Tailoring the Structure and Properties of Epitaxial Europium Tellurides on Si(100) through Substrate Temperature Control

Abstract

:1. Introduction

2. Methods

3. Results and Discussions

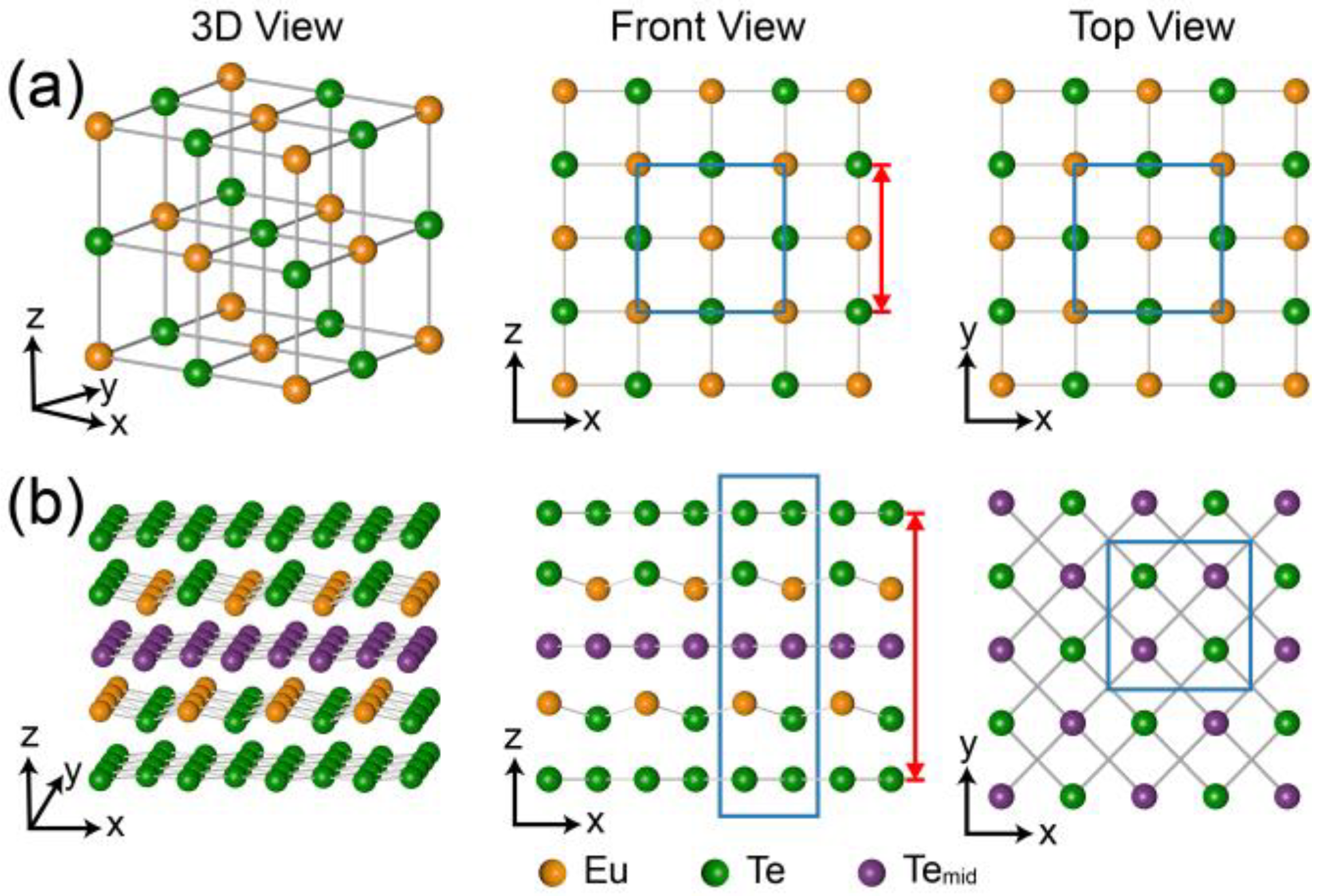

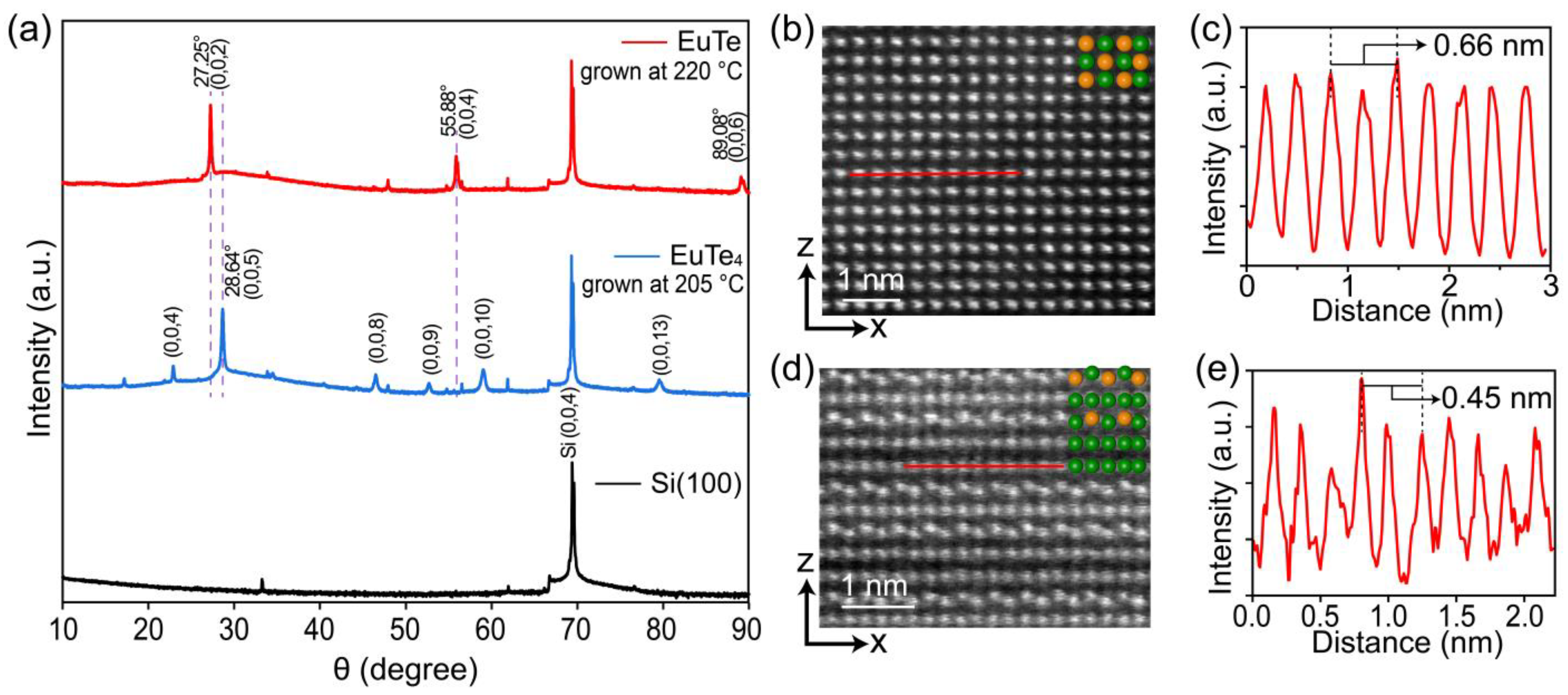

3.1. Growth and Structural Characteristics of EuTe and EuTe4 Films

