Femtosecond Laser Fabrication of High-Linearity Liquid Metal-Based Flexible Strain Sensor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Strain Sensor

2.2.1. Fabrication of the Substrate

2.2.2. Patterning the Fe-LM Electrode

2.2.3. Assembly of the Strain Sensor

2.3. Characterization

3. Results

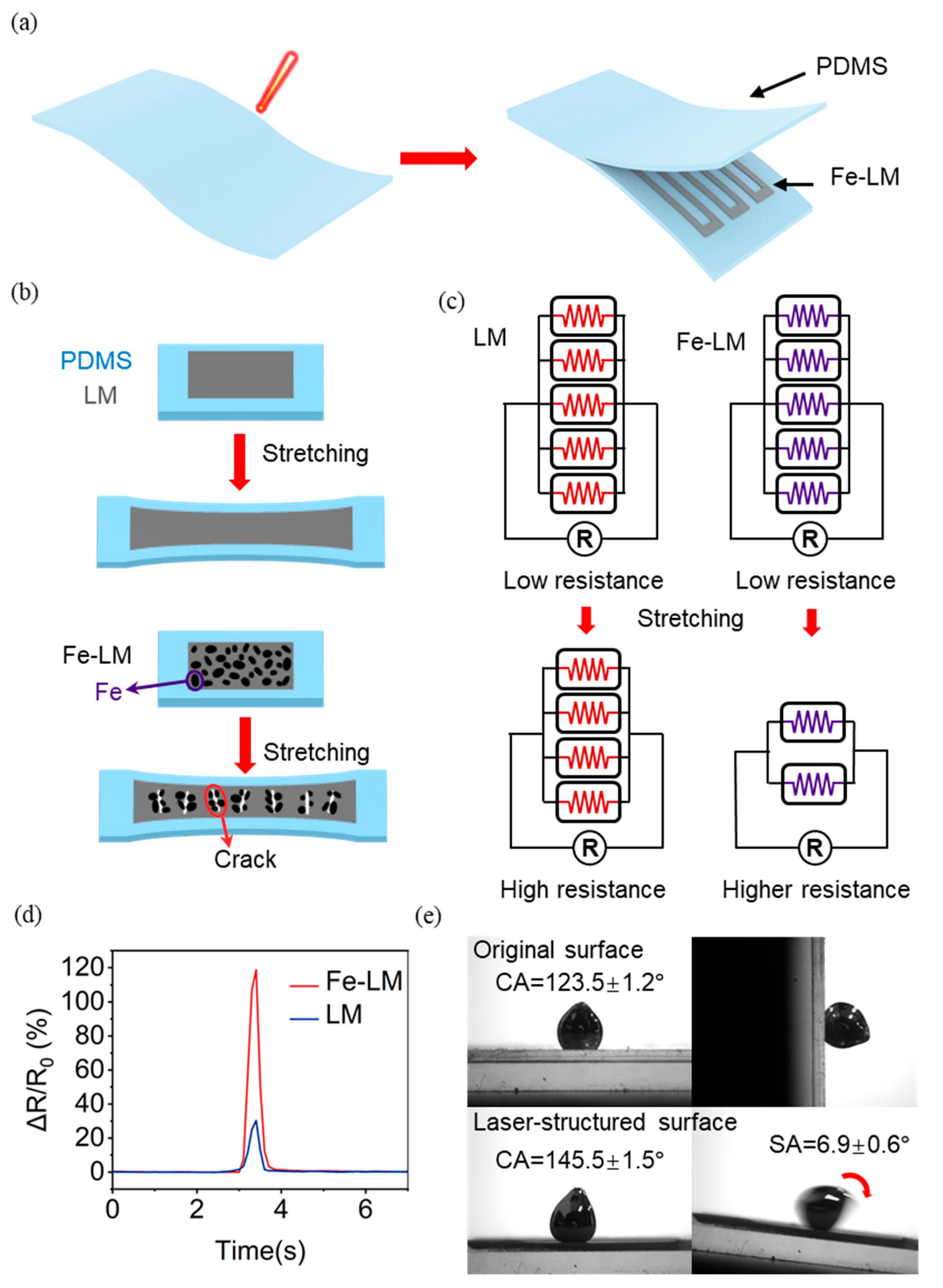

3.1. Construction of Resistive Strain Sensor Based on Femtosecond Laser

3.2. Preparation of Fe-LM Electrode

