Measurement and Analysis of Magnetic Properties of Permalloy for Magnetic Shielding Devices under Different Temperature Environments

Abstract

:1. Introduction

2. Measuring Principle of Permalloy’s Magnetic Properties

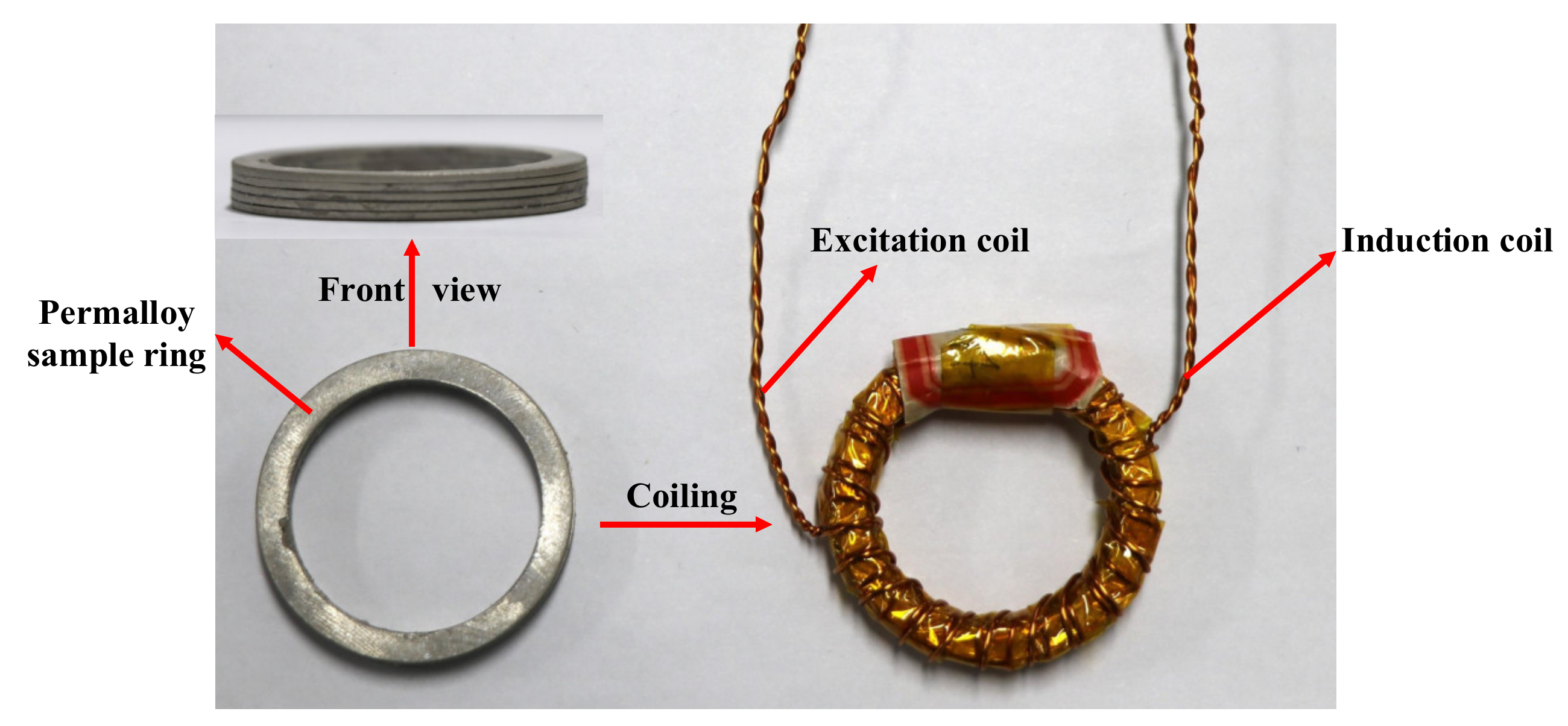

2.1. Dimension Parameters of Permalloy

2.2. Measuring of Permalloy’s Magnetic Properties

3. Measurement Results and Discussion

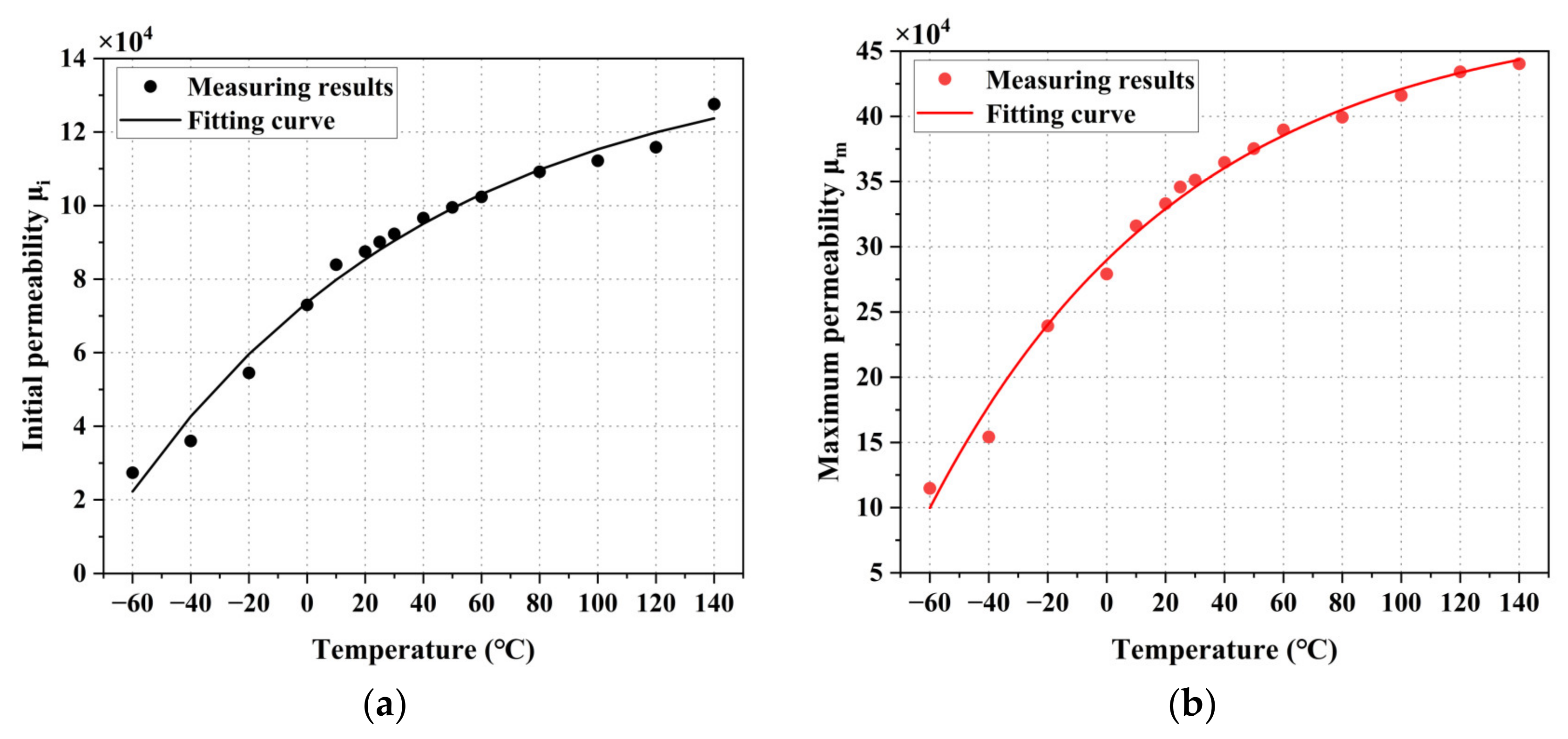

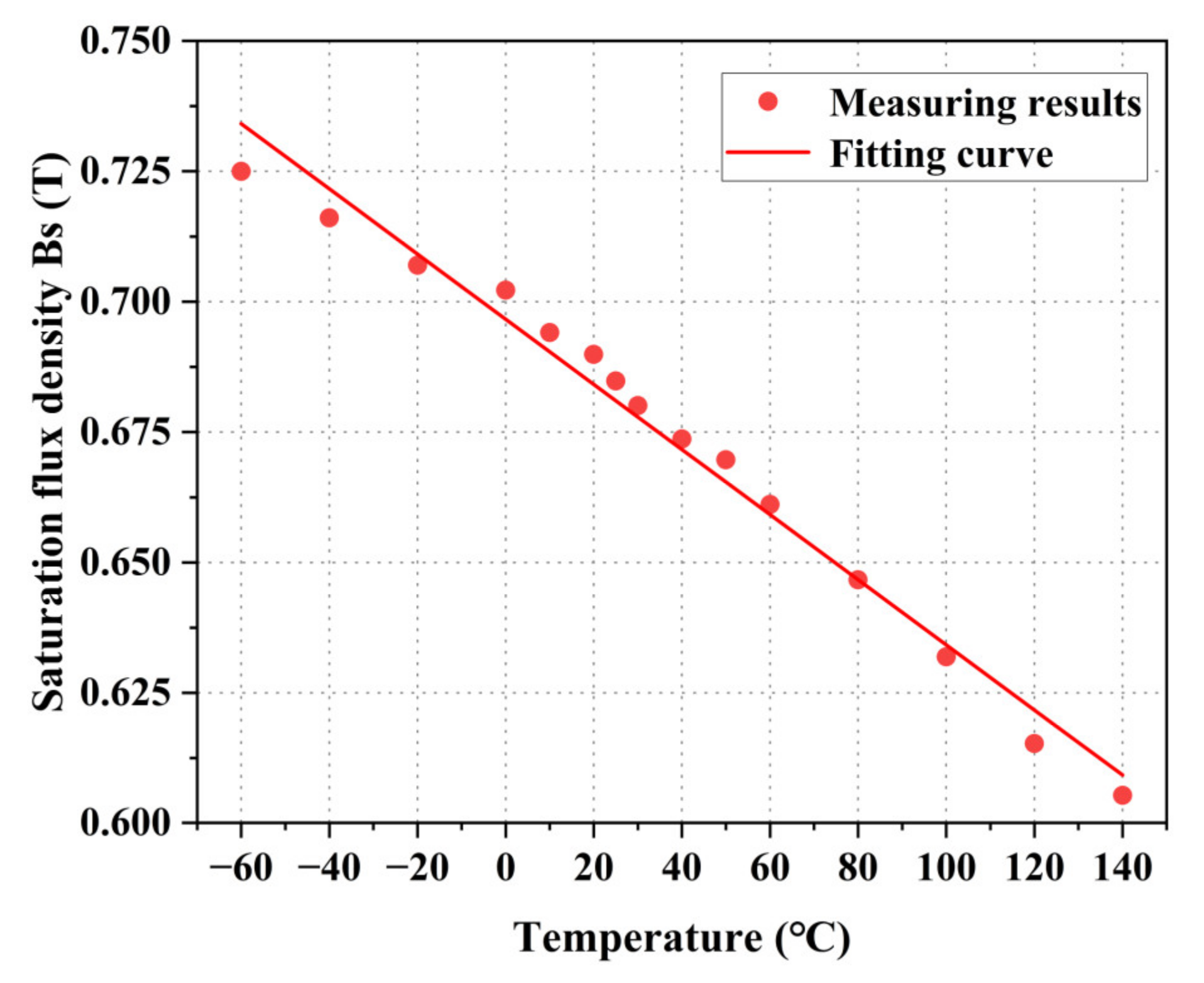

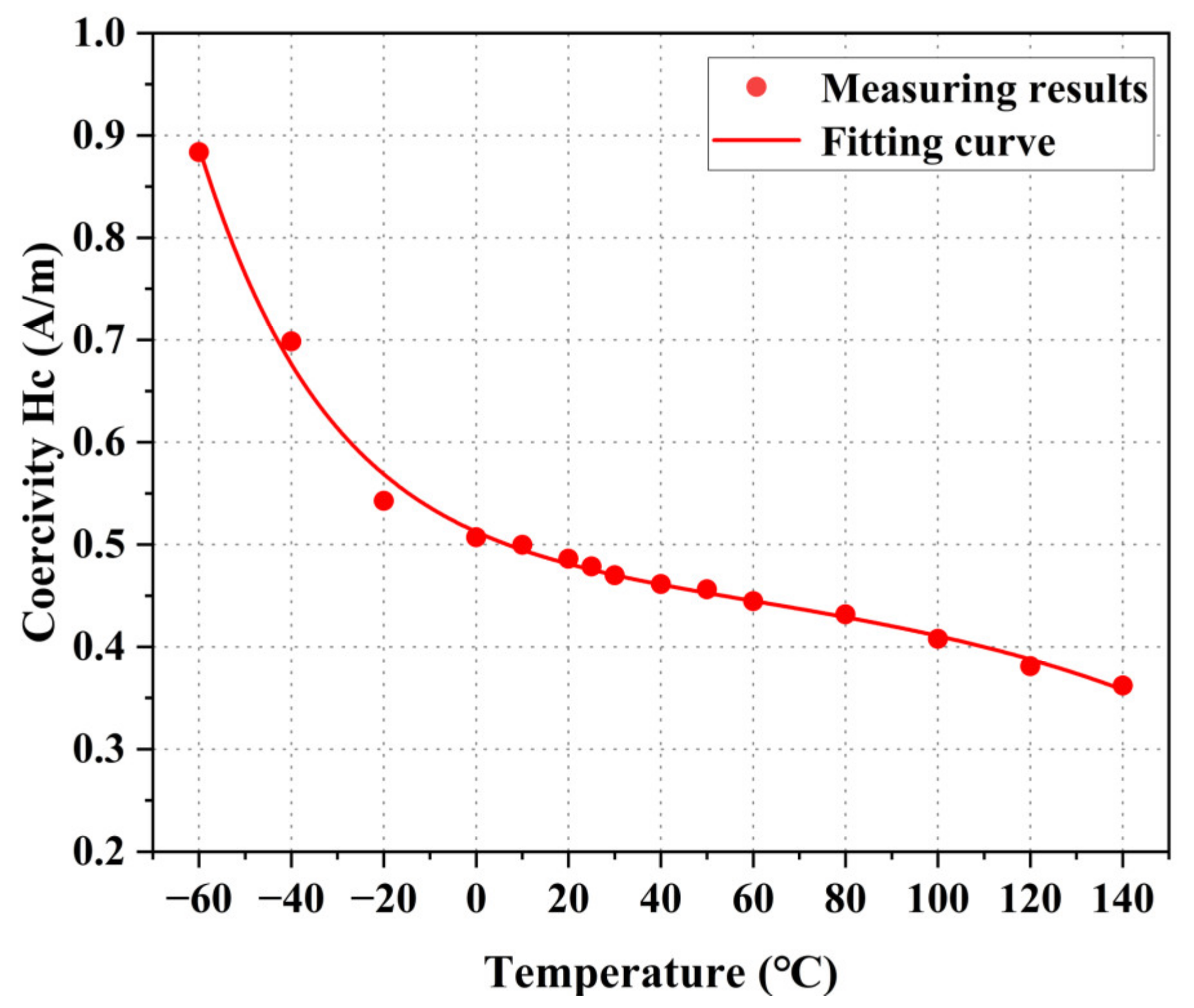

3.1. Measurement of Magnetic Properties at Different Temperatures

- (1)

