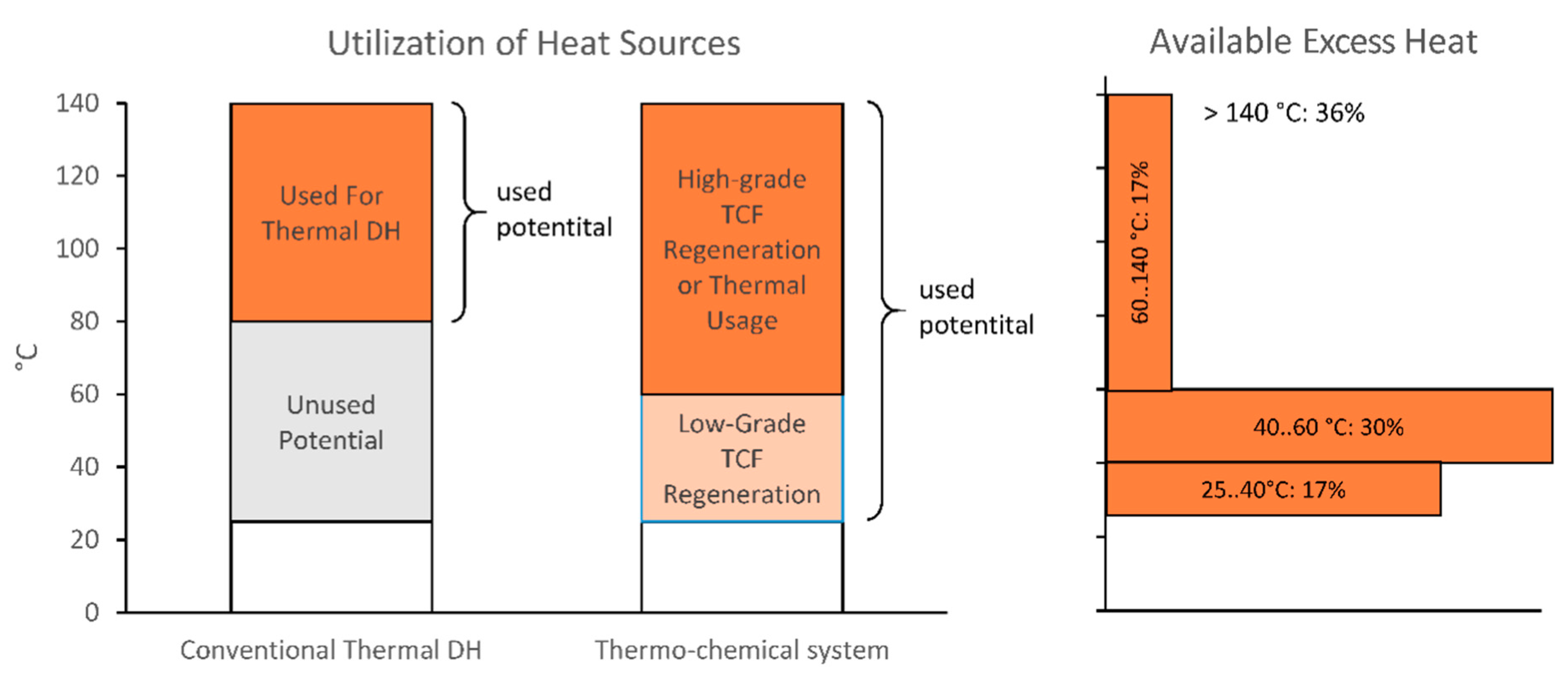

Figure 1.

Temperature levels and utilization of excess heat in industry in Norway (data source: Enova, 2009).

Figure 1.

Temperature levels and utilization of excess heat in industry in Norway (data source: Enova, 2009).

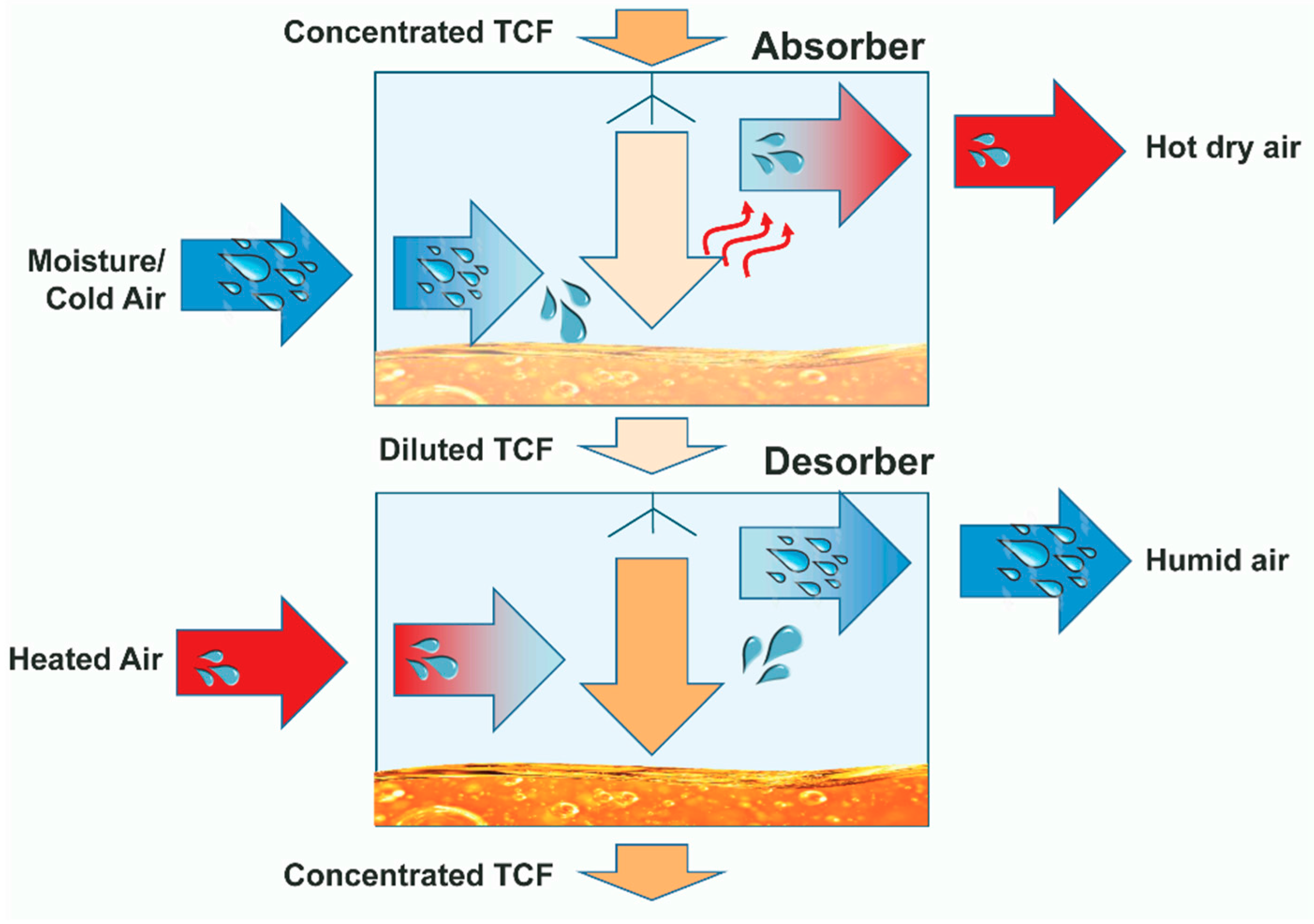

Figure 2.

The basic processes of thermo-chemical systems absorption and desorption.

Figure 2.

The basic processes of thermo-chemical systems absorption and desorption.

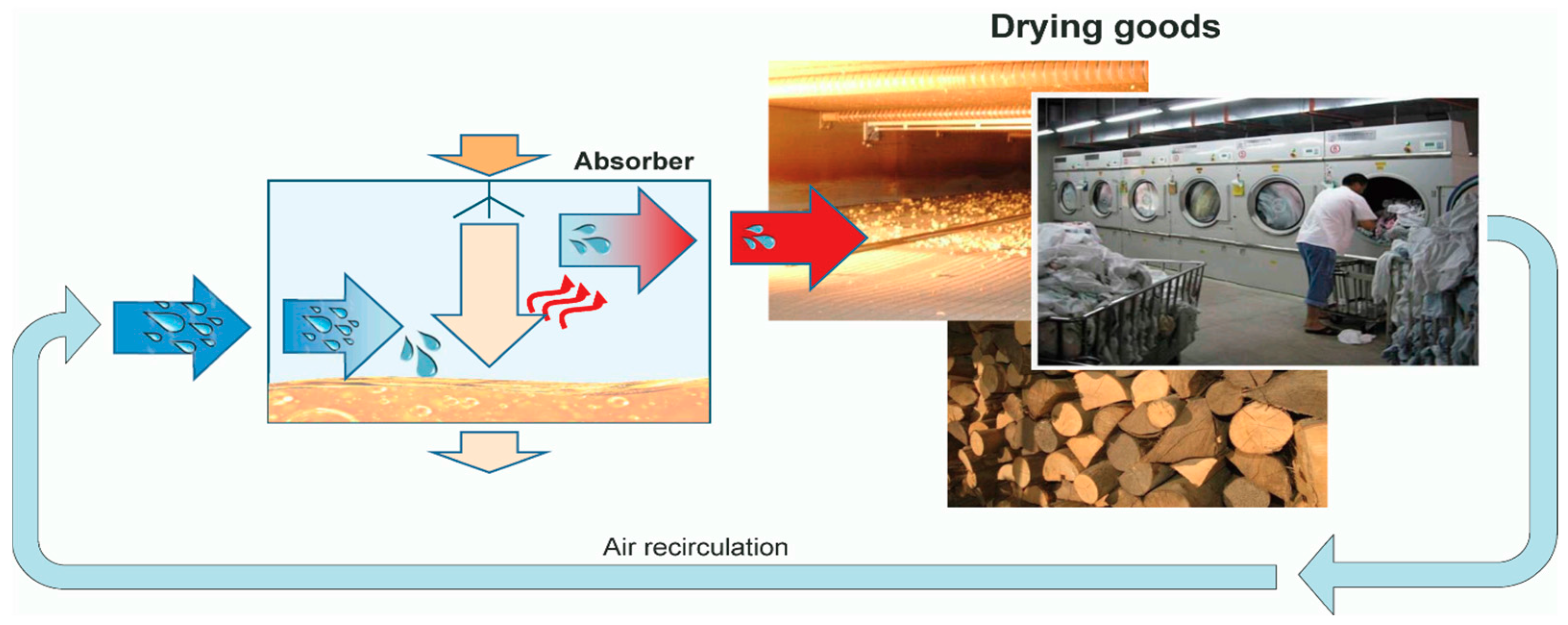

Figure 3.

Basic scheme of the drying process.

Figure 3.

Basic scheme of the drying process.

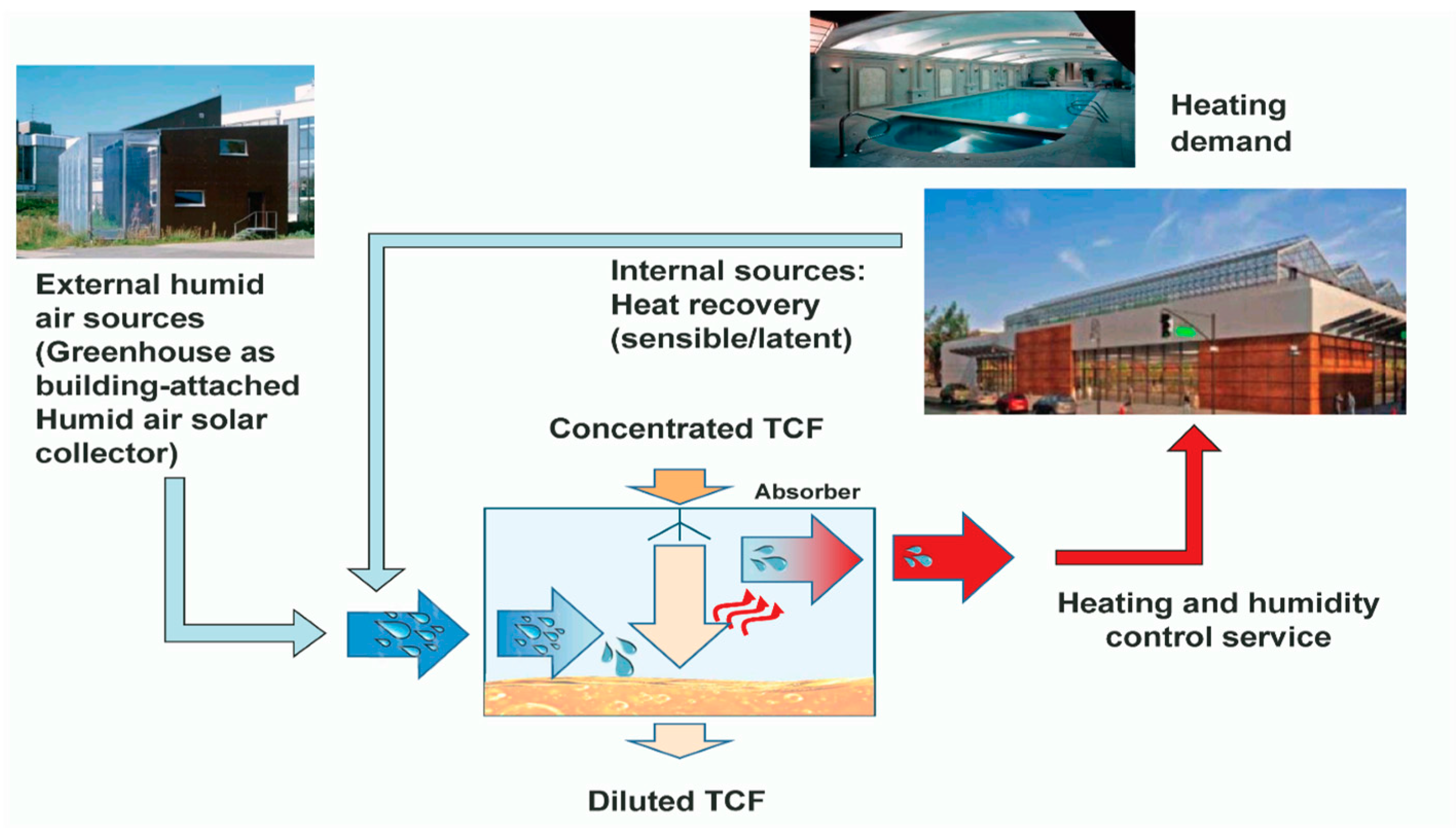

Figure 4.

Basic scheme of the heating and heat recovery process.

Figure 4.

Basic scheme of the heating and heat recovery process.

