Laser-Assisted Micro-Solder Bumping for Copper and Nickel–Gold Pad Finish

Abstract

:1. Introduction

2. Materials and Methods

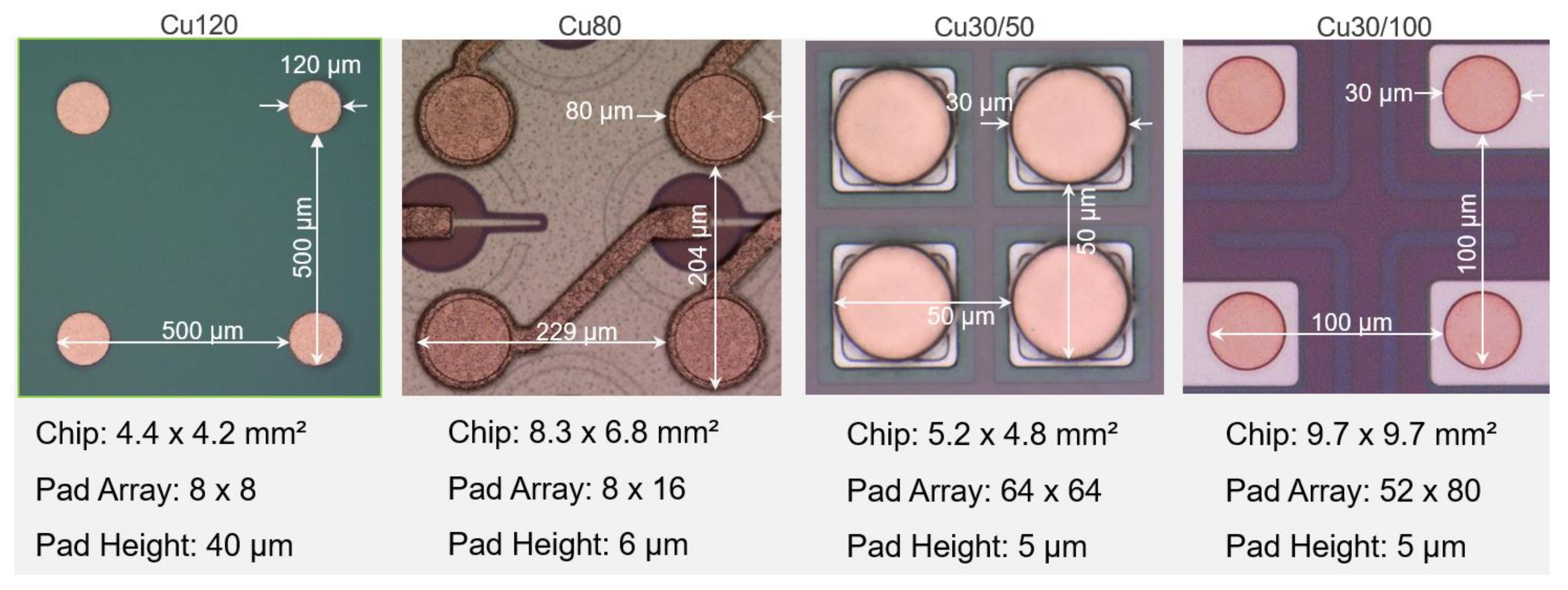

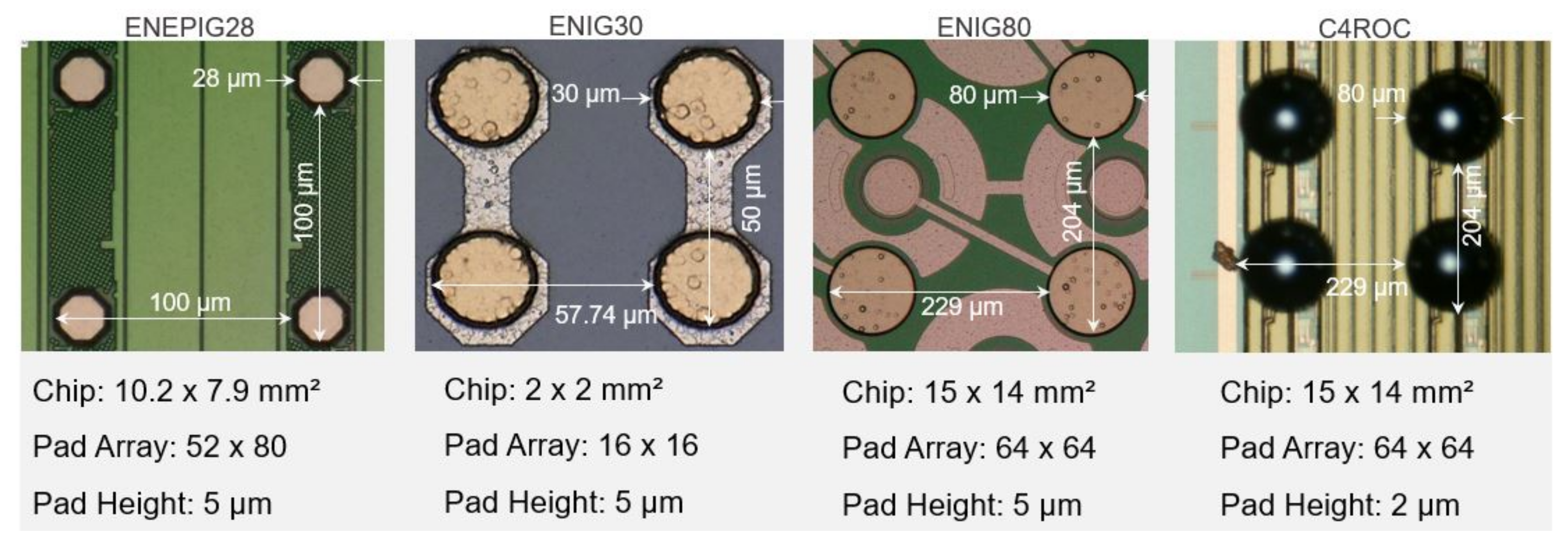

2.1. Samples

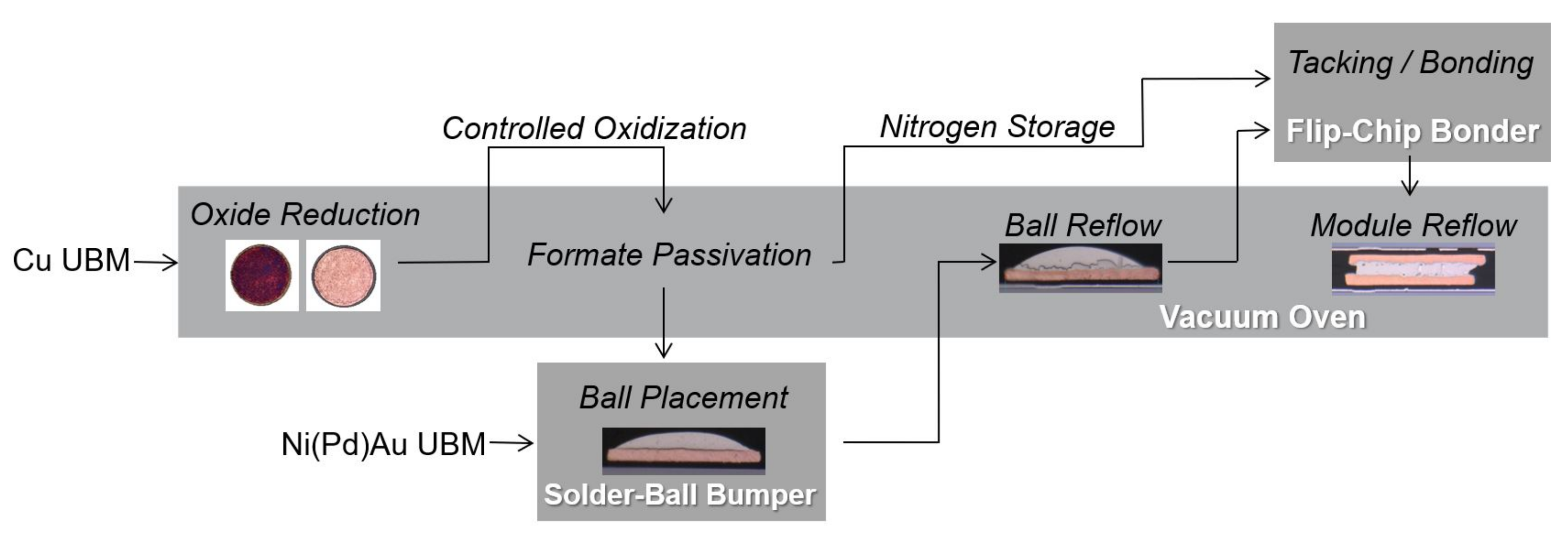

2.2. Processes

2.2.1. Oxide Reduction and Format Passivation

2.2.2. Ball Placement

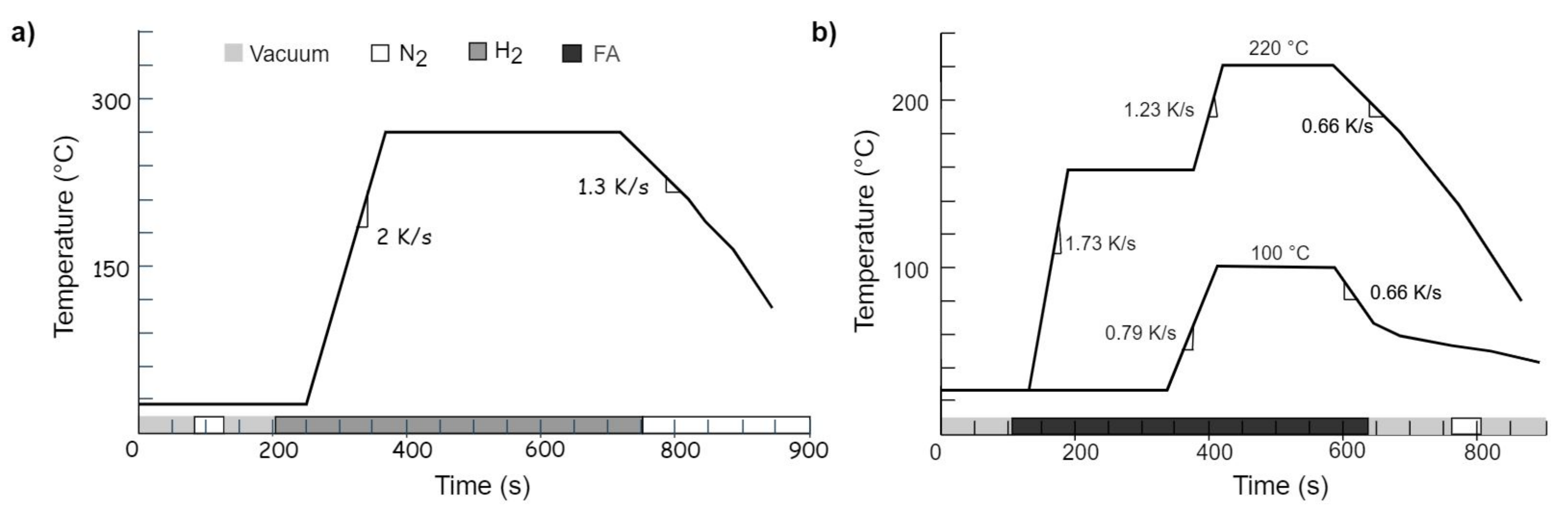

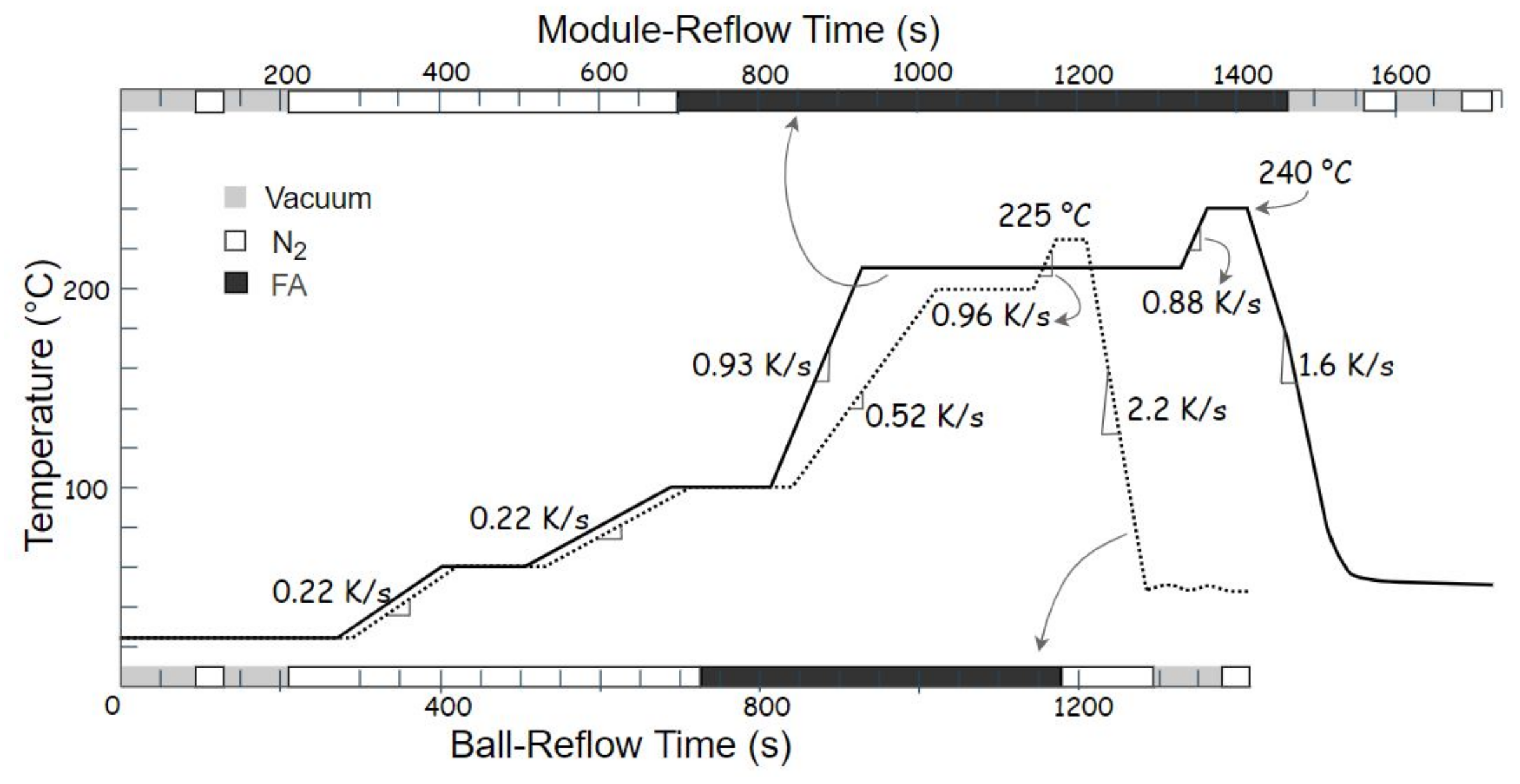

2.2.3. Ball Reflow

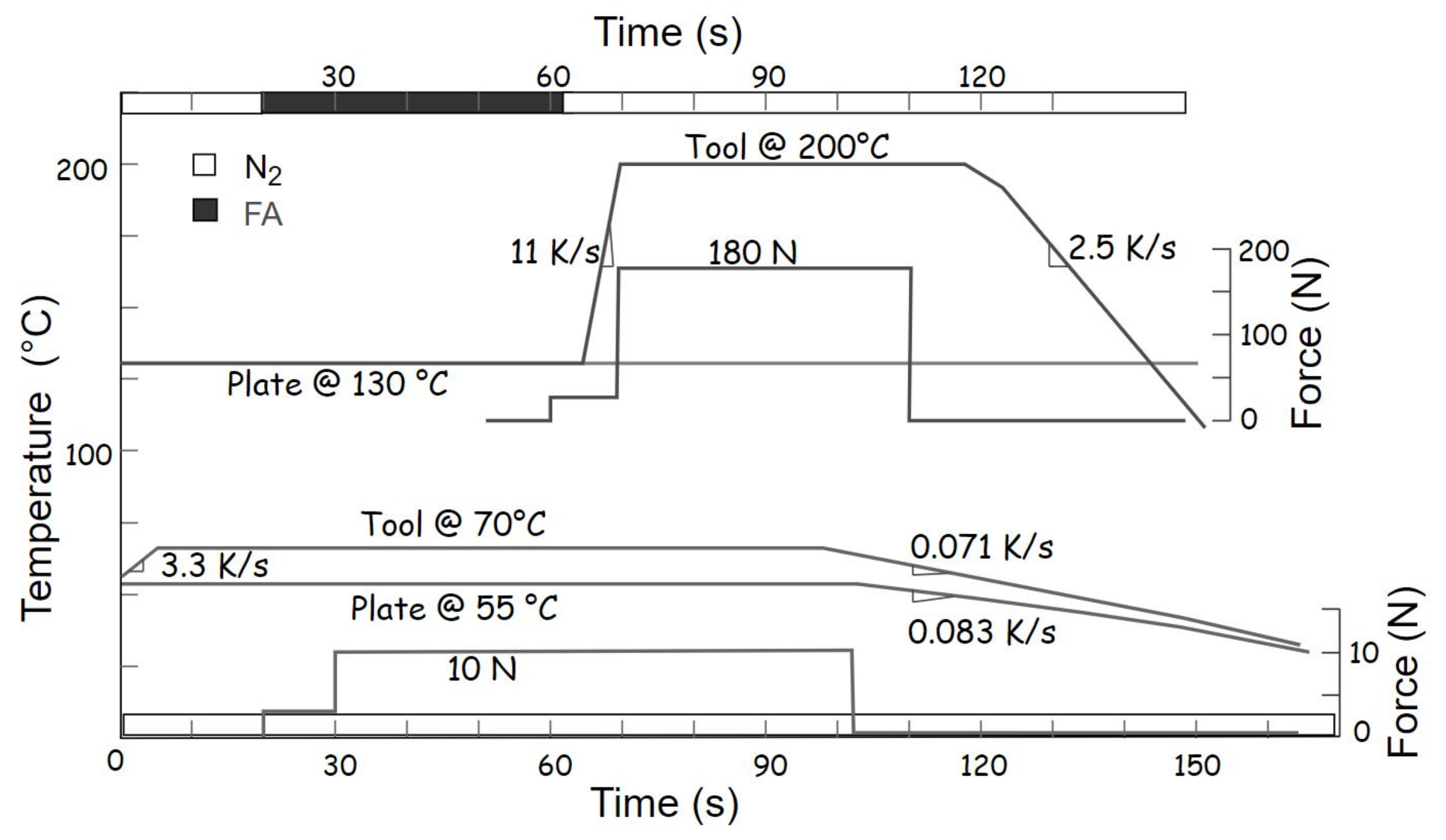

2.2.4. Tacking/Bonding

2.2.5. Module Reflow

2.3. Methods of Analysis

3. Results and Discussion

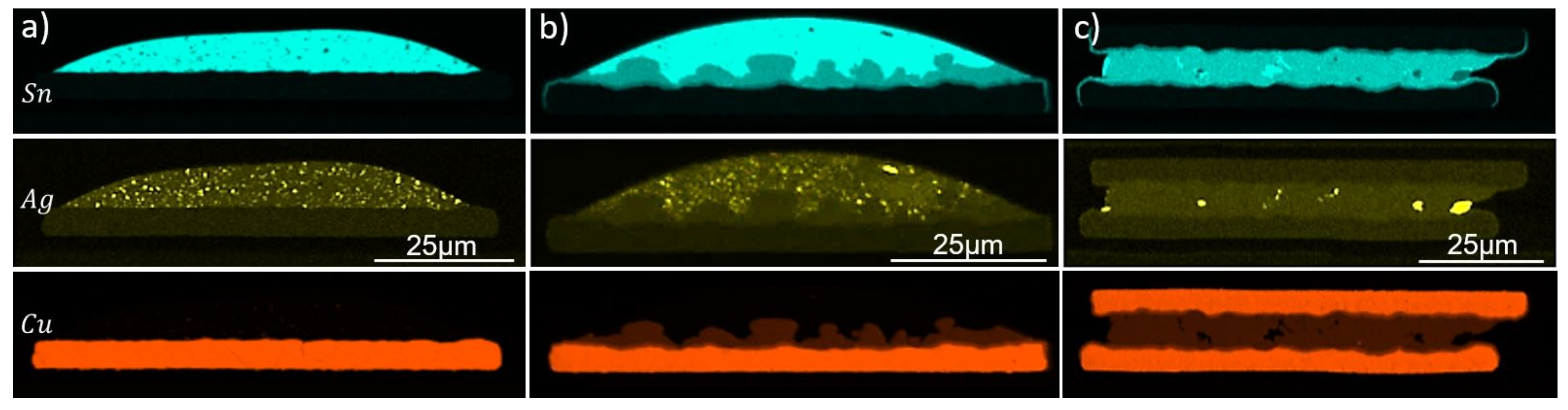

3.1. Wetting Performance