- Calculate the required number of excitation and induction coil turns based on the sample ring size information and perform winding;

- (2)

- Place the wrapped sample ring into a high and low temperature box and affix a temperature sensor;

- (3)

- Open the material magnetic property measuring instrument, preheat for 20 min, and connect the sample to the material magnetic property measuring instrument;

- (4)

- Conduct a temperature rise experiment, and then change to a temperature drop experiment. When the temperature of the incubator reaches the specified temperature, wait for 20 min to observe whether the temperature of the sample temperature sensor is stable at the desired temperature. When stable, conduct a measurement;

- (5)

- Measure the magnetization curve and hysteresis loop of the material at the set ambient temperature point, and then calculate magnetic properties such as permeability.

3.2. Analysis of Measurement Results

3.3. Discussion

- 1.

- The relative permeability and coercivity of permalloy are closely related to the internal stress of the material. As the temperature increases, the internal stress in the permalloy is gradually released, so the relative magnetic permeability and coercive force of the permalloy gradually decrease with the increase in temperature.

- 2.

- The saturation flux density is mainly determined by the saturation magnetization strength . When the temperature is much lower than the Curie temperature of the alloy, the saturation magnetization is similar to the spontaneous magnetization. According to Weiss molecular field theory, a ferromagnet can be equivalent to paramagnetic matter in a huge molecular field, and all atomic magnetic moments tend to be in the same direction, so it can be expressed by the Brillouin function [27,28,29]. Therefore, its saturation magnetization can be expressed by Equation (8) [30]:where is the number of atoms; is the Lande factor; is the total atomic angular momentum; and is a Bohr magneton.

- 3.