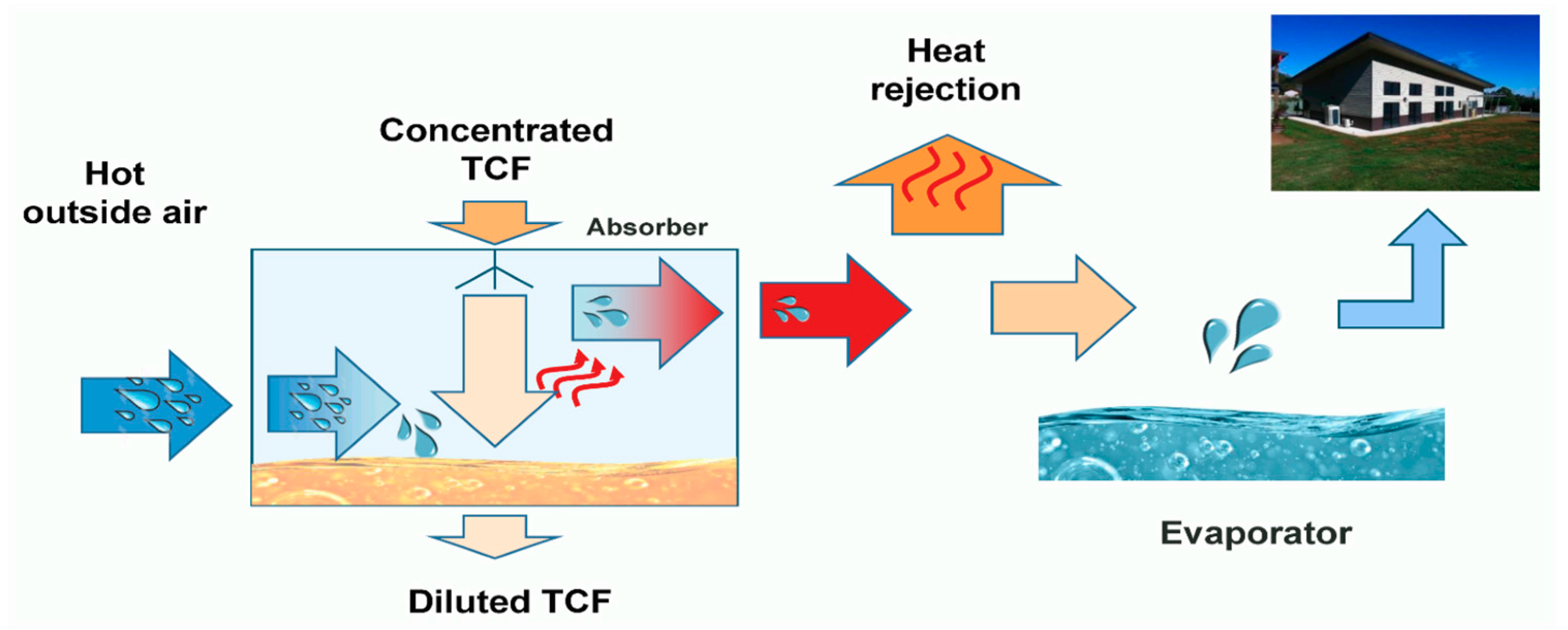

Figure 5.

Basic scheme of the cooling process.

Figure 5.

Basic scheme of the cooling process.

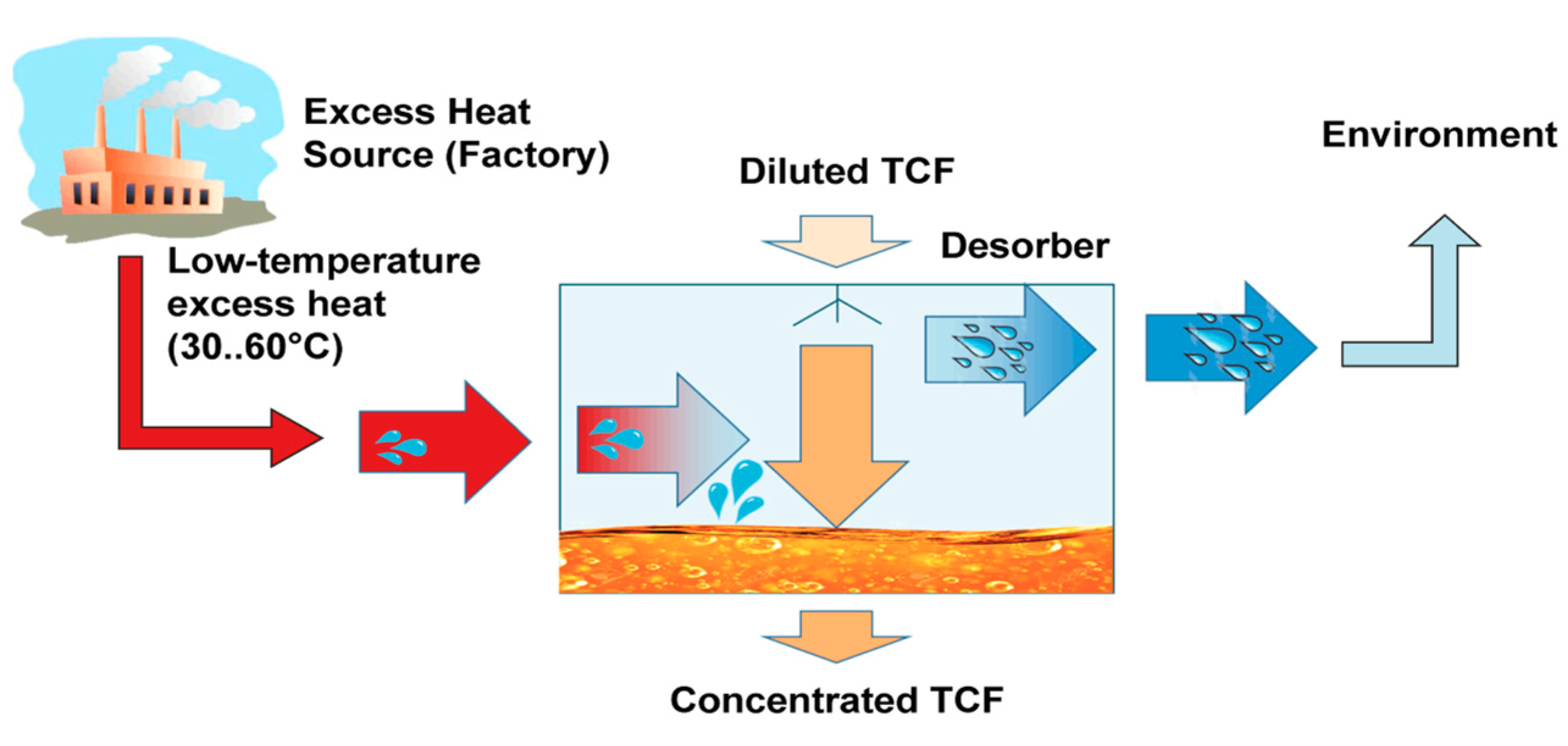

Figure 6.

Regeneration of the TCF by low-grade excess heat.

Figure 6.

Regeneration of the TCF by low-grade excess heat.

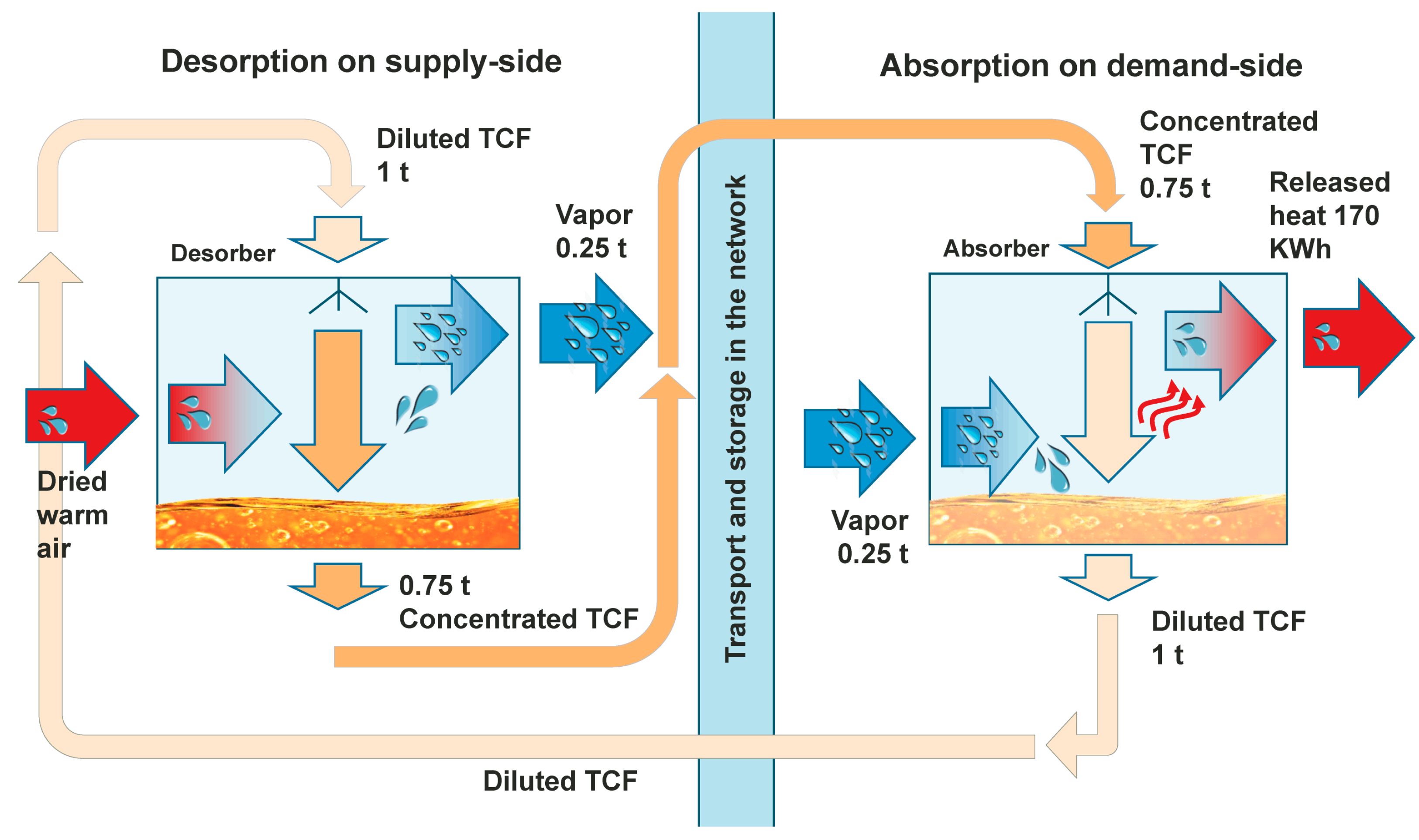

Figure 7.

Desorption and absorption processes with the TCF transport in between forming the thermo-chemical network.

Figure 7.

Desorption and absorption processes with the TCF transport in between forming the thermo-chemical network.

Figure 8.

Example for an absorber and desorber design with an internal TCF heater, vertical textile cylinders and overflow distribution allowing for low flow velocity of the TCF with a long contact time to air (Source: Watergy GmbH).

Figure 8.

Example for an absorber and desorber design with an internal TCF heater, vertical textile cylinders and overflow distribution allowing for low flow velocity of the TCF with a long contact time to air (Source: Watergy GmbH).

