Effect of Boron-Doped Diamond Interlayer on Cutting Performance of Diamond Coated Micro Drills for Graphite Machining

Abstract

:1. Introduction

2. Experimental Section

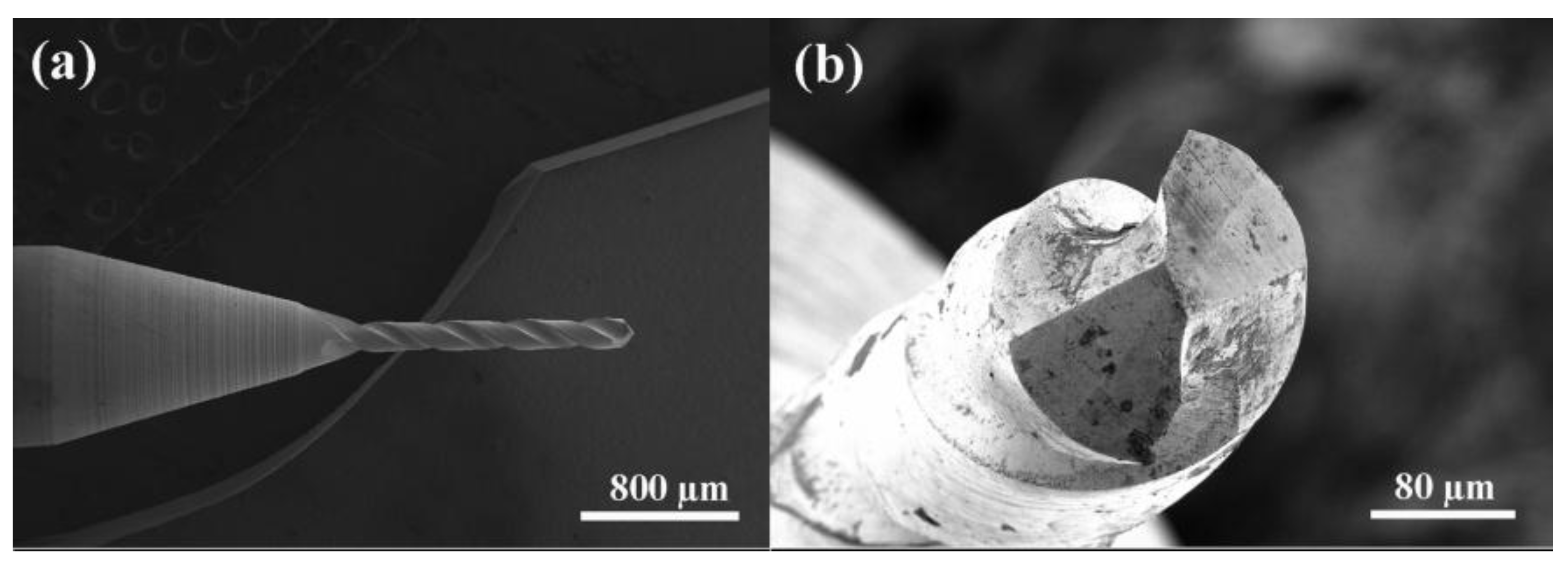

2.1. Fabrication of Diamond Coated Micro Drills

| Types of diamond film | MCD | BDD | BDD + MCD | ||||

| Nucleation | Growth | Nucleation | Growth | Nucleation | Growth1 | Growth2 | |

| B/C atomic ratio [ppm] | 0 | 0 | 3500 | 3500 | 3500 | 3500 | 0 |

| H2 flow [sccm] | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Acetone & H2 mixed flow [sccm] | 80 | 70 | – | – | – | – | 70 |

