Significant Progress for Hot-Deformed Nd-Fe-B Magnets: A Review

Abstract

:1. Introduction

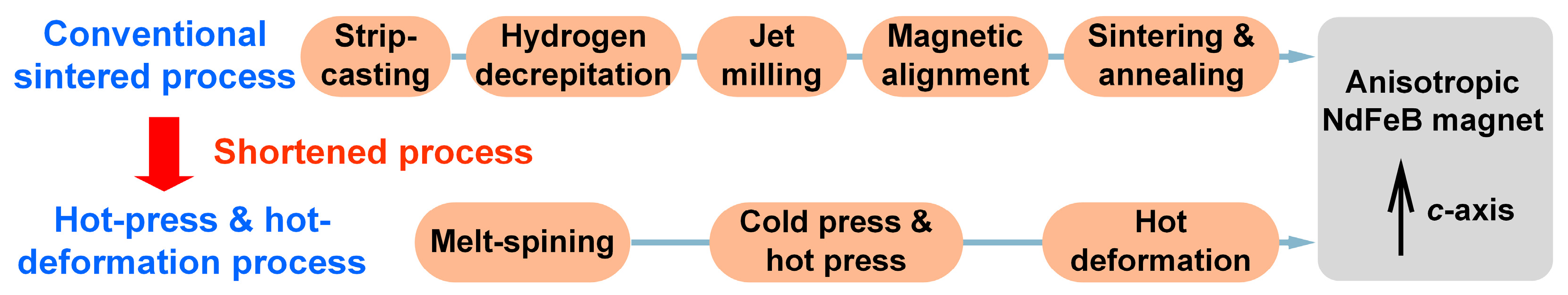

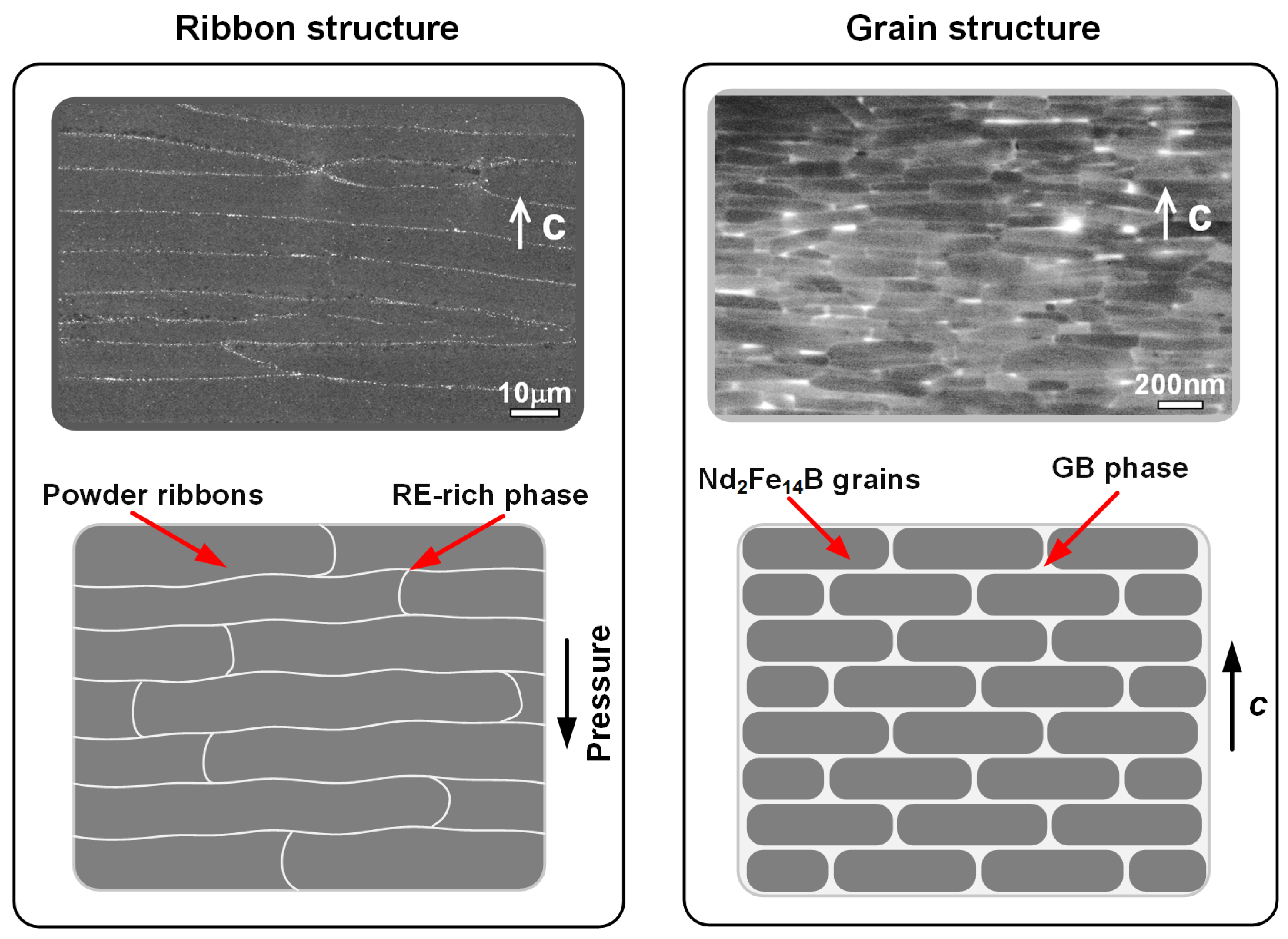

2. Production Process and Microstructural Features of Hot-Deformed Magnets

3. Two Routes for High-Coercivity Hot-Deformed Magnets

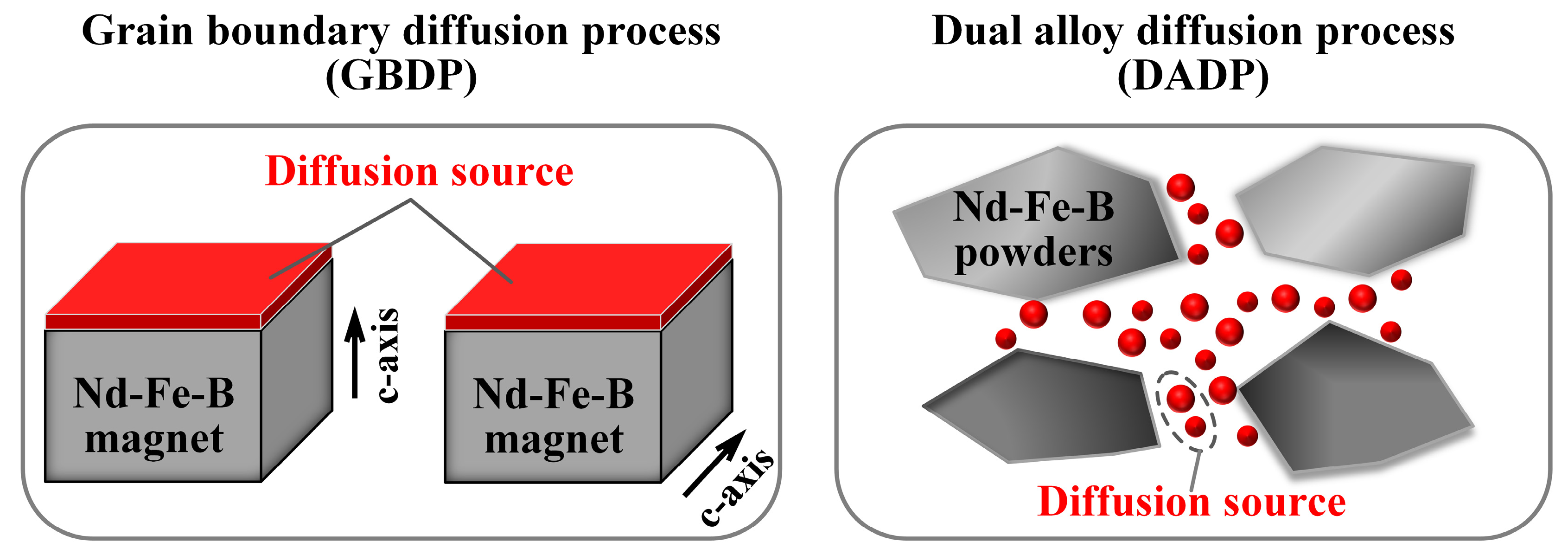

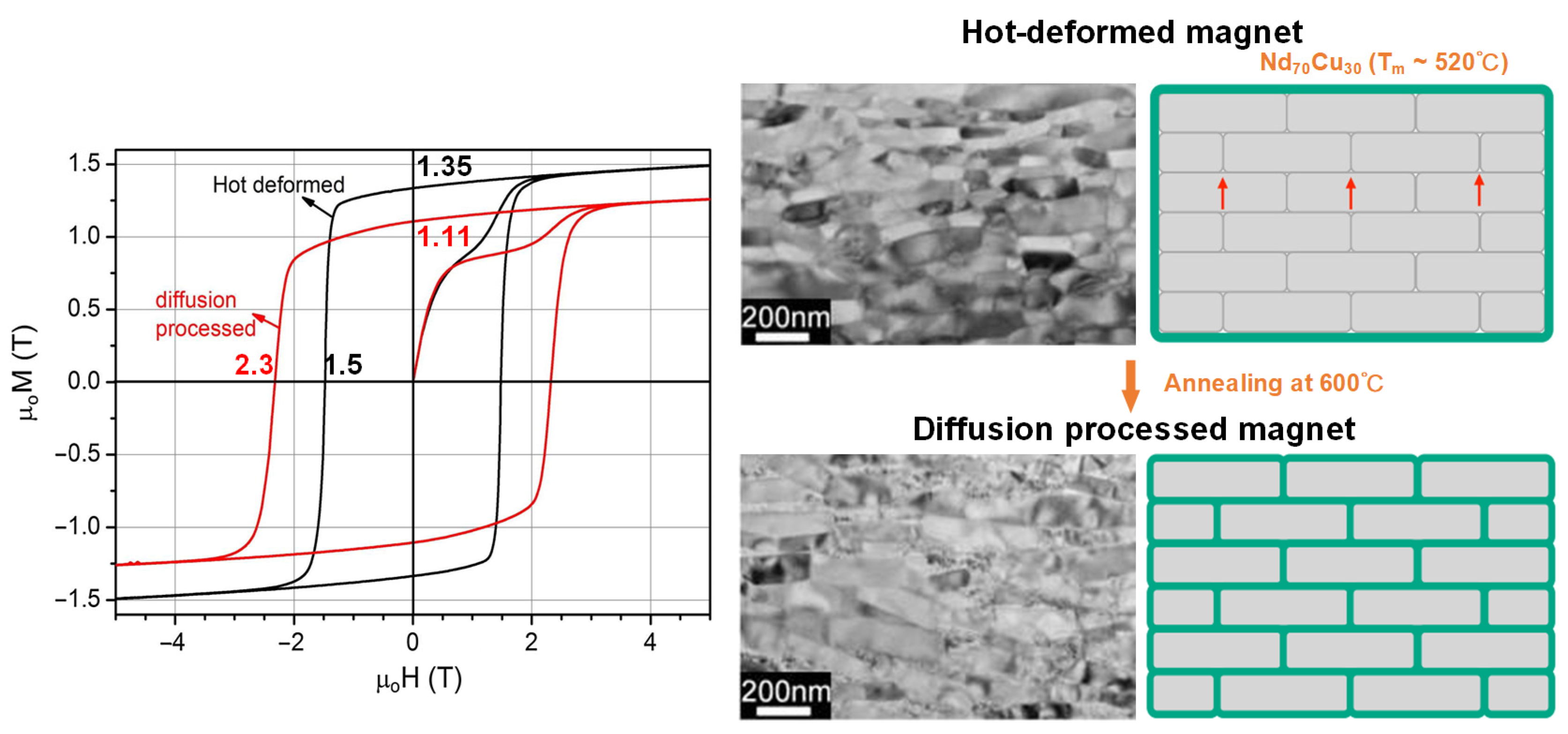

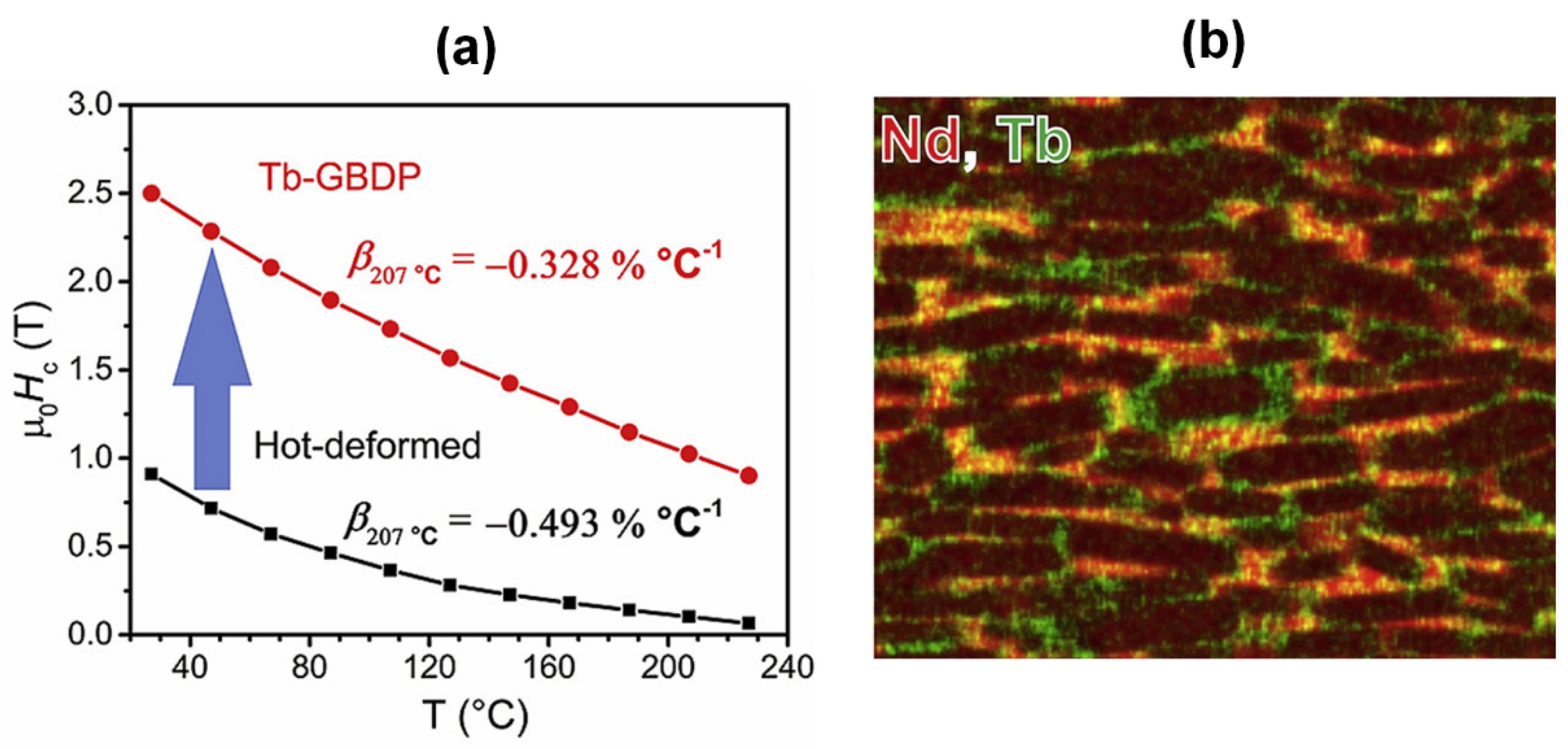

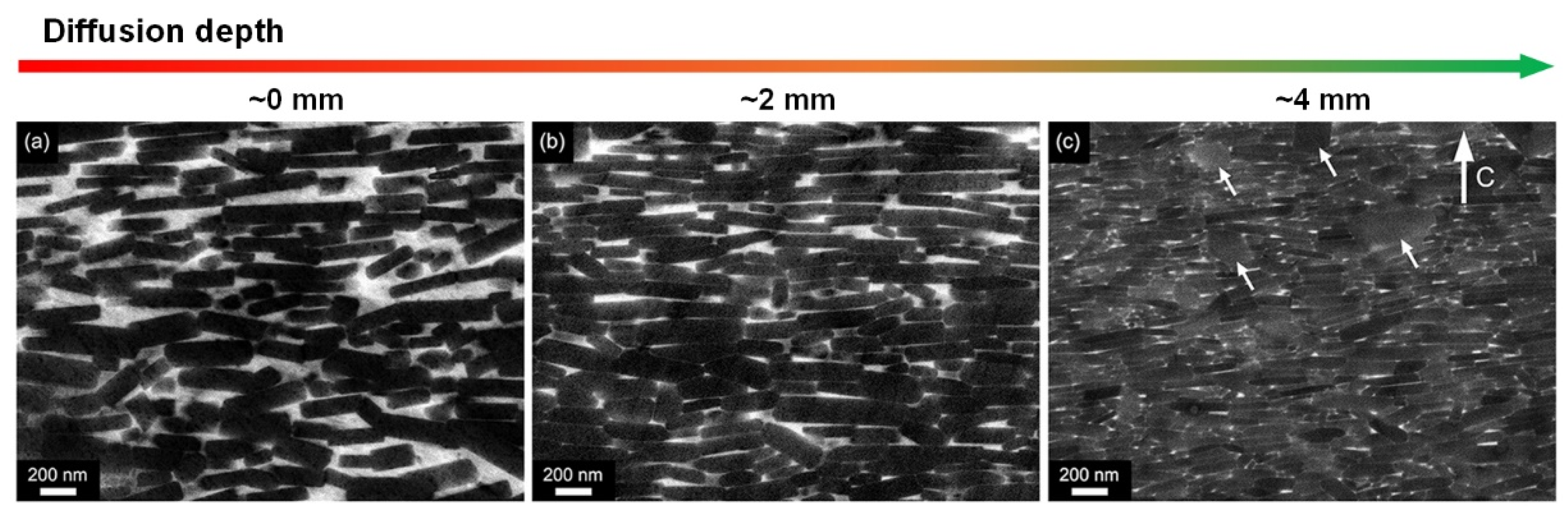

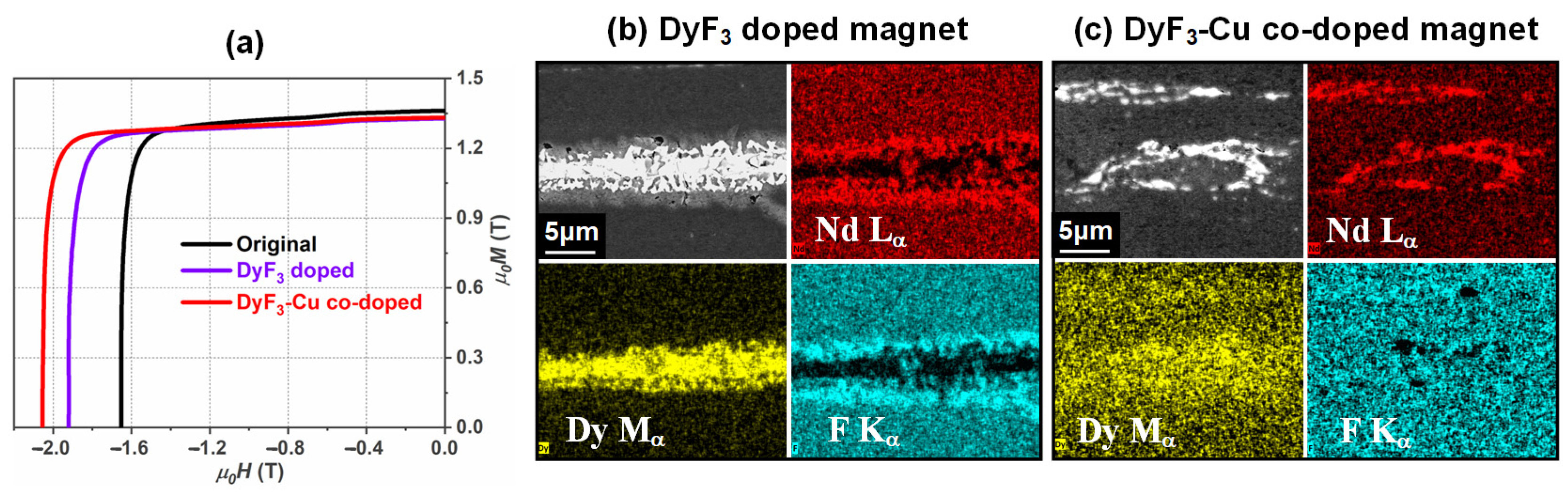

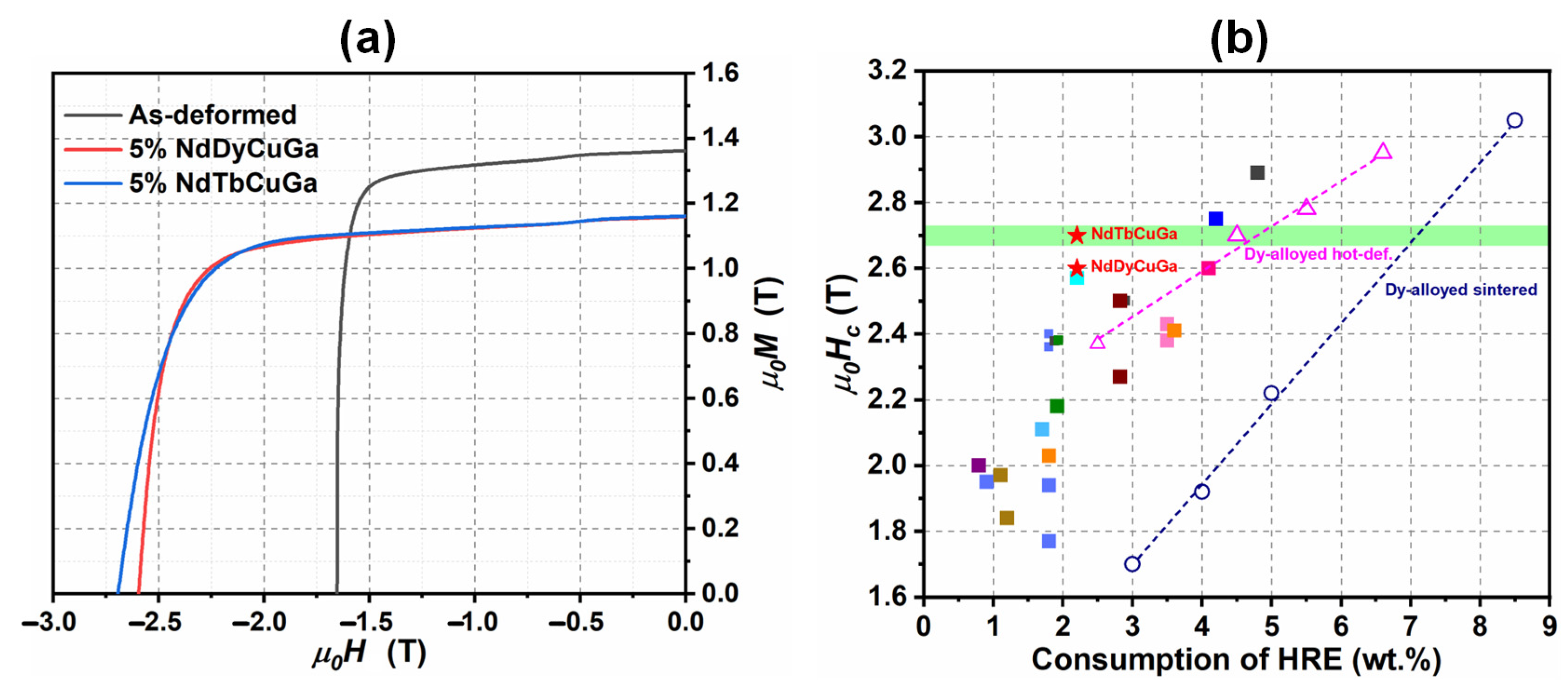

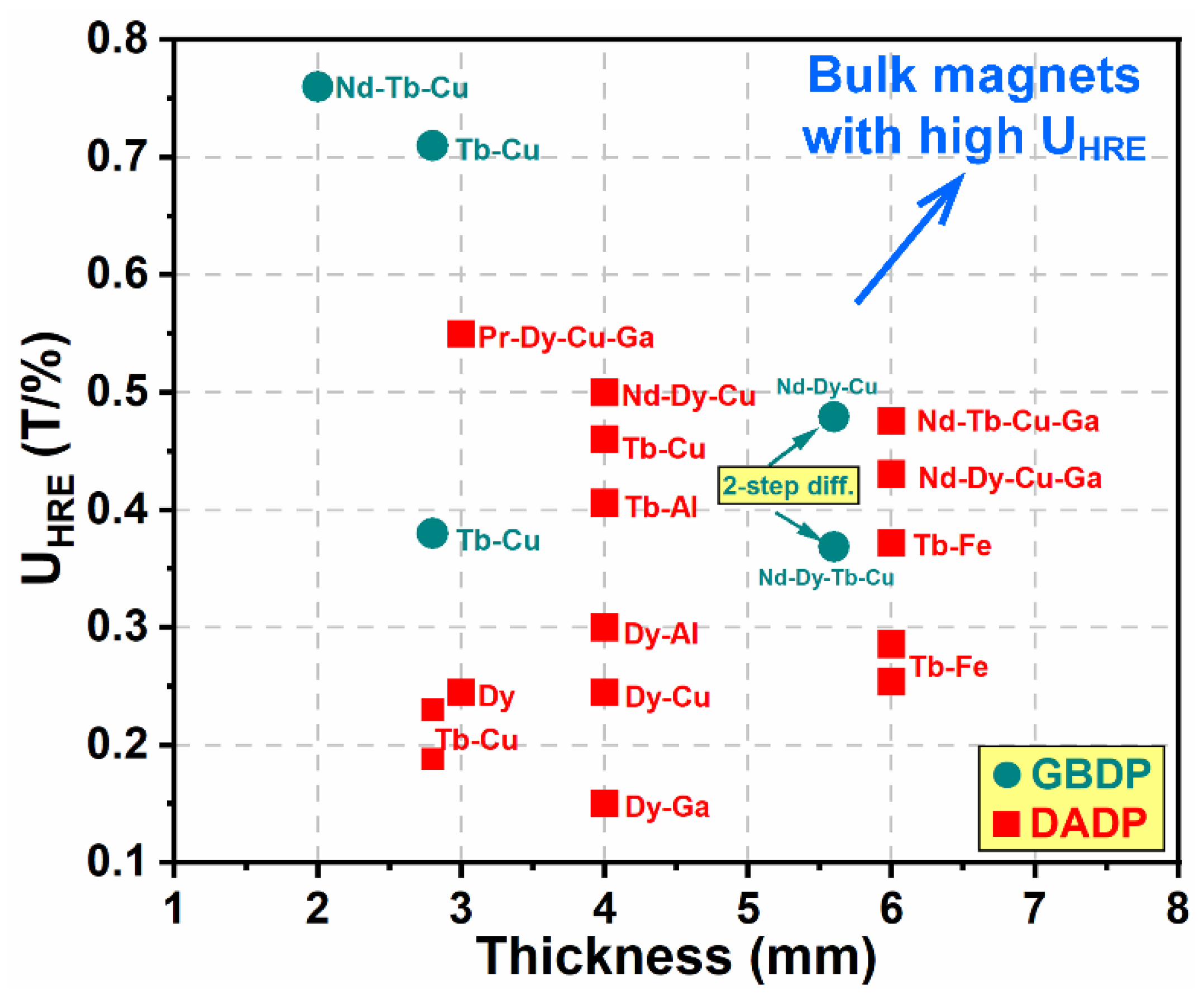

3.1. Progress in Grain Boundary Diffusion Process

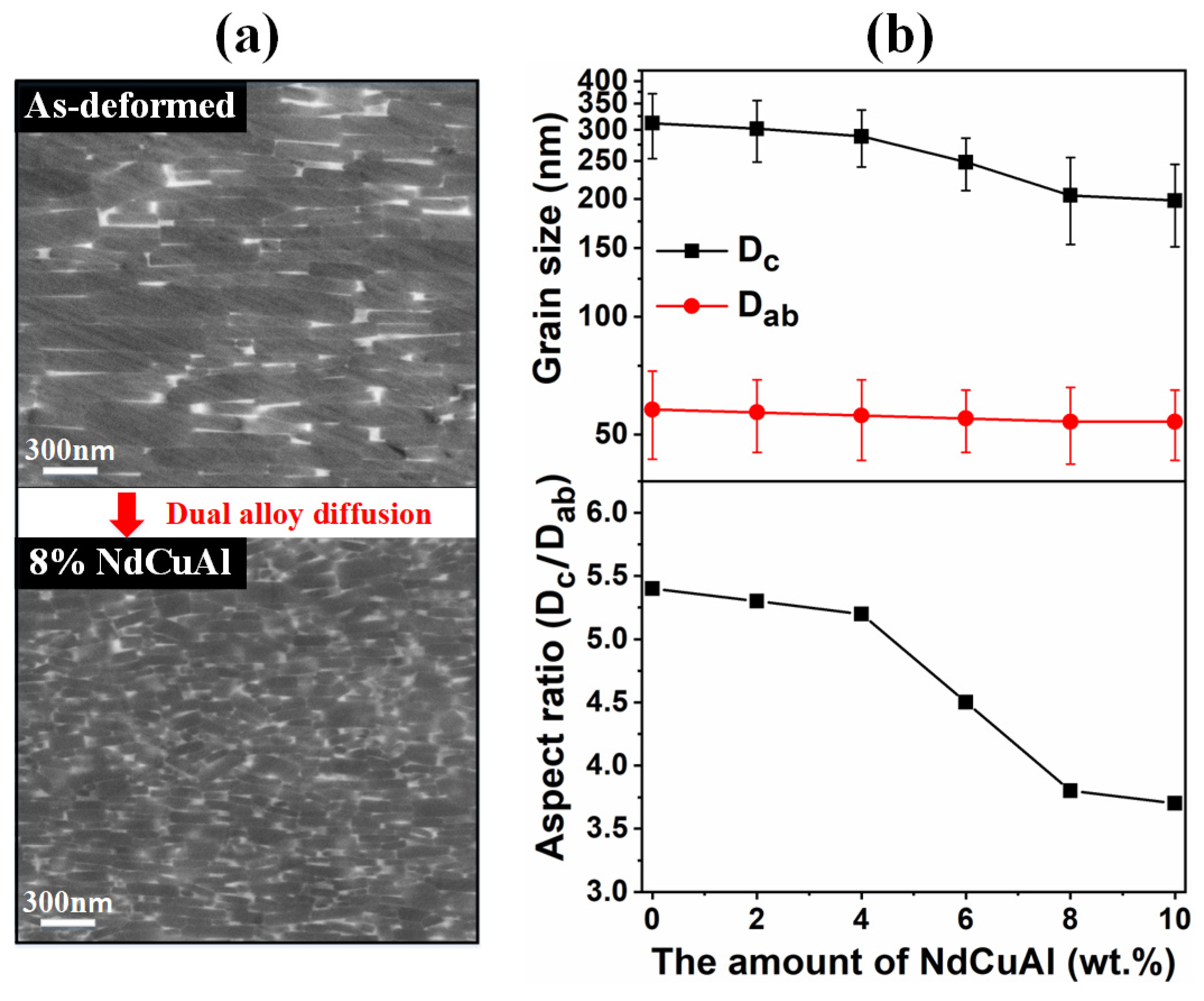

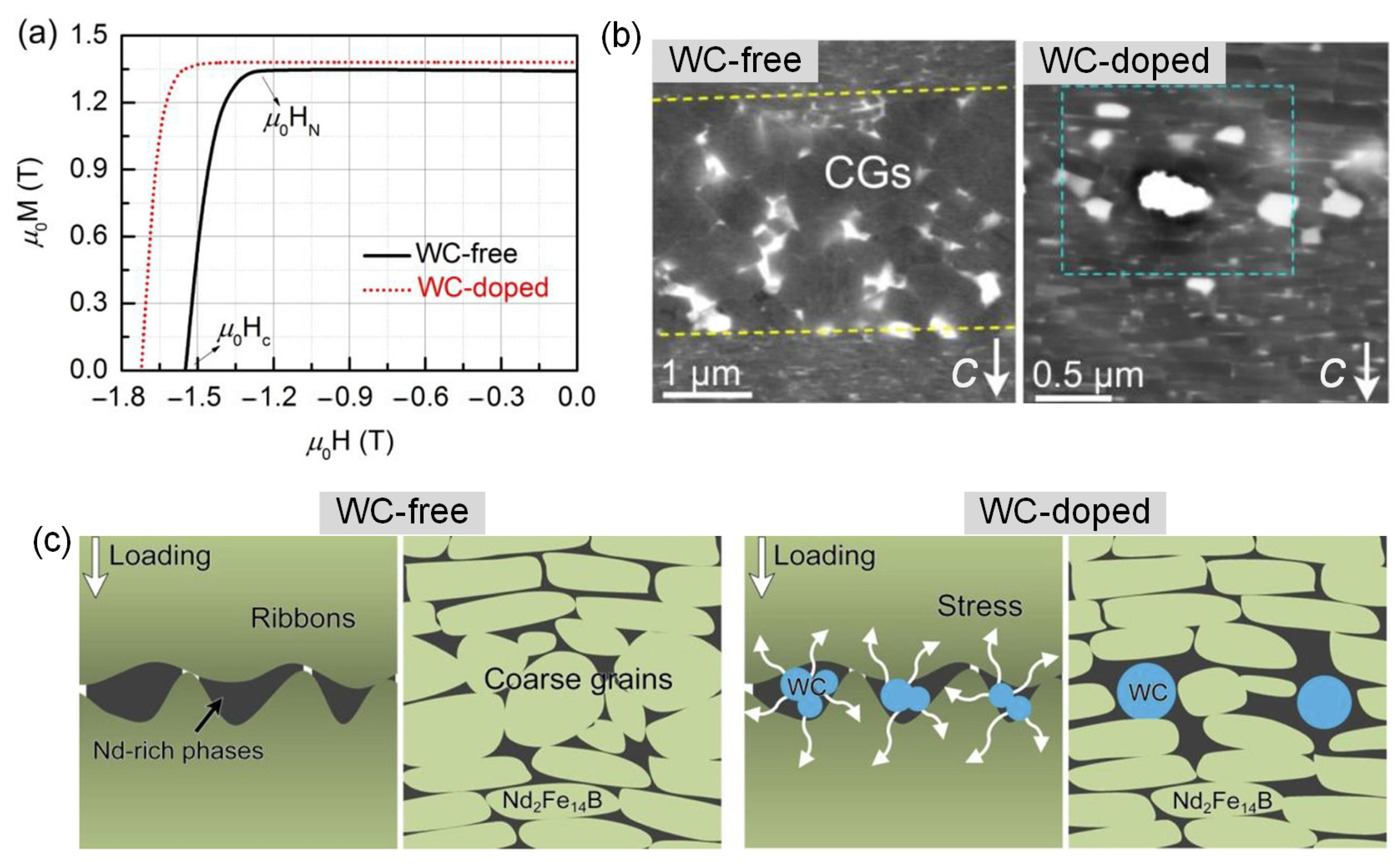

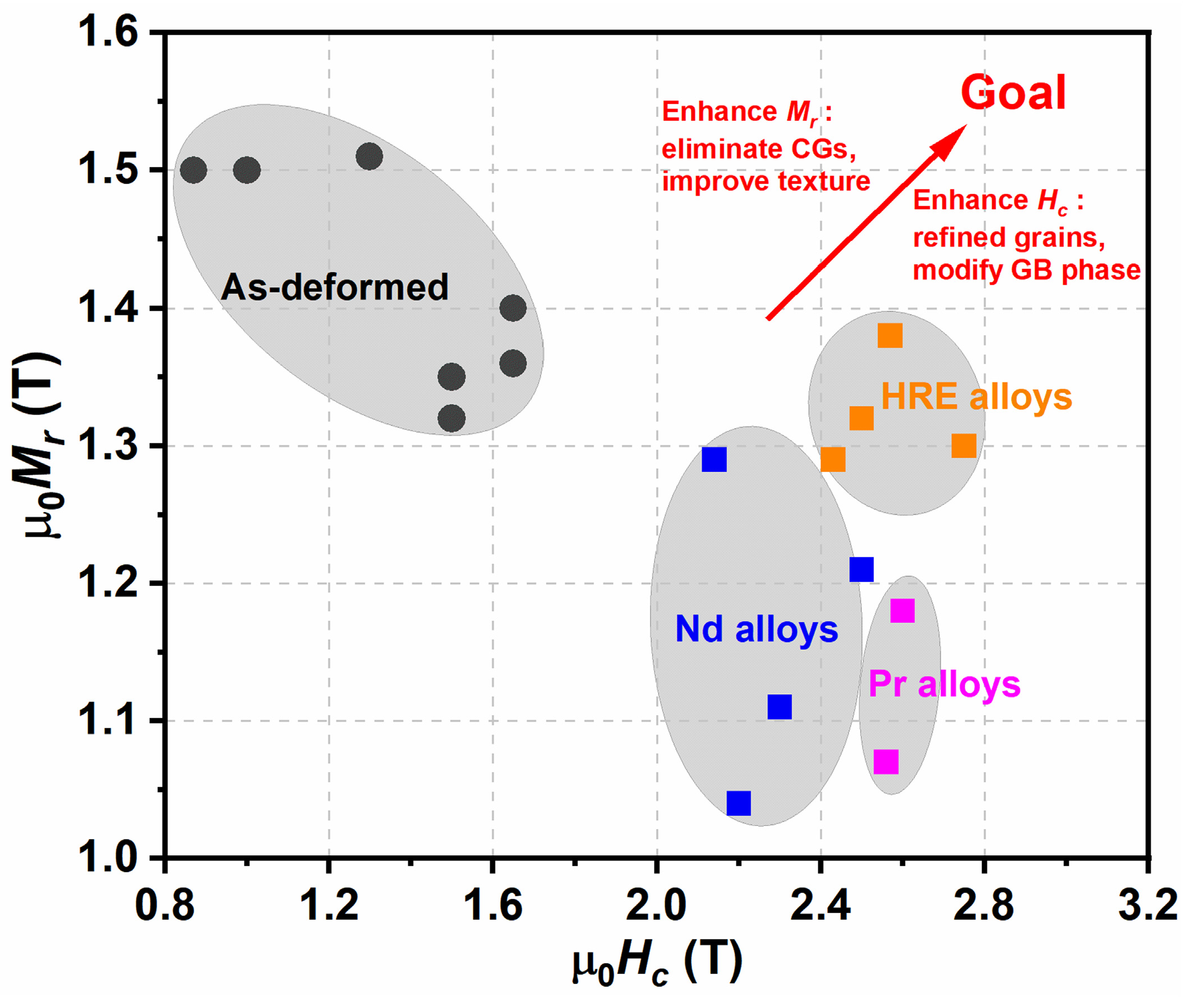

3.2. Progress in Dual Alloy Diffusion Process

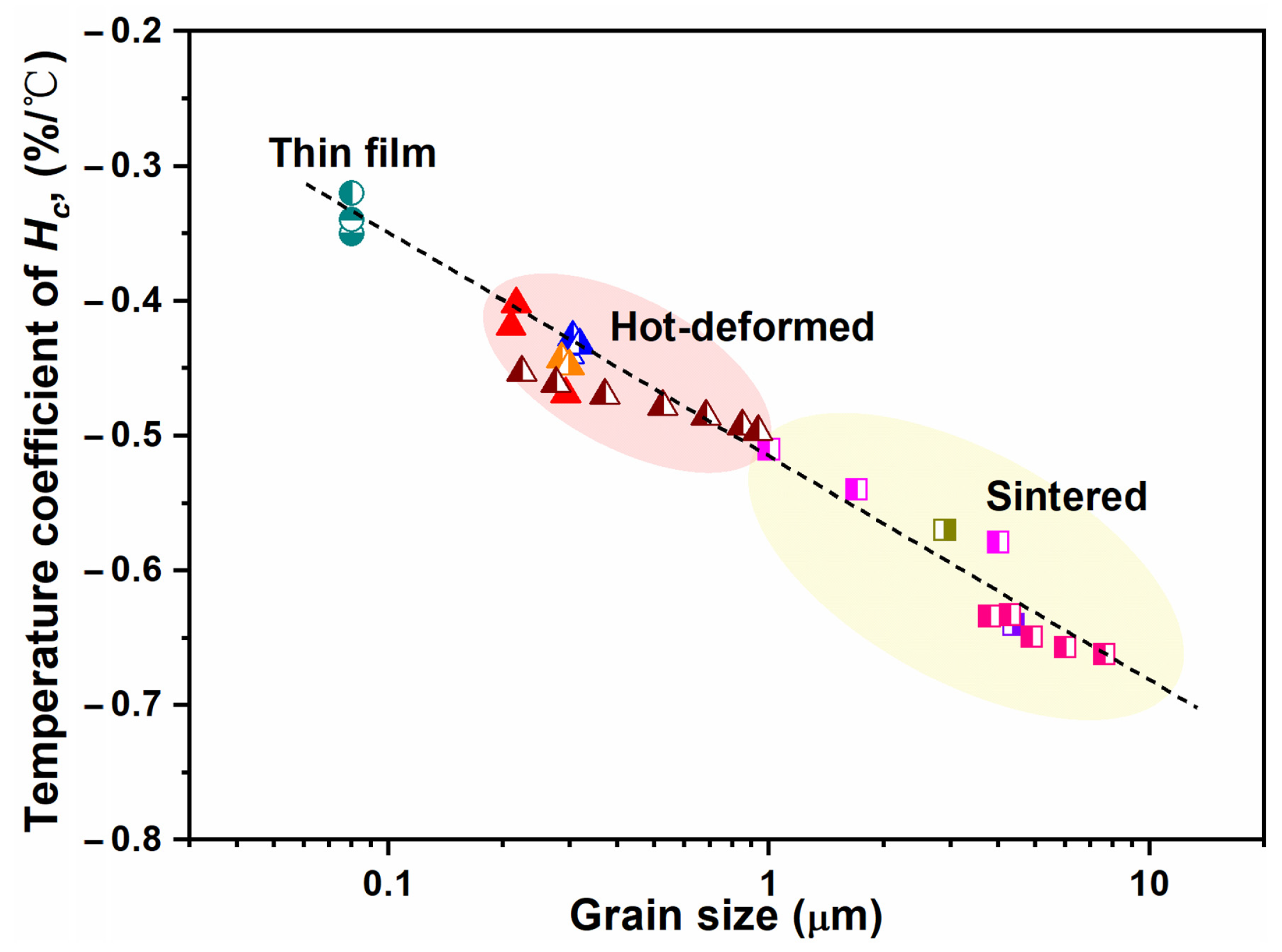

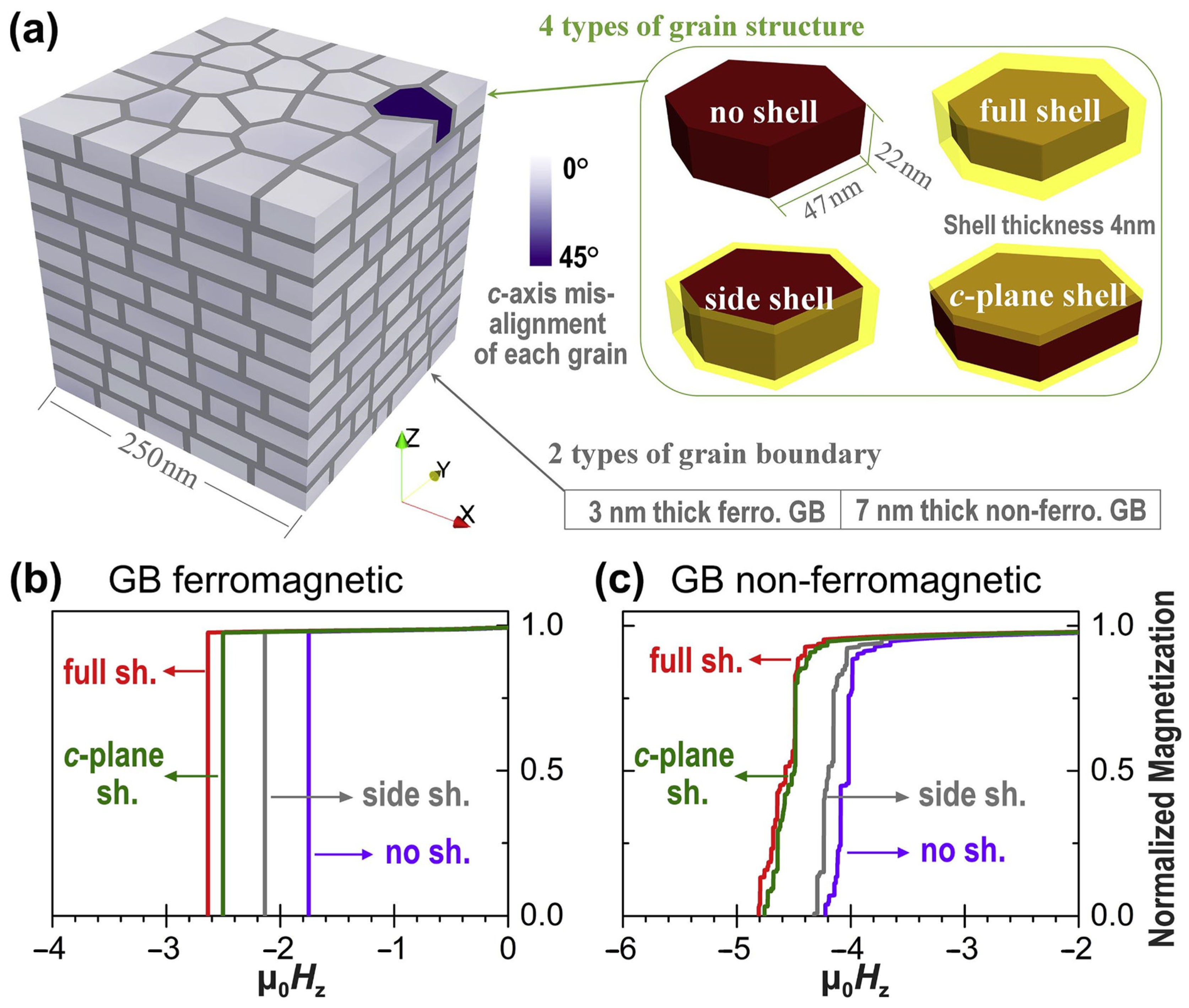

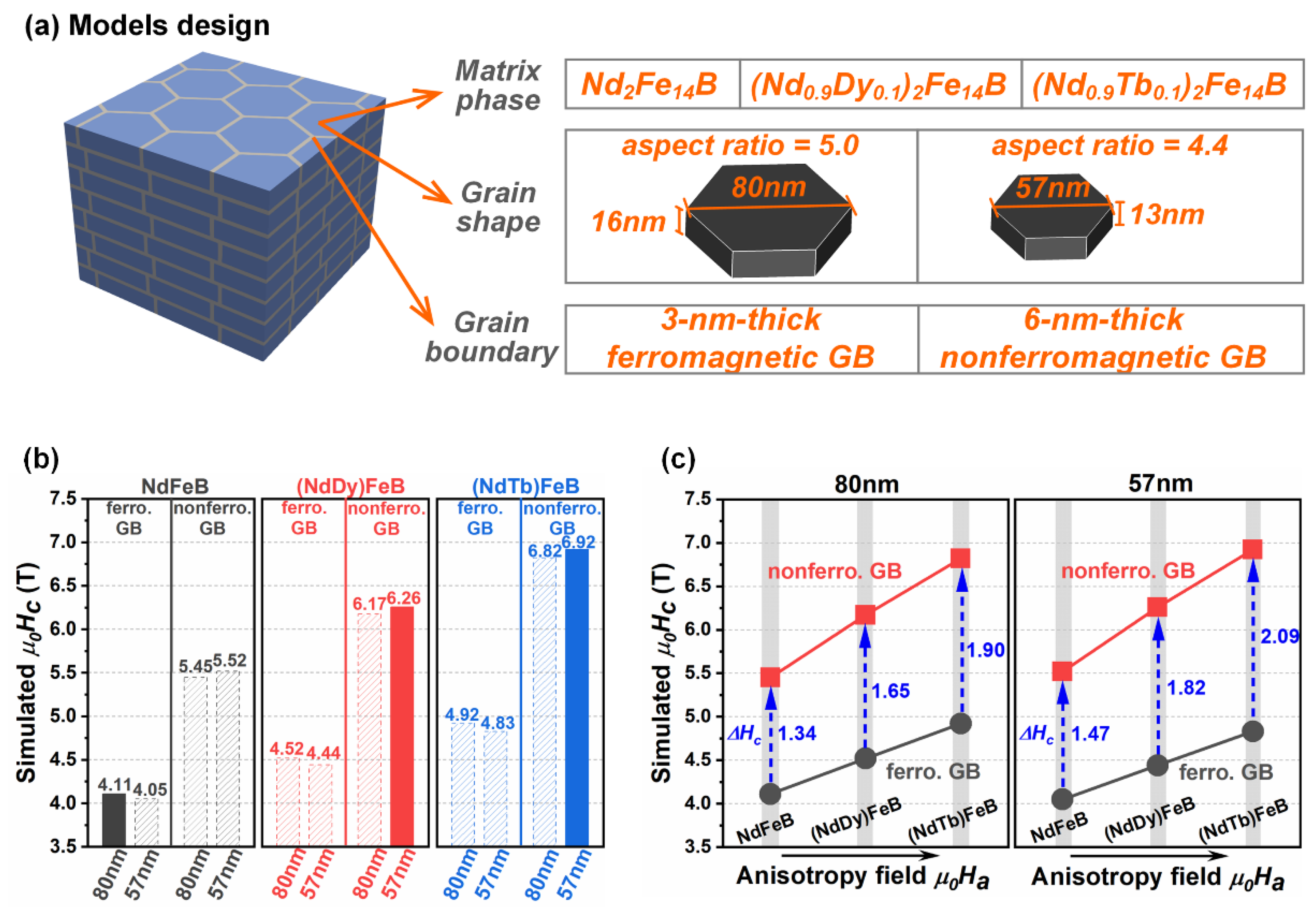

4. Coercivity Mechanisms of Hot-Deformed Magnets

