Prediction of Extrusion Machine Stem Fatigue Life Using Structural and Fatigue Analysis

Abstract

:1. Introduction

2. Design and Structural Strength Analysis

2.1. Extruder Modeling

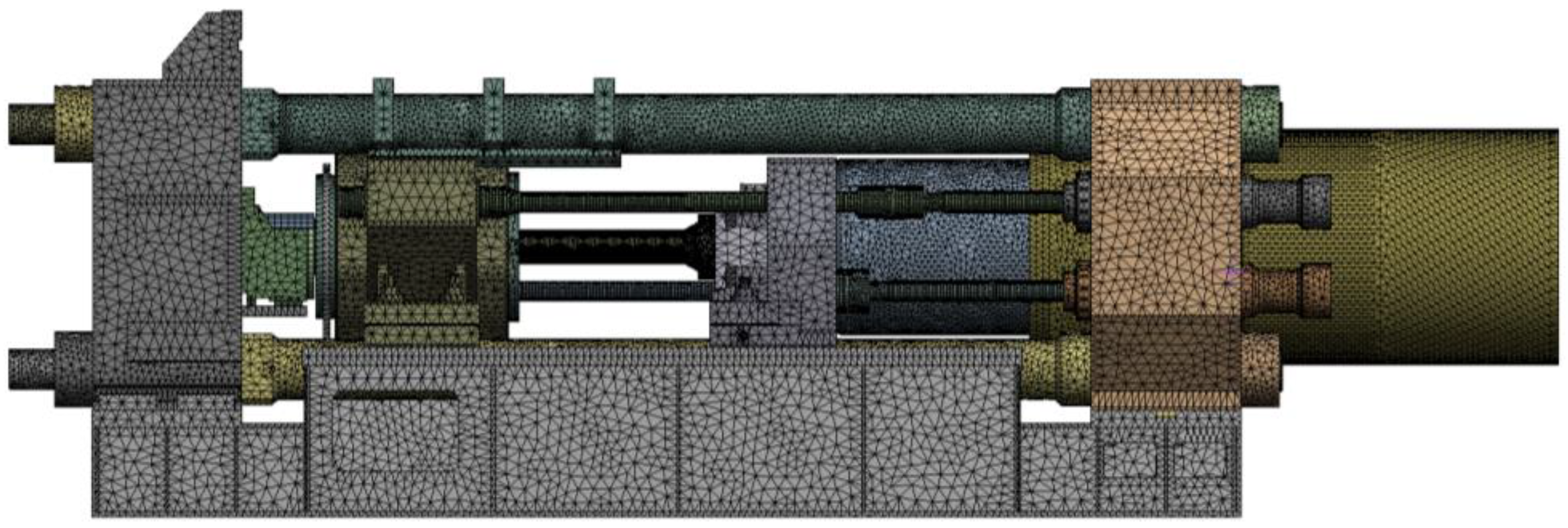

2.2. Finite Element Modeling

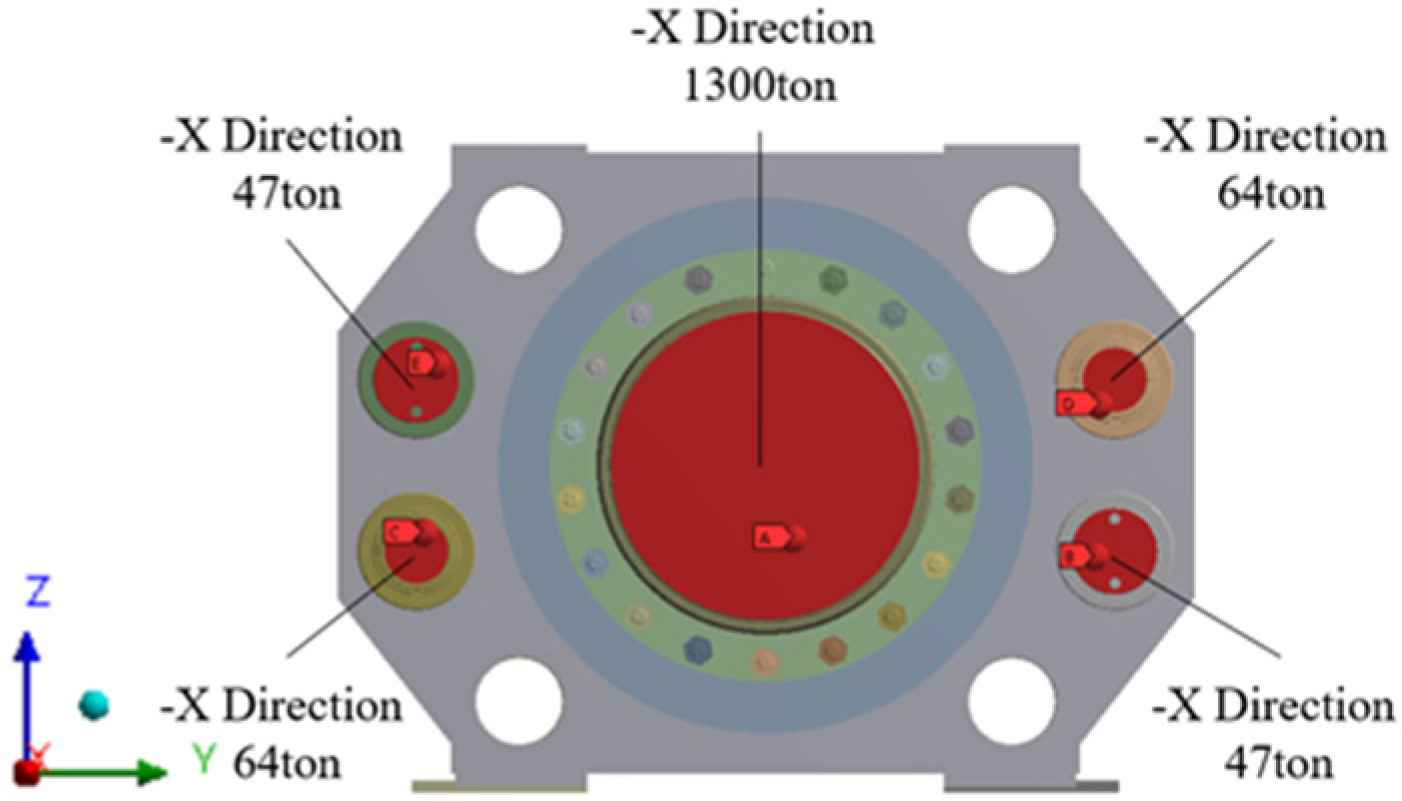

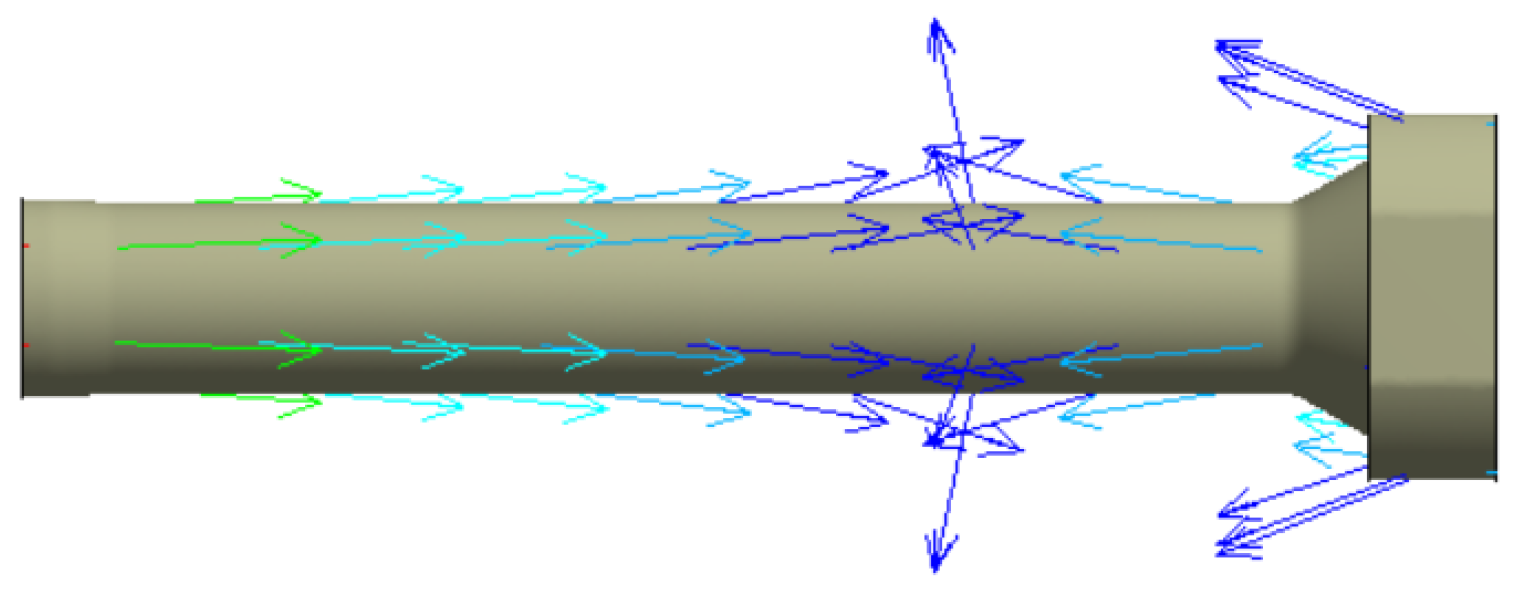

2.3. Boundary and Load Conditions

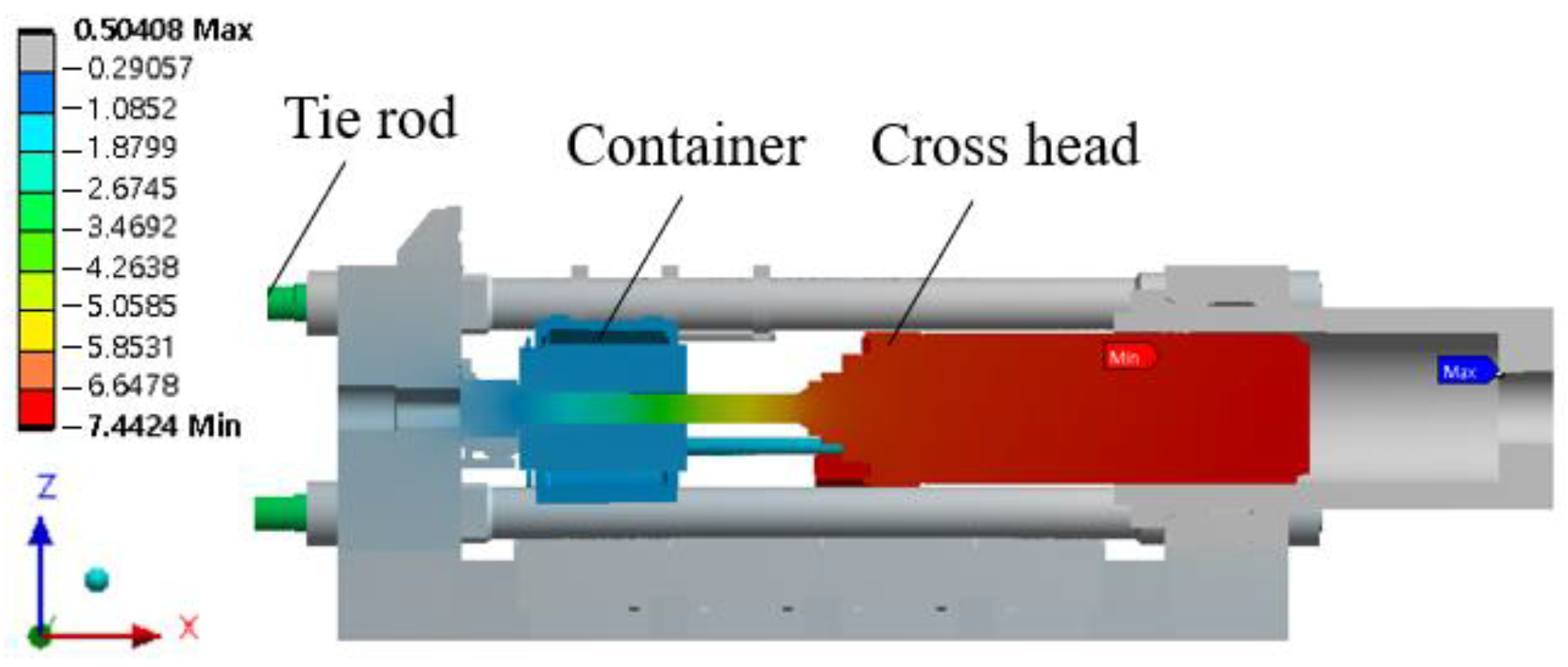

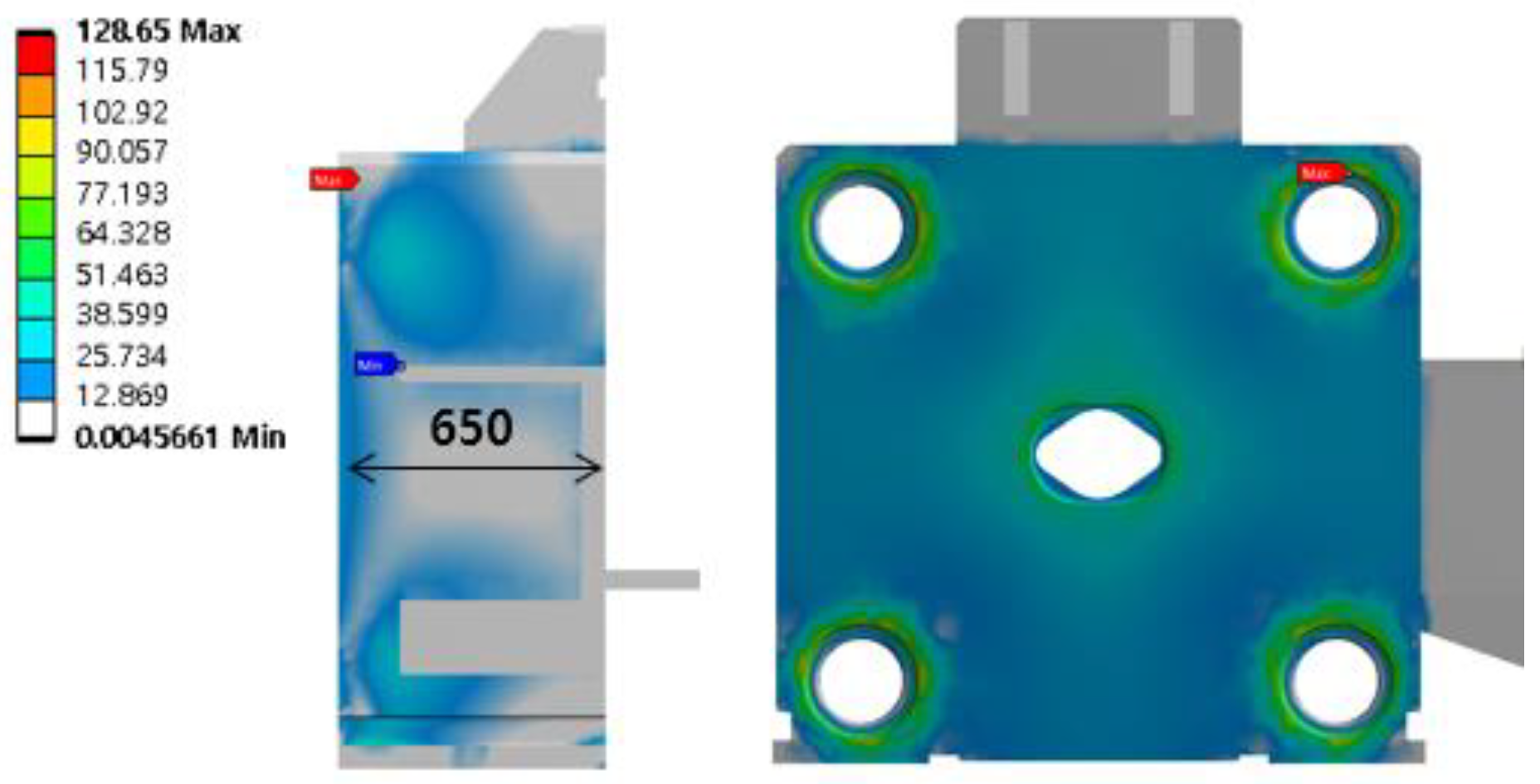

