Strength Analysis of a Rib-Stiffened GLARE-Based Thin-Walled Structure

Abstract

:1. Introduction

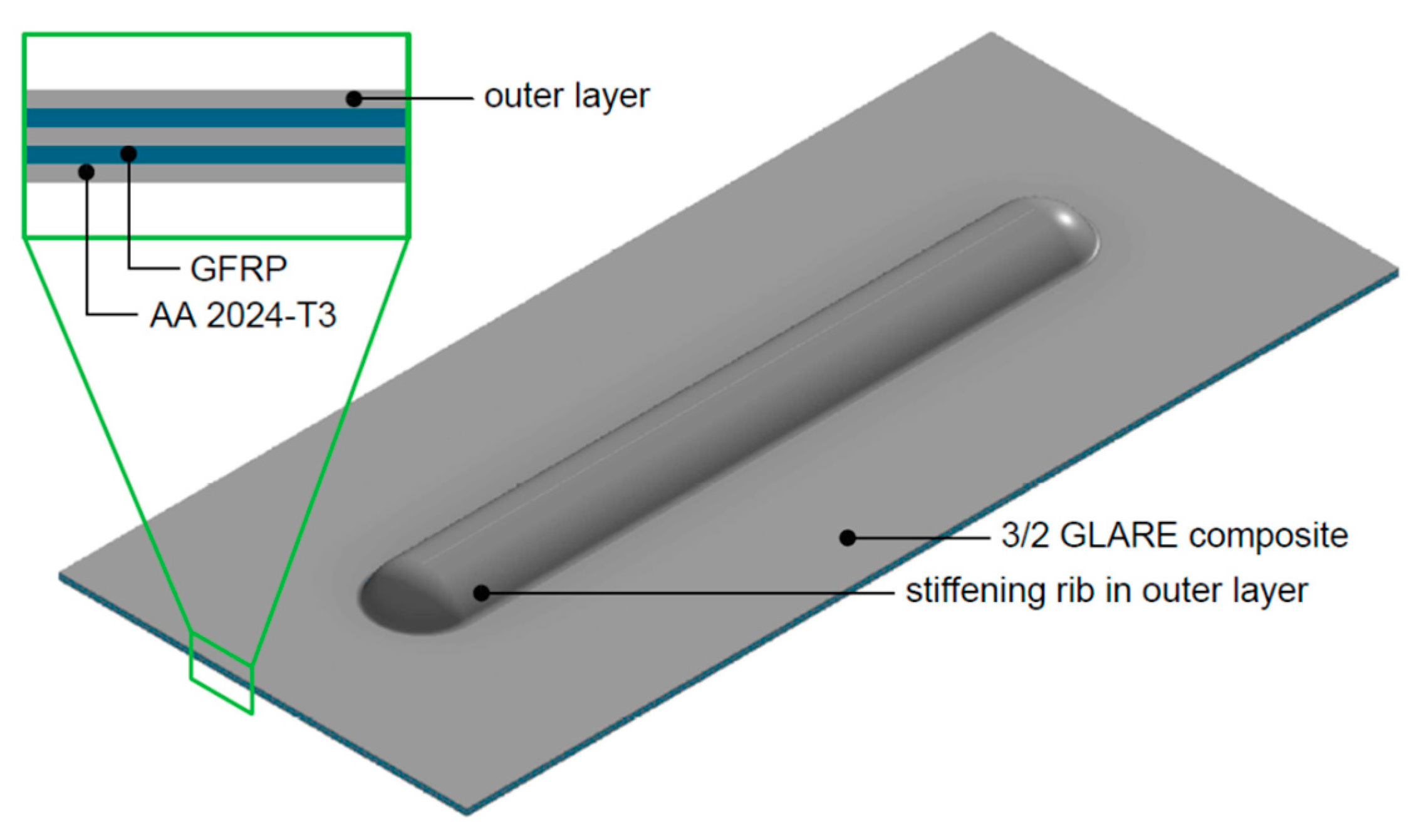

2. Materials and Methods

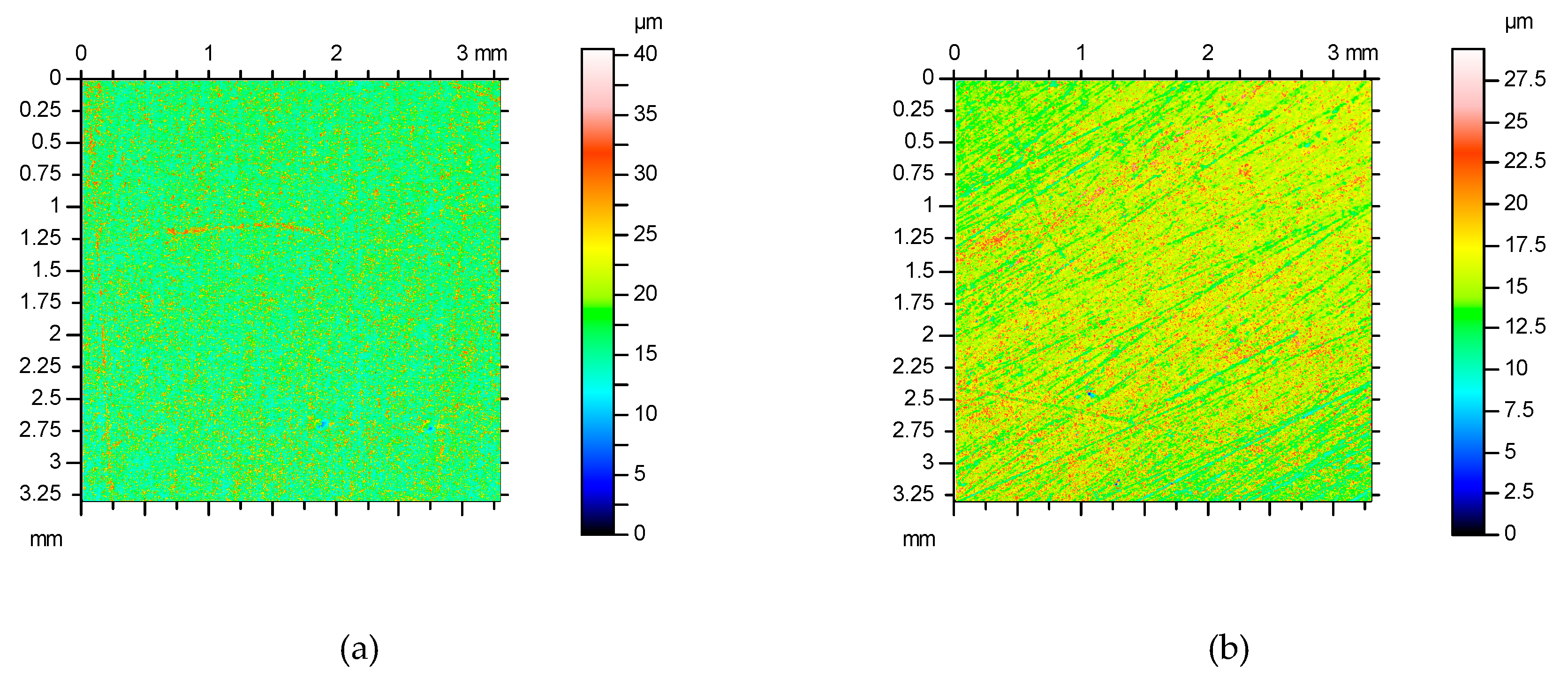

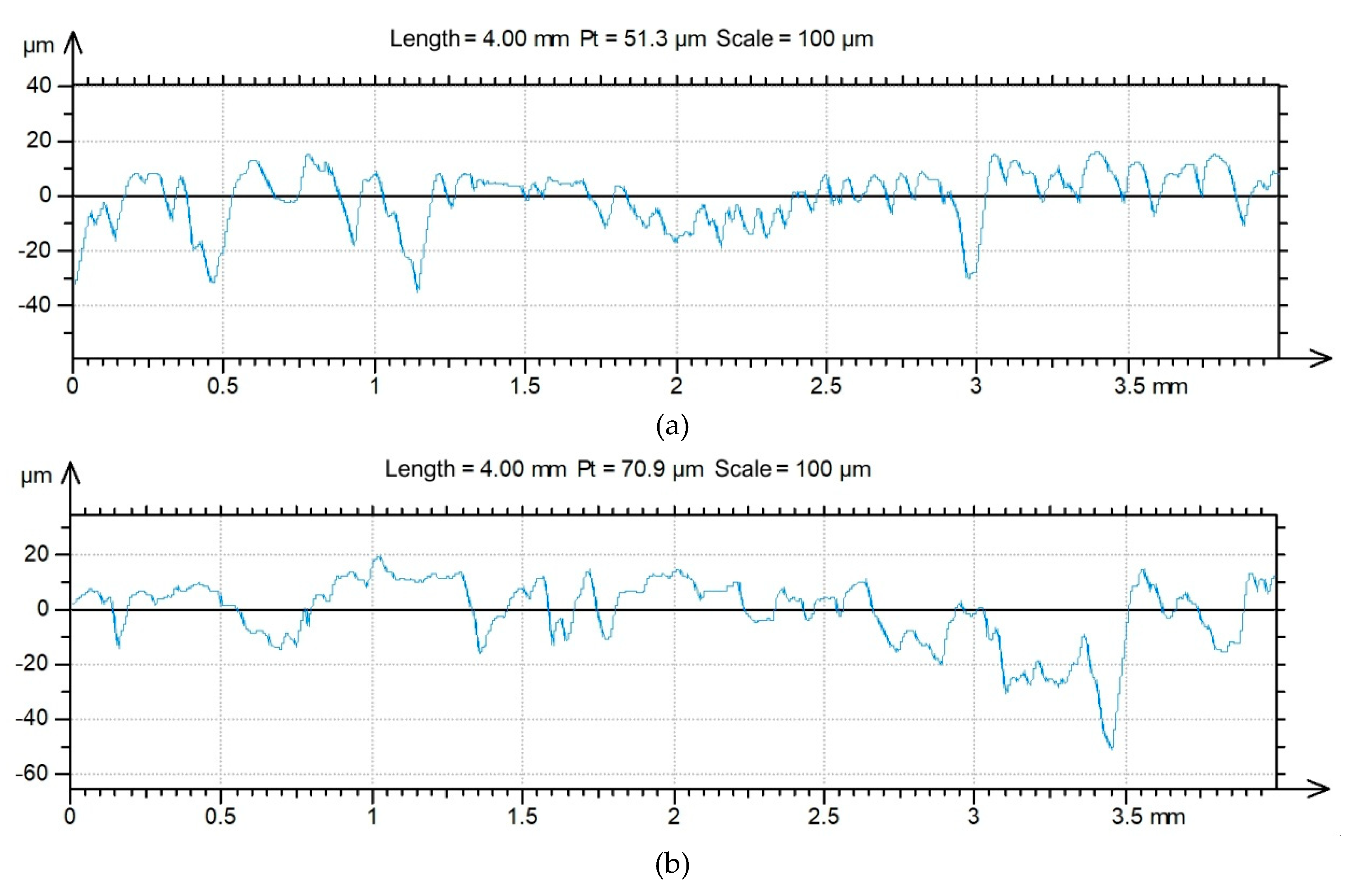

2.1. Materials

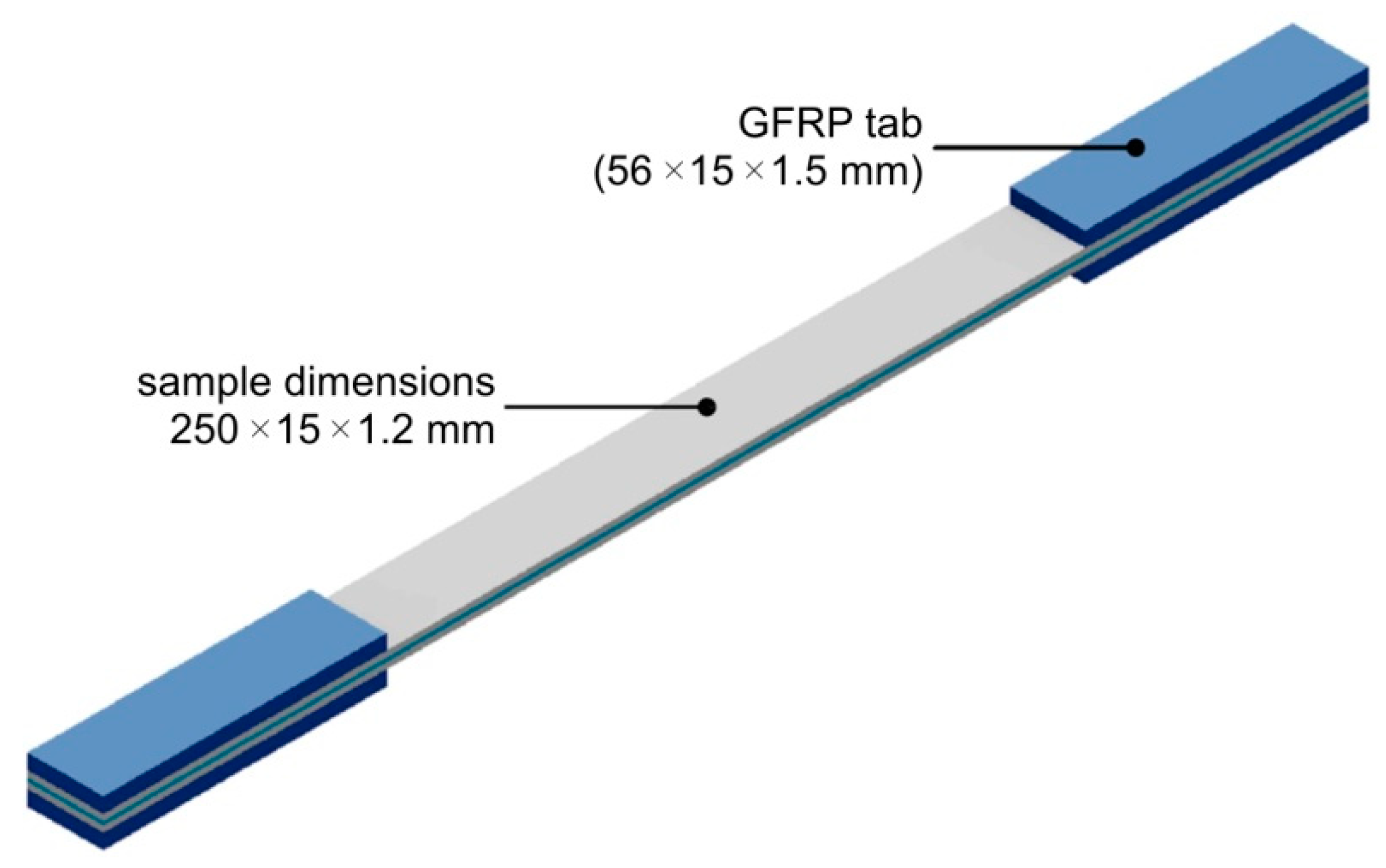

2.2. Uniaxial Tensile Test

2.3. Tensile/Shear and Drum Peel Tests

2.4. Short-Beam Three-Point-Bending Test