3.3. Wettability Control by Femtosecond Laser

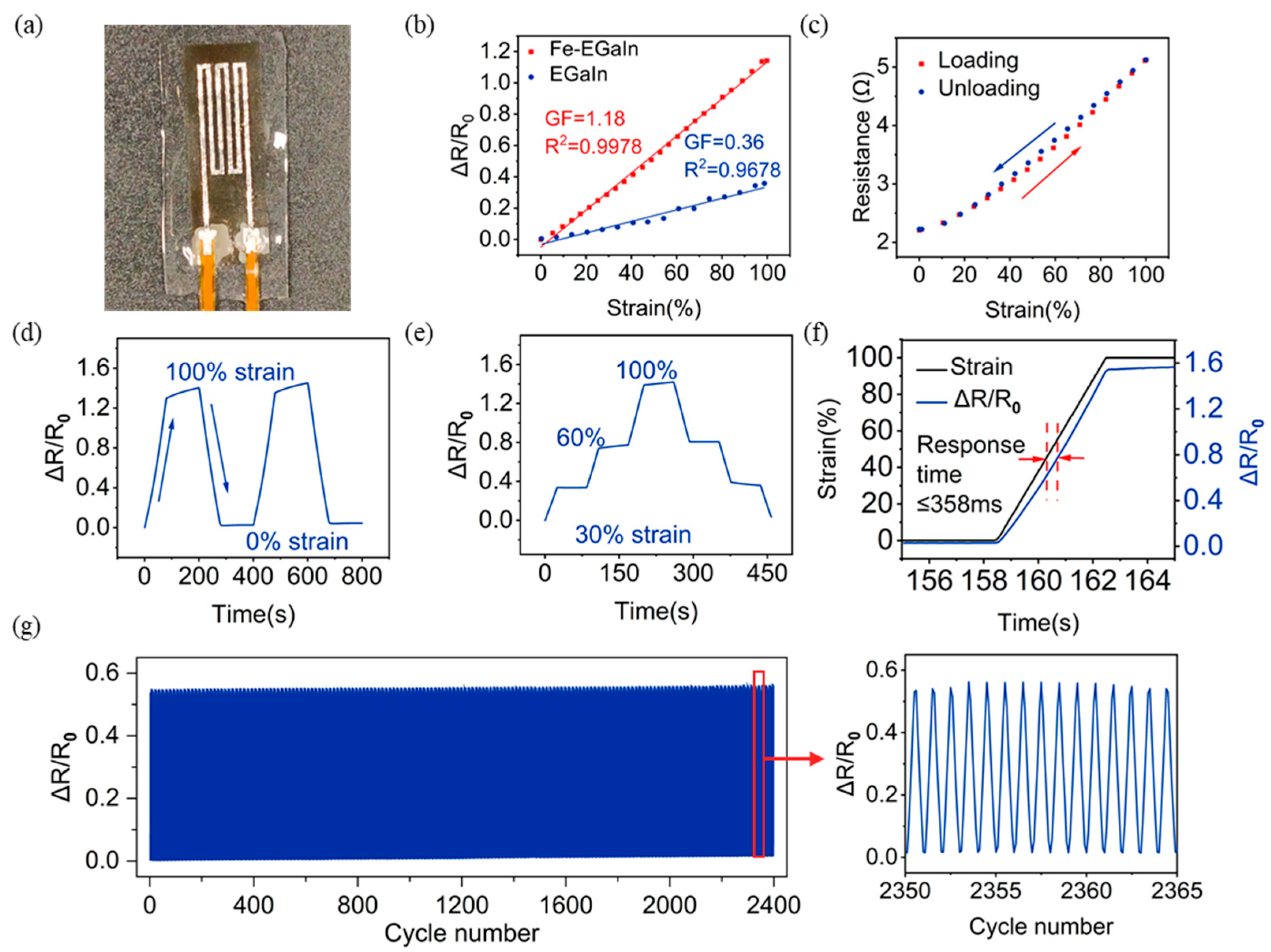

3.4. Sensing Properties of the Strain Sensor

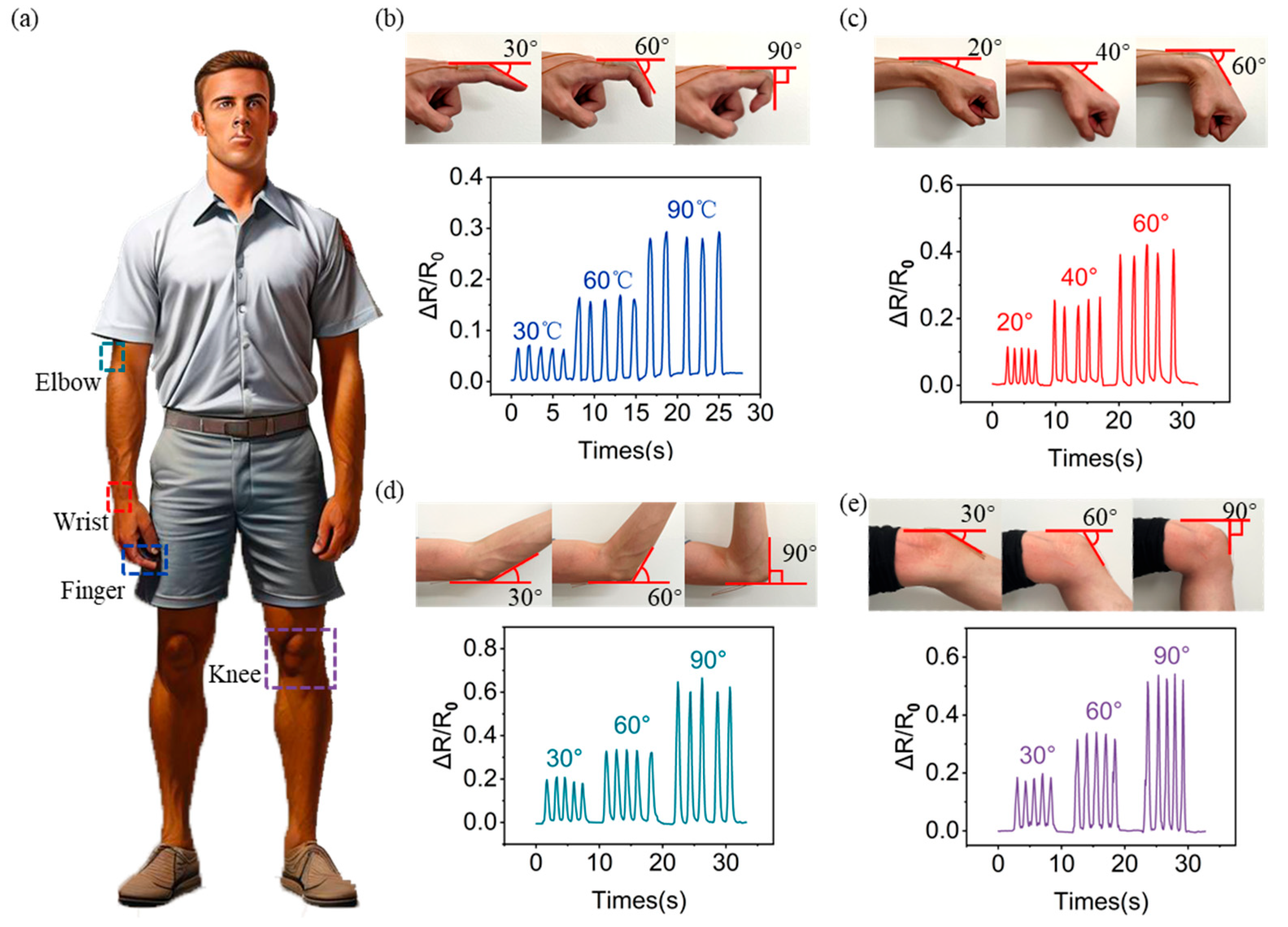

3.5. Applications of the Strain Sensor in Human Body Signal Monitoring

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dickey, M.D. Stretchable and Soft Electronics using Liquid Metals. Adv. Mater. 2017, 29, 1606425. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible Electronics toward Wearable Sensing. Acc. Chem. Res. 2019, 52, 523–533. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kantharaju, P.; Yi, H.; Jacobson, M.; Jeong, H.; Kim, H.; Lee, J.; Matthews, J.; Zavanelli, N.; Kim, H.; et al. Soft wearable flexible bioelectronics integrated with an ankle-foot exoskeleton for estimation of metabolic costs and physical effort. npj Flex. Electron. 2023, 7, 3. [Google Scholar] [CrossRef]

