Daytime Lighting Assessment in Textile Factories Using Connected Windows in Slovakia: A Case Study

Abstract

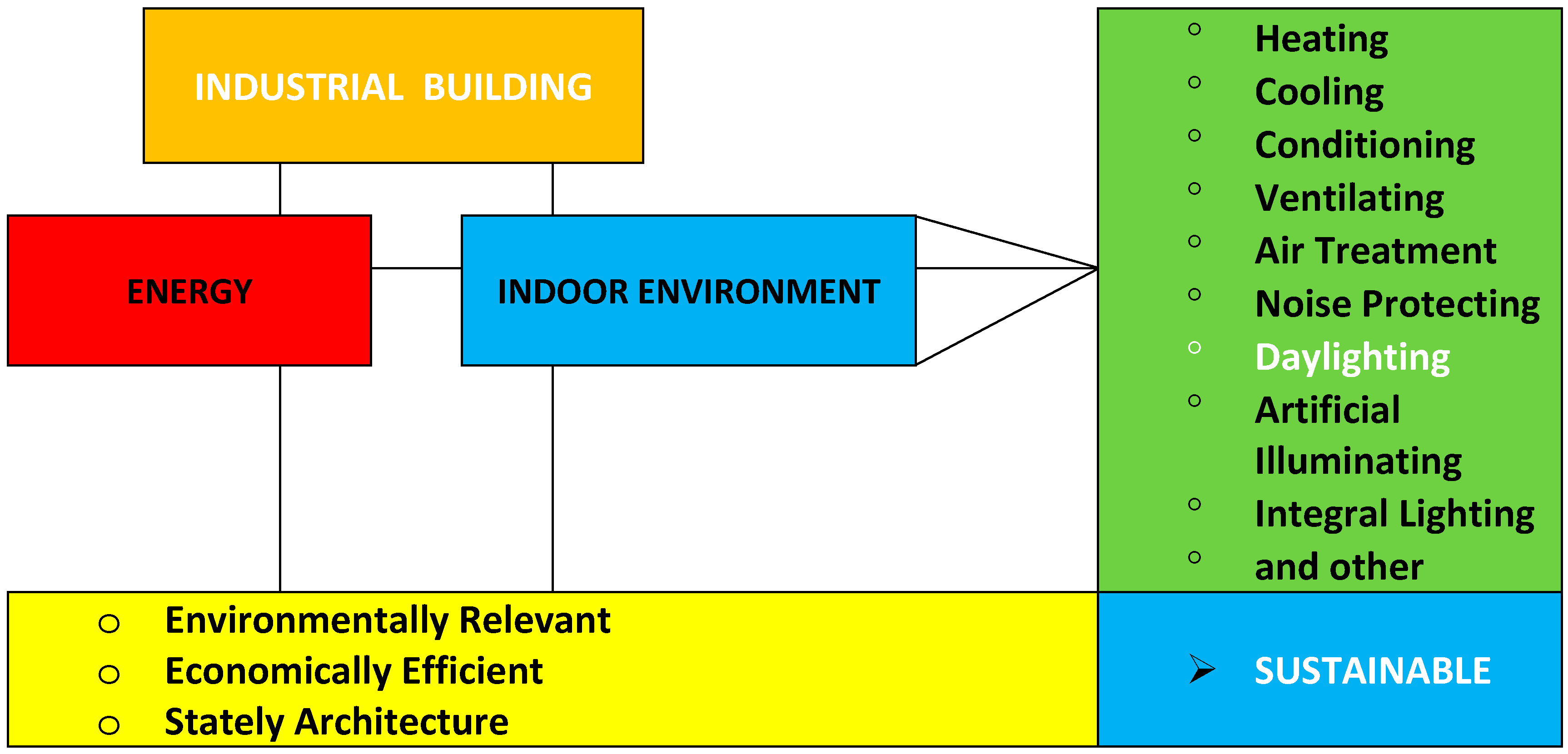

1. Introduction

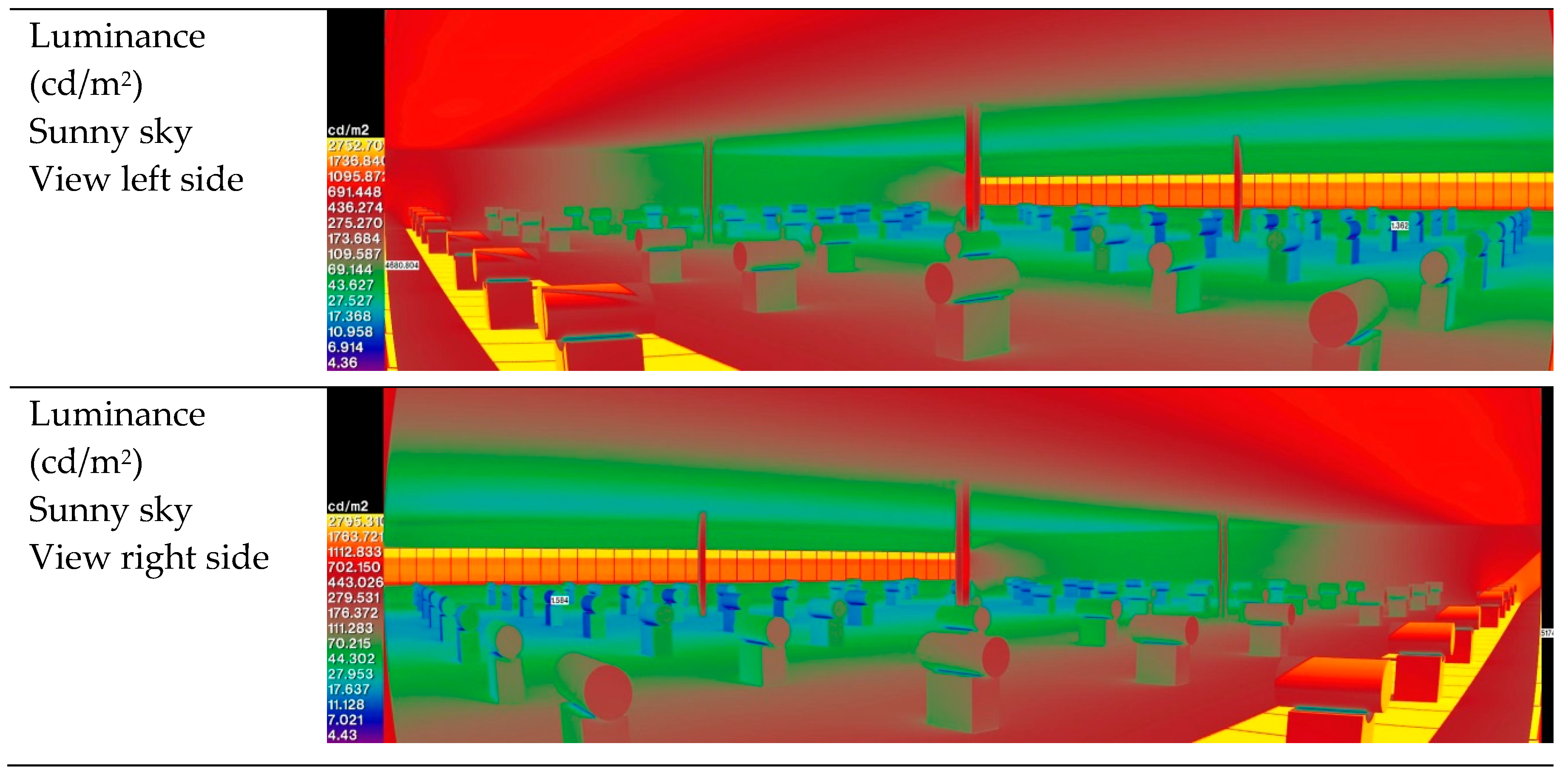

2. The Aim of the Research

2.1. Methodology

