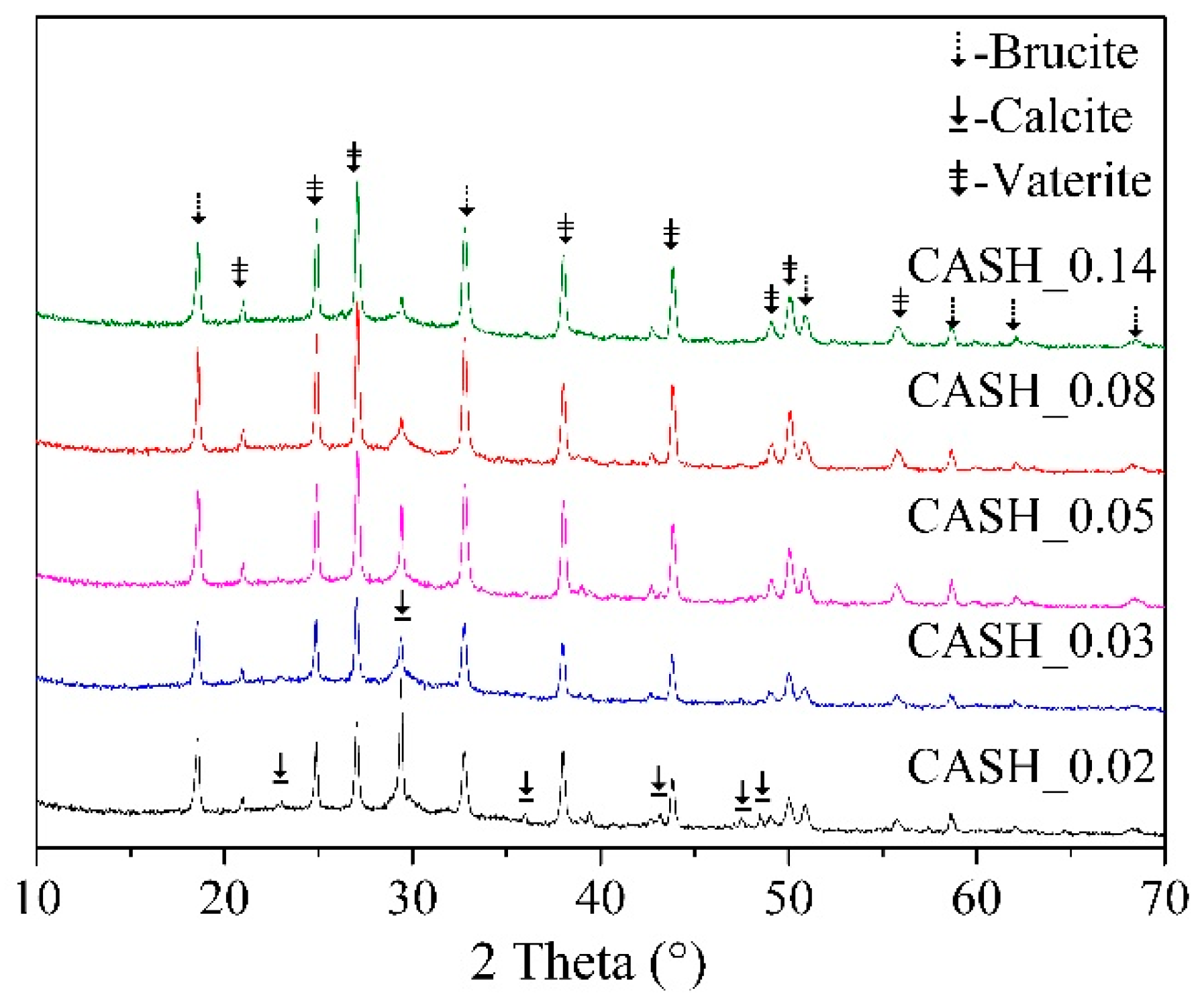

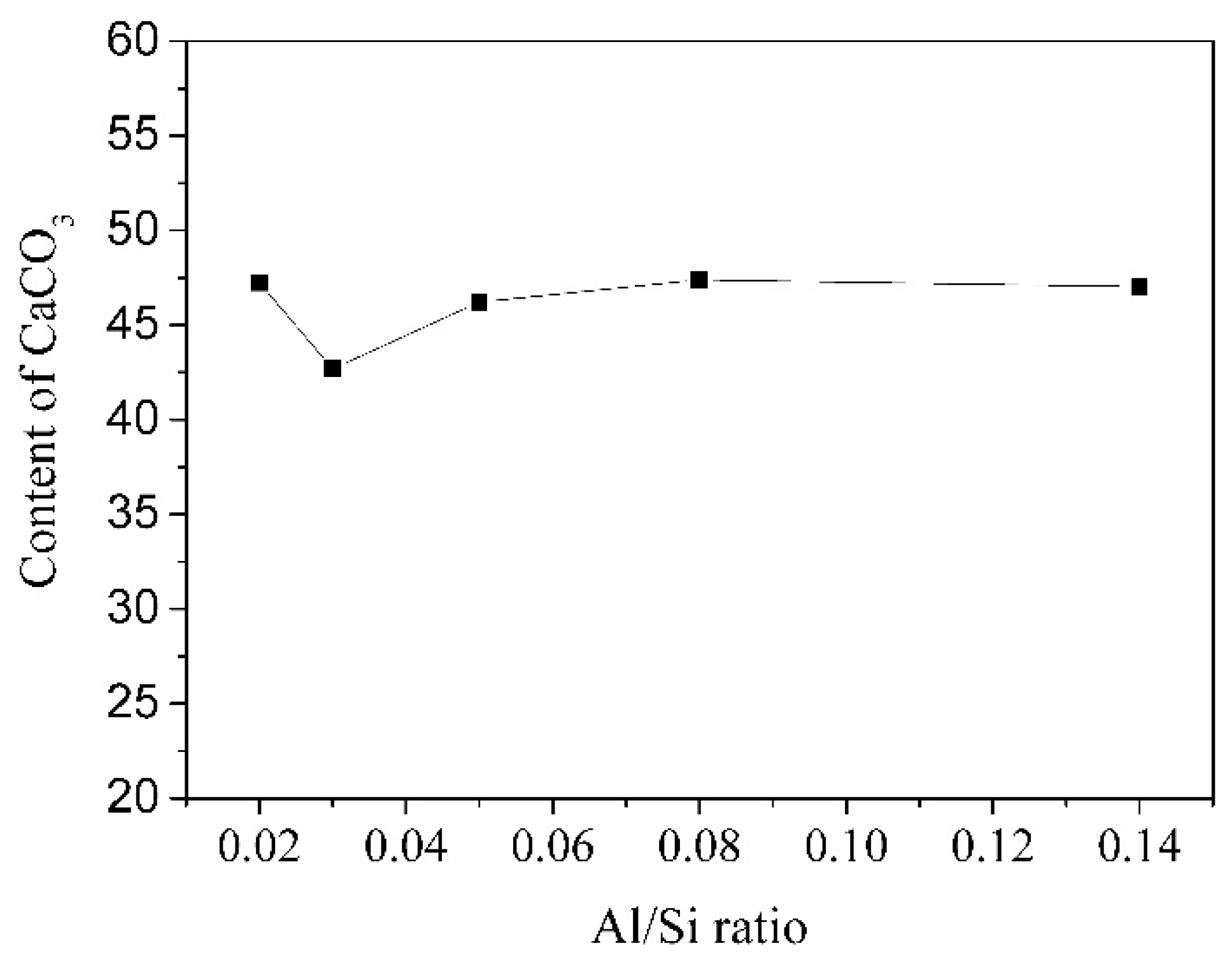

3.3.1. The Effect of Aluminum

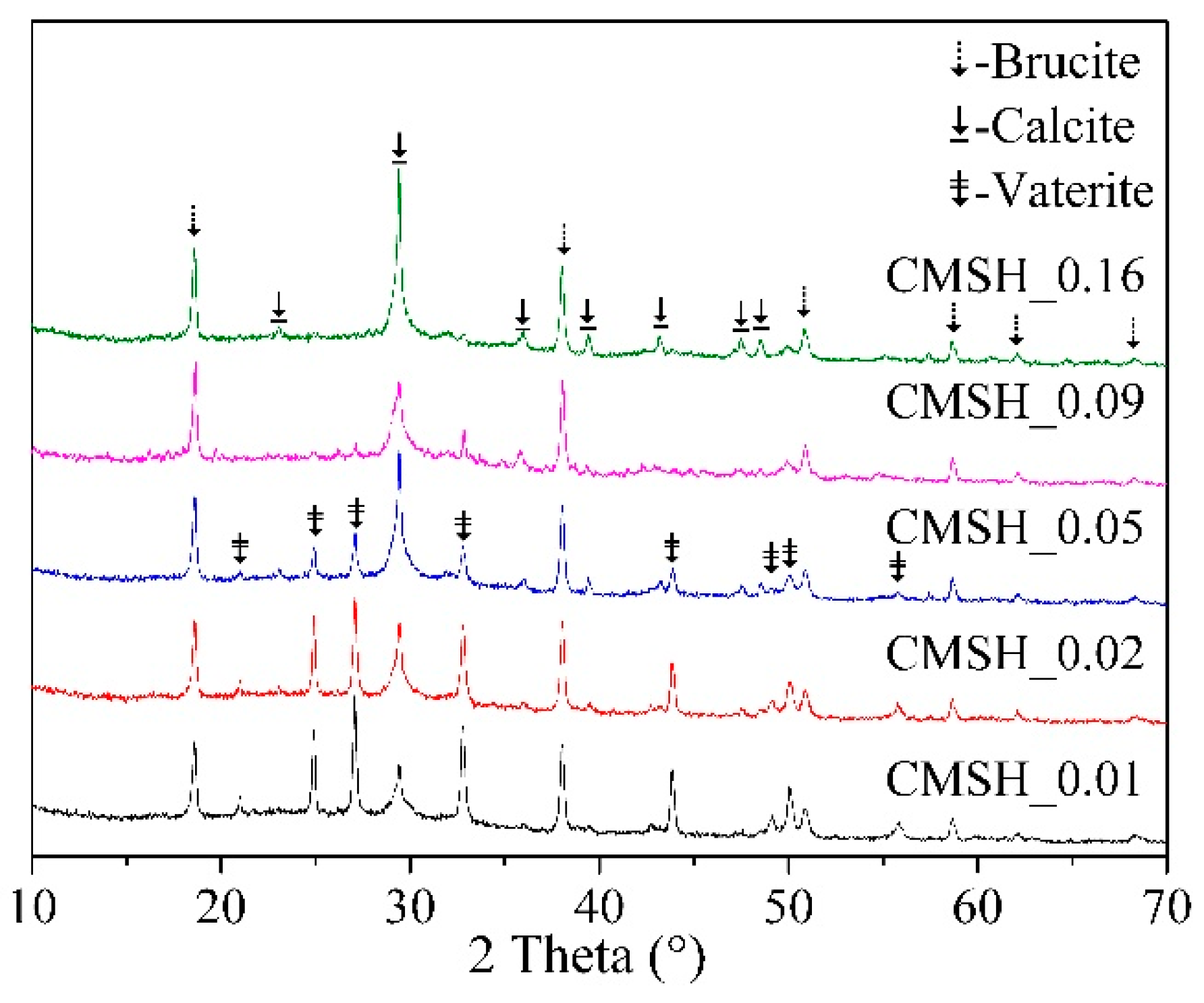

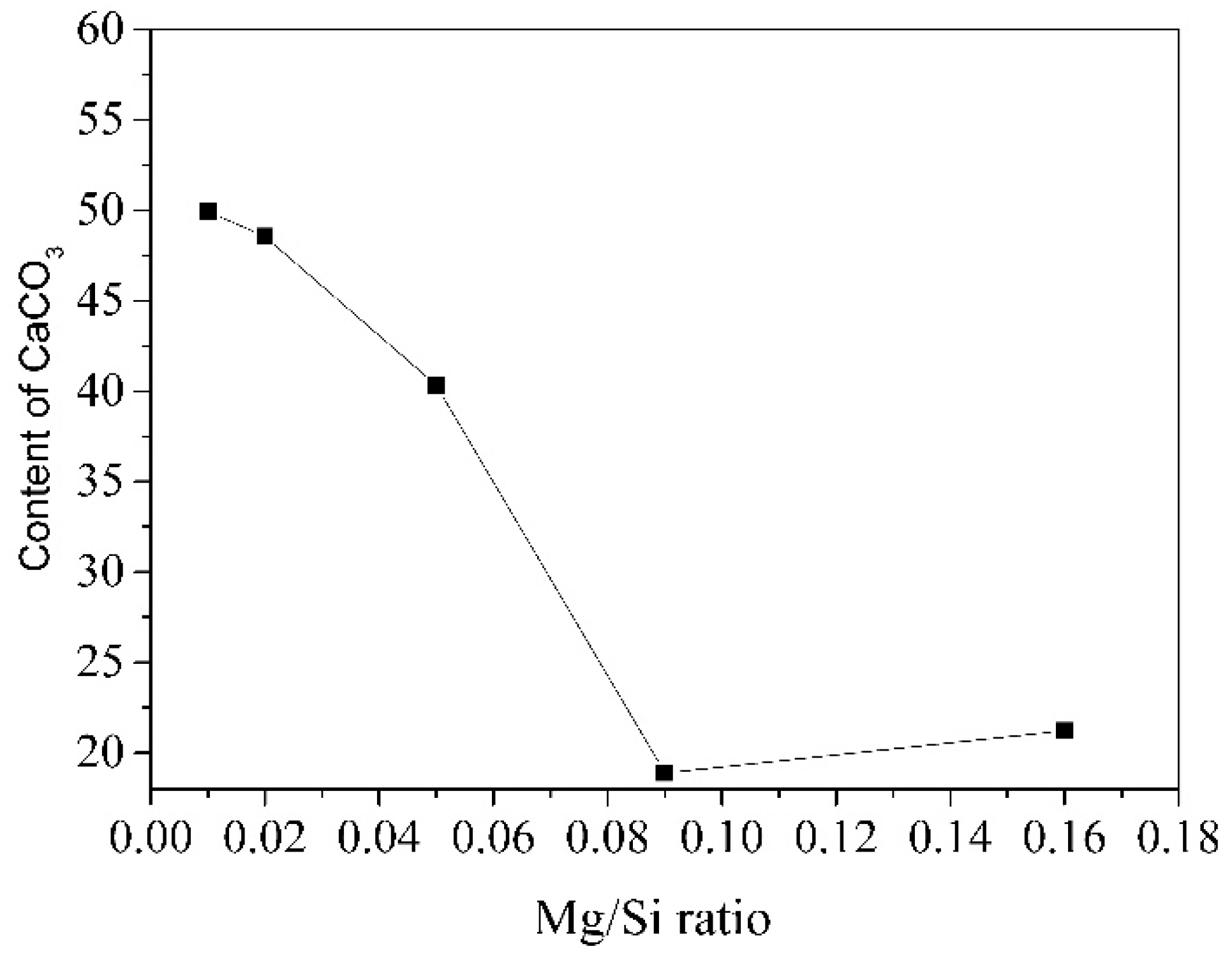

3.3.2. The Effect of Magnesium

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, S.; Peng, X.; Tang, L.; Cao, C.; Zeng, L. Contact-Hardening Behavior of Calcium Silicate Hydrate Powders. Materials 2018, 11, 2367. [Google Scholar] [CrossRef] [PubMed]

- Hung, C.-C.; Wu, Y.-C.; Lin, W.-T.; Chang, J.-J.; Yeih, W.-C. Effect of Mixture Variables on Durability for Alkali-Activated Slag Cementitious. Materials 2018, 11, 2252. [Google Scholar] [CrossRef]

- Song, K.-I.; Song, J.-K.; Lee, B.Y.; Yang, K.-H. Carbonation Characteristics of Alkali-Activated Blast-Furnace Slag Mortar. Adv. Mater. Sci. Eng. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- Li, N.; Farzadnia, N.; Shi, C. Microstructural changes in alkali-activated slag mortars induced by accelerated carbonation. Cem. Concr. Res. 2017, 100, 214–226. [Google Scholar] [CrossRef]