| Acetone & B(OCH3)3&H2 mixed flow [sccm] | – | – | 80 | 70 | 80 | 70 | – |

| Pressure [kPa] | 1.6 | 3.3 | 1.6 | 3.3 | 1.6 | 3.3 | 3.3 |

| Bias current [A] | 0.02 | 0 | 0.02 | 0 | 0.02 | 0 | 0 |

| Duration [h] | 0.5 | 3.5 | 0.5 | 3.5 | 0.5 | 1.5 | 2 |

2.2. Characterization

2.3. Drilling Tests

3. Results and Discussion

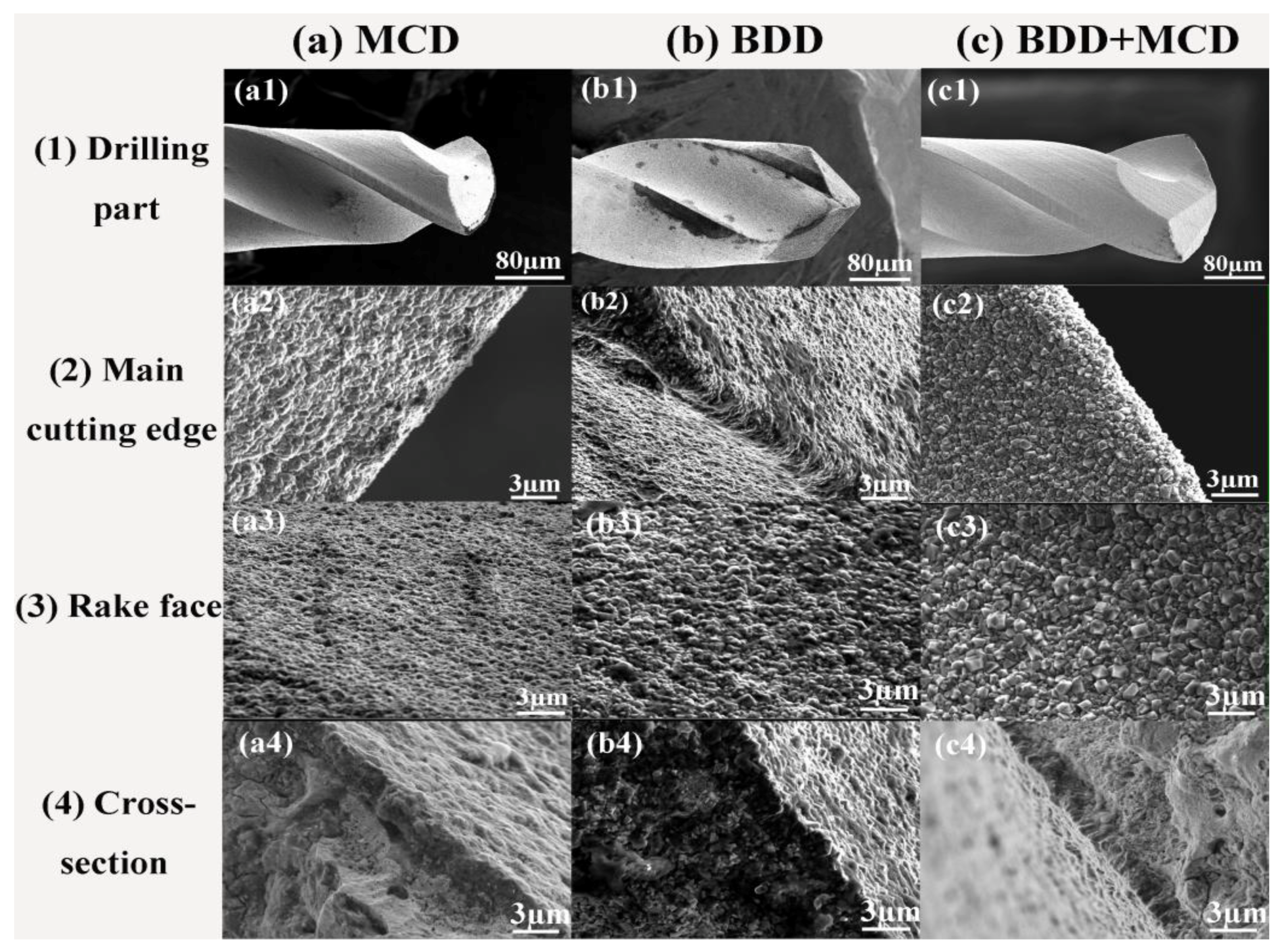

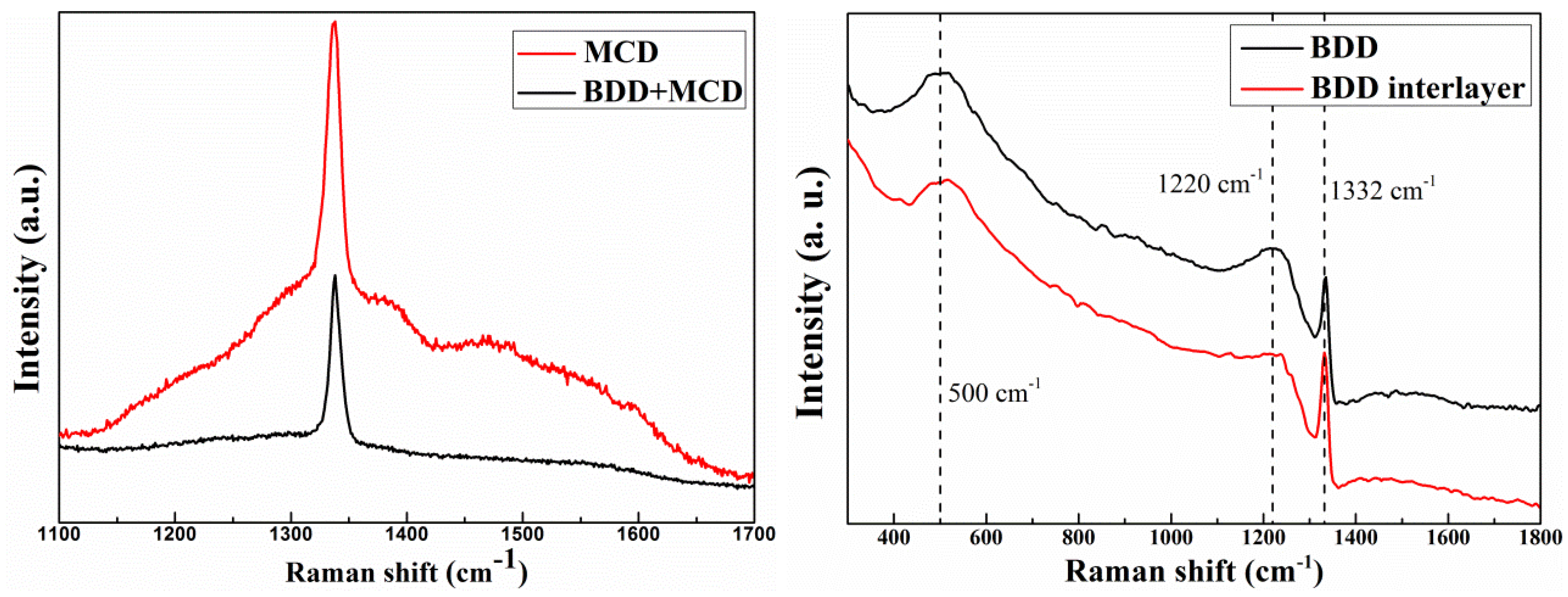

3.1. Characterization of Diamond Coated Micro Drills

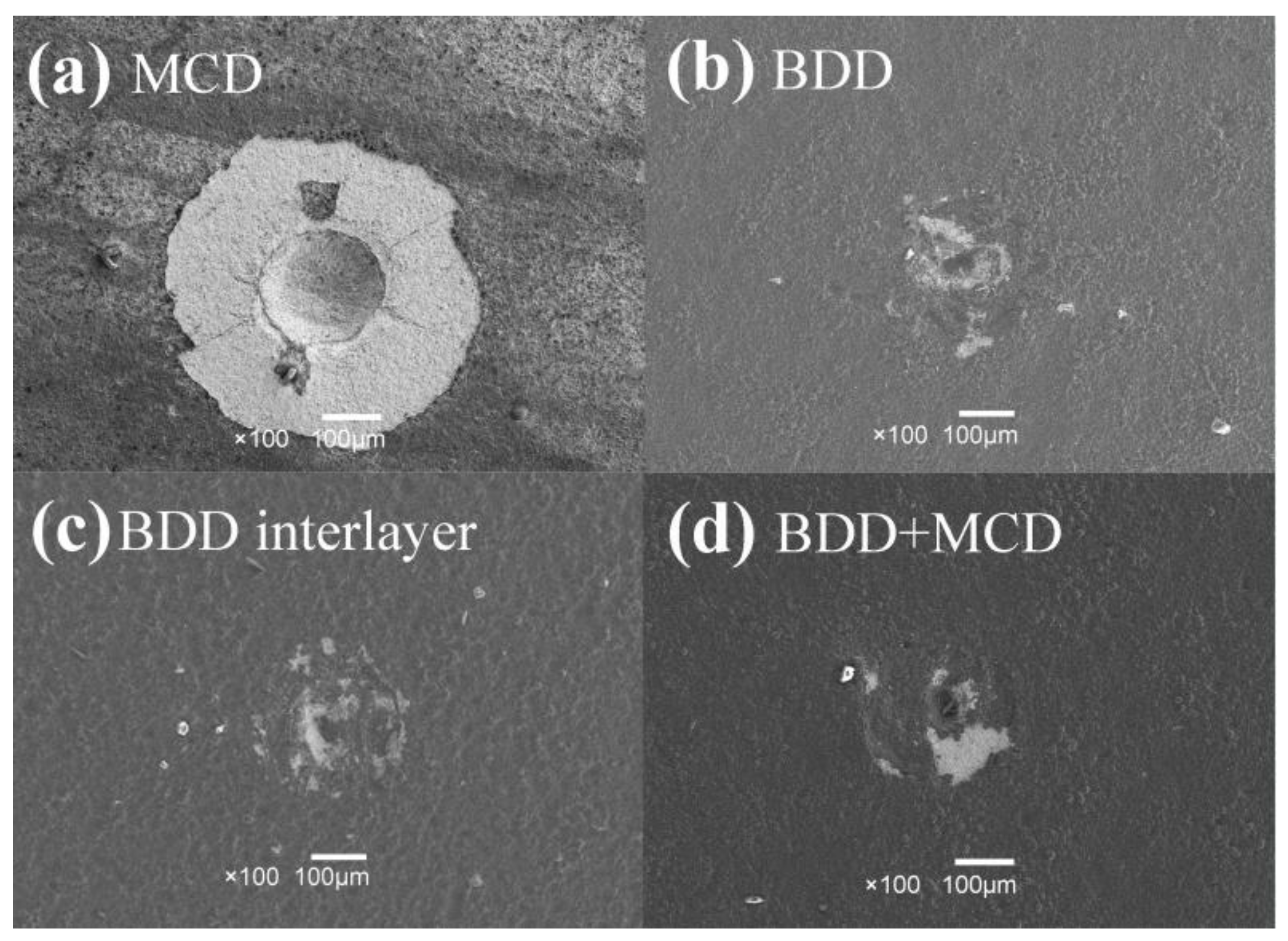

3.2. Results of Rockwell Indentation Test