2.5. Fabrication of GLARE-Based Rib-Stiffened Panels

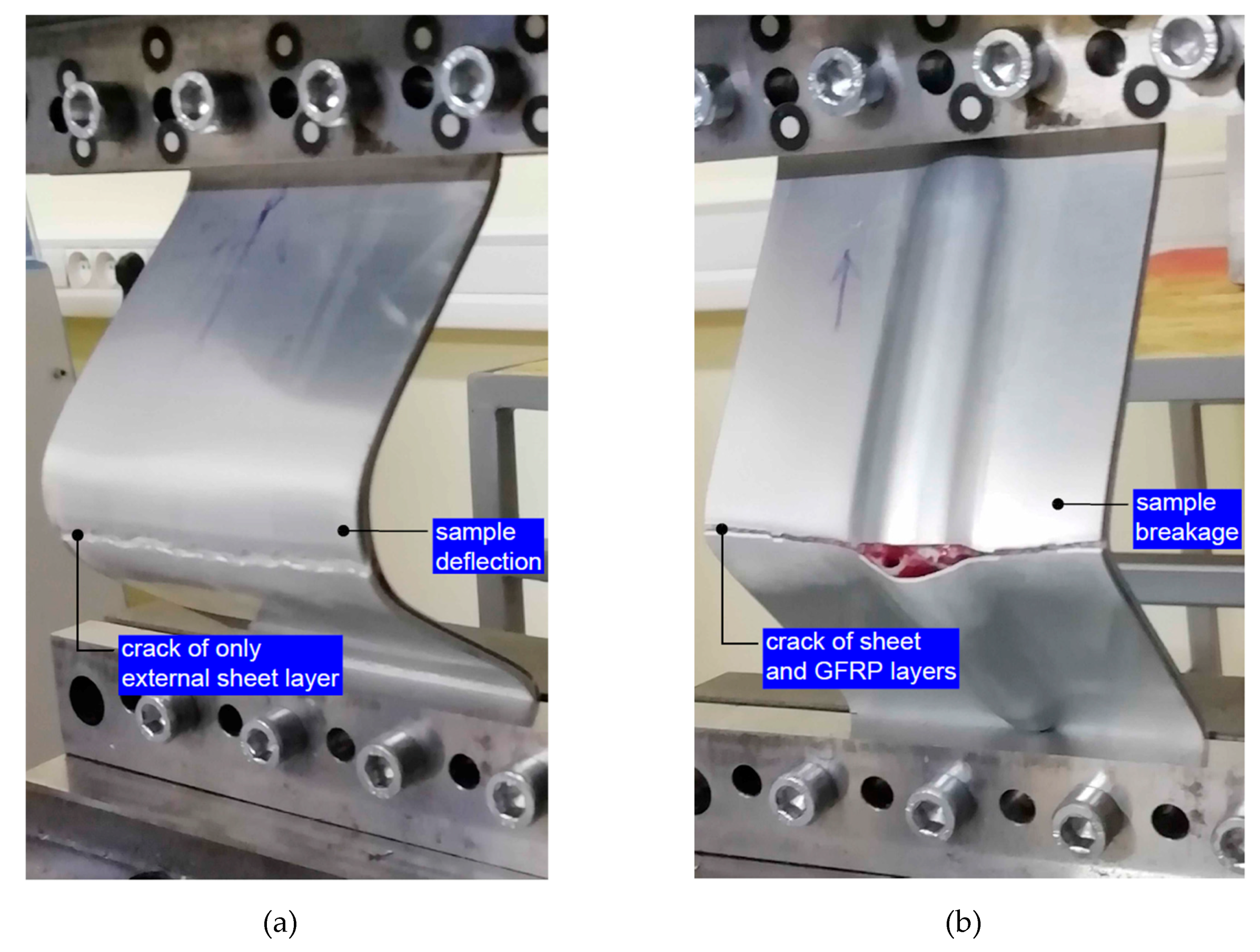

2.6. Buckling Test

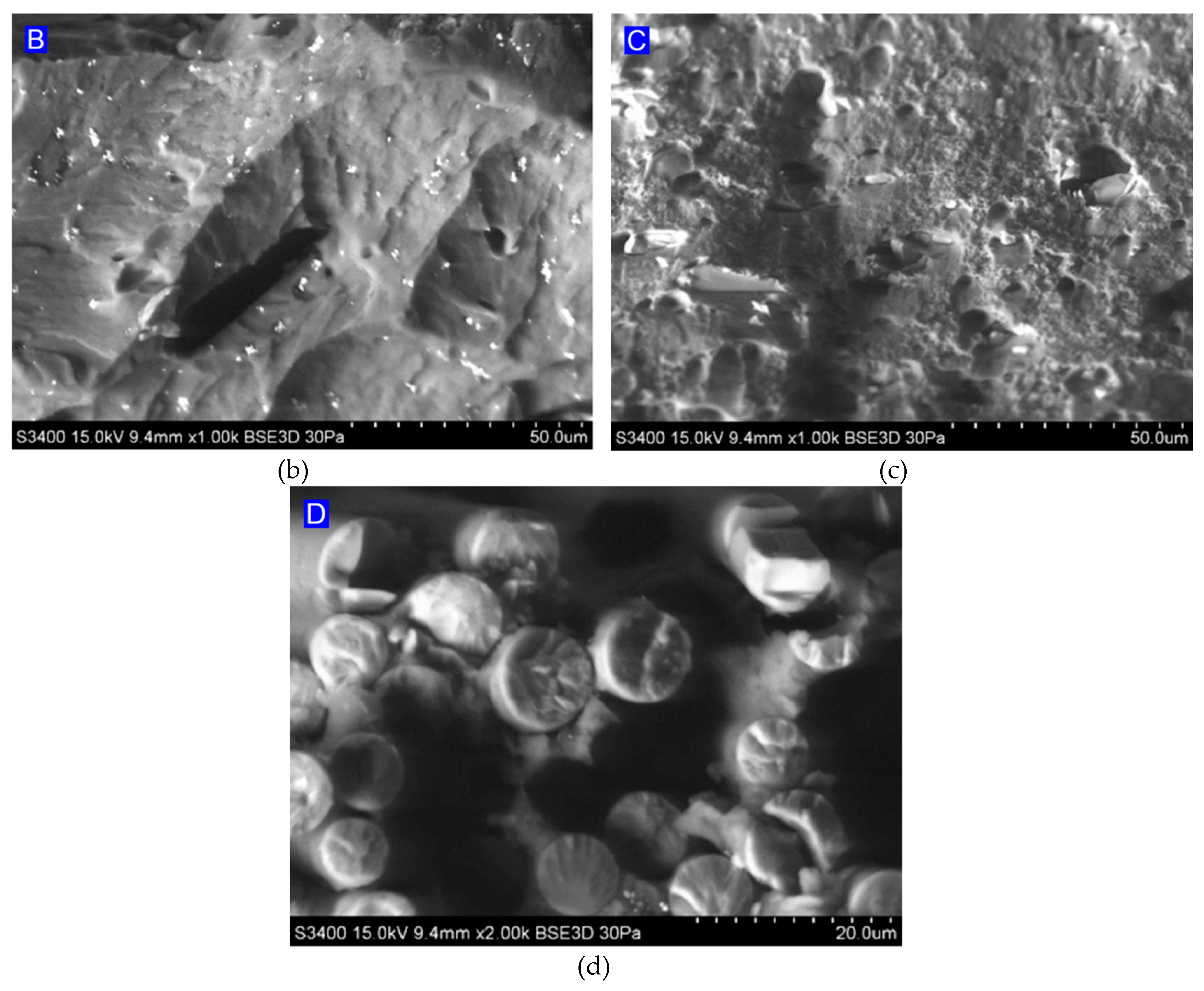

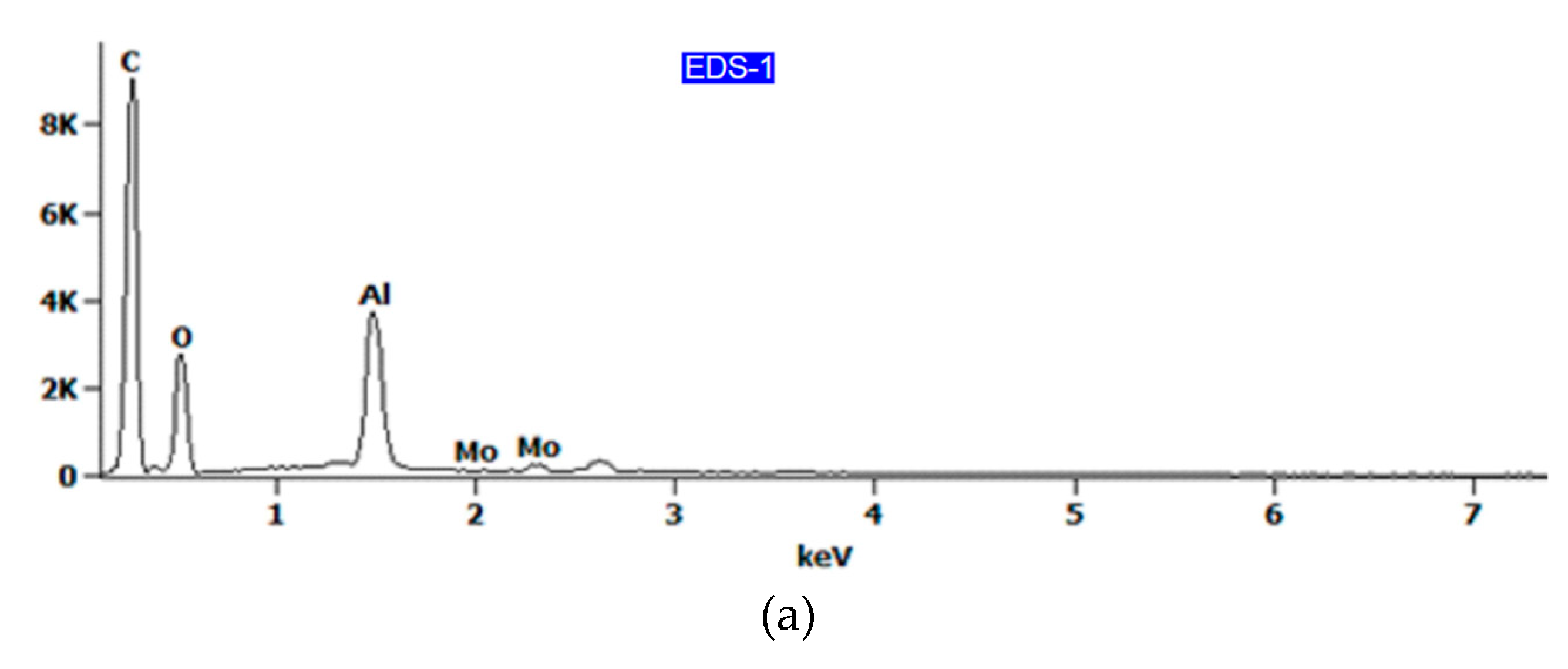

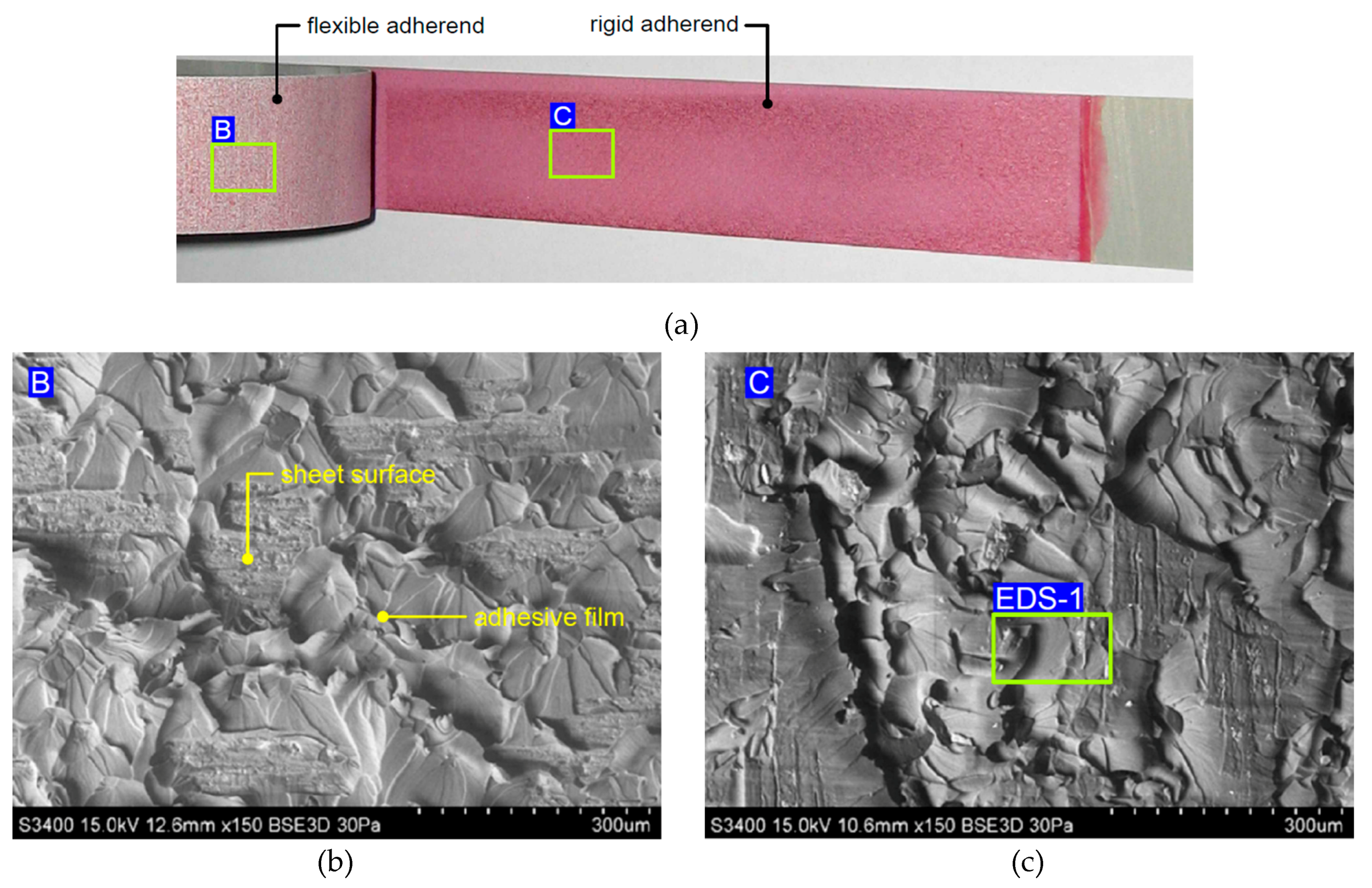

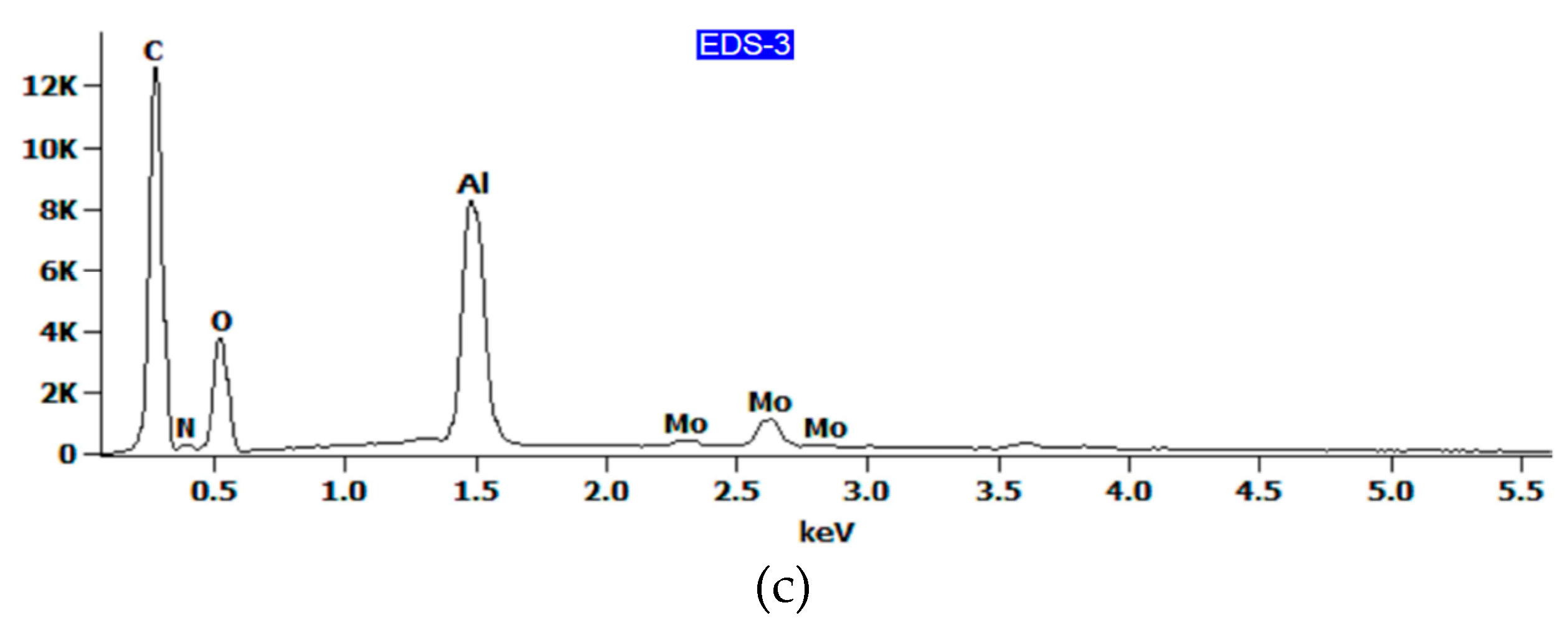

2.7. Microstructural Analysis

3. Results and Discussion

3.1. Uniaxial Tensile Test

3.2. Tensile/Shear Test

3.3. Drum Peel Test

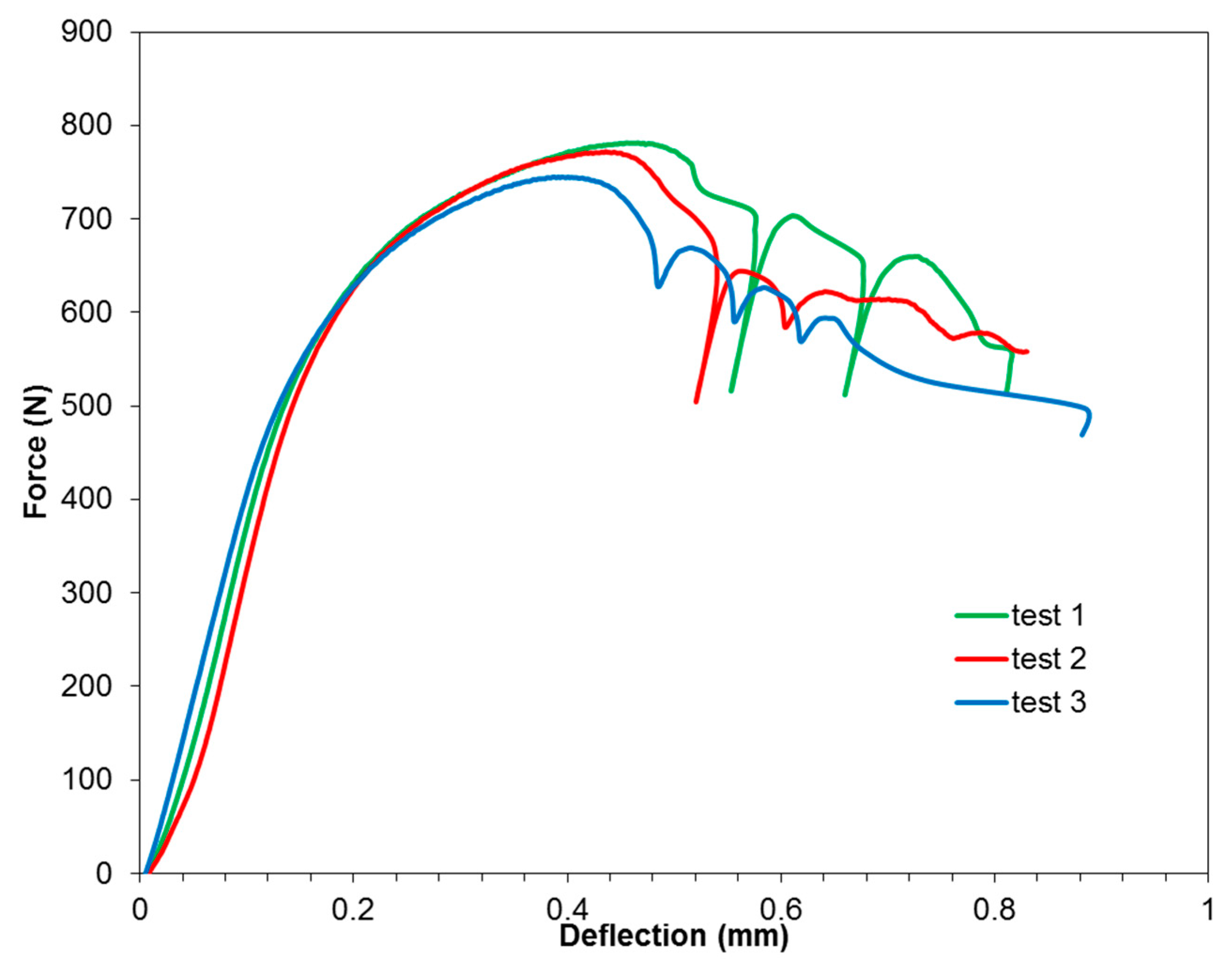

