Understanding the Role of Paper-Ink Interactions on the Lightfastness of Thermochromic Prints

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Determination of Surface Roughness

2.3. Printing Trials

2.4. Determination of Lightfastness

2.5. FTIR Spectroscopy

2.6. Colorimetric Spectroscopy

2.7. Fluorescence Spectroscopy

3. Results

3.1. Surface Roughness Analysis

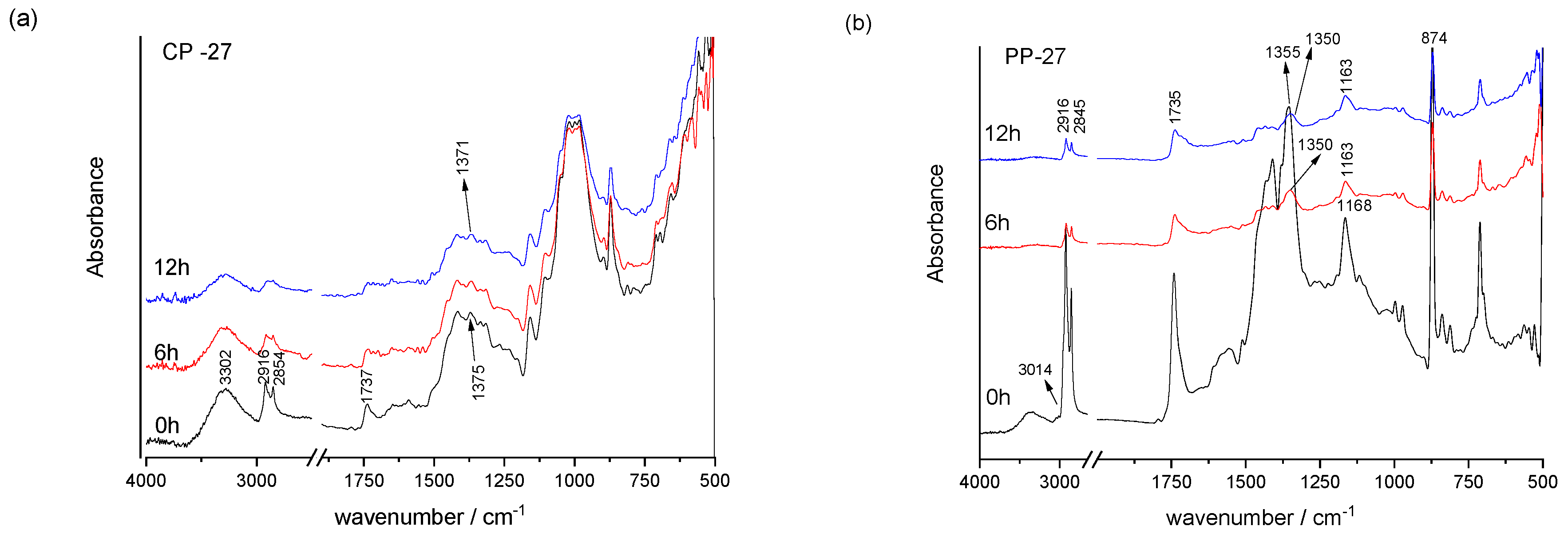

3.2. FTIR Spectroscopy of Thermochromic Ink and Papers

| Band (cm−1) | Assignation | Component |

|---|---|---|

| 3358 | NH stretching | polyurethane |

| 2955–2855 | symmetric and asymmetric CH2 stretching | |

