Modelling of Granular Fracture in Polycrystalline Materials Using Ordinary State-Based Peridynamics

Abstract

:1. Introduction

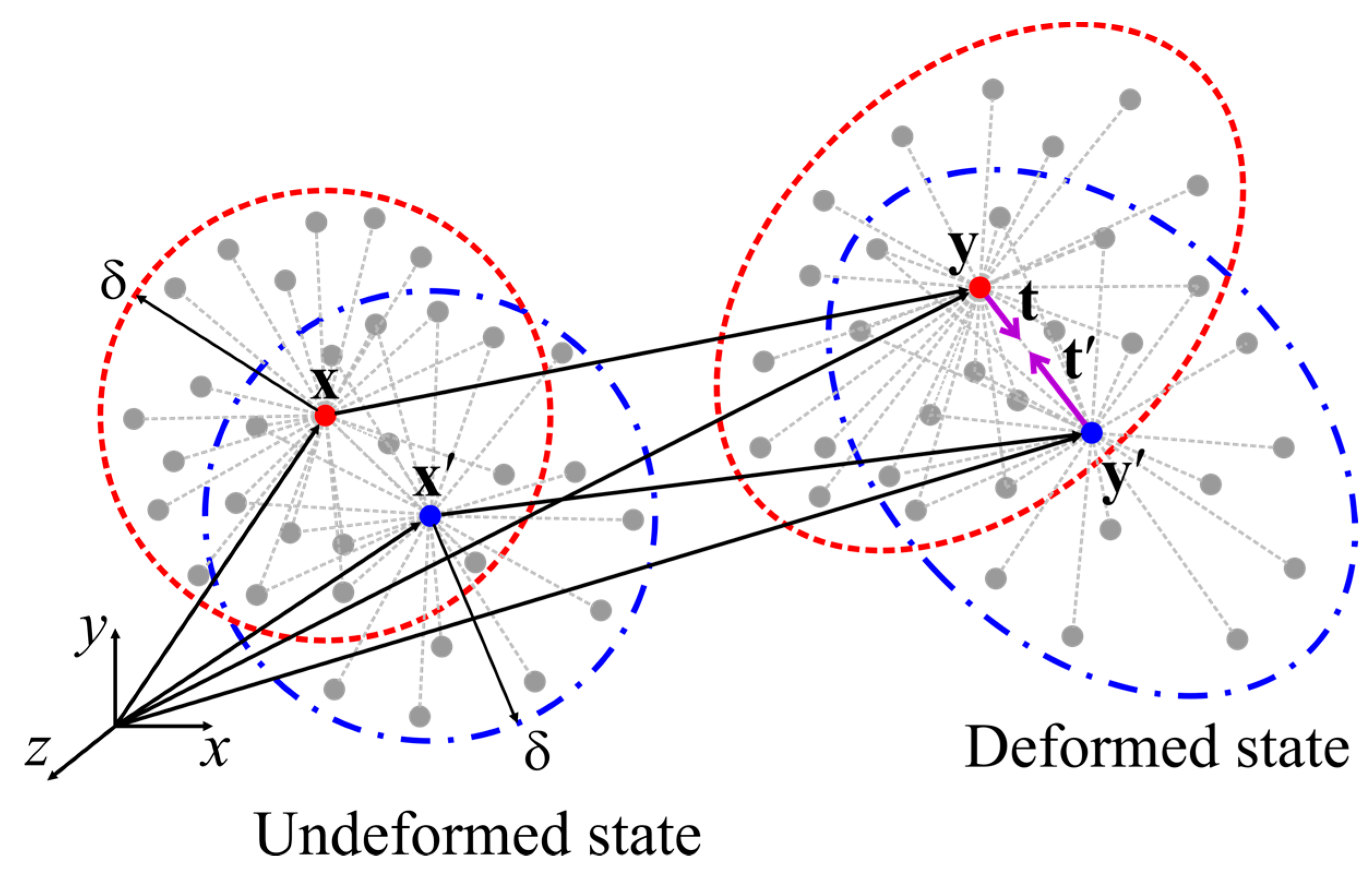

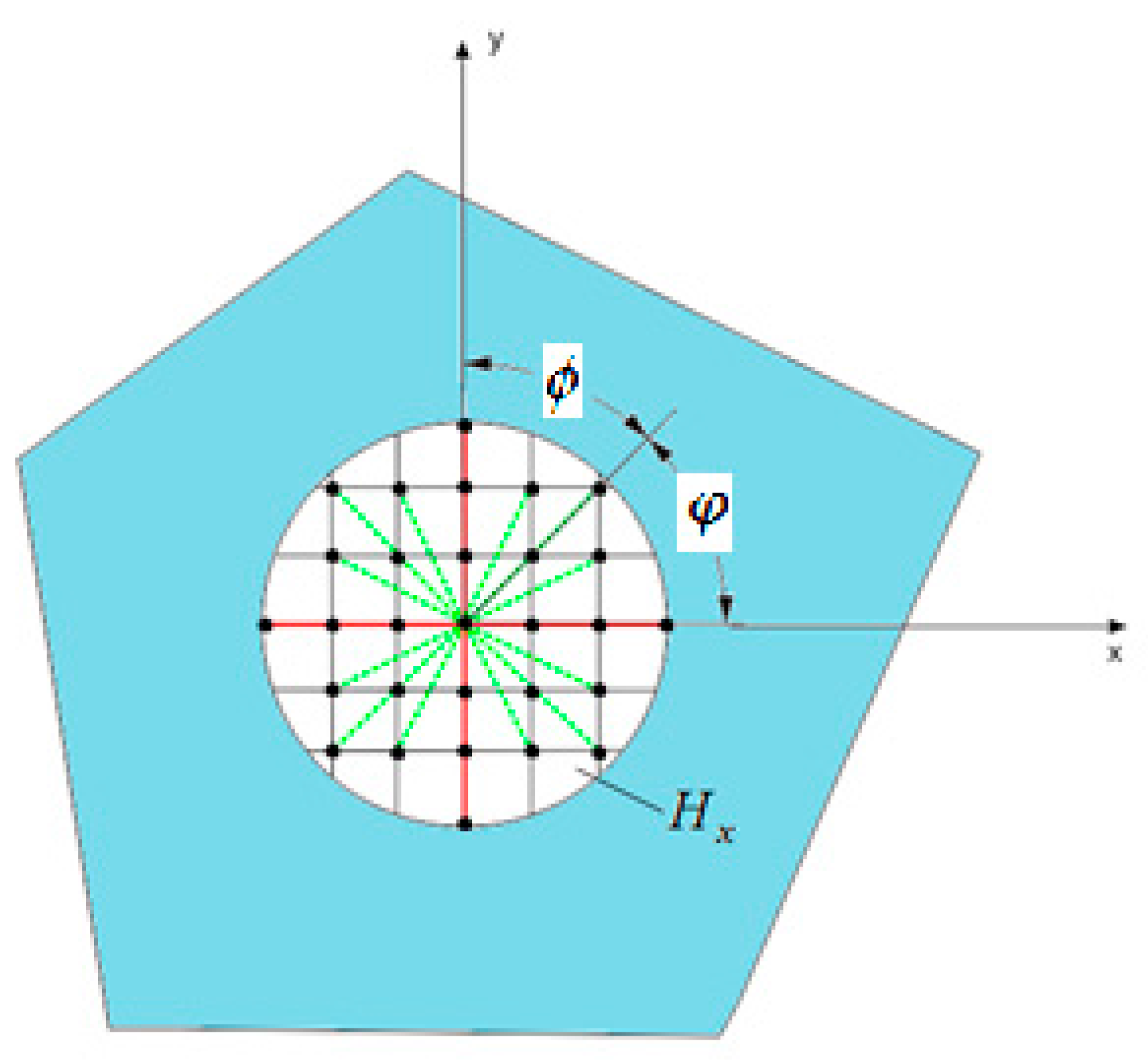

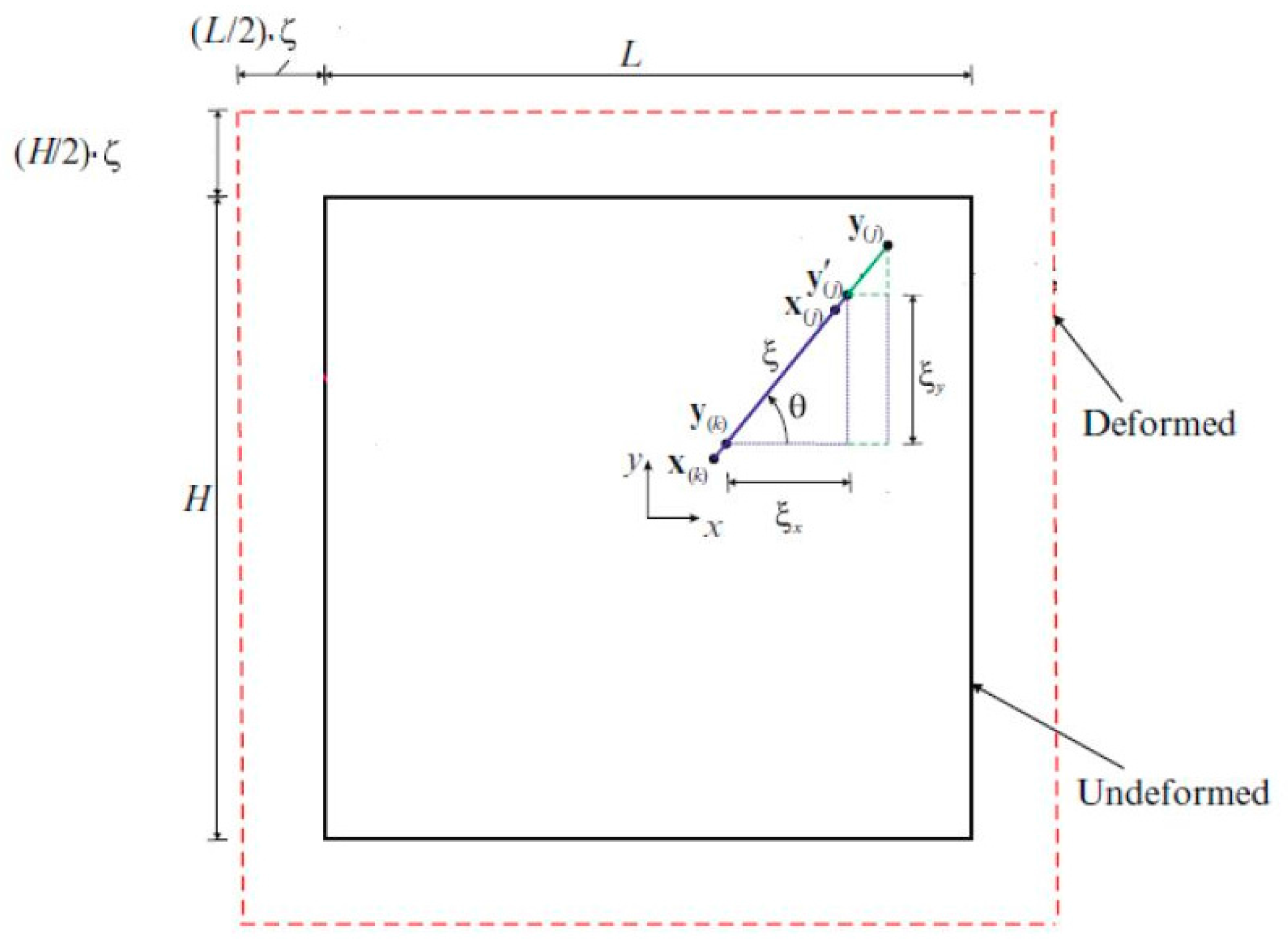

2. Ordinary State-Based Peridynamic Formulation for a Cubic Crystal