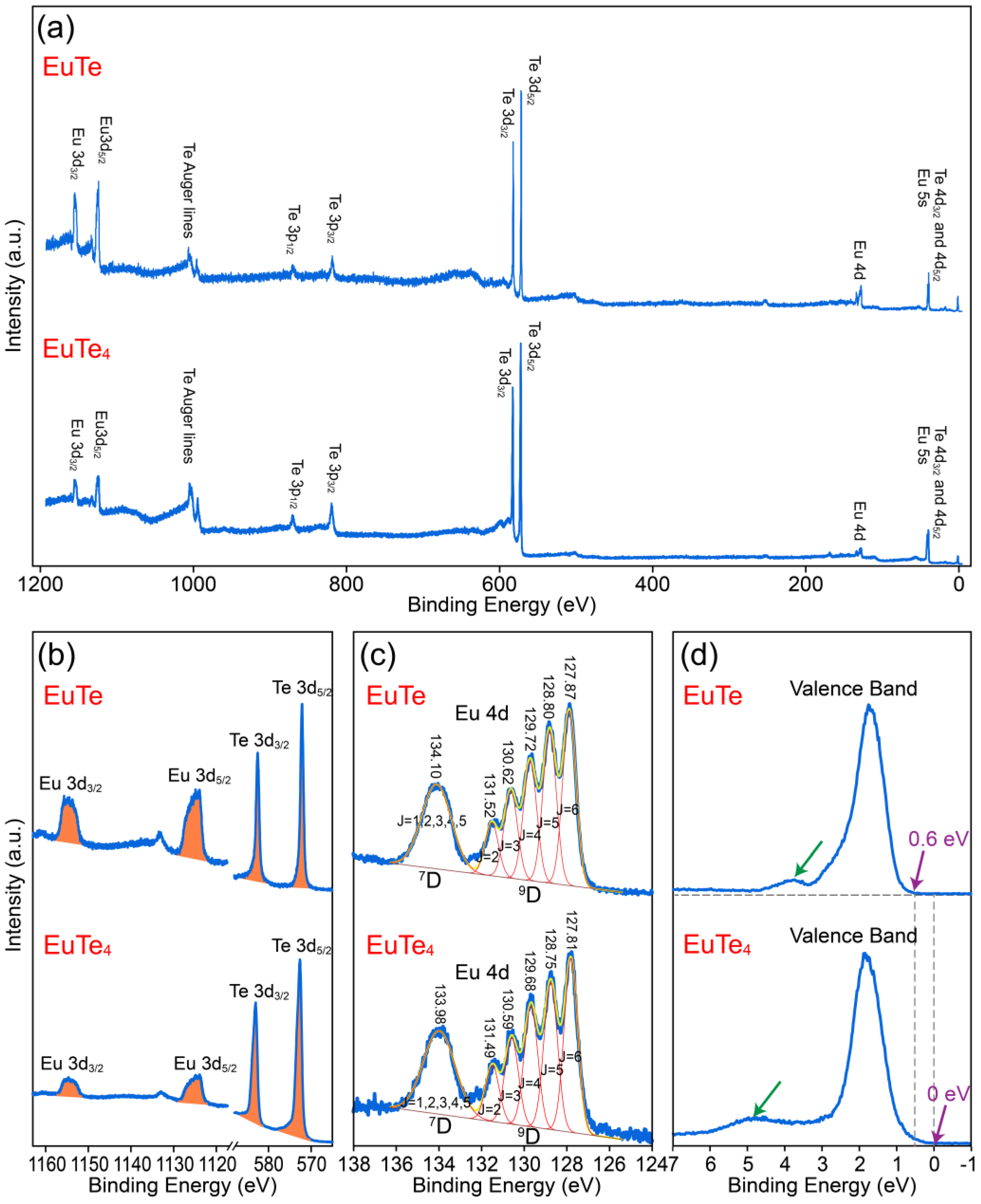

3.2. XPS Differences in EuTe and EuTe4

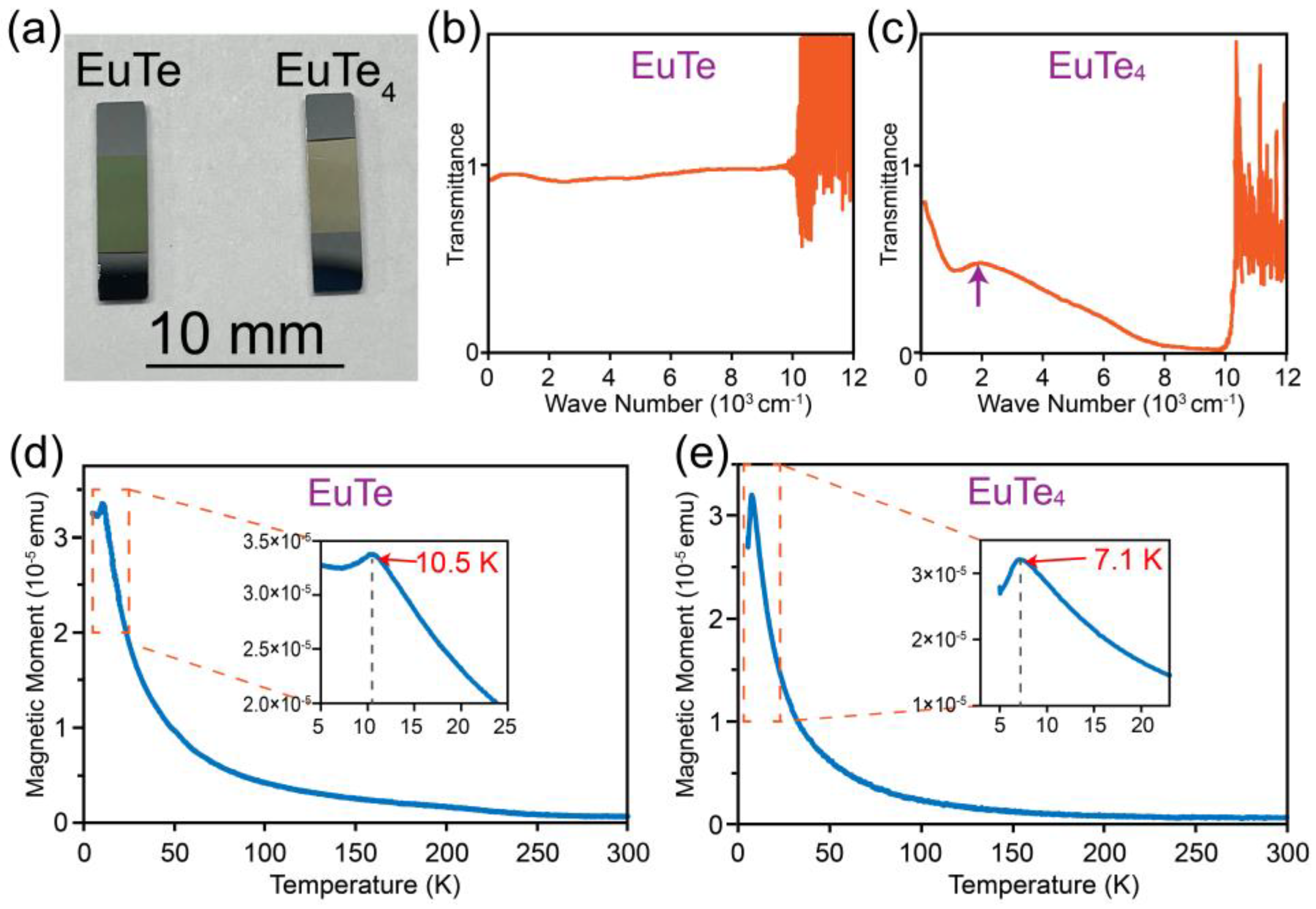

3.3. Physical Property Characterizations of EuTe and EuTe4

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kogar, A.; Zong, A.; Dolgirev, P.E.; Shen, X.; Straquadine, J.; Bie, Y.-Q.; Wang, X.; Rohwer, T.; Tung, I.C.; Yang, Y.; et al. Light-induced charge density wave in LaTe3. Nat. Phys. 2020, 16, 159–163. [Google Scholar] [CrossRef]

- Brouet, V.; Yang, W.L.; Zhou, X.J.; Hussain, Z.; Ru, N.; Shin, K.Y.; Fisher, I.R.; Shen, Z.X. Fermi surface reconstruction in the CDW state of CeTe3 observed by photoemission. Phys. Rev. Lett. 2004, 93, 126405. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.; Kim, D.H.; Kim, H.W.; Denlinger, J.D.; Kim, H.; Kim, J.; Kim, K.; Min, B.I.; Min, B.H.; Kwon, Y.S.; et al. The 7 × 1 Fermi surface reconstruction in a two-dimensional f -electron charge density wave system: PrTe3. Sci. Rep. 2016, 6, 30318. [Google Scholar] [CrossRef] [PubMed]