- Sun, J.Y.; Keplinger, C.; Whitesides, G.M.; Suo, Z.G. Ionic Skin. Adv. Mater. 2014, 26, 7608–7614. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Min, J.; Gao, W. Wearable and Implantable Electronics: Moving toward Precision Therapy. ACS Nano 2019, 13, 12280–12286. [Google Scholar] [CrossRef] [PubMed]

- Araromi, O.A.; Graule, M.A.; Dorsey, K.L.; Castellanos, S.; Foster, J.R.; Hsu, W.H.; Passy, A.E.; Vlassak, J.J.; Weaver, J.C.; Walsh, C.J.; et al. Ultra-sensitive and resilient compliant strain gauges for soft machines. Nature 2020, 587, 219–224. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Ihle, S.J.; Pellegrino, G.S.; Kim, H.; Yea, J.; Jeon, C.Y.; Son, H.C.; Jin, C.; Eberli, D.; Schmid, F.; et al. Stretchable and suturable fibre sensors for wireless monitoring of connective tissue strain. Nat. Electron. 2021, 4, 291–301. [Google Scholar] [CrossRef]

- Garland, N.T.; Schmieder, J.; Johnson, Z.T.; Hjort, R.G.; Chen, B.L.; Andersen, C.; Sanborn, D.; Kjeldgaard, G.; Pola, C.C.; Li, J.Z.; et al. Wearable Flexible Perspiration Biosensors Using Laser-Induced Graphene and Polymeric Tape Microfluidics. ACS Appl. Mater. Interfaces 2023, 15, 38201–38213. [Google Scholar] [CrossRef]

- Zhang, D.B.; Yin, R.; Zheng, Y.J.; Li, Q.M.; Liu, H.; Liu, C.T.; Shen, C.Y. Multifunctional MXene/CNTs based flexible electronic textile with excellent strain sensing, electromagnetic interference shielding and Joule heating performances. Chem. Eng. J. 2022, 438, 135587. [Google Scholar] [CrossRef]

- Dejace, L.; Laubeuf, N.; Furfaro, I.; Lacour, S.P. Gallium-Based Thin Films for Wearable Human Motion Sensors. Adv. Intell. Syst. 2019, 1, 1900079. [Google Scholar] [CrossRef]

- Rahmani, P.; Shojaei, A.; Dickey, M.D. A highly conductive and ultra-stretchable polyaniline/cellulose nanocrystal/polyacrylamide hydrogel with hydrophobic associations for wearable strain sensors. J. Mater. Chem. A 2024, 12, 9552–9562. [Google Scholar] [CrossRef]

- Migliorini, L.; Santaniello, T.; Falqui, A.; Milani, P. Super-Stretchable Resistive Strain Sensor Based on Ecoflex-Gold Nanocomposites. ACS Appl. Nano Mater. 2023, 6, 8999–9007. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.F.; Park, B.; Suh, K.Y.; Kim, T.I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef]

- Atalay, O.; Atalay, A.; Gafford, J.; Wang, H.Q.; Wood, R.; Walsh, C. A Highly Stretchable Capacitive-Based Strain Sensor Based on Metal Deposition and Laser Rastering. Adv. Mater. Technol. 2017, 2, 1700081. [Google Scholar] [CrossRef]

- Zhang, D.G.; Zhang, J.; Wu, Y.L.; Xiong, X.Y.; Yang, J.Y.; Dickey, M.D. Liquid Metal Interdigitated Capacitive Strain Sensor with Normal Stress Insensitivity. Adv. Intell. Syst. 2022, 4, 2100201. [Google Scholar] [CrossRef]

- He, J.J.; Fang, Z.W.; Gao, C.J.; Zhang, W.X.; Guan, X.F.; Lin, J. Graphene enhanced flexible piezoelectric transducers for dynamic strain measurement: From material preparation to application. Smart Mater. Struct. 2023, 32, 025012. [Google Scholar] [CrossRef]

- Gullapalli, H.; Vemuru, V.S.M.; Kumar, A.; Botello-Mendez, A.; Vajtai, R.; Terrones, M.; Nagarajaiah, S.; Ajayan, P.M. Flexible Piezoelectric ZnO-Paper Nanocomposite Strain Sensor. Small 2010, 6, 1641–1646. [Google Scholar] [CrossRef] [PubMed]