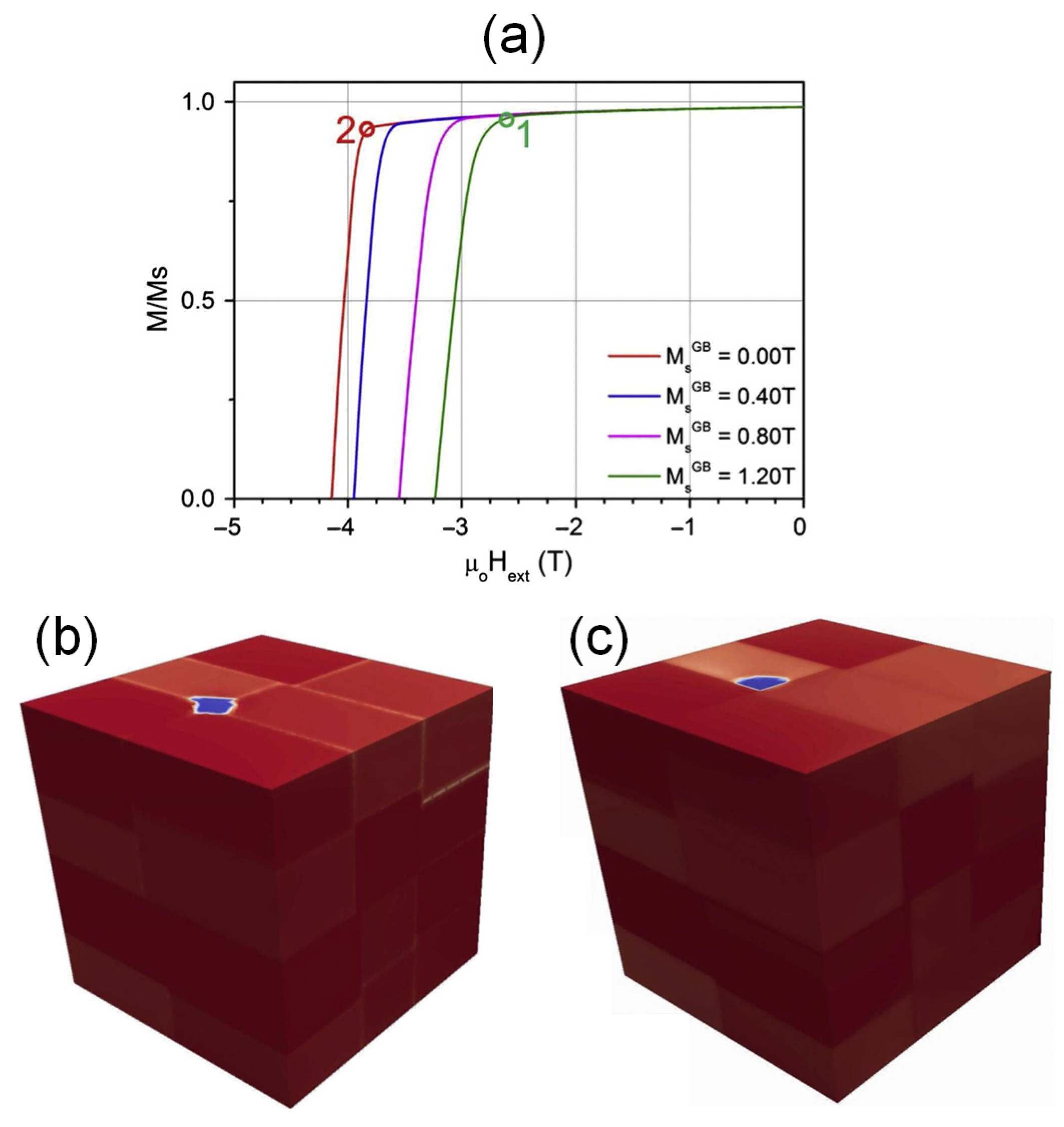

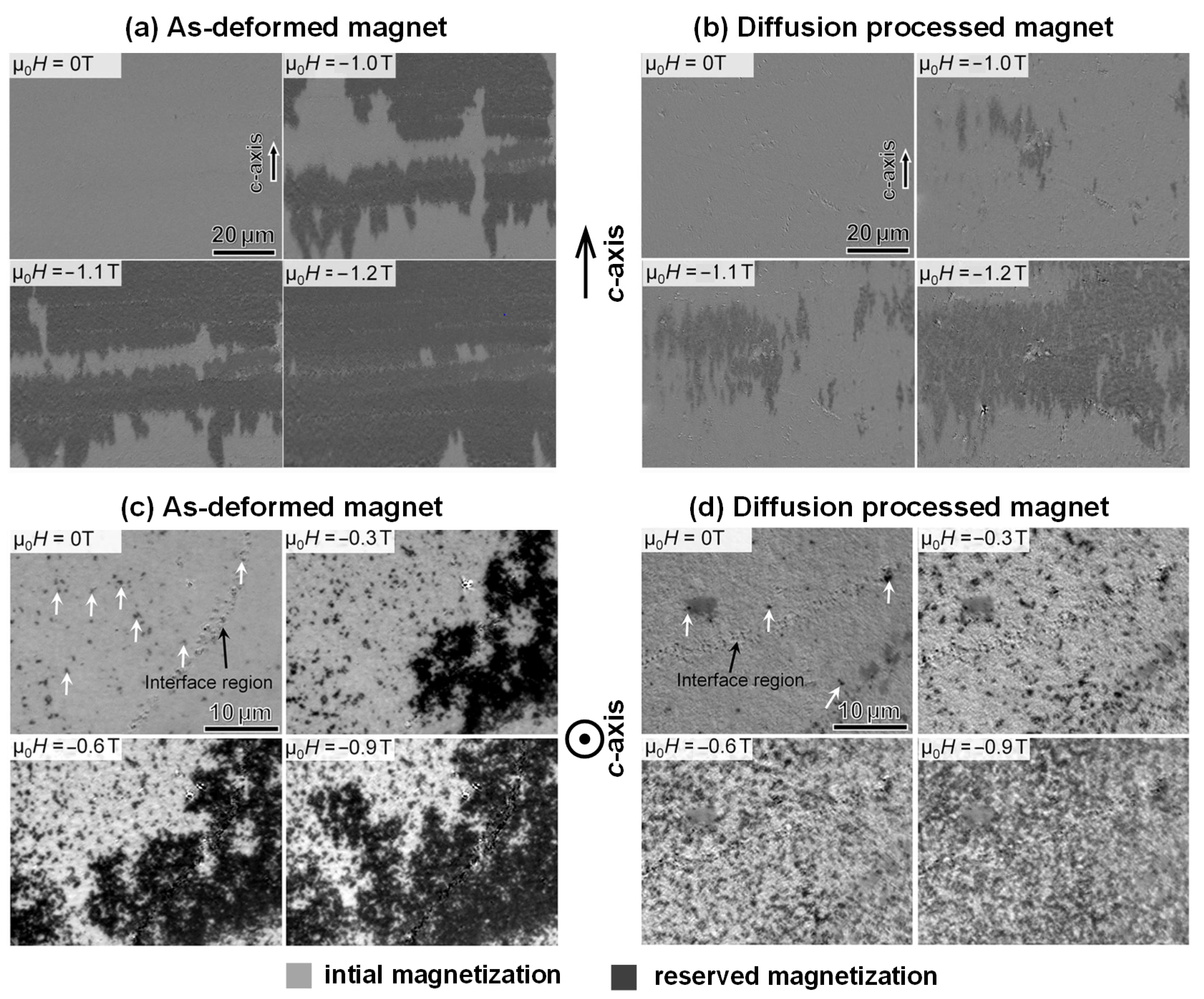

5. Magnetization Reversal Behaviors of Hot-Deformed Magnets

6. Strategy for Higher Magnetic Properties of Hot-Deformed Magnets

7. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiles, D.C. Recent advances and future directions in magnetic materials. Acta Mater. 2003, 51, 5907–5939. [Google Scholar] [CrossRef]

- Coey, J.M.D. Permanent magnet applications. J. Magn. Magn. Mater. 2002, 248, 441–456. [Google Scholar] [CrossRef]

- Croat, J.J.; Herbst, J.F.; Lee, R.W.; Pinkerton, F.E. High-energy product Nd-Fe-B permanent magnets. Appl. Phys. Lett. 1984, 44, 148–149. [Google Scholar] [CrossRef]

- Buschow, K.H.J. New permanent magnet materials. Mater. Sci. Rep. 1986, 1, 1–64. [Google Scholar] [CrossRef]

- Matsuura, Y. Recent development of Nd-Fe-B sintered magnets and their applications. J. Magn. Magn. Mater. 2006, 303, 344–347. [Google Scholar] [CrossRef]

