Optimization of Skid Trails and Log Yards on the Amazon Forest

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area Description

2.2. Census Inventory

2.3. Planning Scenarios

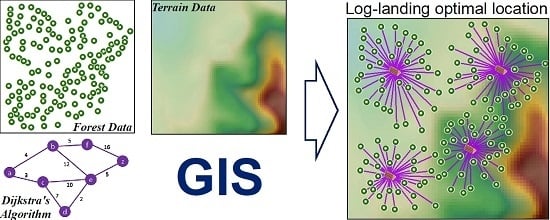

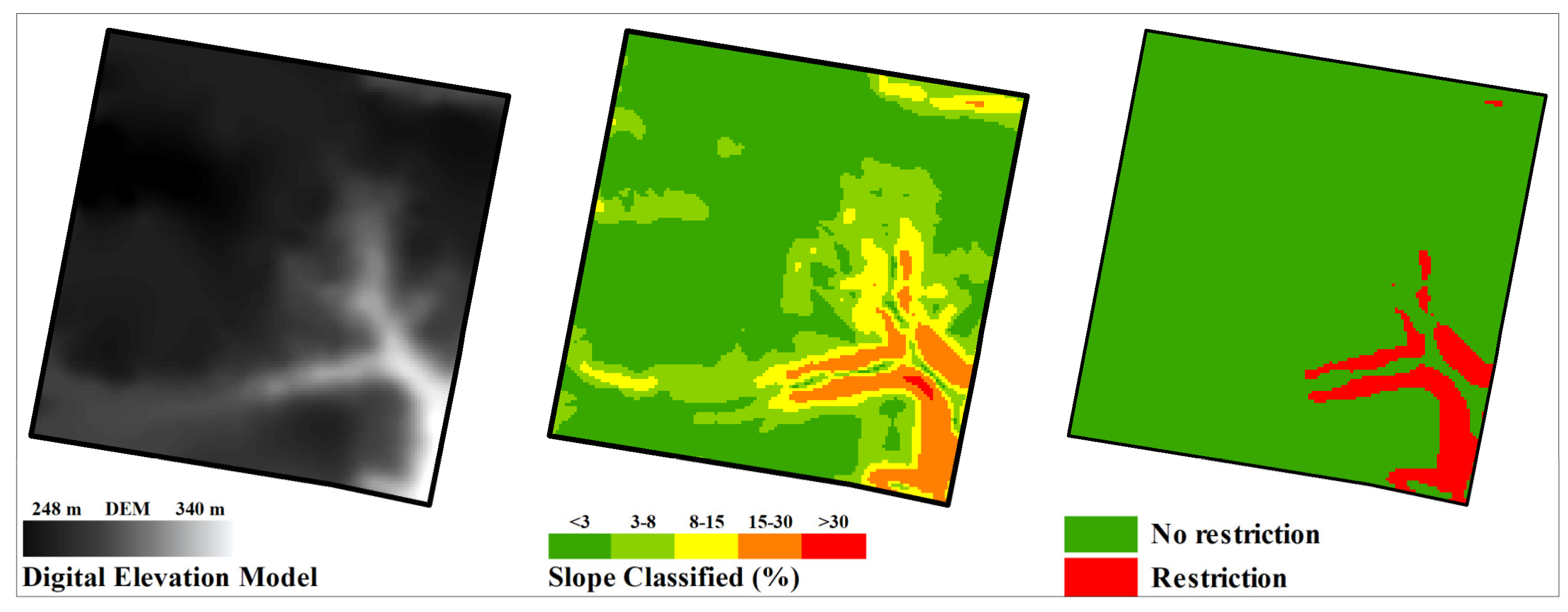

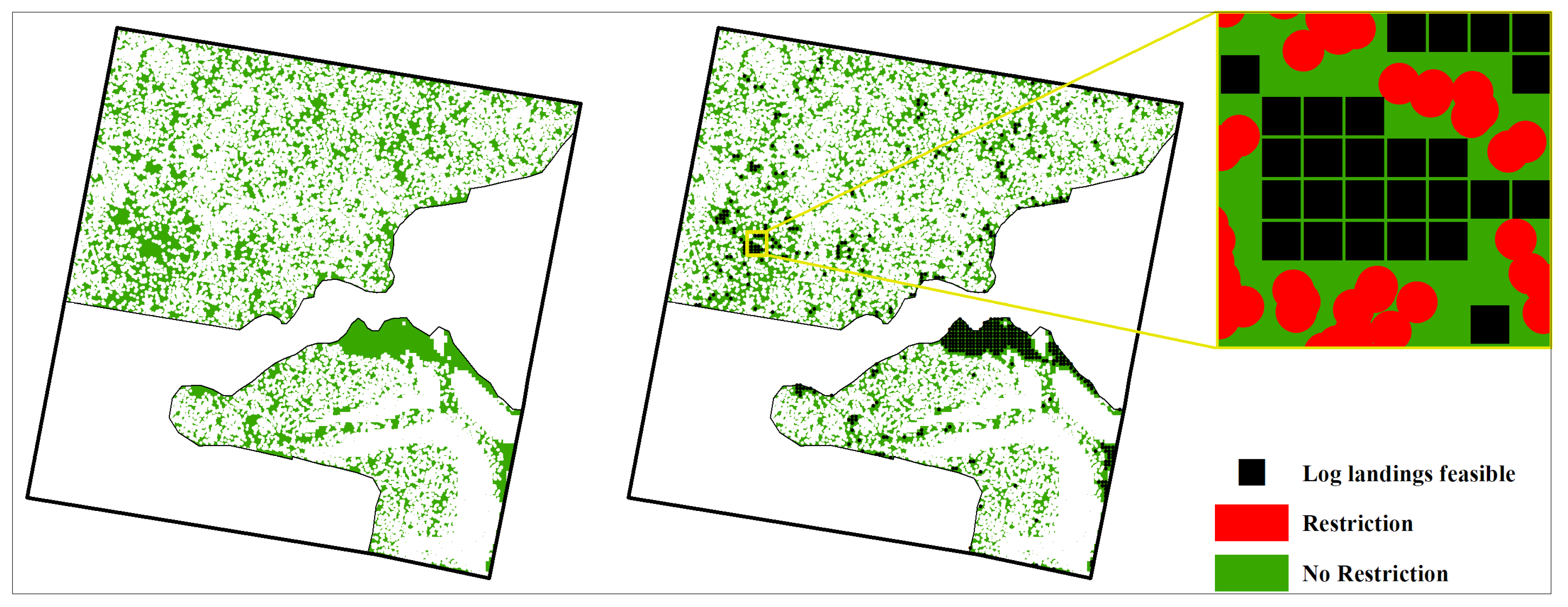

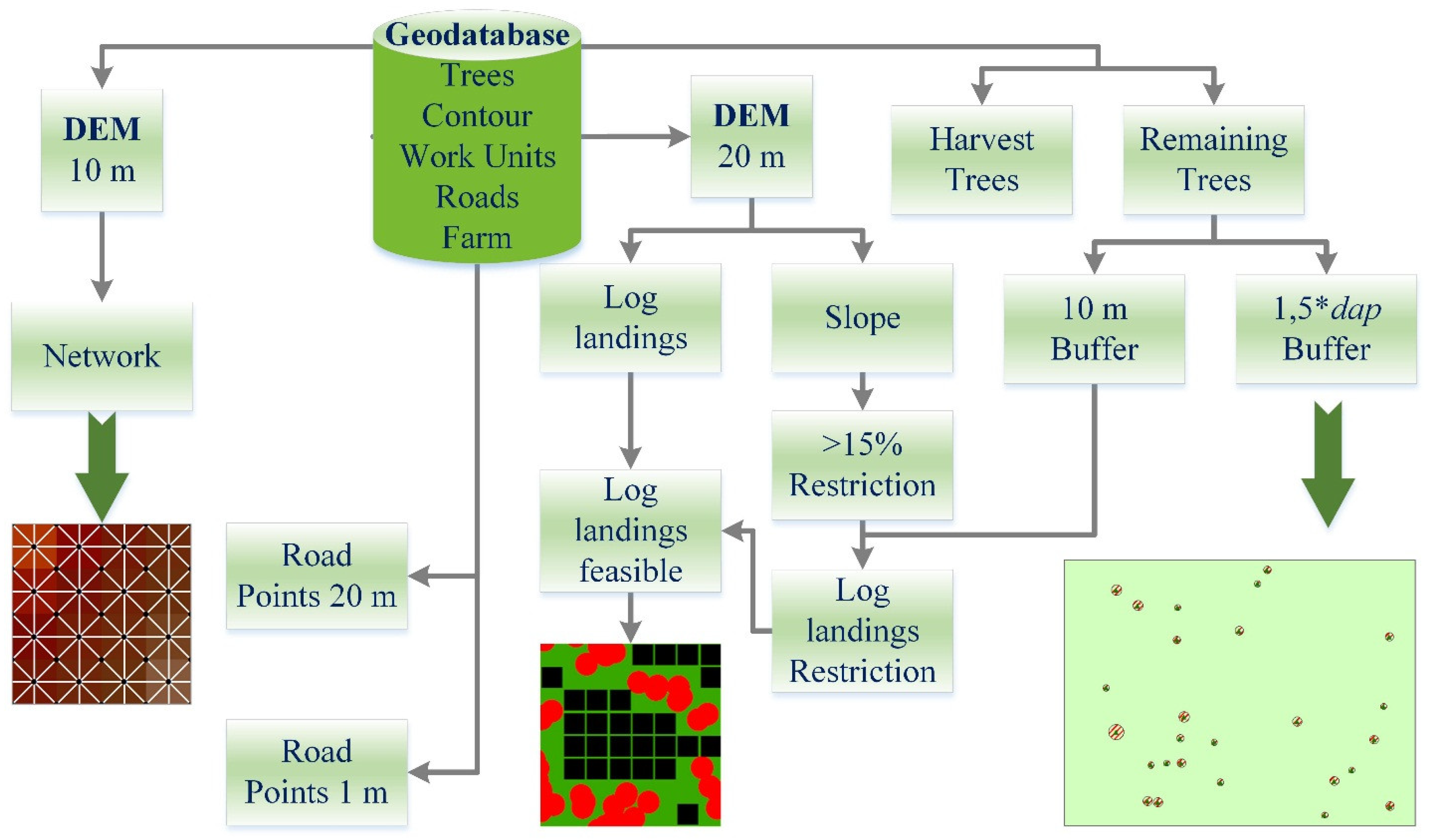

2.4. Database Preparation

2.5. Second and Third Harvest Cycles

2.6. Comparison among Scenarios

- total skid-trail’s distance, in kilometers;

- number of trees, in percentage, with their distances greater than 342 m from the yard, which is considered as the optimal extraction distance [18];

- skid-trails’ and roads’ densities calculated using the formula.

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Blaser, J.; Sarre, A.; Poore, D.; Johnson, S. Status of Tropical Forest Management; ITTO Technical Series N. 38; International Tropical Timber Organization: Yokohama, Japan, 2011. [Google Scholar]

- Groenendijk, P.; Bongers, F.; Zuidema, P.A. Using tree-ring data to improve timber-yield projections for African wet tropical forest tree species. For. Ecol. Manag. 2017, 400, 396–407. [Google Scholar] [CrossRef]

- Köhl, M.; Lasco, R.; Cifuentes, M.; Jonsson, Ö.; Korhonen, K.T.; Mundhenk, P.; Navar, J.J.; Stinson, G. Changes in forest production, biomass and carbon: Results from the 2015 UN FAO Global Forest Resource Assessment. For. Ecol. Manag. 2015, 35, 21–34. [Google Scholar]