- Shuai, L.Y.Z.; Guo, Z.H.; Zhang, P.P.; Wan, J.M.; Pu, X.; Wang, Z.L. Stretchable, self-healing, conductive hydrogel fibers for strain sensing and triboelectric energy-harvesting smart textiles. Nano Energy 2020, 78, 105389. [Google Scholar] [CrossRef]

- Matsuhisa, N.; Chen, X.; Bao, Z.; Someya, T. Materials and structural designs of stretchable conductors. Chem. Soc. Rev. 2019, 48, 2946–2966. [Google Scholar] [CrossRef] [PubMed]

- Szalapak, J.; Zdanikowski, B.; Kadziela, A.; Lepak-Kuc, S.; Dybowska-Sarapuk, L.; Janczak, D.; Raczynski, T.; Jakubowska, M. Carbon-Based Composites with Biodegradable Matrix for Flexible Paper Electronics. Polymers 2024, 16, 686. [Google Scholar] [CrossRef] [PubMed]

- Morales, D.; Podolsky, I.; Mailen, R.W.; Shay, T.; Dickey, M.D.; Velev, O.D. Ionoprinted Multi-Responsive Hydrogel Actuators. Micromachines 2016, 7, 98. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Liu, S.Y.; Huang, X.; Guo, W.; Li, Y.Y.; Wu, H. A stretchable dual-mode sensor array for multifunctional robotic electronic skin. Nano Energy 2019, 62, 164–170. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.K.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z.N. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788–792. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Zhu, Y. Highly conductive and stretchable silver nanowire conductors. Adv. Mater. 2012, 24, 5117–5122. [Google Scholar] [CrossRef] [PubMed]

- Guan, F.; Xie, Y.; Wu, H.; Meng, Y.; Shi, Y.; Gao, M.; Zhang, Z.; Chen, S.; Chen, Y.; Wang, H.; et al. Silver Nanowire-Bacterial Cellulose Composite Fiber-Based Sensor for Highly Sensitive Detection of Pressure and Proximity. ACS Nano 2020, 14, 15428–15439. [Google Scholar] [CrossRef]

- Wagner, S.; Bauer, S. Materials for stretchable electronics. MRS Bull. 2012, 37, 207–217. [Google Scholar] [CrossRef]

- Yun, G.L.; Tang, S.Y.; Sun, S.S.; Yuan, D.; Zhao, Q.B.; Deng, L.; Yan, S.; Du, H.P.; Dickey, M.D.; Li, W.H. Liquid metal-filled magnetorheological elastomer with positive piezoconductivity. Nat. Commun. 2019, 10, 1300. [Google Scholar] [CrossRef] [PubMed]

- Won, P.; Jeong, S.; Majidi, C.; Ko, S.H. Recent advances in liquid-metal-based wearable electronics and materials. iScience 2021, 24, 102698. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.L.; Xu, X.W.; Han, Z.B.; Li, H.; Wang, Q.; Yao, B. Highly stretchable liquid-metal based strain sensor with high sensitivity for human activity monitoring. Mater. Lett. 2022, 308, 131277. [Google Scholar] [CrossRef]

- Xu, K.; Fujita, Y.; Lu, Y.; Honda, S.; Shiomi, M.; Arie, T.; Akita, S.; Takei, K. A Wearable Body Condition Sensor System with Wireless Feedback Alarm Functions. Adv. Mater. 2021, 33, 2008701. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.Z.; Chen, S.; Yuan, B.; Liu, J.; Sun, X.Y. Liquid Metal Transformable Machines. Acc. Mater. Res. 2021, 2, 1227–1238. [Google Scholar] [CrossRef]

- Do, T.N.; Phan, H.; Nguyen, T.Q.; Visell, Y. Miniature Soft Electromagnetic Actuators for Robotic Applications. Adv. Funct. Mater. 2018, 28, 1800244. [Google Scholar] [CrossRef]

- Wu, J.; Tang, S.Y.; Fang, T.; Li, W.; Li, X.; Zhang, S. A Wheeled Robot Driven by a Liquid-Metal Droplet. Adv. Mater. 2018, 30, 1805039. [Google Scholar] [CrossRef] [PubMed]