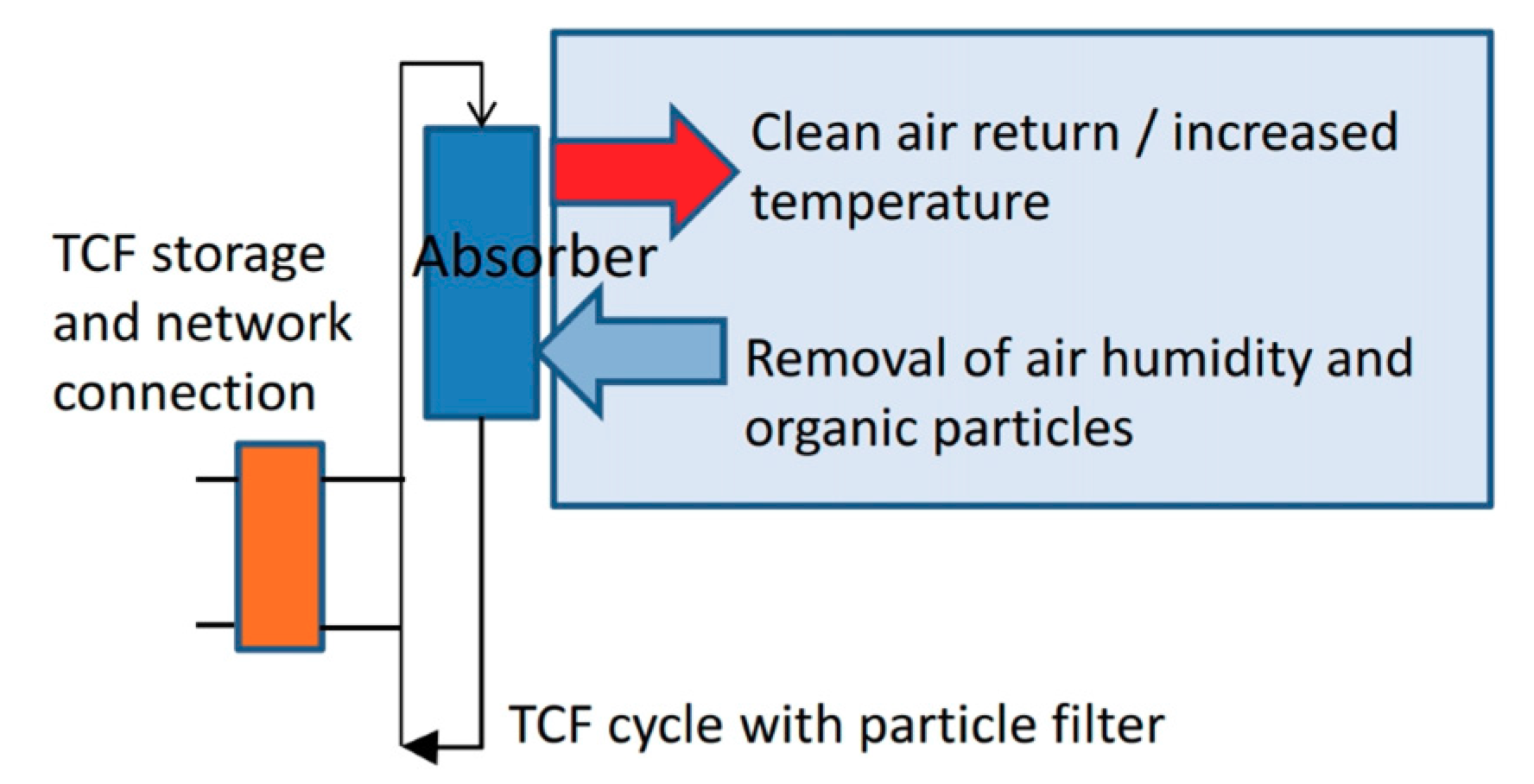

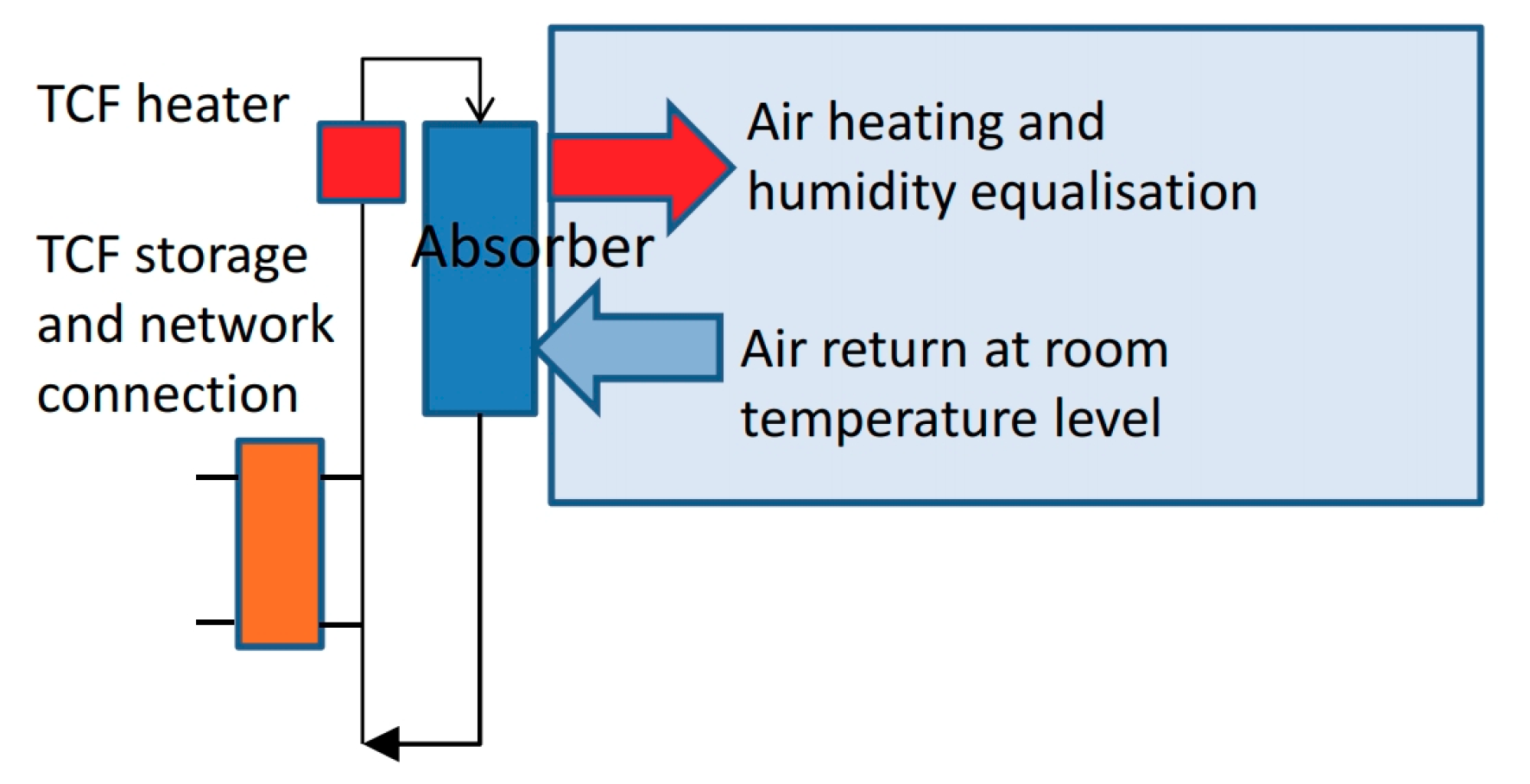

Figure 9.

The thermo-chemical network allows the supply of fluid by a demand-side storage (orange) and dehumidification service within a closed air cycle. Compared to heat recovery ventilation, the supply air from the absorber (blue) is always warmer than the exhaust air from the enclosure. As sensible heat from air and latent heat conversion is transferred to the TCF. There is also the option of heat accumulation and retention of heat release (e.g., collection of heat from internal sources during daytime and use for room pre-heating in the morning). The internal air cycle allows to prevent exceeding humidity limitations and, as providing direct contact between TCF and air, also removes organic particles from the air. This allows to significantly reduce ventilation rates and, by this, also a large part of the energy losses.

Figure 9.

The thermo-chemical network allows the supply of fluid by a demand-side storage (orange) and dehumidification service within a closed air cycle. Compared to heat recovery ventilation, the supply air from the absorber (blue) is always warmer than the exhaust air from the enclosure. As sensible heat from air and latent heat conversion is transferred to the TCF. There is also the option of heat accumulation and retention of heat release (e.g., collection of heat from internal sources during daytime and use for room pre-heating in the morning). The internal air cycle allows to prevent exceeding humidity limitations and, as providing direct contact between TCF and air, also removes organic particles from the air. This allows to significantly reduce ventilation rates and, by this, also a large part of the energy losses.

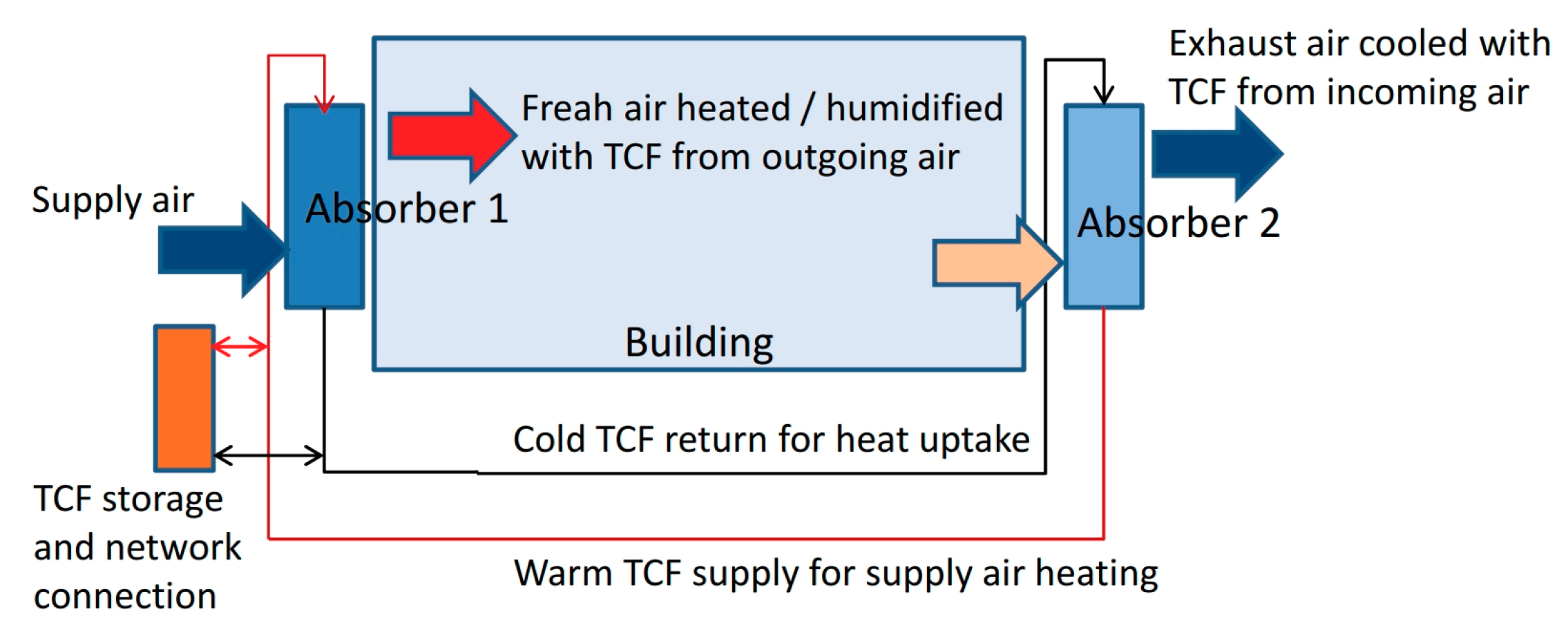

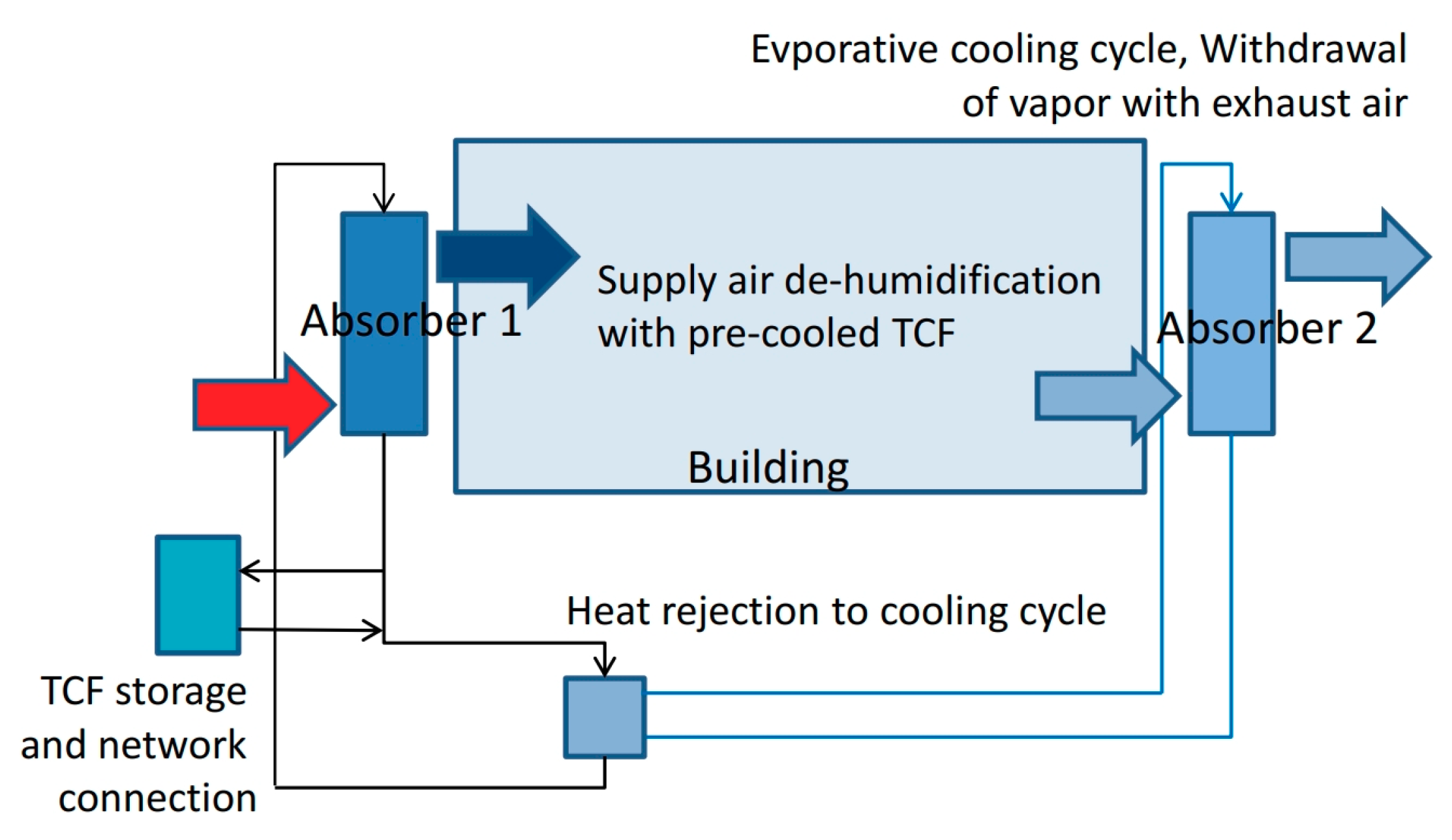

Figure 10.

In heat recovery mode, humidity from the supply air process and internal humidity sources are captured by a second absorber allowing to convert it to sensible heat. The heat is transferred to the TCF and is pumped to the supply air side, where it is used to supply air pre-heating. In contact with ambient air, it strongly cools down and is pumped back to the exhaust air channel.

Figure 10.

In heat recovery mode, humidity from the supply air process and internal humidity sources are captured by a second absorber allowing to convert it to sensible heat. The heat is transferred to the TCF and is pumped to the supply air side, where it is used to supply air pre-heating. In contact with ambient air, it strongly cools down and is pumped back to the exhaust air channel.

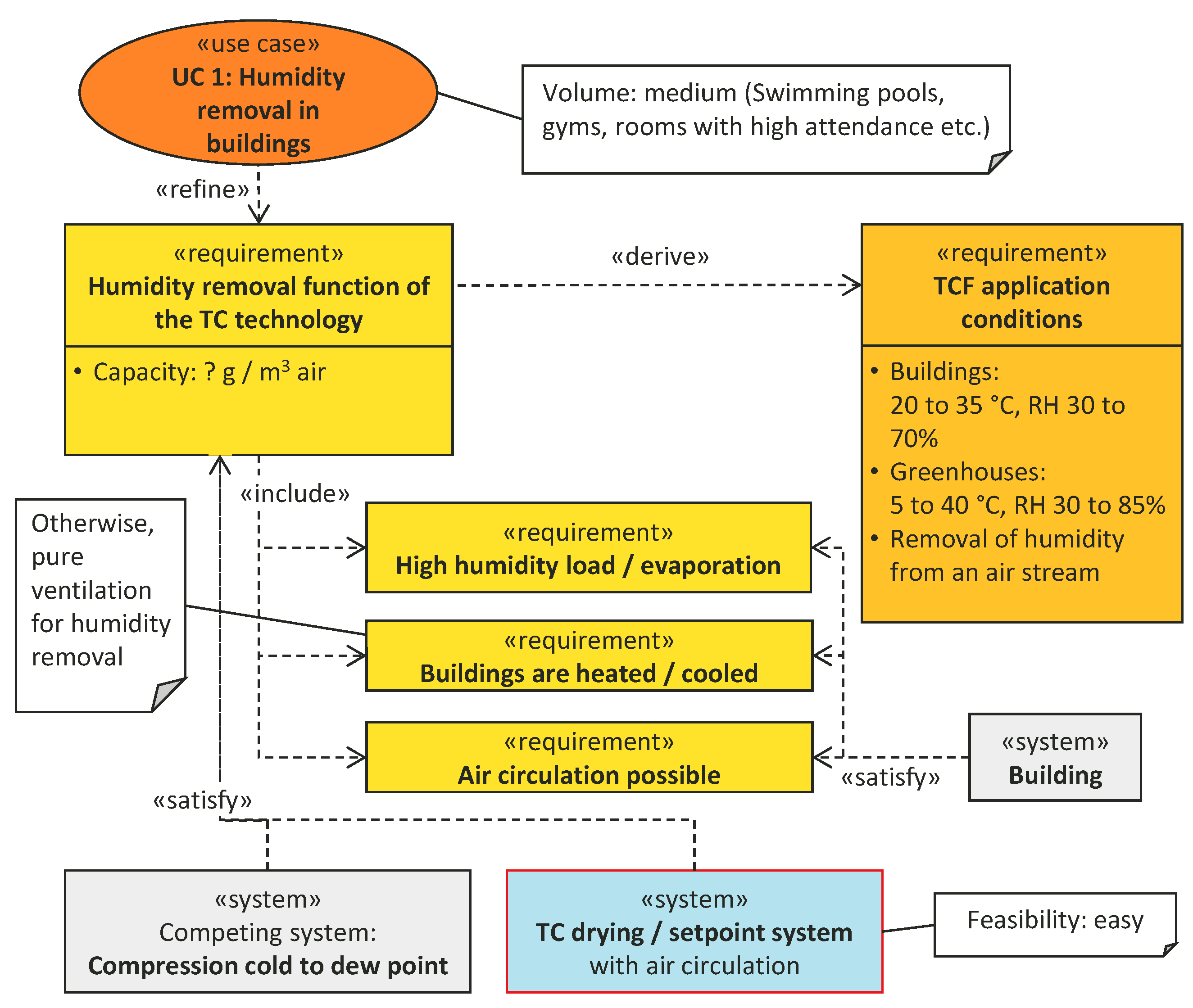

Figure 11.