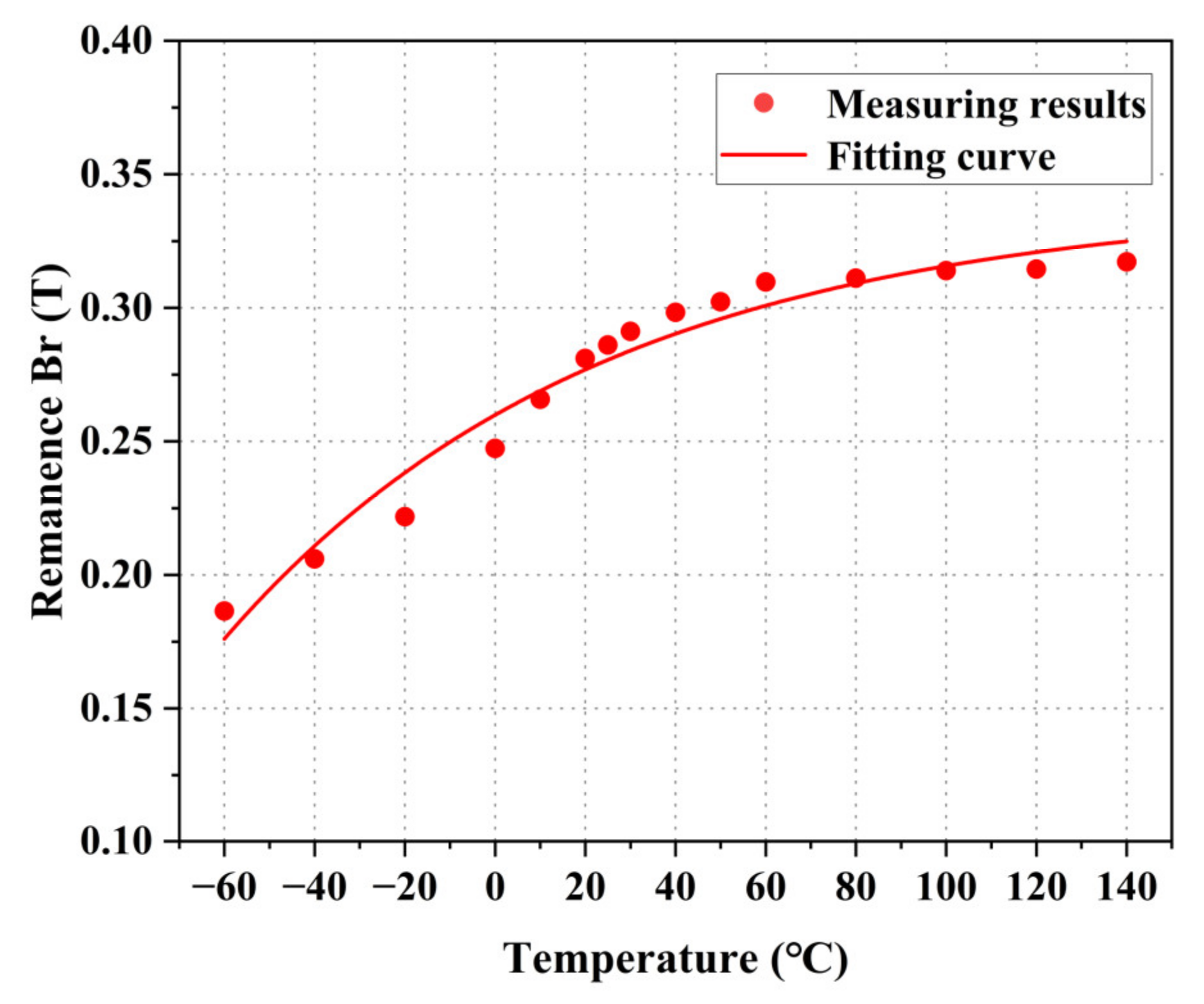

- According to the Weiss molecular field theory, with the increase in temperature, the thermal motion in permalloy increases, which makes the atomic magnetic distances tend to be disordered, leading to an increase in the remanence in permalloy.

- 4.

- In [19], the relative permeability of the electrical steel at 30 °C and 128 °C was analyzed, which increased with increasing temperature. In [20], the relationship between the magnetic properties of ferrite (N87), nanocrystalline (1k107B), and amorphous alloy (1k101) at temperatures ranging from 25 °C to 150 °C was analyzed. The saturation flux density of the three materials decreased with increasing temperature, while the coercivity of nanocrystalline (1k107B) first decreased and then increased with increasing temperature. In [23], the coercivity and saturation flux density of NiFe2O4 ferrite material were analyzed at 27 °C to 150 °C, both of which decreased with increasing temperature. The relationship between the relative permeability, coercivity, and saturation flux density of magnetic materials and temperature is similar to that of this study, proving the correctness of the discussion.

4. Conclusions

- The initial permeability () improves with the increase in temperature as an exponential function, which decreases by 69.64% at −60 °C and increases by 38.23% at 140 °C.

- The maximum permeability () improves with the increase in temperature as an exponential function, which decreases by 38.23% at −60 °C and increases by 25.39% at 140 °C.

- The saturation flux density () recedes with the increase in temperature as a linear function, which increases by 5.87% at −60 °C and decreases by 11.01% at 140 °C.

- The remanence () improves with the increase in temperature as a function of the second-order exponential decay function, which increases by 84.64% at −60 °C and decreases by 22.91% at 140 °C.

- The coercivity () recedes with the increase in temperature as an exponential function, which decreases by 34.81% at −60 °C and increases by 8.93% at 140 °C.

