Experimental and Numerical Comparison of Impact Behavior between Thermoplastic and Thermoset Composite for Wind Turbine Blades

Abstract

:1. Introduction

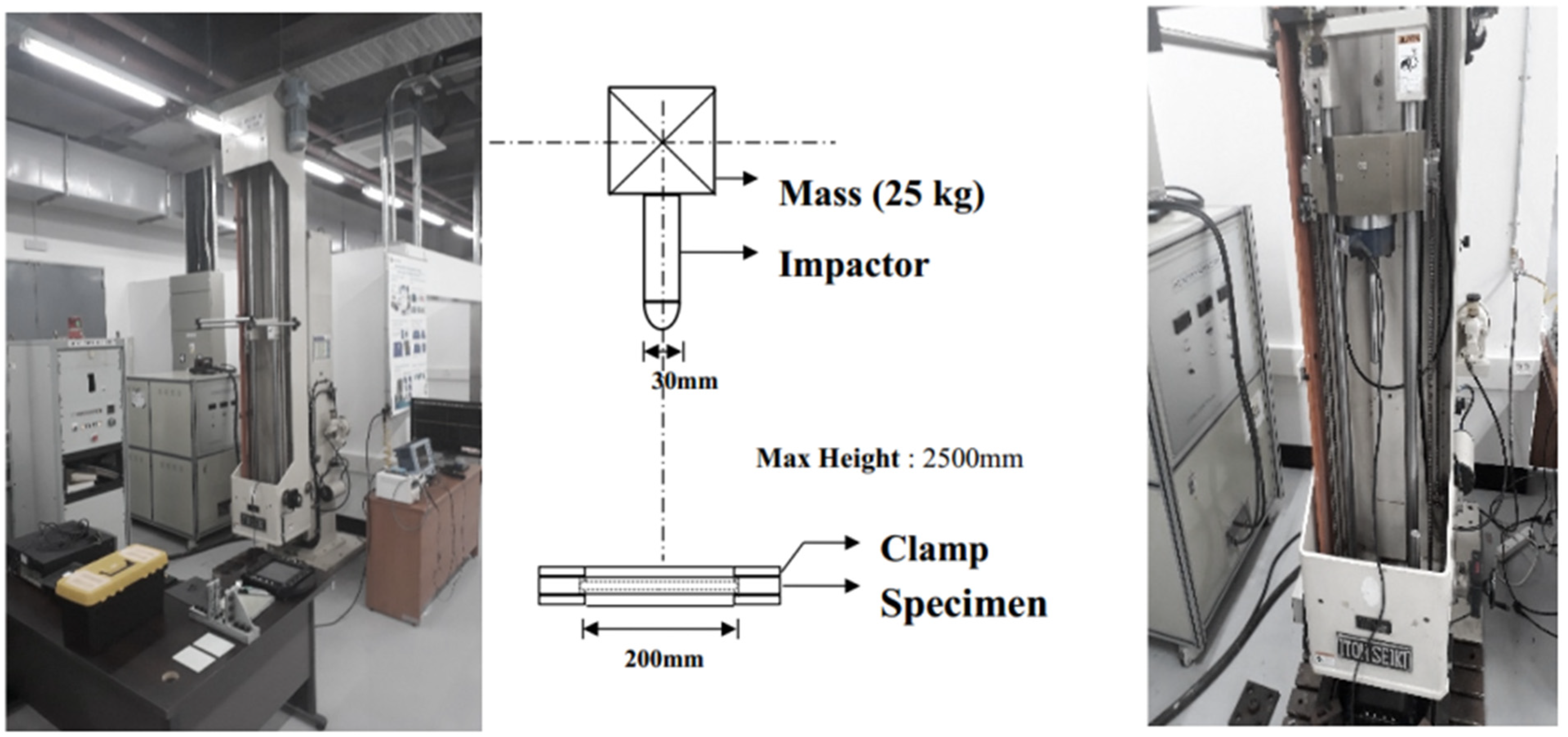

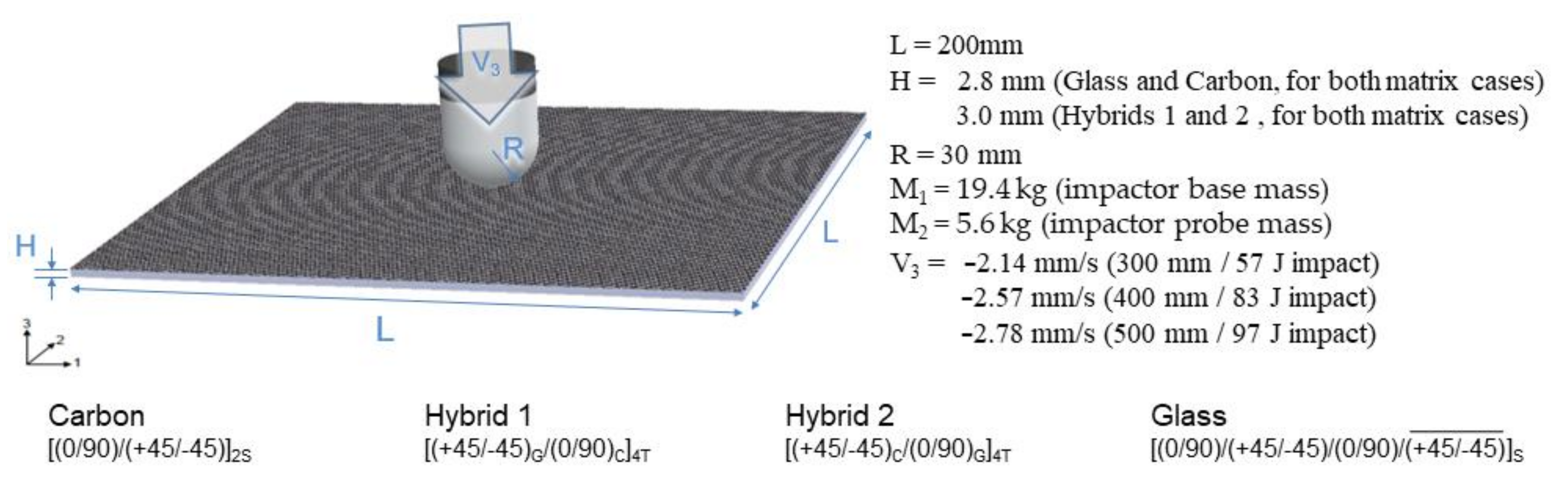

2. Materials and Methods

2.1. Manufacturing Process

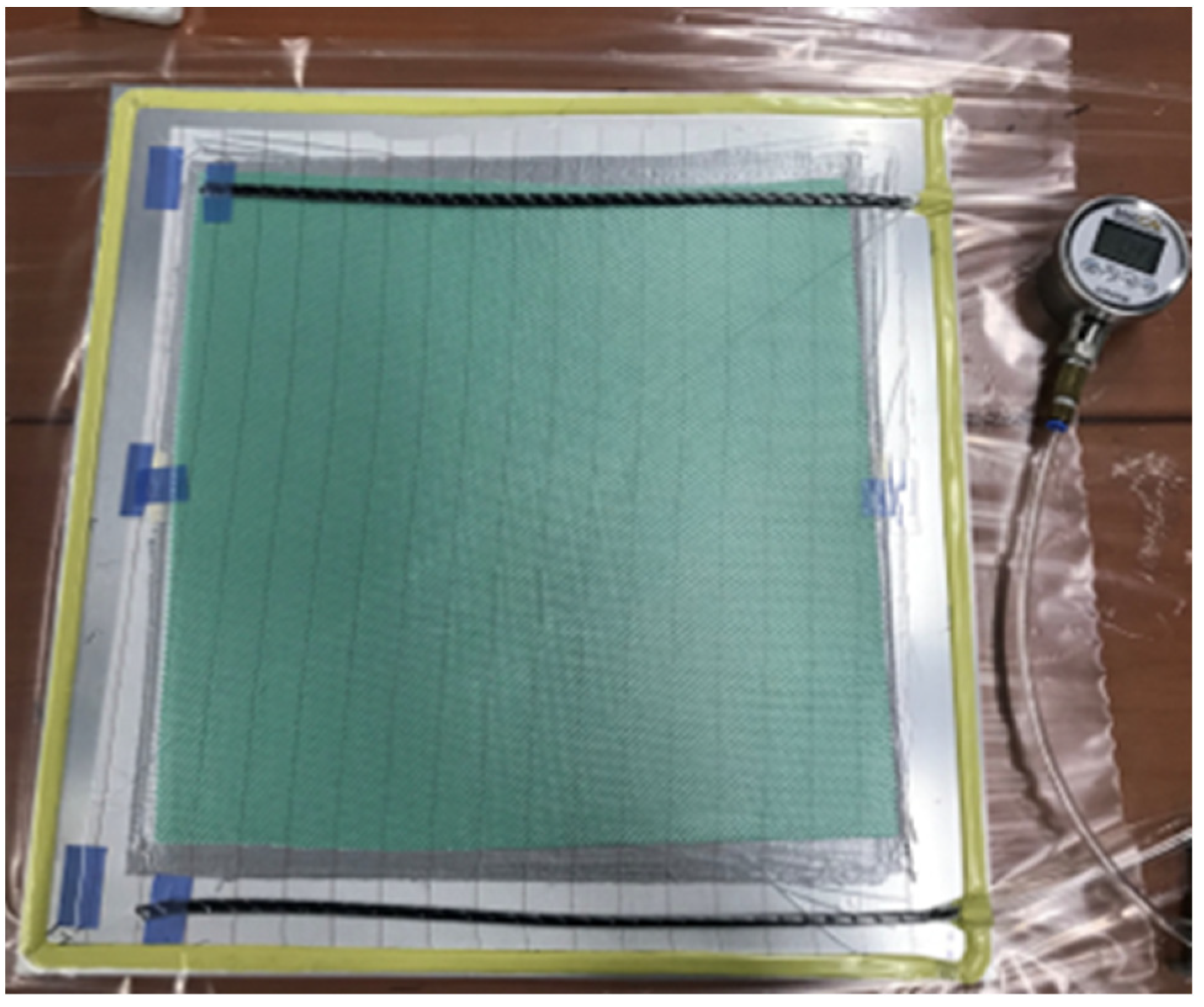

2.2. C-Scan

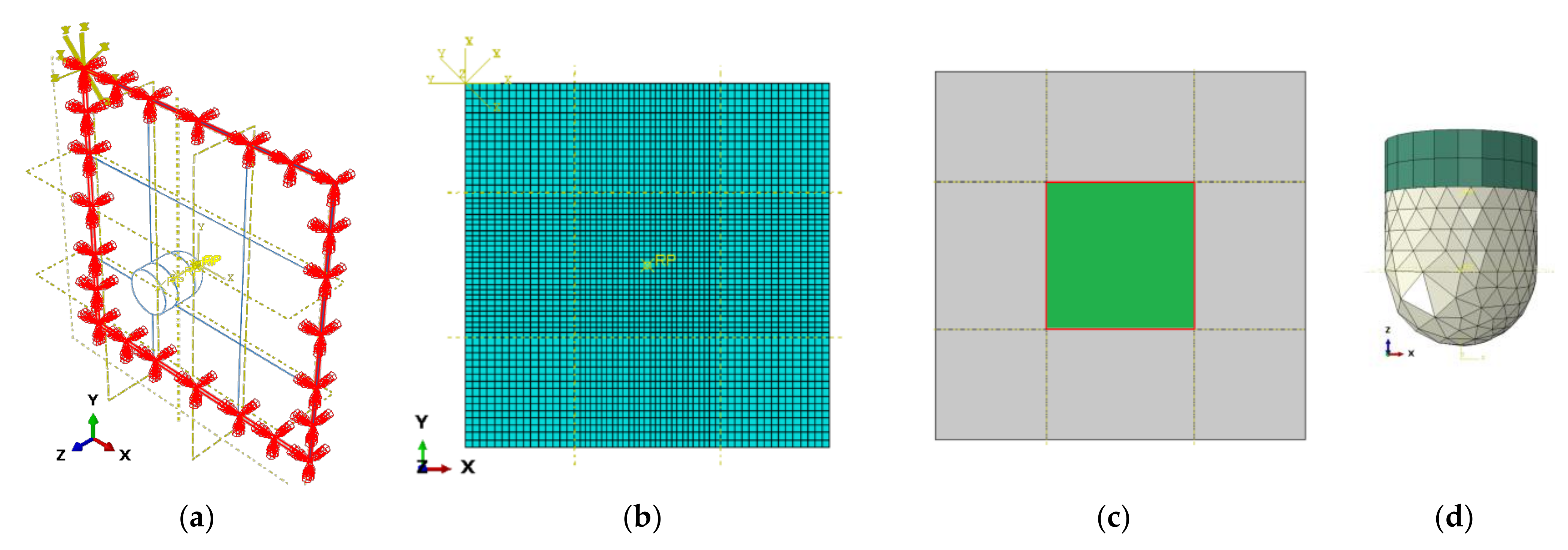

2.3. Numerical Finite Element Models

2.3.1. Materials

2.3.2. Damage Criteria

2.4. Area Measurement Process

3. Results

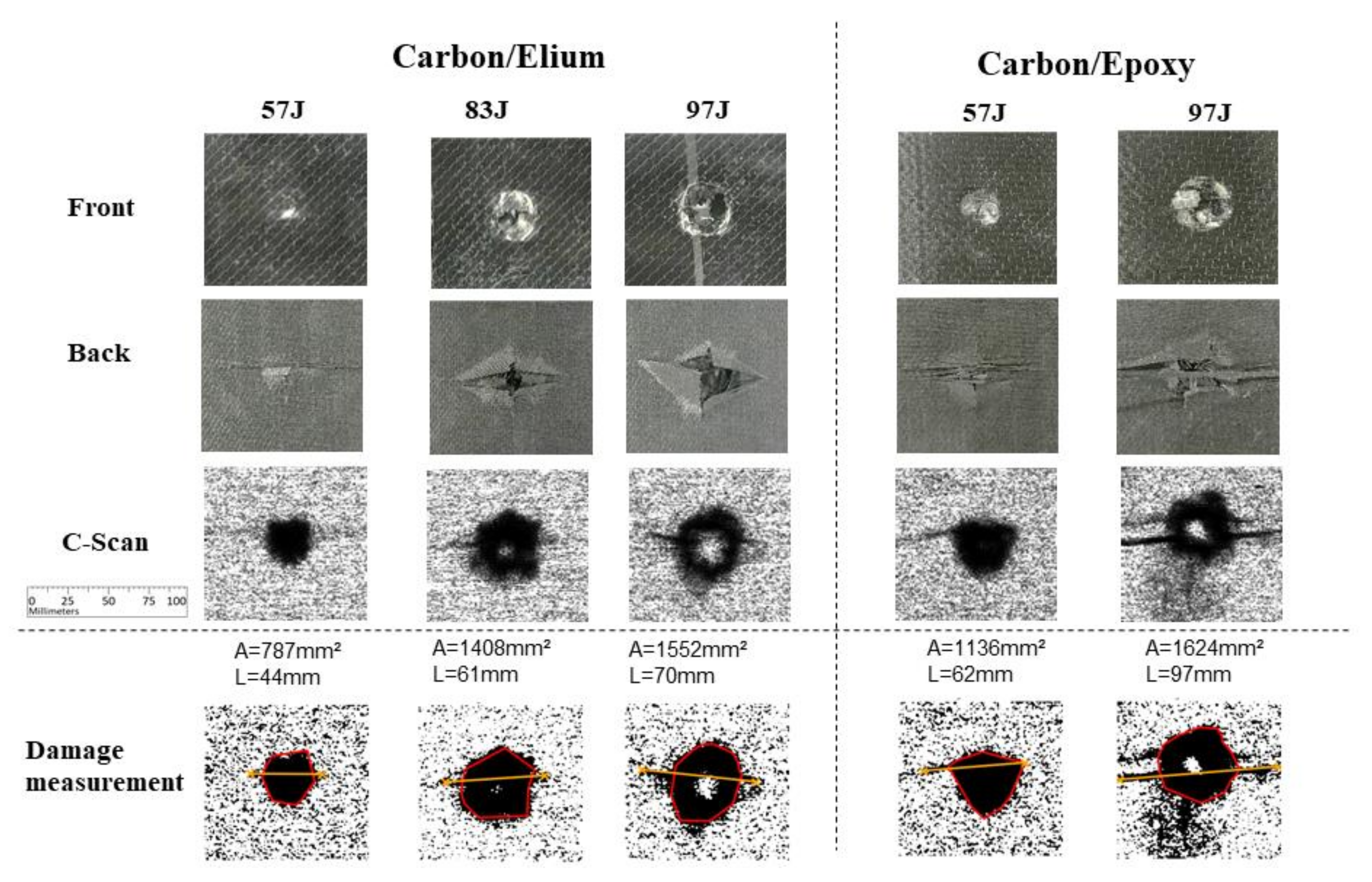

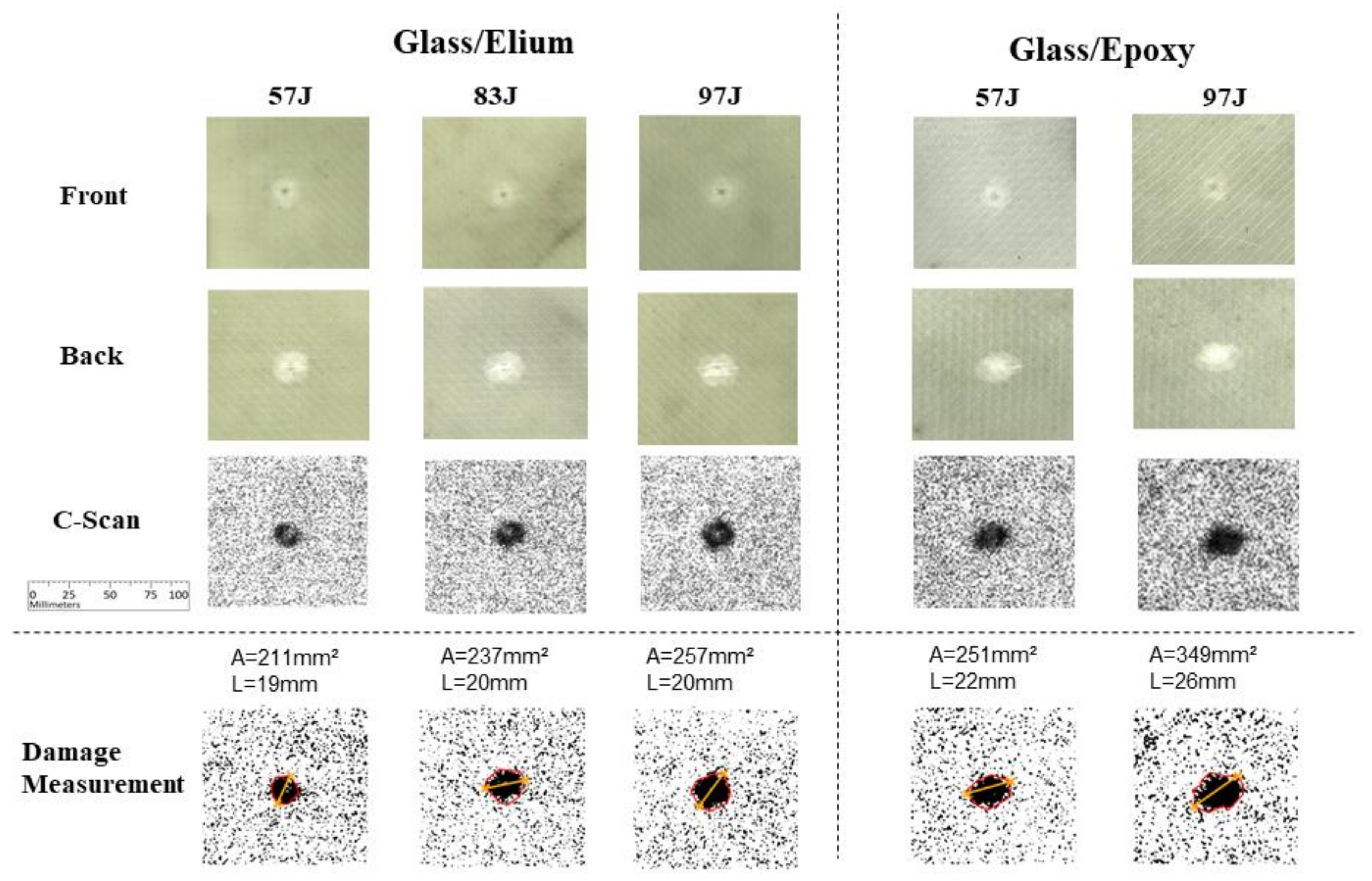

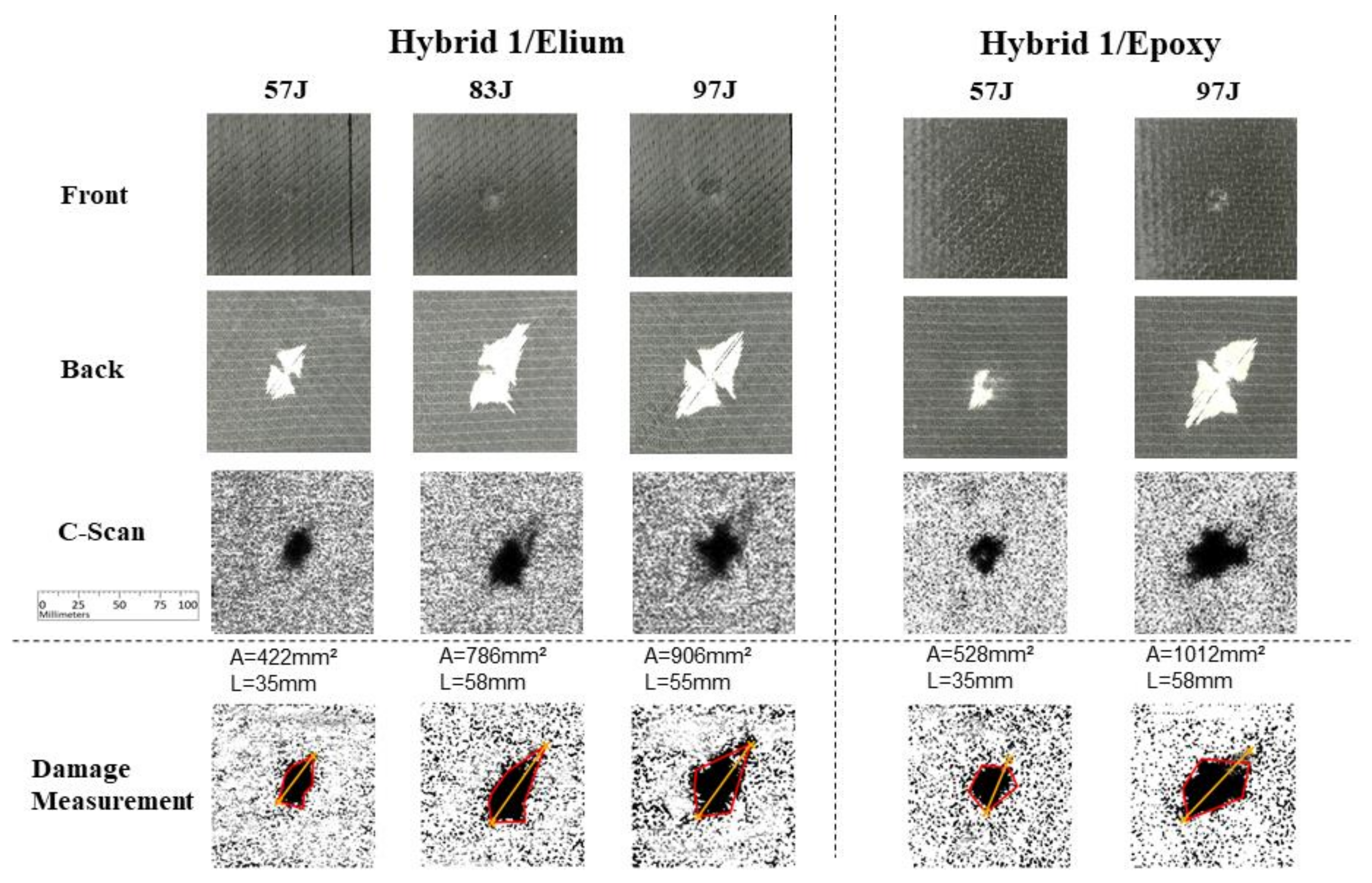

3.1. Experimental Studies

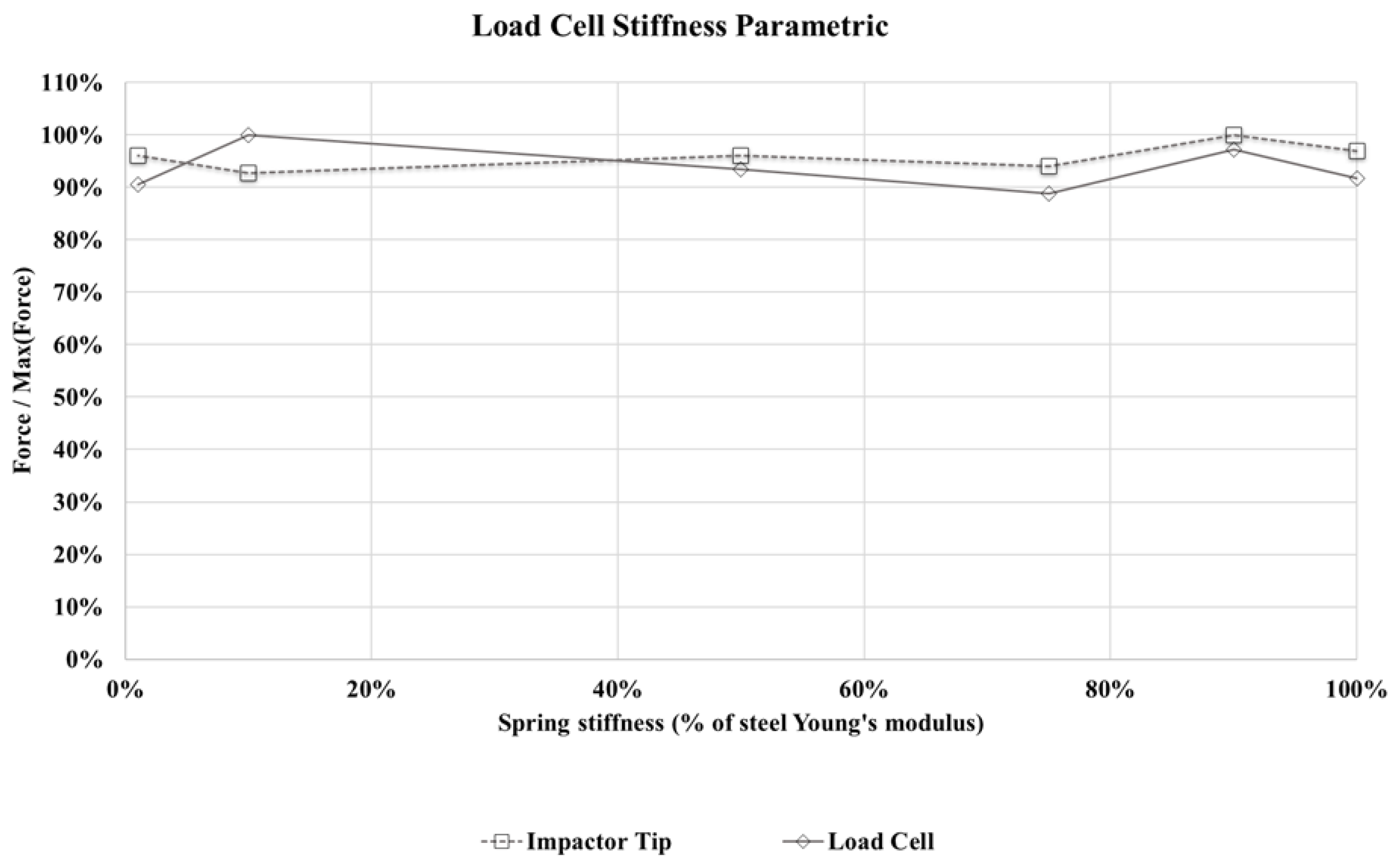

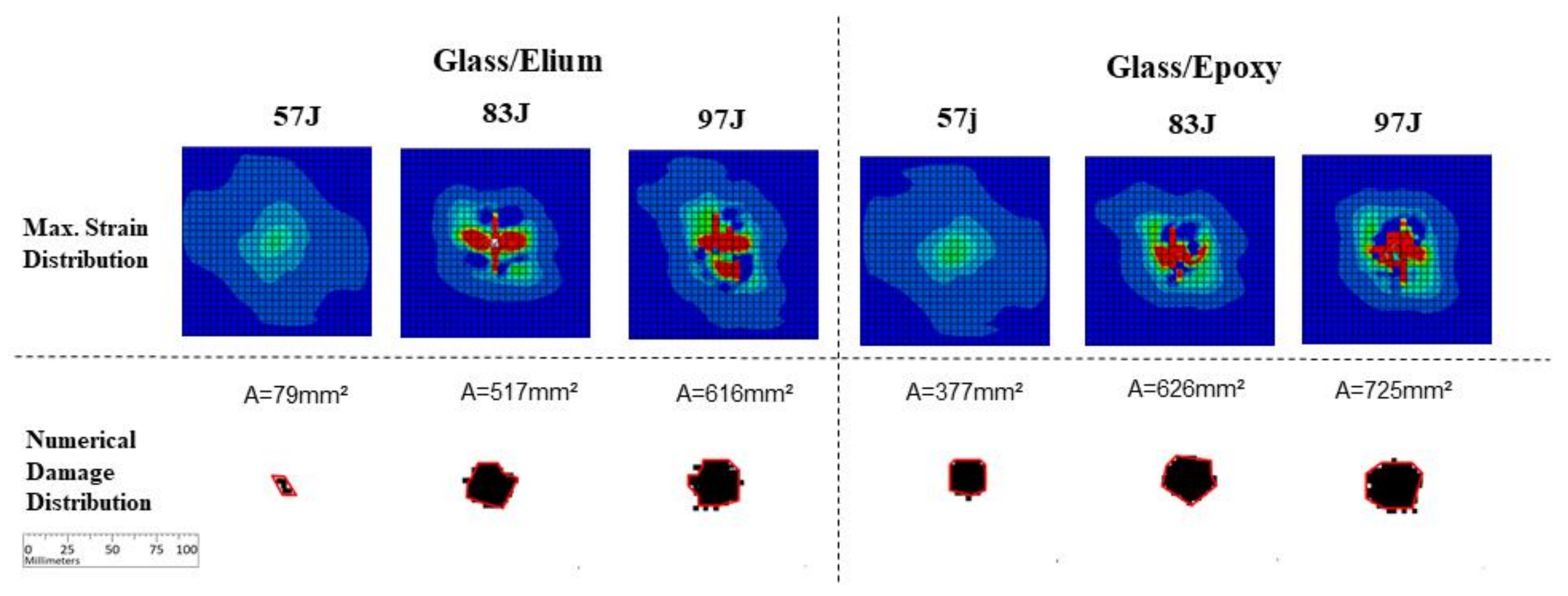

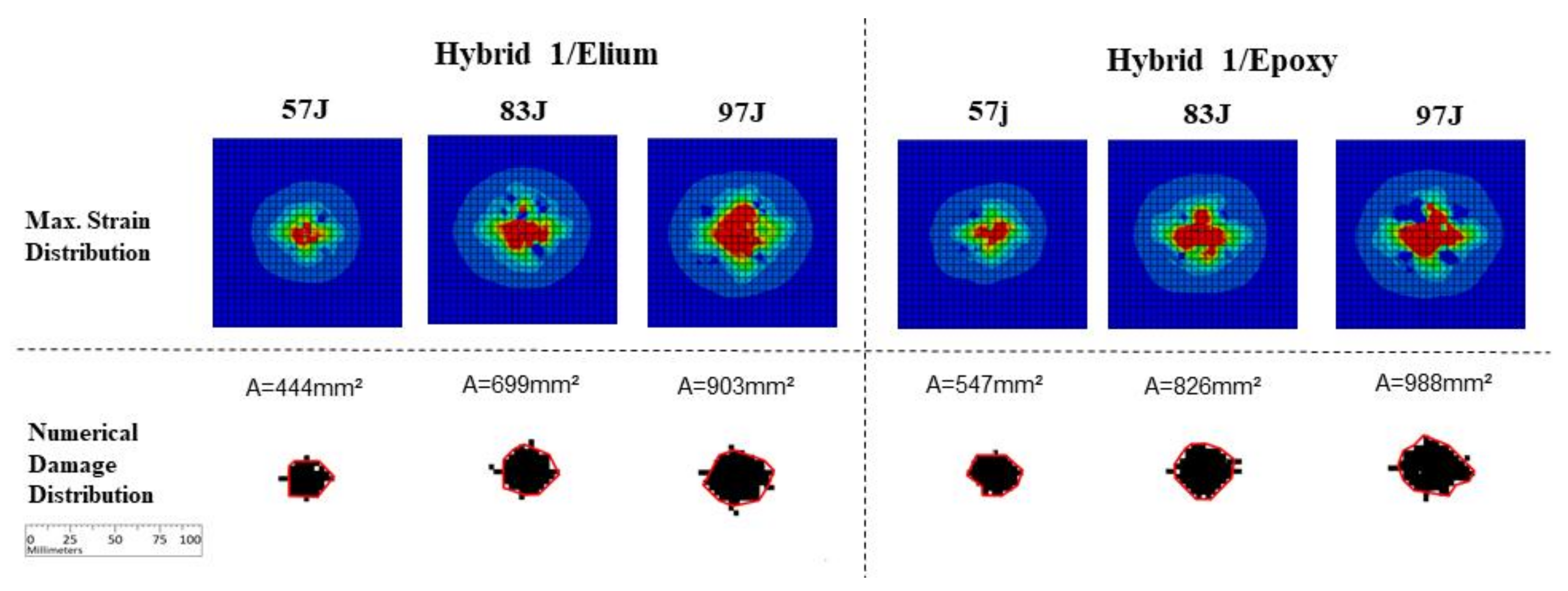

3.2. Numerical Studies

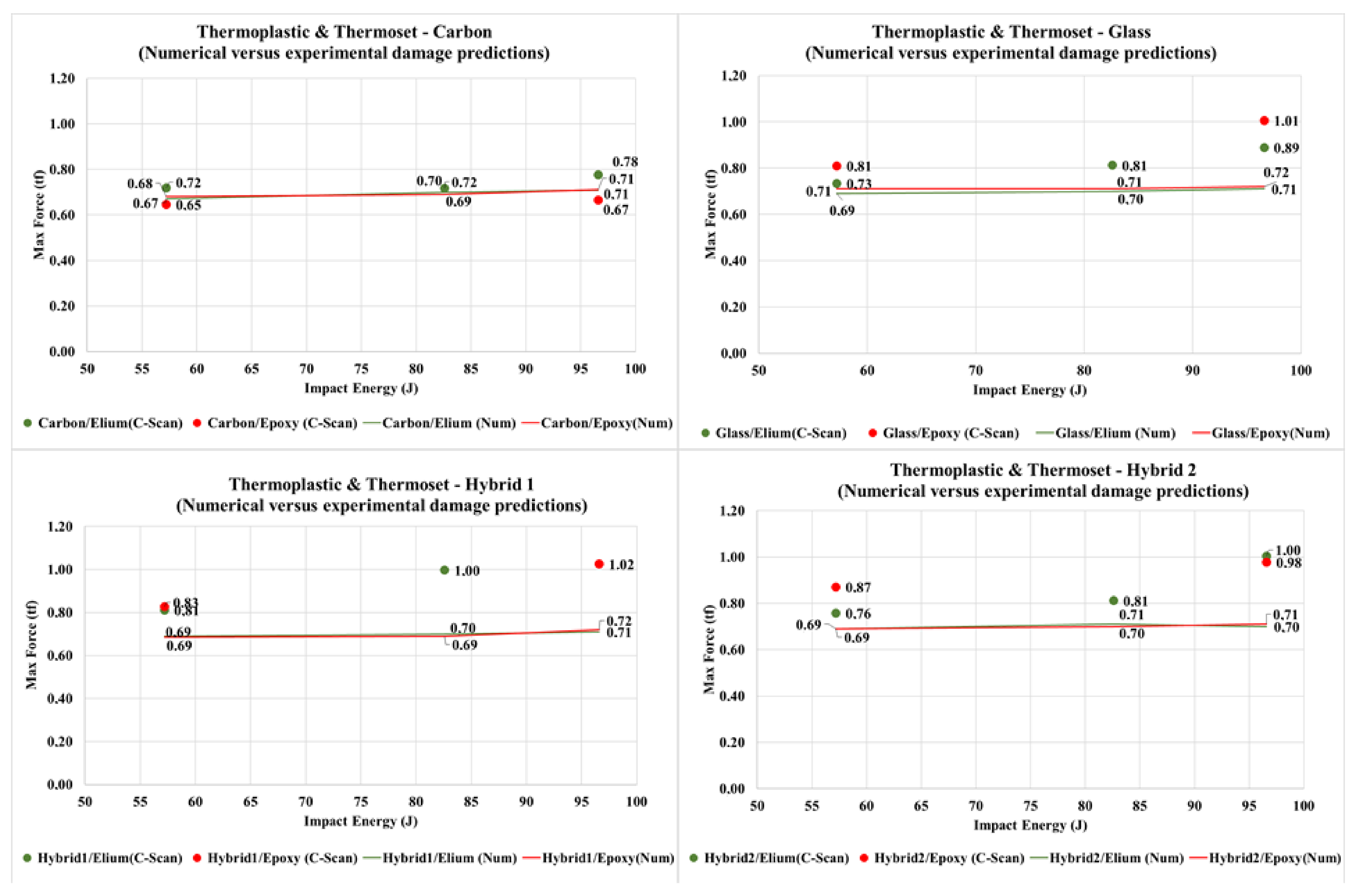

3.3. Analysis