3.2. Bonding at 50 µm Pitch

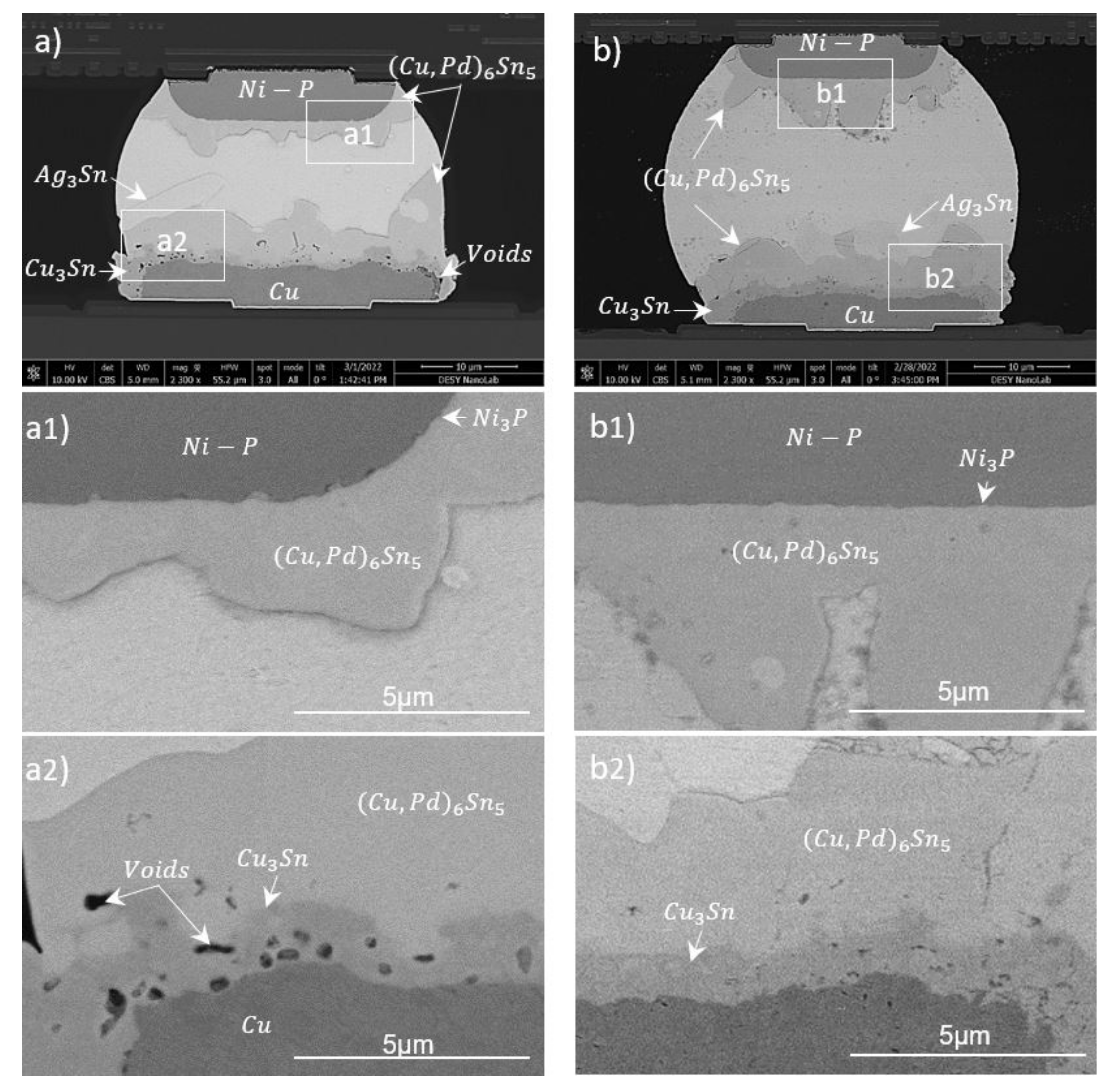

3.3. Intermetallics

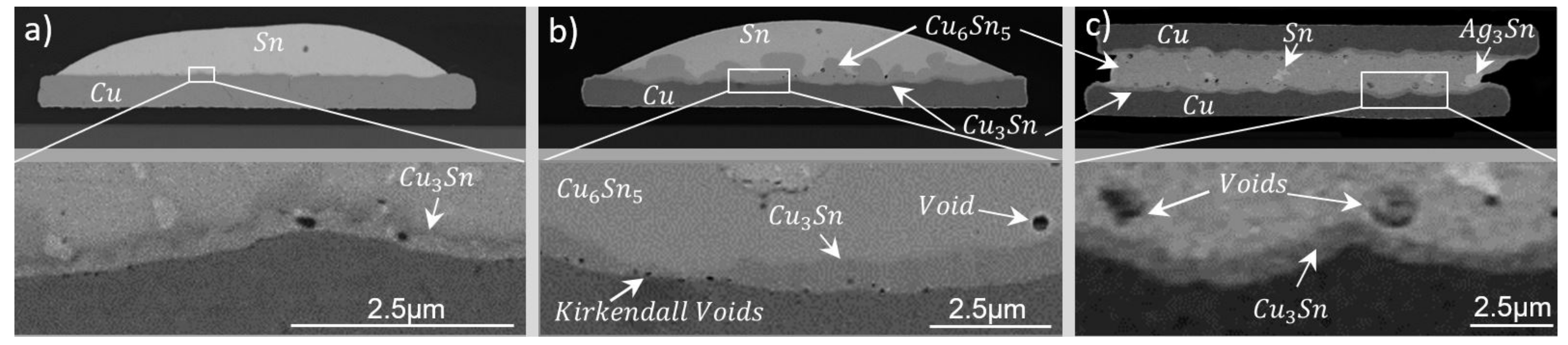

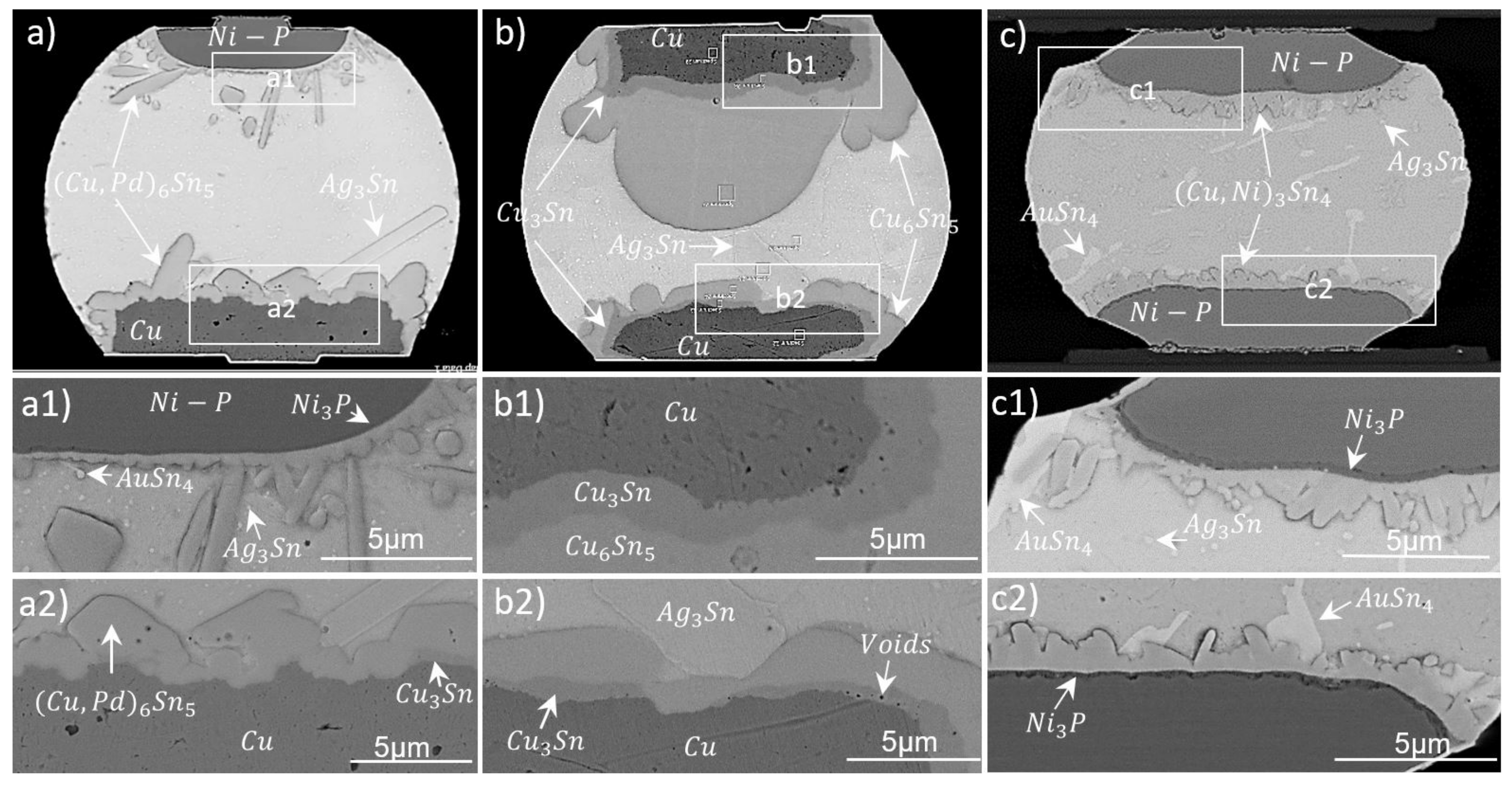

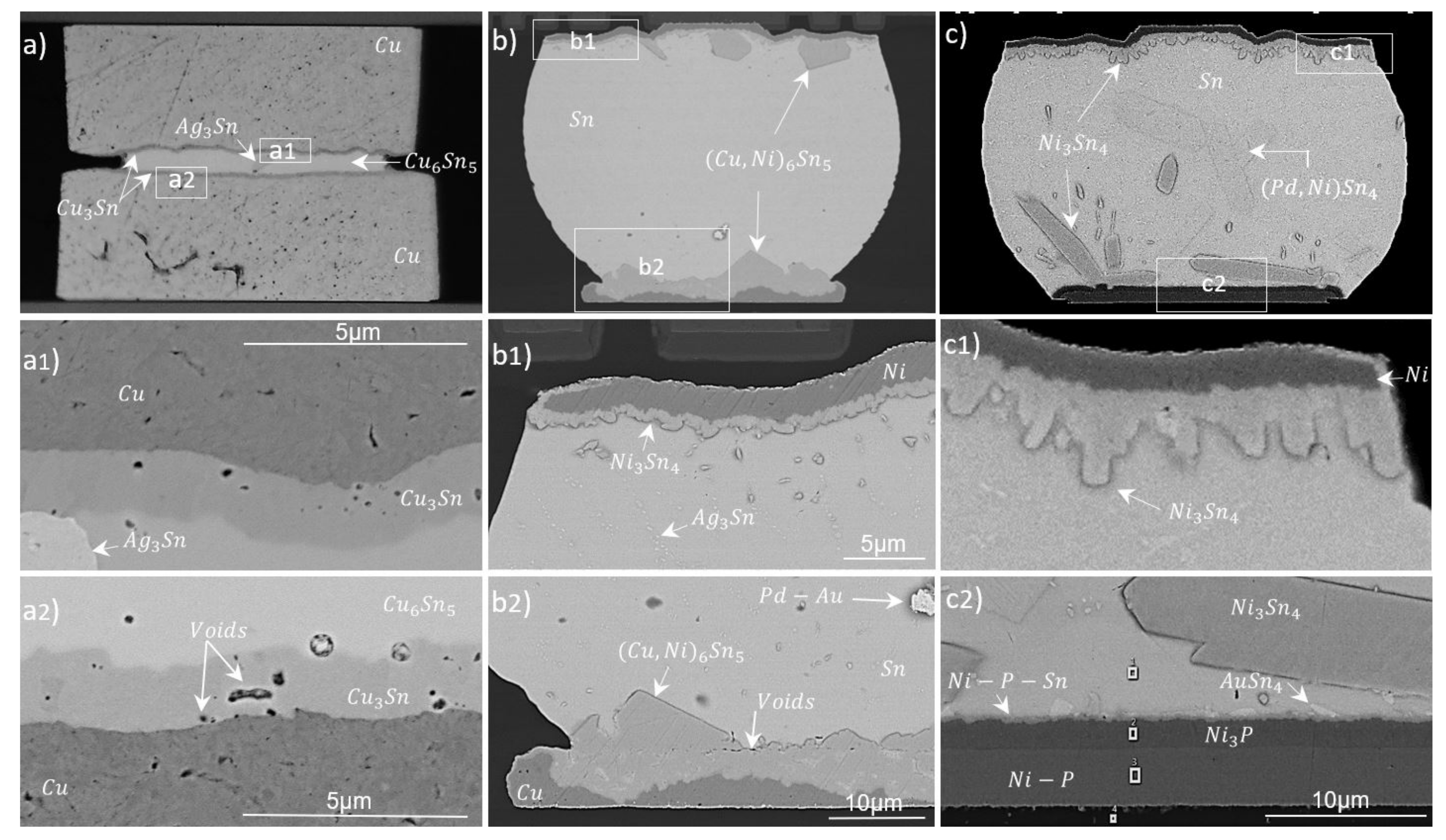

3.3.1. Initial IMCs

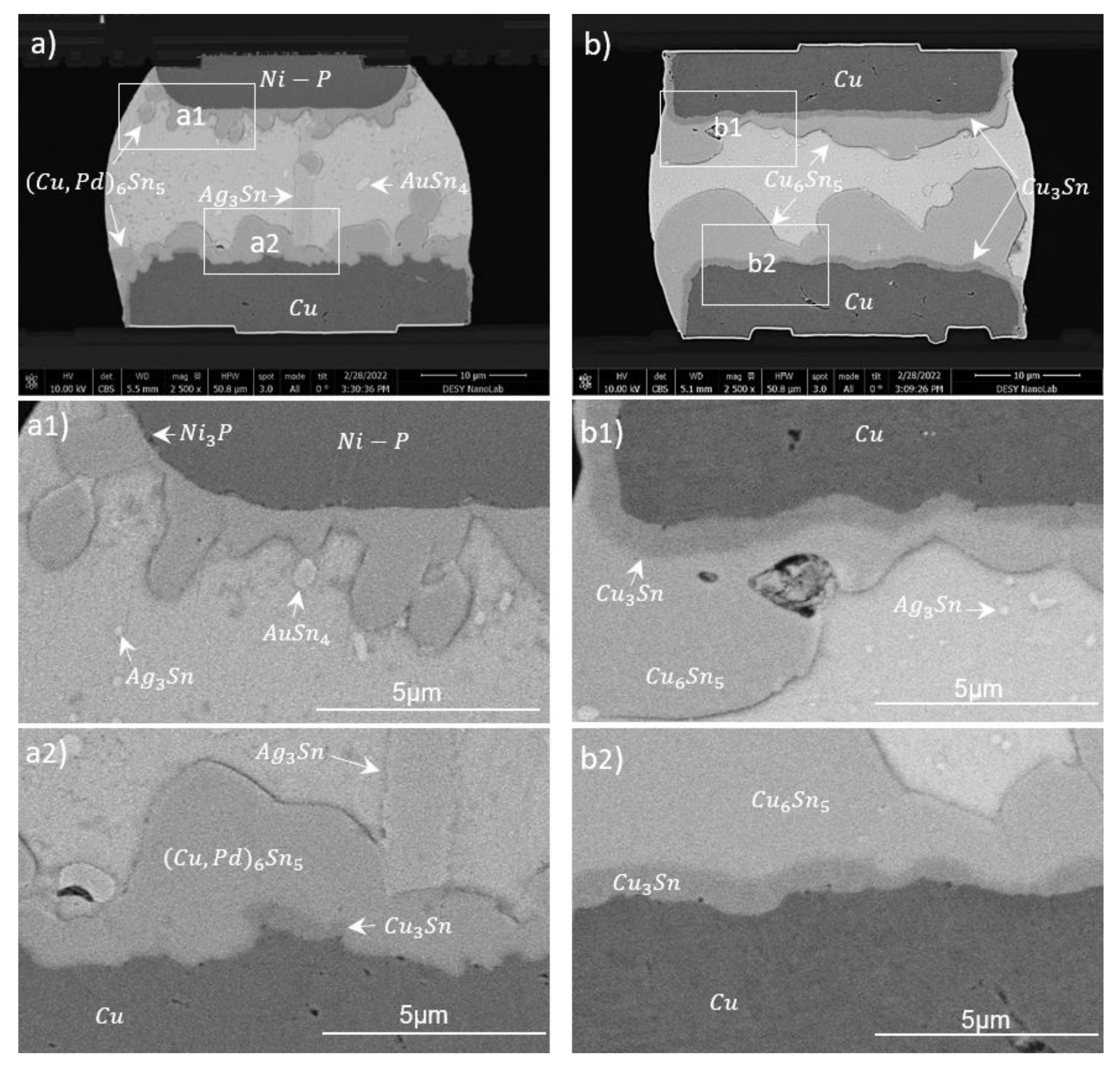

3.3.2. Post-TCT and -HTS IMCs

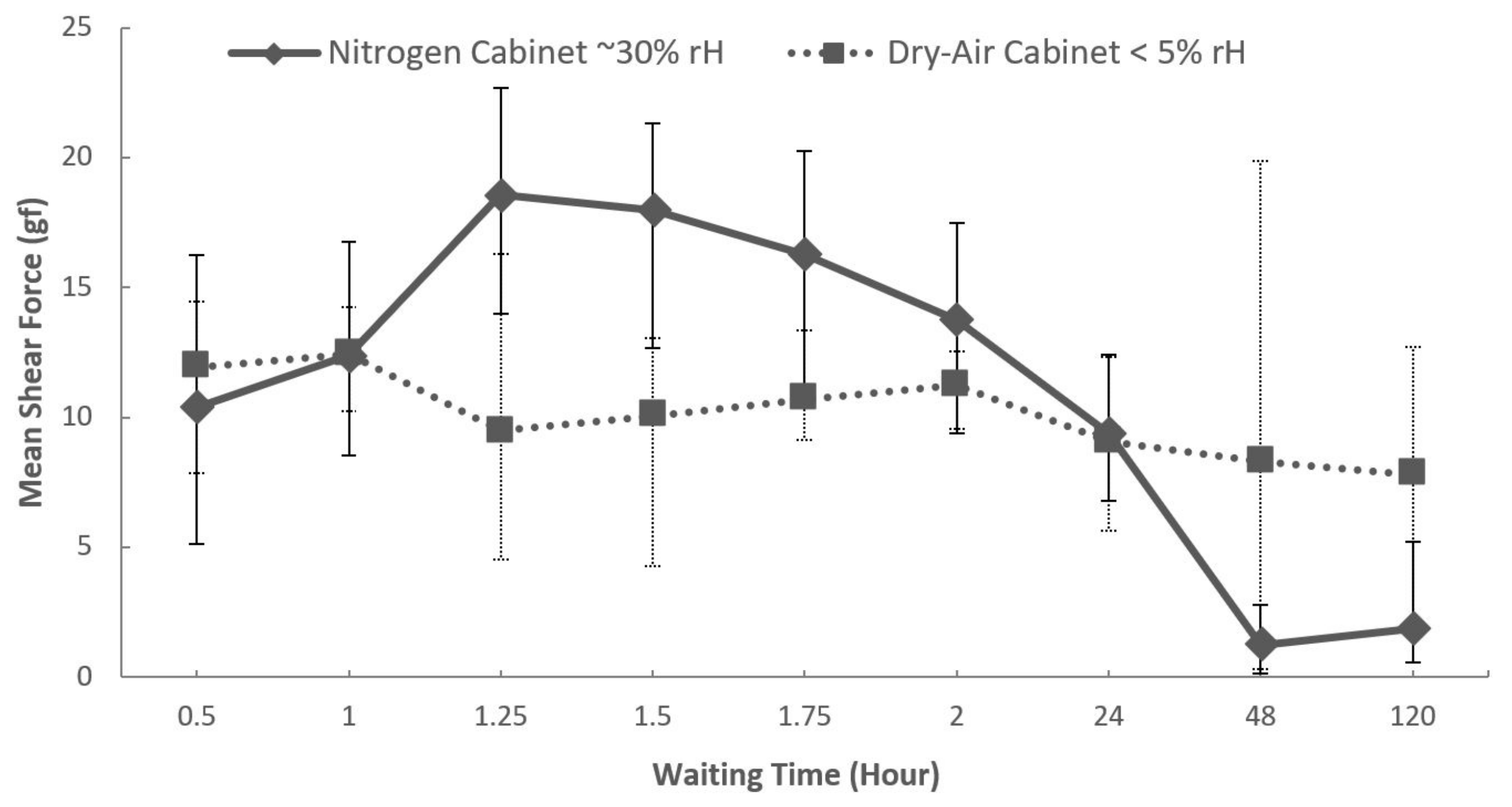

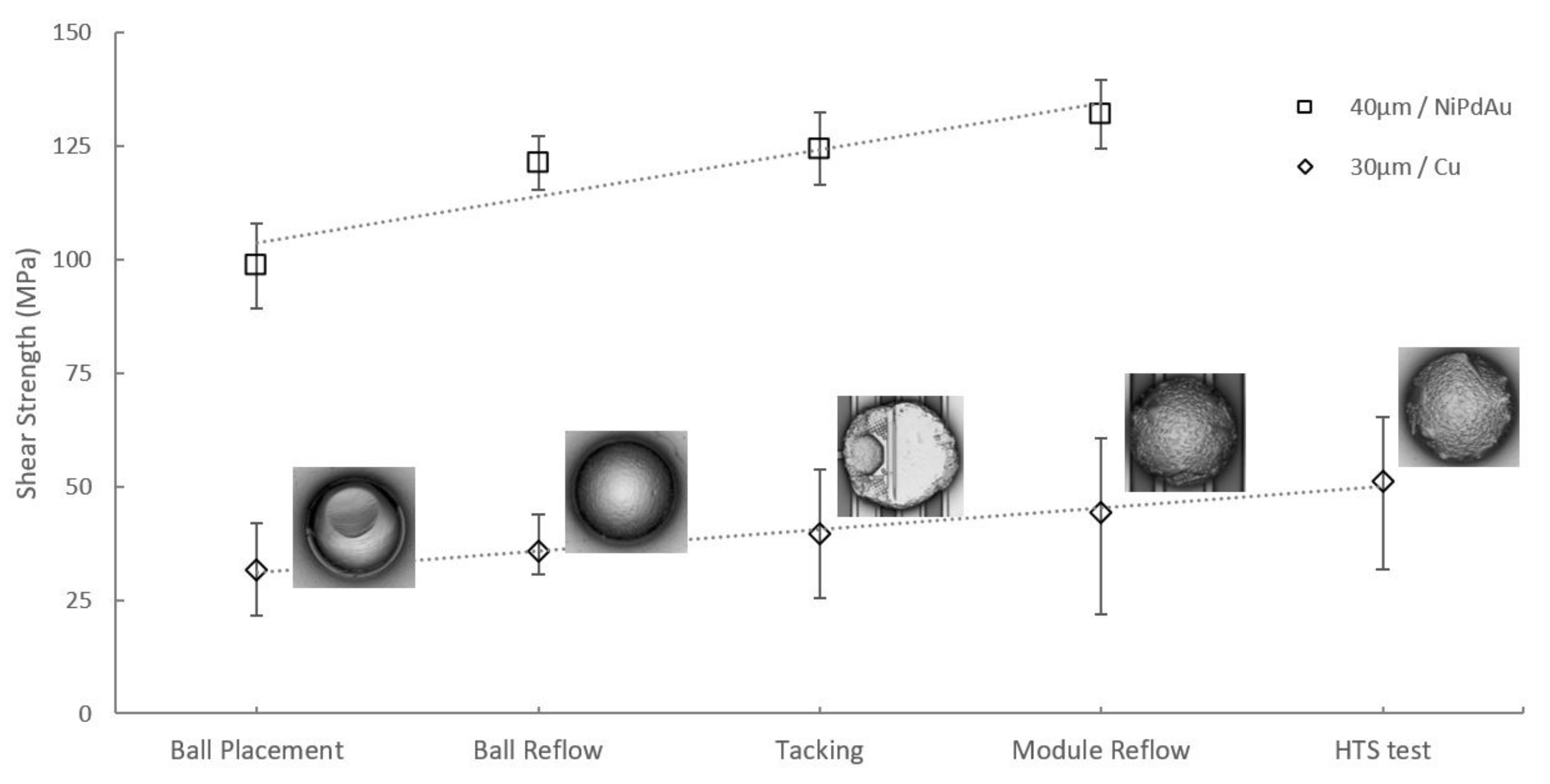

3.4. Shear Strength

3.5. Electrical Test

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Stojanovic, V.; Ram, J.R.; Popovic, M.; Lin, S.; Moazeni, S.; Wade, M.; Sun, C.; Alloatti, L.; Atabaki, A.; Pavanello, F.; et al. Monolithic Silicon Photonic Platforms in State-of-the-Art