3.4. Short-Beam Three-Point-Bending Test

3.5. Buckling Test

4. Conclusions

- The strength of the 2/1 lay-up FMLs tested at −60 °C and 80 °C varies between 347.9 and 354.7 MPa. However, there is an increase in the stiffness of the specimens stretched at −60 °C compared with those tested at 80 °C. The temperature increase does not weaken the intermolecular forces between the 2024-T3 adherends and the glass/epoxy prepreg, resulting in their similar tensile strength.

- Samples tested at a temperature of 80 °C have a greater degree of elasticity than samples tested at a temperature of −60 °C. The tensile/shear strength of the specimens tested at −60 °C and 80 °C was 19.95 and 19.90 MPa, respectively. The fracture mechanism for the specimens tested at both temperatures analysed is based on the combination of cohesive failure in the resin and adhesive failure in the primer.

- No significant effect of temperature on peel strength was demonstrated in the FML variant with adhesive film. A decrease in the stiffness of the joint was noted at elevated temperature, while a reduction in the peel strength of the adhesion joint is more significant. FMLs with an additional adhesive film exhibited stronger adhesion than FMLs without this film because hardened epoxy resin dominated on the surface of the flexible adherend.

- The load–deflection curves determined through short-beam three-point-bending tests show that after maximum load, each curve displays an irregular fluctuation, demonstrating that multiple failures have taken place. The destruction of the FML layers at the interface with Alclad does not affect the FML’s interlaminar strength in the normal operating conditions of FMLs.