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fthenakis, V.; Kim, H.C. Land use and electricity generation: A life-cycle analysis. Renew. Sustain. Energy Rev. 2009, 13, 1465–1474. [Google Scholar] [CrossRef] [Green Version]

- Eker, B.; Akdogan, A.; Vardar, A. Using of Composite Material in Wind Turbine Blades. J. Appl. Sci. 2006, 6, 2917–2921. [Google Scholar] [CrossRef] [Green Version]

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for wind turbine blades: An overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sørensen, B.F.; Jørgensen, E.; Debel, C.P.; Jensen, F.M.; Jensen, H.M.; Jacobsen, T.K.; Halling, K.M. Improved Design of Large Wind Turbine Blade of Fiber Composites Based on Studies of Scale Effects (Phase 1); U.S. Department of Energy: Washington, DC, USA, 2004; Volume 1390, ISBN 87-550-3176-5.

- Aymerich, F. Composite Materials for Wind Turbine Blades: Issues and Challenges; Department of Mechanical, Chemical and Materials Engineering University of Cagliari: Cagliari, Italy, 2012; pp. 29–32. [Google Scholar]

- Subramani, N.; Murali, J.G.; Suresh, P.; Sankar, V.V.A. Review on Hybrid Composite Materials and its Applications. Int. Res. J. Eng. Technol. 2017, 4, 1921–1925. [Google Scholar]

- Kinvi-Dossou, G.; Matadi Boumbimba, R.; Bonfoh, N.; Garzon-Hernandez, S.; Garcia-Gonzalez, D.; Gerard, P.; Arias, A. Innovative acrylic thermoplastic composites versus conventional composites: Improving the impact performances. Compos. Struct. 2019, 217, 1–13. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Ding, Y.; Hall, Z.E.; Kong, X.; Zhou, J.; Blackman, B.R.K.; Kinloch, A.J.; Dear, J.P. A three-dimensional elastic-plastic damage model for predicting the impact behaviour of fibre-reinforced polymer-matrix composites. Compos. Part B Eng. 2020, 201, 108389. [Google Scholar] [CrossRef]