Humidity removal and heat recovery ventilation in buildings use case.

Figure 11.

Humidity removal and heat recovery ventilation in buildings use case.

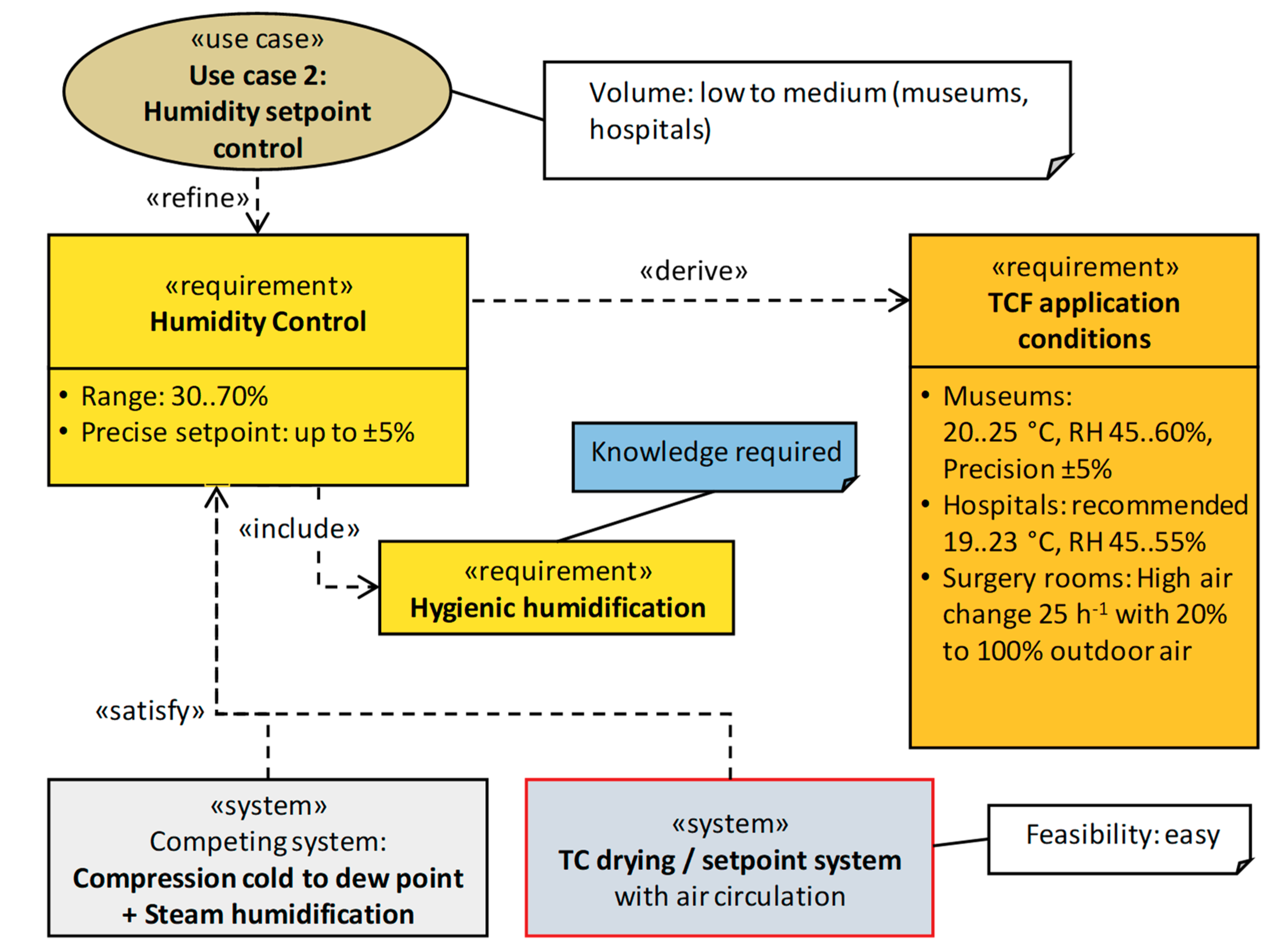

Figure 12.

Set point humidity control in buildings use case.

Figure 12.

Set point humidity control in buildings use case.

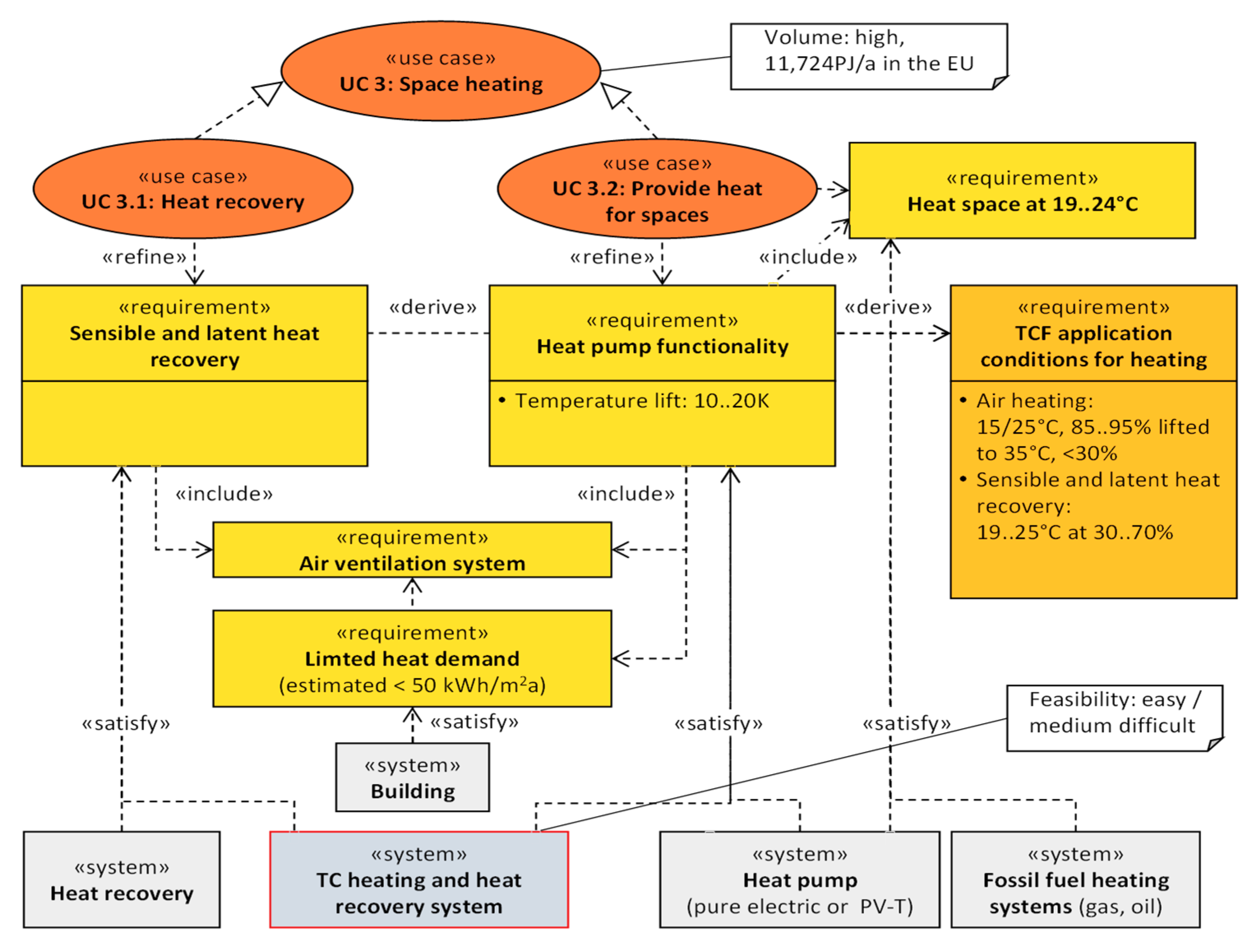

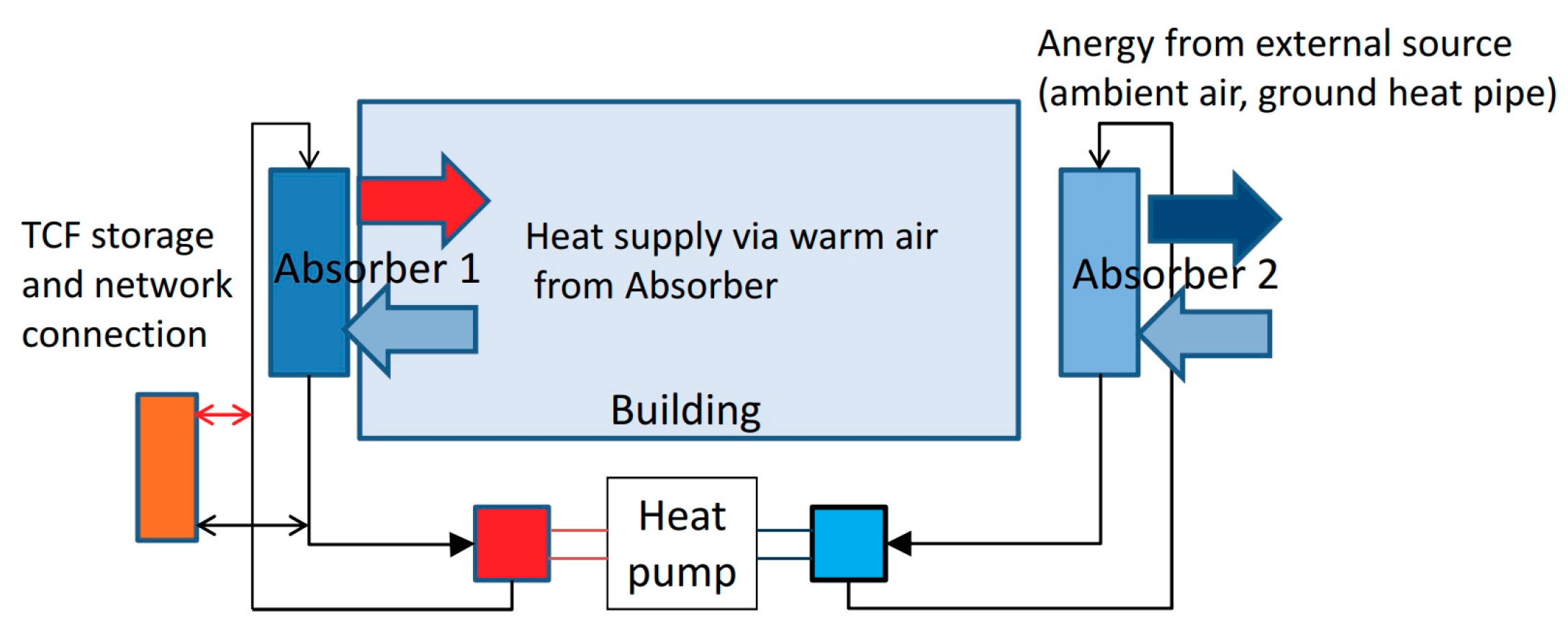

Figure 13.

Use case of space heating with heat recovery.

Figure 13.

Use case of space heating with heat recovery.

Figure 14.

In an internal heating cycle, the absorber provides a warm TCF, heated by an additional low temperature heating device (red) and allows supply of heat and humidity in direct contact to the air in the room. Once, the equilibrium humidity of the salt is reached, additional humidity from internal sources are captured and re-transferred to sensible heat. In ventilation mode, the principle works like in

Figure 2.

Figure 14.

In an internal heating cycle, the absorber provides a warm TCF, heated by an additional low temperature heating device (red) and allows supply of heat and humidity in direct contact to the air in the room. Once, the equilibrium humidity of the salt is reached, additional humidity from internal sources are captured and re-transferred to sensible heat. In ventilation mode, the principle works like in

Figure 2.

Figure 15.

During circulation mode, the second absorber can be used to capture low-temperature heat and latent heat from the ambient air. The circulation mode with TCF allows for reduction of internally-released humidity and organic air compounds, thus, significantly reducing the need for air exchange and related energy consumption.

Figure 15.

During circulation mode, the second absorber can be used to capture low-temperature heat and latent heat from the ambient air. The circulation mode with TCF allows for reduction of internally-released humidity and organic air compounds, thus, significantly reducing the need for air exchange and related energy consumption.

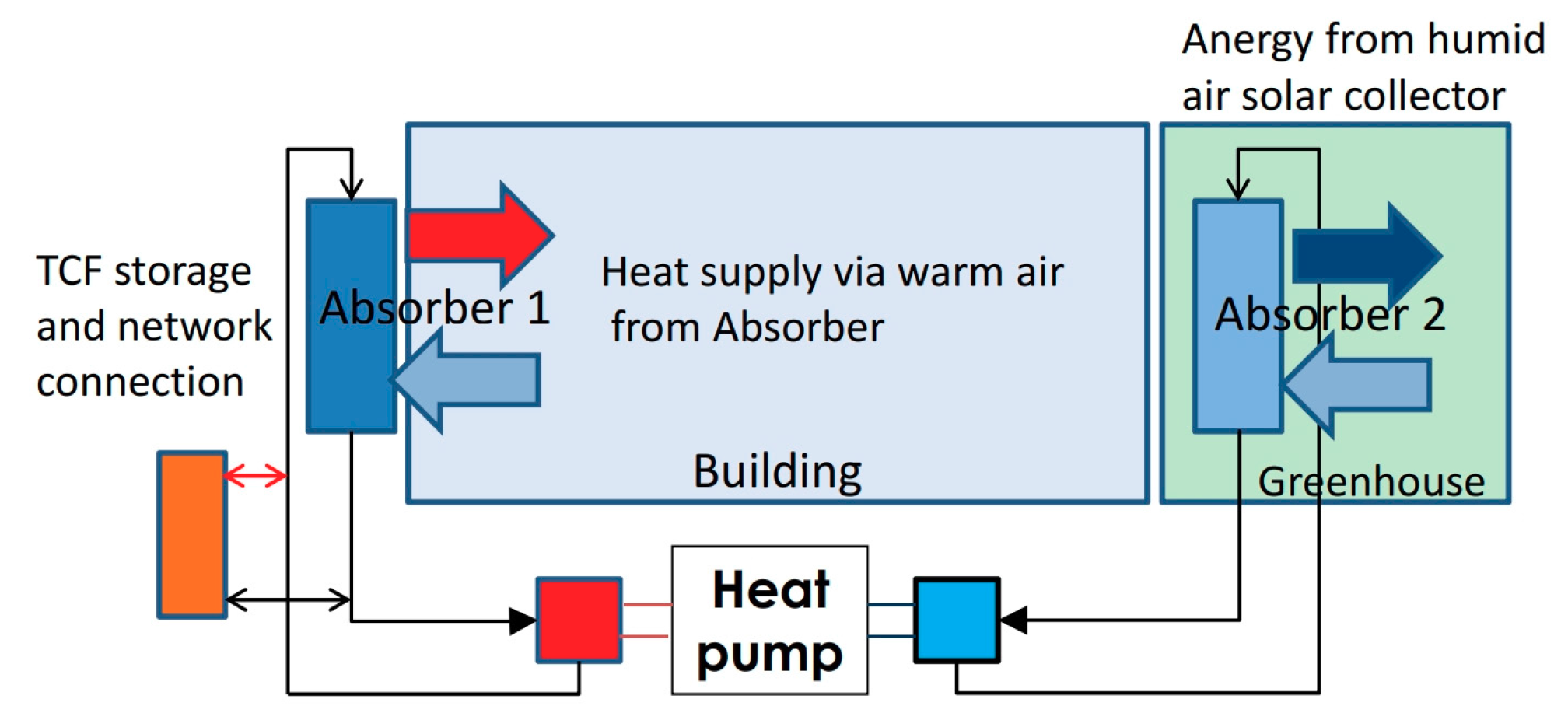

Figure 16.