- Putz, F.E.; Sist, P.; Fredericksen, T.; Dykstra, D. Reduced-impact logging: Challenges and opportunities. For. Ecol. Manag. 2008, 256, 1427–1433. [Google Scholar] [CrossRef]

- Dionisio, L.F.S.; Schwartz, G.; Mazzei, L.; do Carmo Lopes, J.; dos Santos, G.G.A.; de Assis Oliveira, F. Mortality of stocking commercial trees after reduced impact logging in eastern Amazonia. For. Ecol. Manag. 2017, 401, 1–7. [Google Scholar] [CrossRef]

- Calvão, L.B.; Nogueira, D.S.; de Assis Montag, L.F.; Lopes, M.A.; Juen, L. Are Odonata communities impacted by conventional or reduced impact logging? For. Ecol. Manag. 2016, 382, 143–150. [Google Scholar] [CrossRef]

- Chaudhary, A.; Burivalova, Z.; Koh, L.P.; Hellweg, S. Impact of forest management on species richness: Global meta-analysis and economic trade-offs. Sci. Rep. 2016, 6, 23954. [Google Scholar] [CrossRef]

- Pokorny, B.; Sabogal, C.; Silva, J.N.M.; Bernardo, P.; Souza, J.; Zweede, J. Compliance with reduced-impact harvesting guidelines by timber enterprises in terra firme forests of the Brazilian Amazon. Int. For. Rev. 2005, 7, 9–20. [Google Scholar] [CrossRef]

- Talbot, B.; Pierzchała, M.; Astrup, R. Applications of remote and proximal sensing for improved precision in forest operations. Croatian Journal of Forest Engeneering. 2017, 38, 327–336. [Google Scholar]

- Søvde, N.E.; Løkketangen, A.; Talbot, B. Applicability of the GRASP metaheuristic method in designing machine trail layout. For. Sci. Technol. 2013, 9, 187–194. [Google Scholar] [CrossRef]

- Babapour, R.; Naghdi, R.; Ghajar, I.; Mortazavi, Z. Forest road profile optimization using meta-heuristic techniques. Appl. Soft Comput. 2018, 64, 126–137. [Google Scholar] [CrossRef]

- Gumus, S.; Turk, Y. A new skid trail pattern design for farm tractors using linear programing and Geographical information systems. Forests 2016, 7, 306. [Google Scholar] [CrossRef]

- Ezzati, S.; Najafi, A.; Yaghini, M.; Hashemi, A.A.; Bettinger, P. An optimization model to solve skidding problem in steep slope terrain. J. For. Econ. 2015, 21, 250–268. [Google Scholar] [CrossRef]

- Dean, D.J. Finding optimal routes for networks of harvest site access roads using GIS-based techniques. Can. J. For. Res. 1997, 27, 11–22. [Google Scholar] [CrossRef]

- Anderson, A.E.; Nelson, J. Projecting vector-based road networks with a shortest path algorithm. Can. J. For. Res. 2004, 34, 1444–1457. [Google Scholar] [CrossRef]

- Contreras, M.; Chung, W. A computer approach to finding an optimal log landing location and analyzing influencing factors for ground-based timber harvesting. Can. J. For. Res. 2007, 37, 276–292. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Mazrae, M.R.; Lotfalian, M.; Parsakhoo, A. Designing an optimal forest road network by consideration of environmental impacts in GIS. J. Environ. Eng. Landsc. 2012, 20, 58–66. [Google Scholar] [CrossRef]

- Ferreira da Silva, E.; da Silva, G.F.; Figueiredo, E.O.; Binoti, D.H.B.; Mendonça, A.R.; Torres, C.M.M.E.; Pezzopane, J.E.M. Allocation of storage yards in management plans in the Amazon by means of mathematical programming. Forests 2018, 9, 127. [Google Scholar] [CrossRef]