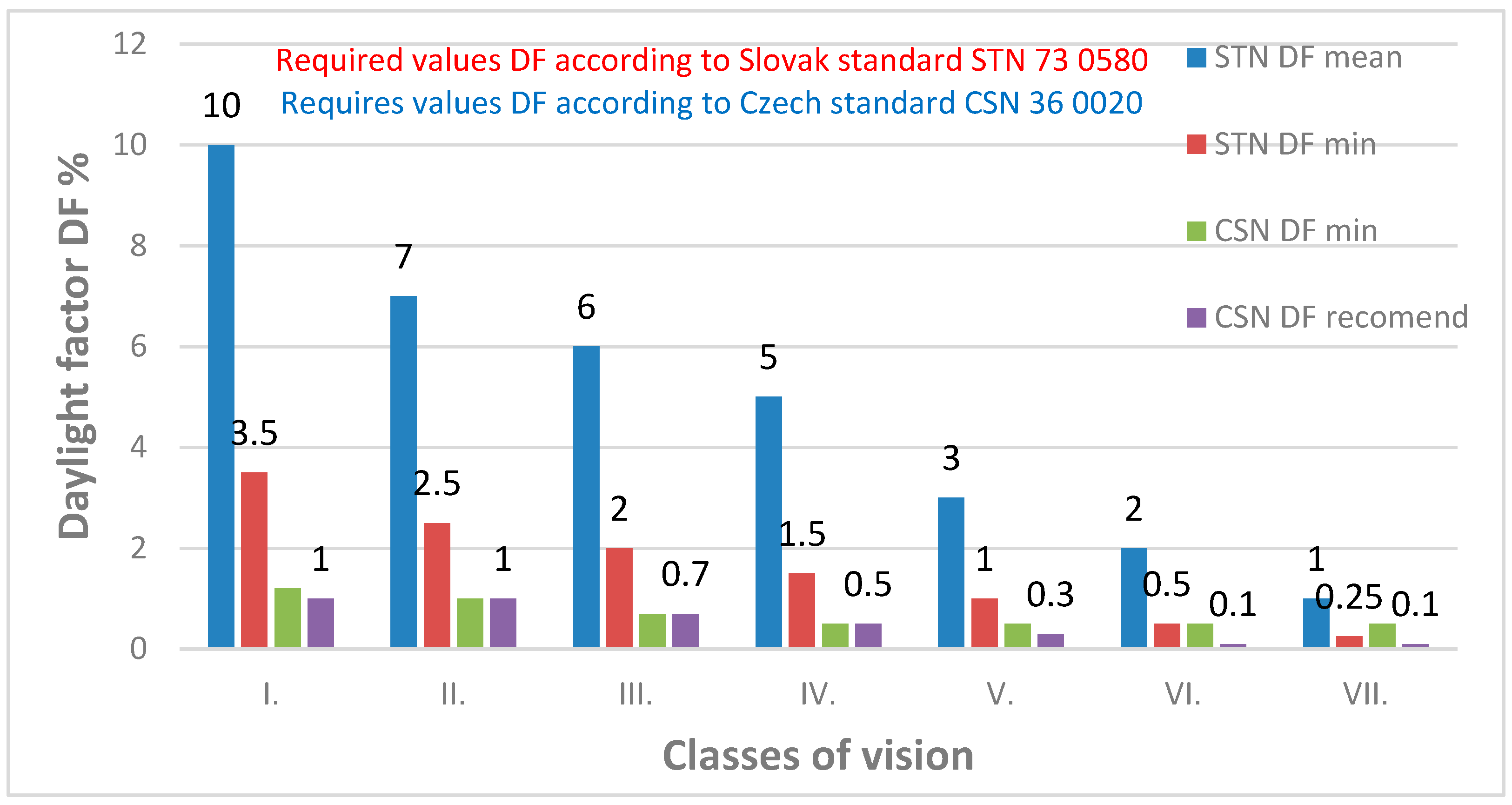

2.2. Daylighting According to Czech (CSN) and Slovak (STN) Standards

2.3. Daylighting According to European Standards

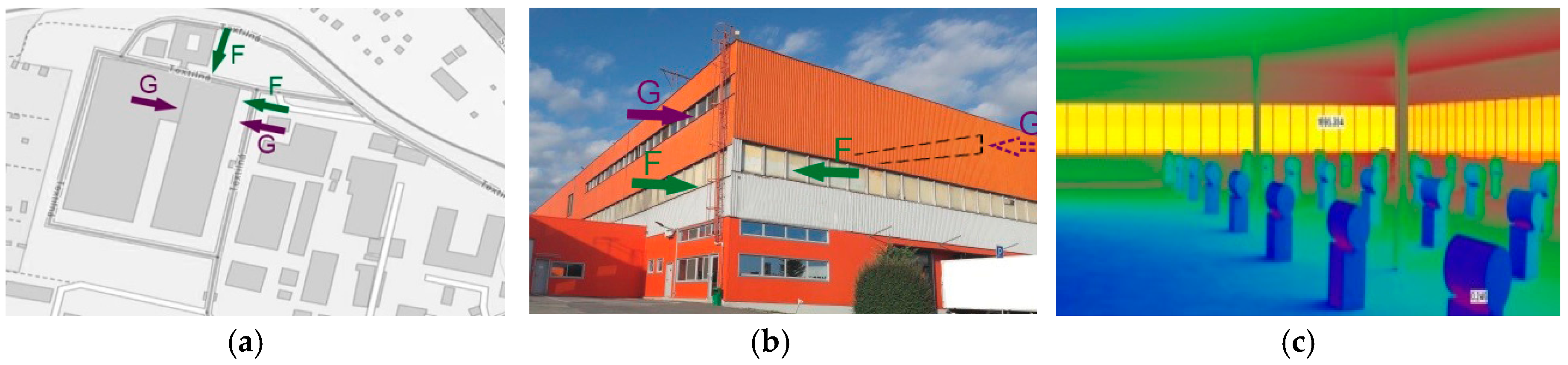

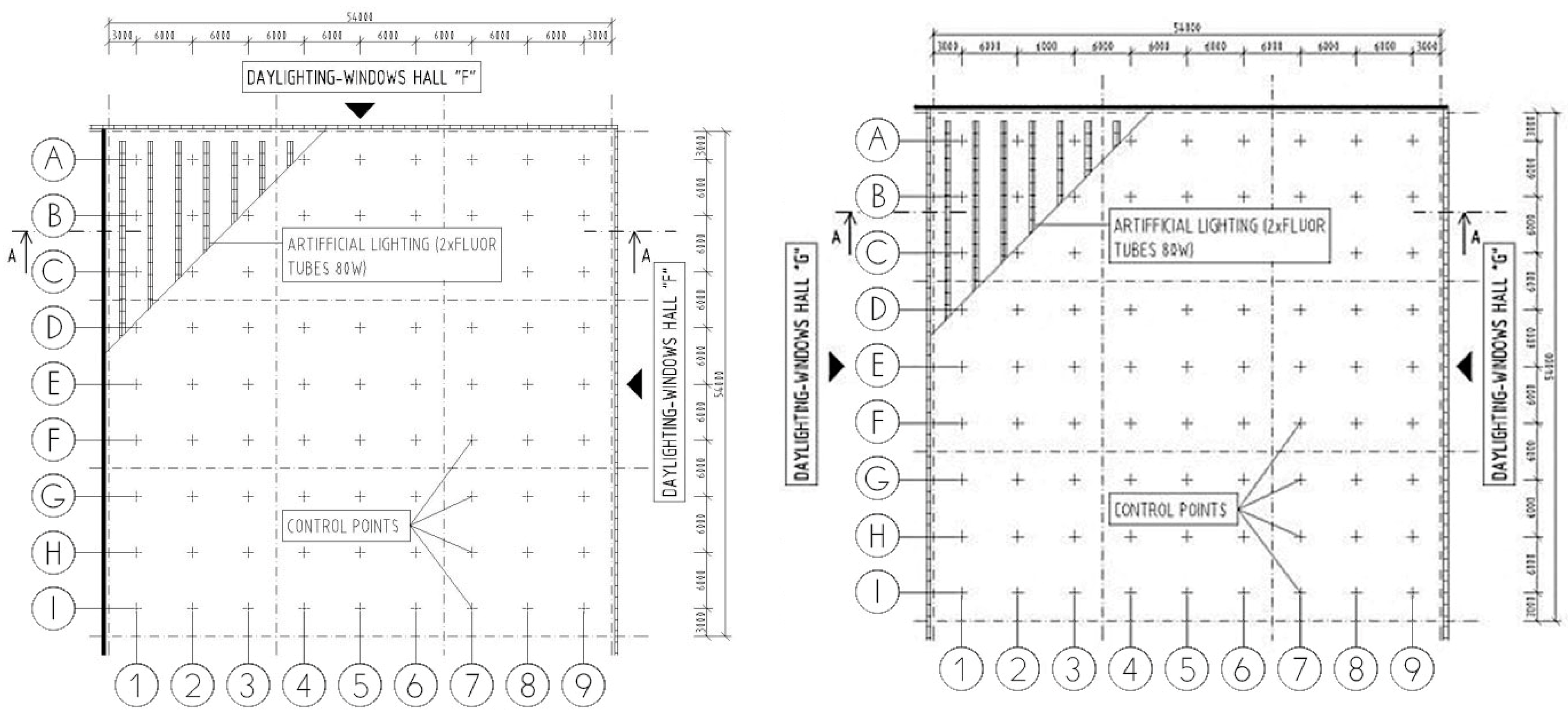

3. A Case Study: Textile Factory

- (1)