- Sevelsted, T.F.; Skibsted, J. Carbonation of C–S–H and C–A–S–H samples studied by 13C, 27Al and 29Si MAS NMR spectroscopy. Cem. Concr. Res. 2015, 71, 56–65. [Google Scholar] [CrossRef]

- Borges, P.H.; Costa, J.O.; Milestone, N.B.; Lynsdale, C.J.; Streatfield, R.E. Carbonation of CH and C–S–H in composite cement pastes containing high amounts of BFS. Cem. Concr. Res. 2010, 40, 284–292. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.B. Resistance of alkali-activated slag concrete to carbonation. Cem. Concr. Res. 2001, 31, 1277–1283. [Google Scholar] [CrossRef]

- Gong, K.; White, C.E. Impact of chemical variability of ground granulated blast-furnace slag on the phase formation in alkali-activated slag pastes. Cem. Concr. Res. 2016, 89, 310–319. [Google Scholar] [CrossRef] [Green Version]

- Kamali, M.; Ghahremaninezhad, A. A Study of Calcium-Silicate-Hydrate/Polymer Nanocomposites Fabricated Using the Layer-By-Layer Method. Materials 2018, 11, 527. [Google Scholar] [CrossRef] [PubMed]

- Bernard, E.; Lothenbach, B.; Cau-Dit-Coumes, C.; Chlique, C.; Dauzères, A.; Pochard, I. Magnesium and calcium silicate hydrates, Part I: Investigation of the possible magnesium incorporation in calcium silicate hydrate (CSH) and of the calcium in magnesium silicate hydrate (MSH). Appl. Geochem. 2018, 89, 229–242. [Google Scholar] [CrossRef]

- Battocchio, F.; Monteiro, P.J.M.; Wenk, H.R. Rietveld refinement of the structures of 1.0 CSH and 1.5 CSH. Cem. Concr. Res. 2012, 42, 1534–1548. [Google Scholar] [CrossRef]

- Lodeiro, I.G.; Macphee, D.E.; Palomo, A.; Fernández-Jiménez, A. Effect of alkalis on fresh C–S–H gels. FTIR analysis. Cem. Concr. Res. 2009, 39, 147–153. [Google Scholar] [CrossRef]

- Renaudin, G.; Russias, J.; Leroux, F.; Frizon, F.; Cau-dit-Coumes, C. Structural characterization of C–S–H and C–A–S–H samples—part I: Long-range order investigated by Rietveld analyses. J. Solid State Chem. 2009, 182, 3312–3319. [Google Scholar] [CrossRef]

- Chen, W.; Brouwers, H.J.H. The hydration of slag, part 1: Reaction models for alkali-activated slag. J. Mater. Sci. 2007, 42, 428–443. [Google Scholar] [CrossRef]

- Myers, R.J.; Bernal, S.A.; San Nicolas, R.; Provis, J.L. Generalized structural description of calcium–sodium aluminosilicate hydrate gels: The cross-linked substituted tobermorite model. Langmuir 2013, 29, 5294–5306. [Google Scholar] [CrossRef]

- Richardson, I.G. Tobermorite/jennite-and tobermorite/calcium hydroxide-based models for the structure of CSH: Applicability to hardened pastes of tricalcium silicate, β-dicalcium silicate, Portland cement, and blends of Portland cement with blast-furnace slag, metakaolin, or silica fume. Cem. Concr. Res. 2004, 34, 1733–1777. [Google Scholar]

- Richardson, I.G. Model structures for C-(A)-S-H (I). Acta Crystallograph. Sec. B Struct. Sci. Cryst. Eng. Mater. 2014, 70, 903–923. [Google Scholar] [CrossRef]

- Myers, R.J.; Bernal, S.A.; Provis, J.L. A thermodynamic model for C-(N-) A-S-H gel: CNASH_ss. Derivation and validation. Cem. Concr. Res. 2014, 66, 27–47. [Google Scholar] [CrossRef]