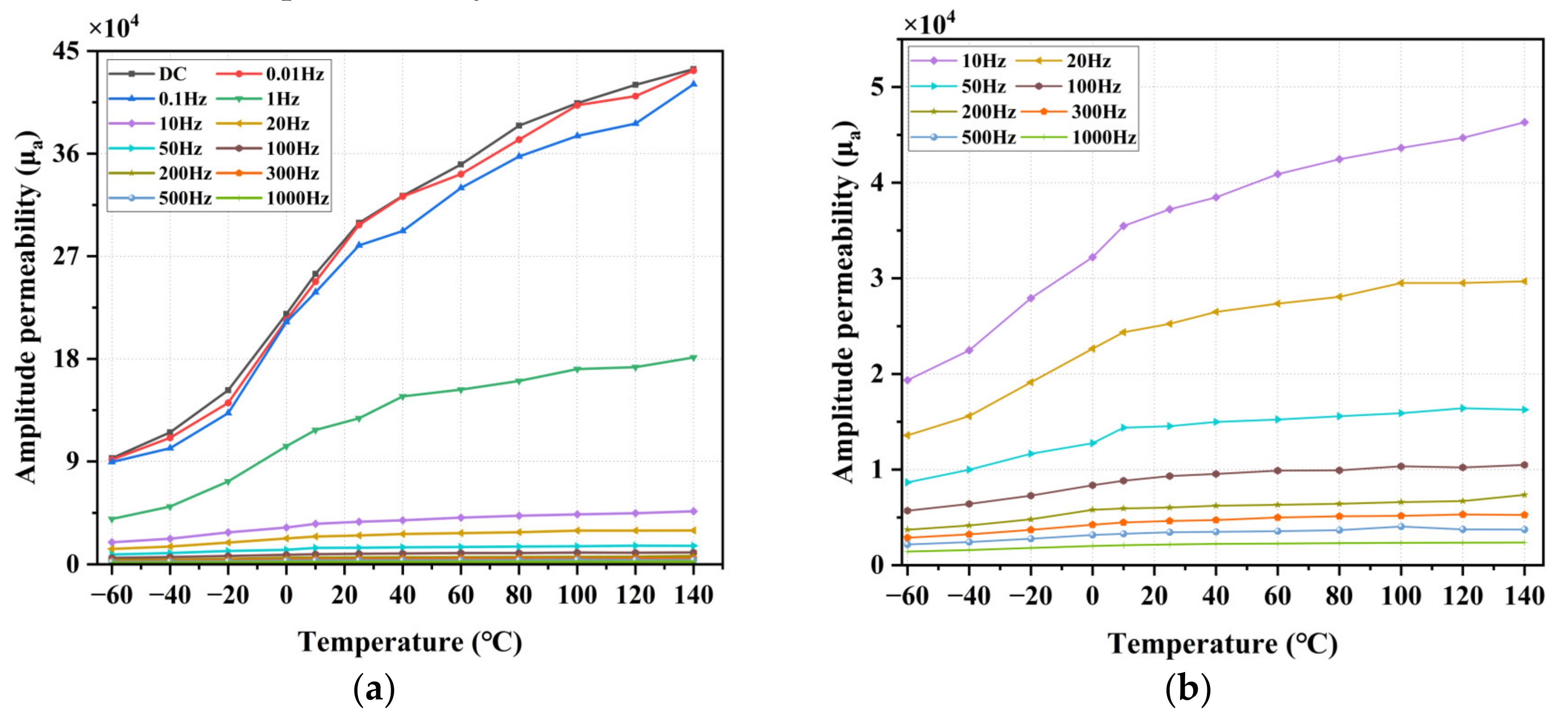

- The AC amplitude permeability () improves with the increase in temperature; it decreases by 69.2% at −60 °C and increases by 45.51% at 140 °C at a frequency of 0.01 Hz, and it decreased by 12.27% at −60 °C and increased by 9.37% at 140 °C at a frequency of 1 kHz. It proves that compared with a higher frequency, the becomes sensitive to temperature changes at a lower frequency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baillet, S. Magnetoencephalography for brain electrophysiology and imaging. Nat. Neurosci. 2017, 20, 327–339. [Google Scholar] [CrossRef] [PubMed]

- Kimball, D.F.J.; Dudley, J.; Li, Y.; Thulasi, S.; Pustelny, S.; Budker, D.; Zolotorev, M. Magnetic shielding and exotic spin-dependent interactions. Phys. Rev. D 2016, 94, 082005. [Google Scholar] [CrossRef]

- Fan, W.; Liu, G.; Li, R.; Quan, W.; Jiang, L.; Duan, L. A three-axis atomic magnetometer for temperature-dependence measurements of fields in a magnetically shielded environment. Meas. Sci. Technol. 2017, 28, 095007. [Google Scholar] [CrossRef]