By integrating a humid air solar collector, e.g., a façade greenhouse, the temperature and humidity rate supplying the heat pump is significantly increased. Greenhouse air can be used if its enthalpy rate is higher than ambient air. Moreover, a part of the façade energy losses of the building are captured by the greenhouse. During phases of sunshine, the higher efficiency of the heat pump, caused by higher feed temperatures can be used to feed a thermal storage (orange box) so that the heat pump can be switched off during the night or during periods without sunshine or expensive electricity.

Figure 16.

By integrating a humid air solar collector, e.g., a façade greenhouse, the temperature and humidity rate supplying the heat pump is significantly increased. Greenhouse air can be used if its enthalpy rate is higher than ambient air. Moreover, a part of the façade energy losses of the building are captured by the greenhouse. During phases of sunshine, the higher efficiency of the heat pump, caused by higher feed temperatures can be used to feed a thermal storage (orange box) so that the heat pump can be switched off during the night or during periods without sunshine or expensive electricity.

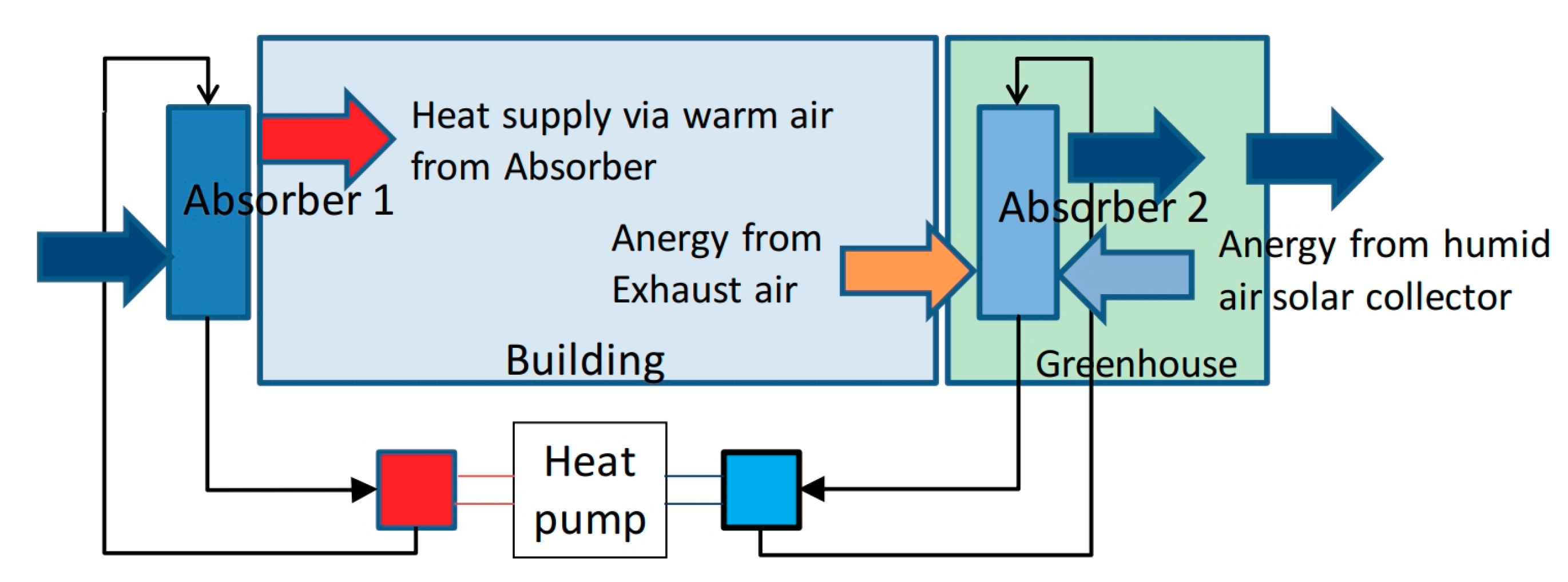

Figure 17.

In ventilation mode, the heat pump can be additionally fed by exhaust air as part of the heat recovery. At least a part of the energy provided for air humidification in the supply air can be recovered.

Figure 17.

In ventilation mode, the heat pump can be additionally fed by exhaust air as part of the heat recovery. At least a part of the energy provided for air humidification in the supply air can be recovered.

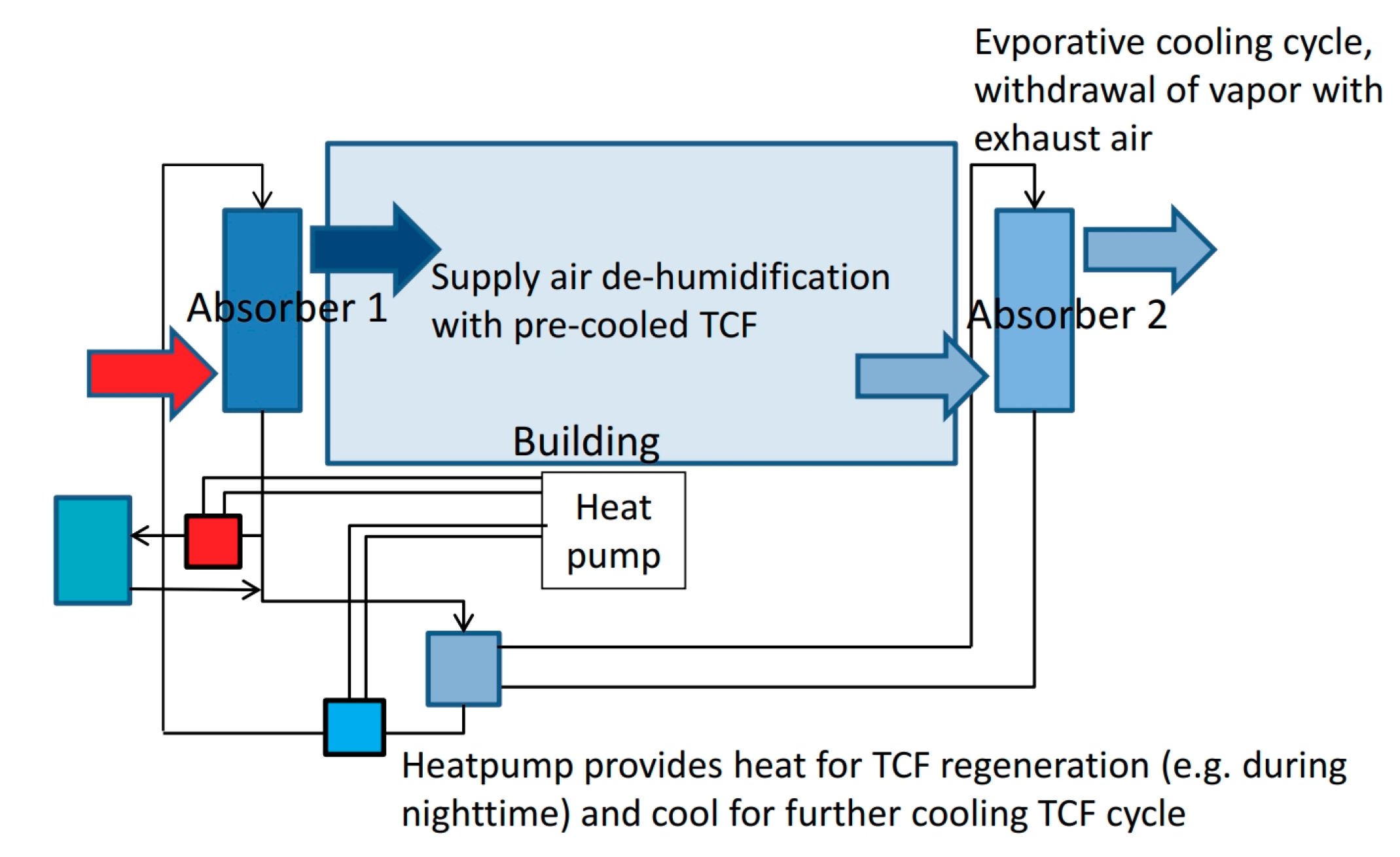

Figure 18.

Cooling use case.

Figure 18.

Cooling use case.

Figure 19.

A heat pump providing additional cooling for areas with higher temperatures and/or humidity loads. The excess heat of the heat pump is not cooled by the evaporation process. This runs at a range of 15–25° and by this it is less vulnerable to legionella growth. Moreover, the heat is stored in the thermal storage (blue box). Heat from the supply air uptake and dehumidification, as well as from the heat pump is stored and can be used during night for TCF regeneration. In this way, a system like this can switch between supply- and demand-side functions in a hybrid network.

Figure 19.

A heat pump providing additional cooling for areas with higher temperatures and/or humidity loads. The excess heat of the heat pump is not cooled by the evaporation process. This runs at a range of 15–25° and by this it is less vulnerable to legionella growth. Moreover, the heat is stored in the thermal storage (blue box). Heat from the supply air uptake and dehumidification, as well as from the heat pump is stored and can be used during night for TCF regeneration. In this way, a system like this can switch between supply- and demand-side functions in a hybrid network.

Figure 20.

A basic cooling function can be provided by evaporation of water in the exhaust air channel. Cool water (blue cycle) helps to remove heat in the TCF (black cycle). The cold TCF can provide supply air dehumidification and cooling in one step. During night, this function can be used to fill a cool storage (blue) that can be used during the phase of highest cooling demand during daytime. The TCF allows dehumidification of air without reaching the dew point. This allows running the air conditioning at significantly higher cooling temperatures (~18 °C instead of ~8 °C).

Figure 20.

A basic cooling function can be provided by evaporation of water in the exhaust air channel. Cool water (blue cycle) helps to remove heat in the TCF (black cycle). The cold TCF can provide supply air dehumidification and cooling in one step. During night, this function can be used to fill a cool storage (blue) that can be used during the phase of highest cooling demand during daytime. The TCF allows dehumidification of air without reaching the dew point. This allows running the air conditioning at significantly higher cooling temperatures (~18 °C instead of ~8 °C).

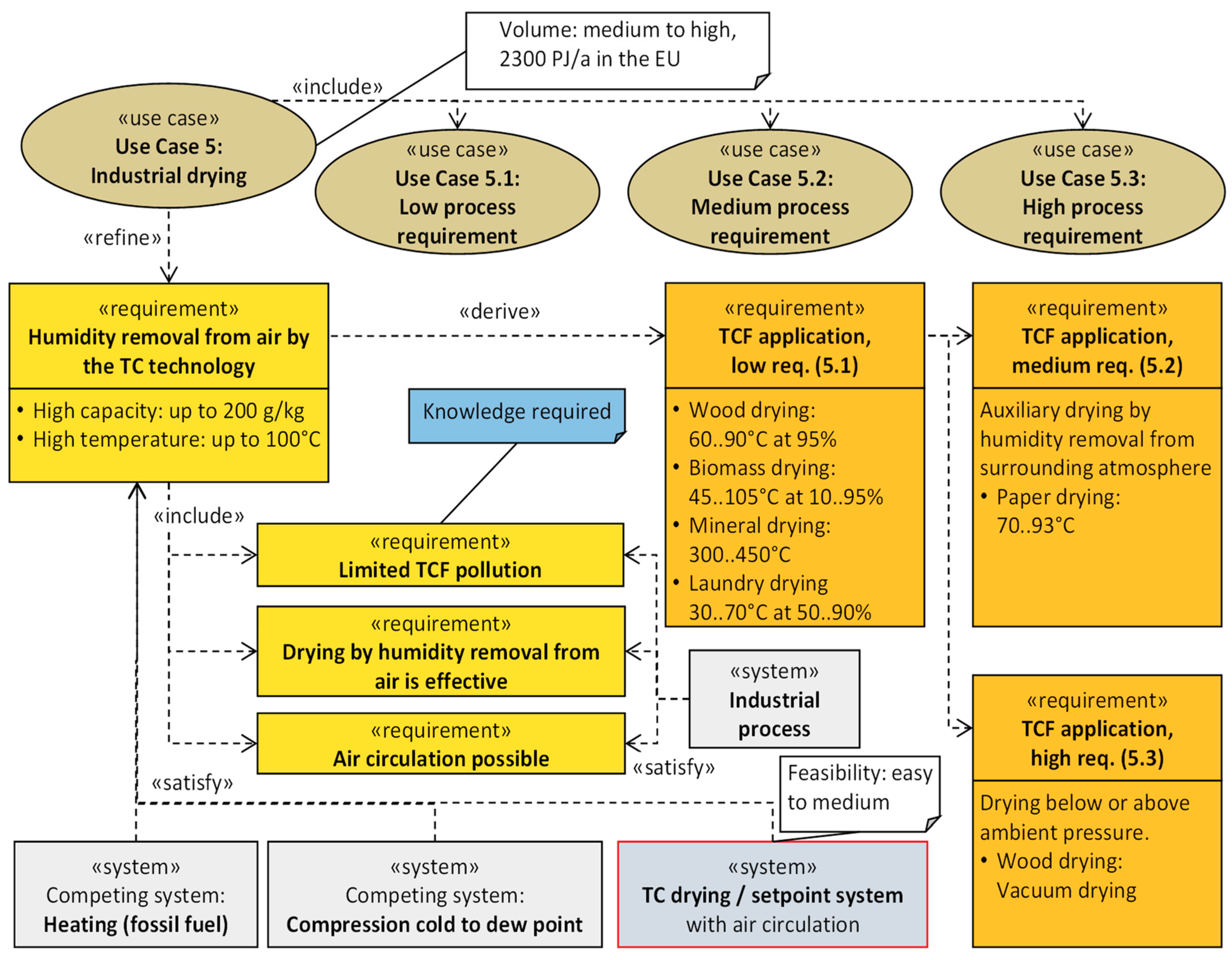

Figure 21.

Industrial drying use case.

Figure 21.

Industrial drying use case.