- Devlin, G.J.; McDonnell, K.; Ward, S. Timber haulage routing in Ireland: An analysis using GIS and GPS. J. Transp. Geogr. 2018, 16, 63–72. [Google Scholar] [CrossRef]

- Grigolato, S.; Mologni, O.; Cavalli, R. GIS Applications in forest operations and road network planning: An overview over the last two decades. Croatian Journal of Forest Engeneering. Theory Appl. For. Eng. 2017, 38, 175–186. [Google Scholar]

- Dijkstra, E.W. A note on two problems in connection with graphs. Numer. Math. 1959, 1, 269–271. [Google Scholar] [CrossRef]

- Ciesielski, K.C.; Falcão, A.X.; Miranda, P.A. Path-value functions for which Dijkstra’s algorithm returns optimal mapping. J. Math. Imaging. Vis. 2016, 60, 1025–1036. [Google Scholar] [CrossRef]

- Figueiredo, E.O.; Lima, Q.S. Coeficientes Técnicos Para Inventário e Manejo Florestal com Emprego do Modelo Digital de Exploração Florestal (Modeflora); Embrapa Acre: Rio Branco, Brazil, 2008. [Google Scholar]

- Silva, J.N.M.; de Carvalho, J.O.P.; Lopes, J. d. C.A.; de Almeida, B.F.; Costa, D.H.M.; de Oliveira, L.C.; Vanclay, J.K.; Skovsgaard, J.P. Growth and yield of a tropical rain forest in the Brazilian Amazon 13 years after logging. For. Ecol. Manag. 1995, 71, 267–274. [Google Scholar] [CrossRef]

- Boltz, F.; Holmes, T.P.; Carter, D.R. Economic and environmental impacts of conventional and reduced-impact logging in Tropical South America: A comparative review. For. Policy Econ. 2003, 5, 69–81. [Google Scholar] [CrossRef]

- Matthews, D.M. Cost Control in the Logging Industry; McGraw-Hill: New York, NY, USA, 1942. [Google Scholar]

- Chung, W.; Stückelberger, J.; Aruga, K.; Cundy, T.W. Forest road network design using a trade-off analysis between skidding and road construction costs. Can. J. For. Res. 2008, 38, 439–448. [Google Scholar] [CrossRef]

- Naderializadeh, N. The effect of the density of candidate roads upon solutions in tactical forest planning. Can. J. For. Res. 2018, 48, 679–688. [Google Scholar] [CrossRef]

- Philippart, J.; Sun, M.; Doucet, J.-L.; Lejeune, P. Mathematical formulation and exact solution for landing location problem in tropical forest selective logging, a case study in Southeast Cameroon. J. For. Econ. 2012, 18, 113–122. [Google Scholar] [CrossRef]

| WU | Yards | Area (ha) | Harvest | Remaining | ||

|---|---|---|---|---|---|---|

| Trees | Vol. (m3) | Trees | Vol. (m3) | |||

| 01 | 2 | 69.8354 | 1667 | 2564.74 | 4335 | 3596.85 |

| 02 | 3 | 54.3693 | 1075 | 1489.95 | 2839 | 2360.38 |

| 03 | 3 | 86.7383 | 2214 | 2238.72 | 4250 | 3030.09 |

| 04 | 3 | 57.2613 | 1245 | 1289.21 | 3615 | 2958.01 |

| 05 | 1 | 66.3268 | 1130 | 1397.94 | 3645 | 2661.48 |

| 06 | 6 | 81.3609 | 1708 | 1853.04 | 3855 | 3025.16 |

| 07 | 5 | 65.6759 | 2709 | 3137.30 | 3248 | 2474.30 |

| Total | 23 | 481.5682 | 11748 | 13970.9 | 25787 | 20106.27 |

| Scenario | Function | Facility | Incident | Constraint |

|---|---|---|---|---|

| 1 | Closest facility | 23 current yards | HT | RT and WUs |

| 2 | Location-allocation | Yards on roadsides | ||

| Closest facility | 23 yards allocated at roadsides | |||

| 3 | Location-allocation | Feasible yards | ||

| Closest facility | 23 allocated yards | |||

| 4 | Location-allocation | Feasible yards | HT | RT |

| Closest facility | 23 allocated yards |

| Parameters | Harvest | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

|---|---|---|---|---|---|

| Total skid-trail’s distance (km) | 1st | 2934 | 2555 (87) | 2364 (81) | 2264 (77) |