- Pizzo, F.; Roehri, N.; Villalon, S.M.; Trebuchon, A.; Chen, S.; Lagarde, S.; Carron, R.; Gavaret, M.; Giusiano, B.; McGonigal, A.; et al. Deep brain activities can be detected with magnetoencephalography. Nat. Neurosci. 2021, 12, 971. [Google Scholar] [CrossRef] [PubMed]

- Chupp, T.; Fierlinger, P.; Ramsey-Musolf, M.; Singh, J. Electric Dipole Moments of the Atoms, Molecules, Nuclei and Particles. Rev. Modern Phys. 2017, 91, 015001. [Google Scholar] [CrossRef]

- Colherinhas, G. Updating atomic charge parameters of aliphatic amino acids: A quest to improve the performance of molecular modeling via sequential molecular dynamics and DFT-GIAO-NMR calculations. Phys. Chem. Chem. Phys. 2021, 23, 8413–8425. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.N.; Lu, J.X.; Yang, K.; Wang, Z.X.; Wang, Y.G.; Sun, B.W.; Zhai, Y.Y.; Han, B.C. Measuring Spin Polarization of a Spin-Exchange Relaxation-Free Atomic Magnetometer at Extremely Large Optical Depths. IEEE Trans. Instrum. Meas. 2022, 71, 22113440. [Google Scholar] [CrossRef]

- Li, Y.; Xu, J.; Kang, X.Y.; Fan, Z.K.; Dong, X.M.; Gao, X.M.; Zhuang, S.L. Design of highly uniform three-dimensional square magnetic field coils for external magnetic shielding of magnetometers. Sens. Actuators A 2021, 331, 113037. [Google Scholar] [CrossRef]

- Fang, X.; Ma, D.; Sun, B.; Xu, X.; Quan, W.; Xiao, Z.; Zhai, Y. A High-Performance Magnetic Shield with MnZn Ferrite and Mu-Metal Film Combination for Atomic Sensors. Materials 2022, 15, 6680. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Fierlinger, P.; Han, J.C.; Li, L.Y.; Liu, T.H.; Schnabel, A.; Stuiber, S.; Voigt, J. Limits of Low Magnetic Field Environments in Magnetic Shields. IEEE Trans. Ind. Electron. 2021, 68, 5385–5395. [Google Scholar] [CrossRef]

- Ma, D.Y.; Lu, J.X.; Fang, X.J.; Dou, Y.; Wang, K.; Gao, Y.A.; Li, S.R.; Han, B.C. A novel low-noise Mu-metal magnetic shield with winding shape. Sens. Actuators A 2022, 346, 113884. [Google Scholar] [CrossRef]

- Hussain, S.; Benabou, A.; Clenet, S.; Lowther, D.A. Temperature Dependence in the Jiles-Atherton Model for Non-Oriented Electrical Steels: An Engineering Approach. IEEE Trans. Magn. 2018, 54, 18191683. [Google Scholar] [CrossRef]

- Nie, K.; Wu, W.P.; Zhang, X.L.; Yang, S.M. Molecular dynamics study on the grain size, temperature, and stress dependence of creep behavior in nanocrystalline nickel. J. Mater. Sci. 2017, 52, 2180–2191. [Google Scholar] [CrossRef]

- Li, C.; Tang, Z.J.; Lin, G.D.; Lin, S.Z.; Huang, Q.H. Modeling the Temperature Dependence of Minor Hysteresis Loops in Ferromagnetic Materials. In Proceedings of the IEEE International Conference on Electronic Information and Communication Technology (ICEICT), Harbin, China, 20–22 August 2016; pp. 505–508. [Google Scholar]

- Nouicer, A.; Nouicer, E.; Mouloud, F. A neural network for incorporating the thermal effect on the magnetic hysteresis of the 3F3 material using the Jiles-Atherton model. J. Magn. Magn. Mater. 2015, 373, 240–243. [Google Scholar] [CrossRef]

- Zou, S.; Zhang, H.; Chen, X.Y.; Fang, J.C. In-situ triaxial residual magnetic field measurement based on optically-detected electron paramagnetic resonance of spin-polarized potassium. Measurement 2022, 187, 110338. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, C.; Yuan, H.; Yin, K.F.; Yang, Y.; Yan, Y.G.; Wang, Y.X.; Zhou, B.Q.; Ning, X.L.; Han, B.C. Indium Tin Oxide Non-Magnetic Heating Film for Miniaturized SERF Gradient Magnetometer. IEEE Sens. J. 2021, 21, 16554–165593. [Google Scholar] [CrossRef]

- Mei, Y.; Xu, L.L. Research on Seasonal Thermal Neutral Temperature in West Lake Scenic Area of Hangzhou, China. Int. J. Environ. Res. Public Health 2022, 19, 14677. [Google Scholar] [CrossRef]