- Type 1 bonds (green dashed lines)—interactions along all directions (),

- Type 2 bonds (red solid lines)—interactions along the directions of ,

3. Derivation of PD Parameters

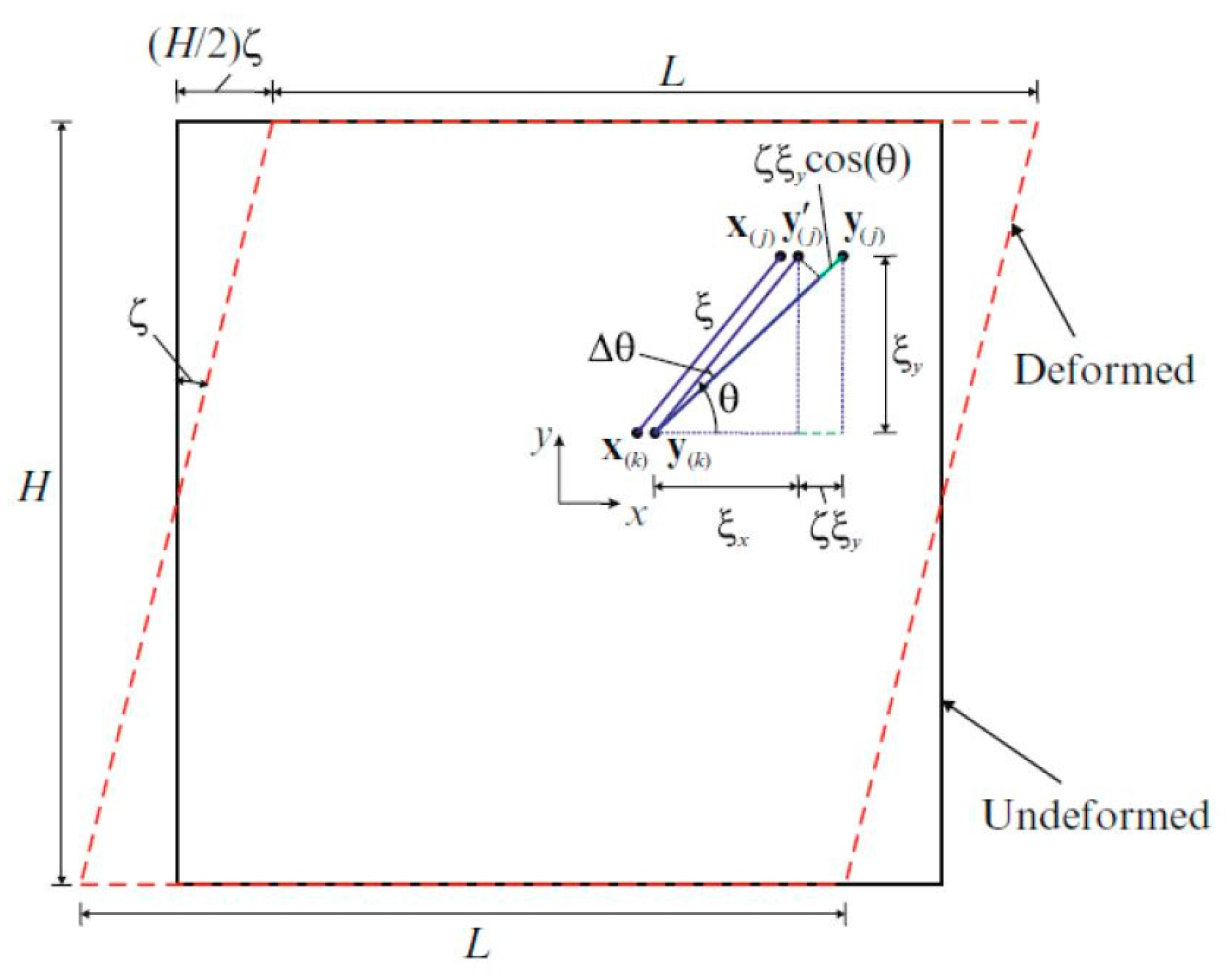

- Simple shear: ;

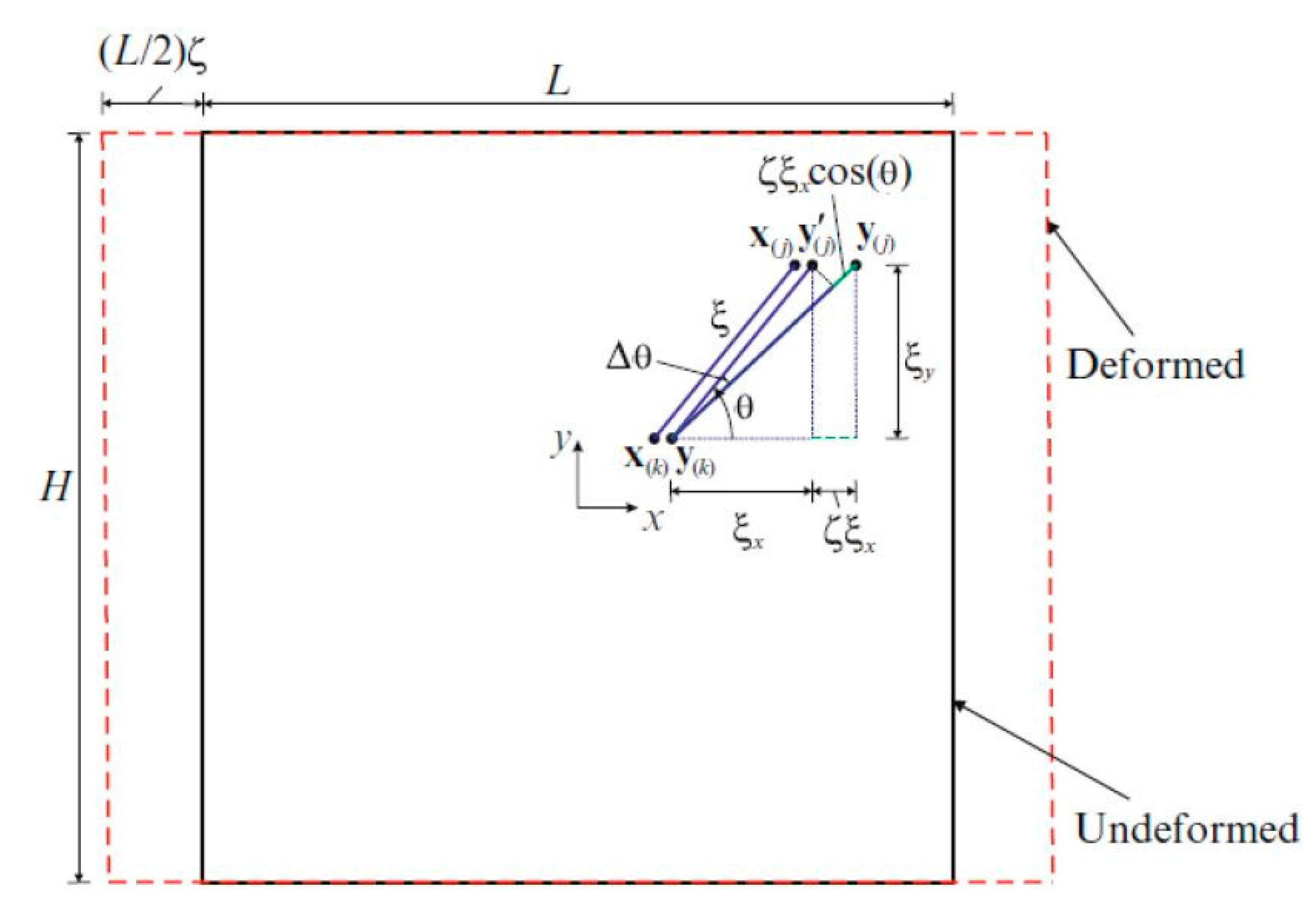

- Uniaxial stretch in crystal orientation direction: ;

- Biaxial stretch: .