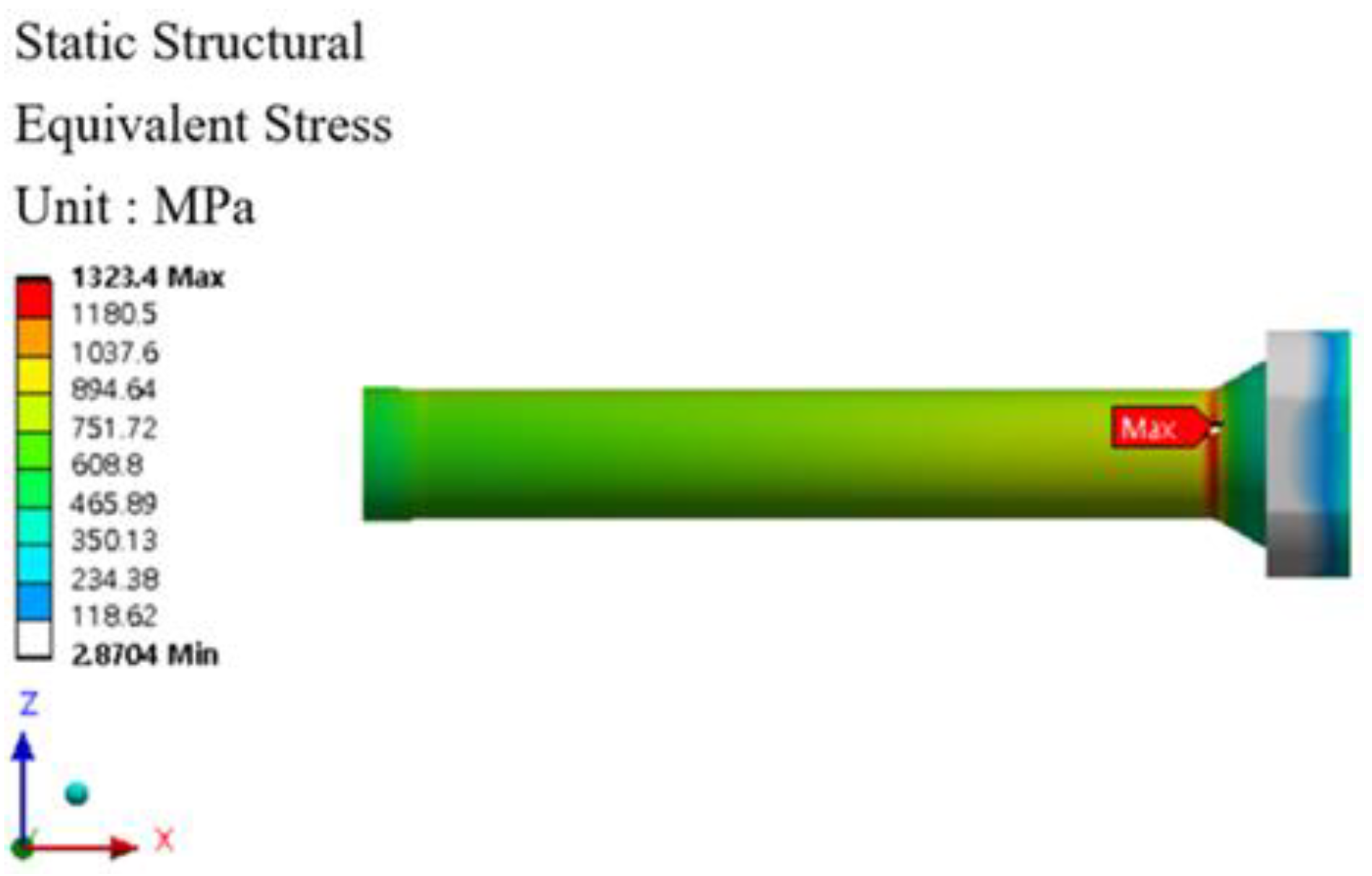

2.4. Results of Structural Strength Analysis

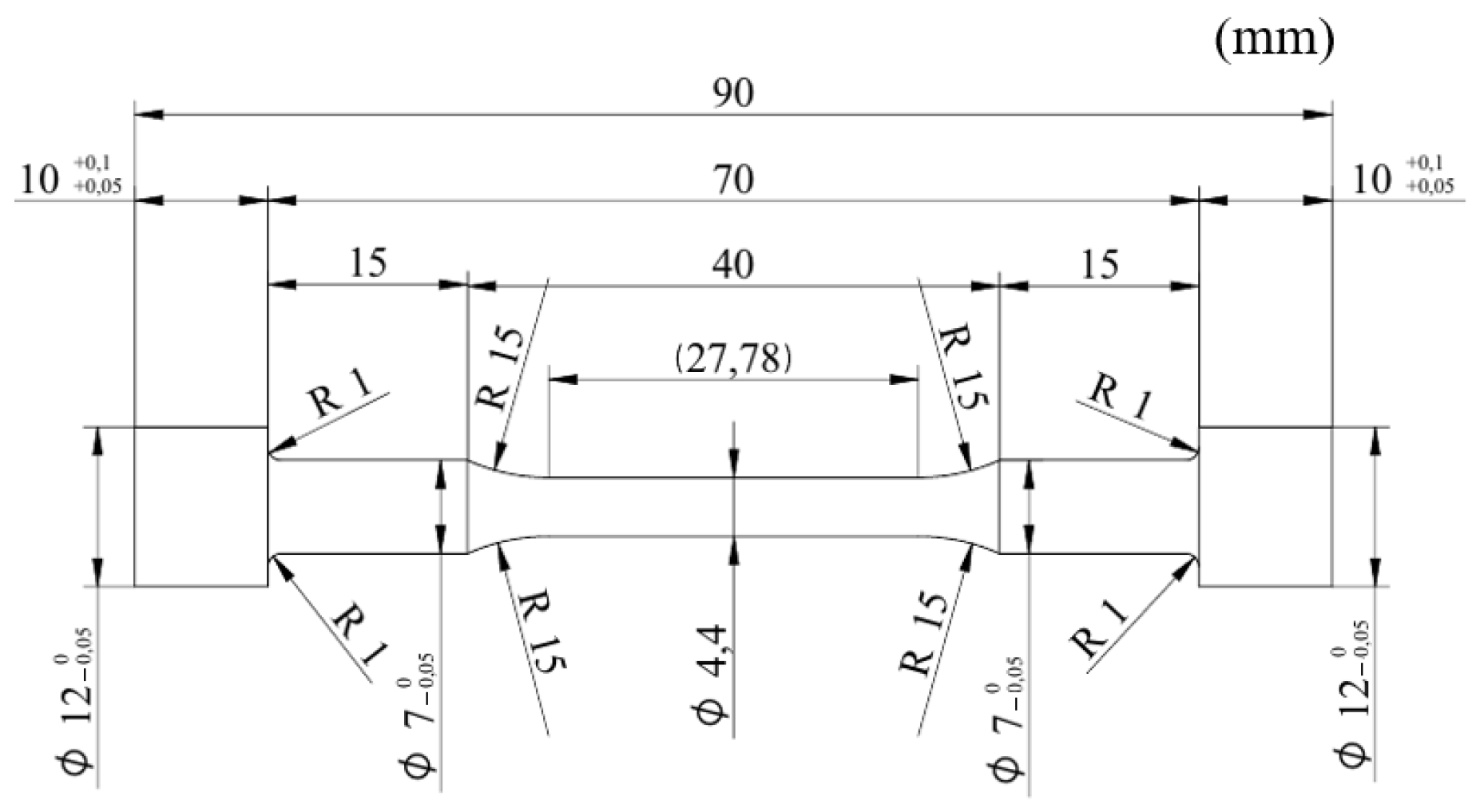

3. Tensile Test

3.1. Material and Test Specimen

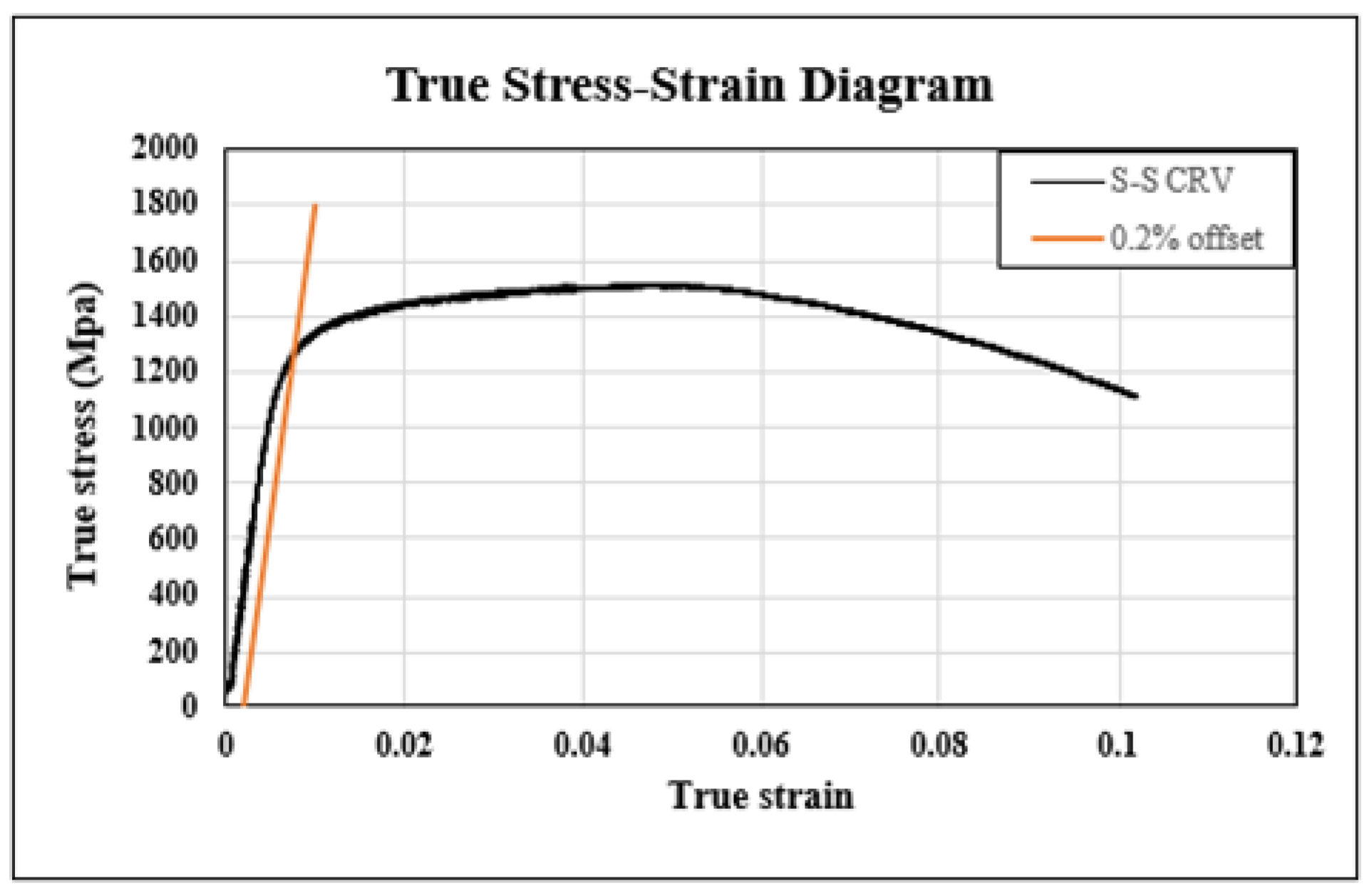

3.2. Room Temperature Tensile Test

3.3. High-Temperature Tensile Test

4. Fatigue Test

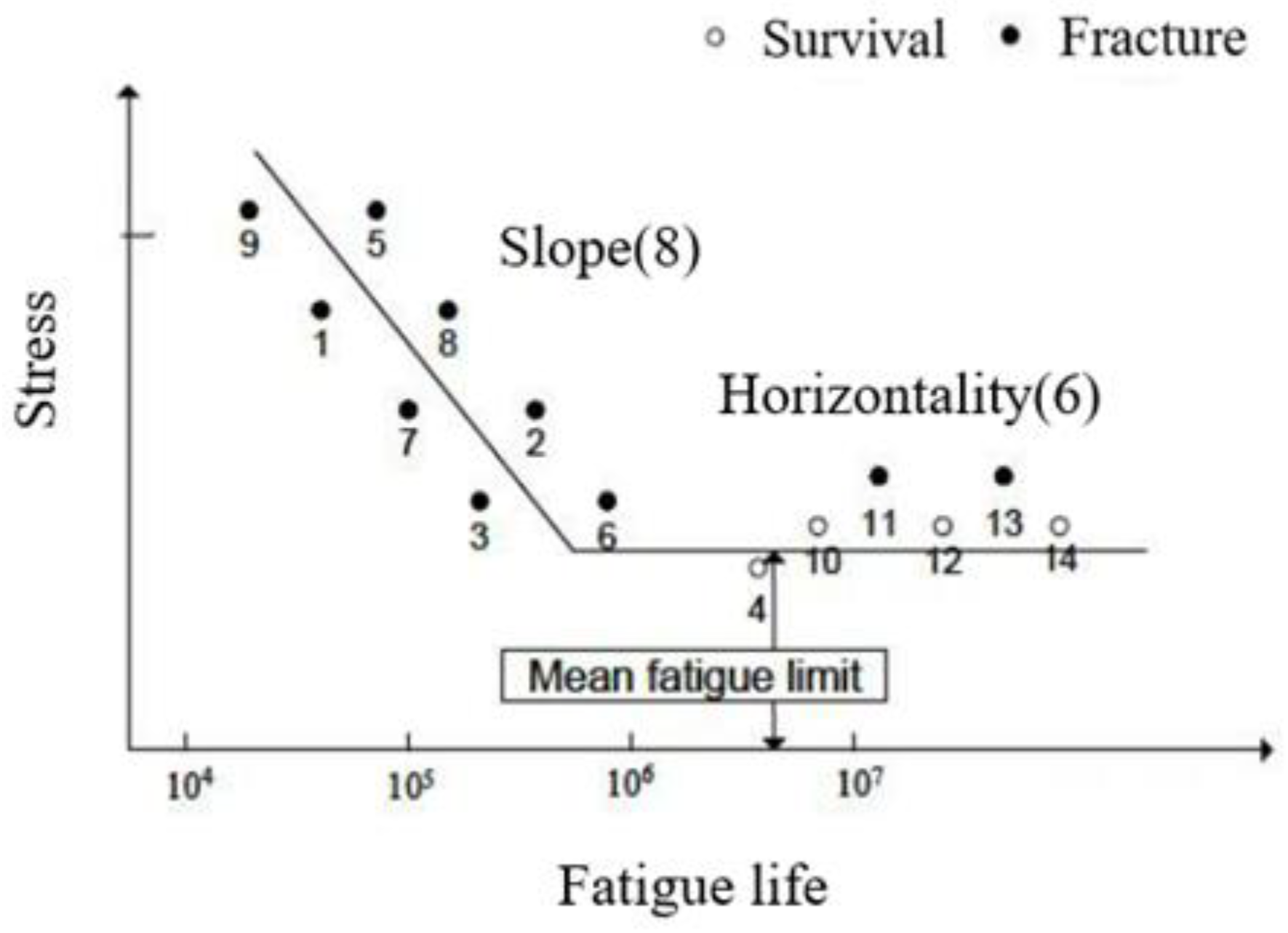

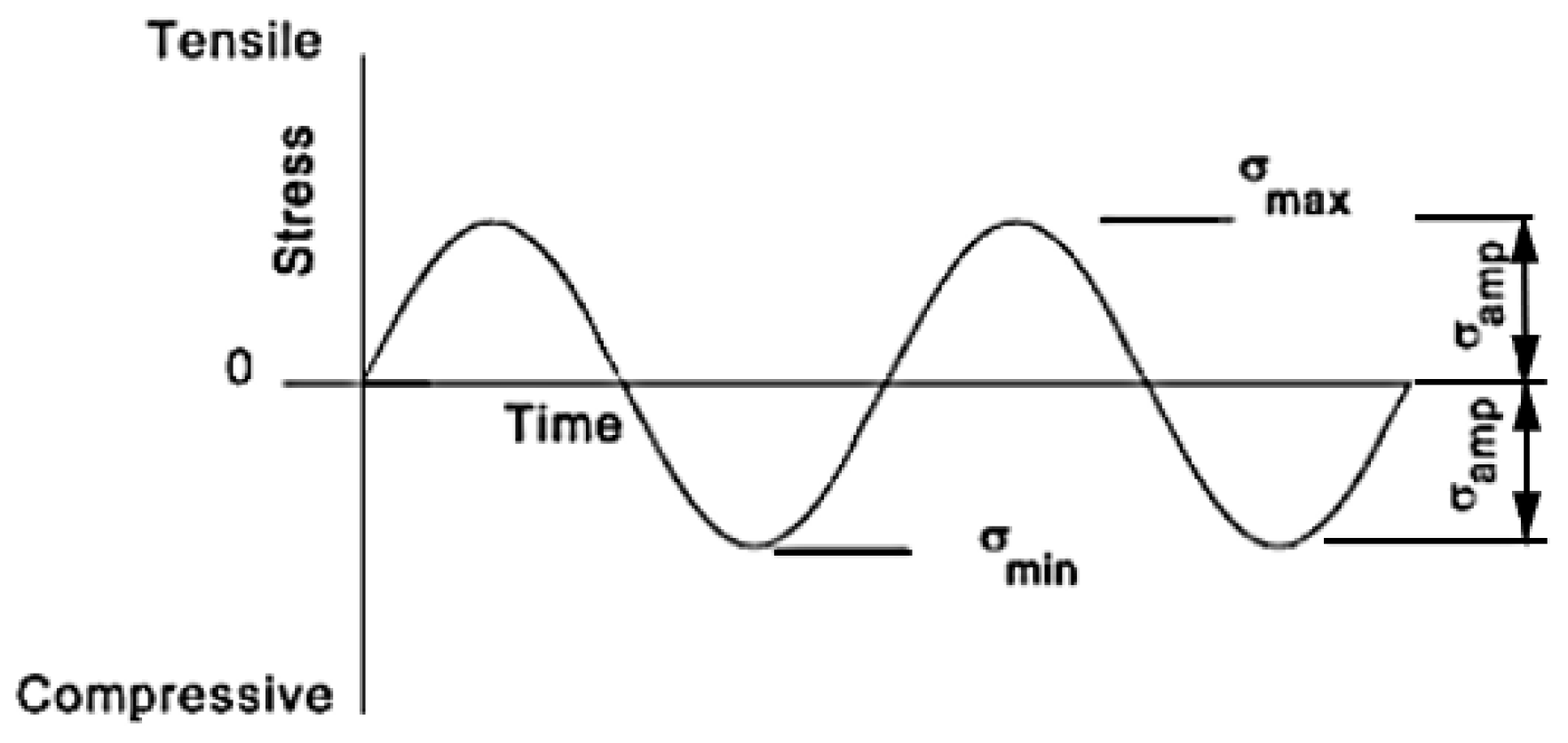

4.1. Fatigue Failure and Fatigue Life