- Kehrer, L.; Wood, J.T.; Böhlke, T. Mean-field homogenization of thermoelastic material properties of a long fiber-reinforced thermoset and experimental investigation. J. Compos. Mater. 2020, 54, 3777–3799. [Google Scholar] [CrossRef]

- Verma, A.S.; Vedvik, N.P.; Gao, Z. Numerical assessment of wind turbine blade damage due to contact/impact with tower during installation. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Busan, Korea, 25–27 August 2017; Volume 276. [Google Scholar]

- Verma, A.S.; Jiang, Z.; Vedvik, N.P.; Gao, Z.; Ren, Z. Impact assessment of a wind turbine blade root during an offshore mating process. Eng. Struct. 2019, 180, 205–222. [Google Scholar] [CrossRef]

- Verma, A.S.; Vedvik, N.P.; Gao, Z. A comprehensive numerical investigation of the impact behaviour of an offshore wind turbine blade due to impact loads during installation. Ocean Eng. 2019, 172, 127–145. [Google Scholar] [CrossRef] [Green Version]

- Verma, A.S.; Vedvik, N.P.; Haselbach, P.U.; Gao, Z.; Jiang, Z. Comparison of numerical modelling techniques for impact investigation on a wind turbine blade. Compos. Struct. 2019, 209, 856–878. [Google Scholar] [CrossRef]

- Keegan, M.H.; Nash, D.; Stack, M. Numerical modelling of hailstone impact on the leading edge of a wind turbine blade. In Proceedings of the EWEA (European Wind Energy Association) Annual Wind Energy Event 2013, Vienna, Austria, 4–7 February 2013. [Google Scholar]

- Ullah, H.; Silberschmidt, V.V. Analysis of impact induced damage in composites for wind turbine blades. In Proceedings of the 2015 Power Generation System and Renewable Energy Technologies (PGSRET), Islamabad, Pakistan, 10–11 June 2015. [Google Scholar] [CrossRef] [Green Version]