- Sun, G.K.; Young, J.F.; Kirkpatrick, R.J. The role of Al in C–S–H: NMR, XRD, and compositional results for precipitated samples. Cem. Concr. Res. 2006, 36, 18–29. [Google Scholar] [CrossRef]

- Pegado, L.; Labbez, C.; Churakov, S.V. Mechanism of aluminium incorporation into C–S–H from ab initio calculations. J. Mater. Chem. 2014, 2, 3477–3483. [Google Scholar] [CrossRef]

- Lognot, I.; Klur, I.; Nonat, A. NMR and Infrared Spectroscopies of CSH and Al-Substituted CSH Synthesised in Alkaline Solutions//Nuclear Magnetic Resonance Spectroscopy of Cement-Based Materials; Springer: Berlin/Heidelberg, Germany, 1998; pp. 189–196. [Google Scholar]

- Colombet, P.; Grimmer, A.R.; Zanni, H.; Sozzani, P. Nuclear Magnetic Resonance Spectroscopy of Cement-Based Materials; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Andersen, M.D.; Jakobsen, H.J.; Skibsted, J. A new aluminium-hydrate species in hydrated Portland cements characterized by 27Al and 29Si MAS NMR spectroscopy. Cem. Concr. Res. 2006, 36, 3–17. [Google Scholar] [CrossRef]

- Faucon, P.; Delagrave, A.; Richet, C.; Marchand, J.M.; Zanni, H. Aluminum Incorporation in Calcium Silicate Hydrates (C−S−H) Depending on Their Ca/Si Ratio. J. Phys. Chem. B 1999, 103, 7796–7802. [Google Scholar] [CrossRef]

- Qian, G.; Xu, G.; Li, H.; Li, A. Mg-Xonotlite and its coexisting phases. Cem. Concr. Res. 1997, 27, 315–320. [Google Scholar] [CrossRef]

- L’Hôpital, E.; Lothenbach, B.; Kulik, D.; Scrivener, K. Influence of calcium to silica ratio on aluminium uptake in calcium silicate hydrate. Cem. Concr. Res. 2016, 85, 111–121. [Google Scholar] [CrossRef]

- Pytel, Z.; Małolepszy, J. DTA studies of phases synthesized in the system CaO-MgO-SiO2-H2O. Silicat. Ind. 2000, 7–8, 81–85. [Google Scholar]

- Komarneni, S.; Breval, E.; Roy, D.; Roy, R. Reactions of some calcium silicates with metal cations. Cem. Concr. Res. 1988, 18, 204–220. [Google Scholar] [CrossRef]

- Shrivastava, O.P.; Komarneni, S.; Breval, E. Mg2+ uptake by synthetic tobermorite and xonotlite. Cem. Concr. Res. 1991, 21, 83–90. [Google Scholar] [CrossRef]

- Bernard, E.; Dauzères, A.; Lothenbach, B. Magnesium and calcium silicate hydrates, Part II: Mg-exchange at the interface “low-pH” cement and magnesium environment studied in a CSH and MSH model system. Appl. Geochem. 2018, 89, 210–218. [Google Scholar] [CrossRef]

- Roosz, C.; Vieillard, P.; Blanc, P.; Gaboreau, S.; Gailhanou, H.; Braithwaite, D.; Montouillout, V.; Denoyel, R.; Henocq, P.; Madé, B. Thermodynamic properties of CSH, CASH and MSH phases: Results from direct measurements and predictive modelling. Appl. Geochem. 2018, 92, 140–156. [Google Scholar] [CrossRef]

- Gruyaert, E.; Van den Heede, P.; De Belie, N. Carbonation of slag concrete: Effect of the cement replacement level and curing on the carbonation coefficient—Effect of carbonation on the pore structure. Cem. Concr. Compos. 2013, 35, 39–48. [Google Scholar] [CrossRef]

- Mo, L.; Panesar, D.K. Accelerated carbonation–A potential approach to sequester CO2 in cement paste containing slag and reactive MgO. Cem. Concr. Compos. 2013, 43, 69–77. [Google Scholar] [CrossRef]