- measurement of daylight value,

- (2)

- determination of the marginal conditions for the calculation of the DF,

- (3)

- calculation and simulation of the daylight situations using the simulation program,

- (4)

- confrontation of measured and calculated DF values, and

- (5)

- the derived simplified formula for the window design depending on the floor area to determine the minimum DF (for integral lighting as a basis).

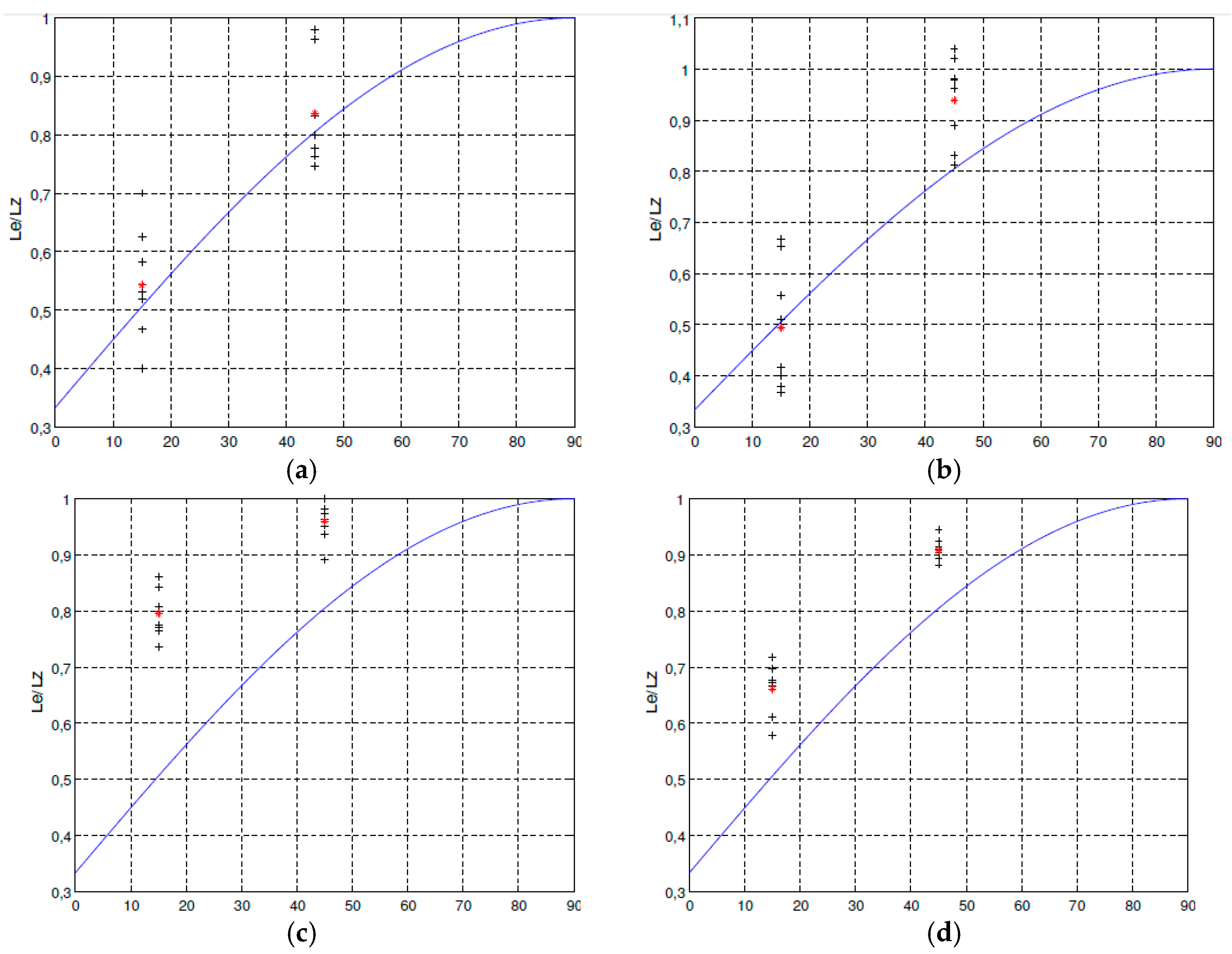

3.1. Daylight Measurements

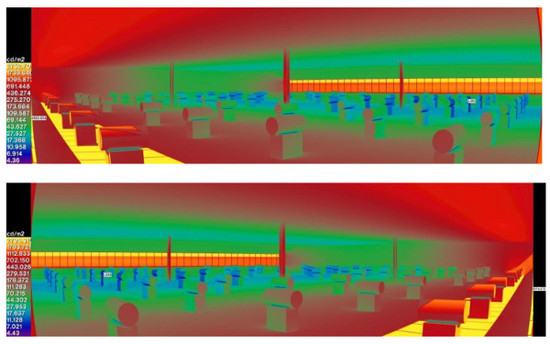

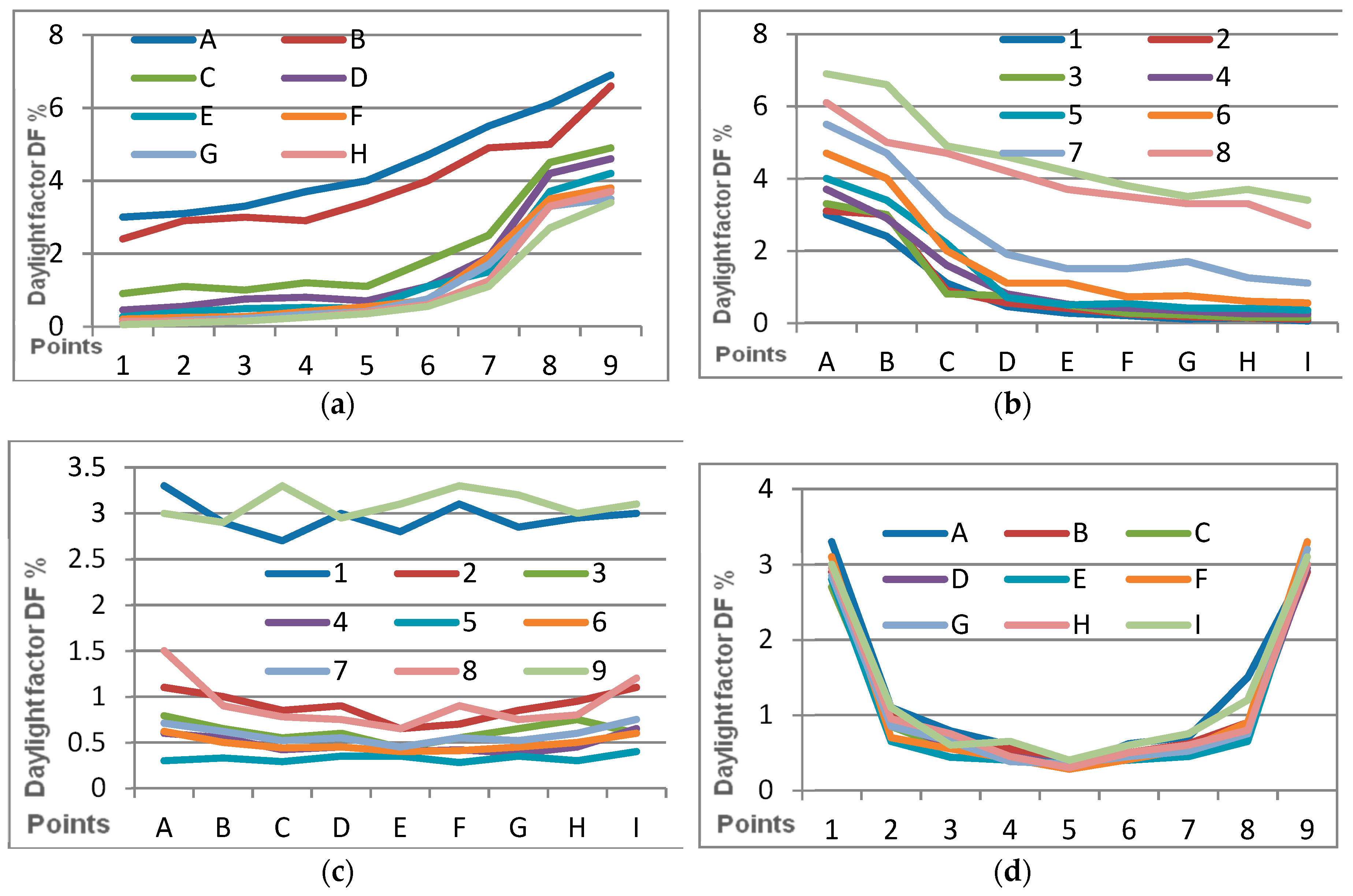

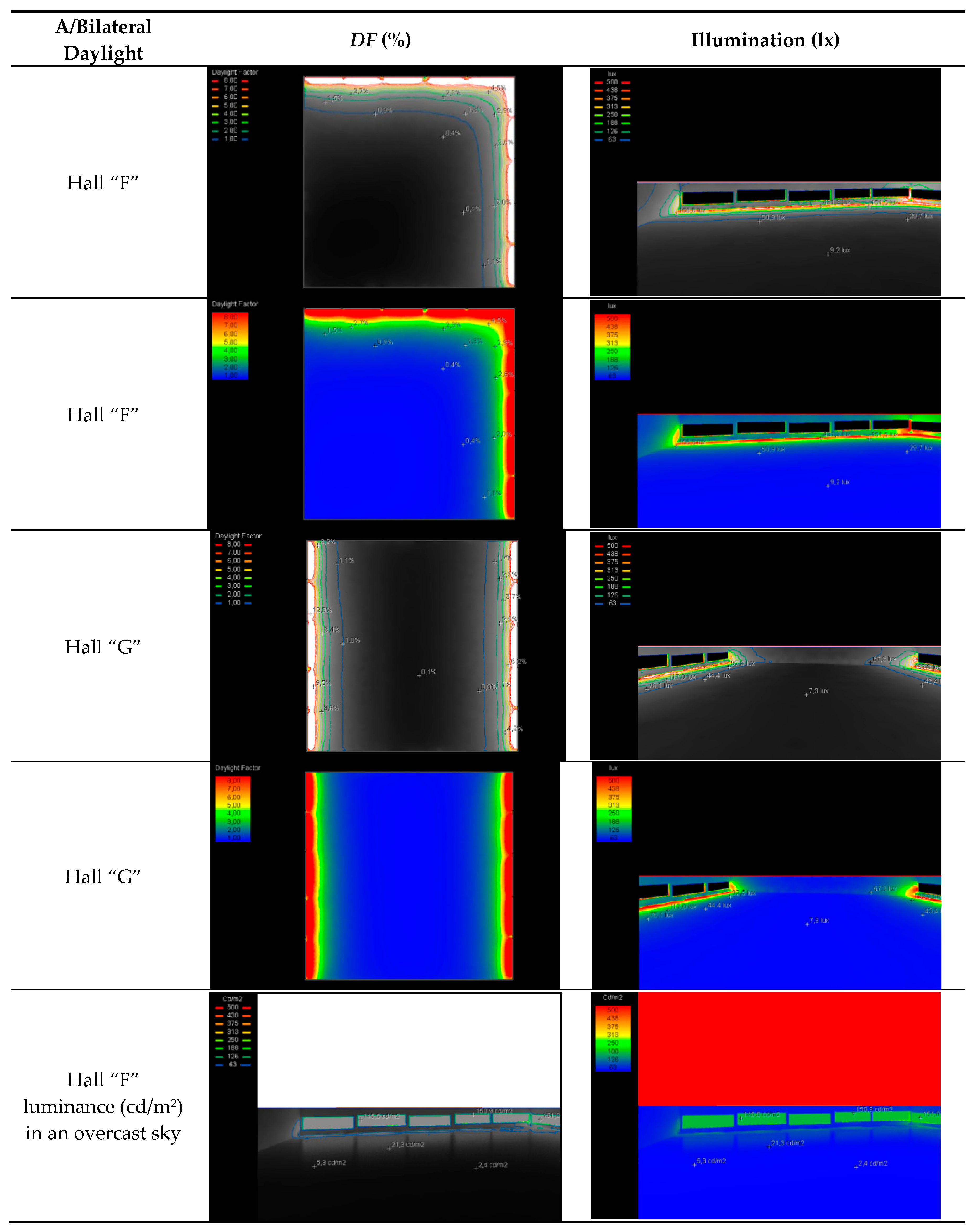

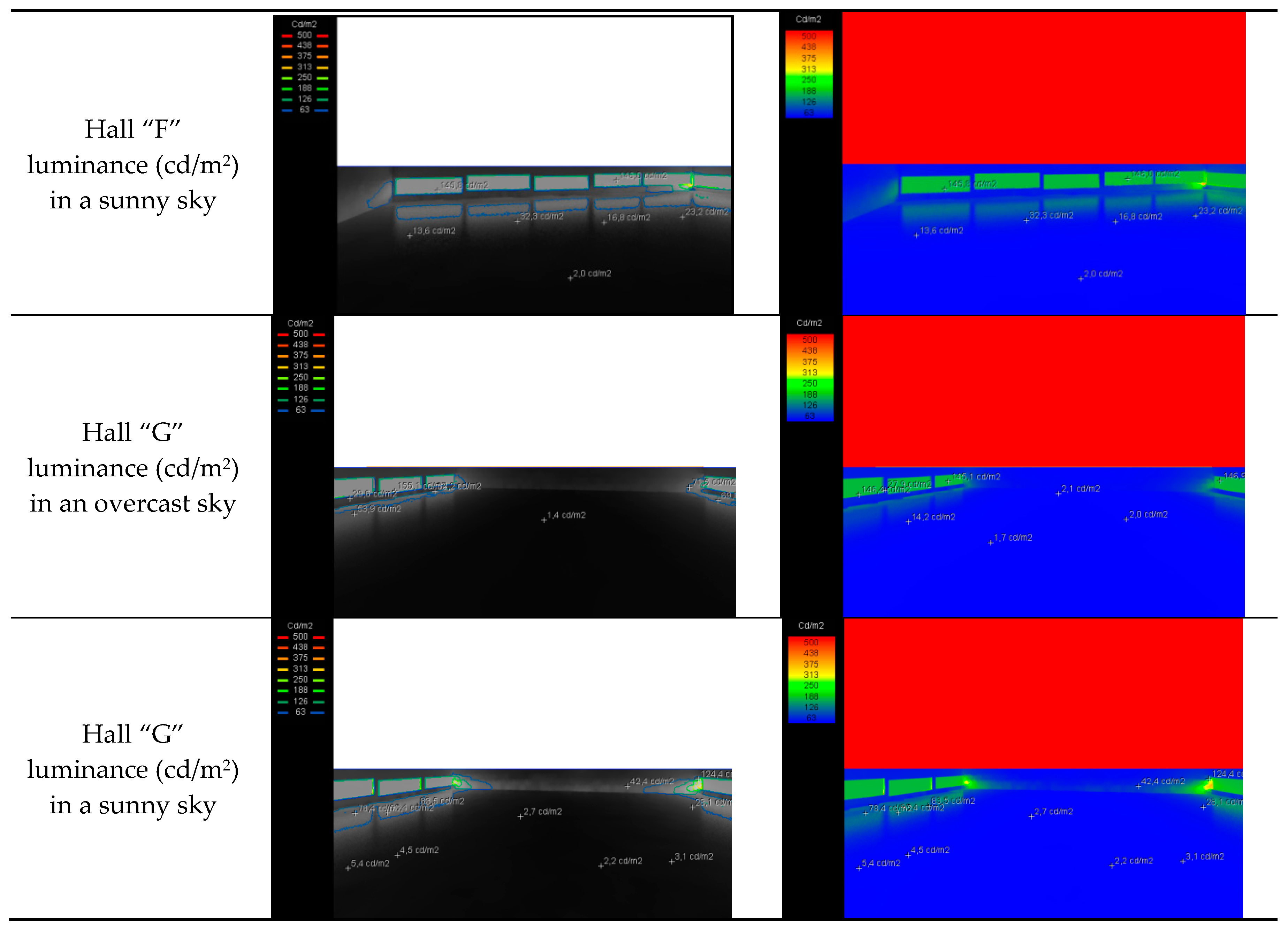

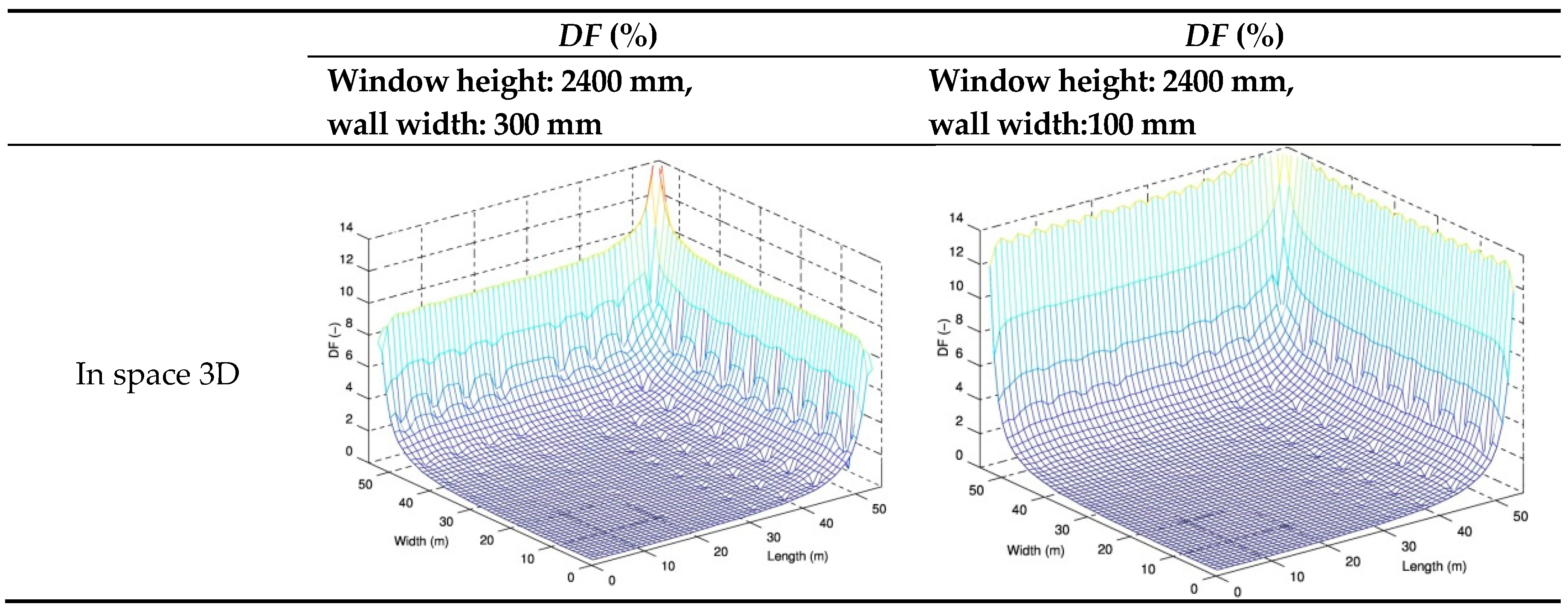

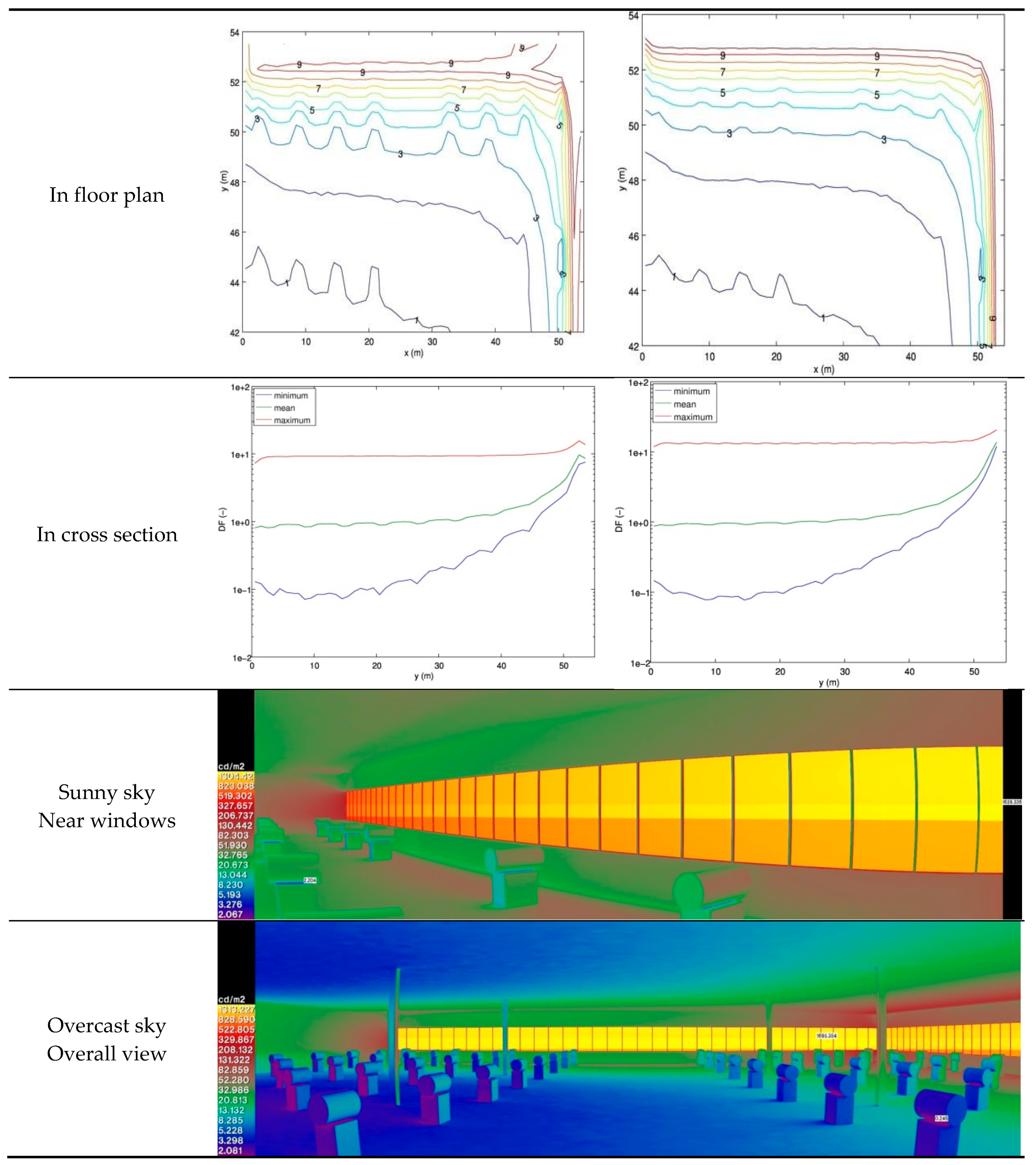

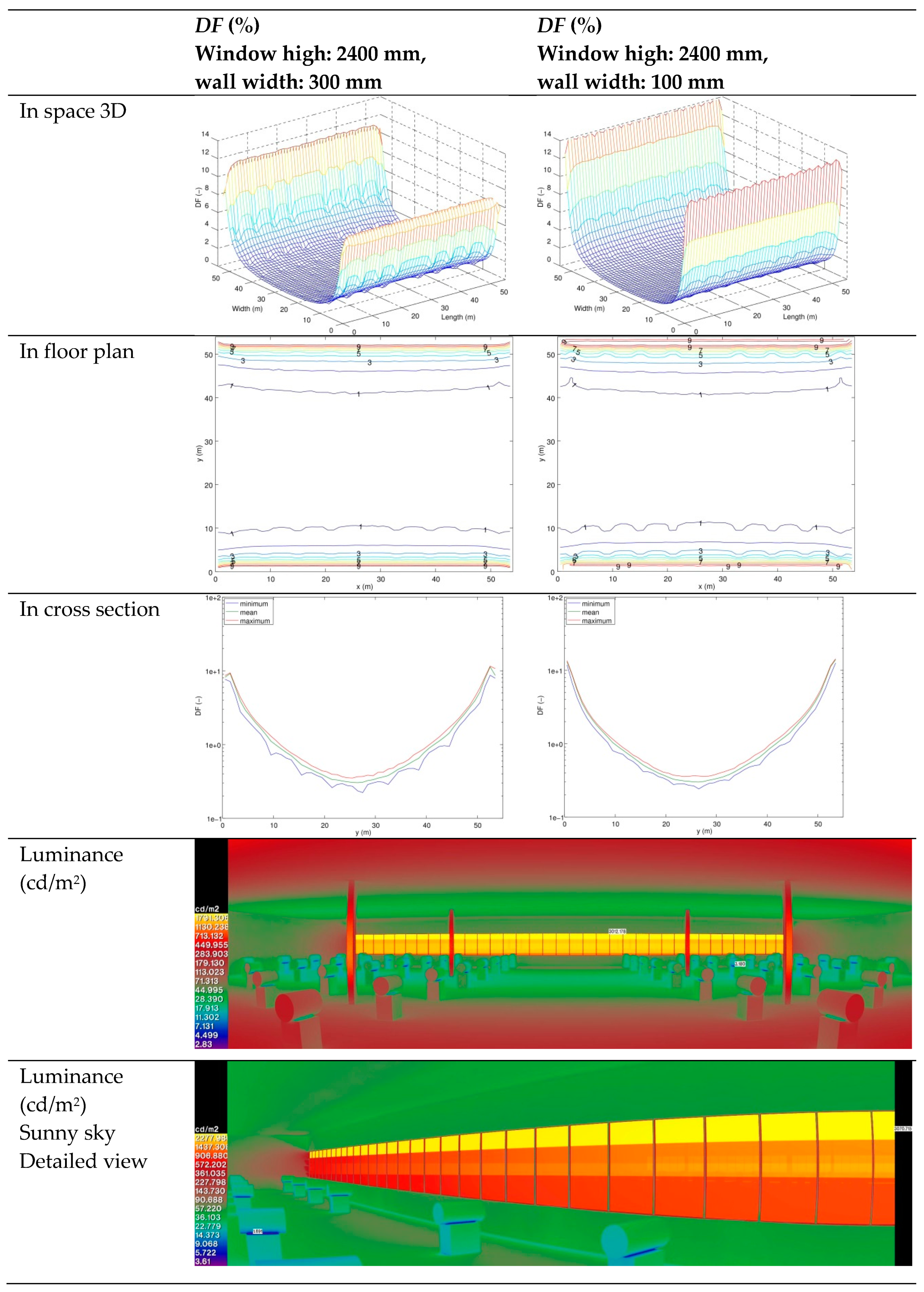

3.2. Daylight Calculations

3.3. Evaluation of the Case Study

- Dρ,max—Maximum internal reflected daylight factor (%).

- Dρ,mean—Mean (average) internal reflected daylight factor (%).

- Dρ,min—Minimum internal reflected daylight factor (%).

- Dw—Distance from daylight opening (m).

- Td—Distance of the outermost point from the windows in the space considered.