- Fotouhi, M.; Damghani, M.; Leong, M.C.; Fotouhi, S.; Jalalvand, M.; Wisnom, M.R. A comparative study on glass and carbon fibre reinforced laminated composites in scaled quasi-static indentation tests. Compos. Struct. 2020, 245, 112327. [Google Scholar] [CrossRef]

- Liu, Y.J.; Jiang, Z.; Wen, H.M. Predicting impact induced delamination of FRP laminates. Int. J. Impact Eng. 2020, 137, 103436. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, Q.; Curiel-Sosa, J.L.; Bui, T.Q. Ballistic performance and damage simulation of fiber metal laminates under high-velocity oblique impact. Int. J. Damage Mech. 2020, 29, 1011–1034. [Google Scholar] [CrossRef]

- Meon, M.S.; Nor, N.H.M.; Shawal, S.; Saedon, J.B.; Rao, M.N.; Schröder, K.-U. On the Modelling Aspect of Low- Velocity Impact Composite Laminates. J. Mech. Eng. 2020, 17, 13–25. [Google Scholar]

- Larsen, K. Recycling wind turbine blades. Renew. Energy Focus 2009, 9, 70–73. [Google Scholar] [CrossRef]

- Murray, R.E.; Beach, R.; Barnes, D.; Snowberg, D.; Berry, D.; Rooney, S.; Jenks, M.; Gage, B.; Boro, T.; Wallen, S.; et al. Structural validation of a thermoplastic composite wind turbine blade with comparison to a thermoset composite blade. Renew. Energy 2021, 164, 1100–1107. [Google Scholar] [CrossRef]

- Thomas, L.; Ramachandra, M. Advanced materials for wind turbine blade—A Review. Mater. Today Proc. 2018, 5, 2635–2640. [Google Scholar] [CrossRef]

- Forcier, L.-C.; Joncas, S. Development of a structural optimization strategy for the design of next generation large thermoplastic wind turbine blades. Struct. Multidiscip. Optim. 2012, 45, 889–906. [Google Scholar] [CrossRef]

- Murray, R.E.; Jenne, S.; Snowberg, D.; Berry, D.; Cousins, D. Techno-economic analysis of a megawatt-scale thermoplastic resin wind turbine blade. Renew. Energy 2019, 131, 111–119. [Google Scholar] [CrossRef]

- Fonte, R.; Xydis, G. Wind turbine blade recycling: An evaluation of the European market potential for recycled composite materials. J. Environ. Manag. 2021, 287, 112269. [Google Scholar] [CrossRef] [PubMed]

- Jensen, J.P. Evaluating the environmental impacts of recycling wind turbines. Wind Energy 2019, 22, 316–326. [Google Scholar] [CrossRef]

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Fox, T.R. Recycling Wind Turbine Blade Composite Material as Aggregate in Concrete. Master’s Thesis, Iowa State University, Ames, IA, USA, 2016; p. 57. [Google Scholar]

- Andersen, P.D.; Bonou, A.; Beauson, J.; Brønsted, P. Recycling of wind turbines. In DTU International Energy Report 2014: Wind Energy—Drivers and Barriers for Higher Shares of Wind in the Global Power Generation Mix; Larsen, H.H., Petersen, L.S., Eds.; DTU: Kongens Lyngby, Denmark, 2014. [Google Scholar]

- Åkesson, D.; Foltynowicz, Z.; Christéen, J.; Skrifvars, M. Microwave pyrolysis as a method of recycling glass fibre from used blades of wind turbines. J. Reinf. Plast. Compos. 2012, 31, 1136–1142. [Google Scholar] [CrossRef]

- Mamanpush, S.H.; Li, H.; Englund, K.; Tabatabaei, A.T. Recycled wind turbine blades as a feedstock for second generation composites. Waste Manag. 2018, 76, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Kazemi, M.E.; Shanmugam, L.; Lu, D.; Wang, X.; Wang, B.; Yang, J. Mechanical properties and failure modes of hybrid fiber reinforced polymer composites with a novel liquid thermoplastic resin, Elium®. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105523. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C. Low-velocity impact response of carbon fibre composites with novel liquid Methylmethacrylate thermoplastic matrix. Compos. Struct. 2018, 203, 696–708. [Google Scholar] [CrossRef]

- Al-Hajaj, Z.; Sy, B.L.; Bougherara, H.; Zdero, R. Impact properties of a new hybrid composite material made from woven carbon fibres plus flax fibres in an epoxy matrix. Compos. Struct. 2019, 208, 346–356. [Google Scholar] [CrossRef]

- Bunea, M.; Cîrciumaru, A.; Buciumeanu, M.; Bîrsan, I.G.; Silva, F.S. Low velocity impact response of fabric reinforced hybrid composites with stratified filled epoxy matrix. Compos. Sci. Technol. 2019, 169, 242–248. [Google Scholar] [CrossRef]

- Guida, M.; Sellitto, A.; Marulo, F.; Riccio, A. Analysis of the impact dynamics of shape memory alloy hybrid composites for advanced applications. Materials 2019, 12, 153. [Google Scholar] [CrossRef] [Green Version]

- Obande, W.; Ray, D.; Brádaigh, C.M.Ó. Viscoelastic and drop-weight impact properties of an acrylic-matrix composite and a conventional thermoset composite—A comparative study. Mater. Lett. 2019, 238, 38–41. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C.; Bert, A.; Yi Di, B.; Makam, R.; Gohel, G. Flexural characteristics of novel carbon methylmethacrylate composites. Compos. Commun. 2019, 13, 129–133. [Google Scholar] [CrossRef]

- Cousins, D.S. Advanced Thermoplastic Composites for Wind Turbine Blade Manufacturing; Colorado School of Mines: St. Golden, CO, USA, 2018. [Google Scholar]

- Murray, R.E.; Swan, D.; Snowberg, D.; Berry, D.; Beach, R.; Rooney, S. Manufacturing a 9-meter thermoplastic composite wind turbine blade. In Proceedings of the 32nd Technical Conference of the American Society for Composites 2017, West Lafayette, IN, USA, 23–25 October 2017; Volume 1, pp. 29–43. [Google Scholar] [CrossRef] [Green Version]

- Teuwen, J.J.E. Thermoplastic Composite Wind Turbine Blades: Kinetics and Processability; TU Delft University: Delft, The Netherlands, 2011. [Google Scholar]

- Vallons, K.; Adolphs, G.; Lucas, P.; Lomov, S.V.; Verpoest, I. Quasi-UD glass fibre NCF composites for wind energy applications: A review of requirements and existing fatigue data for blade materials. Mech. Ind. 2013, 14, 175–189. [Google Scholar] [CrossRef]

- Mohamed, M.H.; Wetzel, K.K. 3D woven carbon/glass hybrid spar cap for wind turbine rotor blade. J. Sol. Energy Eng. Trans. ASME 2006, 128, 562–573. [Google Scholar] [CrossRef]

- Ong, C.; Tsai, S.W. The Use of Carbon Fibers in Wind Turbine Blade Design: A SERI-8 Blade Example; SAND2000-0478; U.S. Department of Energy: Washington, DC, USA, 2000. [Google Scholar]

- Papa, I.; Ricciardi, M.R.; Calzolari, A.; Langella, A.; Tirillò, J.; Sarasini, F.; Lopresto, V. Mechanical behavior and damage degree of hybrid glass/carbon composites at low temperature. Polym. Compos. 2021, 42, 2432–2444. [Google Scholar] [CrossRef]

- Pérez-Martín, M.J.; Enfedaque, A.; Dickson, W.; Gálvez, F. Impact behavior of hybrid glass/carbon epoxy composites. J. Appl. Mech. Trans. ASME 2013, 80, 1–7. [Google Scholar] [CrossRef]

- Sutcliffe, M.P.F.; Monroy Aceves, C.; Stronge, W.J.; Choudhry, R.S.; Scott, A.E. Moderate speed impact damage to 2D-braided glass-carbon composites. Compos. Struct. 2012, 94, 1781–1792. [Google Scholar] [CrossRef] [Green Version]

- Kistaiah, N.; Udaya Kiran, C.; Ramachandra Reddy, G.; Sreenivasa Rao, M. Mechanical characterization of hybrid composites: A review. J. Reinf. Plast. Compos. 2014, 33, 1364–1372. [Google Scholar] [CrossRef]

- Nguyen, H.; Zatar, W.; Mutsuyoshi, H. Hybrid Polymer Composites for Structural Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 9780081007860. [Google Scholar]

- Banerjee, S.; Sankar, B. V Mechanical properties of hybrid composites using finite element method based micromechanics. Compos. Part B Eng. 2014, 58, 318–327. [Google Scholar] [CrossRef]