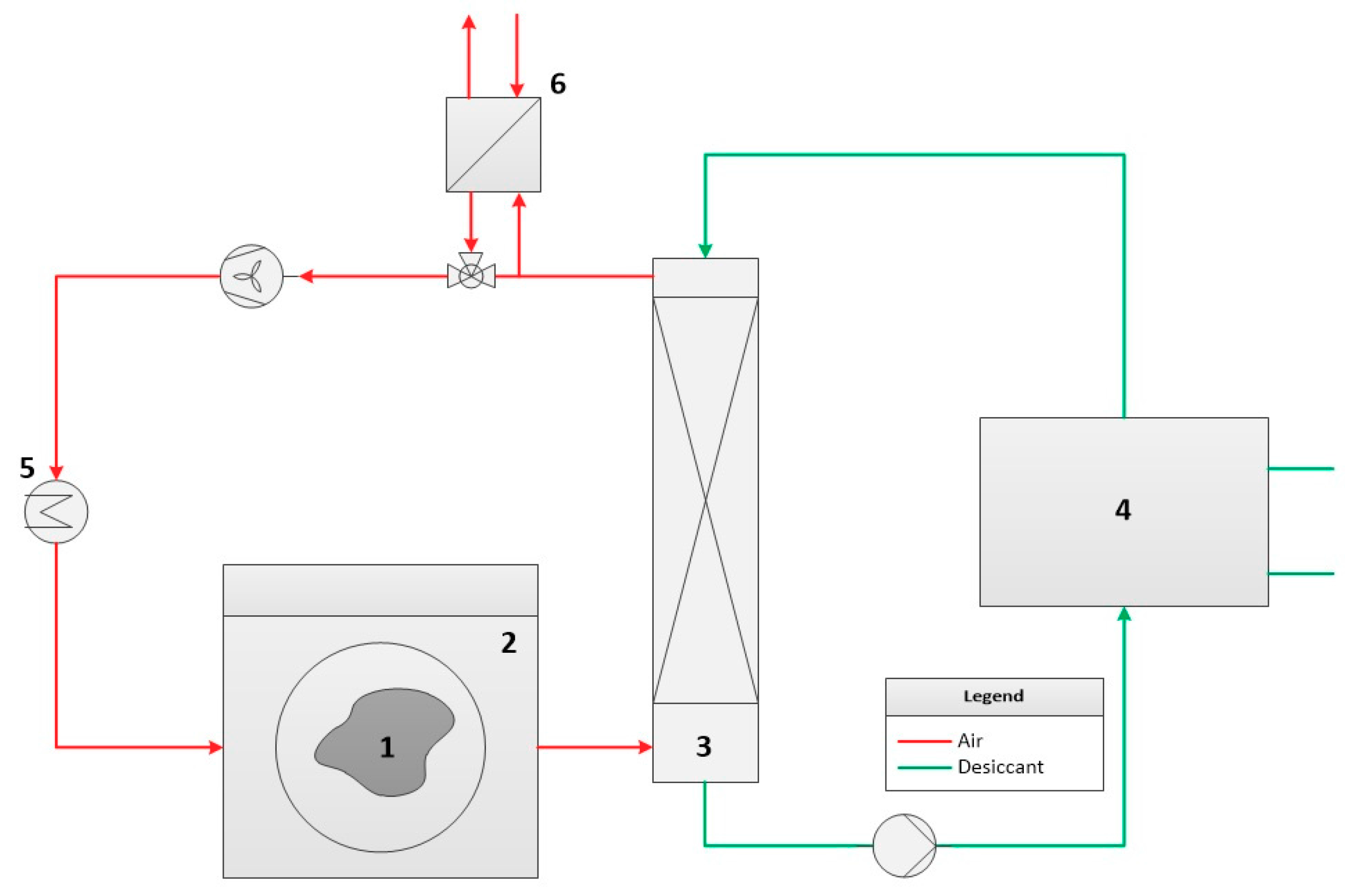

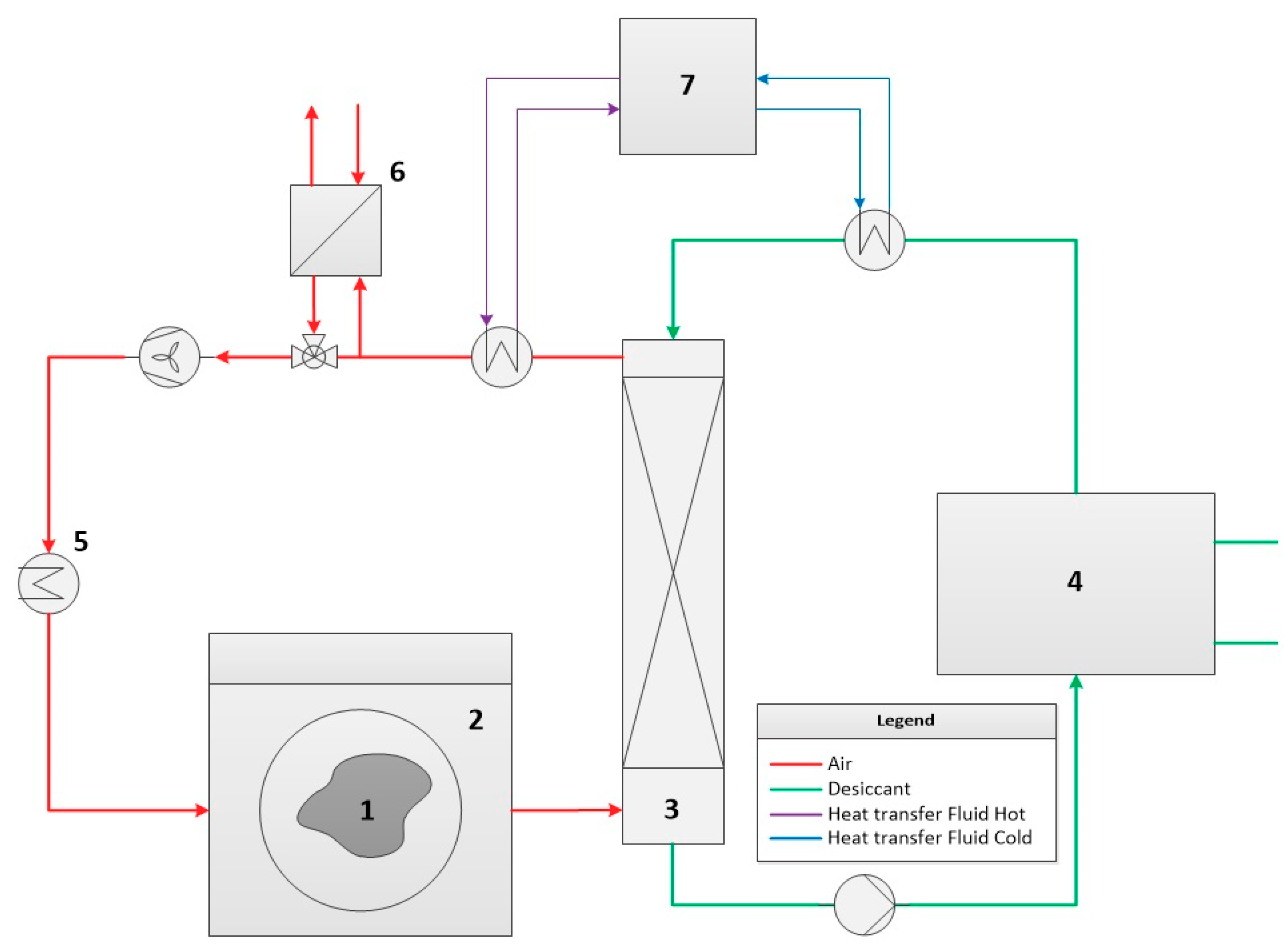

Figure 22.

Absorber box (3) allows recovering sensible heat from humid air in the exhaust air of the drying chamber (2) with the help of a liquid TCF from local storage (4) or from the network directly. In this way, the dry/hot air produced can be redirected back to the chamber (2). Fresh air supply is only needed to remove particles or exhaust gases coming from the drying material (1) or from the heating process (5). A further heat recovery unit (6) can be used for additional energy efficiency in case of economic justification.

Figure 22.

Absorber box (3) allows recovering sensible heat from humid air in the exhaust air of the drying chamber (2) with the help of a liquid TCF from local storage (4) or from the network directly. In this way, the dry/hot air produced can be redirected back to the chamber (2). Fresh air supply is only needed to remove particles or exhaust gases coming from the drying material (1) or from the heating process (5). A further heat recovery unit (6) can be used for additional energy efficiency in case of economic justification.

Figure 23.

The absorption process recovers heat from air. If needed, the heat released can also be captured from the heated TCF to support the heating cycle of the drying unit. This might be used in a conductive process, where heat is not provided to the air but to the drying material (1) through a conductive heater (2).

Figure 23.

The absorption process recovers heat from air. If needed, the heat released can also be captured from the heated TCF to support the heating cycle of the drying unit. This might be used in a conductive process, where heat is not provided to the air but to the drying material (1) through a conductive heater (2).

Figure 24.

A heat pump-driven drying process can be combined with the absorption process. In this way, the set point humidity and temperature of the air can be controlled separately.

Figure 24.

A heat pump-driven drying process can be combined with the absorption process. In this way, the set point humidity and temperature of the air can be controlled separately.

Figure 25.

Use case of a surgery room air-conditioning with TCF technology [

18], modified.

Figure 25.

Use case of a surgery room air-conditioning with TCF technology [

18], modified.

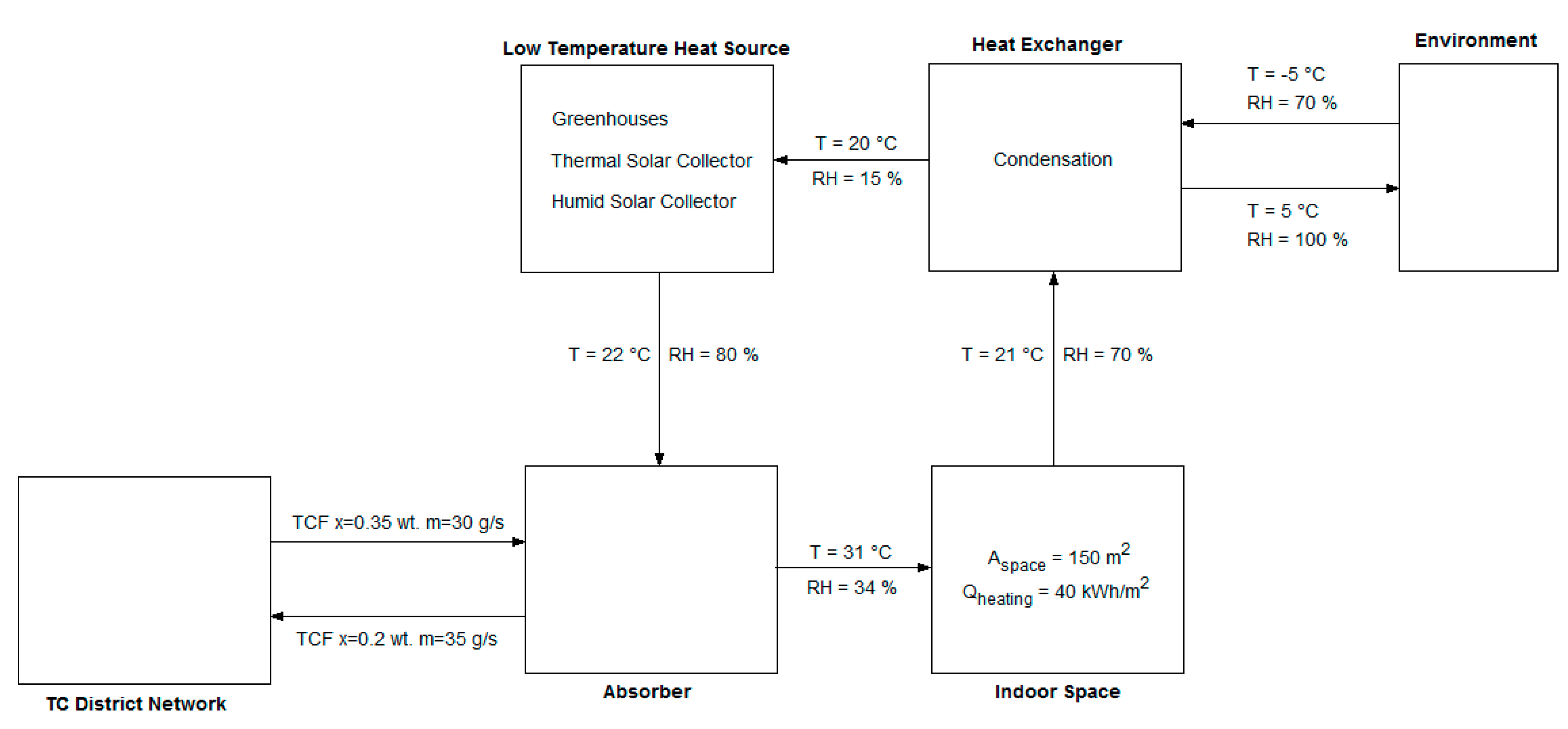

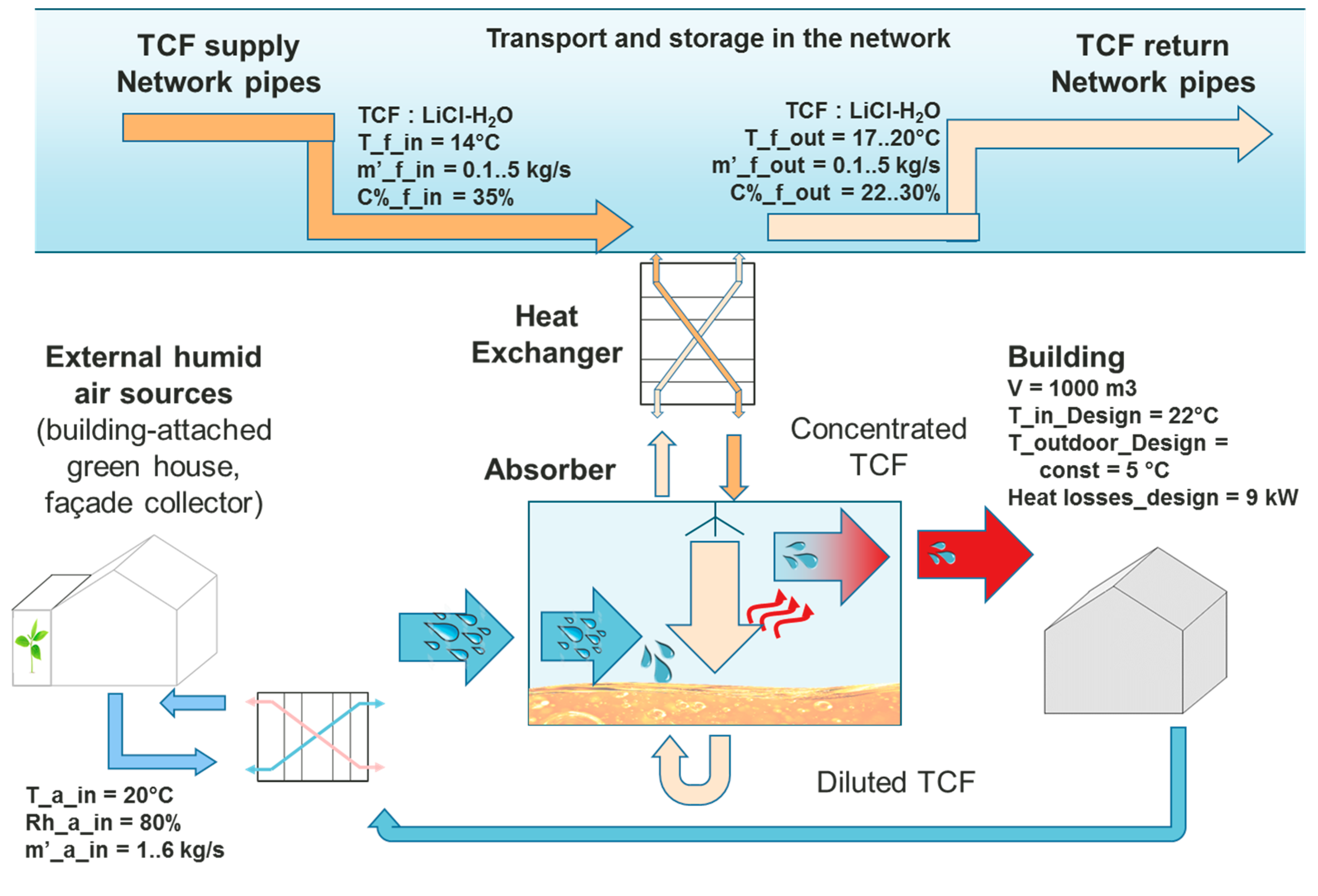

Figure 26.