CMOS SOI Processes. Opt. Express (OSA) 2018, 26, 13106–13121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.; Kibune, M.; Toda, A.; Hayakawa, A.; Akiyama, T.; Sekiguchi, S.; Ebe, H.; Imaizumi, N.; Akahoshi, T.; Akiyama, S.; et al. A 25 Gb/s Hybrid Integrated Silicon Photonic Transceiver in 28 nm CMOS and SOI. In Proceedings of the IEEE International Solid State Circuit Conference (ISSCC), San Francisco, CA, USA, 22–26 February 2015; pp. 1–3. [Google Scholar]

- Janta-Polczynski, A.; Cyr, E.; Langlois, R.; Fortier, P.; Taira, Y.; Boyer, N.; Barwicz, T. Solder-Reflowable Single-Mode Fiber Array Assembly in High Throughput Manufacturing Facilities. In Proceedings of the Optical Interconnects XIX, SPIE, San Francisco, CA, USA, 7 June 2019; Volume 10924, pp. 140–152. [Google Scholar]

- De Dobbelaere, P.; Dahl, A.; Mekis, A.; Chase, B.; Weber, B.; Welch, B.; Foltz, D.; Armijo, G.; Masini, G.; McGee, G.; et al. Advanced Silicon Photonics Technology Platform Leveraging a Semiconductor Supply Chain. In Proceedings of the IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017; pp. 34.1.1–34.1.4. [Google Scholar]

- Ko, C.-T.; Chen, K.-N. Wafer-Level Bonding/Stacking Technology for 3D Integration. Microelectron. Reliab. 2010, 50, 481–488. [Google Scholar] [CrossRef]