| 1724 | C=O stretching | |

| 1365 | C–N stretching | |

| 1101 | C–O–C stretching | |

| 1531 | C–NH bending | |

| 1617, 1462 | ring stretching of the phenyl moiety | |

| 1636 | double bond (C=C) | acrylates |

| 810, 987, 1408 | deformation of CH2=CH– | |

| 1060, 1190, 1294 | C–O stretching | |

| 1462 | –CH2– bending | polyurethane and acrylate |

| 1271 | C–N and C–O stretching |

| Band (cm−1) | Assignation |

|---|---|

| 3014 | =C-H stretching |

| 2916–2845 | symmetric and asymmetric CH2 stretching |

| 1737–1722 | C=O stretching |

| 1636–1531 | C=C stretching |

| 1463 | CH, CH2 stretching |

| 1234–1100 | C-O-C stretching of the ester functionalities |

| 997 | C–O–C stretching |

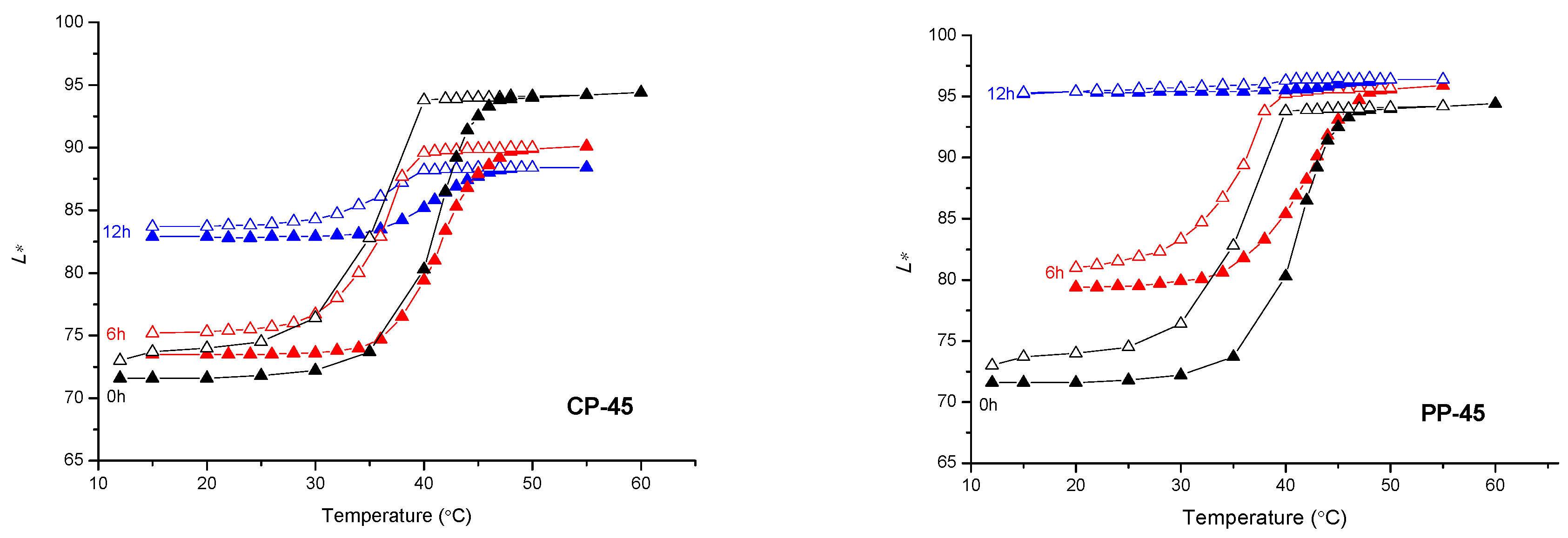

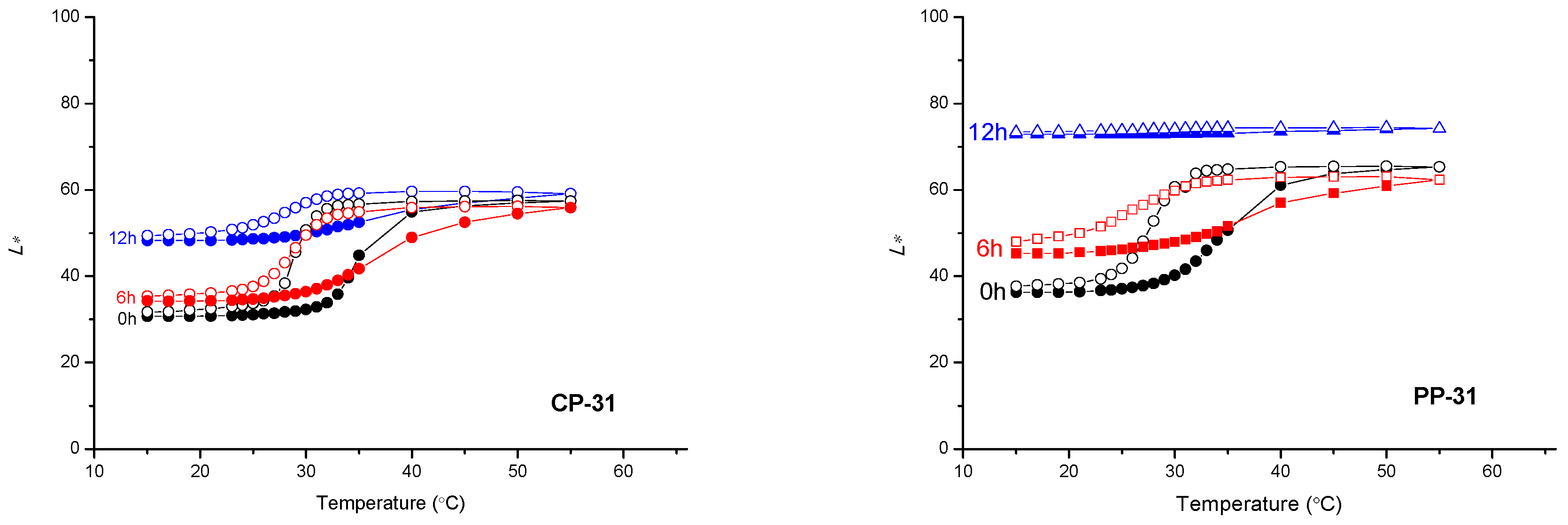

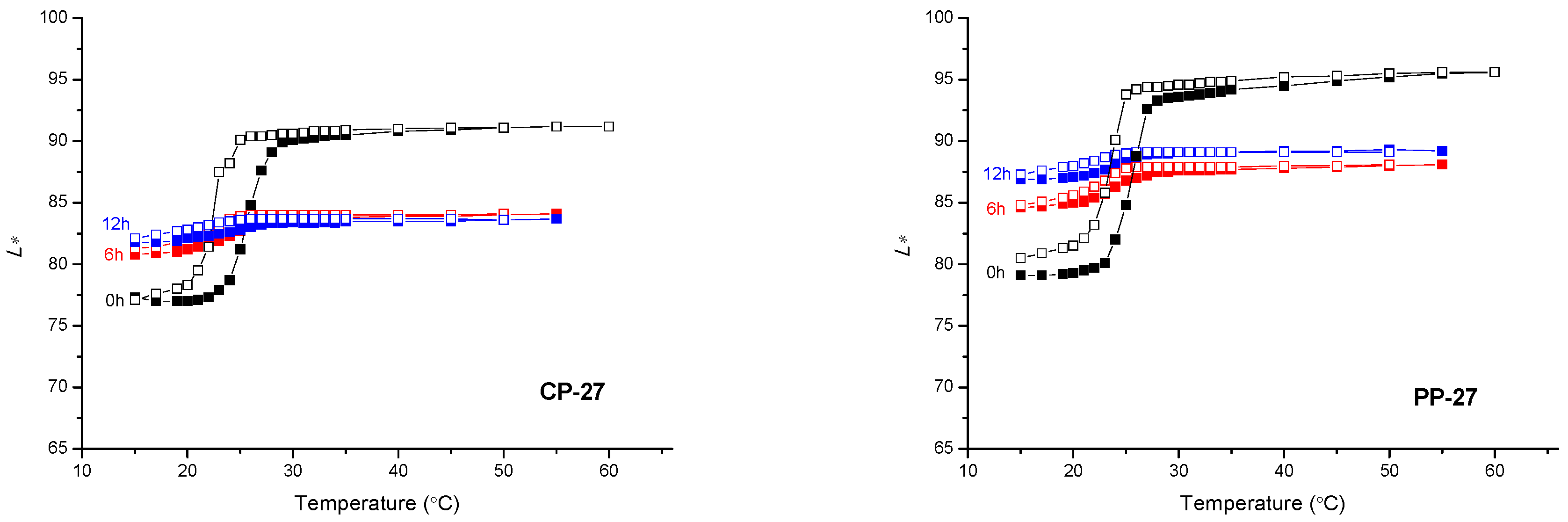

3.3. Colorimetric Properties

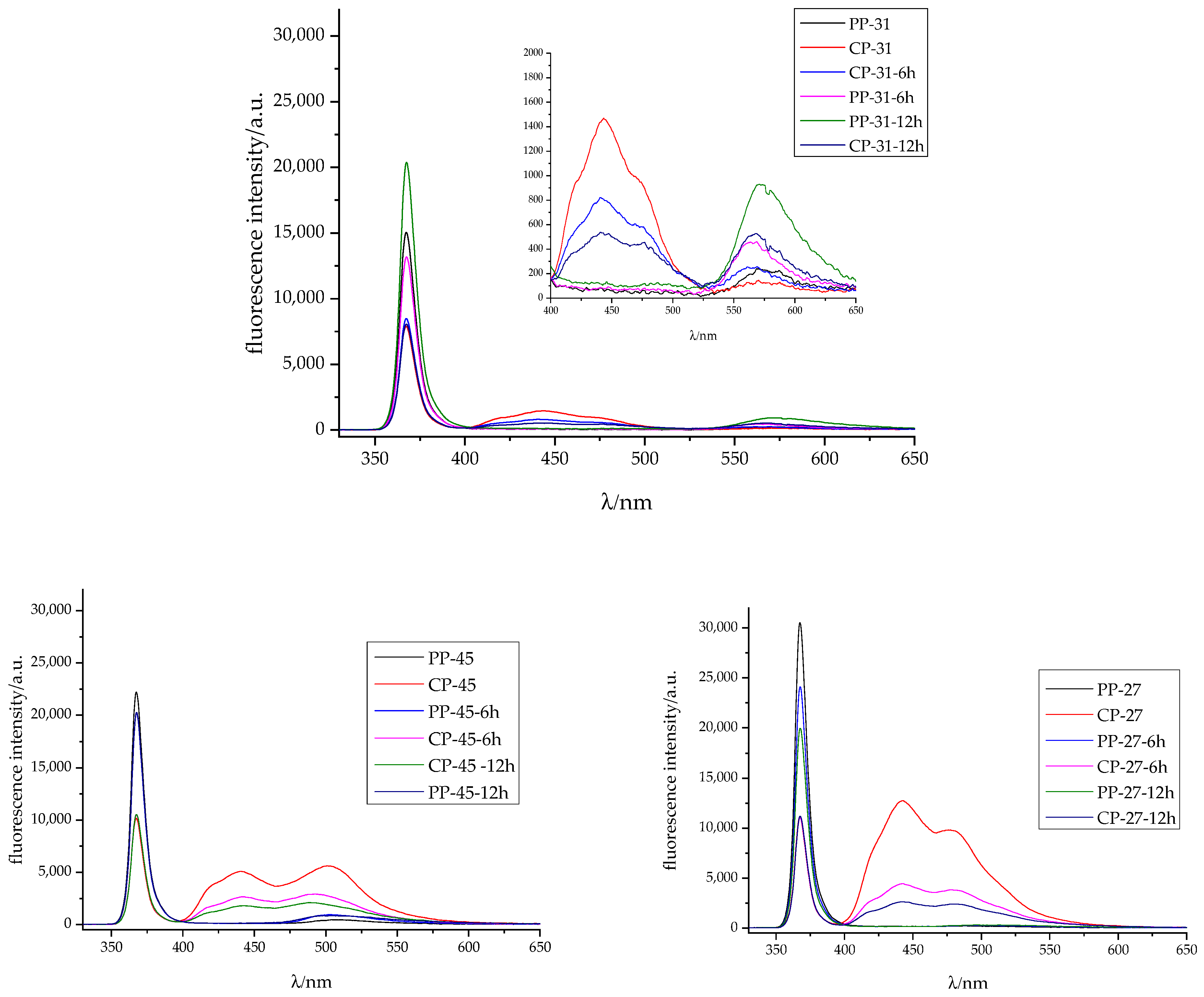

3.4. Fluorescence Spectroscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Johansson, L. Creation of Printed Dynamic Images. Ph.D. Thesis, Linköping University, Linköping, Sweden, 2006. [Google Scholar]

- Alshammari, K.F.; Alrefaei, A.F.; Sayqal, A.; Almahri, A.; Ibarhiam, S.F.; Mogharbel, A.T.; El-Metwaly, N.M. Development of Thermochromic Ink Using the Anthocyanidin-Based Red-Cabbage Extract for Anticounterfeiting Applications. ACS Omega 2022, 7, 48215–48223. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, C.; Chen, S.; Cui, Z.; Zhong, Y. Reversible Thermochromic Ink based on Crystal Violet Lactone/Boric Acid/Hexadecyl Alcohol for Anti-Counterfeiting Printing. J. Imaging Sci. Technol. 2022, 66, 1–7. [Google Scholar] [CrossRef]

- Worbin, L. Designing Dynamic Textile Pattern. Ph.D. Thesis, University of Gothenburg, Gothenburg, Sweden, 2010. [Google Scholar]