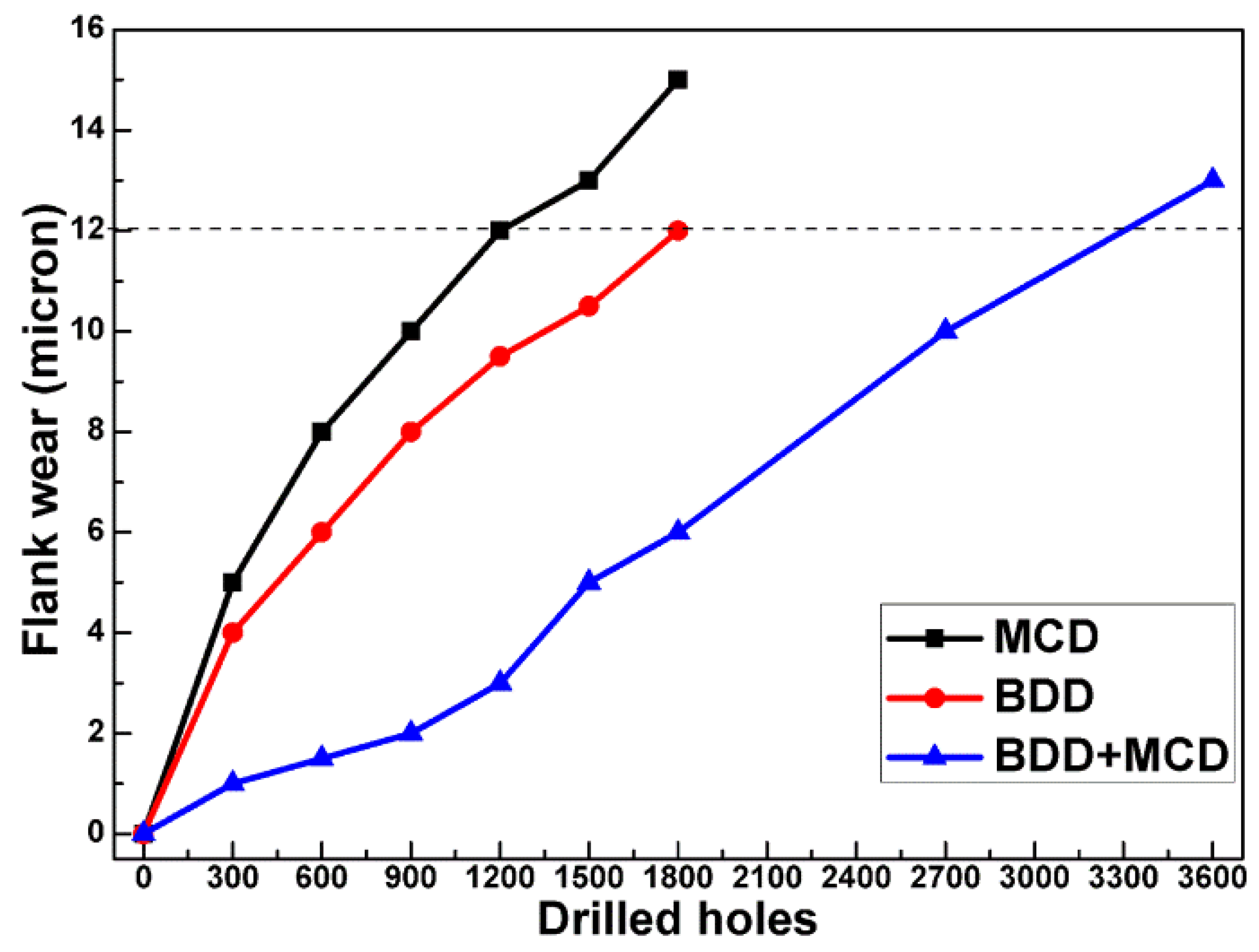

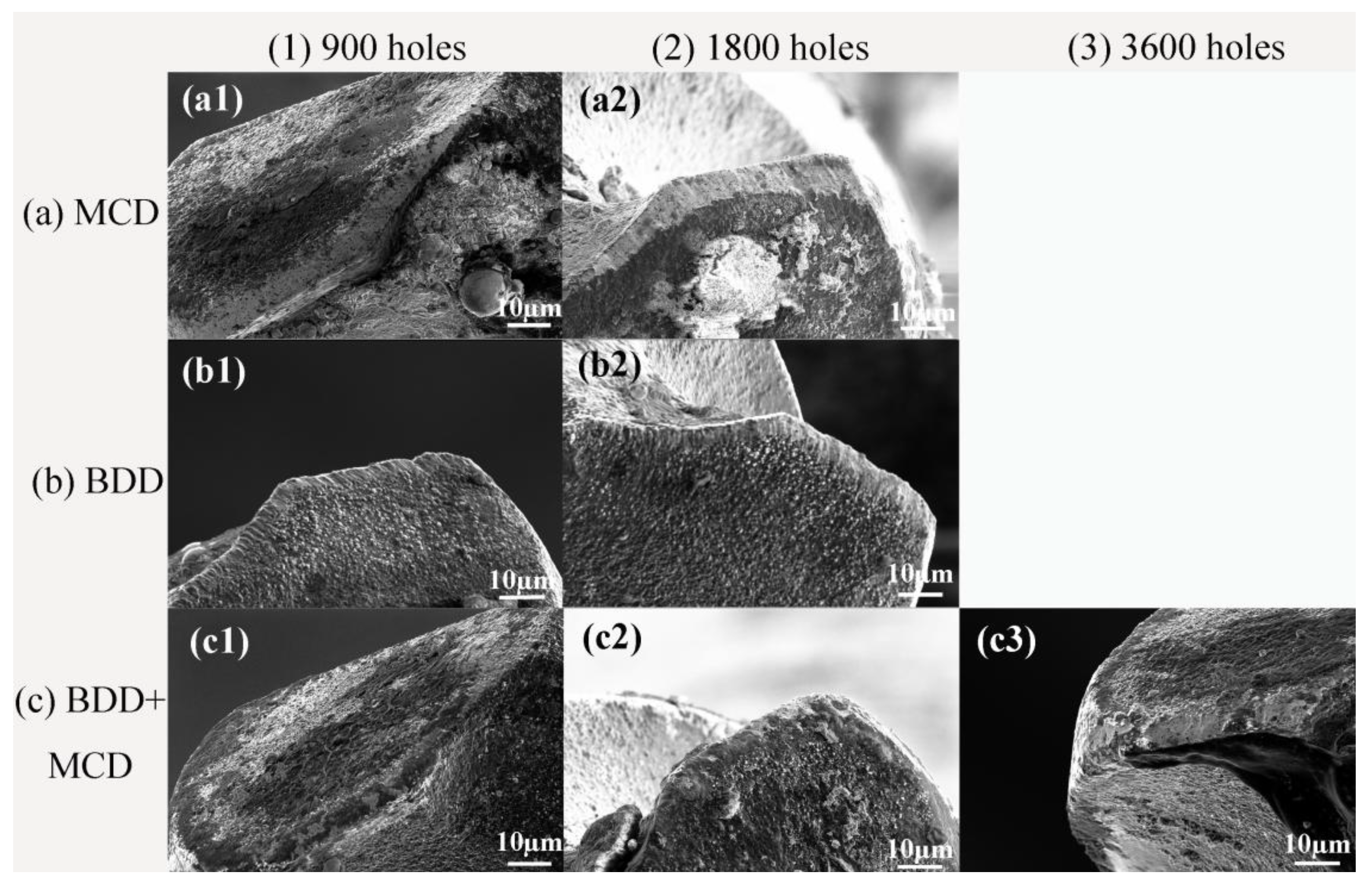

3.3. Results of Drilling Tests

4. Conclusions

Acknowledgments

Conflict of Interest

References

- Yao, X.L.; Zeng, Z.Z.; Chen, J.L. Electrode erosion of a high energy impulse spark gap switch. Plas. Sci.Technol. 2005, 7, 3157–3160. [Google Scholar] [CrossRef]

- Almeida, F.; Sacramento, J.; Oliveira, F.; Silva, R. Micro-and nano-crystalline CVD diamond coated tools in the turning of EDM graphite. Surf. Coat. Technol. 2008, 203, 271–276. [Google Scholar] [CrossRef]

- Cabral, G.; Reis, P.; Polini, R.; Titus, E.; Ali, N.; Davim, J.; Grácio, J. Cutting performance of time-modulated chemical vapour deposited diamond coated tool inserts during machining graphite. Diam. Relat. Mater. 2006, 15, 1753–1758. [Google Scholar] [CrossRef]