- AW—Area of the window structures (m2).

- AF—Area of the floor (m2).

- B—can be calculated by:

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kontadakis, A.; Tsangrassoulis, A.; Doulos, L.; Topalis, F. An active sunlight redirection system for daylight enhancement beyond the perimeter zone. Build. Environ. 2017, 113, 267–279. [Google Scholar] [CrossRef]

- Tsangrassoulis, Α.; Doulos, L.; Santamouris, M.; Fontoynont, M.; Maamari, F.; Wilson, M.; Jacobs, A.; Solomon, J.; Zimmerman, A.; Pohl, W.; et al. On the energy efficiency of a prototype hybrid daylighting system. Sol. Energy 2005, 79, 56–64. [Google Scholar] [CrossRef]

- Doulos, L.T.; Tsangrassoulis, A.; Kontaxis, P.A.; Kontadakis, A.; Topalis, F.V. Harvesting daylight with LED or T5 fluorescent lamps? The role of dimming. Energy Build. 2017, 140, 336–347. [Google Scholar] [CrossRef]

- Doulos, L.; Tsangrassoulis, A.; Topalis, F. The role of spectral response of photosensors in daylight responsive systems. Energy Build. 2008, 40, 588–599. [Google Scholar] [CrossRef]

- Bellia, L.; Fragliasso, F.; Stefanizzi, E. Why are daylight-linked controls (DLCs) not so spread? A literature review. Build. Environ. 2016, 106, 301–312. [Google Scholar] [CrossRef]

- Bellia, L.; Pedace, A.; Fragliasso, F. The impact of the software’s choice on dynamic daylight simulations’ results: A comparison between daysim and 3ds max design®. Sol. Energy 2015, 122, 249–263. [Google Scholar] [CrossRef]

- Shishegar, N.; Boubekri, M. Natural light and productivity: Analyzing the impacts of daylighting on students’ and workers’ health and alertness. In Proceedings of the International Conference on “Health, Biological and Life Science” (HBLS-16), Istanbul, Turkey, 18–19 April 2016. [Google Scholar]

- Friborg, O.; Rosenvinge, J.; Wynn, R.; Gradisar, M. Sleep timing, phonotype, mood, and behavior at an arctic latitude (69° N). Sleep Med. 2014, 15, 798–807. [Google Scholar] [CrossRef] [PubMed]

- McColl, S.L.; Wilkinson, F. Visual contrast gain control in migraine: Measures of visual cortical excitability and inhibition. Cephalalgia 2000, 20, 74–84. [Google Scholar] [CrossRef] [PubMed]