3.1. First Loading Condition (Simple Shear )

3.2. Second Loading Condition (Uniaxial Stretch in Crystal Orientation Direction: )

3.3. Third Loading Condition (Biaxial Stretch: )

4. Numerical Results and Discussion

4.1. Material Data

4.2. Static Analysis

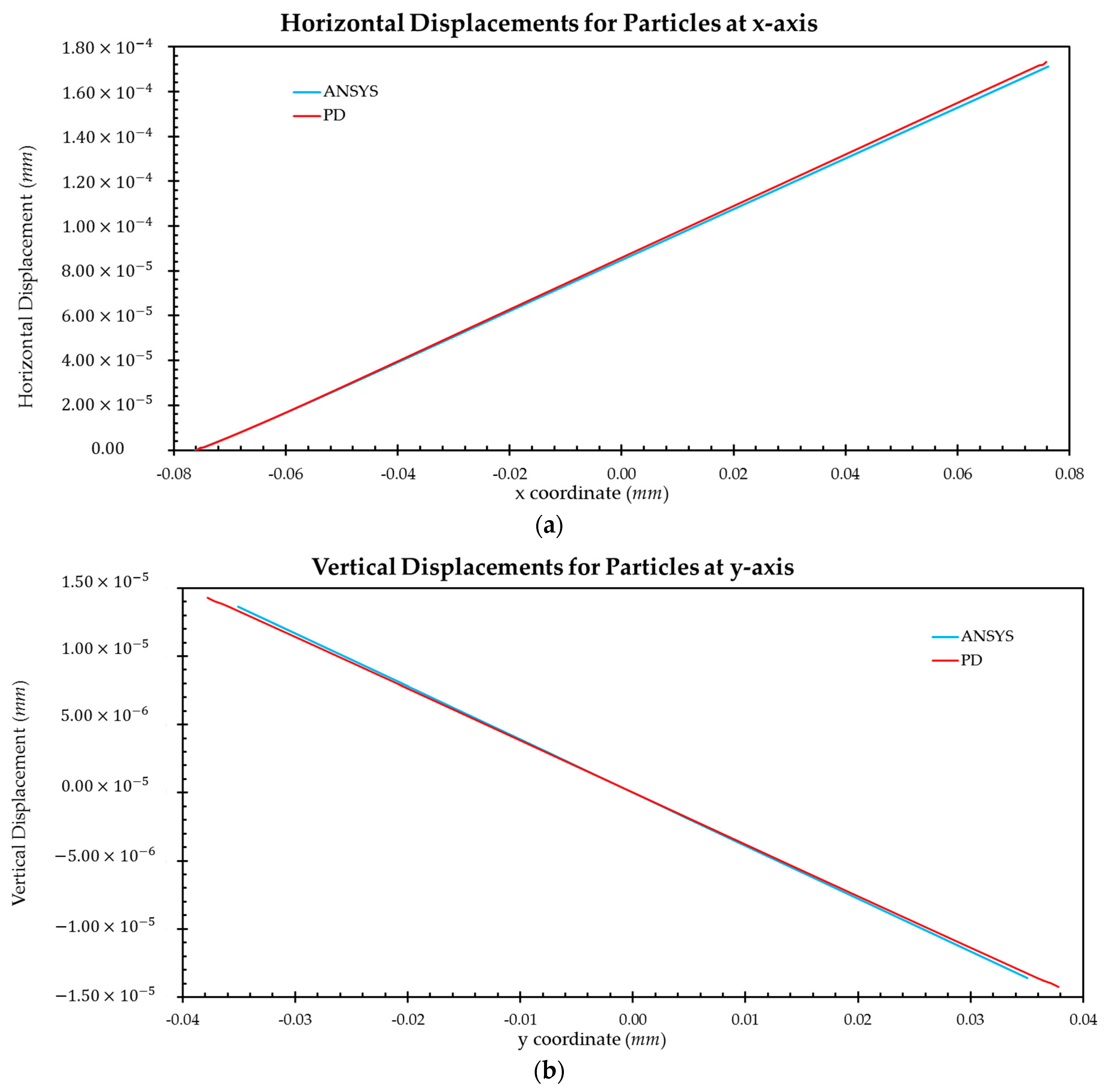

4.2.1. Static Analysis of Nb Single Crystal

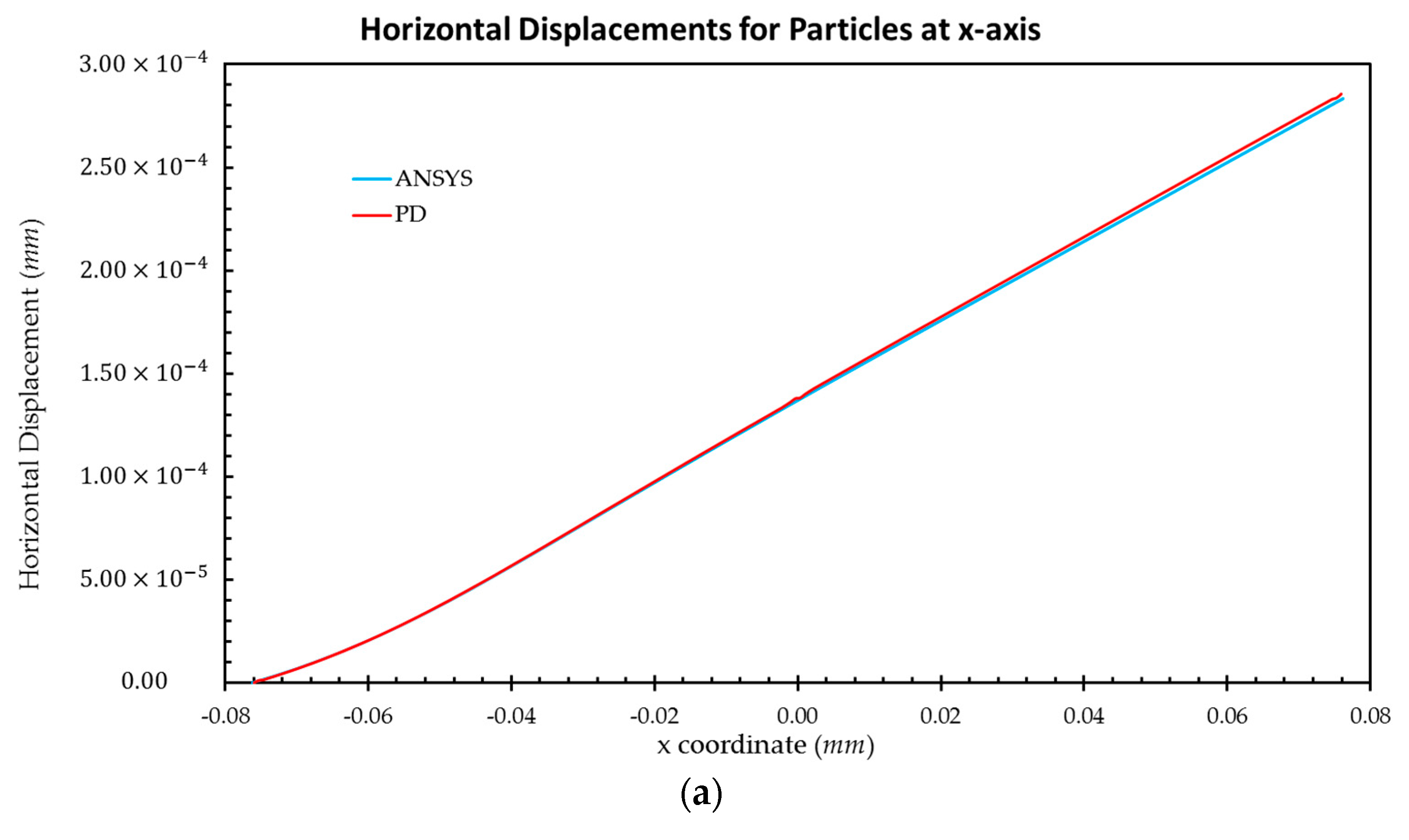