- Chen, M.; Jian, X.G.; Sun, F.H.; Hu, B.; Liu, X.S. Development of diamond-coated drills and their cutting performance. J. Mater. Process. Techol. 2002, 129, 81–85. [Google Scholar] [CrossRef]

- Shen, B.; Sun, F.H.; Xue, H.; Chen, M.; Zhang, Z.M. Study on fabrication and cutting performance of high quality diamond coated PCB milling tools with complicated geometries. Surf. Eng. 2009, 25, 70–76. [Google Scholar] [CrossRef]

- Ko, T.J.; Kim, H.S. An experimental study on microcutting of silicon using a micromilling machine. Int. J. Adv. Manuf. Technol. 2008, 39, 85–91. [Google Scholar] [CrossRef]

- Zhang, Z.; He, X.; Shen, H.; Sun, F.; Chen, M.; Wan, Y. Pre-treatment for diamond coatings on free-shape WC-Co tools. Diam. Relat. Mater. 2000, 9, 1749–1752. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, Z.; Chen, M.; Shen, H. Fabrication and application of high quality diamond-coated tools. J. Mater. Process. Techol. 2002, 129, 435–440. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, Z.; Chen, M.; Shen, H. Improvement of adhesive strength and surface roughness of diamond films on Co-cemented tungsten carbide tools. Diam. Relat. Mater. 2003, 12, 711–718. [Google Scholar] [CrossRef]

- Li, Y.; Tang, Y.; Yang, Q.; Shimada, S.; Wei, R.; Lee, K.; Hirose, A. Al-enhanced nucleation and adhesion of diamond films on WC-Co substrates. Int. J. Refract. Meta 2008, 26, 465–471. [Google Scholar] [CrossRef]

- Cabral, G.; Gabler, J.; Lindner, J.; Grácio, J.; Polini, R. A study of diamond film deposition on WC-Co inserts for graphite machining: Effectiveness of SiC interlayers prepared by HFCVD. Diam. Relat. Mater. 2008, 17, 1008–1014. [Google Scholar] [CrossRef]

- Polini, R.; Barletta, M.; Cristofanilli, G. Wear resistance of nano-and micro-crystalline diamond coatings onto WC-Co with Cr/CrN interlayers. Thin Solid Film 2010, 519, 1629–1635. [Google Scholar] [CrossRef]

- Polini, R.; Barletta, M. On the use of CrN/Cr and CrN interlayers in hot filament chemical vapour deposition (HF-CVD) of diamond films onto WC-Co substrates. Diam. Relat. Mater. 2008, 17, 325–335. [Google Scholar] [CrossRef] [Green Version]

- Tang, W.; Wang, Q.; Wang, S.; Lu, F. A comparison in performance of diamond coated cemented carbide cutting tools with and without a boride interlayer. Surf. Coat. Techol. 2002, 153, 298–303. [Google Scholar] [CrossRef]

- Cappelli, E.; Orlando, S.; Mattei, G.; Armigliato, A. Boron nitride thin films deposited by RF plasma reactive pulsed laser ablation as interlayer between WC-Co hard metals and CVD diamond films. Surf. Coat. Technol. 2004, 180, 184–189. [Google Scholar] [CrossRef]

- Kalss, W.; Bohr, S.; Haubner, R.; Lux, B.; Griesser, M.; Spicka, H.; Grasserbauer, M.; Wurzinger, P. Influence of boron on diamond growth on WC-Co hardmetals. Int. J. Refract. Meta 1996, 14, 137–144. [Google Scholar] [CrossRef]

- May, P.; Ludlow, W.; Hannaway, M.; Heard, P.; Smith, J.; Rosser, K. Raman and conductivity studies of boron-doped microcrystalline diamond, facetted nanocrystalline diamond and cauliflower diamond films. Diam. Relat. Mater. 2008, 17, 105–117. [Google Scholar] [CrossRef]

- Ferreira, N.; Abramof, E.; Corat, E.; Trava-Airoldi, V. Residual stresses and crystalline quality of heavily boron-doped diamond films analysed by micro-Raman spectroscopy and X-ray diffraction. Carbon 2003, 41, 1301–1308. [Google Scholar] [CrossRef]