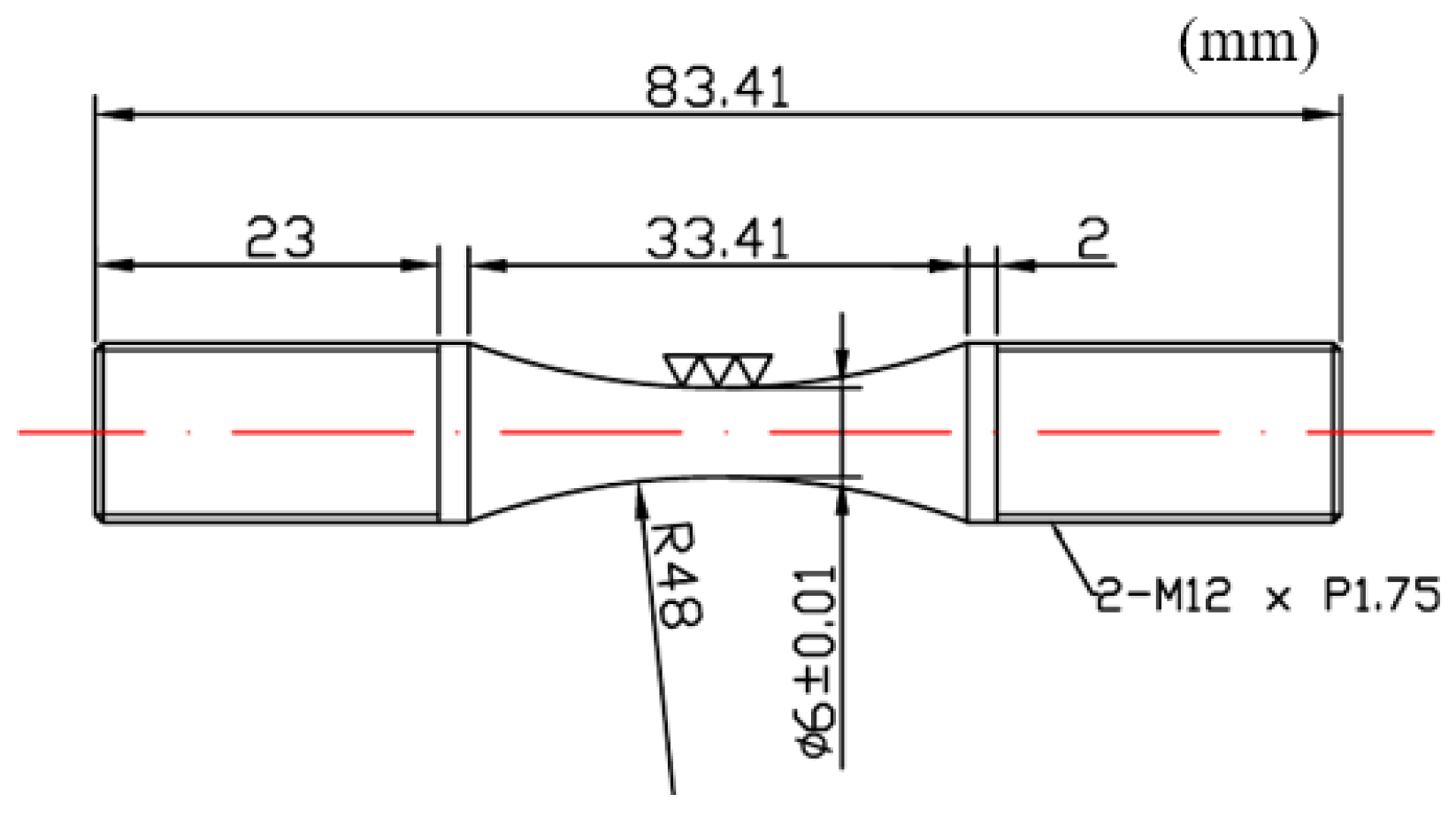

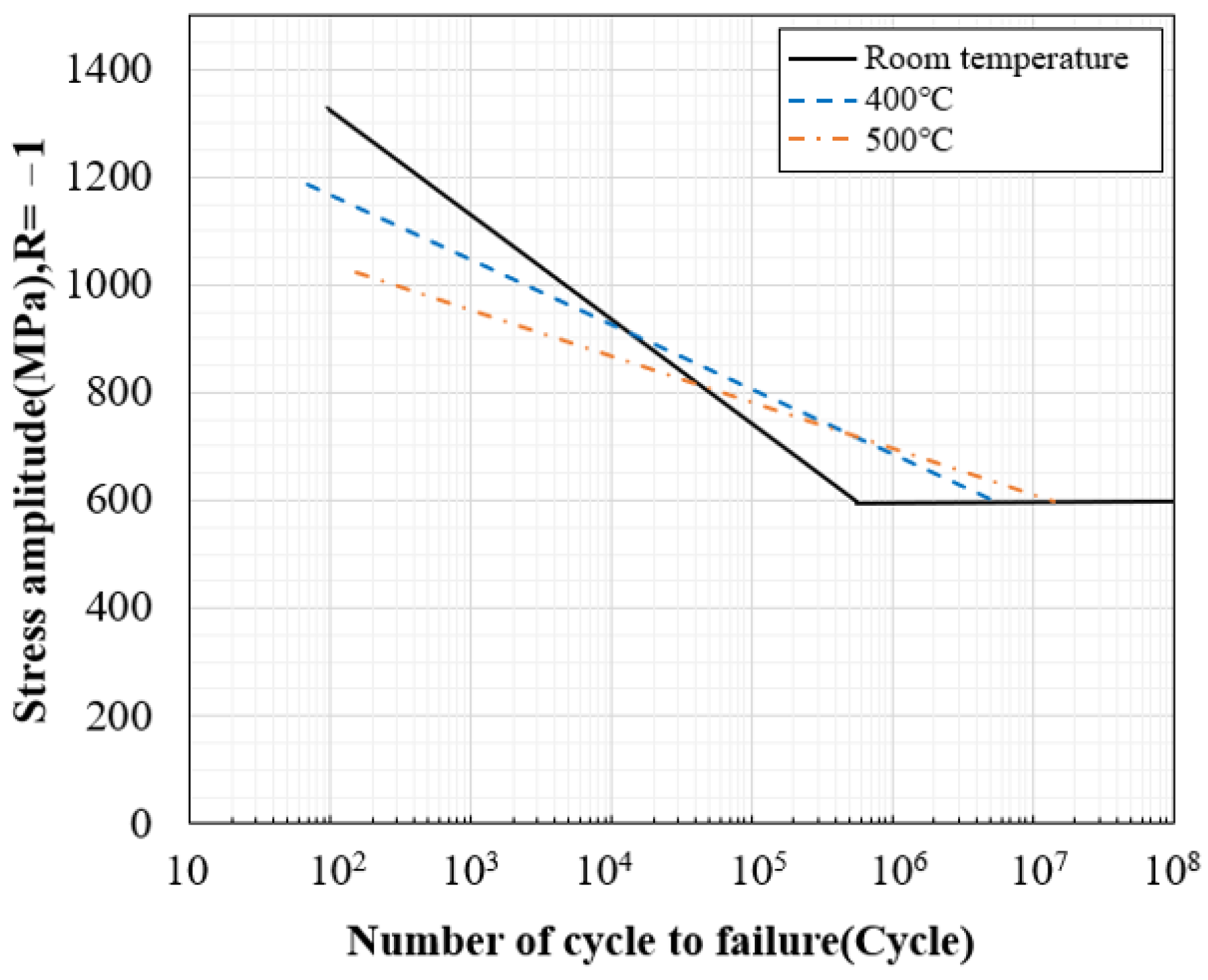

4.2. S–N Curve

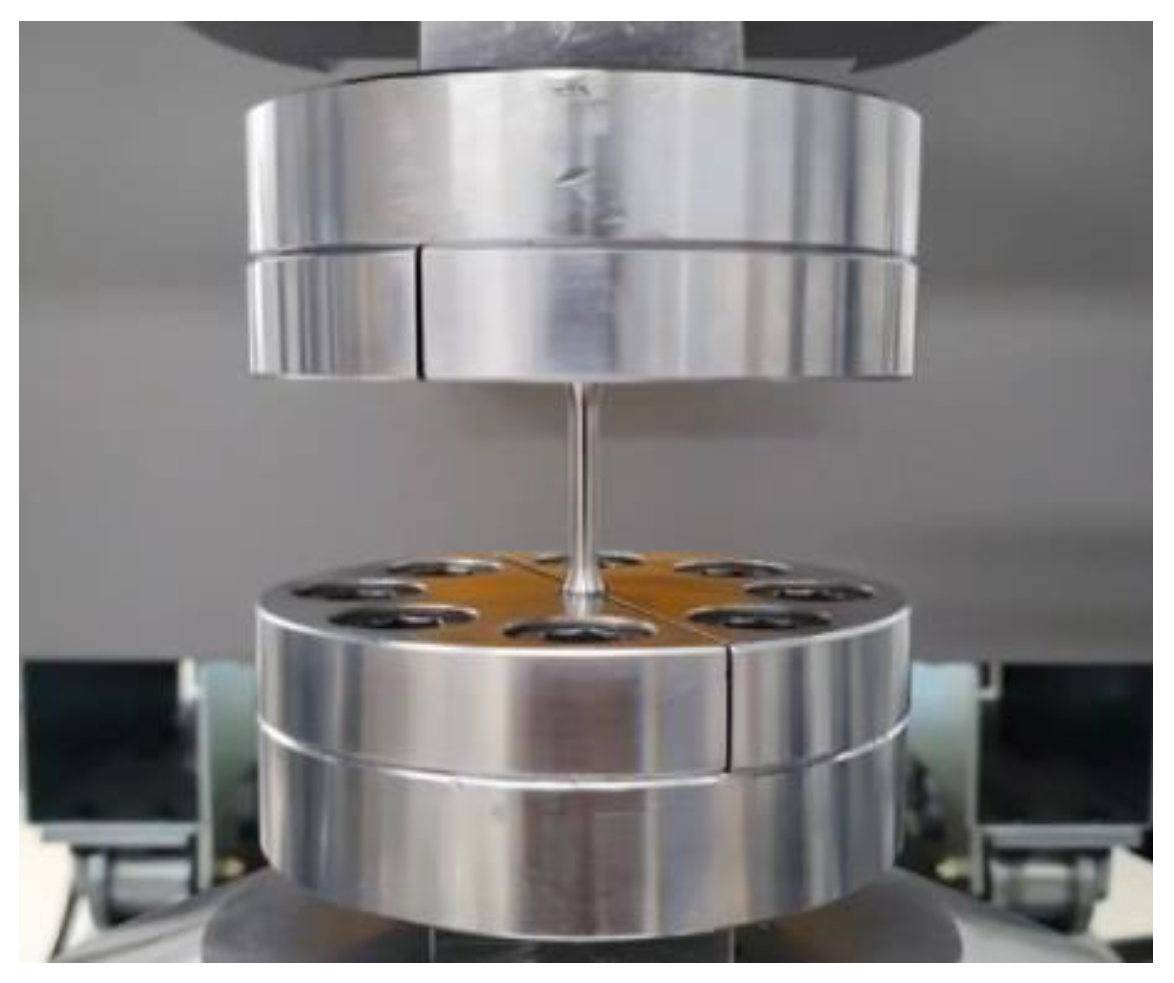

4.3. Fatigue Test Method

4.4. Fatigue Test Results

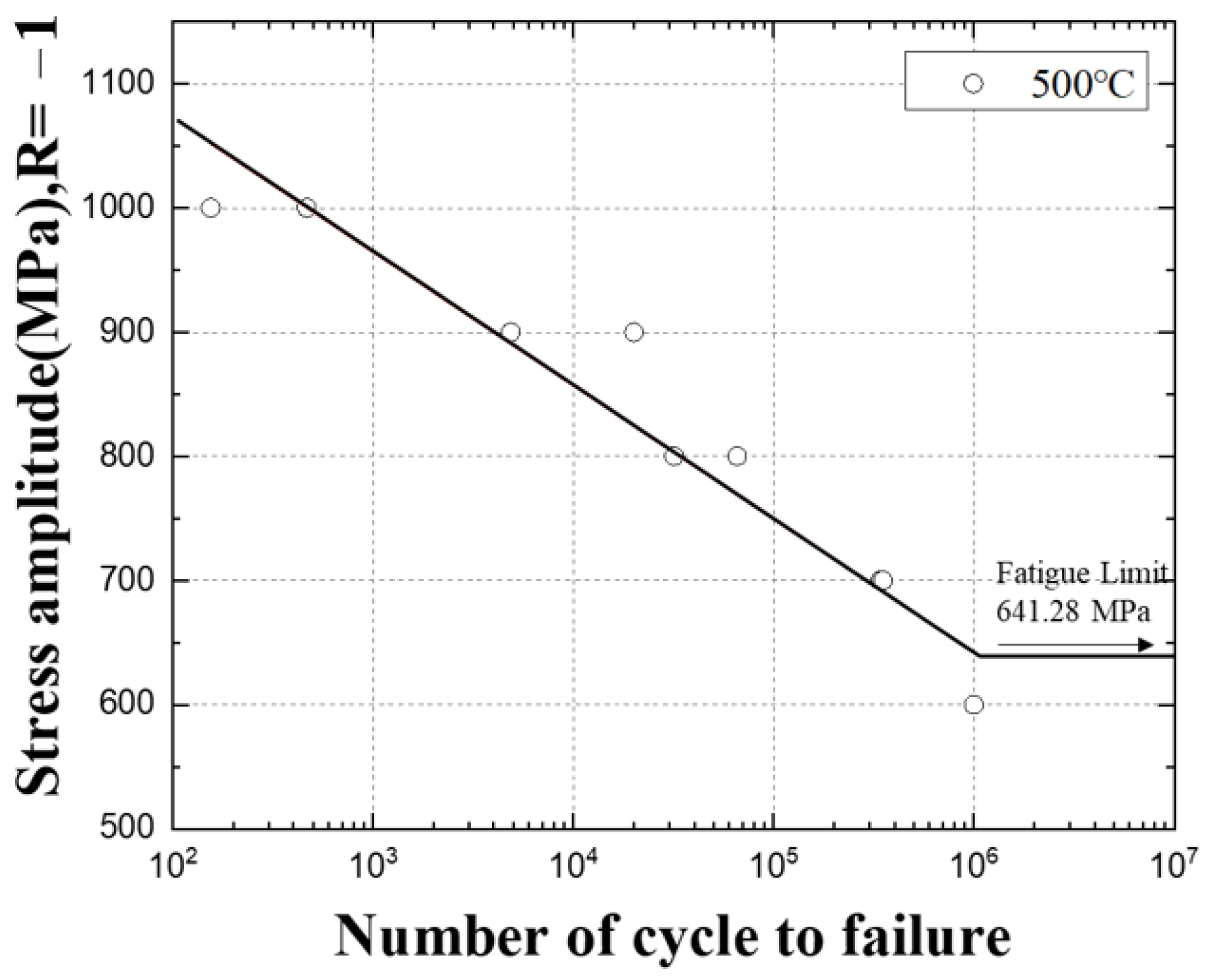

4.5. High-Temperature Fatigue Test Results

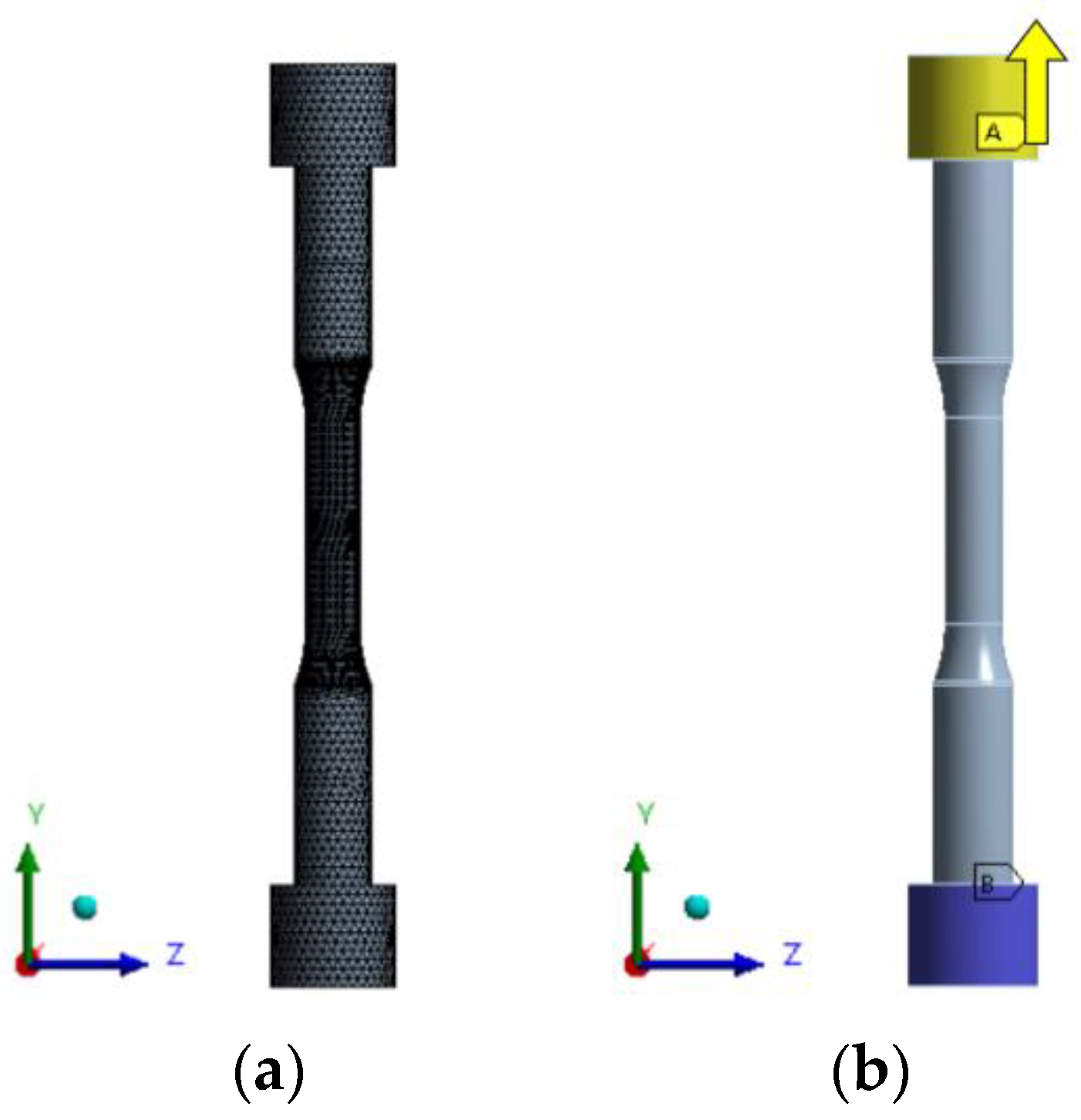

5. Finite Element Analysis of Fatigue Test Specimens

5.1. Finite Element Modeling of Fatigue Test Specimens

