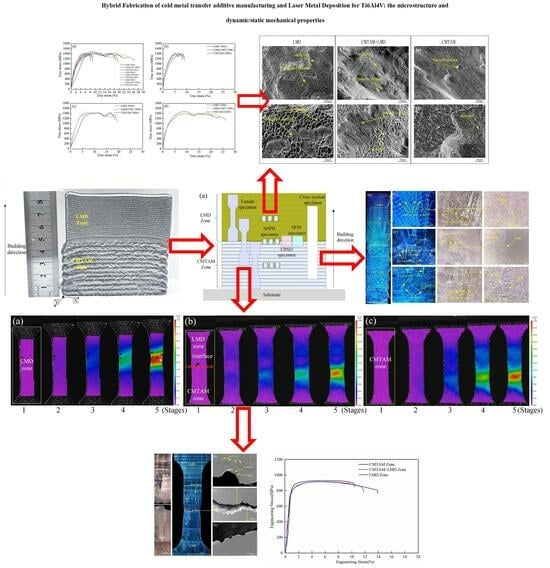

Hybrid Fabrication of Cold Metal Transfer Additive Manufacturing and Laser Metal Deposition for Ti6Al4V: The Microstructure and Dynamic/Static Mechanical Properties

Abstract

:1. Introduction

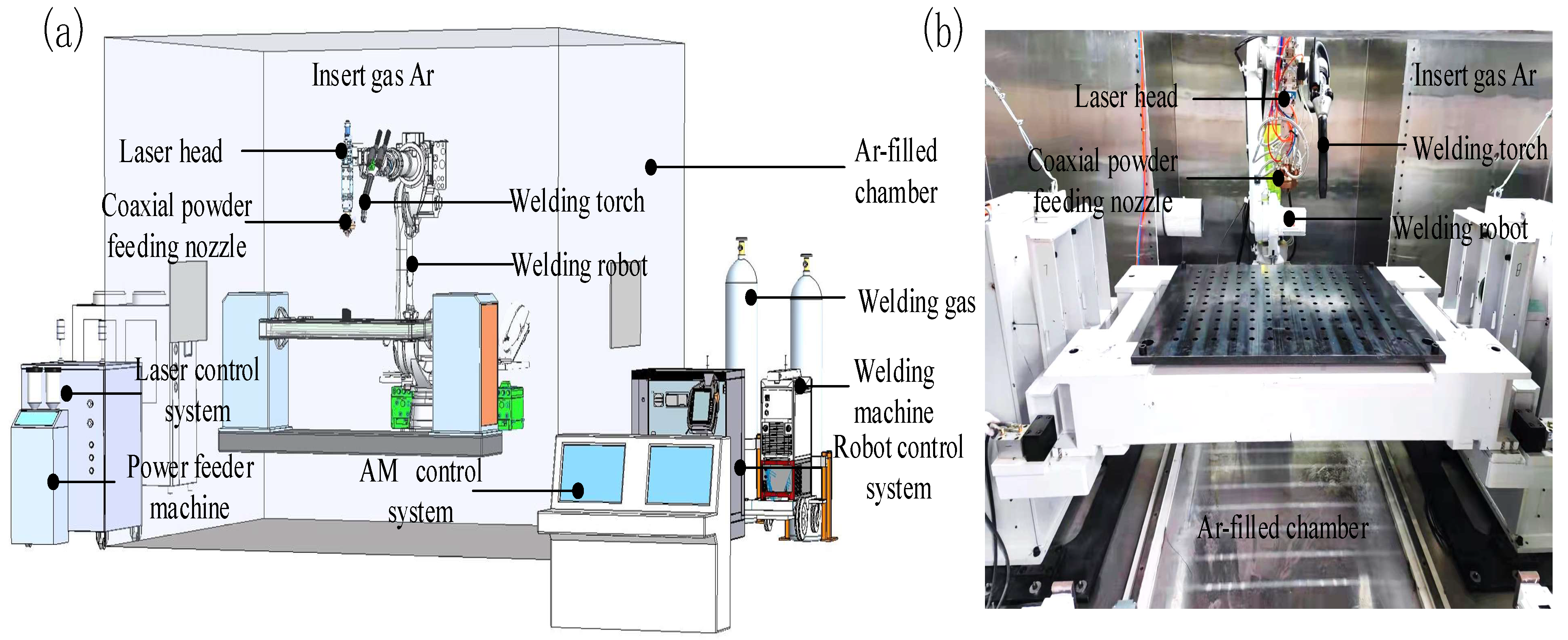

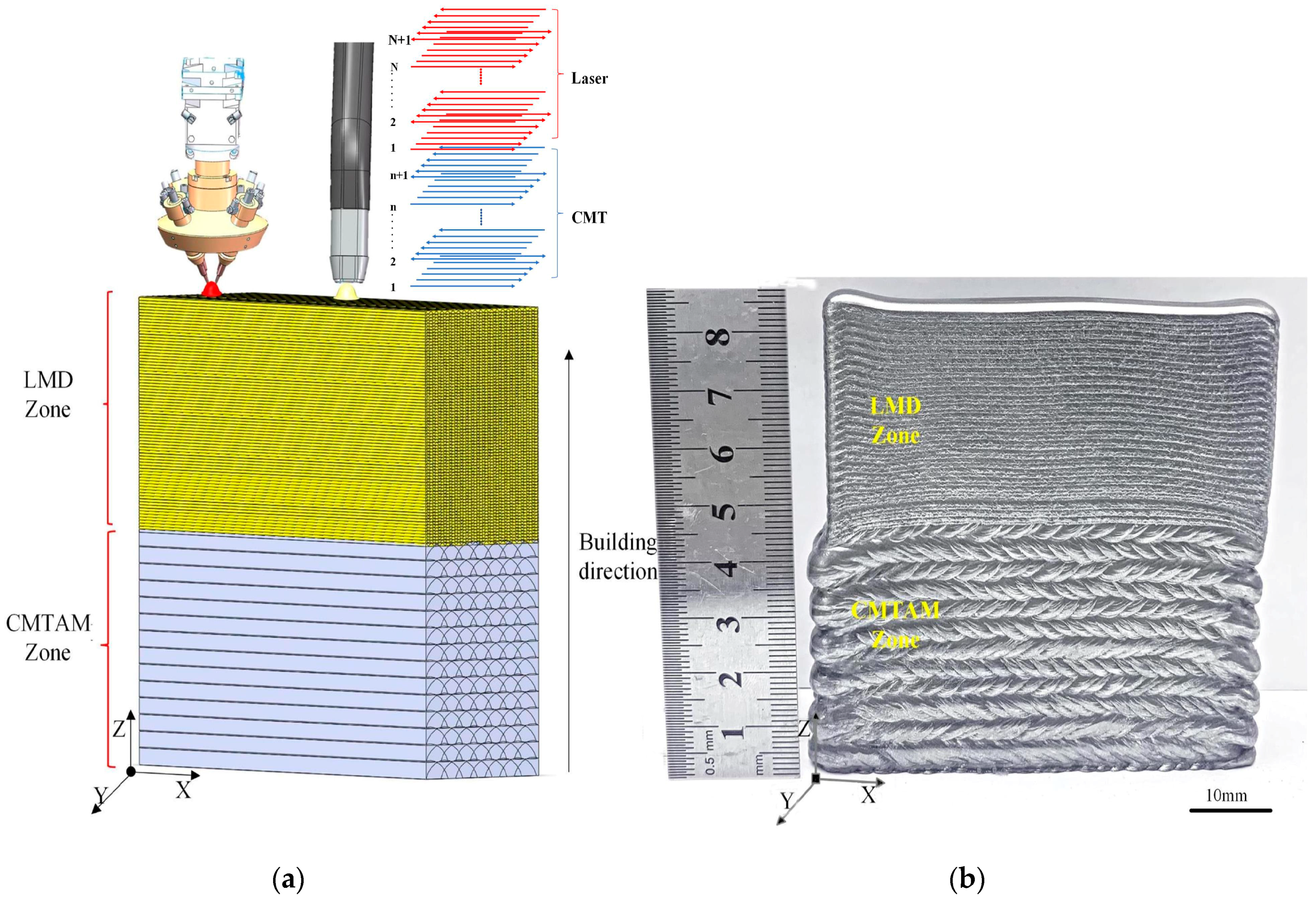

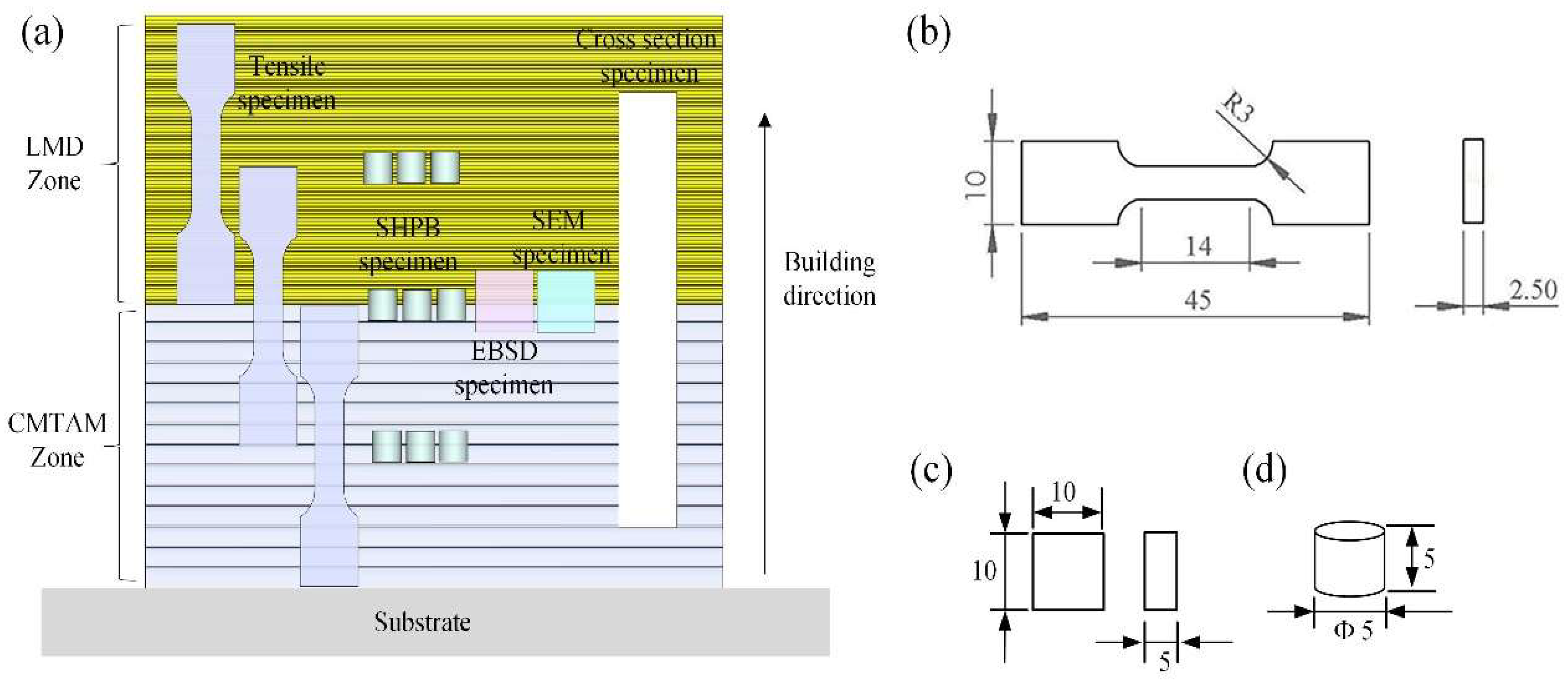

2. Experimental Details

2.1. Materials and Equipment

2.2. Manufacturing Process

2.3. Microstructure Characterization

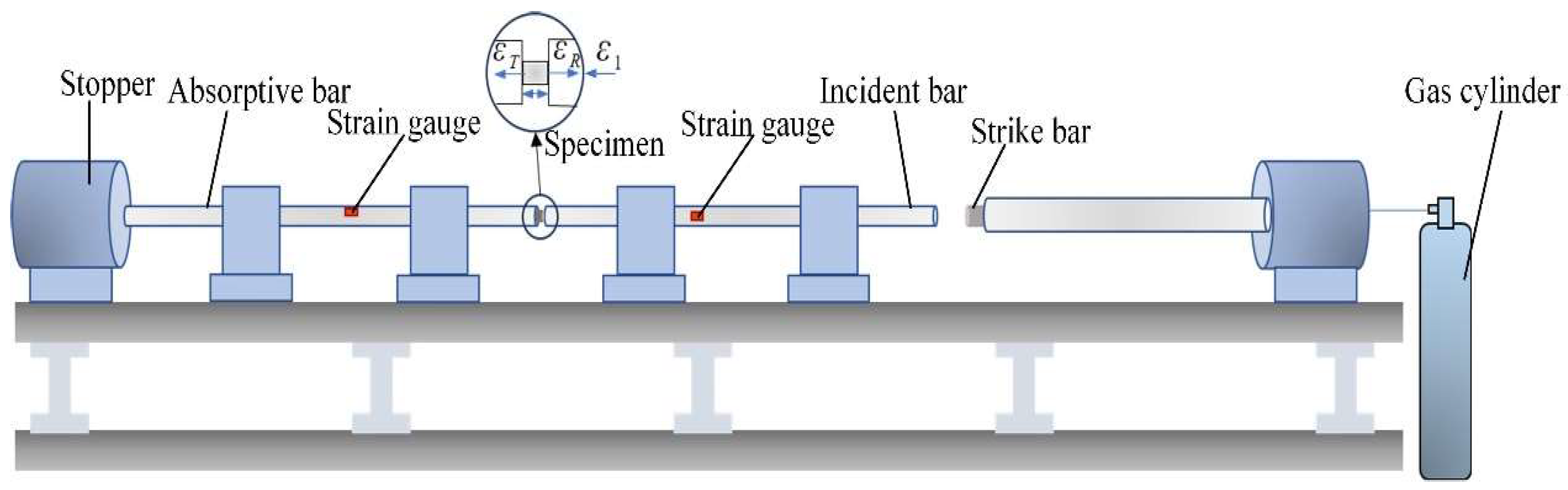

2.4. Mechanical Analysis

3. Results and Discussion

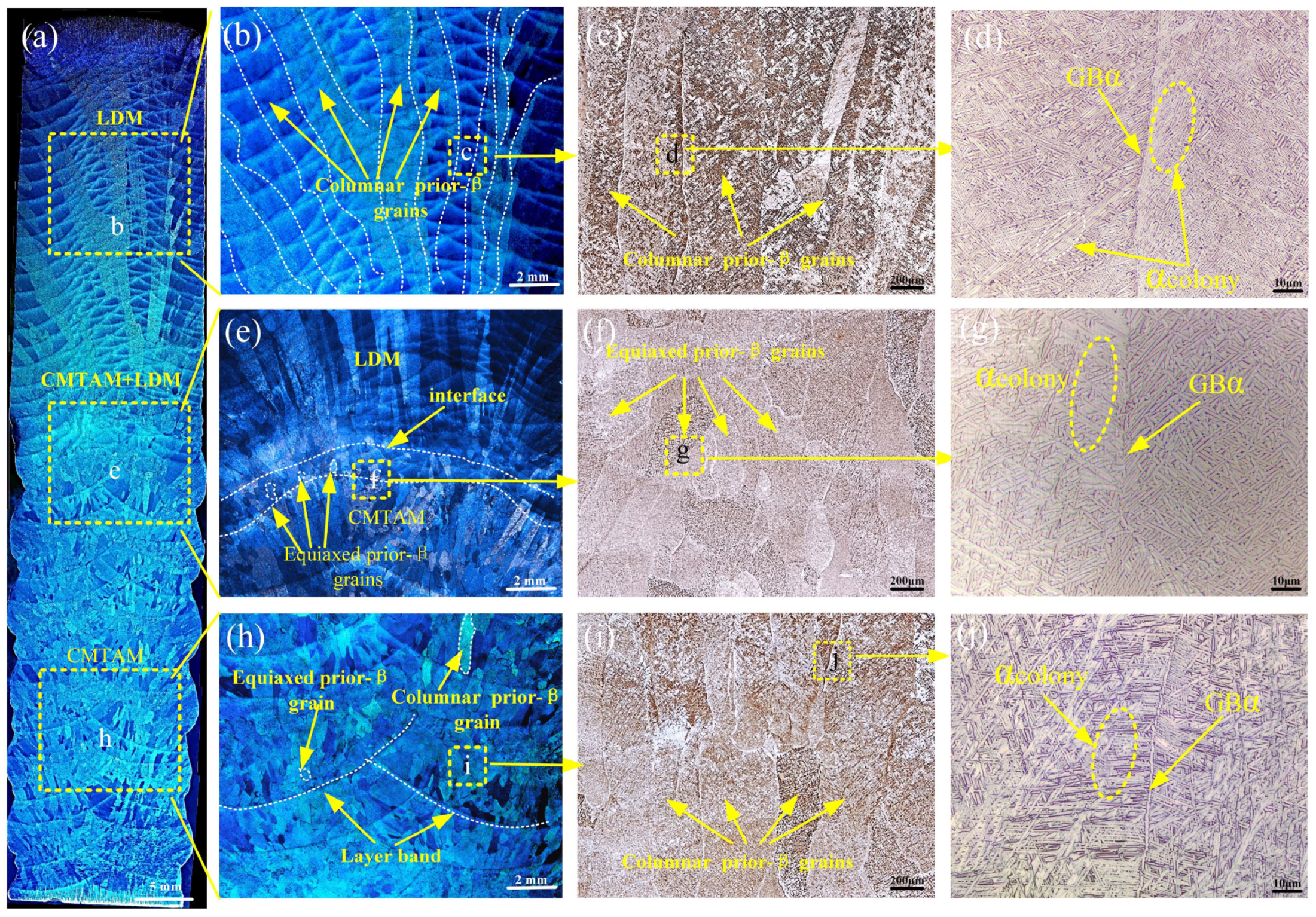

3.1. Initial Microstructure of the As-Built Sample

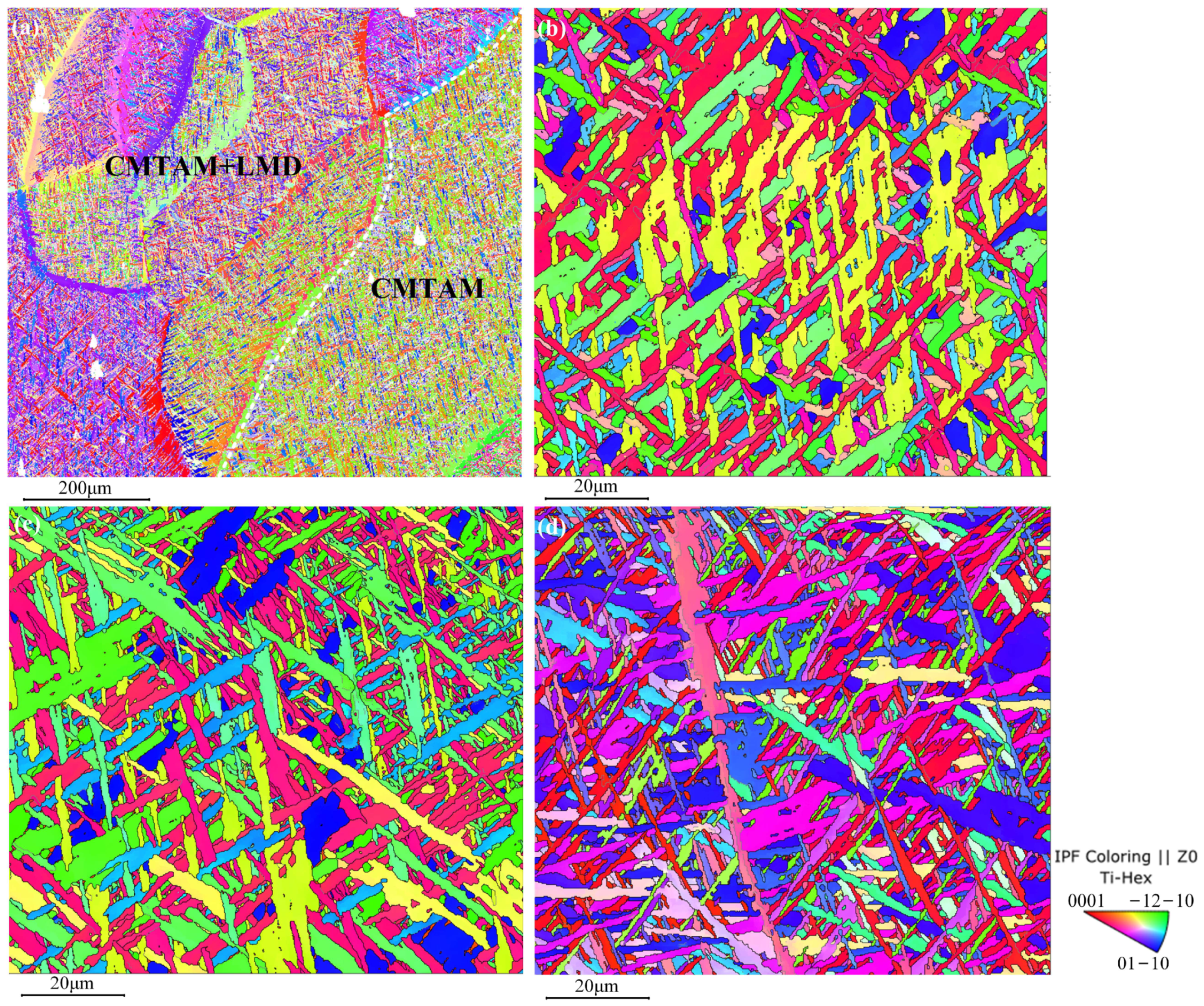

3.2. Texture Evolution

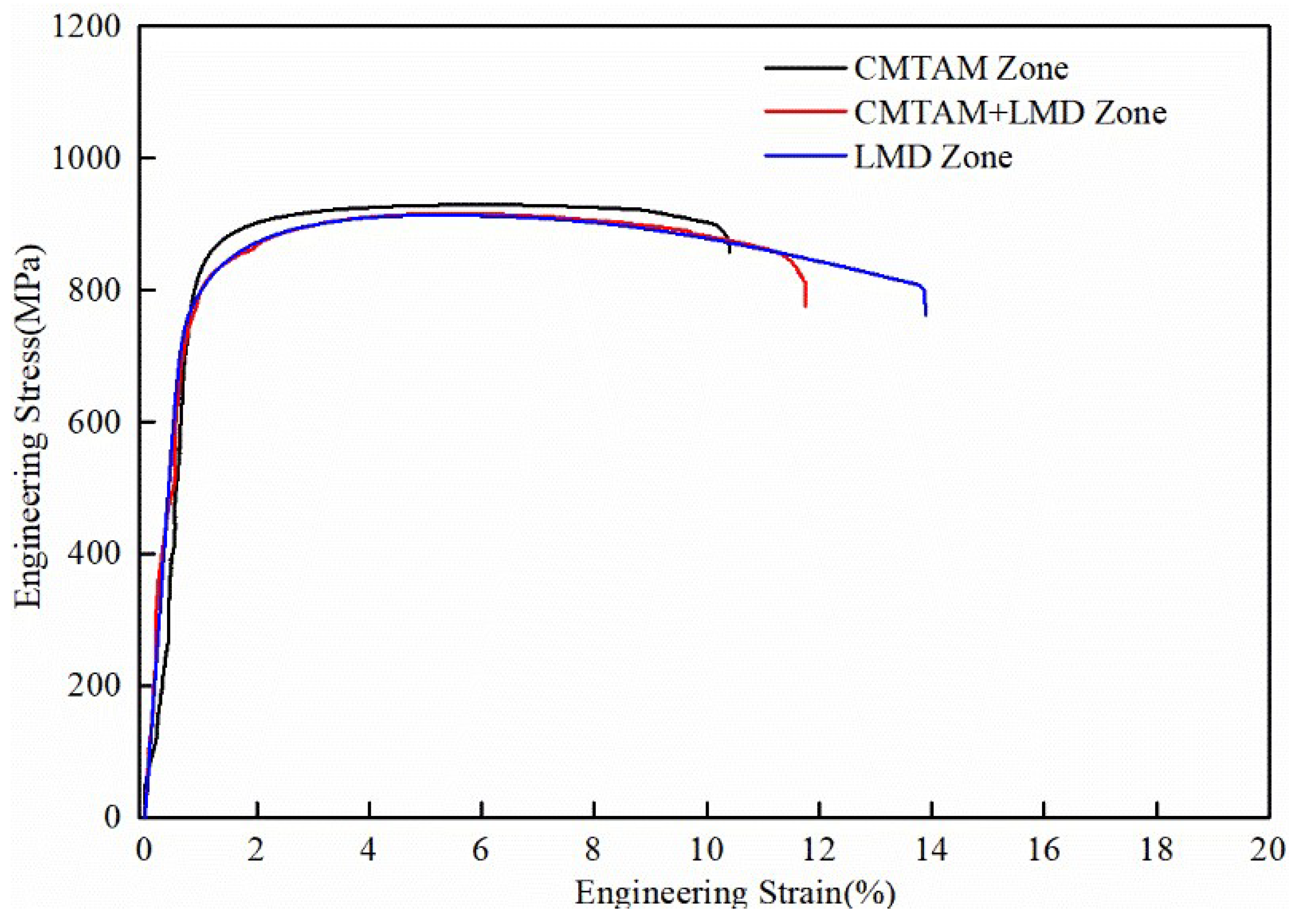

3.3. Uniaxial Tensile Behavior

3.4. Dynamic Mechanical Properties

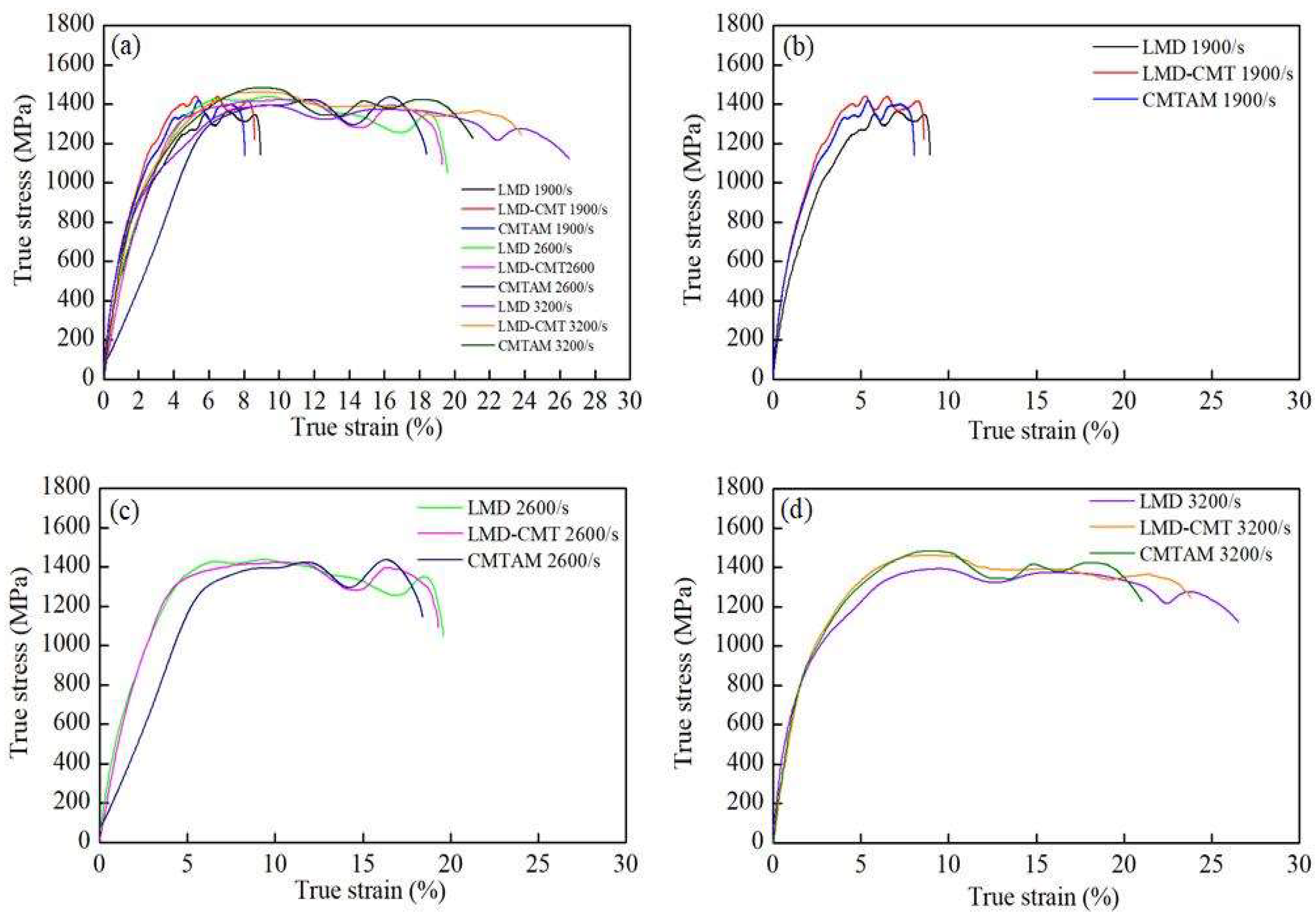

3.4.1. Dynamic Stress–Strain Response

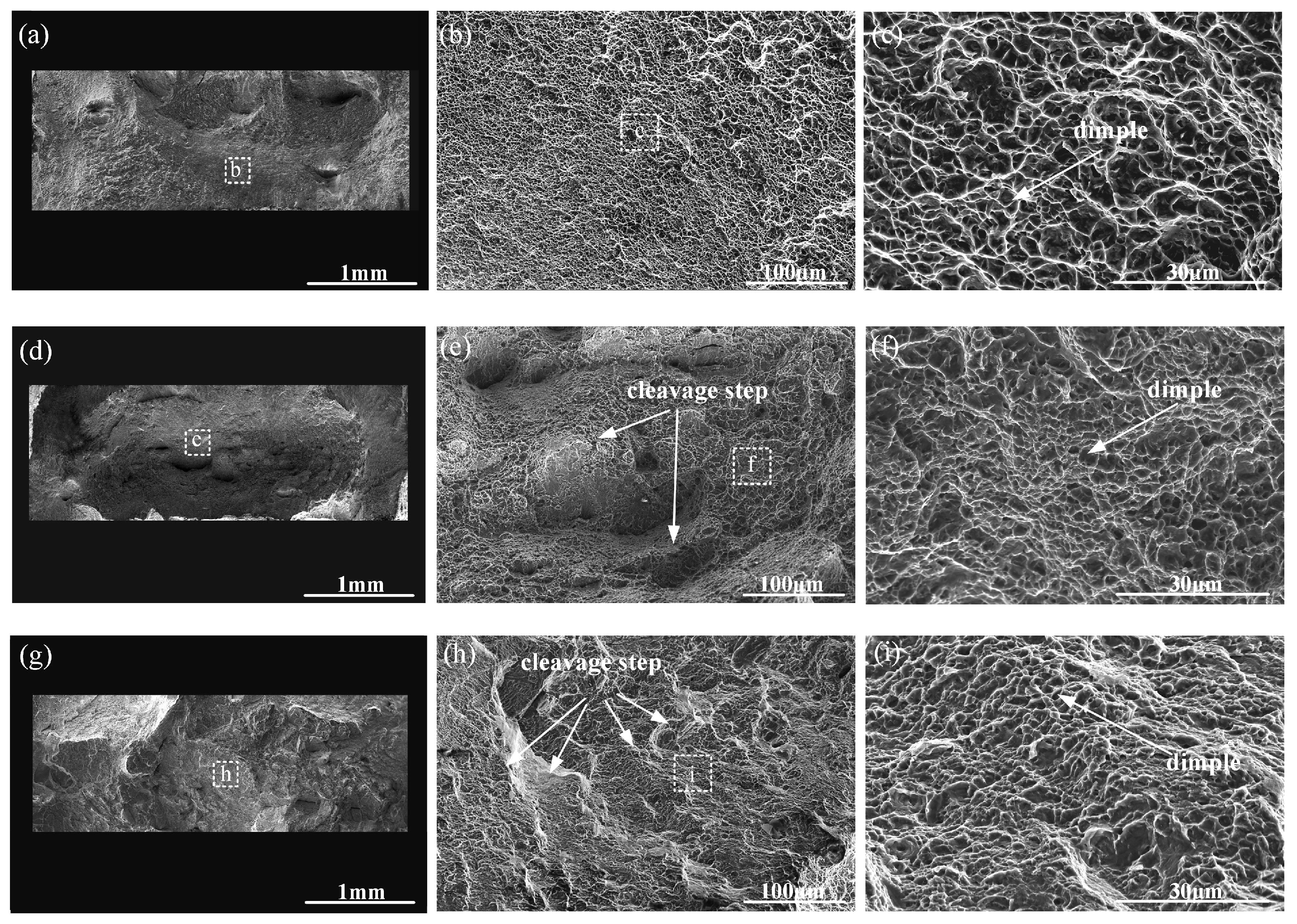

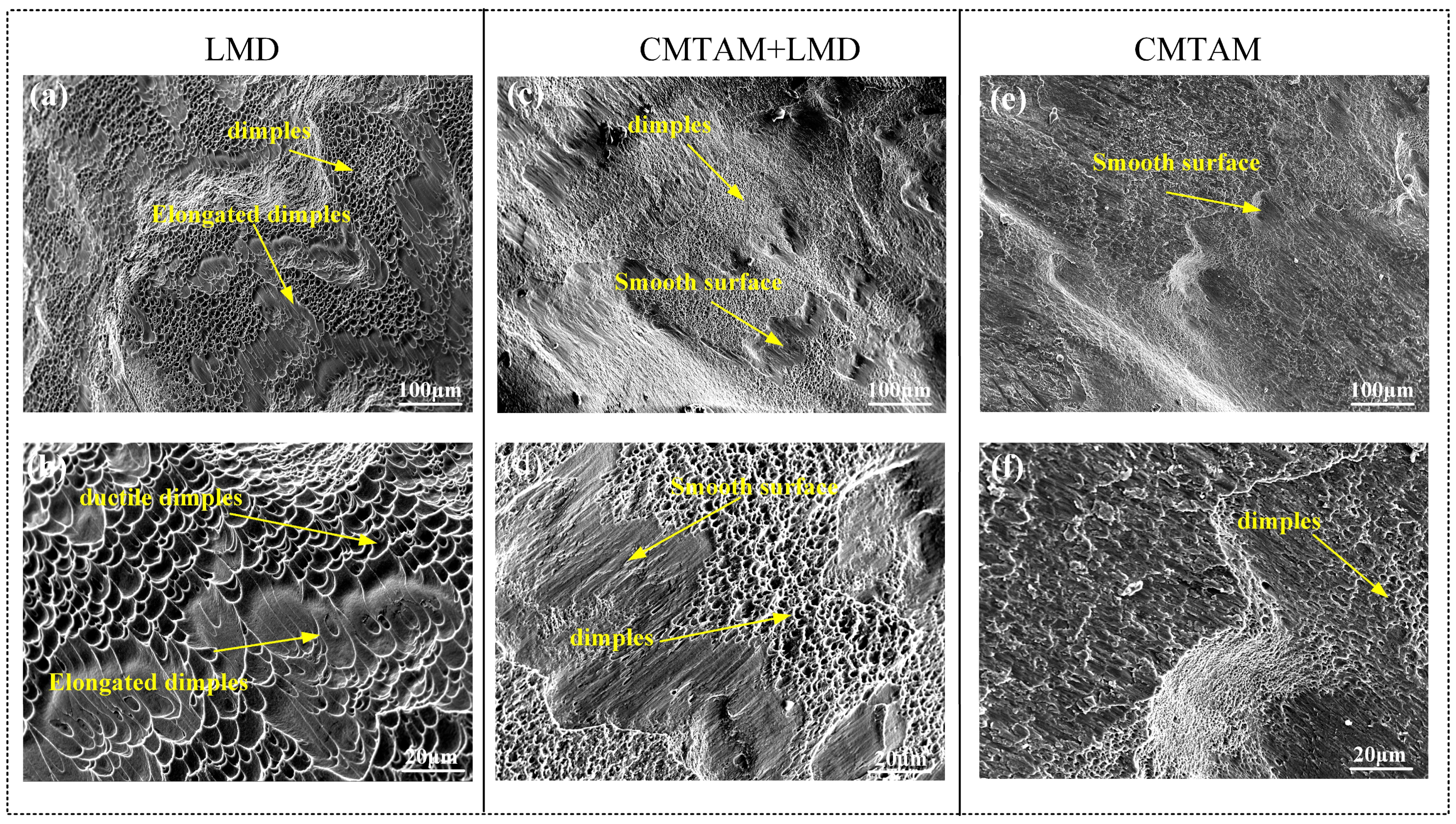

3.4.2. Fracture Morphology

4. Conclusions

- (1)