- Sugimoto, S. Current status and recent topics of rare-earth permanent magnets. J. Phys. D Appl. Phys. 2011, 44, 064001. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.; Brüeck, E.; Chen, C.; Sankar, S.; Liu, J. Magnetic materials and devices for the 21st century: Stronger, lighter, and more energy efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef]

- Coey, J.M.D. Perspective and Prospects for Rare Earth Permanent Magnets. Engineering 2020, 6, 119–131. [Google Scholar] [CrossRef]

- Herbst, J.F. R2Fe14B materials: Intrinsic properties and technological aspects. Rev. Mod. Phys. 1991, 63, 819–898. [Google Scholar] [CrossRef]

- Hono, K.; Sepehri-Amin, H. Strategy for high-coercivity Nd-Fe-B magnets. Scr. Mater. 2012, 67, 530–535. [Google Scholar] [CrossRef]

- Watanabe, N.; Itakura, M.; Nishida, M. Microstructure of high coercivity Nd-Fe-Co-Ga-B hot-deformed magnet improved by the Dy diffusion treatment. J. Alloys Compd. 2013, 557, 1–4. [Google Scholar] [CrossRef]

- Loewe, K.; Brombacher, C.; Katter, M.; Gutfleisch, O. Temperature-dependent Dy diffusion processes in Nd-Fe-B permanent magnets. Acta Mater. 2015, 83, 248–255. [Google Scholar] [CrossRef]

- Xu, X.D.; Sasaki, T.T.; Li, J.N.; Dong, Z.J.; Sepehri-Amin, H.; Kim, T.H.; Ohkubo, T.; Schrefl, T.; Hono, K. Microstructure of a Dy-free Nd-Fe-B sintered magnet with 2 T coercivity. Acta Mater. 2018, 156, 146–157. [Google Scholar] [CrossRef]

- Korent, M.; Tang, X.; Sepehri-Amin, H.; Hioki, K.; Soderžnik, K.; Kobe, S.; Ohkubo, T.; Hono, K. Significant coercivity enhancement of hot-deformed bulk magnets by two-step diffusion process using a minimal amount of Dy. Scr. Mater. 2021, 205, 114207. [Google Scholar] [CrossRef]

- Liang, L.; Man, T.; Wu, C.; Zhang, P.; Liu, X.; Yan, M. Coercivity enhancement of Dy-free Nd-Fe-B sintered magnets by intergranular adding Ho63.4Fe36.6 alloy. J. Magn. Magn. Mater. 2016, 397, 139–144. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Ohkubo, T.; Hono, K. The mechanism of coercivity enhancement by the grain boundary diffusion process of Nd-Fe-B sintered magnets. Acta Mater. 2013, 61, 1982–1990. [Google Scholar] [CrossRef]

- Kim, T.H.; Lee, S.R.; Kim, H.J.; Lee, M.W.; Jang, T.S. Simultaneous application of Dy-X (X = F or H) powder doping and dip-coating processes to Nd-Fe-B sintered magnets. Acta Mater. 2015, 93, 95–104. [Google Scholar] [CrossRef]

- Liu, Z.; He, J.; Ramanujan, R.V. Significant progress of grain boundary diffusion process for cost-effective rare earth permanent magnets: A review. Mater. Des. 2021, 209, 110004. [Google Scholar] [CrossRef]

- Hono, K.; Ohkubo, T.; Sepehri-Amin, H. Microstructure-coercivity relationships of Nd-Fe-B base permanent magnets. J. Jpn. Inst. Met. 2012, 76, 2. [Google Scholar] [CrossRef] [Green Version]

- Fukada, T.; Matsuura, M.; Goto, R.; Tezuka, N.; Sugimoto, S.; Une, Y.; Sagawa, M. Evaluation of the microstructural contribution to the coercivity of fine-grained Nd-Fe-B sintered magnets. Mater. Trans. 2012, 53, 1967–1971. [Google Scholar] [CrossRef] [Green Version]

- Uestuener, K.; Katter, M.; Rodewald, W. Dependence of the Mean Grain Size and Coercivity of Sintered Nd-Fe-B Magnets on the Initial Powder Particle Size. IEEE Trans. Magn. 2006, 42, 2897–2899. [Google Scholar] [CrossRef]

- Guo, S.; Yang, X.; Fan, X.; Ding, G.; Cao, S.; Zheng, B.; Chen, R.; Yan, A. The Effect of Grain Size on the Diffusion Efficiency and Microstructure of Sintered Nd-Fe-B Magnets by Tb Grain Boundary Diffusion. Materials 2022, 15, 4987. [Google Scholar] [CrossRef] [PubMed]

- Nothnagel, P.; Müller, K.H.; Eckert, D.; Handstein, A. The influence of particle size on the coercivity of sintered NdFeB magnets. J. Magn. Magn. Mater. 1991, 101, 379. [Google Scholar] [CrossRef]

- Xia, X.; Liu, M.; Zhang, T.; Wen, H.; Dong, Q.; Zhang, L.; Zhou, L.; Li, M. Improvement of thermal stability in hot-deformed Nd-Fe-B magnets by grain refinement. Scr. Mater. 2020, 178, 129–133. [Google Scholar] [CrossRef]