| 2nd | 3277 | 2863 (87) | 2628 (80) | 2557 (78) | |

| 3rd | 3296 | 2884 (87) | 2668 (81) | 2572 (78) | |

| Number of trees (%) with their distances greater than 342 m | 1st | 21.8 | 15.5 (71) | 6.8 (31) | 4.8 (22) |

| 2nd | 25.0 | 16.2 (65) | 6.5 (26) | 3.3 (13) | |

| 3rd | 25.8 | 17.0 (66) | 6.9 (27) | 4.6 (18) | |

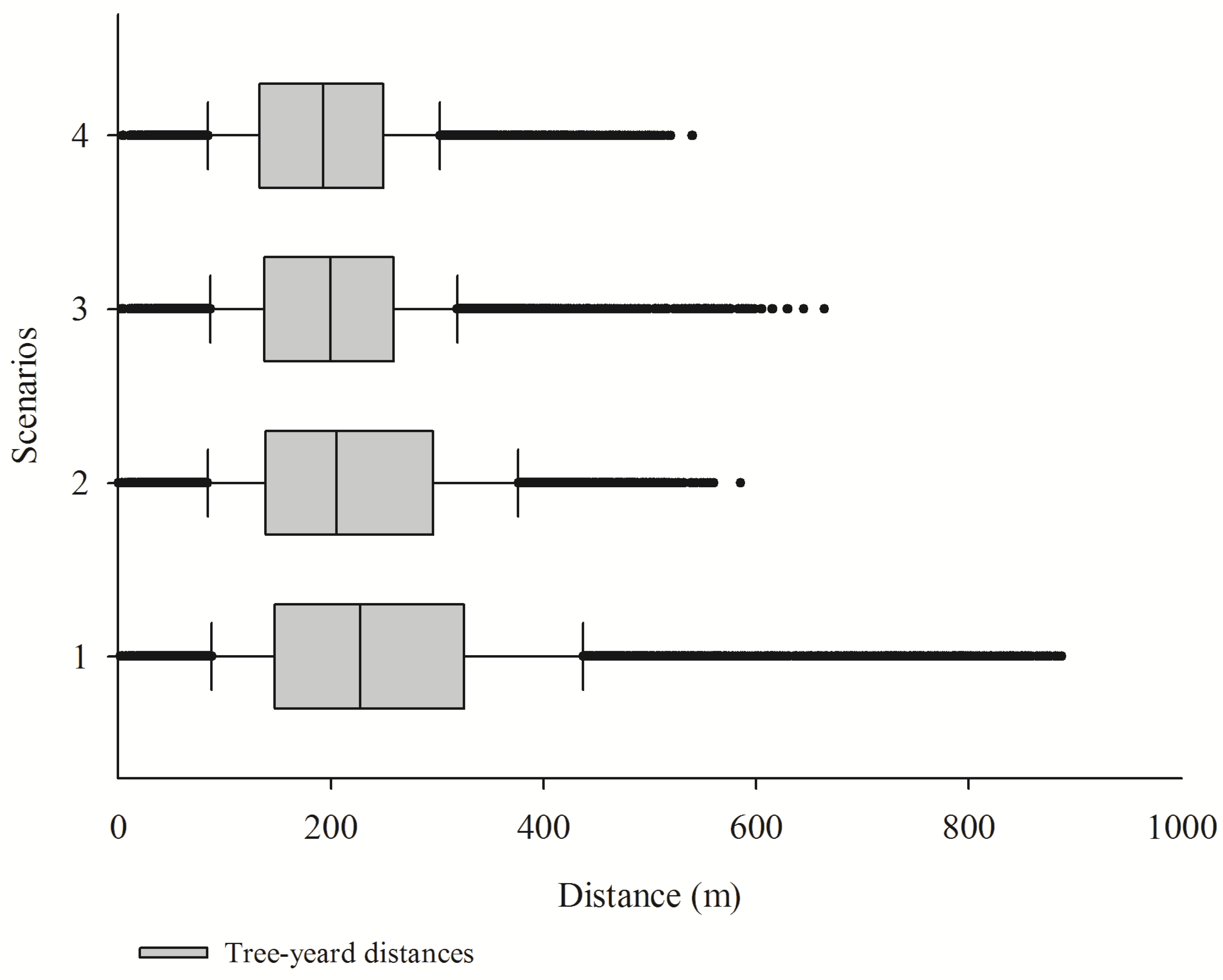

| Average trail distances (m) | 1st | 232 | 215 (93) | 201 (86) | 193 (83) |

| 2nd | 232 | 216 (93) | 205 (88) | 196 (84) | |

| 3rd | 232 | 217 (94) | 207 (89) | 196 (85) | |

| CV (%) | 1st | 46.8 | 45.4 (97) | 42.9 (92) | 41.3 (88) |

| 2nd | 46.0 | 44.6 (97) | 43.2 (94) | 40.9 (89) | |

| 3rd | 46.7 | 44.6 (96) | 42.6 (91) | 40.8 (87) | |

| Skid-trail’s density (km ha−1) | 1st | 6.09 | 5.30 (87) | 4.91 (81) | 4.70 (77) |

| 2nd | 6.81 | 5.94 (87) | 5.46 (80) | 5.31 (78) | |

| 3rd | 6.84 | 5.99 (88) | 5.54 (81) | 5.34 (78) | |

| Road density (km ha−1) | 1st | 0.04 | 0.03 (82) | 0.04 (90) | 0.02 (59) |

| Harvest | Total Costs (US$) | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

|---|---|---|---|---|---|

| 1st | Skidding | 205,351 | 178,828 (87) | 165,493 (81) | 158,500 (77) |

| Yards | - | 868 | 868 | 868 | |

| Total | 205,351 | 179,695 (88) | 166,361 (81) | 159,368 (78) | |