- Kooroshnia, M. Leuco Dye-Based Thermochromic Inks: Recipes As a Guide for Designing Textile Surfaces. In Proceedings of the 13th AUTEX World Textile Conference, Dresden, Germany, 22–24 May 2013. [Google Scholar]

- Bamfield, P. Chromic Phenomena: Technological Applications of Colour Chemistry, 2nd ed.; Royal Society of Chemistry: London, UK, 2010. [Google Scholar]

- MacLaren, D.C.; White, M.A. Competition between dye-developer and solvent-developer interactions in a reversible thermochromic system. J. Mater. Chem. 2003, 13, 1701–1704. [Google Scholar] [CrossRef]

- Hakami, A.; Srinivasan, S.S.; Biswas, P.K.; Krishnegowda, A.; Wallen, S.L.; Stefanakos, E.K. Review on thermochromic materials: Development, characterization, and applications. J. Coat. Technol. Res. 2022, 19, 377–402. [Google Scholar] [CrossRef]

- Arman Kandirmaz, E.; Ozcan, A.; Er Ulusoy, D. Production of thermochromic microcapsulated inks for smart packaging and examination of printability properties. Pigment Resin Technol. 2020, 49, 273–281. [Google Scholar] [CrossRef]

- Seeboth, A.; Lotzsch, D. Thermochromic Phenomena in Polymers; Smithers Rapra Technology Limited: Shropshire, UK, 2008. [Google Scholar]

- Liu, B.; Rasines Mazo, A.; Gurr, P.A.; Qiao, G.G. Reversible Nontoxic Thermochromic Microcapsules. ACS Appl. Mater. Interfaces 2020, 12, 9782–9789. [Google Scholar] [CrossRef]

- Bourque, A.N.; White, M.A. Control of thermochromic behaviour in crystal violet lactone (CVL)/alkyl gallate/alcohol ternary mixtures. Can. J. Chem. 2014, 93, 22–31. [Google Scholar] [CrossRef]

- Hajzeri, M.; Bašnec, K.; Bele, M.; Klanjšek Gunde, M. Influence of developer on structural, optical and thermal properties of a benzofluoran-based thermochromic composite. Dyes Pigm. 2015, 113, 754–762. [Google Scholar] [CrossRef]

- Seeboth, A.; Klukowska, A. Thermochromic polymer materials. Chin. J. Polym. Sci. 2007, 25, 123–135. [Google Scholar]

- Friškovec, M.; Kulčar, R.; Klanjšek Gunde, M. Advances in Printing and Media Technology. In Proceedings of the 37th International Research Conference of Iarigai, Montreal, QC, Canada, 12–15 September 2010; pp. 1–7. [Google Scholar]

- Cabral, I.D.; Souto, A.P.; Worbin, L. Dynamic Light Filters; Springer: Florença, Italy, 2020. [Google Scholar]

- Seeboth, A.; Lo, D.; Ruhmann, R.; Muehling, O. Thermochromic Polymers—Function by Design. Chem. Rev. 2014, 114, 3037–3068. [Google Scholar]

- Friškovec, M.; Kulčar, R.; Klanjšek Gunde, M. Light fastness and high-temperature stability of thermochromic printing inks. Color. Technol. 2013, 129, 214–222. [Google Scholar] [CrossRef]

- Jamnicki Hanzer, S.; Kulčar, R.; Vukoje, M.; Marošević Dolovski, A. Assessment of Thermochromic Packaging Prints ’ Resistance to UV Radiation and Various Chemical Agents. Polymers 2023, 15, 1208. [Google Scholar] [CrossRef]

- Pugh, S.L.; Guthrie, J.T. Some characteristics of pigments that affect the kinetics of fading of prints made from water-based liquid ink formulations. Dyes Pigm. 2002, 55, 109–121. [Google Scholar] [CrossRef]

- Oda, H. Photostabilization of organic thermochromic pigments: Action of benzotriazole type UV absorbers bearing an amphoteric counter-ion moiety on the light fastness of color formers. Dyes Pigm. 2008, 76, 270–276. [Google Scholar] [CrossRef]

- Oda, H. New developments in the stabilization of leuco dyes: Effect of UV absorbers containing an amphoteric counter-ion moiety on the light fastness of color formers. Dyes Pigm. 2005, 66, 103–108. [Google Scholar] [CrossRef]