- Yumigeta, K.; Qin, Y.; Li, H.; Blei, M.; Attarde, Y.; Kopas, C.; Tongay, S. Advances in rare-earth tritelluride quantum materials: Structure, properties, and synthesis. Adv. Sci. 2021, 8, 2004762. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.S.; Huan, S.C.; Liu, Z.H.; Liu, W.L.; Liu, Z.T.; Lu, X.L.; Huang, Z.; Jiang, Z.C.; Wang, X.; Yu, N.; et al. Electronic structure of the high-mobility two-dimensional antiferromagnetic metal GdTe3. Phys. Rev. Mater. 2020, 4, 114005. [Google Scholar] [CrossRef]

- Lei, S.; Lin, J.; Jia, Y.; Gray, M.; Topp, A.; Farahi, G.; Klemenz, S.; Gao, T.; Rodolakis, F.; McChesney, J.L.; et al. High mobility in a van der Waals layered antiferromagnetic metal. Sci. Adv. 2020, 6, eaay6407. [Google Scholar] [CrossRef] [PubMed]

- Lv, B.Q.; Zong, A.; Wu, D.; Rozhkov, A.V.; Fine, B.V.; Chen, S.-D.; Hashimoto, M.; Lu, D.-H.; Li, M.; Huang, Y.B.; et al. Unconventional hysteretic transition in a charge density wave. Phys. Rev. Lett. 2022, 128, 036401. [Google Scholar] [CrossRef]

- Zhang, Q.Q.; Shi, Y.; Zhai, K.Y.; Zhao, W.X.; Du, X.; Zhou, J.S.; Gu, X.; Xu, R.Z.; Li, Y.D.; Guo, Y.F.; et al. Thermal hysteretic behavior and negative magnetoresistance in the charge density wave material EuTe4. Phys. Rev. B 2023, 107, 115141. [Google Scholar] [CrossRef]

- Van Houten, S. Magnetic interaction in EuS, EuSe, and EuTe. Phys. Lett. 1962, 2, 215–216. [Google Scholar] [CrossRef]

- Oliveira, N.F.; Foner, S.; Shapira, Y.; Reed, T.B. EuTe. I. Magnetic behavior of insulating and conducting single crystals. Phys. Rev. B 1972, 5, 2634–2646. [Google Scholar] [CrossRef]

- Silberstein, R.P.; Schmutz, L.E.; Tekippe, V.J.; Dresselhaus, M.S.; Aggarwal, R.L. Magnetic phase-dependent Raman scattering in EuSe and EuTe. Solid State Commun. 1976, 18, 1173–1177. [Google Scholar] [CrossRef]

- Will, G.; Pickart, S.J.; Nathans, R. Antiferromagnetic structure of EuTe. J. Phys. Chem. Solids 1963, 24, 1679–1681. [Google Scholar] [CrossRef]

- Springholz, G.; Bauer, G. Strain relaxation by coherent three-dimensional islanding in molecular-beam epitaxy of EuTe on PbTe(111). Phys. Rev. B 1993, 48, 10998–11009. [Google Scholar] [CrossRef] [PubMed]

- Kępa, H.; Springholz, G.; Giebultowicz, T.M.; Goldman, K.I.; Majkrzak, C.F.; Kacman, P.; Blinowski, J.; Holl, S.; Krenn, H.; Bauer, G. Magnetic interactions in EuTe epitaxial layers and EuTe/PbTe superlattices. Phys. Rev. B 2003, 68, 024419. [Google Scholar] [CrossRef]

- Bergomi, L.; Chen, J.J. Magnetic susceptibility of EuTe/PbTe Heisenberg antiferromagnetic superlattices: Experimental and theoretical studies. Phys. Rev. B 1997, 56, 3281–3289. [Google Scholar] [CrossRef]

- Zinn, W. Microscopic studies of magnetic properties and interactions recent results on europium-monochalcogenides. J. Magn. Magn. Mater. 1976, 3, 23–36. [Google Scholar] [CrossRef]

- Wachter, P. Chapter 19 Europium chalcogenides: EuO, EuS, EuSe and EuTe. In Handbook on the Physics and Chemistry of Rare Earths; Elsevier: Amsterdam, The Netherlands, 1979; Volume 2, pp. 507–574. [Google Scholar]