Use case of space heating with TCF technology [

20].

Figure 26.

Use case of space heating with TCF technology [

20].

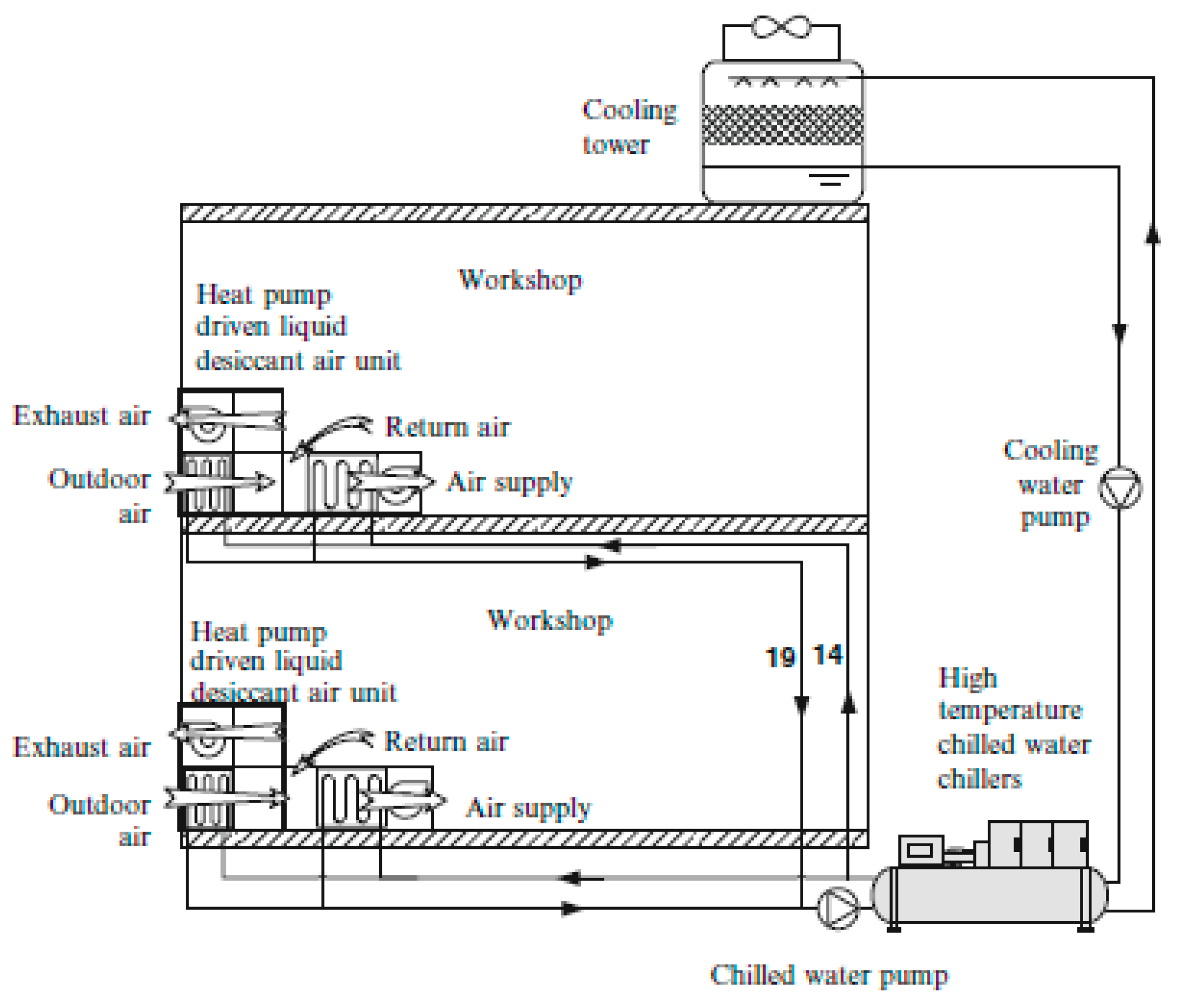

Figure 27.

Use case of temperature and humidity control with TCF technology in a banknote printing workshop [

22].

Figure 27.

Use case of temperature and humidity control with TCF technology in a banknote printing workshop [

22].

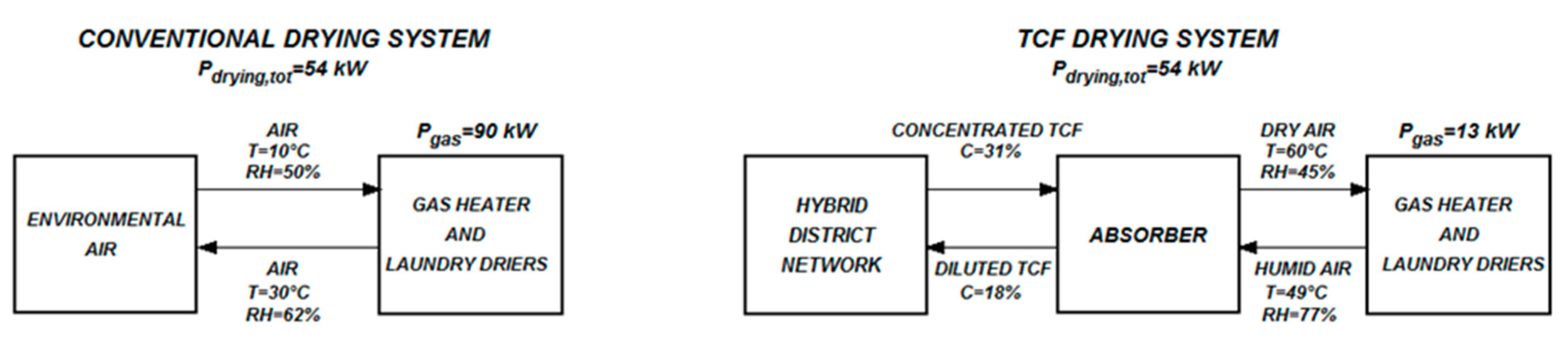

Figure 28.

Comparison between conventional and TCF-based industrial laundry dryers [

21].

Figure 28.

Comparison between conventional and TCF-based industrial laundry dryers [

21].

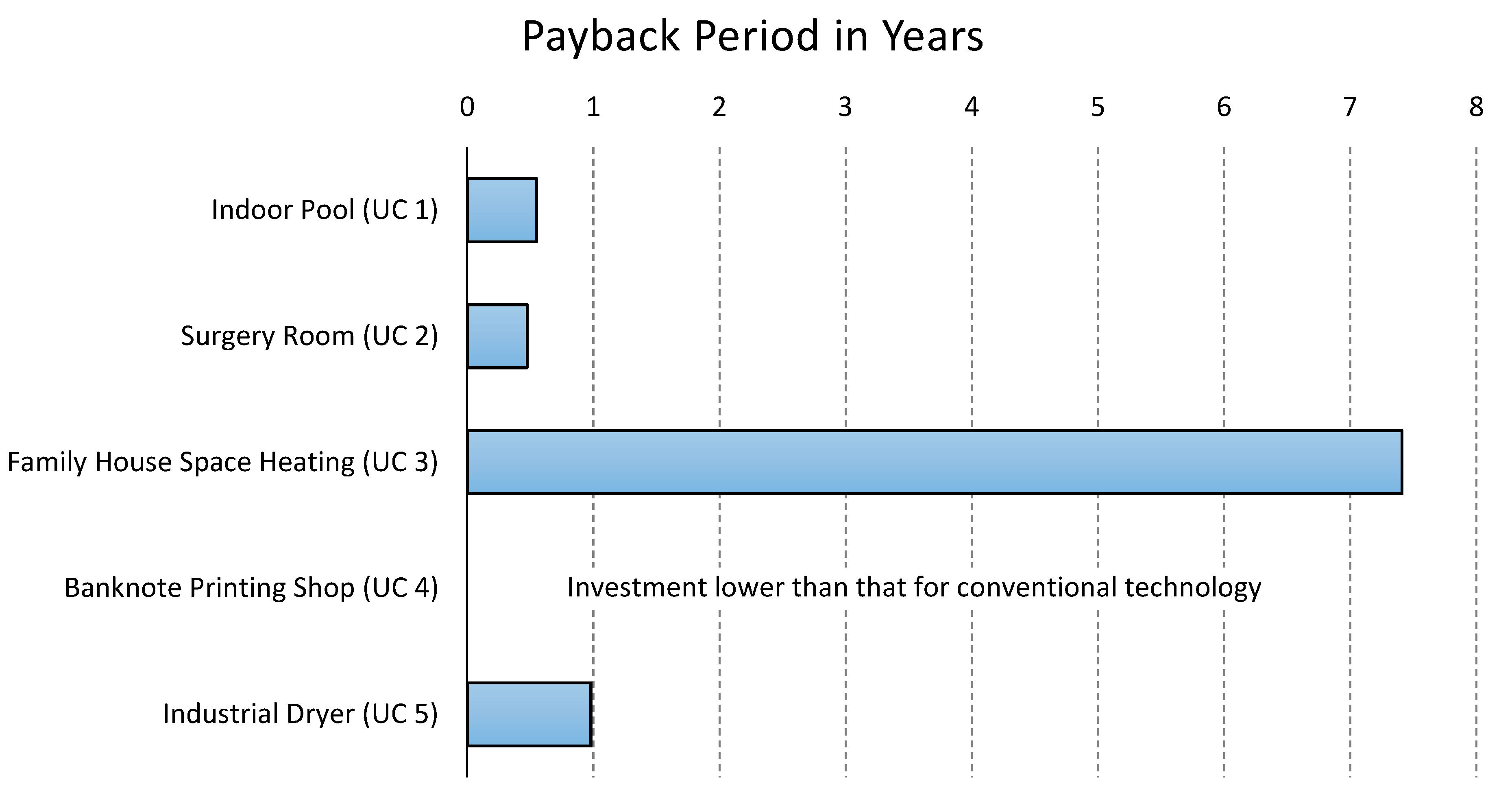

Figure 29.

Payback period with TCF technology replacement.

Figure 29.

Payback period with TCF technology replacement.

Figure 30.

Flowcharts of the heating and heating recovery, including the absorption process.

Figure 30.

Flowcharts of the heating and heating recovery, including the absorption process.

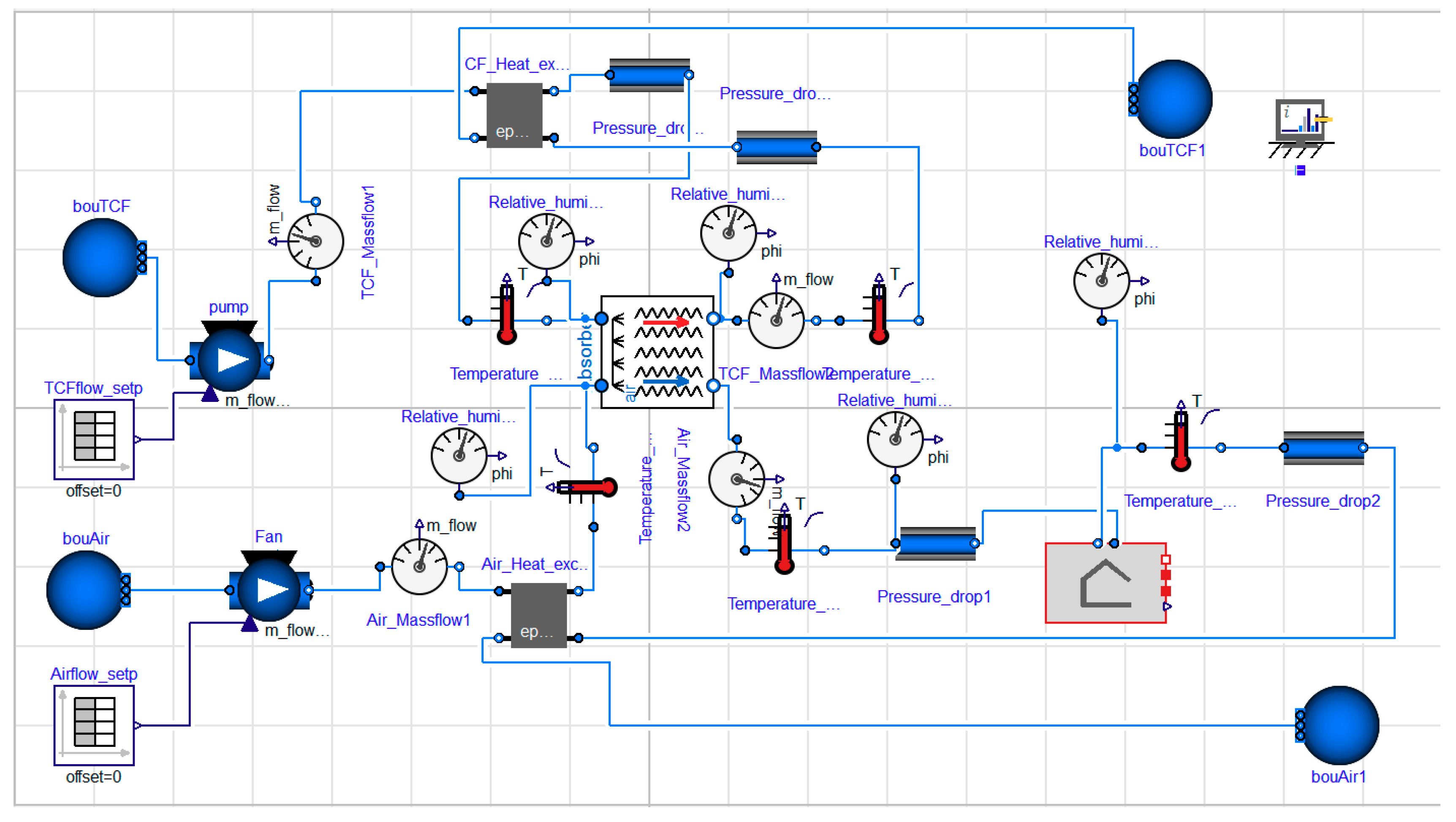

Figure 31.

Modelica/(Dymola) model for the building, space heating Case 3.

Figure 31.

Modelica/(Dymola) model for the building, space heating Case 3.