- Oda, H. Photostabilization of organic thermochromic pigments. Part 2: Effect of hydroxyarylbenzotriazoles containing an amphoteric counter-ion moiety on the light fastness of color formers. Dyes Pigm. 2008, 76, 400–405. [Google Scholar] [CrossRef]

- Vukoje, M.; Kulčar, R.; Itrić Ivanda, K.; Bota, J.; Cigula, T. Improvement in Thermochromic Offset Print UV Stability by Applying PCL Nanocomposite Coatings. Polymers 2022, 14, 1484. [Google Scholar] [CrossRef]

- Friškovec, M.; Kulčar, R.; Hauptman, N.; Klanjšek Gunde, M. Ultraviolet protection of thermochromic printings. In Proceedings of the 5th International Symposium on Novelities in Graphics, Ljubljana, Slovenia, 27–29 May 2010. [Google Scholar]

- Kulčar, R.; Vukoje, M.; Krajnović, I.; Rožić, M. Influence of recycled fibres in paper on the UV stability of thermochromic prints. In Proceedings of the 10th International Symposium GRID 2020, Department of Graphic Engineering and Design, Faculty of Technical Sciences, University of Novi Sad, Novi Sad, Serbia, 13–14 November 2020; pp. 161–168. [Google Scholar]

- ISO 187:2022; Paper, Board and Pulps—Standard Atmosphere for Conditioning and Testing and Procedure for Monitoring the Atmosphere and Conditioning of Samples. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- European Organisation for Tehnical Approval (EOTA). Exposure Procedure for Artificial Weathering—TR 010; EOTA: Brussels, Belgium, 2004. [Google Scholar]

- ASTM D3424-09; ASTM International. Standard Test Methods for Evaluating the Relative Lightfastness and Weatherability of Printed Mater. ASTM Internationa: West Conshohocken, PA, USA, 2010; pp. 1–5.

- CIE Central Bureau. Colorimetry, 3rd ed.; CIE Central Bureau: Vienna, Austria, 2004. [Google Scholar]

- Ciolacu, D.; Ciolacu, F.; Popa, V.I. Amorphous Cellulose—Structure and Characterization. Cellul. Chem. Technol. 2011, 45, 13–21. [Google Scholar] [CrossRef]

- Łojewski, T.; Miśkowiec, P.; Molenda, M.; Lubańska, A.; Łojewska, J. Artificial versus natural ageing of paper. Water role in degradation mechanisms. Appl. Phys. A Mater. Sci. Process. 2010, 100, 625–633. [Google Scholar] [CrossRef]

- Ferreira, P.J.; Gamelas, A.; Moutinho, I.M.; Ferreira, A.G.; Go, N.; Molleda, C.; Figueiredo, M.M. Application of FT-IR-ATR Spectroscopy to Evaluate the Penetration of Surface Sizing Agents into the Paper Structure. Ind. Eng. Chem. Res. 2009, 48, 3867–3872. [Google Scholar]

- Grilj, S.; Klanjšek Gunde, M.; Szentgyörgyvölgyi, R.; Gregor-Svetec, D. FT-IR and UV/VIS analysis of classic and recycled papers. Papíripar 2012, 56, 7–13. [Google Scholar]

- Fardim, P.; Durán, N. Effects of kraft pulping on the interfacial properties of Eucalyptus pulp fibres. J. Braz. Chem. Soc. 2005, 16, 915–921. [Google Scholar] [CrossRef]

- Gopanna, A.; Mandapati, R.N.; Thomas, S.P.; Rajan, K.; Chavali, M. Fourier transform infrared spectroscopy (FTIR), Raman spectroscopy and wide-angle X-ray scattering (WAXS) of polypropylene (PP)/cyclic olefin copolymer (COC) blends for qualitative and quantitative analysis. Polym. Bull. 2019, 76, 4259–4274. [Google Scholar] [CrossRef]

- Vukoje, M.; Miljanić, S.; Hrenović, J.; Rožić, M. Thermochromic ink–paper interactions and their role in biodegradation of UV curable prints. Cellulose 2018, 25, 6121–6138. [Google Scholar] [CrossRef]

- Vukoje, M.; Kulčar, R.; Itrić, K.; Rožić, M. Spectroscopic evaluation of thermochromic printed cardboard biodegradation. In Proceedings of the Ninth International Symposium GRID, nNovi Sad, Srbija, 17–19 December 2018; pp. 87–96. [Google Scholar]