- Cook, A.; Parekh, D.P.; Ladd, C.; Kotwal, G.; Panich, L.; Durstock, M.; Dickey, M.D.; Tabor, C.E. Shear-Driven Direct-Write Printing of Room-Temperature Gallium-Based Liquid Metal Alloys. Adv. Eng. Mater. 2019, 21, 1900400. [Google Scholar] [CrossRef]

- Andrews, J.B.; Mondal, K.; Neumann, T.V.; Cardenas, J.A.; Wang, J.; Parekh, D.P.; Lin, Y.L.; Ballentine, P.; Dickey, M.D.; Franklin, A.D. Patterned Liquid Metal Contacts for Printed Carbon Nanotube Transistors. ACS Nano 2018, 12, 5482–5488. [Google Scholar] [CrossRef] [PubMed]

- Tandel, R.; Gozen, B.A. Direct-Ink-writing of liquid metal-graphene-based polymer composites: Composition-processing-property relationships. J. Mater. Process. Technol. 2022, 302, 117470. [Google Scholar] [CrossRef]

- Zou, Z.F.; Chen, Y.W.; Yuan, S.; Luo, N.; Li, J.C.; He, Y. 3D Printing of Liquid Metals: Recent Advancements and Challenges. Adv. Funct. Mater. 2023, 33, 2213312. [Google Scholar] [CrossRef]

- Liu, J.; Yang, S.; Liu, Z.; Guo, H.; Liu, Z.; Xu, Z.; Liu, C.; Wang, L. Patterning sub-30 µm liquid metal wires on PDMS substrates via stencil lithography and pre-stretching. J. Micromech. Microeng. 2019, 29, 095001. [Google Scholar] [CrossRef]

- Wang, B.; Wu, K.; Hjort, K.; Guo, C.; Wu, Z. High-Performance Liquid Alloy Patterning of Epidermal Strain Sensors for Local Fine Skin Movement Monitoring. Soft Robot. 2019, 6, 414–421. [Google Scholar] [CrossRef] [PubMed]

- Bandodkar, A.J.; Nuñez-Flores, R.; Jia, W.Z.; Wang, J. All-Printed Stretchable Electrochemical Devices. Adv. Mater. 2015, 27, 3060–3065. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yu, Y.; Yang, J.; Liu, J. Fast Fabrication of Flexible Functional Circuits Based on Liquid Metal Dual-Trans Printing. Adv. Mater. 2015, 27, 7109–7116. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Tang, J.B.; Dong, S.J.; Lin, J.; Wang, H.Z.; Liu, J.; Rao, W. One-Step Liquid Metal Transfer Printing: Toward Fabrication of Flexible Electronics on Wide Range of Substrates. Adv. Mater. Technol. 2018, 3, 1800265. [Google Scholar] [CrossRef]

- Bharambe, V.; Parekh, D.P.; Ladd, C.; Moussa, K.; Dickey, M.D.; Adams, J.J. Vacuum-filling of liquid metals for 3D printed RF antennas. Addit. Manuf. 2017, 18, 221–227. [Google Scholar] [CrossRef]

- Lin, Y.L.; Gordon, O.; Khan, M.R.; Vasquez, N.; Genzer, J.; Dickey, M.D. Vacuum filling of complex microchannels with liquid metal. Lab Chip 2017, 17, 3043–3050. [Google Scholar] [CrossRef] [PubMed]

- Eaker, C.B.; Joshipura, I.D.; Maxwell, L.R.; Heikenfeld, J.; Dickey, M.D. Electrowetting without external voltage using paint-on electrodes. Lab Chip 2017, 17, 1069–1075. [Google Scholar] [CrossRef] [PubMed]

- Diebold, A.V.; Watson, A.M.; Holcomb, S.; Tabor, C.; Mast, D.; Dickey, M.D.; Heikenfeld, J. Electrowetting-actuated liquid metal for RF applications. J. Micromech. Microeng. 2017, 27, 025010. [Google Scholar] [CrossRef]

- Handschuh-Wang, S.; Gan, T.S.; Wang, T.; He, B.; Han, P.G.; Stadler, F.J.; Zhou, X.C. Vibration-Enabled Mobility of Liquid Metal. Adv. Funct. Mater. 2024, 12, 2313474. [Google Scholar] [CrossRef]