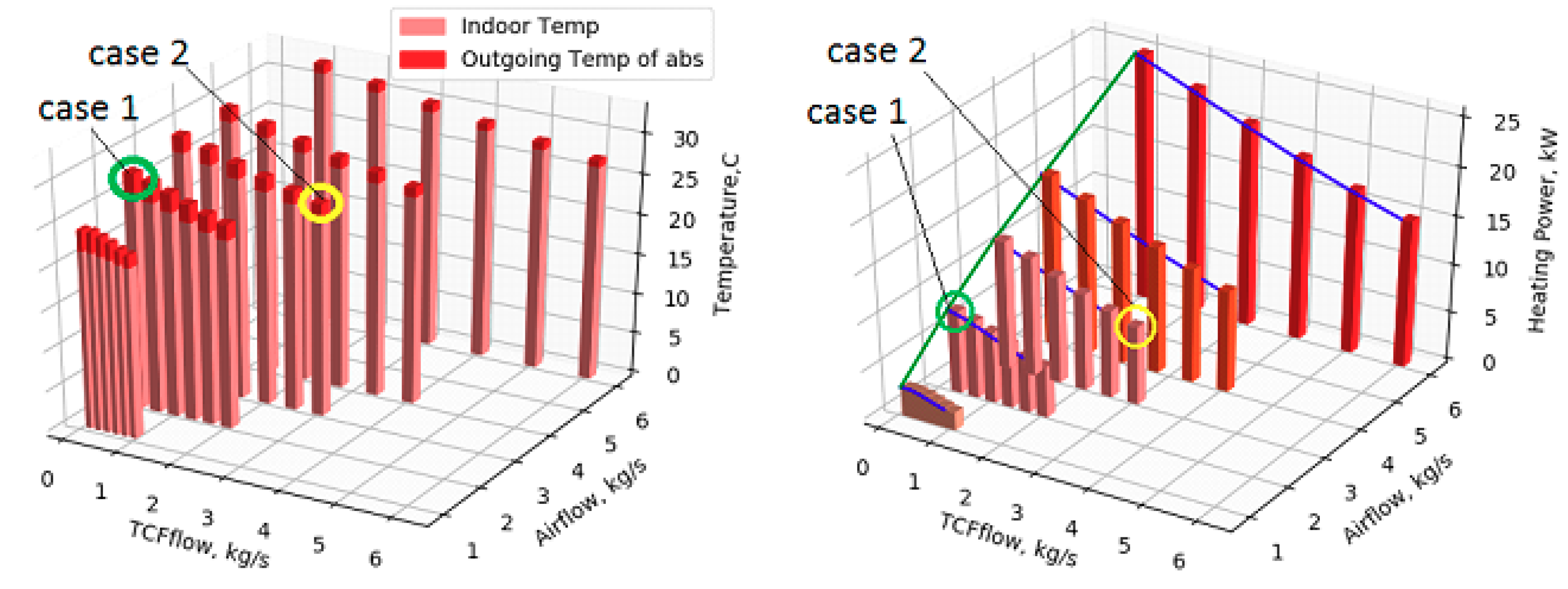

Figure 32.

(Left) Indoor temperature and outgoing temperature of the absorber versus airflows and TCF flows. (Right) Heating power versus airflows and TCF flows.

Figure 32.

(Left) Indoor temperature and outgoing temperature of the absorber versus airflows and TCF flows. (Right) Heating power versus airflows and TCF flows.

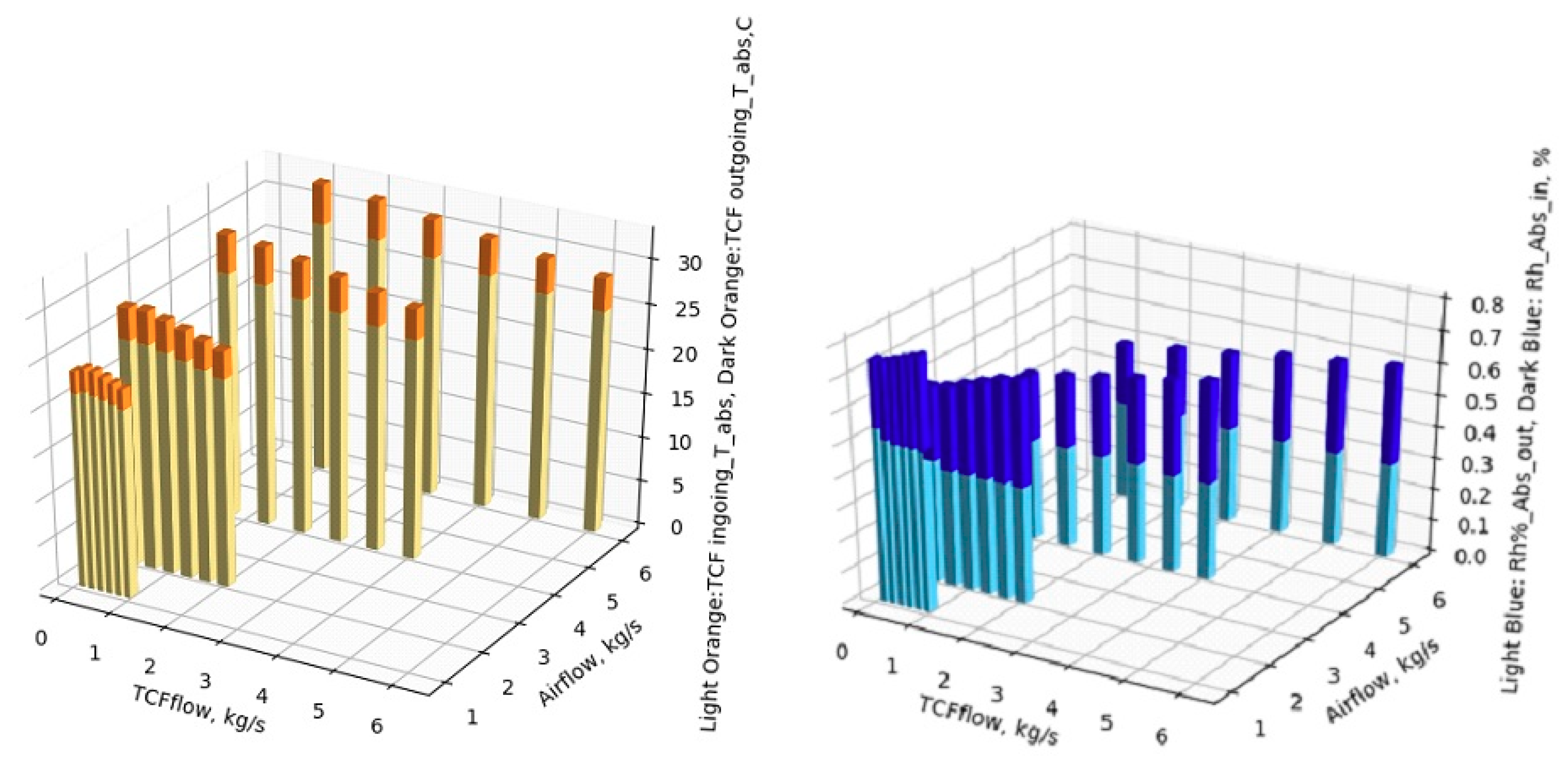

Figure 33.

(Left) TCF ingoing temperature and outgoing temperature of the absorber versus airflows and TCF flows. (Right) Relative humidity of the ingoing flow and outgoing flow versus airflows and TCF flows.

Figure 33.

(Left) TCF ingoing temperature and outgoing temperature of the absorber versus airflows and TCF flows. (Right) Relative humidity of the ingoing flow and outgoing flow versus airflows and TCF flows.

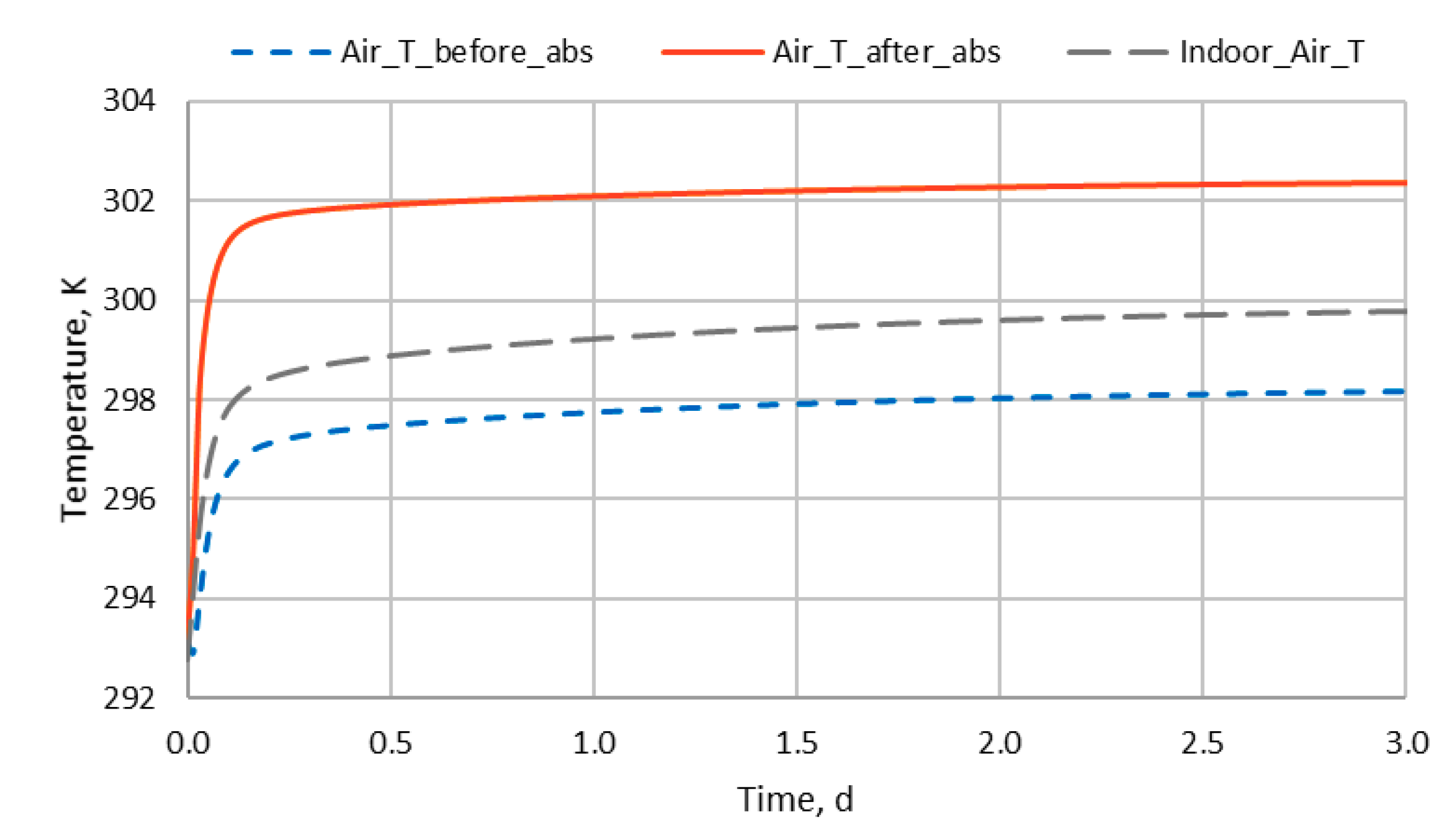

Figure 34.

Ingoing temperature before the absorber (orange solid line), outgoing temperature after the absorber (blue dash line) and indoor temperature of the building (grey long dashed line).

Figure 34.

Ingoing temperature before the absorber (orange solid line), outgoing temperature after the absorber (blue dash line) and indoor temperature of the building (grey long dashed line).

Table 1.

Comparison of energy consumption and economic savings of conventional and TCF technology for air-conditioning in a banknote printing workshop [

22].

Table 1.

Comparison of energy consumption and economic savings of conventional and TCF technology for air-conditioning in a banknote printing workshop [

22].

| | Original System | TCF + High Temperature Chiller |

|---|

| Devices | Chiller | Reheat | TCF system | Chiller |

| Rated cooling capacity | 1574 kW | - | 206 kW | 837 kW |

| Rated power consumption | 463 kW | - | 56 kW | 164 kW |

| Rated reheat consumption | - | 532 kW | - | - |

| Power consumption (summer) | 1167 MWh | | 554 MWh | |

| Gas consumption (summer) | 230,003 m3 | | - | |

| Operating cost (summer) | 1,370,000 CNY | | 440,000 CNY | |

| 174,536.15 € * | 56,055.4 € * |

Table 2.

Modelica model components.

Table 2.

Modelica model components.

| Models | Description |

|---|

| Fan/pump model | Described by mass-flow and pressure [26]. |

| Absorber model | A finite volume model, with a cross-flow configuration, as developed by Fürst [27]; the interaction nodes are two nodes for air, two nodes for TCF. The dehumidification process is adiabatic, i.e., no heat is exchanged with the environment. The interface of the humid air and TCF are in equilibrium with respect to temperature and humidity. |

| Medium model | LiCl-H2O model is developed by Fürst [27] based on the thermodynamic properties and its equations of state are based on the paper of Pàtek and Klomfar [28]. |

| Building model | The model is based on the Structure model of the IDEAS library [25]. |

| Heat exchanger model | Heat exchanger of TCF circuit is TCF–TCF, heat exchanger of the air circuit is air–air, from the IDEAS library [25]. |

| Pressure drop model | Described by mass-flow and pressure, IDEAS library [25]. |

| Constant source model | For temperature and humidity, IDEAS library [25]. |

| Thermostat model and relative humidity sensor model | To measure the temperature and relative humidity, IDEAS library [25]. |

Table 3.

Building model conditions.

Table 3.

Building model conditions.

| Parameters | Value | Unit |

|---|

| U value for outer wall, roof and ground | 0.30 | W/m2K |

| U value for windows | 1.015 | W/m2K |

| The volume of the building | 1000 | m3 |

| Indoor design temperature | 22 | °C |

| Outdoor design temperature | 5 | °C |

| Maximum heat losses | 9 | kW |

| Outdoor temperature was assumed to be constant to have static building heat losses | 5 | °C |

Table 4.

External humid air source conditions.

Table 4.

External humid air source conditions.

| Parameters | Value | Unit |

|---|

| Input temperature | 20 | °C |

| Relative humidity | 75% | |

| Absolute humidity | 11 | g/kg |

| Mass flows through the absorber | 1–6 | kg/s |

Table 5.

TCF supply source conditions.

Table 5.

TCF supply source conditions.

| Parameters | Value | Unit |

|---|

| Input temperature | 14 | °C |

| Concentration | 35% | |

| Mass flows through the absorber | 1–5 | kg/s |

Table 6.

The airflow values with the corresponding TCF flows.

Table 6.

The airflow values with the corresponding TCF flows.

| Airflows, kg/s | TCF Flows, kg/s |

|---|

| | | | | | | |

| 1 | 0.17 | 0.33 | 0.50 | 0.67 | 0.83 | 1 |

| 2 | 0.33 | 0.67 | 1 | 1.33 | 1.67 | 2 |

| 3 | 3 | 2.5 | 2 | 1.5 | 1 | 0.5 |

| 4 | 0.67 | 1.33 | 2 | 2.67 | 3.33 | 4 |

| 6 | 1 | 2 | 3 | 4 | 5 | 6 |

Table 7.

Selected values of the absorption input/output temperatures and the required heating power versus airflow and TCF flow at 1.5 days.

Table 7.

Selected values of the absorption input/output temperatures and the required heating power versus airflow and TCF flow at 1.5 days.

| Time, d | T before abs, K | T after abs, K | Indoor T of Building | Airflow, kg/s | TCF flow, kg/s | Heating Power, kW |

|---|

| 1.5 | 298 | 302.2 | 299.2 | 2 | 0.33 | 9 |

Table 8.

Different cases to show the pumping and heating power of the absorber with different airflows and TCF flows at 1.5 days.

Table 8.

Different cases to show the pumping and heating power of the absorber with different airflows and TCF flows at 1.5 days.

| | Airflow, kg/s | TCF $low, kg/s | Airflow, TCF Flow Ratio (kg/kg) | Pumping Power, kW | Heating Power, kW | Power Ratio |

|---|

| Case 1 | 2 | 0.33 | 0.165 | 0.647 | 9 | 0.0688 |

| Case 2 | 3 | 3 | 1 | 0.967 | 8.2 | 0.10631 |