- Vallons, K.; Duque, I.; Lomov, S.V.; Verpoest, I. Fibre orientation effects on the tensile properties of biaxial carbon/epoxy NCF composites. In Proceedings of the ICCM International Conference on Composite Materials, Melbourne, Australia, 11–16 August 2009. [Google Scholar]

- Lomov, S.V.; Ivanov, D.S.; Vallons, K.; Verpoest, I.; Klimshin, D.V.; Truong, T.C. Peculiarities of damage behaviour of NCF carbon/epoxy laminates under tension. In Proceedings of the ICCM International Conference on Composite Materials, Kyoto, Japan, 8–13 July 2007. [Google Scholar]

- Kinvi-Dossou, G.; Bonfoh, N.; Matadi Boumbimba, R.; Koutsawa, Y.; Lachaud, F.; Nyoungue, A.; Gerard, P. A mesoscale modelling approach of glass fibre/Elium acrylic woven laminates for low velocity impact simulation. Compos. Struct. 2020, 252, 112671. [Google Scholar] [CrossRef]

- Edgren, F. Compressive failure of NCF composites. In Proceedings of the 20th Technical Conference of the American Society for Composites 2005, Philadelphia, PA, USA, 7–9 September 2005; Volume 3, ISBN 9781622762828. [Google Scholar]

- ASTM. D7136: Standard test method for measuring the damage resistance of a fiber-renforced polymer matrix composite to a drop-weight impact. In Annual Book of ASTM Standards; ASTM International: West Conshocken, PA, USA, 2014; pp. 1–16. [Google Scholar] [CrossRef]

- Camanho, P.; Davila, C.G. Mixed-Mode Decohesion Finite Elements in for the Simulation Composite of Delamination Materials; NASA: Washington, DC, USA, 2002. [CrossRef]

- Simulia. ABAQUS (2014) CAE User’s Manual, Version 6.14; Simulia: Johnston, RI, USA, 2014. [Google Scholar]

- Koloor, S.S.R.; Karimzadeh, A.; Yidris, N.; Petrů, M.; Ayatollahi, M.R.; Tamin, M.N. An energy-based concept for yielding of multidirectional FRP composite structures using a mesoscale lamina damage model. Polymers 2020, 12, 157. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koloor, S.S.R.; Ayatollahi, M.R.; Tamin, M.N. Elastic-damage deformation response of fiber-reinforced polymer composite laminates with lamina interfaces. J. Reinf. Plast. Compos. 2017, 36, 832–849. [Google Scholar] [CrossRef]

- Koloor, S.S.; Khosravani, M.R.; Hamzah, R.I.R.; Tamin, M.N. FE model-based construction and progressive damage processes of FRP composite laminates with different manufacturing processes. Int. J. Mech. Sci. 2018, 141, 223–235. [Google Scholar] [CrossRef]

- Nakatani, H.; Kosaka, T.; Osaka, K.; Sawada, Y. Damage characterization of titanium/GFRP hybrid laminates subjected to low-velocity impact. Compos. Part A Appl. Sci. Manuf. 2011, 42, 772–781. [Google Scholar] [CrossRef]

- Shi, Y.; Swait, T.; Soutis, C. Modelling damage evolution in composite laminates subjected to low velocity impact. Compos. Struct. 2012, 94, 2902–2913. [Google Scholar] [CrossRef]

- Toray Carbon Fiber Toray T700 Technical Data Sheet. Available online: https://www.toraycma.com/page.php?id=661 (accessed on 2 February 2021).

- Arkema Elium Liquid Thermoplastics Technical Data Sheet. Available online: https://www.arkema.com/global/en/products/product-finder/product-range/incubator/elium_resins/ (accessed on 8 August 2020).

- Daniel, I.M.; Ishai, O. Engineering Mechanics of Composite Materials; Oxford University Press: Oxford, UK, 2006; ISBN 9780195150971. [Google Scholar]

- Lorriot, T.; El Yagoubi, J.; Fourel, J.; Tison, F. Non-conventional Glass fiber NCF composites with thermoset and thermoplastic matrices. In Proceedings of the International Conference on Composite Materials (ICCM 2015), Copenhagen, Danemark, 19–24 July 2015. [Google Scholar]

- Fadhil, B.M. Effect of Plies Stacking Sequence and Tube Geometry on the Crush Behavior of Tube under Low Velocity Impact—Numerical Study. Int. J. Mech. Appl. 2013, 3, 44–51. [Google Scholar] [CrossRef]

- Dávila, C.G.; Camanho, P.P.; Turon, A. Cohesive Elements for Shells; NASA: Washington, DC, USA, 2007.

- Chen, B.Y.; Tay, T.E.; Baiz, P.M.; Pinho, S.T. Numerical analysis of size effects on open-hole tensile composite laminates. Compos. Part. A Appl. Sci. Manuf. 2013, 47, 52–62. [Google Scholar] [CrossRef]

- Kinvi-Dossou, G. Étude de la Résistance à l’ Impact et de l’ Endommagement des Composites Stratifiés à Matrice Elium Acrylique: Caractérisation Expérimentale et Modélisation Numérique Multi-Échelle. Ph.D. Thesis, Université de Lorraine, Lorraine, France, 2018. [Google Scholar]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Experimental investigation on suitability of carbon fibre thin plies for racquets. Proc. Inst. Mech. Eng. Part P J. Sport. Eng. Technol. 2016, 230, 64–72. [Google Scholar] [CrossRef]

- Alfred Franklin, V.; Christopher, T. Fracture energy estimation of DCB specimens made of glass/epoxy: An experimental study. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef] [Green Version]

- Lapczyk, I.; Hurtado, J.A. Progressive damage modeling in fiber-reinforced materials. Compos. Part. A Appl. Sci. Manuf. 2007, 38, 2333–2341. [Google Scholar] [CrossRef]

- Hashin, Z.; Rotem, A. A Fatigue Failure Criterion for Fiber Reinforced Materials. J. Compos. Mater. 1973, 7, 448–464. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Liu, J.; Ding, Y.; Zhou, J.; Kong, X. Effects of Impactor Geometry on the Low-Velocity Impact Behaviour of Fibre-Reinforced Composites: An Experimental and Theoretical Investigation Content Courtesy of Springer Nature, Terms of Use Apply: Rights Reserved: Content Courtesy of Springer Natu. Appl. Compos. Mater. 2020, 27, 533–553. [Google Scholar] [CrossRef]

- Hashin, Z. Failure criteria for unidirectional fiber composites. J. Appl. Mech. Trans. ASME 1980. [Google Scholar] [CrossRef]

- Benzeggagh, M.L.; Kenane, M. Measurement of Mixed-Mode Delamination Fracture Toughness of Unidirectional Glass/Epoxy Composites with Mixed-Mode Bending Apparatus. Compos. Sci. Technol. 1996, 24, 859–865. [Google Scholar] [CrossRef]

- Tan, R.; Xu, J.; Sun, W.; Liu, Z.; Guan, Z.; Guo, X. Relationship between matrix cracking and delamination in CFRP cross-ply laminates subjected to low velocity impact. Materials 2019, 12, 3990. [Google Scholar] [CrossRef] [Green Version]

- Nobuyuki, O. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar]

- Scikit-Image Thresholding. Available online: https://scikit-image.org/docs/0.13.x/auto_examples/xx_applications/plot_thresh-610olding.html (accessed on 1 May 2021).