- Rožić, M.; Šegota, N.; Vukoje, M.; Kulčar, R.; Šegota, S. Description of Thermochromic Offset Prints Morphologies Depending on Printing Substrate. Appl. Sci. 2020, 10, 8095. [Google Scholar] [CrossRef]

- Gómez, N.; Molleda, C.; Quintana, E.; Carbajo, J.M.; Rodríguez, A.; Villar, J.C. Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR FT-IR) Applied to Study the Distribution of Ink Components in Printed Newspapers. Appl. Spectrosc. 2016, 70, 1537–1545. [Google Scholar] [CrossRef]

- Sherazi, S.T.H.; Talpur, M.Y.; Mahesar, S.A.; Kandhro, A.A.; Arain, S. Main fatty acid classes in vegetable oils by SB-ATR-Fourier transform infrared (FTIR) spectroscopy. Talanta 2009, 80, 600–606. [Google Scholar] [CrossRef]

- Lerma-García, M.J.; Ramis-Ramos, G.; Herrero-Martínez, J.M.; Simó-Alfonso, E.F. Authentication of extra virgin olive oils by Fourier-transform infrared spectroscopy. Food Chem. 2010, 118, 78–83. [Google Scholar] [CrossRef]

- Vukoje, M.; Rožić, M.; Miljanić, S.; Pasanec Preprotić, S. Biodegradation of thermochromic offset prints. Nord. Pulp Pap. Res. J. 2017, 32, 289–298. [Google Scholar] [CrossRef]

- Vlachos, N.; Skopelitis, Y.; Psaroudaki, M.; Konstantinidou, V.; Chatzilazarou, A.; Tegou, E. Applications of Fourier transform-infrared spectroscopy to edible oils. Anal. Chim. Acta 2006, 573–574, 459–465. [Google Scholar] [CrossRef]

- Koivula, H.; Preston, J.S.; Heard, P.J.; Toivakka, M. Visualisation of the distribution of offset ink components printed onto coated paper. Colloids Surf. A Physicochem. Eng. Asp. 2008, 317, 557–567. [Google Scholar] [CrossRef]

- Vijayan, J.G.; Chandrashekar, A.; AG, J.; Prabhu, T.N.; Kalappa, P. Polyurethane and its composites derived from bio-sources: Synthesis, characterization and adsorption studies. Polym. Polym. Compos. 2022, 30, 1–18. [Google Scholar] [CrossRef]

- Oprea, S.; Potolinca, V.O.; Gradinariu, P.; Joga, A.; Oprea, V. Synthesis, properties, and fungal degradation of castor-oil-based polyurethane composites with different cellulose contents. Cellulose 2016, 23, 2515–2526. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, W.; Wang, X.; Mu, Y. Effect of average functionality on properties of UV-curable waterborne polyurethane-acrylate. Prog. Org. Coat. 2010, 68, 201–207. [Google Scholar] [CrossRef]

- Merlatti, C.; Perrin, F.X.; Aragon, E.; Margaillan, A. Natural and artificial weathering characteristics of stabilized acrylic-urethane paints. Polym. Degrad. Stab. 2008, 93, 896–903. [Google Scholar] [CrossRef]

- Oprea, S.; Doroftei, F. Biodegradation of polyurethane acrylate with acrylated epoxidized soybean oil blend elastomers by Chaetomium globosum. Int. Biodeterior. Biodegrad. 2011, 65, 533–538. [Google Scholar] [CrossRef]

- Hu, J.; Li, X.; Gao, J.; Zhao, Q. Ageing behavior of acrylic polyurethane varnish coating in artificial weathering environments. Prog. Org. Coat. 2009, 65, 504–509. [Google Scholar] [CrossRef]

- Bénard, F.; Mailhot, B.; Mallégol, J.; Gardette, J.L. Photoageing of an electron beam cured polyurethane acrylate resin. Polym. Degrad. Stab. 2008, 93, 1122–1130. [Google Scholar] [CrossRef]

- Munajad, A.; Subroto, C. Fourier transform infrared (FTIR) spectroscopy analysis of transformer paper in mineral oil-paper composite insulation under accelerated thermal aging. Energies 2018, 11, 364. [Google Scholar] [CrossRef]

- Gomez, N.A.; Abonia, R.; Cadavid, H.; Vargas, I.H. Chemical and spectroscopic characterization of a vegetable oil used as dielectric coolant in distribution transformers. J. Braz. Chem. Soc. 2011, 22, 2292–2303. [Google Scholar] [CrossRef]

- Abbott, P.S. Printing Science: Principles and Practice. 2018. Available online: https://www.stevenabbott.co.uk/_downloads/Printing%20Science%20Principles%20and%20Practice.pdf (accessed on 8 January 2023).