| 2nd | Skidding | 229,418 | 200,388 (87) | 183,930 (80) | 179,004 (78) |

| Yards | - | - | - | - | |

| Total | 229,418 | 200,388 (87) | 183,930 (80) | 179,004 (78) | |

| 3rd | Skidding | 230,738 | 201,879 (87) | 186,743 (81) | 180,021 (78) |

| Yards | - | - | - | - | |

| Total | 230,738 | 201,879 (87) | 186,743 (81) | 180,021 (78) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sales, A.; Gonzáles, D.G.E.; Martins, T.G.V.; Silva, G.C.C.; Spletozer, A.G.; Telles, L.A.d.A.; Siviero, M.A.; Lorenzon, A.S. Optimization of Skid Trails and Log Yards on the Amazon Forest. Forests 2019, 10, 252. https://doi.org/10.3390/f10030252

Sales A, Gonzáles DGE, Martins TGV, Silva GCC, Spletozer AG, Telles LAdA, Siviero MA, Lorenzon AS. Optimization of Skid Trails and Log Yards on the Amazon Forest. Forests. 2019; 10(3):252. https://doi.org/10.3390/f10030252

Chicago/Turabian StyleSales, Agust, Duberlí Geomar Elera Gonzáles, Thales Guilherme Vaz Martins, Gabriela Cristina Costa Silva, Aline Gonçalves Spletozer, Lucas Arthur de Almeida Telles, Marco Antonio Siviero, and Alexandre Simões Lorenzon. 2019. "Optimization of Skid Trails and Log Yards on the Amazon Forest" Forests 10, no. 3: 252. https://doi.org/10.3390/f10030252