- Katunin, A.; Wronkowicz-Katunin, A.; Dragan, K. Impact Damage Evaluation in Composite Structures Based on Fusion of Results of Ultrasonic Testing and X-ray Computed Tomography. Sensors 2020, 20, 1867. [Google Scholar] [CrossRef] [Green Version]

- Hassen, A.A.; Taheri, H.; Vaidya, U.K. Non-Destructive Investigation of Thermoplastic Reinforced Composites Ahmed. Compos. Part B Eng. 2010, 2, 617–638. [Google Scholar]

- Boria, S.; Belingardi, G.; Fiumarella, D.; Scattina, A. Experimental crushing analysis of thermoplastic and hybrid composites. Compos. Struct. 2019, 226, 111241. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Ramnath, B.V.; Hemalatha, J. Mechanical Behaviour of Glass and Carbon Fibre Reinforced Composites at Varying Strain Rates and Temperatures. Procedia Mater. Sci. 2014, 6, 1405–1418. [Google Scholar] [CrossRef] [Green Version]

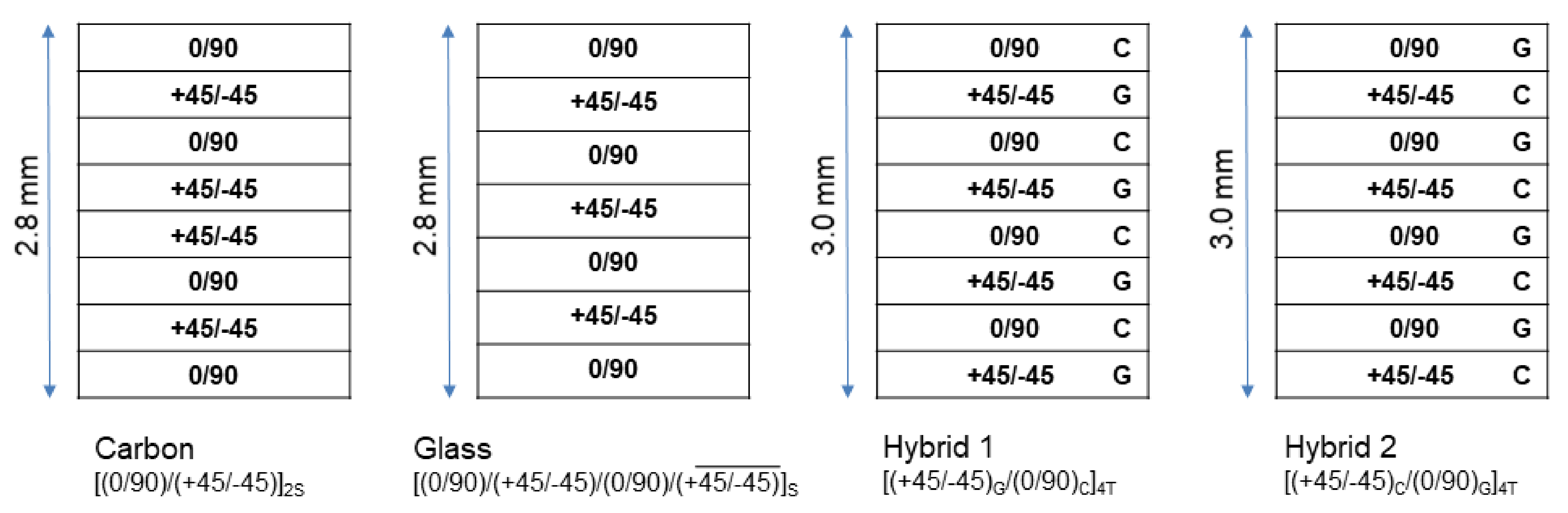

| Reinforcement | Matrix | Layup Sequence | |

|---|---|---|---|

| Carbon/ELIUM | Carbon NCF (Chomarat Co., Ltd., Paris, Paris Region France) | ELIUM 188O (Arkema Co., Ltd., Lacq, Pyrénées-Atlantiques, France) | [(0/90)/(+45/−45)] 2S |

| Carbon/Epoxy | EPR-L20 (Hexion Co., Ltd., Colombus, OH, USA) | ||

| Glass/ELIUM | Glass NCF (HANKUK Carbon Co., Ltd., Miryang-si, Gyeongsangnam-do, South Korea) | ELIUM 188O (Arkema Co., Ltd., Lacq, Pyrénées-Atlantiques, France) | [(0/90)/(+45/−45)/(0/90)/] S |

| Glass/Epoxy | EPR-L20 (Hexion Co., Ltd., Colombus, OH, USA) | ||

| Hybrid 1/ELIUM | Carbon NCF (Chomarat Co., Ltd., Paris, Paris Region France) Interleaved with Glass NCF (HANKUK Carbon Co., Ltd., Miryang-si, Gyeongsangnam-do, South Korea) | ELIUM 188O (Arkema Co., Ltd., Lacq, Pyrénées-Atlantiques, France) | [(+45/−45) G/(0/90) C] 4T |

| Hybrid 1/Epoxy | EPR-L20 (Hexion Co., Ltd., Colombus, OH, USA) | ||

| Hybrid 2/ELIUM | ELIUM 188O (Arkema Co., Ltd., Lacq, Pyrénées-Atlantiques, France) | [(+45/−45) C/(0/90) G] 4T | |

| Hybrid 2/Epoxy | EPR-L20 (Hexion Co., Ltd., Colombus, OH, USA) |

| Carbon/Elium | Carbon/Epoxy | Glass/Elium | Glass/Epoxy | |||||

|---|---|---|---|---|---|---|---|---|

| Longitudinal Stiffness (GPa) | 141 | [63,64] | 141 | [63] | 45,0 | [64,65] | 45 | [65] |

| Transverse Stiffness (GPa) | 7.3 | [39,58] | 7.2 | [58] | 14.3 | [39,66] | 14.1 | [66] |

| Shear Stiffness (GPa) | 3.4 | [58,64] | 3.4 | [58] | 4.9 | [39] | 6.4 | [66] |

| In-plane Poisson’s Ratio ν12/ν23 | 0.34 | [58,64] | 0.34 | [58] | 0.22 | [39] | 0.245 | [66] |

| Longitudinal Tensile Strength (MPa) | 2040 | [63,64] | 2040 | [63] | 1725 | [64,65] | 1725 | [65] |

| Longitudinal Compressive Strength (MPa) | 1192 | [58,64] | 1192 | [58] | 620 | [64,65] | 620 | [67] |

| Transverse Tensile Strength (MPa) | 24.8 | [58,64] | 19.6 | [58] | 102.1 | [39,58,61] | 80,6 | [58,61] |

| Transverse Compressive Strength (MPa) | 94.7 | [58,64] | 92.3 | [58] | 330.3 | [39,58] | 322 | [58] |

| Shear Strength (MPa) | 51 | [58,64] | 51 | [58] | 49.7 | [66] | 54.5 | [58] |

| Longitudinal Tensile Fracture Energy (N/m) | 48,400 | [58,64] | 48,400 | [58] | 32,000 | [58,64] | 32,000 | [58] |

| Longitudinal Compressive Fracture Energy (N/m) | 60,300 | [58,64] | 60,300 | [58] | 20,000 | [58,64] | 20,000 | [58] |

| Transverse Tensile Fracture Energy (N/m) | 4500 | [58,64] | 4500 | [58] | 4500 | [58,64] | 4500 | [58] |

| Transverse Compressive Fracture Energy (N/m) | 8500 | [58,64] | 8500 | [58] | 4500 | [58,64] | 4500 | [58] |

| Carbon/Elium | Carbon/Epoxy | Glass/Elium | Glass/Epoxy | |||||

|---|---|---|---|---|---|---|---|---|

| Maximum Nominal Stress N (MPa) | 40 | [64,69] | 40 | [69] | 70 | [70] | 65 | [70] |

| Maximum Nominal Stress S1 (MPa) | 50 | [64,69] | 50 | [69] | 80 | [70] | 72 | [70] |

| Maximum Nominal Stress S2 (MPa) | 50 | [64,69] | 50 | [69] | 80 | [70] | 72 | [70] |

| Damage Evolution Normal Fracture Energy (N/m) | 1970 | [71] | 293 | [69] | 1880 | [70] | 1075 | [72] |

| Damage Evolution 1st Shear Fracture Energy (N/m) | 631 | [64,69] | 631 | [69] | 3840 | [70] | 4000 | [73] |

| Damage Evolution 2nd Shear Fracture Energy (N/m) | 631 | [64,69] | 631 | [69] | 3840 | [70] | 4000 | [73] |

| Benzeggagh-Kenane Exponent | 1 | [64,69] | 1 | [69] | 1 | a | 1 | a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinto, T.H.L.; Gul, W.; Torres, L.A.G.; Cimini, C.A., Jr.; Ha, S.K. Experimental and Numerical Comparison of Impact Behavior between Thermoplastic and Thermoset Composite for Wind Turbine Blades. Materials 2021, 14, 6377. https://doi.org/10.3390/ma14216377

Pinto THL, Gul W, Torres LAG, Cimini CA Jr., Ha SK. Experimental and Numerical Comparison of Impact Behavior between Thermoplastic and Thermoset Composite for Wind Turbine Blades. Materials. 2021; 14(21):6377. https://doi.org/10.3390/ma14216377

Chicago/Turabian StylePinto, Thiago Henrique Lara, Waseem Gul, Libardo Andrés González Torres, Carlos Alberto Cimini, Jr., and Sung Kyu Ha. 2021. "Experimental and Numerical Comparison of Impact Behavior between Thermoplastic and Thermoset Composite for Wind Turbine Blades" Materials 14, no. 21: 6377. https://doi.org/10.3390/ma14216377