- Vanhanen, J.; Rinkiö, M.; Aumanen, J.; Korppi-Tommola, J.; Kolehmainen, E.; Kerkkänen, T.; Törmä, P. Characterization of used mineral oil condition by spectroscopic techniques. Appl. Opt. 2004, 43, 4718–4722. [Google Scholar] [CrossRef]

- Kyriakidis, B.N.; Skarkalis, P. Fluorescence Spectra Measurement of Olive Oil and Other Vegetable Oils. J. AOAC Int. 2000, 83, 1435–1439. [Google Scholar]

- Wolfbeis, O.S.; Leiner, M. Charakterisierung von Speiseölen mit Hilfe der Fluoreszenztopographie-(Fluorimetrische analyse, X)1. Mikrochim. Acta 1984, 82, 221–233. [Google Scholar] [CrossRef]

- Zandomeneghi, M.; Carbonaro, L.; Caffarata, C. Fluorescence of vegetable oils: Olive oils. J. Agric. Food Chem. 2005, 53, 759–766. [Google Scholar] [CrossRef]

- Guimet, F.; Ferré, J.; Boqué, R. Rapid detection of olive-pomace oil adulteration in extra virgin olive oils from the protected denomination of origin “Siurana” using excitation-emission fluorescence spectroscopy and three-way methods of analysis. Anal. Chim. Acta 2005, 544, 143–152. [Google Scholar] [CrossRef]

- Sikorska, E.; Romaniuk, A.; Khmelinskii, I.V.; Herance, R.; Bourdelande, J.L.; Sikorski, M.; Koziol, J. Characterization of Edible Oils Using Total Luminescence Spectroscopy. J. Fluoresc. 2004, 14, 25–35. [Google Scholar]

| Sample Abbreviation | Colour | TA, °C | Printing Technique | Drying Media | Drying Mechanism |

|---|---|---|---|---|---|

| TC45 | green to yellow | 45 | offset | Air | Oxypolymerization |

| TC31 | purple to pink | 31 | screen | UV | UV curing |

| TC27 | blue to colourless | 27 | offset | Air | Penetration/Oxypolymerization |

| Printing Substrate | Roughness/µm | |||

|---|---|---|---|---|

| Unprinted | TC27 | TC45 | TC31 | |

| CP | 4.01 ± 0.39 | 3.59 ± 0.31 | 3.74 ± 0.21 | 1.78 ± 0.24 |

| PP | 0.35 ± 0.05 | 0.33 ± 0.02 | 0.34 ± 0.03 | 0.23 ± 0.06 |

| Sample | Tmax (°C) | CIEDE2000max | TCC, Original | TCC, after 6 h | TCC, after 12 h |

|---|---|---|---|---|---|

| CP-31 | 32 | 28.8 | 34.8 | 29.6 | 14.6 |

| PP-31 | 30 | 27.2 | 38.4 | 21.6 | 1.3 |

| CP-45 | 40 | 16.3 | 24.3 | 19.7 | 19 |

| PP-45 | 40 | 15.3 | 25.5 | 20.1 | 2.9 |

| CP-27 | 25 | 11.4 | 17.6 | 4.5 | 2.4 |

| PP-27 | 25 | 10.9 | 19.7 | 6.1 | 3.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulčar, R.; Vukoje, M.; Itrić Ivanda, K.; Cigula, T.; Jamnicki Hanzer, S. Understanding the Role of Paper-Ink Interactions on the Lightfastness of Thermochromic Prints. Materials 2023, 16, 3225. https://doi.org/10.3390/ma16083225

Kulčar R, Vukoje M, Itrić Ivanda K, Cigula T, Jamnicki Hanzer S. Understanding the Role of Paper-Ink Interactions on the Lightfastness of Thermochromic Prints. Materials. 2023; 16(8):3225. https://doi.org/10.3390/ma16083225

Chicago/Turabian StyleKulčar, Rahela, Marina Vukoje, Katarina Itrić Ivanda, Tomislav Cigula, and Sonja Jamnicki Hanzer. 2023. "Understanding the Role of Paper-Ink Interactions on the Lightfastness of Thermochromic Prints" Materials 16, no. 8: 3225. https://doi.org/10.3390/ma16083225