- The interface between the LMD and CMTAM zones showed significant grain refinement due to laser remelting, consisting mainly of fine equiaxed prior-β grains, with a microstructure of lamellar α and basketweave α + β inside the grains.

- (2)

- The LMD zone exhibited higher texture intensity compared to the CMTAM and the CMT-LMD hybrid zone, indicating significant anisotropy. The CMTAM zone and the CMT-LMD hybrid zone had higher dislocation densities than the LMD zone.

- (3)

- The interface between the hybrid additive manufacturing specimens exhibited good bonding and tensile mechanical properties. During the tensile testing process, fracture occurs in the CMTAM zone due to interface strengthening caused by remelting at the interface between CMTAM and LMD.

- (4)

- With the increase in the strain rate, the dynamic compressive strength and total strain increased for all specimens of the CMTAM, LMD and CMT-LMD hybrid zones. High-performance structures with a good combination of strength and ductility were achieved through cold metal transfer and laser hybrid additive manufacturing, and the CMT-LMD hybrid additive manufacturing zone displayed a higher energy absorption capacity during high-strain-rate dynamic impact.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Liu, Y.; Sha, G.; Jin, S.; Hou, Z.; Bayat, M.; Yang, N.; Tan, Q.; Yin, Y.; Liu, S.; et al. Designing against phase and property heterogeneities in additively manufactured titanium alloys. Nat. Commun. 2022, 13, 4660. [Google Scholar] [CrossRef]

- Zhang, G.; Lu, X.; Li, J.; Chen, J.; Lin, X.; Wang, M.; Tan, H.; Huang, W. In-situ grain structure control in directed energy deposition of Ti-6Al-4V. Addit. Manuf. 2022, 55, 102865. [Google Scholar]

- Baufeld, B.; Biest, O.V.D.; Gault, R. Additive manufacturing of Ti–6Al–4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, S106–S111. [Google Scholar] [CrossRef]

- Baufeld, B.; Brandl, E.; van der Biest, O. Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti–6Al–4V components fabricated by laser-beam deposition and shaped metal deposition. J. Mater. Process. Technol. 2011, 211, 1146–1158. [Google Scholar] [CrossRef]