- Scheer, E.; Wosnitza, J.; v. Löhneysen, H.; Kürsch, R.; Lang, M.; Steglich, F. Critical exponents of EuTe from specific-heat and thermal-expansion measurements. J. Magn. Magn. Mater. 1992, 104–107, 175–176. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, Q.-Y.; Yuan, Y.-H.; Zhang, X.; Liu, H.; Liu, Z.-T.; Zhang, H.-Y.; Song, J.-J.; Zhao, Y.-Z.; Wu, F.-Y.; et al. Angle-resolved photoemission spectroscopy study of charge density wave order in the layered semiconductor EuTe4. Phys. Rev. B 2022, 106, L201108. [Google Scholar] [CrossRef]

- Wu, D.; Liu, Q.M.; Chen, S.L.; Zhong, G.Y.; Su, J.; Shi, L.Y.; Tong, L.; Xu, G.; Gao, P.; Wang, N.L. Layered semiconductor EuTe4 with charge density wave order in square tellurium sheets. Phys. Rev. Mater. 2019, 3, 024002. [Google Scholar] [CrossRef]

- Rathore, R.; Pathak, A.; Gupta, M.K.; Mittal, R.; Kulkarni, R.; Thamizhavel, A.; Singhal, H.; Said, A.H.; Bansal, D. Evolution of static charge density wave order, amplitude mode dynamics, and suppression of Kohn anomalies at the hysteretic transition in EuTe4. Phys. Rev. B 2023, 107, 024101. [Google Scholar] [CrossRef]

- Springholz, G.; Bauer, G.; Schilcher, K. Epitaxial growth of EuTe on PbTe (111) influenced by strain-induced coherent 3D islanding. MRS Online Proc. Libr. 1993, 317, 137. [Google Scholar] [CrossRef]

- Springholz, G.; Yuan, S.; Bauer, G.; Kriechbaum, M.; Krenn, H. EuTe/PbTe superlattices: MBE growth and optical characterization. MRS Online Proc. Libr. 1993, 301, 353. [Google Scholar] [CrossRef]

- Frank, N.; Springholz, G.; Bauer, G.H. Strain induced islanding of EuTe epitaxial films observed by in-situ RHEED and STM investigations. Mater. Sci. Forum 1993, 143–147, 1623–1628. [Google Scholar] [CrossRef]

- Chen, J.J.; Dresselhaus, G.; Dresselhaus, M.S.; Springholz, G.; Pichler, C.; Bauer, G. Magnetization studies of type-II antiferromagnetic EuTe/PbTe superlattices. Phys. Rev. B 1996, 54, 402–410. [Google Scholar] [CrossRef] [PubMed]

- Heiss, W.; Prechtl, G.; Springholz, G. Giant tunability of exciton photoluminescence emission in antiferromagnetic EuTe. Phys. Rev. B 2001, 63, 165323. [Google Scholar] [CrossRef]

- Ramachandran, V.; Smith, A.R.; Feenstra, R.M.; Greve, D.W. Temperature dependence of molecular beam epitaxy of GaN on SiC (0001). J. Vac. Sci. Technol. A 1999, 17, 1289–1293. [Google Scholar] [CrossRef]

- Saito, Y.; Harima, H.; Kurimoto, E.; Yamaguchi, T.; Teraguchi, N.; Suzuki, A.; Araki, T.; Nanishi, Y. Growth temperature dependence of indium nitride crystalline quality grown by RF-MBE. Phys. Status Solidi 2002, 234, 796–800. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, T.; Feng, Y.P.; Wee, A.T.S.; Wang, Z. MBE-grown ultrathin PtTe2 films and their layer-dependent electronic structures. Nanoscale 2022, 14, 7650–7658. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Han, D.; Bao, Y.; Cheng, F.; Ding, Z.; Tan, S.J.R.; Loh, K.P. Observation of gap opening in 1T′ phase MoS2 nanocrystals. Nano Lett. 2018, 18, 5085–5090. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Pai, W.W.; Chan, Y.H.; Sun, W.L.; Xu, C.Z.; Lin, D.S.; Chou, M.Y.; Fedorov, A.V.; Chiang, T.C. Large quantum-spin-Hall gap in single-layer 1T’ WSe2. Nat. Commun. 2018, 9, 2003. [Google Scholar] [CrossRef] [PubMed]