- Lin, M.; Wang, H.; Yi, P.; Yan, A. Effects of excessive grain growth on the magnetic and mechanical properties of hot-deformed NdFeB magnets. J. Magn. Magn. Mater. 2010, 322, 2268–2271. [Google Scholar] [CrossRef]

- Rong, C.; Wu, Y.; Wang, D.; Zhang, Y.; Poudyal, N.; Kramer, M.; Liu, J. Effect of pressure loading rate on the crystallographic texture of NdFeB nanocrystalline magnets. J. Appl. Phys. 2012, 111, 07A717. [Google Scholar] [CrossRef] [Green Version]

- Hou, Y.; Huang, Y.; Liu, Z.; Zeng, D.; Ma, S.; Zhong, Z. Hot deformed anisotropic nanocrystalline NdFeB based magnet prepared from spark plasma sintered melt spun powders. Mater. Sci. Eng. B 2013, 178, 990–997. [Google Scholar] [CrossRef]

- Lewis, L.; Zhu, Y.; Welch, D. Ferromagnetic grain boundary signature in die-upset Re -Fe-B magnets. Scr. Metall. Mater. 1995, 33, 1775–1780. [Google Scholar] [CrossRef] [Green Version]

- Sepehri-Amin, H.; Ohkubo, T.; Nagashima, S.; Yano, M.; Shoji, T.; Kato, A.; Schrefl, T.; Hono, K. High-coercivity ultrafine-grained anisotropic Nd-Fe-B magnets processed by hot deformation and the Nd-Cu grain boundary diffusion process. Acta Mater. 2013, 61, 6622–6634. [Google Scholar] [CrossRef]

- Mishra, R. Crystallographic and magnetic alignment in die-upset Nd-Fe-B magnets. J. Mater. Eng. 1989, 11, 87–93. [Google Scholar] [CrossRef]

- Brown, D.; Ma, B.M.; Chen, Z.M. Developments in the processing and properties of NdFeb-type permanent magnets. J. Magn. Magn. Mater. 2002, 248, 432–440. [Google Scholar] [CrossRef]

- Grunberger, W.; Hinz, D.; Kirchner, A.; Muller, K.H.; Schultz, L. Hot deformation of nanocrystalline Nd-Fe-B alloys. J. Alloys Compd. 1997, 257, 293–301. [Google Scholar] [CrossRef]

- Fuerst, C.D.; Brewer, E.G. High-remanence rapidly solidified Nd-Fe-B: Die-upset magnets (invited). J. Appl. Phys. 1993, 73, 5751–5756. [Google Scholar] [CrossRef]

- Mishra, R.K. Microstructure of melt-spun Nd-Fe-B magnequench magnets. J. Magn. Magn. Mater. 1986, 54–57, 450–456. [Google Scholar] [CrossRef]

- Mishra, R.K.; Chu, T.Y.; Rabenberg, L.K. The development of the microstructure of die-upset Nd-Fe-B magnets. J. Magn. Magn. Mater. 1990, 84, 88–94. [Google Scholar] [CrossRef]

- Korent, M.; Komelj, M.; Šturm, S.; Rožman, K.Z.; Kobe, S.; Soderžnik, K.Z.; Soderžnik, M. Magnetic properties and microstructure evolution of hot-deformed Nd-Fe-B magnets produced by low-pressure spark-plasma sintering. J. Magn. Magn. Mater. 2020, 515, 169279. [Google Scholar] [CrossRef]

- Manaf, A.; Buckley, R.A.; Davies, H.A. New nanocrystalline high-remanence Nd-Fe-B alloys by rapid solidification. J. Magn. Magn. Mater. 1993, 128, 302–306. [Google Scholar] [CrossRef]

- Tenaud, P.; Chamberod, A.; Vanoni, F. Texture in Nd-Fe-B magnets analysed on the basis of the determination of Nd2Fe14B single crystals easy growth axis. Solid State Commun. 1987, 63, 303–305. [Google Scholar] [CrossRef]

- Mishra, R.K.; Brewer, E.G.; Lee, R.W. Grain growth and alignment in hot deformed Nd-Fe-B magnets. J. Appl. Phys. 1988, 63, 3528–3530. [Google Scholar] [CrossRef]

- Wang, Y.R.; Guruswamy, S.; Panchanathan, V. Texture study in hot deformed magnequench NdFeB magnets. J. Appl. Phys. 1997, 81, 4450–4452. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Hirosawa, S.; Hono, K. Chapter 4-Advances in Nd-Fe-B based permanent magnets. In Handbook of Magnetic Materials; Elsevier: Amsterdam, The Netherlands, 2018; Volume 27, pp. 269–372. [Google Scholar]

- Yoshida, Y.; Yoshikawa, N. Chapter 8-Hot Formed NdFeB Magnets, Modern Permanent Magnets; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Sawston, UK, 2022; pp. 251–304. [Google Scholar]

- Fidler, J.; Schrefl, T. Overview of Nd-Fe-B magnets and coercivity (invited). J. Appl. Phys. 1996, 79, 5029–5034. [Google Scholar] [CrossRef]

- Leonowicz, M.; Davies, H.A. Effect of Nd content on induced anisotropy in hot deformed FeNdB magnets. Mater. Lett. 1994, 19, 275–279. [Google Scholar] [CrossRef]

- Liu, J.; Sepehri-Amin, H.; Ohkubo, T.; Hioki, K.; Hattori, A.; Schrefl, T.; Hono, K. Effect of Nd content on the microstructure and coercivity of hot-deformed Nd-Fe-B permanent magnets. Acta Mater. 2013, 61, 5387–5399. [Google Scholar] [CrossRef]

- Xu, F.; Wang, J.; Dong, X.; Zhang, L.; Wu, J. Grain boundary microstructure in DyF3-diffusion processed Nd-Fe-B sintered magnets. J. Alloys Compd. 2011, 509, 7909–7914. [Google Scholar] [CrossRef]

- Cao, X.; Chen, L.; Guo, S.; Chen, R.; Yan, G.; Yan, A. Impact of TbF3 diffusion on coercivity and microstructure in sintered Nd-Fe-B magnets by electrophoretic deposition. Scr. Mater. 2016, 116, 40–43. [Google Scholar] [CrossRef]

- Di, J.; Ding, G.; Tang, X.; Yang, X.; Guo, S.; Chen, R.; Yan, A. Highly efficient Tb-utilization in sintered Nd-Fe-B magnets by Al aided TbH2 grain boundary diffusion. Scr. Mater. 2018, 155, 50–53. [Google Scholar] [CrossRef]

- Tang, M.; Bao, X.; Lu, K.; Sun, L.; Li, J.; Gao, X. Boundary structure modification and magnetic properties enhancement of Nd-Fe-B sintered magnets by diffusing (PrDy)-Cu alloy. Scr. Mater. 2016, 117, 60–63. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, L.; Jin, Y.; Cheng, Y. Simultaneous enhancement of the coercivity and remanence at high temperatures in a sintered Nd-Fe-B magnet after grain boundary diffusion with Dy60Co40 alloy. Mater. Charact. 2018, 144, 547–553. [Google Scholar] [CrossRef]

- Woodcock, T.; Ramasse, Q.; Hrkac, G.; Shoji, T.; Yano, M.; Kato, A.; Gutfleisch, O. Atomic-scale features of phase boundaries in hot deformed Nd-Fe-Co-B-Ga magnets infiltrated with a Nd-Cu eutectic liquid. Acta Mater. 2014, 77, 111–124. [Google Scholar] [CrossRef]

- Liu, L.; Sepehri-Amin, H.; Ohkubo, T.; Yano, M.; Kato, A.; Shoji, T.; Hono, K. Coercivity enhancement of hot-deformed Nd-Fe-B magnets by the eutectic grain boundary diffusion process. J. Alloys Compd. 2016, 666, 432–439. [Google Scholar] [CrossRef] [Green Version]

- Akiya, T.; Liu, J.; Sepehri-Amin, H.; Ohkubo, T.; Hioki, K.; Hattori, A.; Hono, K. Low temperature diffusion process using rare earth-Cu eutectic alloys for hot-deformed Nd-Fe-B bulk magnets. J. Appl. Phys. 2014, 115, 17A766. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Liu, L.; Ohkubo, T.; Yano, M.; Shoji, T.; Kato, A.; Schrefl, T.; Hono, K. Microstructure and temperature dependent of coercivity of hot-deformed Nd-Fe-B magnets diffusion processed with Pr-Cu alloy. Acta Mater. 2015, 99, 297–306. [Google Scholar] [CrossRef] [Green Version]

- Sepehri-Amin, H.; Liu, J.; Ohkubo, T.; Hioki, K.; Hattori, A.; Hono, K. Enhancement of coercivity of hot-deformed Nd-Fe-B anisotropic magnet by low-temperature grain boundary diffusion of Nd60Dy20Cu20 eutectic alloy. Scr. Mater. 2013, 69, 647–650. [Google Scholar] [CrossRef]

- Liu, L.; Sepehri-Amin, H.; Ohkubo, T.; Yano, M.; Kato, A.; Sakuma, N.; Shoji, T.; Hono, K. Coercivity enhancement of hot-deformed Nd-Fe-B magnets by the eutectic grain boundary diffusion process using Nd62Dy20Al18 alloy. Scr. Mater. 2017, 129, 44–47. [Google Scholar] [CrossRef]

- Li, J.; Liu, L.; Sepehri-Amin, H.; Tang, X.; Ohkubo, T.; Sakuma, N.; Shoji, T.; Kato, A.; Schrefl, T.; Hono, K. Coercivity and its thermal stability of Nd-Fe-B hot-deformed magnets enhanced by the eutectic grain boundary diffusion process. Acta Mater. 2018, 161, 171–181. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, F.; Zheng, Y.; Wen, H.; Zhang, L.; Zhou, L. Anisotropic behavior of grain boundary diffusion in hot-deformed Nd-Fe-B magnet. Scr. Mater. 2017, 129, 1–5. [Google Scholar] [CrossRef]

- Tang, X.; Li, J.; Sepehri-Amin, H.; Ohkubo, T.; Hioki, K.; Hattori, A.; Hono, K. Improved coercivity and squareness in bulk hot-deformed Nd-Fe-B magnets by two-step eutectic grain boundary diffusion process. Acta Mater. 2021, 203, 116479. [Google Scholar] [CrossRef]

- Tang, X.; Chen, R.; Yin, W.; Lin, M.; Lee, D.; Yan, A. Mechanism analysis of coercivity enhancement of hot deformed Nd-Fe-B magnets by DyF3 diffusion. IEEE Trans. Magn. 2013, 49, 3237–3239. [Google Scholar] [CrossRef]