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti-6Al-4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Lin, Z.; Song, K.; Yu, X. A review on wire and arc additive manufacturing of titanium alloy. J. Manuf. Process. 2021, 70, 24–45. [Google Scholar] [CrossRef]

- Sridharan, N.; Chaudhary, A.; Nandwana, P.; Babu, S.S. Texture Evolution During Laser Direct Metal Deposition of Ti-6Al-4V. JOM 2016, 68, 772–777. [Google Scholar] [CrossRef]

- Chen, Z.; Peng, Y.; Zhang, X.; Fan, J.; He, S.; Kong, J.; Wang, K. Influence of trace silicon addition on microstructure and properties of Ti-6Al-4V fabricated by wire arc additive manufacturing. J. Mater. Res. Technol. 2023, 23, 1347–1359. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and Mechanical Properties of Wire and Arc Additive Manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2012, 44, 968–977. [Google Scholar] [CrossRef]

- Brandl, E.; Baufeld, B.; Leyens, C.; Gault, R. Additive manufactured Ti-6Al-4V using welding wire: Comparison of laser and arc beam deposition and evaluation with respect to aerospace material specifications. Phys. Procedia 2010, 5, 595–606. [Google Scholar] [CrossRef]

- Lin, J.J.; Lv, Y.H.; Liu, Y.X.; Xu, B.S.; Sun, Z.; Li, Z.G.; Wu, Y.X. Microstructural evolution and mechanical properties of Ti-6Al-4V wall deposited by pulsed plasma arc additive manufacturing. Mater. Des. 2016, 102, 30–40. [Google Scholar] [CrossRef]

- Farabi, E.; Klein, T.; Schnall, M.; Primig, S. Effects of high deposition rate during cold metal transfer additive manufacturing on microstructure and properties of Ti-6Al-4V. Addit. Manuf. 2023, 71, 103592. [Google Scholar] [CrossRef]

- Gou, J.; Wang, Z.; Hu, S.; Shen, J.; Tian, Y.; Zhao, G.; Chen, Y. Effects of ultrasonic peening treatment in three directions on grain refinement and anisotropy of cold metal transfer additive manufactured Ti-6Al-4V thin wall structure. J. Manuf. Process. 2020, 54, 148–157. [Google Scholar] [CrossRef]

- Selvi, S.; Vishvaksenan, A.; Rajasekar, E. Cold metal transfer (CMT) technology—An overview. Def. Technol. 2018, 14, 28–44. [Google Scholar] [CrossRef]

- Tirupataiah, K.; Kiran, D.V.; Venkaiah, N. Iron aluminide FGM thin wall fabrication using CMT-based twin wire arc additive manufacturing process. Mater. Lett. 2023, 349, 134836. [Google Scholar] [CrossRef]

- Lehmann, T.; Jain, A.; Jain, Y.; Stainer, H.; Wolfe, T.; Henein, H.; Qureshi, A.J. Concurrent geometry- and material-based process identification and optimization for robotic CMT-based wire arc additive manufacturing. Mater. Des. 2020, 194, 108841. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, Q.; Wang, K.; Peng, Y.; Ding, J.; Kong, J.; Williams, S. Study on microstructure and tensile properties of high nitrogen Cr-Mn steel processed by CMT wire and arc additive manufacturing. Mater. Des. 2019, 166, 107611. [Google Scholar] [CrossRef]

- Lee, T.H.; Kang, M.; Oh, J.H.; Kam, D.-H. Deposition quality and efficiency improvement method for additive manufacturing of Ti–6Al–4V using gas metal arc with CMT. J. Mater. Process. Technol. 2022, 308, 117720. [Google Scholar] [CrossRef]

- Lv, J.; Alexandrov, I.V.; Luo, K.; Lu, H.; Lu, J. Microstructural evolution and anisotropic regulation in tensile property of cold metal transfer additive manufactured Ti-6Al-4V alloys via ultrasonic impact treatment. Mater. Sci. Eng. A 2022, 859, 144177. [Google Scholar] [CrossRef]