- GLARE-based rib-stiffened panels exhibit a higher critical force in the buckling test than the unstiffened FML panel: a 34.5% increase in critical force is observed.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, G.; Yang, J.M. The mechanical behavior of GLARE laminates for aircraft structures. JOM 2005, 57, 72–79. [Google Scholar] [CrossRef]

- Vermeeren, C.A.J.R. An historic overview of the development of fiber metal laminates. Appl. Compos. Mater. 2003, 10, 189–205. [Google Scholar] [CrossRef]

- Chang, P.Y.; Yeh, P.C.; Yang, J.M. Fatigue crack initiation in hybrid boron/glass/aluminum fiber metal laminates. Mater. Sci. Eng. A 2008, 496, 273–280. [Google Scholar] [CrossRef]

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Raišutis, R.; Tumšys, O. Application of dual focused ultrasonic phased array transducer in two orthogonal cross-sections for inspection of multi-layered composite components of the aircraft fuselage. Materials 2020, 13, 1689. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jakubczak, P.; Bienias, J. Non-destructive damage detection in fibre metal laminates. J. Nondestr. Evaluat. 2019, 38, 49. [Google Scholar] [CrossRef] [Green Version]

- Sinke, J. Some Inspection Methods for quality control and in-service inspection of GLARE. Appl. Compos. Mater. 2003, 10, 277–291. [Google Scholar] [CrossRef]

- Bisle, W.; Meier, T.; Mueller, S.; Rueckert, S. In-service inspection concept for GLARE®—An example for the use of new UT array inspection systems. In Proceedings of the 9th ECNDT Conference, Berlin, Germany, 25–29 September 2006. [Google Scholar]

- Advantages and Disadvantages of Using Composite Materials in Airplanes. Available online: https://www.thebalancecareers.com/composite-materials-aircraft-structure-282777 (accessed on 24 May 2020).

- Kawai, M.; Morishita, M.; Tomura, S.; Takamida, K. Inelastic behavior and strength of fiber-metal hybrid composite: GLARE. Int. J. Mech. Sci. 1998, 40, 183–198. [Google Scholar] [CrossRef]

- Alderliesten, R.C.; Homan, J.J. Fatigue and damage tolerance issues of Glare in aircraft structures. Int. J. Fatigue 2006, 28, 1116–1123. [Google Scholar] [CrossRef]

- Woerden, H.J.M.; Sinke, J.; Hooijmeijer, P.A. Maintenance of Glare structures and Glare as riveted or bonded repair material. Appl. Compos. Mater. 2003, 10, 307–329. [Google Scholar] [CrossRef]

- Borgonje, B.; Ypma, M.S. Long term behaviour of Glare. Appl. Compos. Mater. 2003, 10, 243–255. [Google Scholar] [CrossRef]

- Ostapiuk, M.; Bieniaś, J. Fracture analysis and shear strength of aluminum/CFRP and GFRP adhesive joint in fiber metal laminates. Materials 2020, 13, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kötter, B.; Karsten, J.; Körbelin, J.; Fiedler, B. CFRP thin-ply fibre metal laminates: Influences of ply thickness and metal layers on open hole tension and compression properties. Materials 2020, 13, 910. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sinke, J. Development of fibre metal laminates: Concurrent multi-scale modeling and testing. J. Mater. Sci. 2006, 41, 6777–6788. [Google Scholar] [CrossRef]

- Megson, T.H.G. Structural components of aircraft. In Introduction to Aircraft Strustural Analysis, 3rd ed.; Megson, T.H.G., Ed.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 373–393. [Google Scholar]

- Severijns, C.; de Freitas, S.T.; Poulis, J.A. Susceptor-assisted induction curing behaviour of a two component epoxy paste adhesive for aerospace applications. Int. J. Adhes. Adhes. 2017, 75, 155–164. [Google Scholar] [CrossRef] [Green Version]

- Tanrattanakul, V.; Jaroendee, D. Comparison between microwave and thermal curing of glass fiber-epoxy composites: Effect of microwave-heating cycle on mechanical properties. J. Appl. Polym. Sci. 2006, 102, 1059–1070. [Google Scholar] [CrossRef]

- Müller, B.; Palardy, G.; De Freitas, S.T.; Sinke, J. Out-of-autoclave manufacturing of GLARE panels using resistance heating. J. Compos. Mater. 2018, 52, 1661–1675. [Google Scholar] [CrossRef] [Green Version]

- McIlhagger, A.; Archer, E.; McIlhagger, R. Manufacturing processes for composite materials and components for aerospace applications. In Polymer Composites in the Aerospace Industry; Irving, P.E., Soutis, C., Eds.; Woodhead Publishing: Sawston, UK, 2015; pp. 53–75. [Google Scholar]

- Kreculj, D.; Rasuo, B. Impact damage modeling in laminated composite aircraft structures. In Sustainable Composites for Aerospace Applications; Jawad, M., Thariq, M., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 125–153. [Google Scholar]

- Hiken, A. The evolution of the composite fuselage: A manufacturing perspective. In Aerospace Engineering; Dekoulis, G., Ed.; IntechOpen Ltd.: London, UK, 2019; Available online: https://www.intechopen.com/books/aerospace-engineering/the-evolution-of-the-composite-fuselage-a-manufacturing-perspective (accessed on 24 May 2020).

- ISO 6892-1. Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature; International Organisation for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Trzepiecinski, T.; Kubit, A.; Kudelski, R.; Kwolek, P.; Obłój, A. Strength properties of aluminium/glass-fiber-reinforced laminate with additional epoxy adhesive film interlayer. Int. J. Adhes. Adhes. 2018, 85, 29–36. [Google Scholar] [CrossRef]

- Rans, C.D.; Alderliesten, R.C.; Benedictus, R. Predicting the influence of temperature on fatigue crack propagation in fibre metal laminates. Eng. Fract. Mech. 2011, 78, 2193–2201. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Sun, S.; Zheng, Q.; Li, D.; Wen, J. Long-term atmospheric corrosion behaviour of aluminium alloys 2024 and 7075 in urban, coastal and industrial environments. Corros. Sci. 2009, 51, 719–727. [Google Scholar] [CrossRef]

- ASTM D2344. Standard Test Method for Short-Beam Strength of Polymer–Matrix Composite Materials and Their Laminates; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Liu, C.; Du, D.; Li, H.; Hu, Y.; Xu, Y.; Tian, J.; Tao, G.; Tao, J. Interlaminar failure behavior of GLARE laminates under short-beam three-point-bending load. Compos. Part B Eng. 2016, 97, 361–367. [Google Scholar] [CrossRef]

- Doan, Q.H.; Thai, D.K.; Tran, N.L. A numerical study of the effect of component dimensions on the critical buckling load of a GFRP composite strut under uniaxial compression. Materials 2020, 13, 931. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cintra, G.G.; Cardoso, D.C.T.; Vieira, J.D. Parameters affecting local buckling response of pultruded GFRP I-columns: Experimental and numerical investigation. Compos. Struct. 2019, 222, 110897. [Google Scholar] [CrossRef]

- Elchalakani, M.; Dong, M.; Karrech, A.; Li, G.; Ali, M.S.; Yang, B. Experimental investigation of rectangular air-cured geopolymer concrete columns reinforced with GFRP bars and stirrups. J. Compos. Constr. 2019, 23, 4019011. [Google Scholar] [CrossRef]