- Smolders, K.C.H.J.; De Kort, Y.A.W.; Cluitmans, P.J.M. Higher light intensity induces modulations in brain activity even during regular daytime working hours. Light. Res. Technol. 2015, 48, 433–448. [Google Scholar] [CrossRef]

- Yao, J.; Chow, D.H.C.; Chi, Y.-W. Impact of Manually Controlled Solar Shades on Indoor Visual Comfort. Sustainability 2016, 8, 727. [Google Scholar] [CrossRef]

- Fabi, V.; Andersen, R.K.; Corgnati, S. Verification of stochastic behavioural models of occupants’ interactions with windows in residential buildings. Build. Environ. 2015, 94, 371–383. [Google Scholar] [CrossRef]

- Gou, Z.; Lau, S.S.; Ye, H. Visual alliesthesia: The gap between comfortable and stimulating illuminance settings. Build. Environ. 2014, 82, 42–49. [Google Scholar] [CrossRef]

- Gou, Z.; Lau, S.S.; Qian, F. Comparison of mood and task performance in naturally-lit and artificially-lit environments. Indoor Built Environ. 2015, 24, 27–36. [Google Scholar] [CrossRef]

- Amundadottir, M.L.; Lockley, S.W.; Andersen, M. Unified framework to evaluate non-visual spectral effectiveness of light for human health. Light. Res. Technol. 2017, 49, 673–696. [Google Scholar] [CrossRef]