- Sawatzki, S.; Dirba, I.; Wendrock, H.; Schultz, L.; Gutfleisch, O. Diffusion processes in hot-deformed Nd-Fe-B magnets with DyF3 additions. J. Magn. Magn. Mater. 2014, 358–359, 163–169. [Google Scholar] [CrossRef]

- Kim, J.; Kwon, H.; Lee, J.; Yu, J. Decomposition of DyF3 and its effect on magnetic performance of DyF3-doped Nd-Fe-B-type hot-deformed magnet. J. Appl. Phys. 2015, 117, 17B505. [Google Scholar] [CrossRef]

- Xia, X.; Wei, G.; Wu, L.; Du, Y.; Tang, X.; Ju, J.; Wu, H.; Chen, R.; Yin, W.; Yan, A. Effect of nano-Cu addition on the diffusion behaviors of Dy in hot-deformed Nd-Fe-B magnets. J. Alloys Compd. 2023, 952, 170014. [Google Scholar] [CrossRef]

- Sawatzki, S.; Kübel, C.; Ener, S.; Gutfleisch, O. Grain boundary diffusion in nanocrystalline Nd-Fe-B permanent magnets with low-melting eutectics. Acta Mater. 2016, 115, 354–363. [Google Scholar] [CrossRef]

- Lee, Y.; Chang, H.; Huang, G.; Shih, C.; Chang, W. Comparison on the coercivity enhancement of hot-deformed Nd2Fe14B-type magnets by doping R70Cu30 (R = Nd, Dy, and Tb) alloy powders. IEEE Trans. Magn. 2017, 53, 2100704. [Google Scholar] [CrossRef]

- Chang, H.; Lin, G.; Wong, Y.; Huang, W.; Chang, W. Coercivity enhancement of hot-deformed NdFeB magnet by doping R80Al20 (R = La, Ce, Dy, Tb) alloy powders. AIP Adv. 2021, 11, 025001. [Google Scholar] [CrossRef]

- Lee, Y.; Wong, Y.; Chang, H.; Chang, W. Coercivity enhancement of hot-deformed NdFeB magnets by doping R80Ga20 (R = Pr, Dy, Tb) alloys. J. Magn. Magn. Mater. 2019, 478, 43–47. [Google Scholar] [CrossRef]

- Liu, Y.; Liao, X.; He, J.; Yu, H.; Zhong, X.; Zhou, Q.; Liu, Z. Magnetic properties and microstructure evolution of in-situ Tb-Cu diffusion treated hot-deformed Nd-Fe-B magnets. J. Magn. Magn. Mater. 2020, 504, 166685. [Google Scholar] [CrossRef]

- Xia, X.; Liu, M.; Zhang, T.; Dong, Q.; Zhang, L.; Zhou, L.; Li, M. Dependence of grain size and aspect ratio on grain boundary additives in hot-deformed Nd-Fe-B magnets. Mater. Charact. 2020, 168, 110543. [Google Scholar] [CrossRef]

- Zhang, T.; Xing, W.; Chen, F.; Liu, S.; Zhang, L.; Yu, R. Microstructure and phase evolution mechanism in hot-pressed and hot-deformed Nd-Fe-B magnets with Nd85Cu15 addition. Acta Mater. 2021, 204, 116493. [Google Scholar] [CrossRef]

- Tang, X.; Li, M.; Ju, J.; Yin, W.; Di, J.; Chen, R.; Yan, A. High thermal stability of hot-deformed Nd-Fe-B magnets by spraying Pr70Cu30 powders on melt-spun powders. J. Magn. Magn. Mater. 2020, 498, 166202. [Google Scholar] [CrossRef]

- Hou, L.; Ju, J.; Yin, W.; Tang, X.; Chen, R.; Xia, A.; Du, Y.; Du, R.; Yan, A. Effect of Pr-Ga dual-alloys diffusion on magnetic properties and thermal stability of hot-deformed PrNd-Fe-B magnets. J. Rare Earths 2022, 40, 457–461. [Google Scholar] [CrossRef]

- Lee, Y.; Huang, G.; Shih, C.; Chang, W.; Chang, H.; You, J. Coercivity enhancement in hot deformed Nd2Fe14B-type magnets by doping low-melting RCu alloys (R = Nd, Dy, Nd + Dy). J. Magn. Magn. Mater. 2017, 439, 1–5. [Google Scholar] [CrossRef]

- Xia, X.; Tang, X.; Du, Y.; Wu, H.; Ju, J.; Wu, L.; Chen, R.; Yin, W.; Zhang, L.; Yan, A. Significant enhancement in the coercivity and thermal stability of bulk hot-deformed Nd-Fe-B magnets by intergranular addition of Nd-Dy/Tb-Cu-Ga alloys. Acta Mater. 2022, 232, 117945. [Google Scholar] [CrossRef]

- Liu, Q.; Tang, X.; Chen, R.; Wang, Z.; Ju, J.; Yin, W.; Yan, A.; Xu, H. Effect of Tb-Fe diffusion on magnetic properties and thermal stability of hot-deformed magnets. J. Alloys Compd. 2019, 773, 1108–1113. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, W.; Wang, J.; Jin, C.; Chen, R.; Ju, J.; Tang, X.; Lee, D.; Yan, A. Hot-deformed Nd-Fe-B magnet with macroscopic composite structure. Appl. Phys. Lett. 2017, 111, 182407. [Google Scholar] [CrossRef]

- Huang, X.; Li, J.; Rehman, S.U.; Qu, P.; He, L.; Zeng, L.; Yu, X.; Yang, M.; Zhong, Z. Microstructure evolution and coercivity enhancement in Pr50Dy20Cu15Ga15-doped hot-deformed Nd-Fe-B magnets. J. Magn. Magn. Mater. 2020, 503, 166637. [Google Scholar] [CrossRef]

- Zhang, T.; Xing, W.; Chen, F.; Zhang, L.; Yu, R. Improvement of coercivity and its thermal stability of hot-deformed Nd-Fe-B magnets processed by Tb70Cu30 doping and subsequent Nd85Cu15 diffusion. Acta Mater. 2021, 220, 117296. [Google Scholar] [CrossRef]

- Kronmüller, H.; Durst, K.; Sagawa, M. Analysis of the magnetic hardening mechanism in RE-FeB permanent magnets. J. Magn. Magn. Mater. 1988, 74, 291–302. [Google Scholar] [CrossRef]

- Hirosawa, S.; Matsuura, Y.; Yamamoto, H.; Fujimura, S.; Sagawa, M.; Yamaguchi, H. Magnetization and magnetic anisotropy of R2Fe14B measured on single crystals. J. Appl. Phys. 1986, 59, 873–878. [Google Scholar] [CrossRef]

- Liu, J.; Sepehri-Amin, H.; Ohkubo, T.; Hioki, K.; Hattori, A.; Schrefl, T.; Hono, K. Grain size dependence of coercivity of hot-deformed Nd-Fe-B anisotropic magnets. Acta Mater. 2015, 82, 336–343. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, F.; Wang, J.; Zhang, L.; Zou, Z.; Wang, Z.; Lu, F.; Hu, B. Improvement of magnetic performance of hot-deformed Nd-Fe-B magnets by secondary deformation process after Nd-Cu eutectic diffusion. Acta Mater. 2016, 118, 374–382. [Google Scholar] [CrossRef]

- Bance, S.; Seebacher, B.; Schrefl, T.; Exl, L.; Winklhofer, M.; Hrkac, G.; Zimanyi, G.; Shoji, T.; Yano, M.; Sakuma, N.; et al. Grain-size dependent demagnetizing factors in permanent magnets. J. Appl. Phys. 2014, 116, 233903. [Google Scholar] [CrossRef] [Green Version]

- Fischbacher, J.; Kovacs, A.; Gusenbauer, M.; Oezelt, H.; Exl, L.; Bance, S.; Schrefl, T. Micromagnetics of rare-earth efficient permanent magnets. J. Phys. D Appl. Phys. 2018, 51, 193002. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Ohkubo, T.; Gruber, M.; Schrefl, T.; Hono, K. Micromagnetic simulations on the grain size dependence of coercivity in anisotropic Nd-Fe-B sintered magnets. Scr. Mater. 2014, 89, 29–32. [Google Scholar] [CrossRef] [Green Version]

- Soderžnik, M.; Li, J.; Liu, L.; Sepehri-Amin, H.; Ohkubo, T.; Sakuma, N.; Shoji, T.; Kato, A.; Schrefl, T.; Hono, K. Magnetization reversal process of anisotropic hot-deformed magnets observed by magneto-optical Kerr effect microscopy. J. Alloys Compd. 2019, 771, 51–59. [Google Scholar] [CrossRef]

- Hioki, K. High performance hot-deformed Nd-Fe-B magnets (Review). Sci. Technol. Adv. Mater. 2021, 22, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Li, M.; Chen, R.; Lei, F.; Jin, C.; Wang, Z.; Ju, J.; Yin, W.; Lee, D.; Yan, A. Coercivity enhancement by inhibiting the formation of coarse grains region in hot-deformed Nd-Fe-B magnets with WC nano-particles addition. Scr. Mater. 2017, 132, 49–52. [Google Scholar] [CrossRef]

- Wang, Z.; Pei, K.; Zhang, J.; Chen, R.; Xia, W.; Wang, J.; Li, M.; Yan, A. Correlation between the microstructure and magnetic configuration in coarse-grain inhibited hot-deformed Nd-Fe-B magnets. Acta Mater. 2019, 167, 103–111. [Google Scholar] [CrossRef]

| Magnet Types | α | Neff |

|---|---|---|

| Sintered magnets | 0.6–0.7 | 1.4–1.8 |

| Nanocrystalline magnets | 0.6–0.9 | 0.75–1.0 |

| HD magnets | ~0.8 | 0.8–1.4 |

| Thin film magnets | 0.26–0.41 | 0.05–0.42 |

| Diffusion Process | Diffusion Source | α | HA | Neff | Ms |

|---|---|---|---|---|---|

| GBDP | HRE-free alloys | ↑ | ↑ | ||

| HRE-containing alloys | ↑ | ↑ | ↑ | ↓ | |

| DADP | HRE-free alloys | ↑ | ↓ | ||

| HRE-containing alloys | ↑ | ↑ | ↓ | ↓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, R.; Xia, X.; Tang, X.; Yan, A. Significant Progress for Hot-Deformed Nd-Fe-B Magnets: A Review. Materials 2023, 16, 4789. https://doi.org/10.3390/ma16134789

Chen R, Xia X, Tang X, Yan A. Significant Progress for Hot-Deformed Nd-Fe-B Magnets: A Review. Materials. 2023; 16(13):4789. https://doi.org/10.3390/ma16134789

Chicago/Turabian StyleChen, Renjie, Xianshuang Xia, Xu Tang, and Aru Yan. 2023. "Significant Progress for Hot-Deformed Nd-Fe-B Magnets: A Review" Materials 16, no. 13: 4789. https://doi.org/10.3390/ma16134789