5.2. Fatigue Analysis Conditions of Test Specimen

5.3. Fatigue Analysis Results of the Fatigue Test Specimen

6. Fatigue Analysis

6.1. Purpose of Fatigue Analysis

6.2. Types of Fatigue Analysis

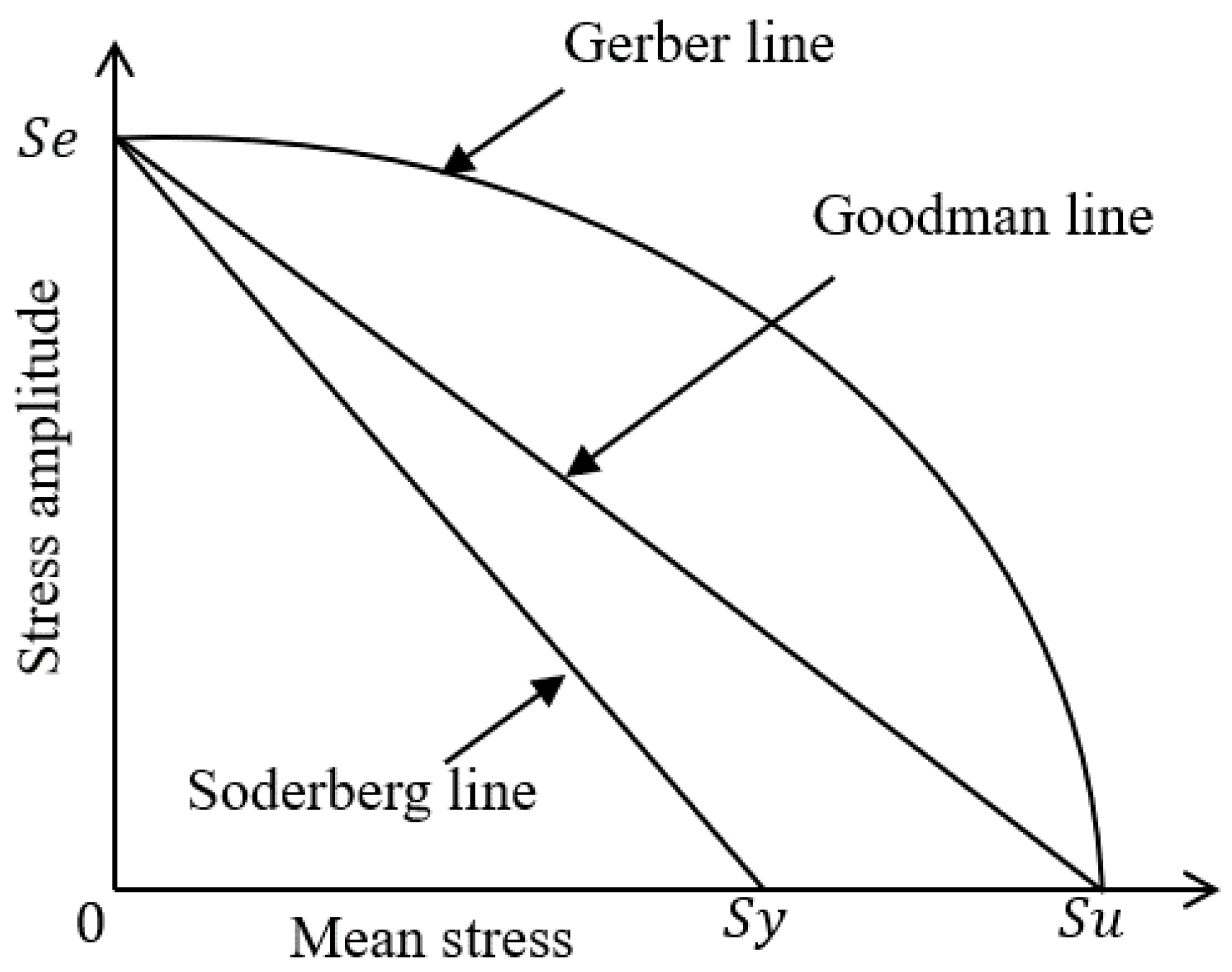

6.3. Effect of Mean Stress

6.4. Stress Concentration Factor

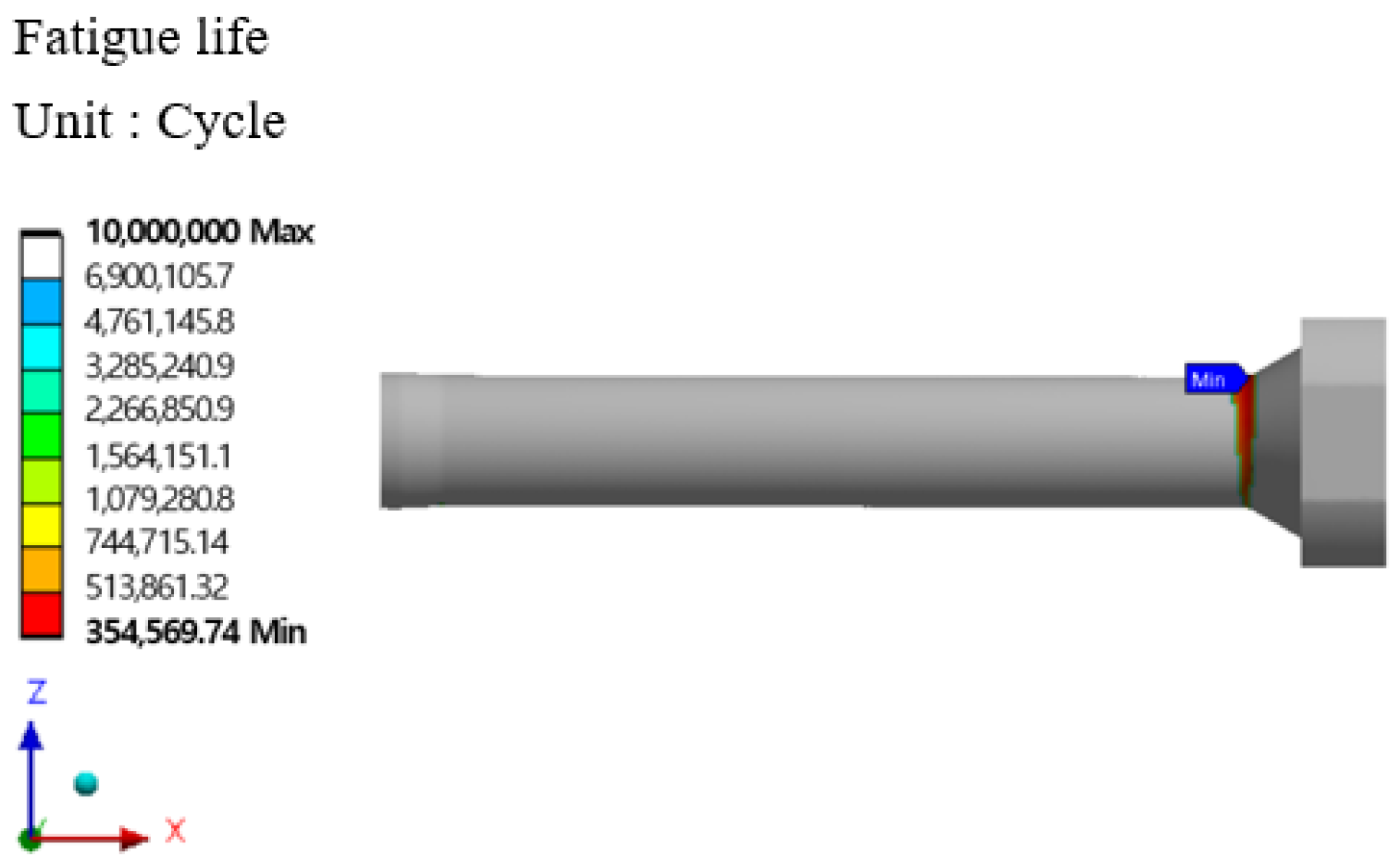

6.5. Prediction of the Life of Extrusion Press Stem

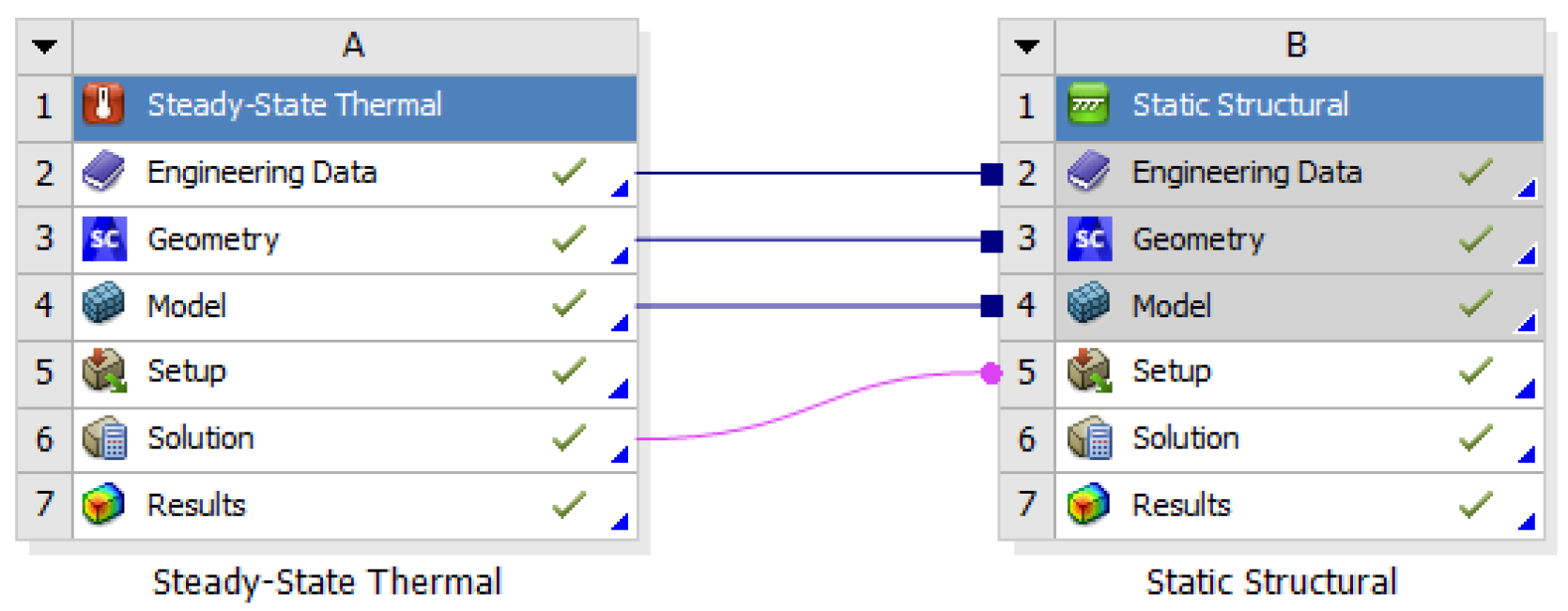