- Lee, J.H.; Moon, J.W.; Kim, S. Analysis of occupants’ visual perception to refine indoor lighting environment for office tasks. Energies 2014, 7, 4116–4139. [Google Scholar] [CrossRef]

- Wang, N.; Boubekri, M. Design recommendations based on cognitive, mood and preference assessments in a sunlit workspace. Light. Res. Technol. 2011, 43, 55–72. [Google Scholar] [CrossRef]

- Yokoya, M.; Yamamoto, S.; Yamauchi, Y.; Yamamoto, S.; Ouda, O.; Nakaguchi, T.; Tsumura, N. Subjective evaluation of specular appearance for multiple observations using projector-based appearance reproduction. In International Workshop on Computational Color Imaging, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 6626. [Google Scholar]

- Lee, K.S.; Han, K.J.; Lee, J.W. Feasibility Study on Parametric Optimization of Daylighting in Building Shading Design. Sustainability 2016, 8, 1220. [Google Scholar] [CrossRef]

- Hirning, M.B.; Isoardi, G.L.; Cowling, I. Discomfort glare in open plan green buildings. Energy Build. 2014, 70, 427–440. [Google Scholar] [CrossRef]

- Hirning, M.; Coyne, S.; Cowling, I. The use of luminance mapping in developing discomfort glare research. J. Light Vis. Environ. 2010, 34, 101–104. [Google Scholar] [CrossRef][Green Version]

- Shen, H.; Tzempelikos, A. Daylight-linked synchronized shading operation using simplified model-based control. Energy Build. 2017, 145, 200–212. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M.; Pošiváková, T.; Čonková, E. Indoor Analysis of Environment in Buildings. Chem. Listy 2017, 111, 398–403. [Google Scholar]

- Švajlenka, J.; Kozlovská, M.; Pošiváková, T. Assessment and biomonitoring indoor environment of buildings. Int. J. Environ. Health Res. 2017, 27, 427–439. [Google Scholar] [CrossRef] [PubMed]

- Baker, N.; Steemers, K. Daylight Design of Buildings: A Handbook for Architects and Engineers; Book Routledge: Abingdon, UK, 2014; 260p, ISBN 978-1134-257-348. [Google Scholar]

- Lyons, L.S. Handbook of Industrial Lighting; Elsevier: Amsterdam, The Netherlands, 2013; p. 224. [Google Scholar]

- Dolníková, E.; Katunský, D. Hodnotenie Svetelnej Pohody Pri Kombinovanom Osvetľovacom Systéme V Priemyselných Halách; TUKE Košice: Košice, Slovakia, 2017; p. 151. [Google Scholar]

- Kalousek, M.; Mohelníková, J. Influence of Window on Solar Gains and Daylight Level. Adv. Mater. Res. 2014, 1041, 175–179. [Google Scholar] [CrossRef]

- Ferencikova, M.; Darula, S. Availability of daylighting in school operating time. Light Eng. 2017, 25, 71–78. [Google Scholar]

- Moazzeni, M.H.; Ghiabaklou, Z. Investigating the influence of light shelf geometry parameters on daylight performance and visual comfort, a case study of educational space in Tehran, Iran. Buildings 2016, 6, 26. [Google Scholar] [CrossRef]

- Krüger, E.L.; Fonseca, S.D. Evaluating daylighting potential and energy efficiency in a classroom building. J. Renew. Sustain. Energy 2011, 3, 63112. [Google Scholar] [CrossRef]

- Piderit Moreno, M.B.; Labarca, C.Y. Methodology for assessing daylighting design strategies in classroom with a climate-based method. Sustainability 2015, 7, 880–897. [Google Scholar] [CrossRef]

- Xue, P.; Mak, C.M.; Huang, Y. Quantification of luminous comfort with dynamic daylight metrics in residential buildings. Energy Build. 2016, 117, 99–108. [Google Scholar] [CrossRef]

- Nebia, B.; Tabet Aoul, K. Overheating and Daylighting; Assessment Tool in Early Design of London’s High-Rise Residential Buildings. Sustainability 2017, 9, 1544. [Google Scholar] [CrossRef]

- Iringova, A. Impact of external shading on light comfort and energy efficiency in apartment buildings. Appl. Mech. Mater. 2017, 861, 485–492. [Google Scholar] [CrossRef]

- Mohsenin, M.; Hu, J. Assessing daylight performance in atrium buildings by using Climate Based Daylight Modeling. Sol. Energy 2015, 119, 553–560. [Google Scholar] [CrossRef]

- Berardi, U.; Anaraki, H.K. The benefits of light shelves over the daylight illuminance in office buildings in Toronto. Indoor Built Environ. 2016, 27, 244–262. [Google Scholar] [CrossRef]

- Gonzalez, J.; Fiorito, F. Daylight design of office buildings: Optimisation of external solar shadings by using combined simulation methods. Buildings 2015, 5, 560–580. [Google Scholar] [CrossRef]

- Pellegrino, A.; Cammarano, S.; Verso, V.R.; Corrado, V. Impact of daylighting on total energy use in offices of varying architectural features in Italy: Results from a parametric study. Build. Environ. 2017, 113, 151–162. [Google Scholar] [CrossRef]

- Costanzo, V.; Donn, M. Thermal and visual comfort assessment of natural ventilated office buildings in Europe and North America. Energy Build. 2017, 140, 210–223. [Google Scholar] [CrossRef]

- Konis, K. Evaluating daylighting effectiveness and occupant visual comfort in a side-lit open-plan office building in San Francisco, California. Build. Environ. 2013, 59, 662–677. [Google Scholar] [CrossRef]

- Mistrick, R.; Casey, C.; Chen, L.; Sarith Subramaniam, S. Computer modeling of daylight-integrated photocontrol of electric lighting systems. Buildings 2015, 5, 449–466. [Google Scholar] [CrossRef]

- Nasrollahi, N.; Shokri, E. Daylight illuminance in urban environments for visual comfort and energy performance. Renew. Sustain. Energy Rev. 2016, 66, 861–874. [Google Scholar] [CrossRef]

- Reinhart, C.F.; Wienold, J. The daylighting dashboard—A simulation-based design analysis for daylit spaces. Build. Environ. 2011, 46, 386–396. [Google Scholar] [CrossRef]

- Amorim, R.; López, J.C.; Molina-Moreno, V.; Peña-García, A. Use of Natural Light vs. Cold LED Lighting in Installations for the Recovery of Victims of Gender Violence: Impact on Energy Consumption and Victims’ Recovery. Sustainability 2017, 9, 562. [Google Scholar] [CrossRef]

- Shen, E.; Hu, J.; Patel, M. Energy and visual comfort analysis of lighting and daylight control strategies. Build. Environ. 2014, 78, 155–170. [Google Scholar] [CrossRef]

- Uriarte, U.; Hernández, R.J.; Zamora, J.L.; Isalgue, A. Side-view atmospheres under outdoor midday high luminance. Buildings 2016, 6, 53. [Google Scholar] [CrossRef]

- Gunay, H.B.; O’Brien, W.; Beausoleil-Morrison, I.; Gilani, S. Development and implementation of an adaptive lighting and blinds control algorithm. Build. Environ. 2017, 113, 185–199. [Google Scholar] [CrossRef]

- Jia, L.; Afshari, S.; Mishra, S.; Radke, R.J. Simulation for pre-visualizing and tuning lighting controller behavior. Energy Build. 2014, 70, 287–302. [Google Scholar] [CrossRef]

- Doulos, L.; Tsangrassoulis, A.; Topalis, F. Multi-criteria decision analysis to select the optimum position and proper field of view of a photosensor. Energy Convers. Manag. 2014, 86, 1069–1077. [Google Scholar] [CrossRef]

- Doulos, L.; Tsangrassoulis, A.; Topalis, F. Quantifying energy savings in daylight responsive systems: The role of dimming electronic ballasts. Energy Build. 2008, 40, 36–50. [Google Scholar] [CrossRef]

- Veitch, J.A.; Whitehead, L.A.; Mossman, M.; Pilditch, T.D. Chromaticity-matched but spectrally different light source effects on simple and complex color judgments. Color Res. Appl. 2014, 39, 263–274. [Google Scholar] [CrossRef][Green Version]