- Joshipura, I.D.; Persson, K.A.; Truong, V.K.; Oh, J.H.; Kong, M.; Vong, M.H.; Ni, C.J.; Alsafatwi, M.; Parekh, D.P.; Zhao, H.; et al. Are Contact Angle Measurements Useful for Oxide-Coated Liquid Metals? Langmuir 2021, 37, 10914–10923. [Google Scholar] [CrossRef] [PubMed]

- Hao, S.W.; Shao, C.Y.; Meng, L.; Cui, C.; Xu, F.; Yang, J. Tannic Acid-Silver Dual Catalysis Induced Rapid Polymerization of Conductive Hydrogel Sensors with Excellent Stretchability, Self-Adhesion, and Strain-Sensitivity Properties. ACS Appl. Mater. Interfaces 2020, 12, 56509–56521. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Lee, J.; Yang, D.; Park, B.C.; Ryu, S.; Park, I. A stretchable strain sensor based on a metal nanoparticle thin film for human motion detection. Nanoscale 2014, 6, 11932–11939. [Google Scholar] [CrossRef] [PubMed]

- Sang, C.Y.; Wang, S.W.; Jin, X.Y.; Cheng, X.Y.; Xiao, H.N.; Yue, Y.Y.; Han, J.Q. Nanocellulose-mediated conductive hydrogels with NIR photoresponse and fatigue resistance for multifunctional wearable sensors. Carbohydr. Polym. 2024, 333, 121947. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Lai, D.T.H.; Su, B.; Si, K.J.; Ma, Z.; Yap, L.W.; Guo, P.Z.; Cheng, W.L. Highly Stretchy Black Gold E-Skin Nanopatches as Highly Sensitive Wearable Biomedical Sensors. Adv. Electron. Mater. 2015, 1, 1400063. [Google Scholar] [CrossRef]

- Aslanidis, E.; Skotadis, E.; Tsoukalas, D. Resistive crack-based nanoparticle strain sensors with extreme sensitivity and adjustable gauge factor, made on flexible substrates. Nanoscale 2021, 13, 3263–3274. [Google Scholar] [CrossRef] [PubMed]

- Shintake, J.; Piskarev, Y.; Jeong, S.H.; Floreano, D. Ultrastretchable Strain Sensors Using Carbon Black-Filled Elastomer Composites and Comparison of Capacitive versus Resistive Sensors. Adv. Mater. Technol. 2018, 3, 1700284. [Google Scholar] [CrossRef]

| Materials | GF | Strain | Cycle | Source |

|---|---|---|---|---|

| Fe-LM | 1.18 | 100% | 2400 | This work |

| PAM@CNC/TA-Ag NC hydrogels | 1.02 | 100% | 500 | [49] |

| Silver nanoparticle film | 1.2 (5%), 2.05 (20%) | 20% | 1000 | [50] |

| BPTP composite conductive hydrogels | 1.4 (0–60%), 6 (60–120%) | 120% | 1000 | [51] |

| Ultrathin gold nanowires | 6.9–9.9 | 350% | 5000 | [52] |

| Pt nanoparticles | 7998 (4.17%), 2.6 × 108 (7.2%) | 7.2% | 1000 | [53] |

| Ecoflex-CB | 1.62–3.37 | 500% | 10,000 | [54] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Zhang, C.; Li, H.; Luo, Z.; Zhang, Y.; Hou, X.; Yang, Q.; Chen, F. Femtosecond Laser Fabrication of High-Linearity Liquid Metal-Based Flexible Strain Sensor. Materials 2024, 17, 1979. https://doi.org/10.3390/ma17091979

Li C, Zhang C, Li H, Luo Z, Zhang Y, Hou X, Yang Q, Chen F. Femtosecond Laser Fabrication of High-Linearity Liquid Metal-Based Flexible Strain Sensor. Materials. 2024; 17(9):1979. https://doi.org/10.3390/ma17091979

Chicago/Turabian StyleLi, Cheng, Chengjun Zhang, Haoyu Li, Zexiang Luo, Yuanchen Zhang, Xun Hou, Qing Yang, and Feng Chen. 2024. "Femtosecond Laser Fabrication of High-Linearity Liquid Metal-Based Flexible Strain Sensor" Materials 17, no. 9: 1979. https://doi.org/10.3390/ma17091979