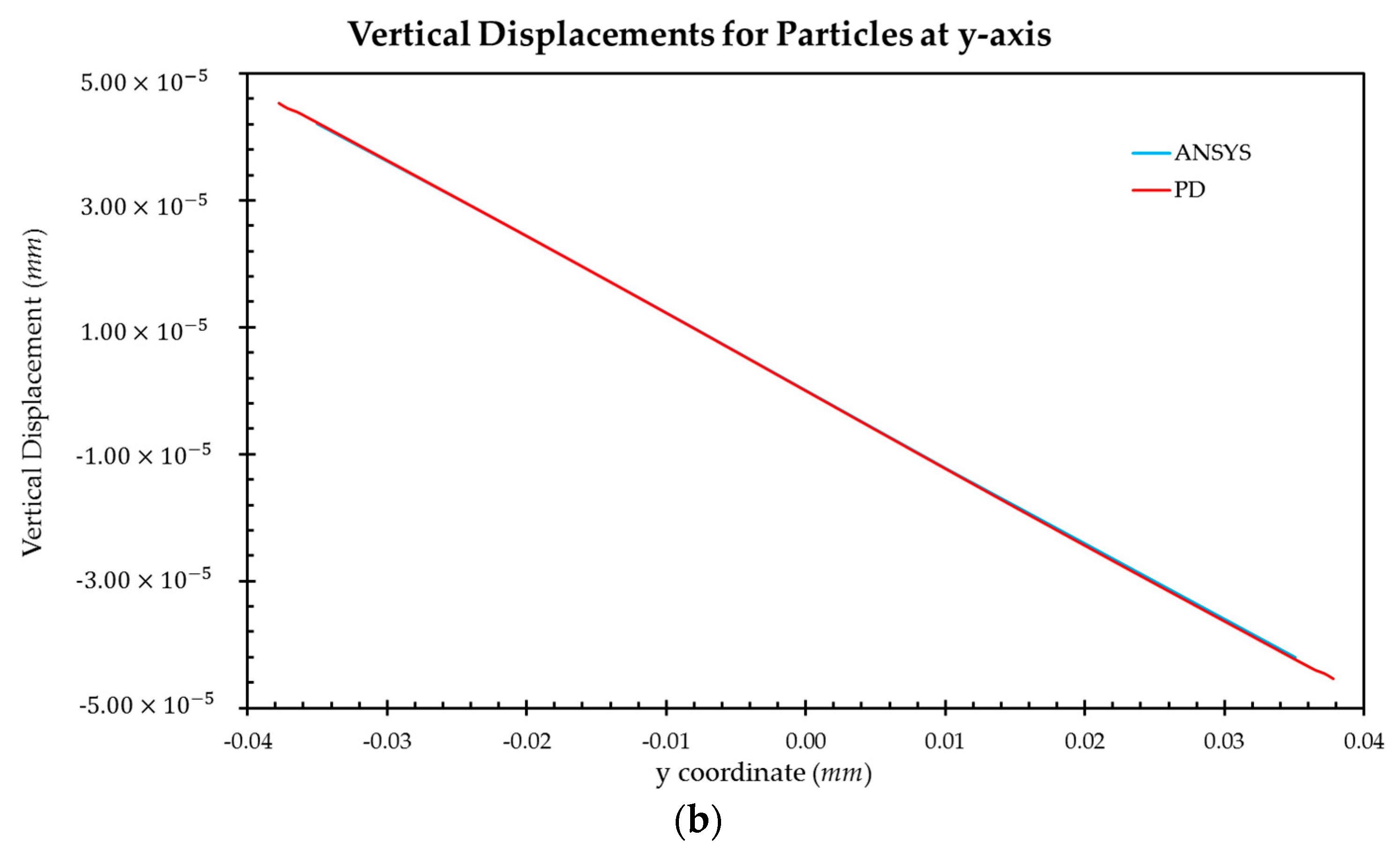

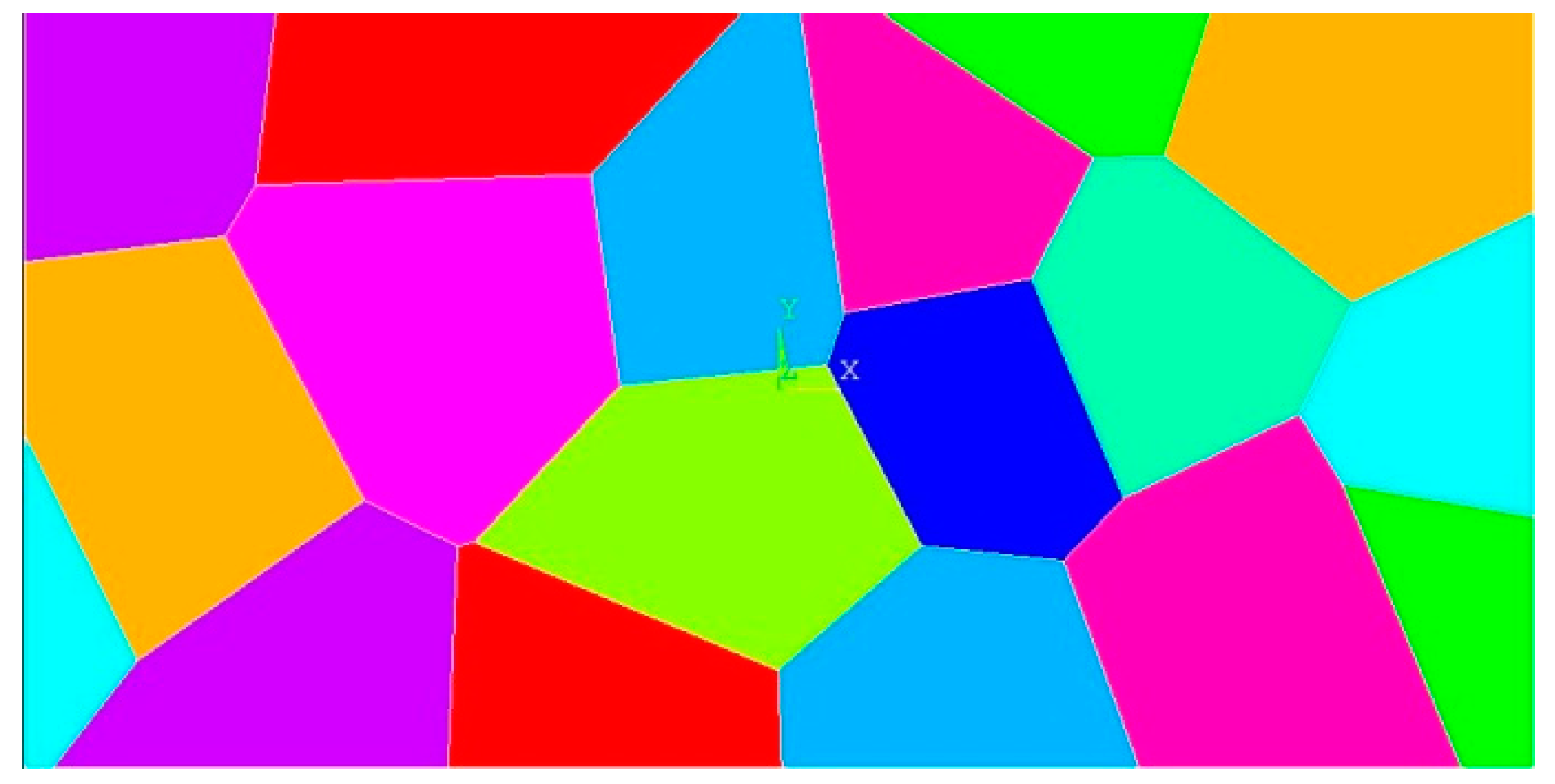

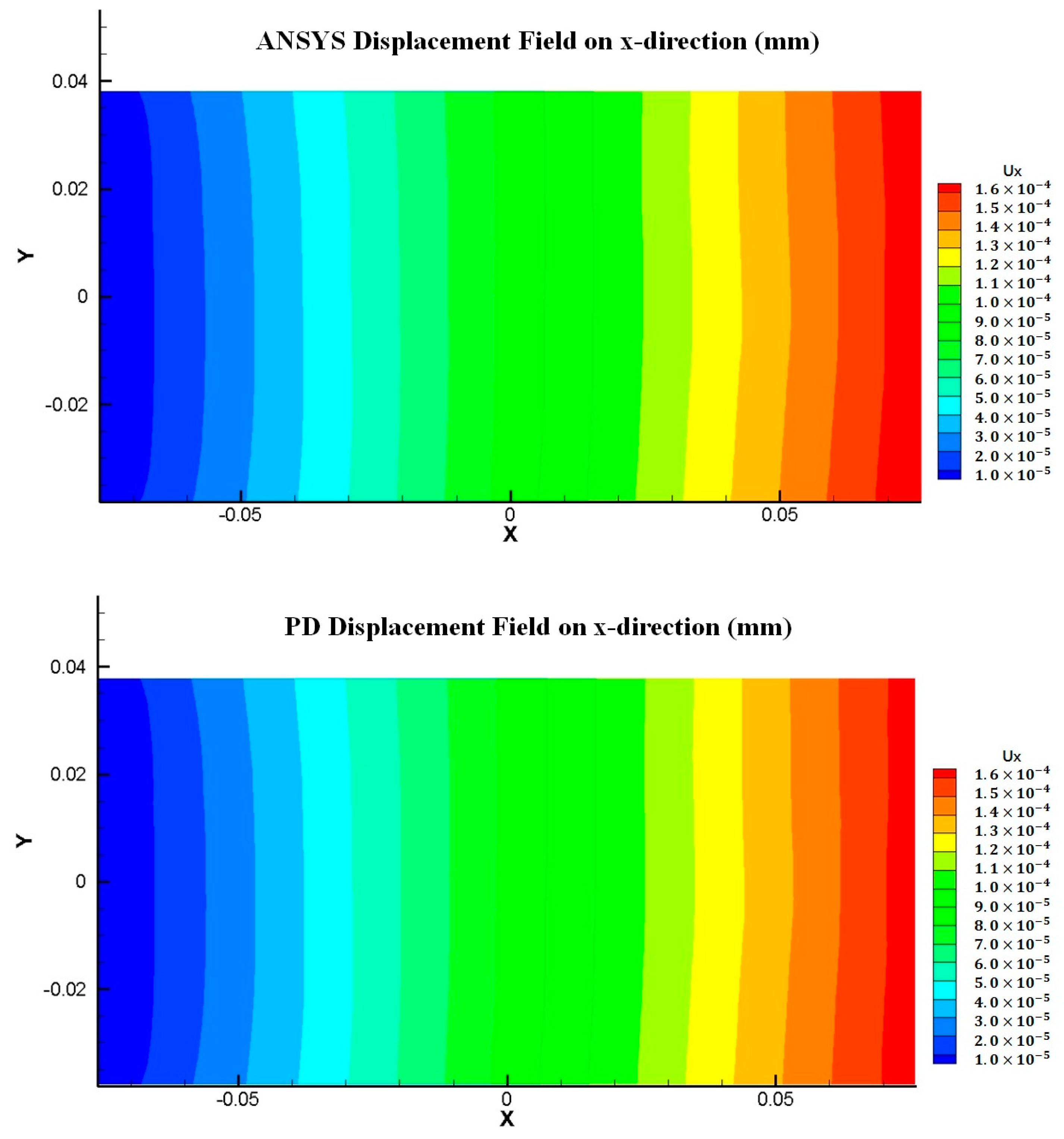

4.2.2. Static Analysis of Mo Polycrystal

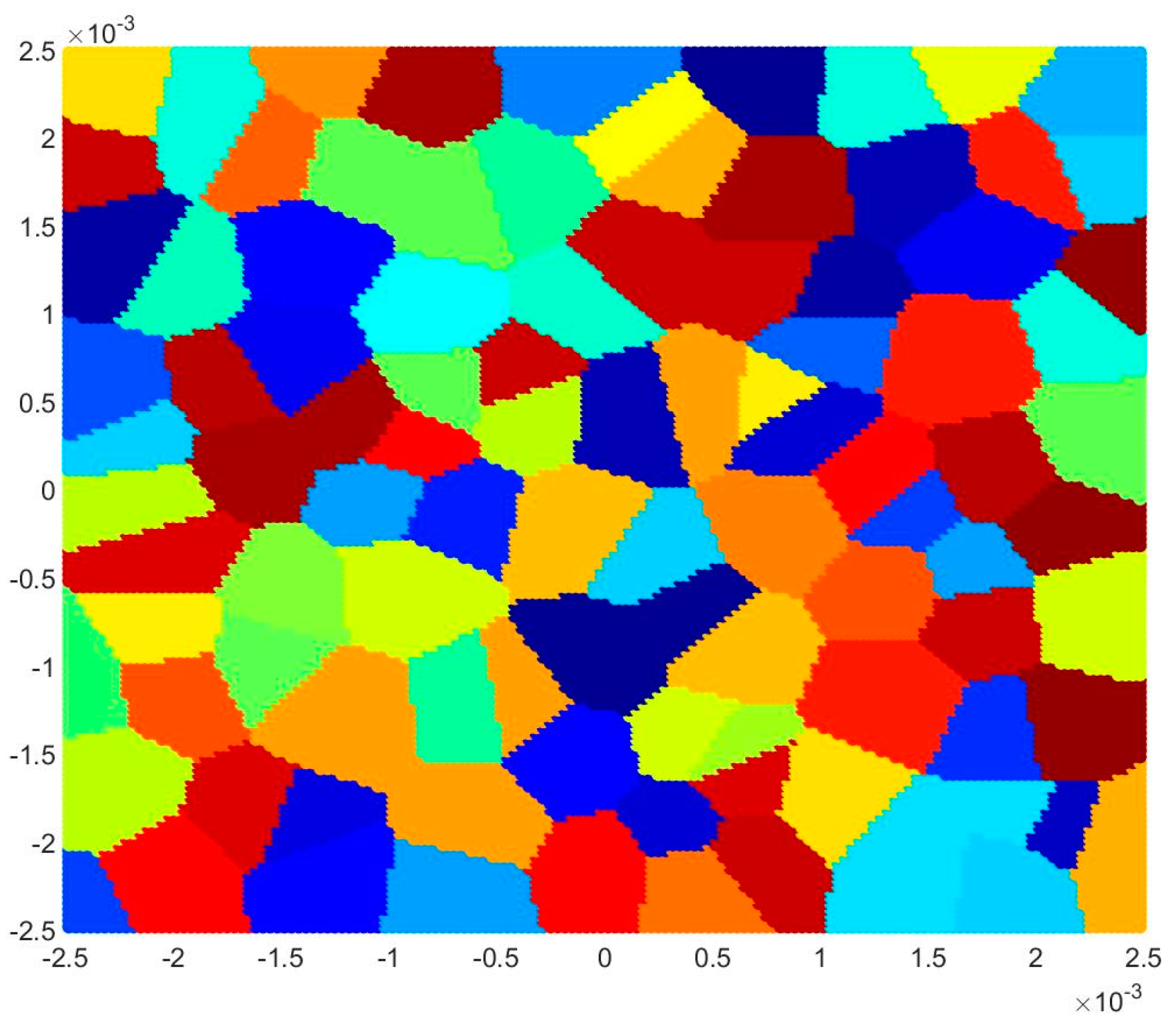

4.3. Dynamic Analysis of Mo Polycrystals

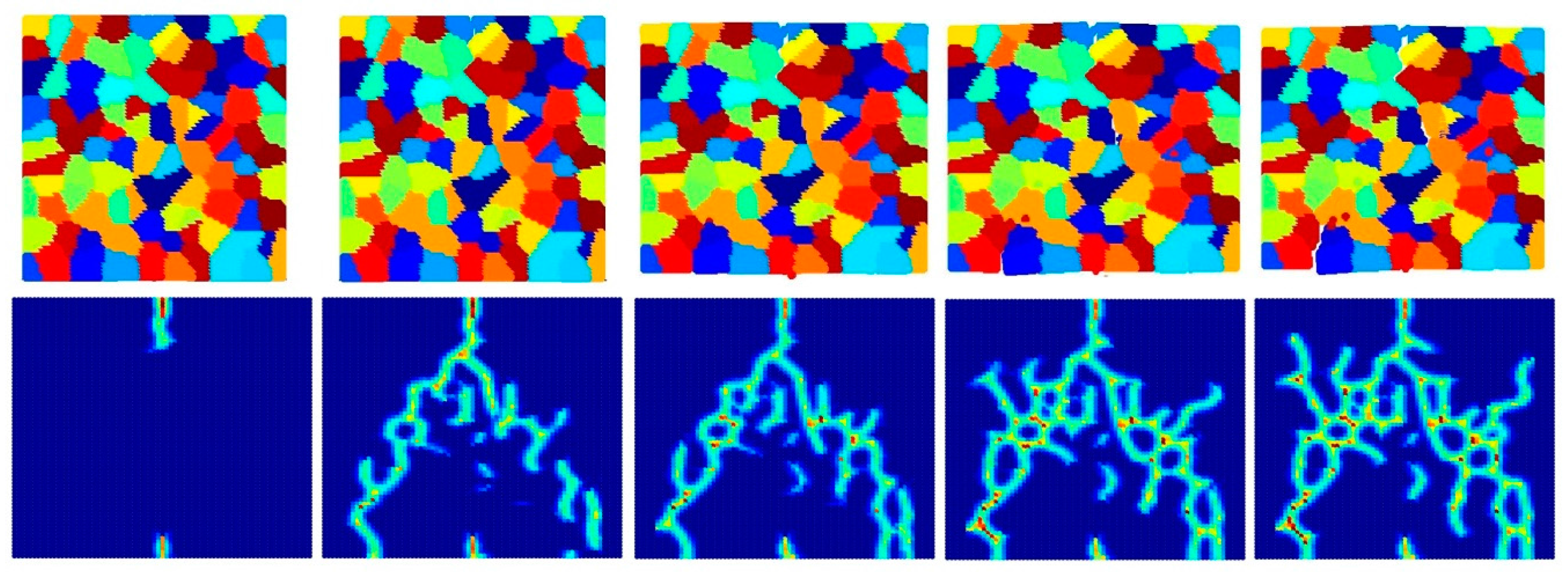

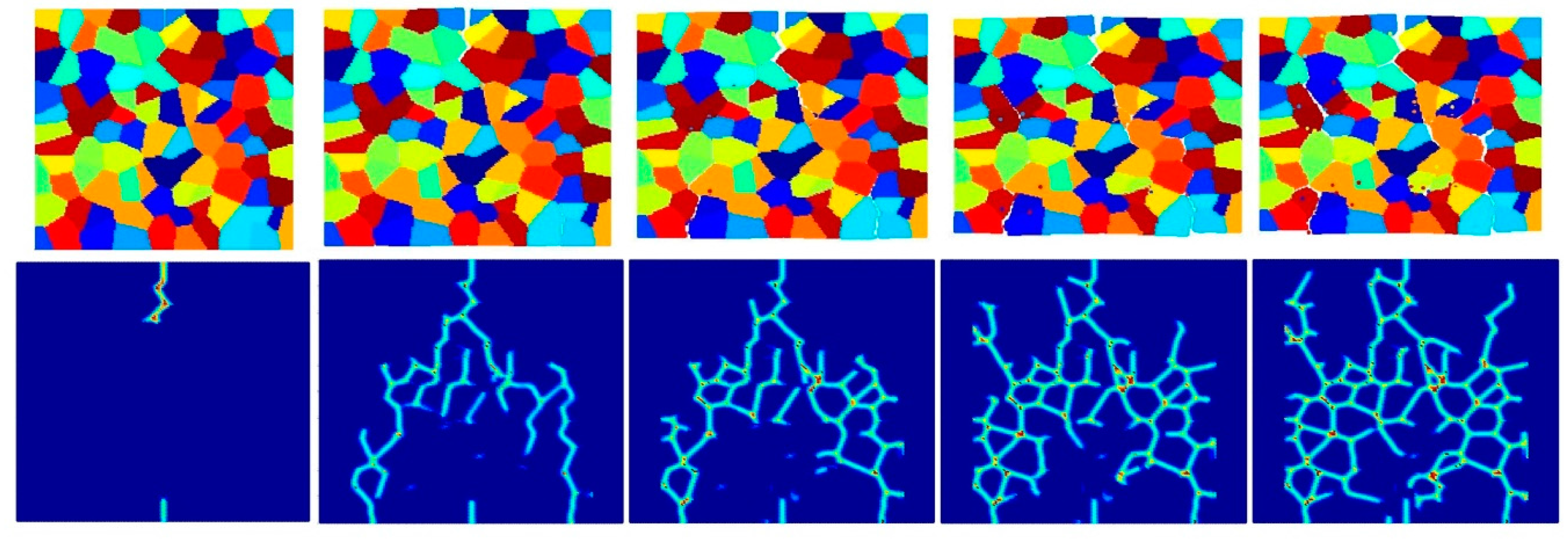

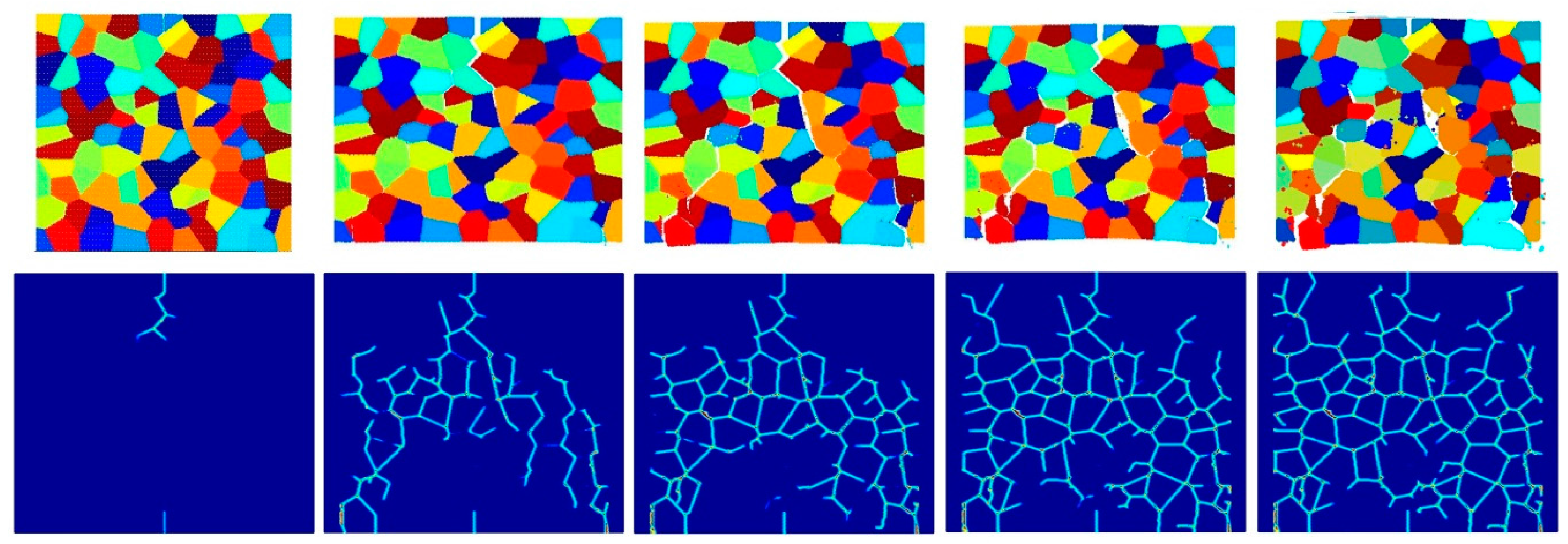

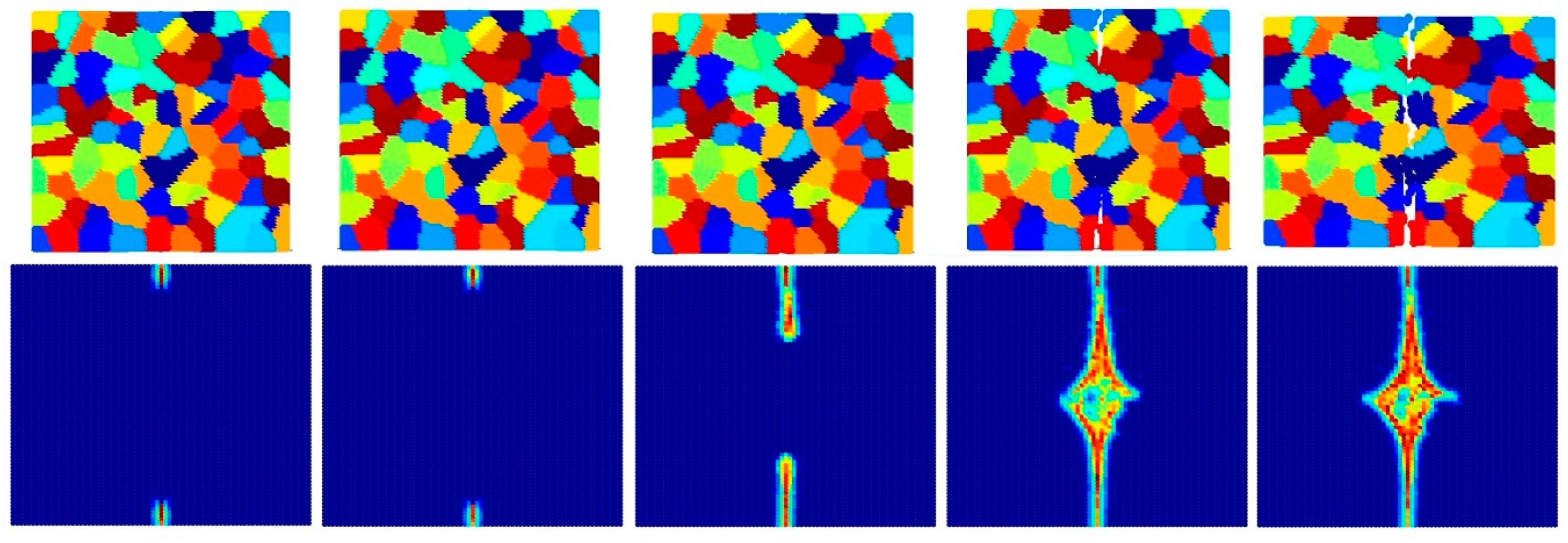