- Cheng, Y.-L.; Lee, C.-Y.; Huang, Y.-L. Noble and Precious Metals-Properties, Nanoscale Effects and Applications; IntechOpen: London, UK, 2018; Chapter 10; pp. 215–250. [Google Scholar]

- Gao, G.; Mirkarimi, L.; Fountain, G.; Suwito, D.; Theil, J.; Workmann, T.; Uzoh, C.; Guevara, G.; Lee, B.; Huyhn, M.; et al. Low Temperature Hybrid Bonding for Die to Wafer Stacking Applications. In Proceedings of the IEEE 71th Electronic Components and Technology Conference (ECTC), Online, 1 June–4 July 2021; pp. 383–389. [Google Scholar]

- Chong, S.C.; Xie, L.; Li, H.; Lim, S.H. Development of Multi-Die Stacking with Cu-Cu Interconnects using Gang Bonding Approach. In Proceedings of the IEEE 70th Electronic Components and Technology Conference (ECTC), Online, 26–29 May 2020; pp. 188–193. [Google Scholar]

- Jangam, S.C.; Bajwa, A.; Mogera, U.; Ambhore, P.; Colosimo, T.; Chylak, B.; Iyer, S.S. Fine-Pitch (≤10 µm) direct Cu-Cu Interconnects using in-Situ Formic Acid Vapor Treatment. In Proceedings of the IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 620–627. [Google Scholar]

- Labie, R.; Ruythooren, W.; Baert, K.; Beyne, E.; Swinnen, B. Resistance to Electromigration of Purely Intermetallic Micro-Bump Interconnections for 3D-Device Stacking. In Proceedings of the IEEE International Interconnect Technology Conference, Burlingame, CA, USA, 1–4 June 2008; pp. 19–21. [Google Scholar]