- Xiao, L.J.; Yu, G.D.; Zou, J.B.; Xu, Y.X.; Liang, W.Y. Experimental analysis of magnetic properties of electrical steel sheets under temperature and pressure coupling environment. J. Magn. Magn. Mater. 2019, 475, 282–289. [Google Scholar] [CrossRef]

- Yang, M.; Li, Y.J.; Yang, Q.X.; Lin, Z.W.; Yue, S.C.; Wang, H.M.; Liu, C.C. Magnetic Properties Measurement and Analysis of High Frequency Core Materials Considering Temperature Effect. IEEE Trans. Appl. Supercond. 2020, 30, 19464487. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, Q.; Li, Y.; Lin, Z.; Yang, M. Temperature Dependence of Powder Cores Magnetic Properties for Medium-Frequency Applications. IEEE Trans. Magn. 2022, 58, 21531074. [Google Scholar] [CrossRef]

- Bukreev, D.A.; Derevyanko, M.S.; Moiseev, A.A.; Semirov, A.V.; Savin, P.A.; Kurlyandskaya, G.V. Magnetoimpedance and Stress-Impedance Effects in Amorphous CoFeSiB Ribbons at Elevated Temperatures. Materials 2020, 13, 3216. [Google Scholar] [CrossRef] [PubMed]

- Dafri, M.; Ladjimi, A.; Mendaci, S.; Babouri, A. Phenomenological Model of the Temperature Dependence of Hysteresis Based on the Preisach Model. J. Supercond. Novel Magn. 2021, 34, 1453–1458. [Google Scholar] [CrossRef]

- Brialmont, S.; Fagnard, J.F.; Vanderheyden, B.; Mazaleyrat, F.; Hahn, S.; Patel, A.; Vanderbemden, P. Measurement of Magnetic Hysteresis Loops of the Ni-5at.%W Alloy Substrate as a Function of Temperature in a Stack of 2G HTS-Coated Conductor Annuli. IEEE Trans. Appl. Supercond. 2022, 32, 22029785. [Google Scholar] [CrossRef]

- Ladjimi, A.; Mekideche, M.R. Modeling of Thermal effects on Magnetic Hysteresis using the Jiles-Atherton Model. Przegl. Elektrotech. 2012, 88, 253–256. [Google Scholar]

- Chen, J.; Wang, D.; Cheng, S.; Wang, Y. Measurement and Modeling of Temperature Effects on Magnetic Property of Non-oriented Silicon Steel Lamination. In Proceedings of the IEEE International Magnetics Conference, Beijing, China, 11–15 May 2015. [Google Scholar]

- Tebble, R.S.; Craik, D.J. Magnetic Materials; Wiley-Interscience: Hoboken, NJ, USA, 1969. [Google Scholar]

- Arrott, A.S. Approximations to Brillouin functions for analytic descriptions of ferromagnetism. J. Appl. Phys. 2008, 103, 07C715. [Google Scholar] [CrossRef]

- Harrison, R.G. Variable-domain-size theory of spin ferromagnetism. IEEE Trans. Magn. 2004, 40, 1506–1515. [Google Scholar] [CrossRef]

- Mi, Y.; Peng, X.L. Fundamentals of Magnetism and Magnetic Materials; Zhejiang University Press: Zhejiang, China, 2019. [Google Scholar]

| Symbol | Parameters | Value |

|---|---|---|

| A | Outer diameter | 40 mm |

| B | Inner diameter | 32 mm |

| C | Thickness | 5 mm |

| Sx | Lamination coefficient | 99 |

| Le | Effective magnetic circuit length | 112.16 mm |

| Ae | Effective cross-sectional area | 19.52 mm2 |

| N1 | Turns of the excitation coil | 40 |

| N2 | Turns of the induction coil | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Ren, J.; Li, J.; Huang, Y. Measurement and Analysis of Magnetic Properties of Permalloy for Magnetic Shielding Devices under Different Temperature Environments. Materials 2023, 16, 3253. https://doi.org/10.3390/ma16083253

Sun J, Ren J, Li J, Huang Y. Measurement and Analysis of Magnetic Properties of Permalloy for Magnetic Shielding Devices under Different Temperature Environments. Materials. 2023; 16(8):3253. https://doi.org/10.3390/ma16083253

Chicago/Turabian StyleSun, Jinji, Jianyi Ren, Jin Li, and Yuejing Huang. 2023. "Measurement and Analysis of Magnetic Properties of Permalloy for Magnetic Shielding Devices under Different Temperature Environments" Materials 16, no. 8: 3253. https://doi.org/10.3390/ma16083253