6.6. Heat Transfer Analysis and Results

6.7. Extruder High-Temperature Stem Fatigue Life Prediction

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, M.G.; Kim, J.M.; Jo, M.J.; Cho, C.D. Structural Analysis and Evaluation on the Durability and Safety of Extrusion Press. Trans. Korean Soc. Mech. Eng. 2009, 5, 376–381. [Google Scholar]

- Suh, C.M.; Suh, C.H.; Suh, M.S. VHCF Characteristics of SCMH2 Steel Depending on the Surface Treatment Conditions. J. KWJS 2013, 31, 47–53. [Google Scholar]

- Qiu, Y.; Park, S.C.; Cho, H.Y. Prediction of forming limits in cold open-die extrusion process. Trans. Korean Soc. Mech. Eng. A 2020, 44, 435–441. [Google Scholar] [CrossRef]

- Song, D.H.; Park, Y.B.; Kim, M.E. Comparision between Forward Extrusion and Upsetting Process for Preform with Stepped Shape. In Proceedings of the Korean Society for Technology of Plasticity Conference; The Korean Society for Technology of Plasticity: Seoul, Republic of Korea, 2000; pp. 82–85. [Google Scholar]

- Kim, K.W.; Kim, Y.T.; Lee, S.J.; Kim, W.J.; Cho, H.Y. Process Design for Forward and Backward Extrusion of Asymmetric Parts using FEM. J. Ind. Sci. Technol. Inst. 2022, 1, 69–74. [Google Scholar]

- Park, H.J.; Yoon, D.J.; Na, K.H.; Cho, N.S. Hydrostatic Extruder Development. Korean Soc. Technol. Plast. 1993, 4, 44–49. [Google Scholar]