- Azarniya, A.; Colera, X.G.; Mirzaali, M.J.; Sovizi, S.; Bartolomeu, F.; Weglowski, M.K.S.; Wits, W.W.; Yap, C.Y.; Ahn, J.; Miranda, G.; et al. Additive manufacturing of Ti–6Al–4V parts through laser metal deposition (LMD): Process, microstructure, and mechanical properties. J. Alloys Compd. 2019, 804, 163–191. [Google Scholar] [CrossRef]

- Shrestha, S.; Panakarajupally, R.P.; Kannan, M.; Morscher, G.; Gyekenyesi, A.L.; Scott-Emuakpor, O.E. Analysis of microstructure and mechanical properties of additive repaired Ti–6Al–4V by Direct Energy Deposition. Mater. Sci. Eng. A 2020, 806, 140604. [Google Scholar] [CrossRef]

- Lv, H.; Zhang, Z.; Chen, Y.; Liu, Y.; Chen, H.; Chen, Y.; Cheng, J.; She, J.; He, H.; Chen, J. The anisotropy of high cycle fatigue property and fatigue crack growth behavior of Ti–6Al–4V alloy fabricated by high-power laser metal deposition. Mater. Sci. Eng. A 2022, 853, 143745. [Google Scholar] [CrossRef]

- Ye, H.; Le, F.; Wei, C.; Ye, K.; Liu, S.; Wang, G. Fatigue crack growth behavior of Ti-6Al-4V alloy fabricated via laser metal deposition: Effects of building orientation and heat treatment. J. Alloys Compd. 2021, 868, 159023. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, K.; Li, Y.; Chen, Y.; Yang, M.; Wang, M.; Clare, A.T. Composition fine-tuning for directed energy deposition of Ti-6Al-4V. J. Mater. Process. Technol. 2022, 299, 159023. [Google Scholar] [CrossRef]

- Choi, Y.R.; Sun, S.D.; Liu, Q.; Brandt, M.; Qian, M. Influence of deposition strategy on the microstructure and fatigue properties of laser metal deposited Ti-6Al-4V powder on Ti-6Al-4V substrate. Int. J. Fatigue 2020, 130, 105236. [Google Scholar] [CrossRef]

- Ma, G.; Yu, C.; Tang, B.; Li, Y.; Niu, F.; Wu, D.; Bi, G.; Liu, S. High-mass-proportion TiCp/Ti-6Al-4V titanium matrix composites prepared by directed energy deposition. Addit. Manuf. 2020, 35, 101323. [Google Scholar]

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. Multiple material additive manufacturing—Part 1: A review. Virtual Phys. Prototyp. 2013, 8, 19–50. [Google Scholar] [CrossRef]

- Madhavadas, V.; Srivastava, D.; Chadha, U.; Raj, S.A.; Sultan, M.T.H.; Shahar, F.S.; Shah, A.U.M. A review on metal additive manufacturing for intricately shaped aerospace components. CIRP J. Manuf. Sci. Technol. 2022, 39, 18–36. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Waqar, S.; Garcia-Collado, A.; Gupta, M.K.; Krolczyk, G.M. A technical overview of metallic parts in hybrid additive manufacturing industry. J. Mater. Res. Technol. 2022, 18, 384–395. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Xiao, B. A market assessment of additive manufacturing potential for the aerospace industry. J. Manuf. Process. 2021, 68, 728–738. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; Plessis, A.D. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Sepulveda-Navarrete, D.A.; Gutierrez, P.S.; Lopes, A.; Rome, J.I.; Goyal, V.K.; Espalin, D. Ultrasonically embedded wires in multi-material parts produced by hybrid additive manufacturing. Addit. Manuf. 2023, 73, 103662. [Google Scholar] [CrossRef]

- Malej, S.; Godec, M.; Donik, Č.; Balazic, M.; Zettler, R.; Lienert, T.; Pambaguian, L. Hybrid additive manufacturing of Ti-6Al-4V with powder-bed fusion and direct-energy deposition. Mater. Sci. Eng. A 2023, 878, 103662. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.; Zhu, L.; Wang, X.; Han, Q.; Li, S.; Wang, Y.; Setchi, R.; Wang, D. Investigation into the microstructure and dynamic compressive properties of selective laser melted Ti–6Al–4V alloy with different heating treatments. Mater. Sci. Eng. A 2021, 805, 140561. [Google Scholar] [CrossRef]

- Riza, S.H.; Masood, S.H.; Wen, C.; Ruan, D.; Xu, S. Dynamic behaviour of high strength steel parts developed through laser assisted direct metal deposition. Mater. Des. 2014, 64, 650–659. [Google Scholar] [CrossRef]

- Bobbili, R.; Madhu, V. Effect of strain rate and stress triaxiality on tensile behavior of Titanium alloy Ti-10-2-3 at elevated temperatures. Mater. Sci. Eng. A 2016, 667, 33–41. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, J.; Zhu, L.; Chen, H.; Li, Z.; Li, S.; Wang, D.; Wang, Y.; Kosiba, K. Dynamic compressive properties and underlying failure mechanisms of selective laser melted Ti-6Al-4V alloy under high temperature and strain rate conditions. Addit. Manuf. 2022, 54, 102772. [Google Scholar] [CrossRef]

- Almeida, P.M.S.; Williams, S. Innovative process model of Ti-6Al-4V additive layer manufacturing using cold metal transfer (CMT). In Proceedings of the Solid Freeform Fabrication Annual International Symposium, Austin, TX, USA, 9–11 August 2010. [Google Scholar]

- Zhang, C.; Li, Y.; Gao, M.; Zeng, X. Wire arc additive manufacturing of Al-6Mg alloy using variable polarity cold metal transfer arc as power source. Mater. Sci. Eng. A 2018, 711, 415–423. [Google Scholar] [CrossRef]

- Cong, B.; Qi, Z.; Qi, B.; Sun, H.; Zhao, G.; Ding, J. A Comparative Study of Additively Manufactured Thin Wall and Block Structure with Al-6.3%Cu Alloy Using Cold Metal Transfer Process. Appl. Sci. 2017, 7, 275. [Google Scholar] [CrossRef]

- Ola, O.T.; Doern, F.E. A study of cold metal transfer clads in nickel-base INCONEL 718 superalloy. Mater. Des. 2014, 57, 51–59. [Google Scholar] [CrossRef]

- Ke, W.C.; Oliveira, J.P.; Cong, B.Q.; Ao, S.S.; Qi, Z.W.; Peng, B.; Zeng, Z. Multi-layer deposition mechanism in ultra high-frequency pulsed wire arc additive manufacturing (WAAM) of NiTi shape memory alloys. Addit. Manuf. 2022, 50, 102513. [Google Scholar] [CrossRef]

- Chen, Y.; He, Y.; Chen, H.; Zhang, H.; Chen, S. Effect of weave frequency and amplitude on temperature field in weaving welding process. Int. J. Adv. Manuf. Technol. 2014, 75, 803–813. [Google Scholar] [CrossRef]