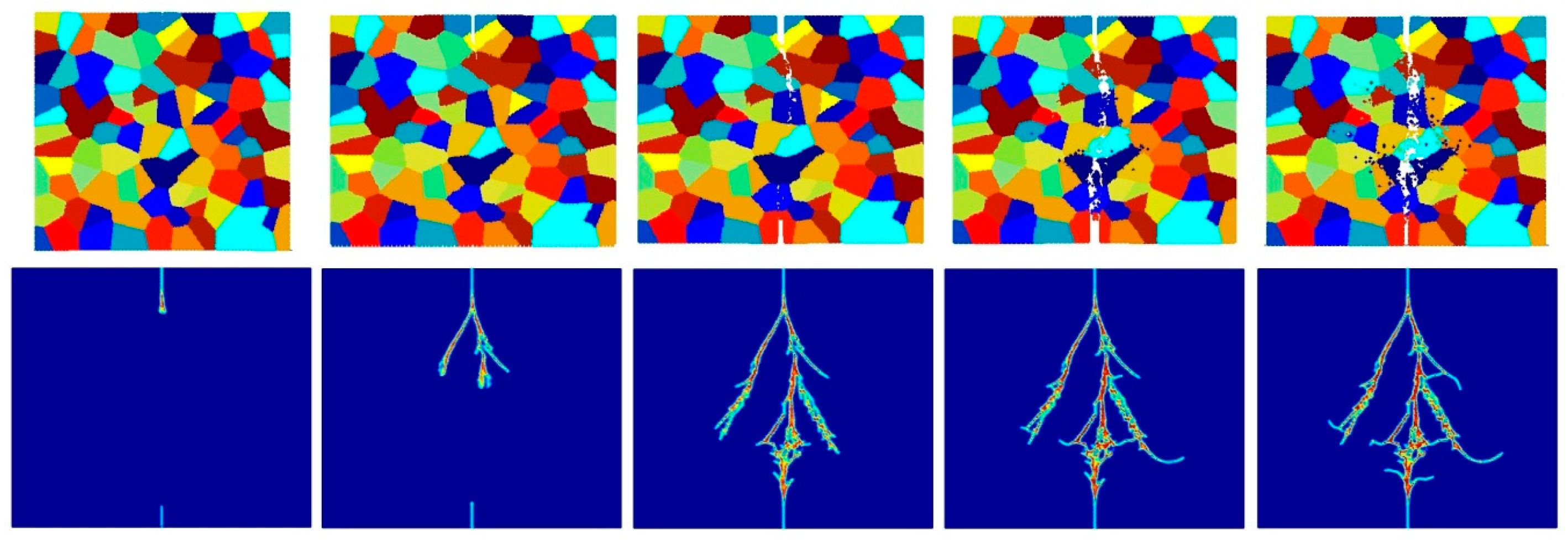

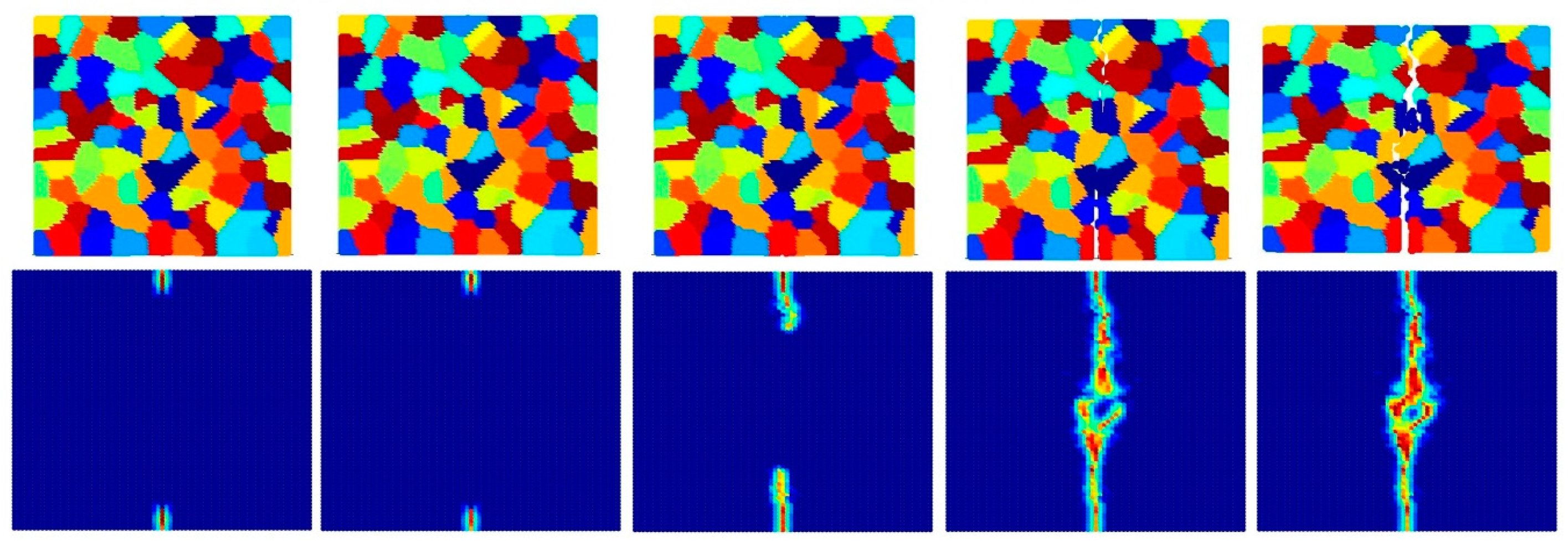

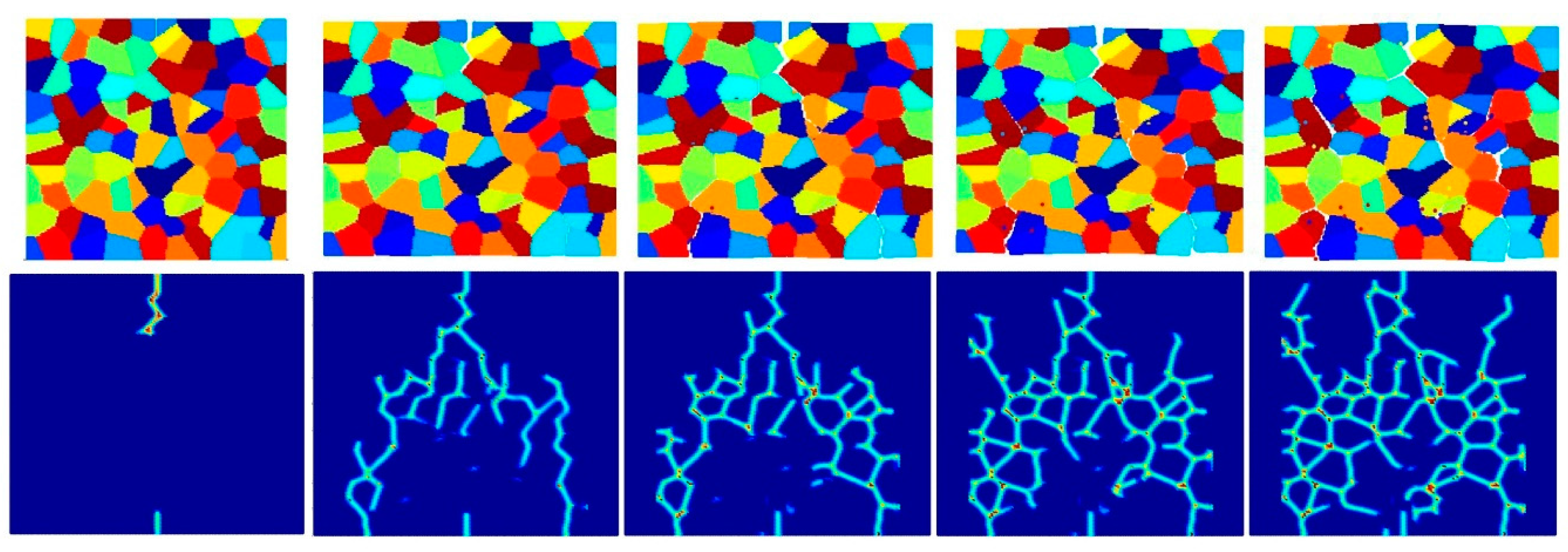

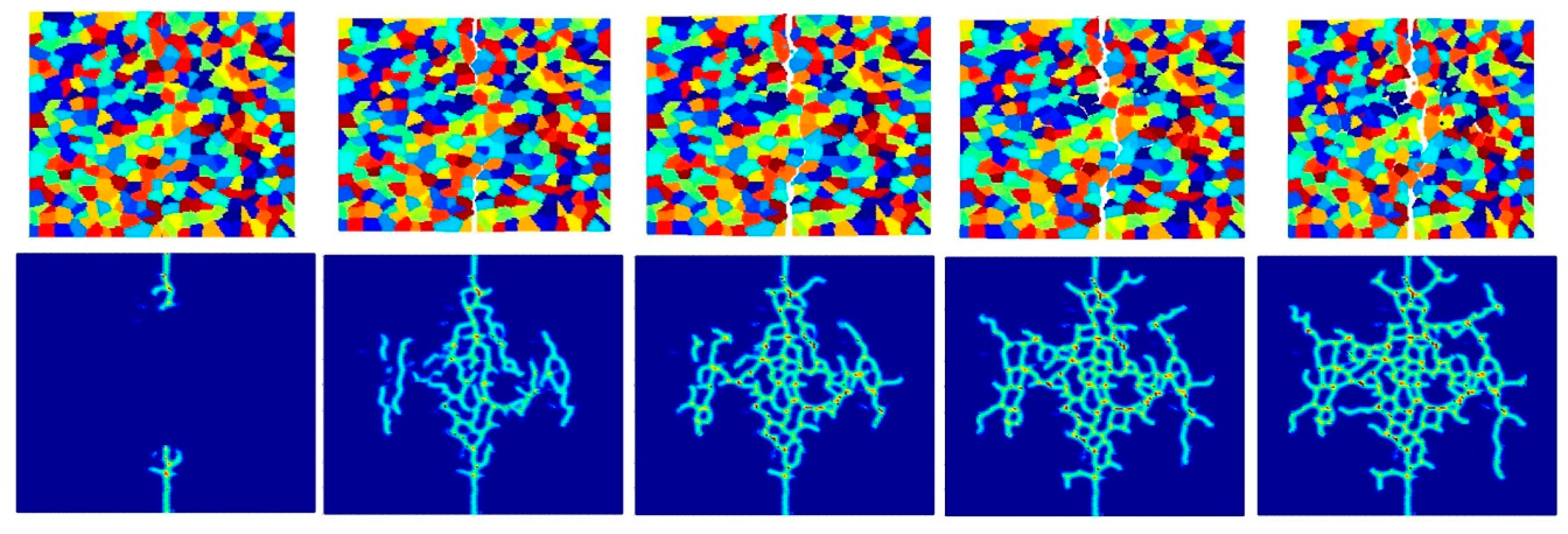

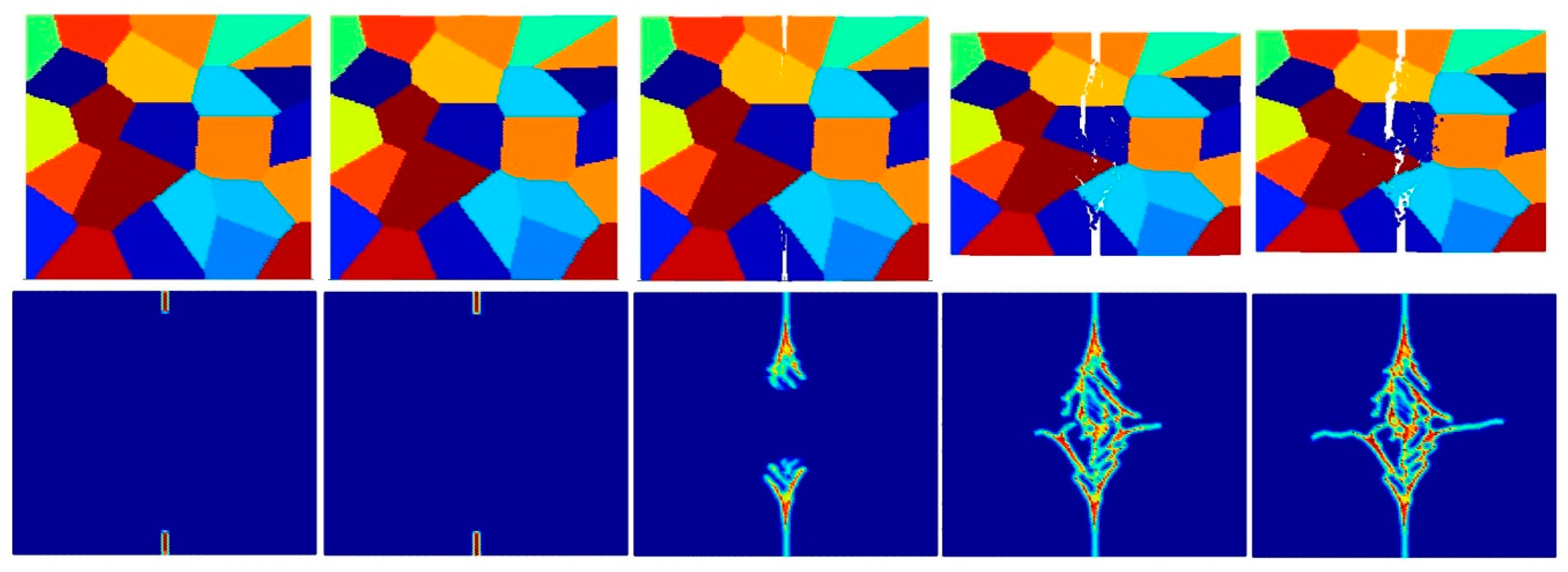

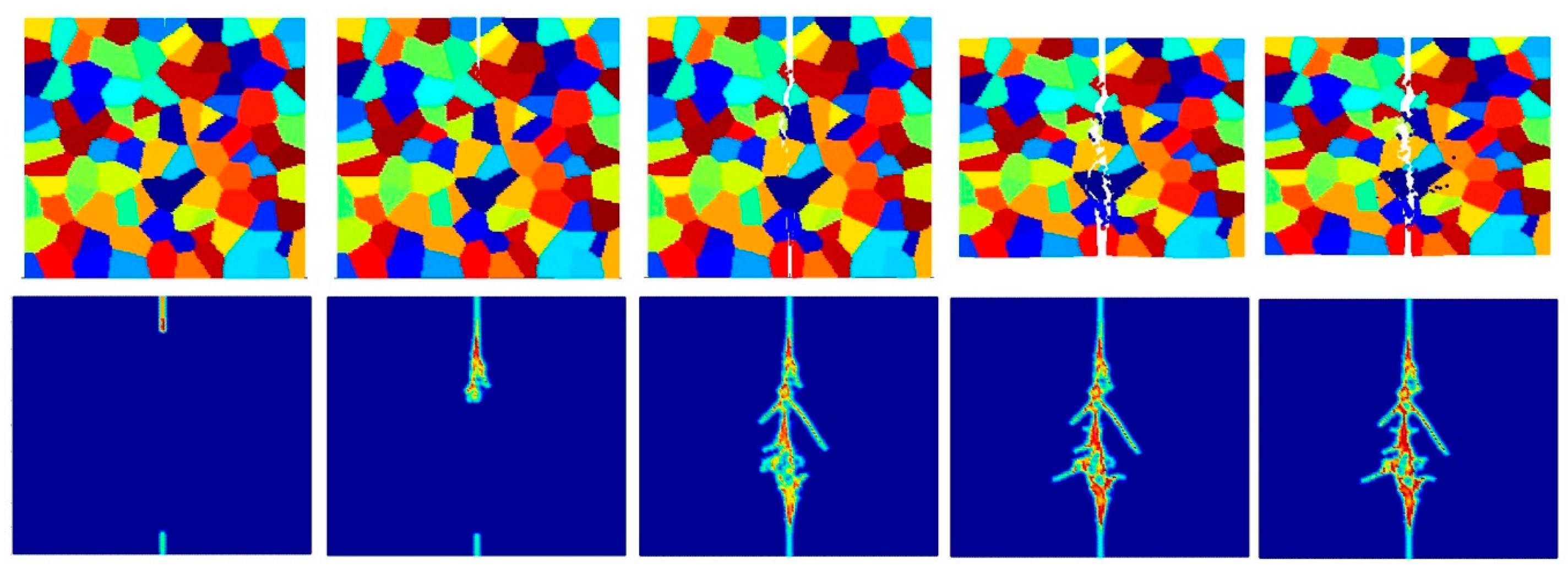

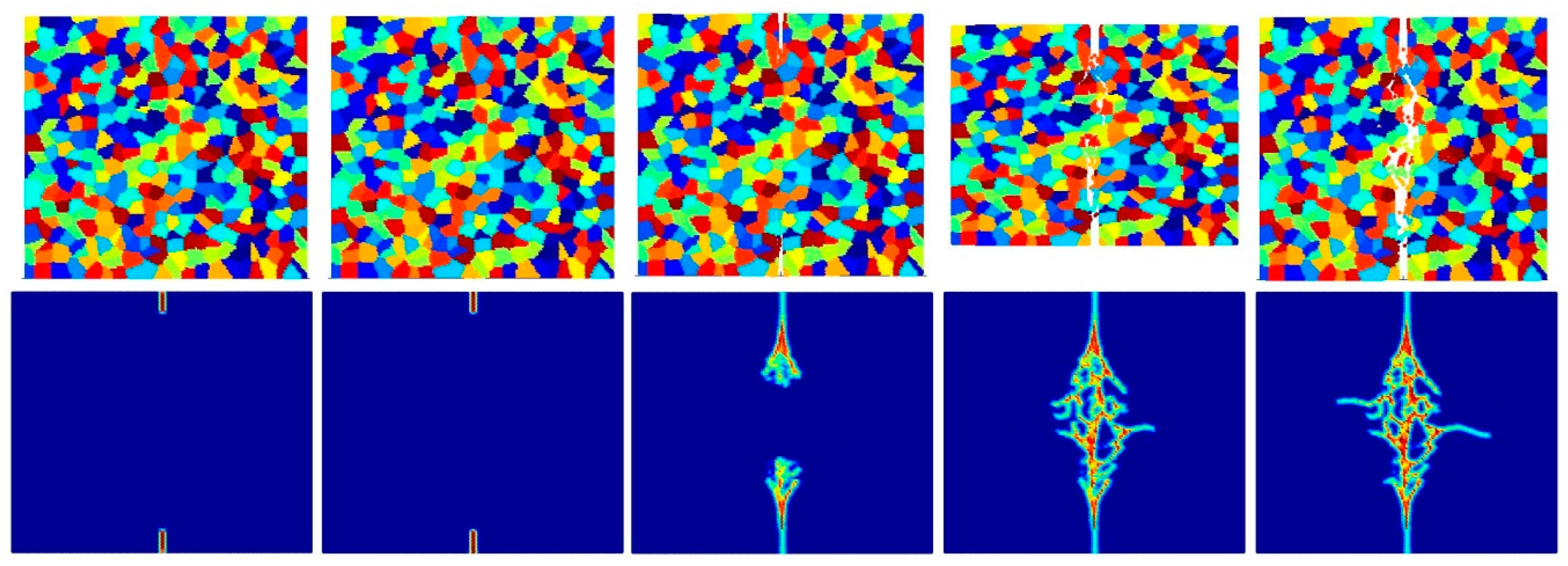

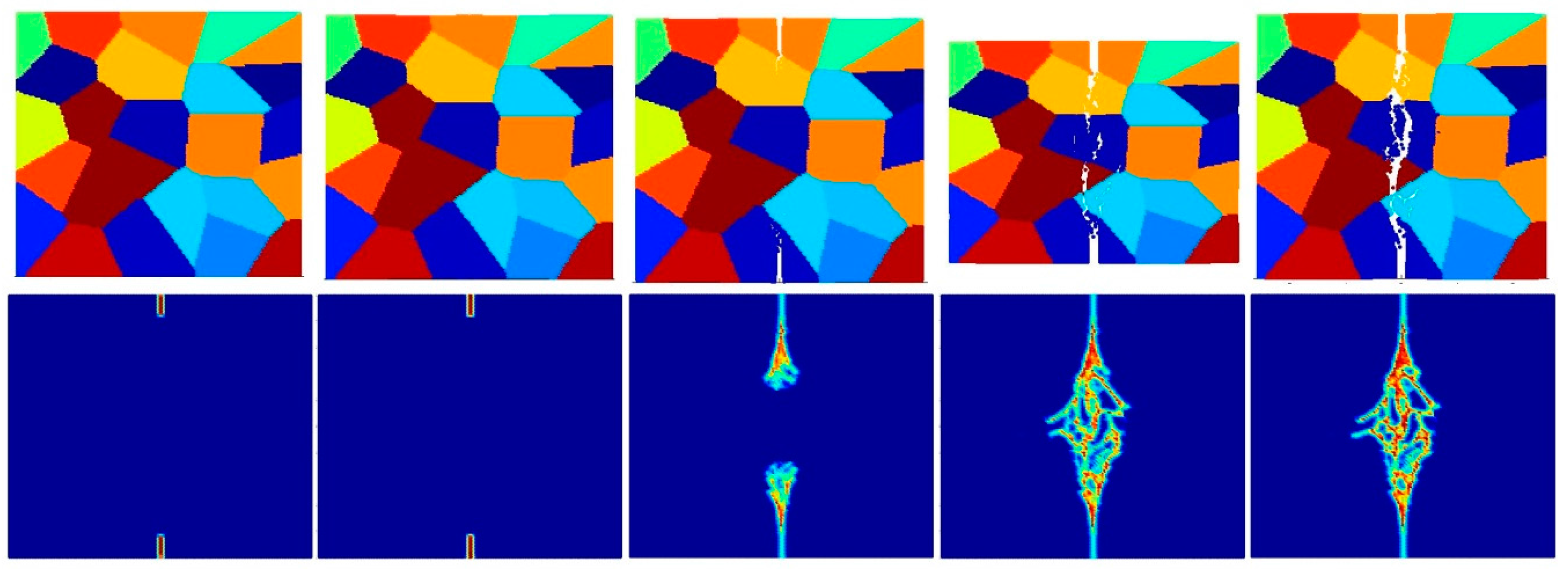

4.3.1. Effect of PD Discretization Size and Interface Strength Coefficient (β)