- Ham, H.W.; Kim, B.M. Optimal die shape design of cold extrusion considering mechanical fatigue and wear resistance. Proc. KSME SOring 4hild/Meering 1998, 4, 777–782. [Google Scholar]

- Kim, S.Y.; Kweon, S.S.; Park, D.K.; Chun, D.W.; Chung, I.S. Durability Test and Fatigue Analysis of Independent Suspension Knuckle for Commercial Vehicle. J. Automob. Eng. KSAE Annu. Conf. Exhib. 2011, 1005–1010. [Google Scholar]

- Kim, J.W.; Kim, B.J.; Jo, I.S.; Moon, Y.H. Analysis of Thermal Shock in Tool Steels for Hot Forging. J. Korean Soc. Heat Treat. 2001, 14, 155–159. [Google Scholar]

- Lee, K.Y.; Kim, T.H.; Lee, H.Y. Acquirement of true stress-strain curve using true fracture strain obtained by tensile test and FE analysis. Trans. Korean Soc. Mech. Eng. A 2009, 33, 1054–1064. [Google Scholar] [CrossRef]

- Yoh, E.G.; Lee, Y.S. Temperature dependence of Mechanical Properties of Die Steel STD61. Trans. Mater. Proc. 2004, 13, 435–440. [Google Scholar]

- Vincent, M.K.; Varghese, V.; Sukumaran, S. Fabrication and analysis of fatigue testing machine. Int. J. Eng. Sci. 2016, 5, 15–19. [Google Scholar]

- Park, D.H.; Jeong, S.U. Fracture probability properties of torsion fatigue of STS304 steel. Trans. Korean Soc. Mech. Eng. 2003, 201–206. [Google Scholar]

- Jeong, S.U. Bending Fatigue Characteristics and Stress Analysis of STS304 Steel. J. Inst. Mar. Ind. 2007, 20, 79–84. [Google Scholar]

- Haidyrah, A.S.R. Characterization of Bending Fatigue Mini-Specimens for Nuclear Materials. Ph.D. Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2015. [Google Scholar]

- Kang, M.S.; Koo, J.M.; Seok, C.S.; Park, J.S. Fatigue Characteristic of High Impact Polystyrene (HR-1360) Materials. Trans. Korean Soc. Mech. Eng. A 2010, 34, 763–769. [Google Scholar] [CrossRef]

- Cho, M.G.; Baek, I.S.; Bae, J.G.; Lee, S.S. Study on krouse type bending fatigue tester for obtaining fatigue life curve. Trans. Korean Soc. Mech. Eng. A 2021, 45, 59–65. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, D.Y. Development of the Algorithm and Software for Optimized S-N Fatigue Test of Structural Steels. J. Korean Soc. Steel Constr. 2018, 30, 137–144. [Google Scholar] [CrossRef]

- Seo, S.K.; Park, J.E.; Cho, Y.H.; Song, S.I. Design of the Staircase Fatigue Tests for the Random Fatigue Limit Model. J. Korean Soc. Qual. Manag. 2007, 35, 107–117. [Google Scholar]

- Jsme, S. Standard Method of Statistical Fatigue Testing. J. Jpn. Soc. Mech. Eng. 1994, 10, 2. [Google Scholar]

- Yang, Y.S.; Bae, J.G.; Park, C.G. Improvement of the bending fatigue resistance of the hyper-eutectoid steel wires used for tire cords by a post-processing annealing. Mater. Sci. Eng. A 2008, 488, 554–561. [Google Scholar] [CrossRef]

- Topic, M.; Allen, C.; Tait, R. The effect of cold work and heat treatment on the fatigue behaviour of 3CR12 corrosion resistant steel wire. Int. J. Fatigue 2007, 29, 49–56. [Google Scholar] [CrossRef]

- ASTM E466; Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2018.

- Akiniwa, Y.; Miyamoto, N.; Tsuru, H.; Tanaka, K. Notch effect on fatigue strength reduction of bearing steel in the very high cycle regime. Int. J. Fatigue 2006, 28, 1555–1565. [Google Scholar] [CrossRef]

- Pyo, D.K. A Study on the Fatigue Strength Reduction Factor under the High Cycle Bending Fatigue. J. Ocean. Eng. Technol. 1992, 6, 71–75. [Google Scholar]

- Park, J.S.; Seok, C.S.; Lee, J.G.; Lee, J.H. Fatigue Characteristic of HIPS (HR-1360) Materials. Trans. Korean Soc. Mech. Eng. A 2000, 129–134. [Google Scholar]

- Park, S.O.; Yoon, J.M.; Oh, H.Y.; Kim, K.W.; Park, G.J. Structural Optimization of a Train Bolster Considering Fatigue. J. Korean Soc. Railw. 2020, 8, 706–714. [Google Scholar] [CrossRef]

- Grover, H.J. Fatigue of Aircraft Structures; US Government Printing Office: Washington, DC, USA, 1967; pp. 317–322.

- Bannantine, J.A.; Comer, J.J.; Handrock, J.S.L. Fundamentals of Metal Fatigue Analysis; Research Supported by the University of Illinois; Prentice Hall: Englewood Cliffs, NJ, USA, 1990; p. 286. [Google Scholar]

- Mouritz, A.P.; Bannister, A. Introduction to Aerospace Materials; Woodhead Publishing: Cambridge, UK, 2012; pp. 469–497. [Google Scholar]

- Goodman, J. Mechanics Applied to Engineering, 8th ed.; Longmans, Green & Co. edition: New York, NY, USA, 1914. [Google Scholar]

- Soderberg, C.R. APM-52-2. Trans. ASME 1930, 52, 13–28. [Google Scholar]

- Seok, C.S.; Kim, H.I.; Chang, P.S.; Joo, J.M.; Kang, J.H. Effect of mean stress on fatigue properties in spring steel. Trans. Korean Soc. Mech. Eng. 2003, 255–260. [Google Scholar]

- Nassiraei, H.; Rezadoost, P. Stress concentration factors in tubular T/Y-joints strengthened with FRP subjected to compressive load in offshore structures. Int. J. Fatigue 2020, 140, 105719. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. Stress concentration factors in tubular T-joints reinforced with external ring under in-plane bending moment. Ocean. Eng. 2022, 266, 112551. [Google Scholar] [CrossRef]

| Material | SKD61 |

|---|---|

| Modulus of elasticity (GPa) | 210 |

| Poisson’s ratio | 0.28 |

| Density (kg/m3) | 7810 |

| Yield stress (MPa) | 1325 |

| Part | Maximum Von-Mises Stress (MPa) | Safety Factor |

|---|---|---|

| Stem | 1152.5 | 1.12 |

| Housing | 163.0 | 2.76 |

| Platen | 128.6 | 2.14 |

| Chemical Composition of SKD61 Steel | |||||

|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | V |

| 0.36 | 1.0 | 0.44 | 5.3 | 1.3 | 0.98 |

| Materials | Modulus (Gpa) | Yield Strength (Mpa) | Ultimate Strength (Mpa) |

|---|---|---|---|

| SKD61 | 224 | 1325 | 1500 |

| Stress Amplitude (Mpa) | Fatigue Life, N (Cycle) | |

|---|---|---|

| 1100 | 2227 | 2190 |

| 1000 | 6870 | 5375 |

| 900 | 24,000 | 21,961 |

| 800 | 47,287 | 39,990 |

| 700 | 102,510 | 113,680 |

| 600 | 106↑ | |

| Stress Amplitude (MPa) | Fatigue Life, N (Cycle) | |

|---|---|---|

| 1000 | 3000 | 2908 |

| 900 | 5134 | 27,259 |

| 800 | 130,684 | 20,038 |

| 700 | 659,863 | 72,690 |

| 600 | 106↑ | |

| Stress Amplitude (MPa) | Fatigue Life, N (Cycle) | |

|---|---|---|

| 1000 | 154 | 465 |

| 900 | 20,049 | 4849 |

| 800 | 65,812 | 31,792 |

| 700 | 340,240 | 351,138 |

| 600 | 106↑ | |

| Stress Amplitude (MPa) | Fatigue Life of Fatigue Tester Specimen (Cycle) | Fatigue Life of Fatigue Analysis (Cycle) |

|---|---|---|

| 1000 | 5375~6870 | 5662 |

| Load Condition | Stress Ratio (R) | Amplitude Ratio (A) |

|---|---|---|

| Fully reversed | −1 | ∞ |

| Zero to max | 0 | 1 |

| Zero to min | ∞ | −1 |

| Temperature | Von-Mises Stress (MPa) | Fatigue Life (Cycle) |

|---|---|---|

| Room Temperature | 1152.5 | 424,998 |

| 400 °C | 1287.7 | 354,569 |

| 500 °C | 1323.4 | 335,937 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-Y.; Kim, J.-W.; Ha, J.-S.; Jo, A.-R.; Lee, S.-Y.; Jeong, M.-S.; Ko, D.-C.; Jang, J.-S. Prediction of Extrusion Machine Stem Fatigue Life Using Structural and Fatigue Analysis. Materials 2023, 16, 3192. https://doi.org/10.3390/ma16083192

Kim D-Y, Kim J-W, Ha J-S, Jo A-R, Lee S-Y, Jeong M-S, Ko D-C, Jang J-S. Prediction of Extrusion Machine Stem Fatigue Life Using Structural and Fatigue Analysis. Materials. 2023; 16(8):3192. https://doi.org/10.3390/ma16083192

Chicago/Turabian StyleKim, Dong-Yul, Ji-Wook Kim, Jin-Su Ha, A-Ra Jo, Sung-Yun Lee, Myeong-Sik Jeong, Dae-Cheol Ko, and Jin-Seok Jang. 2023. "Prediction of Extrusion Machine Stem Fatigue Life Using Structural and Fatigue Analysis" Materials 16, no. 8: 3192. https://doi.org/10.3390/ma16083192