- Kim, J.J.; Foley, E.M.; Taha, M.M.R. Nano-mechanical characterization of synthetic calcium–silicate–hydrate (C–S–H) with varying CaO/SiO2 mixture ratios. Cem. Concr. Compos. 2013, 36, 65–70. [Google Scholar] [CrossRef]

- Mendoza, O.; Giraldo, C.; Camargo, S.S., Jr.; Tobón, J.I. Structural and nano-mechanical properties of Calcium Silicate Hydrate (CSH) formed from alite hydration in the presence of sodium and potassium hydroxide. Cem. Concr. Res. 2015, 74, 88–94. [Google Scholar] [CrossRef]

- Black, L.; Breen, C.; Yarwood, J.; Garbev, K.; Stemmermann, P.; Gasharova, B. Structural Features of C?S?H(I) and Its Carbonation in Air?A Raman Spectroscopic Study. Part II: Carbonated Phases. J. Am. Ceram. Soc. 2007, 90, 908–917. [Google Scholar] [CrossRef]

- Garbev, K.; Stemmermann, P.; Black, L.; Breen, C.; Yarwood, J.; Gasharova, B. Structural features of C–S–H (I) and its carbonation in air—A Raman spectroscopic study. Part I: Fresh phases. J. Am. Ceram. Soc. 2007, 90, 900–907. [Google Scholar] [CrossRef]

- Ashraf, W.; Olek, J. Carbonation activated binders from pure calcium silicates: Reaction kinetics and performance controlling factors. Cem. Concr. Compos. 2018, 93, 85–98. [Google Scholar] [CrossRef]

- Li, X.-G.; Lv, Y.; Ma, B.-G.; Wang, W.-Q.; Jian, S.-W. Decomposition kinetic characteristics of calcium carbonate containing organic acids by TGA. Arab. J. Chem. 2017, 10, S2534–S2538. [Google Scholar] [CrossRef] [Green Version]

- Bernard, E.; Lothenbach, B.; Le Goff, F.; Pochard, I.; Dauzères, A. Effect of magnesium on calcium silicate hydrate (C-S-H). Cem. Concr. Res. 2017, 97, 61–72. [Google Scholar] [CrossRef]

- Black, L.; Garbev, K.; Gee, I. Surface carbonation of synthetic CSH samples: A comparison between fresh and aged CSH using X-ray photoelectron spectroscopy. Cem. Concr. Res. 2008, 38, 745–750. [Google Scholar] [CrossRef]

| Samples a | Initial Ca/Si Ratio | Initial Al/Si Ratio | Initial Mg/Si Ratio | Real Ca/Si Ratio | Real Al/Si Ratio | Real Mg/Si Ratio | MQA b |

|---|---|---|---|---|---|---|---|

| CSH_0.64 | 0.67 | 0 | 0 | 0.64 | 0 | 0 | TGA c |

| CSH_0.87 | 1.0 | 0 | 0 | 0.87 | 0 | 0 | TGA |

| CSH_1.02 | 1.2 | 0 | 0 | 1.02 | 0 | 0 | TGA |

| CSH_1.14 | 1.4 | 0 | 0 | 1.14 | 0 | 0 | TGA |

| CSH_1.25 | 1.6 | 0 | 0 | 1.25 | 0 | 0 | TGA |

| CASH_0.02 | 1.2 | 0.0125 | 0 | 0.77 | 0.018 | 0 | XRD d |

| CASH_0.03 | 1.2 | 0.025 | 0 | 0.80 | 0.034 | 0 | XRD |

| CASH_0.05 | 1.2 | 0.05 | 0 | 0.77 | 0.054 | 0 | XRD |

| CASH_0.08 | 1.2 | 0.1 | 0 | 0.83 | 0.081 | 0 | XRD |

| CASH_0.14 | 1.2 | 0.2 | 0 | 0.86 | 0.14 | 0 | XRD |

| CMSH_0.01 | 1.2 | 0 | 0.0125 | 0.92 | 0 | 0.013 | XRD |

| CMSH_0.02 | 1.2 | 0 | 0.025 | 0.96 | 0 | 0.022 | XRD |

| CMSH_0.05 | 1.2 | 0 | 0.05 | 0.95 | 0 | 0.052 | XRD |

| CMSH_0.09 | 1.2 | 0 | 0.1 | 0.87 | 0 | 0.090 | XRD |

| CMSH_0.16 | 1.2 | 0 | 0.2 | 0.96 | 0 | 0.16 | XRD |

| Samples | Q1 | Q2p | Q2b | Q2u | Q3 | CL | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ppm | % | ppm | % | ppm | % | ppm | % | ppm | % | ||