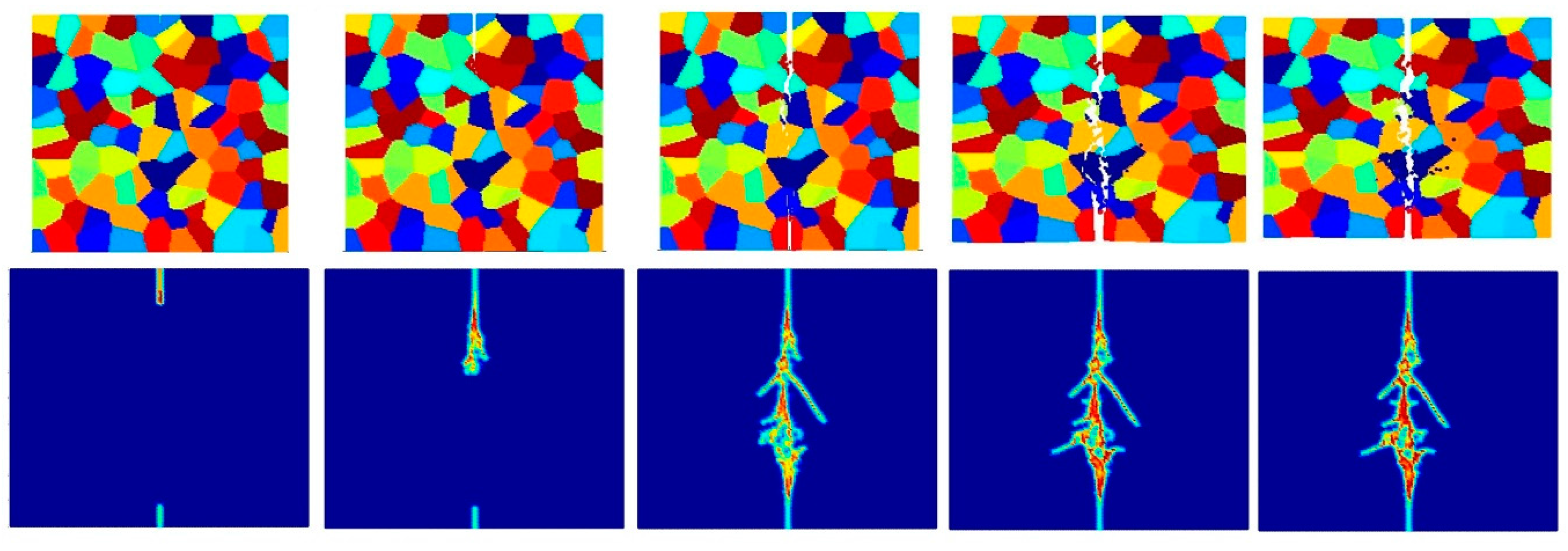

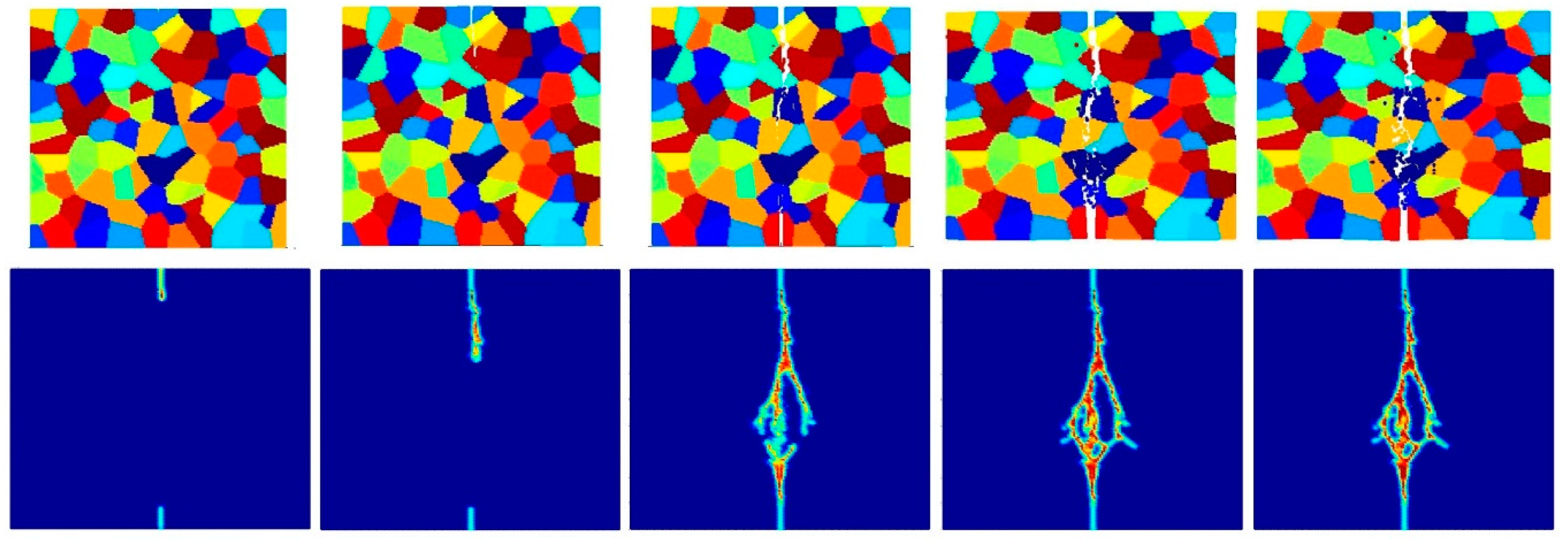

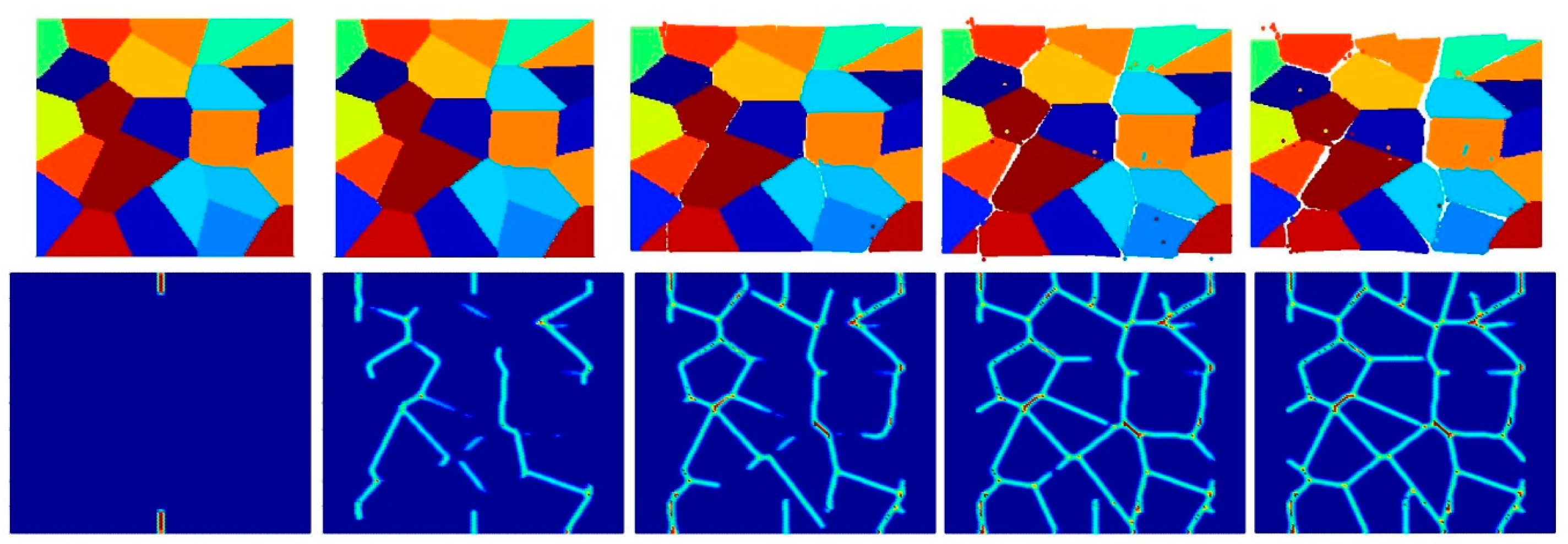

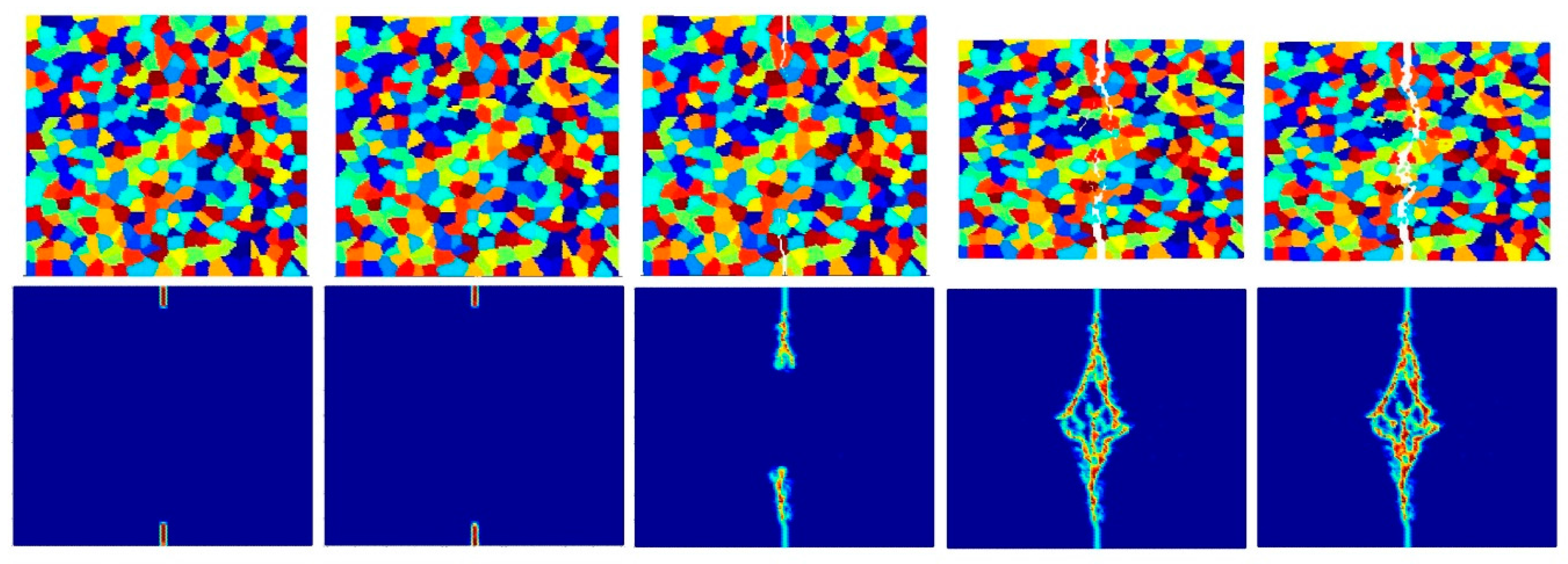

4.3.2. Effect of the Crystal Size

5. Conclusions

- Intergranular and transgranular fracture modes can be captured by changing the interface strength coefficient. As a future study, by comparing the experimental and PD results of crack morphology, actual interface strength coefficients can be estimated.

- The accuracy of simulation can be improved by increasing the total number of particles for intergranular fracture. However, the difference is not significant for transgranular fracture. In order to prevent the simulation from being time-consuming, a good balance should be considered between accuracy and simulation time.