- Perez, R.; Seals, R.; Michalsky, J. All weather model for sky luminance distribution—Preliminary configuration and validation. Sol. Energy 1993, 50, 235–245. [Google Scholar] [CrossRef]

- Igawa, N.; Koga, Y.; Matsuzawa, T.; Nakamura, H. Models of sky radiance distribution and sky luminance distribution. Sol. Energy 2004, 77, 137–157. [Google Scholar] [CrossRef]

- Katunský, D. Aproximatívny výpočet minimálnych činiteľov dennej osvetlenosti vo ve’korozmerových priemyslových halách. Build. Res. J. 1992, 40, 299–311. [Google Scholar]

- Van Bommel, W.J.M.; van den Beld, G.J. Lighting for work: A review of visual and biological effects. Light. Res. Technol. 2004, 36, 255–269. [Google Scholar] [CrossRef]

- Yan, B.; Long, E.; Meng, X.; Zhang, Y.; Hou, D.; Du, X. Influence of user behavior on unsatisfactory indoor thermal environment. Energy Convers. Manag. 2014, 86, 1–7. [Google Scholar] [CrossRef]

- Sokol, N.; Martyniuk-Peczek, J. The review of the selected challenges for an incorporation of daylight assessment methods into urban planning in Poland. Procedia Eng. 2016, 161, 2191–2197. [Google Scholar] [CrossRef]

- Chen, K.W.; Norford, L. Evaluating Urban Forms for Comparison Studies in the Massing Design Stage. Sustainability 2017, 9, 987. [Google Scholar] [CrossRef]

- Labat, M.; Attonaty, K. Numerical estimation and sensitivity analysis of the energy demand for six industrial buildings in France. J. Build. Perform. Simul. 2017, 3, 1–21. [Google Scholar] [CrossRef]

- Gourlis, G.; Ivacic, I. A study on building performance analysis for energy retrofit of existing industrial facilities. Appl. Energy 2016, 184, 1389–1399. [Google Scholar] [CrossRef]

- Pham, K.; Garcia-Hansen, V.; Isoardi, G. Appraisal of the Visual Environment in an Industrial Factory: A Case Study in Subtropical Climates, Solarlits. J. Daylighting 2016, 3, 12–26. [Google Scholar] [CrossRef]

- Alarcon, B.; Aguado, A.; Manga, R.; Josa, A. A value function for assessing sustainability application to industrial buildings. Sustainability 2011, 3, 35–50. [Google Scholar] [CrossRef]

- Katunsky, D.; Dolnikova, E.; Doroudiani, S. Integrated Lighting Efficiency Analysis in Large Industrial Buildings to Enhance Indoor Environmental Quality. Buildings 2017, 7, 47. [Google Scholar] [CrossRef]

- Lombera, J.T.; Rojo, J.C. Industrial building design stage based on a system approach to their environmental sustainability. Constr. Build. Mater. 2010, 24, 438–447. [Google Scholar] [CrossRef]

- Lombera, J.-T.S.-J.; Aprea, I.G. A system approach to the environmental analysis of industrial buildings. Build. Environ. 2010, 45, 673–683. [Google Scholar]

- Standards ČSN 360020. Integral Lighting; CZ Office of Standards, Metrology and Testing Prague: Prague, Czech Republic, 2015.

- Standards STN 730580. Daylighting in Buildings, Part–1 Basic Requirements, 1986 Part–2; Daylighting of Residential Buildings; Slovak Republic Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2000.

- Standards EN 12464-1:2012. Light and Lighting; Lighting of Work Places-Part. 1: Indoor Work Places; Slovak Republic Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2012.

- Draft Standards CEN/TC/ 169/WG 11, 07/2017. EN 17037 Daylight in Buildings (TC169WI00169068); European Committe for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- International Energy Agency (IEA). Solar and Heating Cooling Program, Task 31—Daylighting Buildings in the 21st Century; IEA: Paris, France; Available online: http://task31.iea-shc.org/ (accessed on 2 May 2017).

| Human Eye Recognition Category | Visual Detail Tasks |

|---|---|

| I. Extreme accuracy | The most accurate visual work with limited use of magnification, with the requirement to eliminate errors in definition, stringent control |

| II. High accuracy | Very precise production and control activities, high-precision drawing, hand engraving with very small detailing, fine artwork |

| III. Precise operation | Precision manufacturing and inspection, regular drawing, technical drawing, laboratory, labour-intensive investigations, fine sewing, embroidery |

| IV. Medium accuracy | Medium precision manufacturing and inspection, reading, writing (by hand and machine), routine laboratory work, examinations, treatments, using machines, thicker sewing, knitting, laundry, cooking class, reading room, teaching cabinet, kitchen, doctor’s surgery, office, meeting room, conference room |

| V. Low accuracy | Approximate works, manipulating objects and materials, food consumption and service, leisure activities, physical education, dining room, living room, lounge, hall, gymnasium, swimming pool, storage room, waiting room |

| VI. Very rough work | Maintenance cleaning, showering and washing, changing, walking on public roads open to the public, cloakroom, toilets, corridors |

| VII. Only spatial orientation | Walking, material transport, storage of raw material, supervision |

| Class of Visual Activities | The Ratio of the Luminance of the Observed Object to the Luminance of the Illuminating Opening (Windows) |

|---|---|

| I, II, III | 1:40 |

| IV | 1:100 |

| V, VI, VII | not intended |

| Level of Recommendation for Vertical and Inclined Daylight Opening | Target Illuminance ET (lx) | Fraction of Space for the Target Level Fplane, (%) | Minimum Target Illuminance ETM (lx) | Fraction of Space for Min Target Level Fplane, (%) | Fraction of Daylight Hours Ftime, (%) |

|---|---|---|---|---|---|

| Minimum | 300 | 50% | 100 | 95% | 50% |

| Medium | 500 | 50% | 300 | 95% | 50% |

| High | 750 | 50% | 500 | 95% | 50% |

| Parameter (a) | |||

|---|---|---|---|

| Level of recommendation for view-out | Horizontal sight angle | Outside distance of the view | Number of layers to be seen from at least 75% of the utilized Area: -Sky-Landscape (Urban and/or Nature)-Ground |

| Minimum | ≥14° | ≥6.0 m | At least the landscape layer is included |

| Medium | ≥28° | ≥20.0 m | Landscape layer and one additional layer are included in the same view opening |

| High | ≥54° | ≥50.0 m | All layers are included in the same view opening |

| First Day | |||||

| (a) at the beginning of measurements | (b) at the end of measurements | ||||

| Z | Le/Lz | Average value | Z | Le/Lz | Average value |

| 15° | 0.4–0.7 | 0.55 | 15° | 0.35–0.68 | 0.50 |

| 45° | 0.75–0.85 | 0.85 | 45° | 0.80–1.05 | 0.92 |

| Second Day | |||||

| (a) at the beginning of measurements | (b) at the end of measurements | ||||

| Z | Le/Lz | Average value | Z | Le/Lz | Average value |

| 15° | 0.774–0.86 | 0.80 | 15° | 0.61–0.72 | 0.68 |

| 45° | 0.89–1.0 | 0.95 | 45° | 0.88–0.92 | 0.90 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katunský, D.; Dolníková, E.; Dolník, B. Daytime Lighting Assessment in Textile Factories Using Connected Windows in Slovakia: A Case Study. Sustainability 2018, 10, 655. https://doi.org/10.3390/su10030655

Katunský D, Dolníková E, Dolník B. Daytime Lighting Assessment in Textile Factories Using Connected Windows in Slovakia: A Case Study. Sustainability. 2018; 10(3):655. https://doi.org/10.3390/su10030655

Chicago/Turabian StyleKatunský, Dušan, Erika Dolníková, and Bystrík Dolník. 2018. "Daytime Lighting Assessment in Textile Factories Using Connected Windows in Slovakia: A Case Study" Sustainability 10, no. 3: 655. https://doi.org/10.3390/su10030655

APA StyleKatunský, D., Dolníková, E., & Dolník, B. (2018). Daytime Lighting Assessment in Textile Factories Using Connected Windows in Slovakia: A Case Study. Sustainability, 10(3), 655. https://doi.org/10.3390/su10030655