| CSH_0.64 | 79.00 | 9.37 | 84.17 | 23.16 | 91.46 | 9.76 | 87.00 | 36.27 | 95.35 | 21.44 | 16.77 |

| CSH_0.87 | 79.48 | 24.92 | 85.75 | 59329 | 83.57 | 15.80 | / | / | / | / | 8.03 |

| CSH_1.14 | 79.71 | 33.47 | 85.62 | 41.75 | 83.77 | 24.78 | / | / | / | / | 5.97 |

| CSH_1.25 | 79.34 | 64.37 | 84.54 | 35.63 | / | / | / | / | / | / | 3.11 |

| CASH_0.14 | 79.38 | 19.53 | 85.30 | 44.96 | 82.40 | 30.03 | 88.48 | 4.28 | 91.60 | 1.20 | 10.12 |

| CMSH_0.16 | 79.57 | 20.49 | 85.43 | 37.08 | 82.47 | 22.31 | / | / | 92.20 | 20.08 | 7.80 |

| Samples | Mass Loss (wt. %) from TGA Data c | CCP b | |||

|---|---|---|---|---|---|

| CO2_0 a | CO2_1 | CO2_7 | CO2_28 | ||

| CSH_0.64 | 2.72 | 4.5 | 12.37 | 15.93 | 13.21 |

| CSH_0.87 | 2.69 | 2.97 | 5.53 | 9.12 | 6.43 |

| CSH_1.02 | 3.87 | 4.36 | 5.69 | 12.57 | 8.70 |

| CSH_1.14 | 6.31 | 9.30 | 10.60 | 20.33 | 14.02 |

| CSH_1.25 | 4.71 | 15.95 | 20.94 | 19.56 | 14.85 |

| Samples | Calcite | Vaterite | Total CaCO3 | Amorphous Phase |

|---|---|---|---|---|

| CASH_0.02 | 13.88 | 33.36 | 47.24 | 52.76 |

| CASH_0.03 | 4.90 | 37.79 | 42.69 | 57.31 |

| CASH_0.05 | 6.92 | 39.31 | 46.22 | 53.78 |

| CASH_0.08 | 4.18 | 43.21 | 47.39 | 52.61 |

| CASH_0.14 | 2.77 | 44.25 | 47.03 | 52.97 |

| Samples | Calcite | Vaterite | Total CaCO3 | Other Phase |

|---|---|---|---|---|

| CMSH_0.01 | 17.08 | 32.86 | 49.94 | 50.06 |

| CMSH_0.02 | 15.19 | 33.37 | 48.56 | 51.44 |

| CMSH_0.05 | 20.37 | 19.98 | 40.35 | 59.65 |

| CMSH_0.09 | 16.45 | 2.45 | 18.90 | 81.10 |

| CMSH_0.16 | 20.05 | 1.17 | 21.22 | 78.78 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Yu, Q.; Huang, H.; Yin, S. Effects of Ca/Si Ratio, Aluminum and Magnesium on the Carbonation Behavior of Calcium Silicate Hydrate. Materials 2019, 12, 1268. https://doi.org/10.3390/ma12081268

Li J, Yu Q, Huang H, Yin S. Effects of Ca/Si Ratio, Aluminum and Magnesium on the Carbonation Behavior of Calcium Silicate Hydrate. Materials. 2019; 12(8):1268. https://doi.org/10.3390/ma12081268

Chicago/Turabian StyleLi, Jing, Qijun Yu, Haoliang Huang, and Suhong Yin. 2019. "Effects of Ca/Si Ratio, Aluminum and Magnesium on the Carbonation Behavior of Calcium Silicate Hydrate" Materials 12, no. 8: 1268. https://doi.org/10.3390/ma12081268