- Huebner, H.; Penka, S.; Barchmann, B.; Eigner, M.; Gruber, W.; Nobis, M.; Janka, S.; Kristen, G.; Schneegans, M. Microcontacts with Sub-30 µm Pitch for 3D Chip-on-Chip Integration. Microelectron. Eng. 2006, 83, 2155–2162. [Google Scholar] [CrossRef]

- Mourier, T.; Auffret, J.; Boutafa, L.; Miloud-Ali, N.; Mendizabal, L.; Peray, P.; Castany, O. Self-Assembly and Mass Reflow of Copper Bumps for Flip-Chip Hybridization in Photonic Applications. In Proceedings of the IEEE 71th Electronic Components and Technology Conference (ECTC), Online, 1 June–4 July 2021; pp. 225–230. [Google Scholar]

- Fan, J.; Lim, D.F.; Tan, C.S. Effects of Surface Treatment on the Bonding Quality of Wafer-Level Cu-to-Cu Thermo-Compression Bonding for 3D Integration. IOP J. Micromech. Microeng. 2013, 23, 045025. [Google Scholar] [CrossRef]

- Huffman, A.; Lannon, J.; Lueck, M.; Gregory, C.; Temple, D. Fabrication and Characterization of Metal-to-Metal Interconnect Structure for 3D Integration. IOP J. Instrum. 2009, 4, 03006. [Google Scholar] [CrossRef]

- Bajwa, A.A.; Jangam, S.C.; Pal, S.; Marathe, N.; Bai, T.; Fukushima, T.; Goorsky, M.; Iyer, S.S. Heterogeneous Integration at Fine Pitch (≤10 µm) using Thermal Compression Bonding. In Proceedings of the IEEE 67th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2017; pp. 1276–1284. [Google Scholar]

- Xie, L.; Wickramanayaka, S.; Chong, S.C.; Sekhar, V.N.; Ismeal, D.; Ye, Y.L. 6 µm Pitch High Density Cu-Cu Bonding for 3D IC Stacking. In Proceedings of the IEEE 66th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 31 May–3 June 2016; pp. 2126–2133. [Google Scholar]

- Park, H.; Kim, S.E. Two-Step Plasma Treatment on Copper Surface for Low-Temperature Cu Thermo-Compression Bonding. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 332–338. [Google Scholar] [CrossRef]

- Gao, G.; Mirkarimi, L.; Workman, T.; Fountain, G.; Theil, J.; Guevara, G.; Liu, P.; Lee, B.; Mrozek, P.; Huynh, M.; et al. Low Temperature Cu Interconnect with Chip to Wafer Hybrid Bonding. In Proceedings of the IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 628–635. [Google Scholar]

- Mudrick, J.P.; Sierra-Suarez, J.A.; Jorden, M.B.; Friedmann, T.A.; Jarecki, R.; Henry, M.D. Sub-10 µm Pitch Hybrid Direct Bond Interconnect Development for Die-to-Die Hybridization. In Proceedings of the IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 648–654. [Google Scholar]

- Manda, R.; Matsumoto, R.; Saito, S.; Maruyama, S.; Minari, H.; Hirano, T.; Takachi, T.; Fujii, N.; Yamamoto, Y.; Zaizen, Y.; et al. High-definition Visible-SWIR InGaAs Image Sensor using Cu-Cu Bonding of III-V to Silicon Wafer. In Proceedings of the IEEE International Electron Device Meeting (IEDM), San Francisco, CA, USA, 7–11 December 2019; pp. 16.7.1–16.7.4. [Google Scholar]

- Siang Lim, S.P.; Chong, S.C.; Chidambaram, V. Comprehensive Study on Chip to Wafer Hybrid Bonding Process for Fine Pitch High Density Heterogeneous Applications. In Proceedings of the IEEE 71th Electronic Components and Technology Conference (ECTC), Online, 1 June–4 July 2021; pp. 438–444. [Google Scholar]

- Hong, Z.J.; Liu, D.; Hu, H.W.; Lin, M.C.; Hsieh, T.H.; Chen, K.N. Ultra-High Strength Cu-Cu Bonding under Low Thermal Budget for Chiplet Heterogeneous Applications. In Proceedings of the IEEE 71th Electronic Components and Technology Conference (ECTC), Online, 1 June–4 July 2021; pp. 347–352. [Google Scholar]

- Tsai, Y.C.; Hu, H.W.; Chen, K.N. Low Temperature Copper-Copper Bonding of Non-Planarized Copper Pillar With Passivation. IEEE Electron Device Lett. 2020, 41, 1229–1232. [Google Scholar] [CrossRef]

- Li, Z.; Tomita, Y.; Elsherbini, A.A.; Liu, P.; Sawyer, H.A.; Swan, J.M.; Liff, S.M. Scaling Solder Micro-Bump Interconnect down to 10 µm Pitch for Advanced 3D IC Packages. In Proceedings of the IEEE 71th Electronic Components and Technology Conference (ECTC), Online, 1 June–4 July 2021; pp. 451–456. [Google Scholar]

- Sun, L.; Chen, M.H.; Zhang, L.; He, P.; Xie, L.S. Recent Progress in SLID Bonding in Novel 3D-IC Technologies. J. Alloys Compd. 2019, 818, 152825. [Google Scholar] [CrossRef]

- Jaafar, N.B.; Choong, C.S. Comprehensive Study of Tin-Silver-Copper Lead-Free Alloys on Various Bond Pad Metallisation. In Proceedings of the Electronic Packaging Technology Conference (EPTC), Singapore, 4–6 December 2019; pp. 658–662. [Google Scholar]

- Hansen, K.; Kousar, S.; Pitzl, D.; Arab, S. Fluxless Flip-Chip Bonding using Lead Free Solder Bumping Technique. IOP J. Instrum. 2017, 12, T09006. [Google Scholar] [CrossRef]

- Lujan, P. The Pixel Luminosity Telescope: A Silicon Sensor Detector for Luminosity Measurement at CMS. In Proceedings of the The European Physical Society Conference on High Energy Physics (EPS-HEP), Online, 26–30 July 2021. [Google Scholar]

- Hansen, K.; Klär, H.; Kalavakuru, P.; Reckleben, C.; Venzmer, A.; Wüstenhagen, E.; Schappeit, R.; Zeides, O.-C.; Okrent, F.; Wunderer, C.; et al. Qualification and Integration Aspects of the DSSC Mega-Pixel X-Ray Imager. IEEE Trans. Nucl. Sci. 2019, 66, 1966–1975. [Google Scholar] [CrossRef]

- budatec GmbH. Available online: https://budatec.de/ (accessed on 22 August 2022).

- PacTech GmbH. Available online: https://pactech.com/ (accessed on 22 August 2022).

- finetech GmbH. Available online: https://www.finetech.de/ (accessed on 22 August 2022).

- Dong, C.C.; Schwarz, A.; Roth, D.V. Feasibility of Fluxless Reflow of Lead-Free Solders in Hydrogen and Forming Gas; NEPCON Malaysia 97, Manufacturing Session (1), Kuala Lumpur, Malaysia; Air Products and Chemicals, Inc.: Allentown, PA, USA, 1997. [Google Scholar]

- Kim, J.Y.; Rodriguez, J.A.; Hanson, J.C.; Frenkel, A.I.; Lee, P.L. Reduction of CuO and Cu2O with H2: H Embedding and Kinetic Effects in the Formation of Suboxides. J. Am. Chem. Soc. 2003, 125, 10684–10692. [Google Scholar] [CrossRef] [PubMed]

- Platzman, I.; Brener, R.; Haick, H.; Tannenbaum, R. Oxidation of Polycrystalline Copper Thin Films at Ambient Conditions. J. Phys. Chem. 2008, 112, 1101–1108. [Google Scholar] [CrossRef]

- Sigl, A.; Glinsner, T.; Pichler, C.; Scheiring, C.; Kettner, P. Lowest Cost of Ownership for Chip to Wafer Bonding with the Advanced Chip to Wafer Bonding Process Flow. In Proceedings of the IEEE 11th Electronic Packaging Technology Conference (EPTC), Singapore, 9–11 December 2009; pp. 459–463. [Google Scholar]