- Pre-existing cracks can propagate more easily with decreasing crystal size for inter-granular fracture mode, since there is a higher probability of a pre-existing crack interacting with a grain boundary.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| CZM | cohesive zone model |

| FEM | finite element method |

| CCM | classical continuum mechanics |

| PD | peridynamics |

| BB | bond-based |

| OSB | ordinary state-based |

| NOSB | non-ordinary state-based |

| horizon of a generic particle | |

| radius of the horizon [m] | |

| mechanical response function [N/m6] | |

| bond constant [N/m6] | |

| bond stretch | |

| critical stretch | |

| vector defining the position of a generic particle | |

| vector defining the position of a generic neighbour of particle | |

| vector defining the position of particle in the deformed configuration | |

| vector defining the position of particle in the deformed configuration | |

| body force density field [N/m3] | |

| fracture toughness | |

| plate’s thickness [m] | |

| κ | bulk modulus [N/m2] |

| shear modulus [N/m2] | |

| critical energy release rate [N/m] | |

| [C] | local stiffness matrix |

| [Q] | reduced stiffness matrix |

| grid spacing [m] | |

| bond constant type-1 [N/m6] | |

| bond constant type-2 [N/m6] | |

| undeformed bond length between particles and [m] | |

| ϕ | bond angle with respect to the crystal orientation angle [rad] |

| volume of a generic neighbouring particle [m3] | |

| displacement field at [m] | |

| displacement field at [m] | |

| mass density at [Kg/m3] | |

| acceleration vector field [m/s2] | |

| β | interface strength coefficient |

References

- Herbig, M.; King, A.; Reischig, P.; Proudhon, H.; Lauridsen, E.M.; Marrow, J.; Buffiere, J.-Y.; Ludwig, W. 3-D growth of a short fatigue crack within a polycrystalline microstructure studied using combined diffraction and phase-contrast X-ray tomography. Acta Mater. 2011, 59, 590–601. [Google Scholar] [CrossRef]

- Yan, Y.; Noufi, R.; Al-Jassim, M. Grain-boundary physics in polycrystalline CuInSe2 revisited: Experiment and theory. Phys. Rev. Lett. 2006. [Google Scholar] [CrossRef] [PubMed]

- Gay, P.; Hirsch, P.; Kelly, A. X-ray studies of polycrystalline metals deformed by rolling. III. The physical interpretation of the experimental results. Acta Cryst. 1954, 7, 41–50. [Google Scholar] [CrossRef]

- Sfantos, G.K.; Aliabadi, M.H. A boundary cohesive grain element formulation for modelling intergranular microfracture in polycrystalline brittle materials. Int. J. Numer. Methods Eng. 2007, 69, 1590–1626. [Google Scholar] [CrossRef]

- Kraft, R.; Molinari, J.; Ramesh, K.; Warner, D. Computional micromechanics of dynamic compressive loading of a brittle polycrystalline material using a distribution of grain boundary properties. J. Mech. Phys. Solids 2008, 56, 2618–2641. [Google Scholar] [CrossRef]

- Barut, A.; Guven, I.; Madenci, E. A meshless grain element for micromechanical analysis with crystal plasticity. Int. J. Numer. Methods Eng. 2006, 67, 17–65. [Google Scholar] [CrossRef]

- NSukumar, N.; Srolovitz, D.J.; Baker, T.J.; Prévost, J.-H. Brittle fracture in polycrystalline microstructures with the extended finite element method. Int. J. Numer. Methods Eng. 2003, 56, 2015–2037. [Google Scholar] [CrossRef]

- Sukumar, N.; Srolovitz, D. Finite element-based model for crack propagation in polycrystalline materials. Comput. Appl. Math. 2004, 23, 363–380. [Google Scholar]

- Benedetti, I.; Aliabadi, M. A three-dimensional cohesive-frictional grain-boundary micromechanical model for intergranular degradation and failure in polycrystalline materials. Comput. Methods Appl. Mech. Eng. 2013, 265, 36–62. [Google Scholar] [CrossRef]

- Benedetti, I.; Aliabadi, M. A three-dimensional grain boundary formulation for microstructural modeling of polycrystalline materials. Comput. Mater. Sci. 2012, 67, 249–260. [Google Scholar] [CrossRef]

- Silling, S. Reformulation of elasticity theory for discontinuities and long-range forces. J. Mech. Phys. Solids 2000, 48, 175–209. [Google Scholar] [CrossRef]

- Panchadhara, R.; Gordon, P.A. Application of peridynamic stress intensity factors to dynamic fracture initiation and propagation. Int. J. Fract. 2016, 201, 81–96. [Google Scholar] [CrossRef]

- Madenci, E.; Oterkus, S. Ordinary state-based peridynamics for plastic deformation according to von Mises yield criteria with isotropic hardening. J. Mech. Phys. Solids 2016, 86, 192–219. [Google Scholar] [CrossRef]

- Oterkus, S.; Madenci, E.; Oterkus, E.; Hwang, Y.; Bae, J.; Han, S. Hygro-thermo-mechanical analysis and failure prediction in electronic packages by using peridynamics. In Proceedings of the 2014 IEEE 64th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 27–30 May 2014; pp. 973–982.

- Oterkus, S.; Madenci, E. Peridynamics for antiplane shear and torsional deformations. J. Mech. Mater. Struct. 2015, 10, 167–193. [Google Scholar] [CrossRef] [Green Version]

- Diyaroglu, C.; Oterkus, E.; Oterkus, S.; Madenci, E. Peridynamics for bending of beams and plates with transverse shear deformation. Int. J. Solids Struct. 2015, 69, 152–168. [Google Scholar] [CrossRef]

- Amani, J.; Oterkus, E.; Areias, P.; Zi, G.; Nguyen-Thoi, T.; Rabczuk, T. A non-ordinary state-based peridynamics formulation for thermoplastic fracture. Int. J. Impact Eng. 2016, 87, 83–94. [Google Scholar] [CrossRef]

- Oterkus, E.; Madenci, E. Peridynamics for failure prediction in composites. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012; p. 1692.

- Oterkus, E.; Barut, A.; Madenci, E. Damage growth prediction from loaded composite fastener holes by using peridynamic theory. In Proceedings of the 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Orlando, FL, USA, 12–15 April 2010.

- Askari, E.; Bobaru, F.; Lehoucq, R.; Parks, M.; Silling, S.; Weckner, O. Peridynamics for multiscale materials modeling. J. Phys. Conf. Ser. 2008, 125, 012078. [Google Scholar] [CrossRef]

- Ghajari, M.; Iannucci, L.; Curtis, P. A peridynamic material model for the analysis of dynamic crack propagation in orthotropic media. Comput. Methods Appl. Mech. Eng. 2014, 276, 431–452. [Google Scholar] [CrossRef]

- De Meo, D.; Zhu, N.; Oterkus, E. Peridynamic modeling of granular fracture in polycrystalline materials. J. Eng. Mater. Technol. 2016, 138, 041008. [Google Scholar] [CrossRef]

- Silling, S.A.; Epton, M.; Weckner, O.; Xu, J.; Askari, E. Peridynamic states and constitutive modeling. J. Elast. 2007, 88, 151–184. [Google Scholar] [CrossRef]

- Madenci, E.; Oterkus, E. Peridynamic Theory and Its Application; Springer: New York, NY, USA, 2014. [Google Scholar]

- Li, S.; Hao, W.; Liu, W.K. Mesh-free simulations of shear banding in large deformation. Int. J. Solids Struct. 2000, 37, 7185–7206. [Google Scholar] [CrossRef]

- Li, S.; Hao, W.; Liu, W.K. Numerical simulations of large deformation of thin shell structures using meshfree methods. Comput. Mech. 2000, 25, 102–116. [Google Scholar] [CrossRef]

- Rabczuk, T.; Areias, P.M.A.; Belytschko, T. A simplified meshfree method for shear bands with cohesive surfaces. Int. J. Numer. Methods Eng. 2007, 69, 993–1021. [Google Scholar] [CrossRef]

- Rabczuk, T.; Samaniego, E. Discontinuous modelling of shear bands using adaptive meshfree methods. Comput. Methods Appl. Mech. Eng. 2008, 197, 641–658. [Google Scholar] [CrossRef]

- Rabczuk, T.; Belytschko, T. A three dimensional large deformation meshfree method for arbitrary evolving cracks. Comput. Methods Appl. Mech. Eng. 2007, 196, 2777–2799. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, D.D.; Wu, C.T. Three dimensional fragmentation simulation of concrete structures with a nodally regularized meshfree method. Theor. Appl. Fract. Mech. 2014, 72, 89–99. [Google Scholar] [CrossRef]

- Chuzel-Marmot, Y.; Ortiz, R.; Combescure, A. Three-dimensional SPH-FEM gluing for simulation of fast impacts on concrete slabs. Comput. Struct. 2011, 89, 2484–2494. [Google Scholar] [CrossRef]

- Rabczuk, T.; Areias, P.M.A.; Belytschko, T. A meshfree thin shell method for nonlinear dynamic fracture. Int. J. Numer. Methods Eng. 2007, 72, 524–548. [Google Scholar] [CrossRef]

- Rabczuk, T.; Gracie, R.; Song, J.H.; Belytschko, T. Immersed particle method for fluid-structure interaction. Int. J. Numer. Methods Eng. 2010, 81, 48–71. [Google Scholar] [CrossRef]

- Rabczuk, T.; Belytschko, T. Cracking particles: A simplified meshfree method for arbitrary evolving cracks. Int. J. Numer. Methods Eng. 2004, 61, 2316–2343. [Google Scholar] [CrossRef]

- Rabczuk, T.; Zi, G.; Bordas, S.; Nguyen-Xuan, H. A simple and robust three-dimensional cracking-particle method without enrichment. Comput. Methods Appl. Mech. Eng. 2010, 199, 2437–2455. [Google Scholar] [CrossRef]

- Maurel, B.; Combescure, A. An SPH shell formulation for plasticity and fracture analysis in explicit dynamics. Int. J. Numer. Methods Eng. 2008, 76, 949–971. [Google Scholar] [CrossRef]

- Caleyron, F.; Combescure, A.; Faucher, V.; Potapov, S. SPH modeling of fluid-solid interaction of dynamic failure analysis of fluid-filled thin shells. J. Fluids Struct. 2013, 39, 126–153. [Google Scholar] [CrossRef]

- Monaghan, J.J. Smoothed particle hydrodynamics. Annu. Rev. Astron. Astrophys. 1992, 30, 543–574. [Google Scholar] [CrossRef]

- Krivtsov, A. Molecular dynamics simulation of impact fracture in polycrystalline materials. Meccanica 2003, 38, 61–70. [Google Scholar] [CrossRef]

- Tavarez, F.A.; Plesha, M.E. Discrete element method for modelling solid and particulate materials. Int. J. Numer. Meth. Eng. 2007, 70, 379–404. [Google Scholar] [CrossRef]

- Brighenti, R.; Corbari, N. Dynamic failure in brittle solids and granular matters: A force potential-based particle method. J. Numer. Meth. Eng. 2016, 105, 936–959. [Google Scholar] [CrossRef]

- Anderson, T. Fracture Mechanics—Fundamentals and Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Hosford, W.F. The Mechanics of Crystals and Textured Polycrystals; Oxford University Press: New York, NY, USA, 1993. [Google Scholar]

- Kaw, A.K. Mechanics of Composite Materials, 2nd ed.; Taylor & Francis Group: London, UK; Boca Raton, FL, USA, 2006. [Google Scholar]

- Sturm, D.; Heilmaier, M.; Schneibel, J.; Jehanno, P.; Skrotzki, B.; Saage, H. The influence of silicon on the strength and fracture toughness of molybdenum. Mater. Sci. Eng. A 2007, 463, 107–114. [Google Scholar] [CrossRef]

- Ren, H.; Zhuang, X.; Cai, Y.; Rabczuk, T. Dual-Horizon Peridynamics. Int. J. Numer. Methods Eng. 2016, 108, 1451–1476. [Google Scholar] [CrossRef]

- Ren, H.; Zhuang, X.; Rabczuk, T. A New Peridynamic Formulation with Shear Deformation for Elastic Solid. J. Micromech. Mol. Phys. 2016, 1, 1650009. [Google Scholar] [CrossRef]

| Niobium | Molybdenum | ||||||

|---|---|---|---|---|---|---|---|

| C11 | 239.8 GPa | Q11 | 174.4 GPa | C11 | 441.6 GPa | Q11 | 374.5 GPa |

| C12 | 125.2 GPa | Q12 | 59.82 GPa | C12 | 172.7 GPa | Q12 | 105.4 GPa |

| C44 | 28.22 GPa | Q44 | 28.22 GPa | C44 | 121.9 GPa | Q44 | 121.9 GPa |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, N.; De Meo, D.; Oterkus, E. Modelling of Granular Fracture in Polycrystalline Materials Using Ordinary State-Based Peridynamics. Materials 2016, 9, 977. https://doi.org/10.3390/ma9120977

Zhu N, De Meo D, Oterkus E. Modelling of Granular Fracture in Polycrystalline Materials Using Ordinary State-Based Peridynamics. Materials. 2016; 9(12):977. https://doi.org/10.3390/ma9120977

Chicago/Turabian StyleZhu, Ning, Dennj De Meo, and Erkan Oterkus. 2016. "Modelling of Granular Fracture in Polycrystalline Materials Using Ordinary State-Based Peridynamics" Materials 9, no. 12: 977. https://doi.org/10.3390/ma9120977

APA StyleZhu, N., De Meo, D., & Oterkus, E. (2016). Modelling of Granular Fracture in Polycrystalline Materials Using Ordinary State-Based Peridynamics. Materials, 9(12), 977. https://doi.org/10.3390/ma9120977