- Pal, K.; Pal, S.K. Effect of Pulse Parameters on Weld Quality in Pulsed Gas Metal Arc Welding: A Review. J. Mater. Eng. Perform. 2011, 20, 918–931. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, F.; Wang, H. Effect of the prior-β grain boundaries on mechanical behavior of Ti-6Al-4V alloy processed by laser directed energy deposition. Mater. Sci. Eng. A 2022, 848, 143389. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, G.; Zhou, S.; Sun, C.; Li, B.; An, D.; Zhang, S.; Xiu, S. Effect of laser remelting on microstructure and mechanical properties of Ti–6Al–4V alloy prepared by inside-beam powder feeding. Mater. Sci. Eng. A 2022, 861, 144266. [Google Scholar] [CrossRef]

- Jin, B.; Zhang, N.; Yin, S. Strengthening behavior of AlCoCrFeNi(TiN)x high-entropy alloy coatings fabricated by plasma spraying and laser remelting. J. Mater. Sci. Technol. 2022, 121, 163–173. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Guo, L.; He, J.; Pan, Z.; Wang, L. Laser remelting of plasma-sprayed conventional and nanostructured Al2O3–13wt.%TiO2 coatings on titanium alloy. J. Alloys Compd. 2010, 506, 356–363. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti–6Al–4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Liu, Y.K.; Wang, F.B.; Xu, D.; Wang, J.D.; Jiang, F.C.; Zarinejad, M.; Tong, Y. Microstructure and mechanical properties of laser metal deposited Ti6Al4V alloy with near equiaxed β grain structure. J. Mater. Res. Technol. 2023, 22, 1935–1947. [Google Scholar] [CrossRef]

- Alaghmandfard, R.; Seraj, P.; Sanjari, M.; Pirgazi, H.; Dharmendra, C.; Odeshi, A.G.; Amirkhiz, B.S.; Mohammadi, M. High strain rate deformation behavior, texture and microstructural evolution, characterization of adiabatic shear bands, and constitutive models in electron beam melted Ti-6Al-4V under dynamic compression loadings. J. Mater. Res. Technol. 2022, 21, 4093–4114. [Google Scholar] [CrossRef]

- Guan, X.R.; Chen, Q.; Qu, S.J.; Cao, G.J.; Wang, H.; Ran, X.D.; Feng, A.H.; Chen, D.L. High-strain-rate deformation: Stress-induced phase transformation and nanostructures in a titanium alloy. Int. J. Plast. 2023, 169, 103707. [Google Scholar] [CrossRef]

- Zong, X.; Li, Z.; Li, J.; Cheng, X.; Chen, R.; Tan, C.-W.; Wang, H.-M. High strain rate response of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy fabricated by laser additive manufacturing. J. Alloys Compd. 2019, 781, 47–55. [Google Scholar] [CrossRef]

- Alaghmandfard, R.; Dharmendra, C.; Odeshi, A.G.; Mohammadi, M. Dynamic mechanical properties and failure characteristics of electron beam melted Ti-6Al-4V under high strain rate impact loadings. Mater. Sci. Eng. A Struct. Mater. Prop. Misrostructure Process. 2020, 793, 139794. [Google Scholar] [CrossRef]

- Markovsky, P.E.; Janiszewski, J.; Savvakin, D.G.; Stasiuk, O.O.; Cieplak, K.; Baranowski, P.; Prikhodko, S.V. Mechanical behavior of bilayer structures of Ti64 alloy and its composites with TiC or TiB under quasi-static and dynamic compression. Mater. Des. 2022, 223, 111205. [Google Scholar] [CrossRef]

- Prikhodko, S.V.; Ivasishin, O.M.; Markovsky, P.E.; Savvakin, D.G.; Stasiuk, O.O. Titanium Armor with Gradient Structure: Advanced Technology for Fabrication. In Advanced Technologies for Security Applications; Palestini, C., Ed.; Springer: Dordrecht, The Netherlands, 2020; pp. 127–140. [Google Scholar]

| Element | Al (wt%) | V (wt%) | Fe (wt%) | C (wt%) | N (wt%) | O (wt%) | Ti (wt%) |

|---|---|---|---|---|---|---|---|

| Ti-6Al-4V Wire | 5.96 | 4.07 | 1.5 | 0.0082 | 0.0068 | 0.085 | Bal. |

| Ti-6Al-4V Powder | 6.06 | 4.04 | 0.03 | 0.009 | 0.009 | 0.057 | Bal. |

| Wire Feeding Rate v2/(m·min−1) | Mean Current U/V | Mean Current I/A | Gas Flow Rate Q/(L·min−1) | The Interpass Temperature/°C |

|---|---|---|---|---|

| 4.8 | 19 | 150 | 20 | ≤150 °C |

| Laser Power P/KW | Overlap Ratio% | Scanning Speed v1/(mm·s−1) | Powder Feeding Rate v2/(g·min−1) | Spot Diameter mm | The Interpass Temperature/°C |

|---|---|---|---|---|---|

| 1.8 | 50 | 10 | 7.5 | 2.7 | ≤150 °C |

| Part | α phase | GBα | ||

|---|---|---|---|---|

| Width/μm | Length/μm | Aspect Ratio | Width | |

| LMD | 1.6 | 8 | 5 | 1 |

| CMTAM-LMD | 0.7 | 13 | 17 | 1 |

| CMTAM | 1.3 | 22 | 18 | 2 |

| Sample | YS (Mpa) | UTS (Mpa) | EL (%) |

|---|---|---|---|

| LMD | 801 ± 0.7 | 913 ± 3.1 | 13.9 |

| CMT-LMD | 803 ± 2.1 | 915 ± 2.6 | 11.7 |

| CMT | 828 ± 3.1 | 929 ± 3.2 | 10.4 |

| Sample | True Stress/MPa | True Strain/% | Strain Rate (/s) |

|---|---|---|---|

| LMD1 | 1364 | 8.94 | 1877 |

| LMD2 | 1389 | 19.6 | 2618 |

| LMD3 | 1396 | 26.6 | 3263 |

| CMT-LMD1 | 1426 | 8.61 | 1863 |

| CMT-LMD2 | 1441 | 19.3 | 2639 |

| CMT-LMD3 | 1465 | 23.9 | 3217 |

| CMTAM1 | 1421 | 8.1 | 1917 |

| CMTAM2 | 1438 | 18.4 | 2626 |

| CMTAM3 | 1481 | 21 | 3228 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Liang, Y.; Li, C.; Zhang, X.; Kong, J.; Fan, J.; Wang, K.; Peng, Y. Hybrid Fabrication of Cold Metal Transfer Additive Manufacturing and Laser Metal Deposition for Ti6Al4V: The Microstructure and Dynamic/Static Mechanical Properties. Materials 2024, 17, 1862. https://doi.org/10.3390/ma17081862

Chen Z, Liang Y, Li C, Zhang X, Kong J, Fan J, Wang K, Peng Y. Hybrid Fabrication of Cold Metal Transfer Additive Manufacturing and Laser Metal Deposition for Ti6Al4V: The Microstructure and Dynamic/Static Mechanical Properties. Materials. 2024; 17(8):1862. https://doi.org/10.3390/ma17081862

Chicago/Turabian StyleChen, Zhenwen, Yanning Liang, Cong Li, Xiaoyong Zhang, Jian Kong, Jikang Fan, Kehong Wang, and Yong Peng. 2024. "Hybrid Fabrication of Cold Metal Transfer Additive Manufacturing and Laser Metal Deposition for Ti6Al4V: The Microstructure and Dynamic/Static Mechanical Properties" Materials 17, no. 8: 1862. https://doi.org/10.3390/ma17081862