- Noei, H.; Vonk, V.; Keller, T.F.; Röhlsberger, R.; Stierle, A. DESY NanoLab, Deutsches Elektronen Synchrotron (DESY). J. Large-Scale Res. Facil. 2016, 2, A76. [Google Scholar]

- Youngs, T.G.A.; Haq, S.; Bowker, S. Formic Acid Adsorption and Oxidation on Cu(1 1 0). Surf. Sci. 2008, 602, 1775–1782. [Google Scholar] [CrossRef]

- Ume, I.C.; Gong, J. Evaluation of Lead-Free Solder Bump Voiding Ball Grid Array Packages using Laser Ultrasound and Interferometric Technique. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 1310–1320. [Google Scholar] [CrossRef]

- Yao, P.; Li, X.; Liang, X.; Yu, B. A Study on Optimization of Process Parameters, Microstructure Evolution and Fracture Behavior for Full Cu3Sn Solder Joints in Electronic Packaging. In Proceedings of the IEEE 18th Electronic Packaging Technology Conference (EPTC), Singapore, 30 November–3 December 2016; pp. 135–140. [Google Scholar]

- Tang, C.; Zhu, W.; Chen, Z.; Wang, L. Thermomechanical Reliability of a Cu/Sn-3.5Ag Solder Joint with a Ni Insertion Layer in Flip Chip Bonding for 3D Interconnection. J. Mater. Sci. Mater. Electron. 2021, 32, 11893–11909. [Google Scholar] [CrossRef]

- Bordère, S.; Feuillet, E.; Diot, J.L.; Langlade, R.D.; Silvain, J.-F. Understanding of Void Formation in Cu/Sn-Sn/Cu System During Transient Liquid Phase Bonding Process Through Diffusion Modeling. Metall. Mater. Trans. B 2018, 49, 3343–3356. [Google Scholar] [CrossRef]

- Wang, J.W.; Frear, D.R.; Lee, T.Y.; Tu, K.N. Morphology of Interfacial Reaction between Lead-Free Solders and Electroless Ni-P Under Bump Metallization. J. Appl. Phys. 2000, 88, 6359–6363. [Google Scholar]

- Henao, H.M.; Chu, C.S.; Solis, J.P.; Nogita, K. Experimental Determination of the Sn-Cu-Ni Phase Diagram for Pb-Free Solder Applications. Metall. Mater. Trans. B 2019, 50, 502–516. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.M.; Park, J.Y.; Kim, Y.H. Effect of Pd Thickness on the Interfacial Reaction and Shear Strength in Solder Joints Between Sn-3.0Ag-0.5Cu Solder and Electroless Nickel/Electroless Palladium/Immersion Gold (ENEPIG) Surface Finish. J. Electron. Mater. 2012, 41, 763–773. [Google Scholar] [CrossRef]

- Tan, X.F.; Somidin, F.; McDonald, S.D.; Bermingham, M.J.; Maeno, H.; Matsumura, S.; Nogita, K. In Situ Observation of Liquid Solder Alloys and Solid Substrate Reactions Using High-Voltage Transmission Electron Microscopy. Materials 2022, 15, 510. [Google Scholar] [CrossRef] [PubMed]

- Lasky, C.R. Copper-Tin Intermetallics: Their Importance, Growth Rate, and Nature. In Proceedings of the SMTA International, Rosemont, IL, USA, 14–18 October 2018. [Google Scholar]

- Lee, J.-Y.; Chen, C.-M. Effects of Initial Morphology on Growth Kinetics of Cu6Sn5 at SAC305/Cu Interface during Isothermal Aging. Materials 2022, 15, 4751. [Google Scholar] [CrossRef] [PubMed]

- Chi, P.; Li, Y.; Pan, H.; Wang, Y.; Chen, N.; Li, M.; Gao, L. Effect of Ni(P) Layer Thickness on Interface Reaction and Reliability of Ultrathin ENEPIG Surface Finish. Materials 2021, 14, 7874. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Yang, Y.; Wang, K.; Xu, J.; Chen, J.; Lu, H. Relation between Kirkendall Voids and Intermetallic Compound Layers in the SnAg/Cu Solder Joints. J. Mater. Sci. Mater. Electron. 2012, 23, 124–129. [Google Scholar] [CrossRef]

- Aasmundtveit, K.E.; Luu, T.T.; Vardøy, A.-S.B.; Tollefsen, T.A.; Wang, K.; Hoivik, N. High-Temperature Shear Strength of Solid-Liquid Interdiffusion (SLID) Bonding: Cu-Sn, Au-Sn and Au-In. In Proceedings of the IEEE Electronics System-Integration Conference (ESTC), Helsinki, Finland, 16–18 September 2014. [Google Scholar]

| Bonded Samples | Ball Size | Ball Reflow | Tacking | Module Reflow | |

|---|---|---|---|---|---|

| µm | T (°C), t (s) | T (°C) | F (MPa) | T (°C), t (s) | |

| Cu80-Cu80 | 40 | 225, 45 | 55 | 16 | 270, 1320 |

| ENEPIG28-Cu30/100 | 30 | 225, 45 | 180 | 61 | 240, 100 |

| Cu30/100-Cu30/100 | 30 | 225, 45 | 55 | 3.4 | 270, 1320 |

| ENIG30-ENIG30 | 30 | 225, 45 | 180 | 28 | 240, 75 |

| Cu120-Cu120 | 40 | 225, 45 | 55 | 14 | 270, 1320 |

| C4ROC-Cu80 | 100 | 225, 45 | 55 | 0.5 | 240, 500 |

| C4ROC-ENIG80 | 100 | 225, 45 | 55 | 0.5 | 240, 70 |

| FC Bonder | Vacuum Oven | ||||

|---|---|---|---|---|---|

| Photoresist Removal | Cu Formate | Ar/H2 Plasma + Cu Formate | H2 + Cu Formate | Cu Formate | |

| Shear Force (gf) | 0 | 0.43 | 14.09 | 9.23 | 23.09 |

| Standard Deviation (gf) | 0 | 0.26 | 5.66 | 4.4 | 2.83 |

| Wetting on Cu80 |  |  |  |  |  |

| Bonded Sample | T | t | Type | d0 | k |

|---|---|---|---|---|---|

| (t)-(b) | °C | s | µm | nm/ | |

| Cu80-Cu80 | 270 | 780 | Cu3Sn | 0.8 | 29 |

| Cu6Sn5 | 3.9 | 140 | |||

| ENEPIG28-Cu30/100 | 240 | 100 | Ni3P | 0.13 | 13 (t) |

| Cu-Pd-Sn | 1.95 (t), 3.65 (b) | 195 (t), 365 (b) | |||

| Cu30/100-Cu30/100 | 270 | 1320 | Cu3Sn | 1.5 (t), 0.8 (b) | 41 (t), 22 (b) |

| Cu6Sn5 | 10.7 (t), 2.99 (b) | 295 (t), 82 (b) | |||

| ENIG30-ENIG30 | 240 | 75 | Ni3P | 0.1 | 12 |

| (Cu, Ni)6Sn5 | 1.2 (t), 1.55 (b) | 139 (t), 179 (b) | |||

| Cu120-Cu120 | 270 | 1320 | Cu3Sn | 1.18 | 33 |

| Cu6Sn5 | 2.29 | 63 | |||

| C4ROC-Cu80 | 240 | 500 | (Cu, Ni)6Sn5 | 4.2 (t), 4.7 (b) | 189 (t), 210 (b) |

| C4ROC-ENIG80 | 240 | 70 | Ni3P | 1.4 | 167 (b) |

| Ni-P-Sn | 0.4 | 48 (b) | |||

| Ni3Sn4 | 2.99 (t), 2.12 (b) | 358 (t), 253 (b) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kousar, S.; Hansen, K.; Keller, T.F. Laser-Assisted Micro-Solder Bumping for Copper and Nickel–Gold Pad Finish. Materials 2022, 15, 7349. https://doi.org/10.3390/ma15207349

Kousar S, Hansen K, Keller TF. Laser-Assisted Micro-Solder Bumping for Copper and Nickel–Gold Pad Finish. Materials. 2022; 15(20):7349. https://doi.org/10.3390/ma15207349

Chicago/Turabian StyleKousar, Sumera, Karsten Hansen, and Thomas Florian Keller. 2022. "Laser-Assisted Micro-Solder Bumping for Copper and Nickel–Gold Pad Finish" Materials 15, no. 20: 7349. https://doi.org/10.3390/ma15207349