- Aurrekoetxea, M.; López de Lacalle, L.N.; Llanos, I. Machining stresses and initial geometry on bulk residual stresses characterization by on-machine layer removal. Materials 2020, 13, 1445. [Google Scholar] [CrossRef] [Green Version]

- Zheng, K.; Politis, D.J.; Wang, L.; Lin, J. A review on forming techniques for manufacturing lightweight complex-shaped aluminium panel components. Int. J. Light. Mater. Manuf. 2018, 1, 55–80. [Google Scholar] [CrossRef]

| Thickness t, mm | Poisson’s Ratio ν | Young’s Modulus E, GPa | Yield Stress Rp0,2, MPa | Ultimate Tensile Stress Rm, MPa |

|---|---|---|---|---|

| 0.4 | 0.33 | 72.87 | 302 | 449 |

| 2 | 0.33 | 70.75 | 336 | 478 |

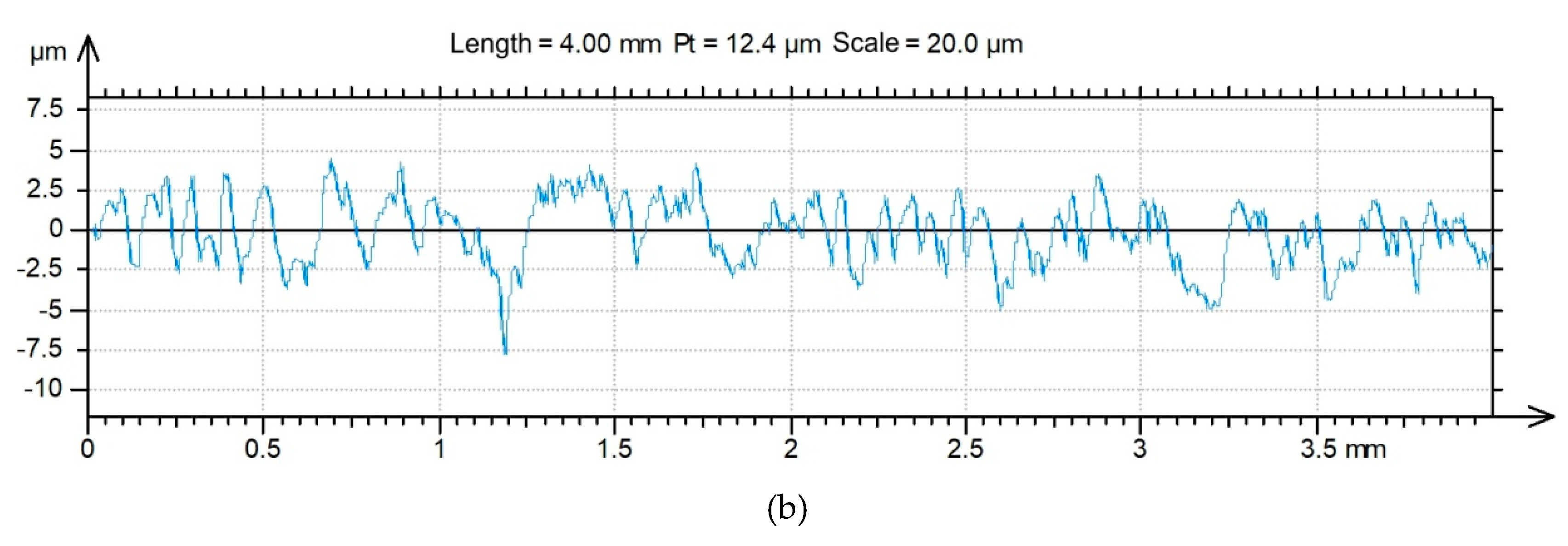

| Roughness Parameter | Sheet Thickness, mm | |

|---|---|---|

| 0.4 | 2 | |

| Sz, μm | 29.4 | 40.5 |

| Sp, μm | 13.7 | 22.9 |

| Str | 0.32 | 0.76 |

| Sv, μm | 15.8 | 17.6 |

| Sq | 2.72 | 4.32 |

| Sku | 4.53 | 3.75 |

| Ssk | 1.18 | 1.39 |

| Sa, μm | 1.97 | 3.36 |

| EDS Spot | C-K | O-K | Mg-K | Al-K | Cl-K | Cu-K | Mo-L |

|---|---|---|---|---|---|---|---|

| EDS-1 | 50.1 | 32.1 | 0.4 | 13.9 | 1.9 | - | 1.6 |

| EDS-2 | - | - | 1.3 | 93.9 | - | 4.8 | - |

| EDS-3 | - | 44.3 | 0.4 | 44.7 | - | 1.3 | 9.3 |

| EDS Spot | C-K | O-K | O-K | Al-K | Mo-L |

|---|---|---|---|---|---|

| EDS-1 | 52.5 | 8.6 | - | 9.7 | - |

| EDS-2 | - | - | 43.2 | 44.9 | 11.9 |

| EDS-3 | 46.3 | 5.4 | 33.1 | 14.1 | 1.0 |

| FML Variant | Direction | Roughness Parameter * | ||||||

|---|---|---|---|---|---|---|---|---|

| Ra, μm | Rq, μm | Rp, μm | Rv, μm | Rz, μm | Rsk | Rku | ||

| with adhesive film | longitudinal | 6.06 | 7.56 | 12.5 | 19.5 | 32.0 | −0.37 | 3.02 |

| transverse | 6.19 | 6.67 | 14.1 | 19.4 | 33.4 | −0.39 | 2.74 | |

| without adhesive film | longitudinal | 1.46 | 1.76 | 3.87 | 3.85 | 7.72 | 0.10 | 2.29 |

| transverse | 1.53 | 1.83 | 3.67 | 4.83 | 8.50 | −0.33 | 2.51 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kubit, A.; Trzepieciński, T.; Krasowski, B.; Slota, J.; Spišák, E. Strength Analysis of a Rib-Stiffened GLARE-Based Thin-Walled Structure. Materials 2020, 13, 2929. https://doi.org/10.3390/ma13132929

Kubit A, Trzepieciński T, Krasowski B, Slota J, Spišák E. Strength Analysis of a Rib-Stiffened GLARE-Based Thin-Walled Structure. Materials. 2020; 13(13):2929. https://doi.org/10.3390/ma13132929

Chicago/Turabian StyleKubit, Andrzej, Tomasz Trzepieciński, Bogdan Krasowski, Ján Slota, and Emil Spišák. 2020. "Strength Analysis of a Rib-Stiffened GLARE-Based Thin-Walled Structure" Materials 13, no. 13: 2929. https://doi.org/10.3390/ma13132929