- Wang, L.; Lei, X.; Shen, B.; Sun, F.; Zhang, Z. Tribological properties and cutting performance of boron and silicon doped diamond films on Co-cemented tungsten carbide inserts. Diam. Relat. Mater. 2013, 33, 54–62. [Google Scholar] [CrossRef]

- Alam, M.; Peebles, D.; Tallant, D. Diamond deposition onto WC-6% Co cutting tool material: Coating structure and interfacial bond strength. Thin Solid Film 1997, 300, 164–170. [Google Scholar] [CrossRef]

- Gonon, P.; Gheeraert, E.; Deneuville, A.; Fontaine, F.; Abello, L.; Lucazeau, G. Characterization of heavily B-doped polycrystalline diamond films using Raman spectroscopy and electron spin resonance. J. Appl. Phys. 1995, 78, 7059–7062. [Google Scholar] [CrossRef]

- Bourgeois, E.; Bustarret, E.; Achatz, P.; Omnès, F.; Blase, X. Impurity dimers in superconducting B-doped diamond: Experiment and first-principles calculations. Phys. Rev. B 2006, 74, 094509:1–094509:8. [Google Scholar] [CrossRef]

- Goss, J.; Briddon, P.; Jones, R.; Teukam, Z.; Ballutaud, D.; Jomard, F.; Chevallier, J.; Bernard, M.; Deneuville, A. Deep hydrogen traps in heavily B-doped diamond. Phys. Rev. B 2003, 68, 235209:1–235209:10. [Google Scholar] [CrossRef]

- Zhang, R.; Lee, S.T.; Lam, Y. Characterization of heavily boron-doped diamond films. Diam. Relat. Mater. 1996, 5, 1288–1294. [Google Scholar] [CrossRef]

- Bernard, M.; Baron, C.; Deneuville, A. About the origin of the low wave number structures of the Raman spectra of heavily boron doped diamond films. Diam. Relat. Mater. 2004, 13, 896–899. [Google Scholar] [CrossRef]

- Brandao, L.E.V.S.; Pires, R.F.; Balzaretti, N.M. Free-standing boron doped CVD diamond films grown on partially stabilized zirconia substrates. Vib. Spectrosc. 2010, 54, 84–88. [Google Scholar] [CrossRef]

- Bouzid Saï, W. An investigation of tool wear in high-speed turning of AISI 4340 steel. Int. J. Adv. Manuf. Technol. 2005, 26, 330–334. [Google Scholar]

- Yan, C.; Mao, H.; Li, W.; Qian, J.; Zhao, Y.; Hemley, R.J. Ultrahard diamond single crystals from chemical vapor deposition. Phys. Status Solidi 2004, 201, R25–R27. [Google Scholar] [CrossRef]

- Li, X.M.; Wang, J.D.; Chen, D.R.; Liu, B.; Liu, F.B. Mechanical properties of diamond thin films characterixed by nano-indentation method (in Chinese). J. Chin. Ceram. Soc. 2005, 33, 1539–1543. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Lei, X.; Wang, L.; Shen, B.; Sun, F.; Zhang, Z. Effect of Boron-Doped Diamond Interlayer on Cutting Performance of Diamond Coated Micro Drills for Graphite Machining. Materials 2013, 6, 3128-3138. https://doi.org/10.3390/ma6083128

Lei X, Wang L, Shen B, Sun F, Zhang Z. Effect of Boron-Doped Diamond Interlayer on Cutting Performance of Diamond Coated Micro Drills for Graphite Machining. Materials. 2013; 6(8):3128-3138. https://doi.org/10.3390/ma6083128

Chicago/Turabian StyleLei, Xuelin, Liang Wang, Bin Shen, Fanghong Sun, and Zhiming Zhang. 2013. "Effect of Boron-Doped Diamond Interlayer on Cutting Performance of Diamond Coated Micro Drills for Graphite Machining" Materials 6, no. 8: 3128-3138. https://doi.org/10.3390/ma6083128