- Feng, R.; Wang, W.; Bao, C.; Zhang, Z.; Wang, F.; Zhang, H.; Yao, J.; Xu, Y.; Yu, P.; Ji, S.-H.; et al. Selective control of phases and electronic structures of monolayer TaTe2. Adv. Mater. 2023, 2302297. [Google Scholar] [CrossRef]

- Knall, J.; Sundgren, J.E.; Hansson, G.V.; Greene, J.E. Indium overlayers on clean Si (100) 2 × 1: Surface structure, nucleation, and growth. Surf. Sci. 1986, 166, 512–538. [Google Scholar] [CrossRef]

- Cai, X.; Lu, Z.; Xu, Z.; Meng, F.; Zhang, Q.; Gu, L.; Feng, J.; Ji, S.-H.; Li, N.; Chen, X. Growth of (111)-orientated GdTe and TmTe thin films by van der Waals molecular beam epitaxy. J. Phys. Chem. C 2021, 125, 15465–15471. [Google Scholar] [CrossRef]

- Koppensteiner, E.; Springholz, G.; Hamberger, P.; Bauer, G. Molecular beam epitaxy of PbTe/EuTe superlattices and their structural investigation by x-ray diffraction using reciprocal space mapping. J. Appl. Phys. 1993, 74, 6062–6071. [Google Scholar] [CrossRef]

- Hüfner, S. Core levels and final states. Photoelectron. Spectrosc. Princ. Appl. 2003, 61–107. [Google Scholar] [CrossRef]

- Heiss, W.; Kirchschlager, R.; Springholz, G.; Chen, Z.; Debnath, M.; Oka, Y. Magnetic polaron induced near-band-gap luminescence in epitaxial EuTe. Phys. Rev. B 2004, 70, 035209. [Google Scholar] [CrossRef]

| EuTe | EuTe4 | EuTe | EuTe4 | ||

|---|---|---|---|---|---|

| Eu 3d3/2 | 0.934 | 0.238 | Te 3d3/2:Eu 3d3/2 | 0.718 | 2.719 |

| Eu 3d5/2 | 1.423 | 0.362 | Te 3d5/2:Eu 3d3/2 | 1.071 | 4.211 |

| Te 3d3/2 | 0.671 | 0.646 | Te 3d3/2:Eu 3d5/2 | 0.471 | 1.782 |

| Te 3d5/2 | 1 | 1 | Te 3d5/2:Eu 3d5/2 | 0.703 | 2.760 |

| Te 3d3/2:Eu 3d3/2 | Te 3d5/2:Eu 3d3/2 | Te 3d3/2:Eu 3d5/2 | Te 3d5/2:Eu 3d5/2 | |

|---|---|---|---|---|

| EuTe4:EuTe | 3.787 | 3.933 | 3.783 | 3.928 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, F.; Qiu, X.; Zhou, J.; Huang, L.; Yang, B.; Liu, J.; Wu, D.; Wang, G.; Zhang, Y. Tailoring the Structure and Properties of Epitaxial Europium Tellurides on Si(100) through Substrate Temperature Control. Materials 2023, 16, 7093. https://doi.org/10.3390/ma16227093

Yu F, Qiu X, Zhou J, Huang L, Yang B, Liu J, Wu D, Wang G, Zhang Y. Tailoring the Structure and Properties of Epitaxial Europium Tellurides on Si(100) through Substrate Temperature Control. Materials. 2023; 16(22):7093. https://doi.org/10.3390/ma16227093

Chicago/Turabian StyleYu, Fan, Xiaodong Qiu, Jinming Zhou, Lin Huang, Bin Yang, Junming Liu, Di Wu, Gan Wang, and Yi Zhang. 2023. "Tailoring the Structure and Properties of Epitaxial Europium Tellurides on Si(100) through Substrate Temperature Control" Materials 16, no. 22: 7093. https://doi.org/10.3390/ma16227093